Patents

Literature

86results about How to "Reduced impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Polypropylene long-carbon-chain nylon blend and preparation method thereof

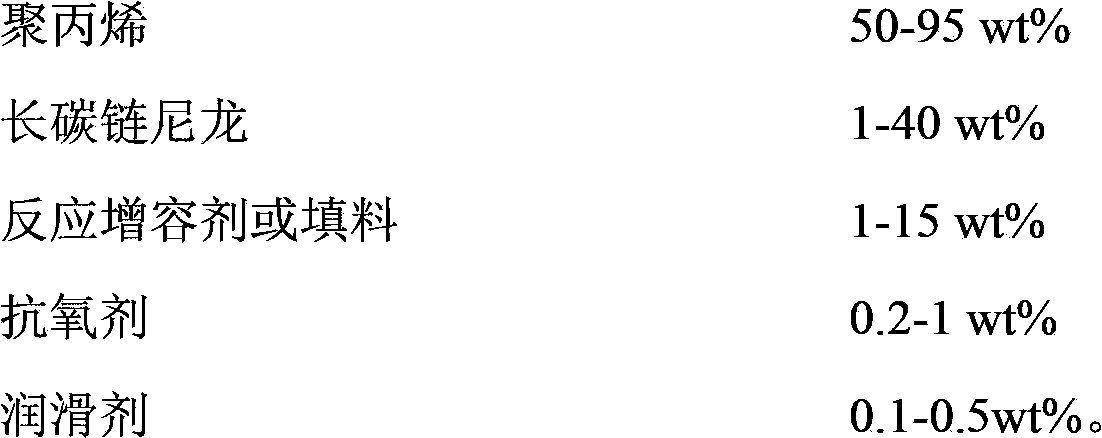

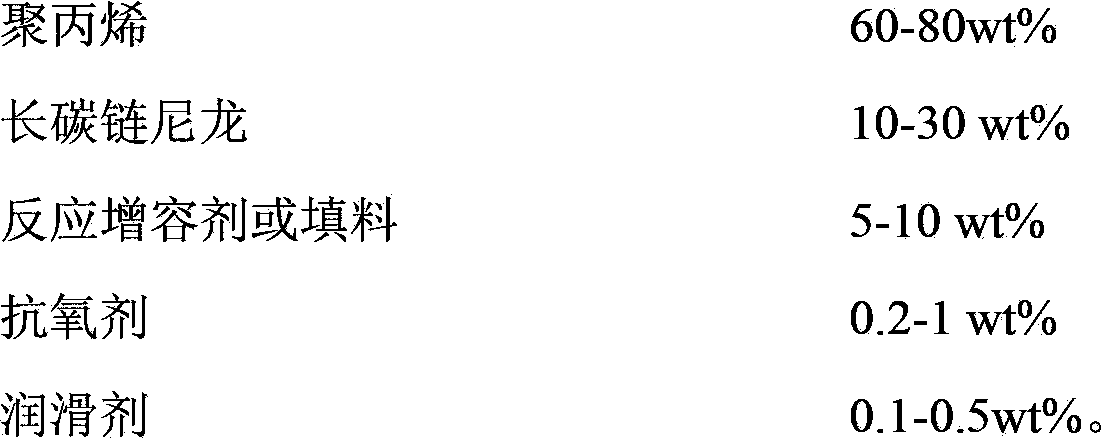

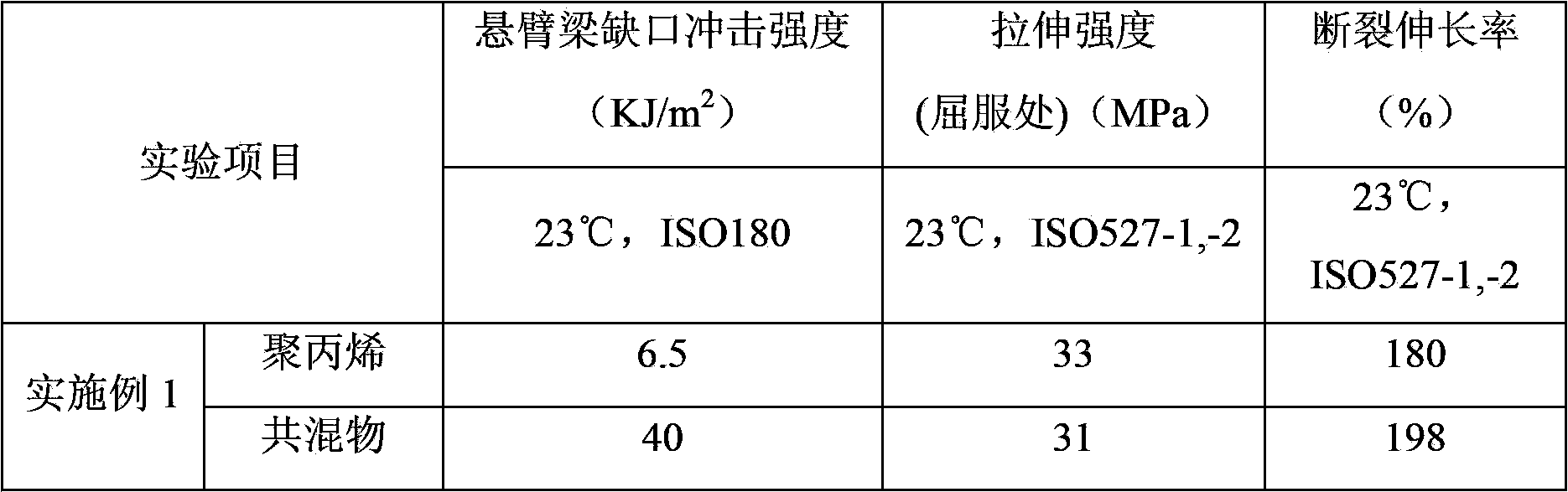

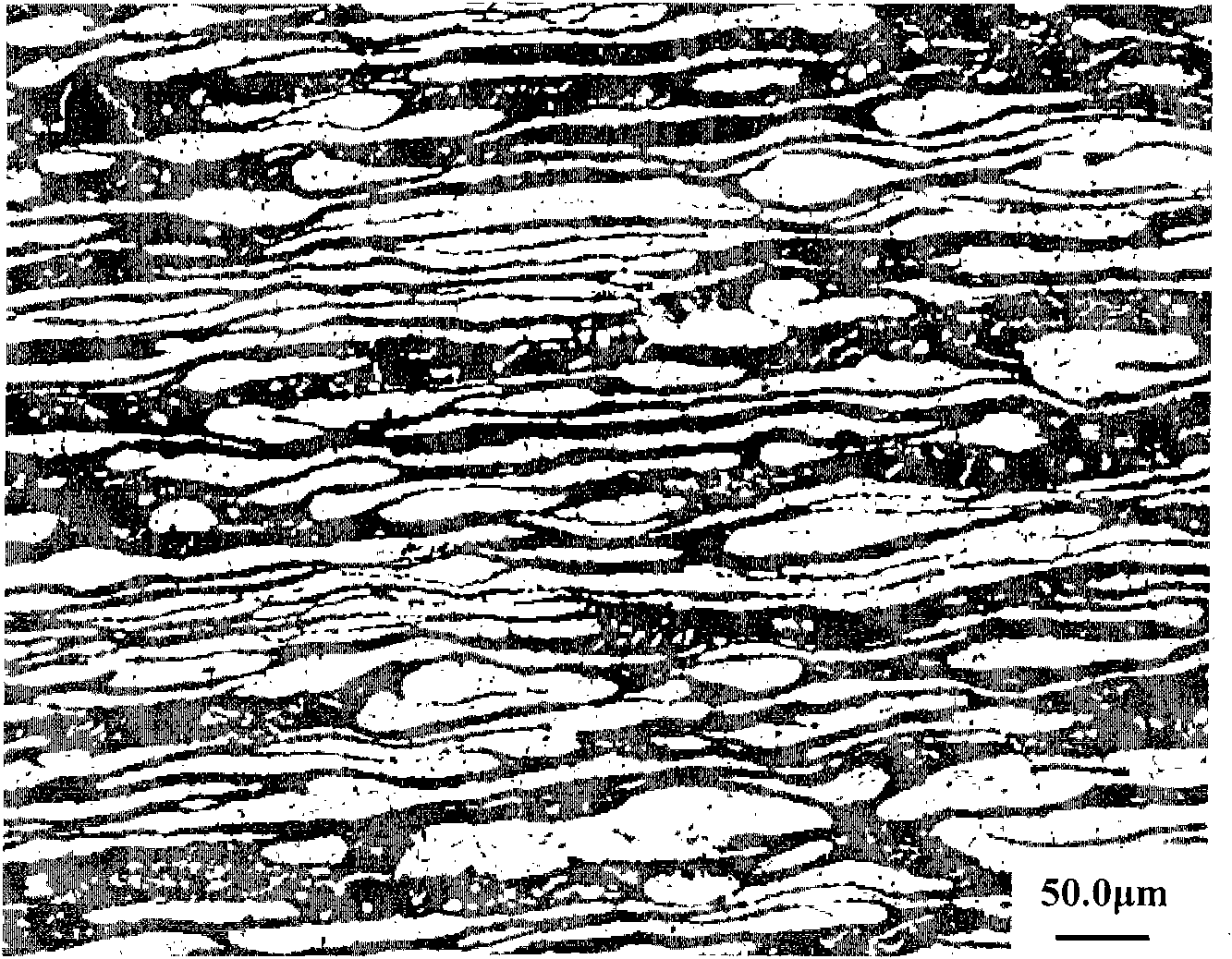

The invention belongs to the field of high-molecular material processing, and specifically relates to a polypropylene long-carbon-chain nylon blend and a preparation method thereof. The high-toughness polypropylene long-carbon-chain nylon blend comprises the following components in percents by mass: 50-95 wt% of polypropylene, 1-40 wt% of long-chain nylon, 1-15 wt% of a reaction compatibilizer or a filling material, 0.2-1 wt% of an anti-oxidant and 0.1-0.5 wt% of a lubricant. By adding the long-carbon-chain nylon and the reaction compatibilizer or the filling material, the toughness of polypropylene is improved, and the blend is not reduced in tensile strength and has relatively low viscosity, the blend is beneficial to extrusion processing, and has extremely good comprehensive performances.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and manufacturing method thereof

InactiveCN101684542AImprove solubilityDecreased low temperature toughnessChemical compositionRoom temperature

The invention discloses a duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and a manufacturing method thereof. The duplex stainless steel comprisesthe following components in mass percentage: 0.01-0.10% of C, 0.2-1.0% of Si, more than 0% and less than 1.5% of Mn, 20.0-22.0% of Cr, 1.8-4.0% of Ni, 0.08-0.2% of N, more than 0% and less than 0.5% of Mo, less than or equal to 1.0% of one or more than one of W and Cu and the balance Fe and inevitable impurities. The invention controls Mn content below 1.5% until zero and simultaneously adjusts the content of elements of N, Ni and the like to ensure that steel has high strength, favourable corrosion resistance and favourable impact toughness at room temperature and low temperature when steel contains no or small amount of noble element Mo; meanwhile, the duplex stainless steel has low cost and small hot working difficulty, can be largely applied in the fields of buildings along the coast,petrochemical industry and the like and can replace 304 austenitic stainless steel of which the nickel content is above 8% at room temperature and lower temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

2Cr13 heat treatment process

InactiveCN101608252AHigh surface hardnessImprove surface wear resistanceFurnace typesQuenching agentsLong axisMechanical equipment

The invention belongs to the field of a heat treatment process for reciprocating-compressor 2Cr13 piston-rods, and is applicable to all reciprocating compressors adopting a 2Cr13 piston-rod heat treatment process and mechanical equipment which requires high toughness and needs post-order surface heat treatment. The process can solve the problem that the prior heat treatment adopted for 2Cr13 piston rods is low in impact toughness, large in high-frequency quenching deformation of long-axis parts, large in hardening cracks and workpiece residual stress, and the like. The process comprises the forging molding of 2Cr13 piston rods, annealing, quenching-tempering, stabilizing, medium-frequency or high-frequency quenching and low-temperature tempering. The 2Cr13 heat treatment process can completely overcome the disadvantages of the prior heat treatment process such as incapability of eliminating residual stress and serious high-frequency quenching workpiece distortion, and is an ideal heat treatment process for long-axis workpieces.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Method for cooling low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling

ActiveCN102676919AAdd lessReduce manufacturing costMetal rolling arrangementsHigh intensityHeating furnace

The invention discloses a method for cooling a low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling, wherein the low-alloy hot-rolled H-shaped steel with the yield strength of 550MPa comprises following components by mass: 0.13-0.18% of C, 0.30-0.50% of Si, 1.40-1.60% of Mn, not more than 0.025% of P, not more than 0.025% of S, 0.10-0.12% of V, 0.010-0.014% of N, 0.003-0.030% of Als, and the balance of iron and residual trace impurities; a rolling process of the H-shaped steel is as follows: heating casting blank in a heating furnace, performing rolling by a cogging mill, performing rolling by a universal rolling mill and quickly cooling the steel in two-stage manner after rolling; the method adopts the two-stage quick cooling method after the H-shaped steel is hot-rolled, so that the high-temperature H-shaped steel is cooled to proper temperature at short time; by using the cooling method after colling, texture state of the H-shaped steel with fine crystal particles and complex phase texture is obtained, adding amount of the alloy elements is drastically reduced, production cost is notably reduced when requirement of high-strength performance is satisfied, and welding performance of the steel and production efficiency are improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

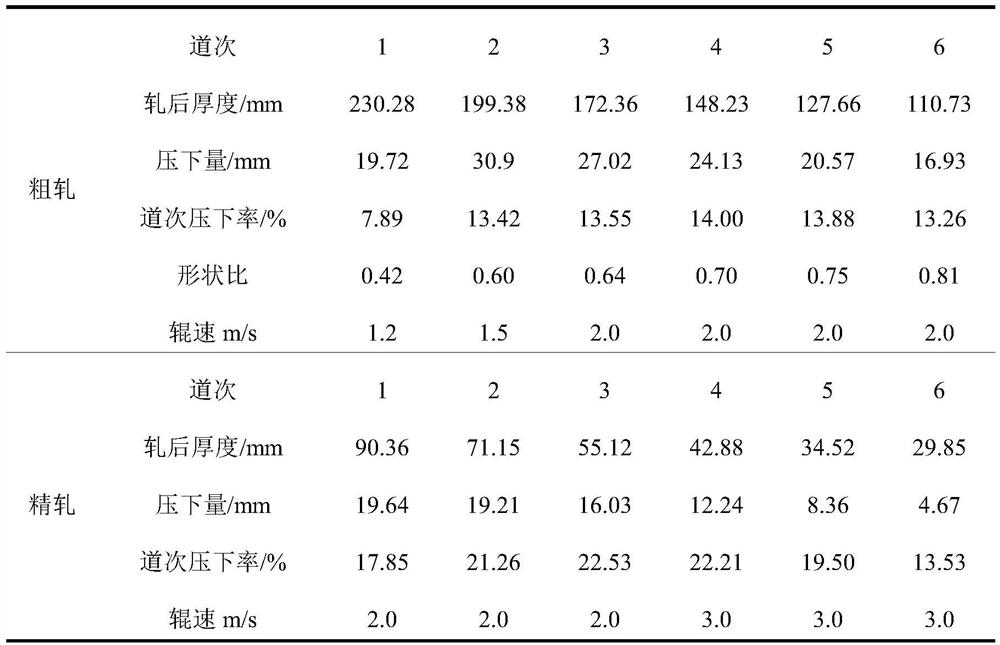

Large-thickness rack steel plate directly produced by continuous casting billet and manufacturing method of large-thickness rack steel plate

The invention relates to a large-thickness rack steel plate directly produced by a continuous casting billet. The steel plate takes Fe as a base component and further comprises the following chemical components by mass percent: 0.10% to 0.16% of C, 0.15% to 0.35% of Si, 0.95% to 1.25% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, greater than or equal to 2.4% and less than or equal to 3.0% of Cr+Mo+Ni+Cu, greater than or equal to 0.08% and less than or equal to 0.13% of Al+V, less than or equal to 0.007% of N and 0.001% to 0.002% of B. A manufacturing method of the large-thickness rack steel plate comprises the following steps of KR molten iron pretreatment, converter smelting, LF (ladle furnace) refining, RH refining, continuous casting, casting billet covering for slow cooling, casting billet clearing, heating, high-pressure water descaling, rolling control, straightening, accumulation slow-cooling or slow cooling under a control condition and tempering. The steel plate is high in strength, good in plasticity, high in Z-direction performance and high in low-temperature toughness. In addition, the steel plate is simple and convenient in production process and low in cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Turbine blade capable of enhancing impact toughness and production technique thereof

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

High-strength high-toughness gas shield flux-cored wire for high-strength steel

ActiveCN104722962ASolve the problem of poor slag draggingImprove welding productivityWelding/cutting media/materialsSoldering mediaIron powderRare earth

The invention provides a high-strength high-toughness gas shield flux-cored wire for high-strength steel and belongs to the technical field of welding materials. The flux-cored wire comprises an outer skin and a flux core. The flux core accounts for 12%-25% of the total weight of flux-cored wire, and the outer skin is made of an industrial pure iron strip. The flux core contains, by weight, graphite powder 0%-10%, TiO2 5%-20%, Mn-Fe alloy 10%-40%, Si-Fe alloy 0.5%-2%, Al-Mg alloy 0.5%-4%, Ni 2%-15%, Cr-Fe alloy 1%-30%, Mo-Fe alloy 1%-30%, Ti-Nb-V-Fe alloy 1%-20%, fluoride 0.5%-3%, trace rare-earth yttrium element oxide Y2O3 smaller than or equal to 1% and the balance iron powder. The high-strength high-toughness gas shield flux-cored wire has the advantages that the flux-cored wire prepared according to the composition proportion is high in strength, high in toughness and moderate in hardness and does not easily carry residues, and a welded joint can be matched with a 1000 MPa high-strength steel plate in an equal strength mode.

Owner:SHOUGANG CORPORATION

Welding method for improving low-temperature impact toughness of low carbon martensite stainless steel welded joint

InactiveCN102794538ASimple processEasy to operateArc welding apparatusWelding/cutting media/materialsMartensitic stainless steelSS - Stainless steel

The invention relates to a welding process, and in particular relates to a welding method for improving the low-temperature impact toughness of a low carbon martensite stainless steel welded joint. The welding method comprises the steps of a pre-welding treatment, a preheating treatment, a welding treatment and an after-welding heat treatment, wherein the temperature of the thermal treatment is 540-570 DEG C. The invention provides a unique process method, the Nieq / Creq equivalence ratio of a welding material is improved based on an original welding process scheme, the energy of a welding wire and foreign carbon leaking into a welded joint are reduced, and simultaneously the post-welding temper temperature is slightly increased.

Owner:KOCEL GROUP +1

Environment friendly AC-DC alkaline low-hydrogen welding rod

InactiveCN102069326AIncreased dust generationFast meltingWelding/cutting media/materialsSoldering mediaFerrosiliconEngineering

The invention relates to an environment friendly AC (alternating current)-DC (direct current) alkaline low-hydrogen welding rod. The welding rod can reduce welding dust, and has a good AC-DC welding technology performance, higher welding rod deposition efficiency and corresponding chemical components and good mechanical properties. So, the invention is conductive to saving energy, reducing emission and reducing environment pollution and is beneficial to the people's livelihood. The welding rod comprises a coating and a welding core, wherein the coating comprises 24-34 parts by weight of marble, 21-32 parts by weight of fluorite, 4-16 parts by weight of iron powder, 3-10 parts by weight of barium carbonate, 2-7 parts by weight of synthetic rutile, 1-4 parts by weight of feldspar, 5-9 parts by weight of medium carbon ferromanganese, 5-12 parts by weight of ferrotitanium, 4-7 parts by weight of No.45 atomized ferrosilicon, 1-2 parts by weight of synthetic mica, 1-3 parts by weight of titanium white and 0.5-1.5 parts by weight of sodium carbonate, and the welding core adopts H08A. The invention is used as a welding rod.

Owner:HARBIN UNIV OF SCI & TECH +1

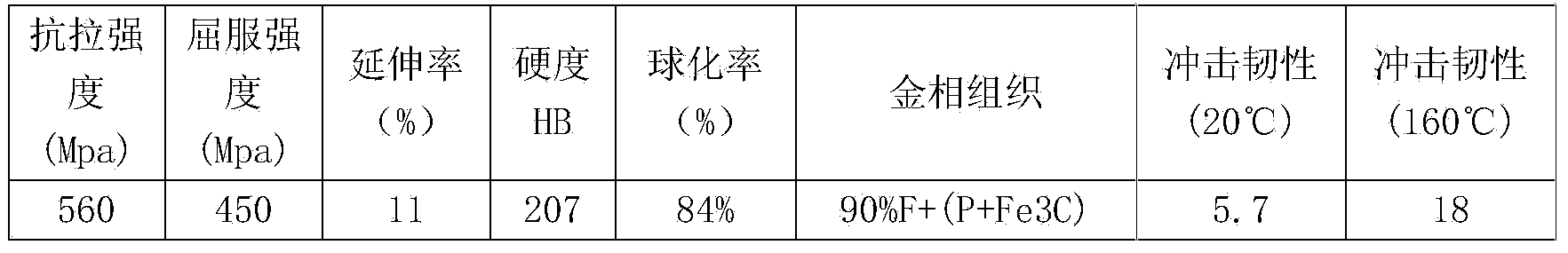

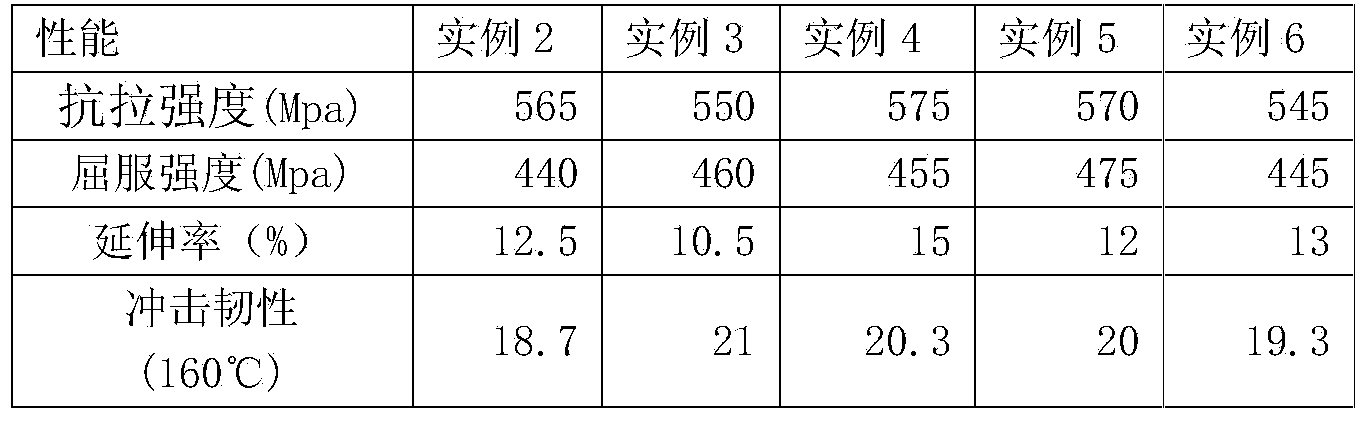

Manufacturing method of heat-resistant high-silicon-molybdenum nodular cast iron

ActiveCN104141088AImprove creep resistanceImprove durabilityProcess efficiency improvementRare-earth elementEnvironmental resistance

The invention relates to a manufacturing method of nodular cast iron for high-temperature parts of combustion engines, in particular to a manufacturing method of heat-resistant high-silicon-molybdenum nodular cast iron. The method comprises the following steps that chemical parameters, raw materials and weight percentage compositions are determined, wherein the nodular cast iron comprises, by weight, 30 percent-40 percent of pig iron, 20 percent-30 percent of scrap steel, 30 percent-40 percent of foundry returns, 1.5 percent-2.0 percent of silicon iron and 1 percent-1.2 percent of ferromolybdenum, and smelting, modification treatment, aging stress relieving technologies are performed. The method is unique, the creep resistance and endurance property of the material are improved, the intensity of the material is enhanced, and the service life of the material is prolonged; the influence on the graphite form by rare earth elements is relieved, the graphite roundness is improved, the fragmentation effect of graphite is relieved, the manufacturing cost and processing costs are reduced, and environmental friendliness and energy saving are facilitated.

Owner:KOCEL EQUIP

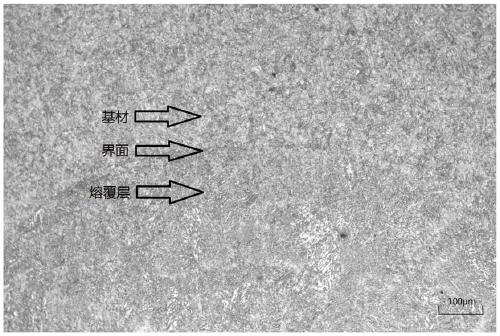

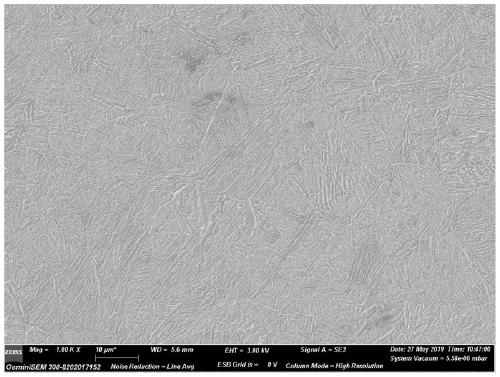

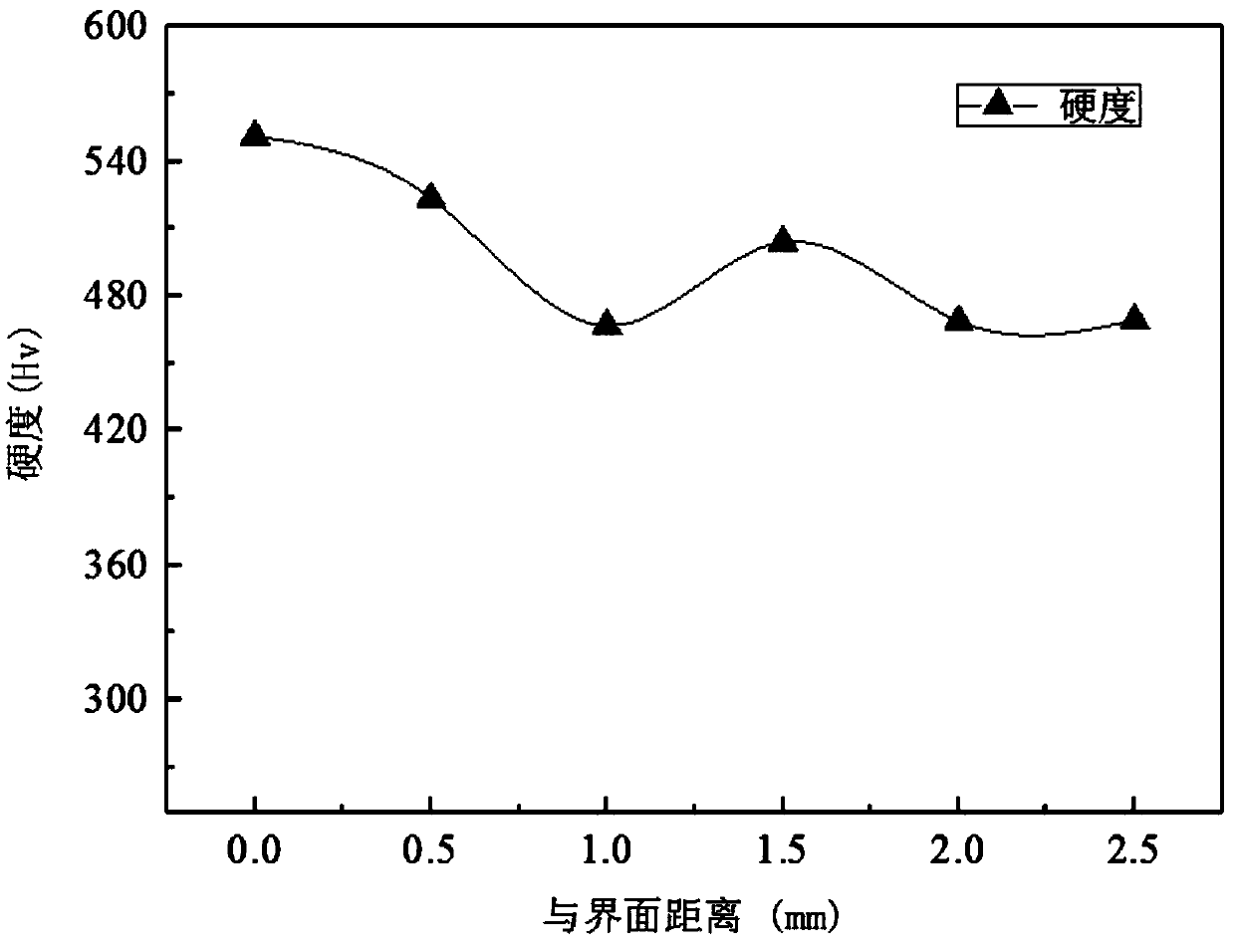

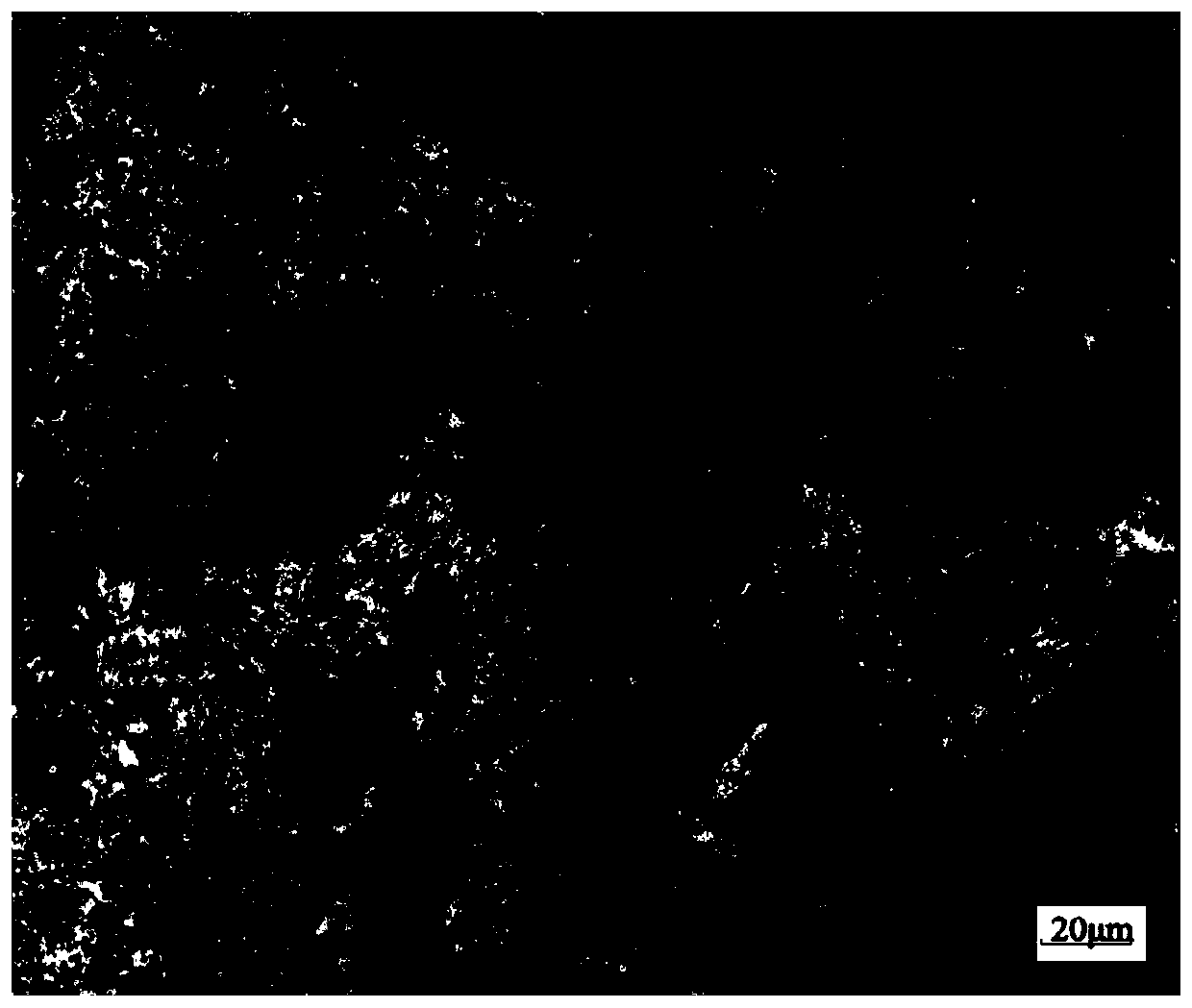

Alloy powder for high-strength bainite steel laser repairing and preparing method of alloy powder

ActiveCN110344053AImprove stabilityReduced impact toughnessMetallic material coating processesSlagAlloy

The invention discloses alloy powder for high-strength bainite steel laser repairing and a preparing method of the alloy powder, and belongs to the technical field of alloy powder materialscience. Thealloy powder comprises various components including, by mass, 0.25%-0.85% of C, 0.8%-3.5% of Si, 0.5%-1.5% of Mn, 0.5%-2.0% of Cr, 0%-2.0% of Ni, 0%-3% of Al, 0.1%-1.5% of Mo and the balance Fe. Thepreparing method comprises the steps that firstly, according to the mass percentages of the components, element burning losses are considered, and raw materials are weighed and placed in a vacuum smelting furnace to be completely melted; secondly, a melted alloy solution is poured into an atomization tower, inert gas is utilized for gas atomization, the solution is crushed by the inert gas, and after cooling, the alloy powder is obtained; and thirdly, a powder screening machine is used for selecting the alloy powder with the target particle size. The alloy powder can be used for high-strengthbainite steel surface and volume damage repairing, after repairing, the sample cladding layer and base material interface structure and performance transition isgood, the repaired layer is free of cracks and slag inclusions; and compared with a base body, the bainite structure is finer, and the hardness is 390-550 Hv.

Owner:GUIZHOU UNIV

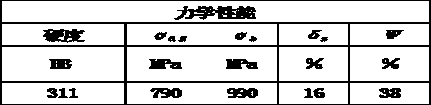

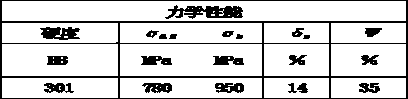

Cr54 steel for high-quality coal mine chain ring and production method thereof

The invention discloses Cr54 steel for a high-quality coal mine chain ring and a production method thereof. The Cr54 steel is characterized by comprising the following chemical components in percentage by weight (%): 0.21-0.24% of C, 0.14-0.20% of Si, 1.20-1.30% of Mn, 0.45-0.55% of Cr, 0.95-1.05% of Ni, 0.025-0.035% of Al, 0.52-0.58% of Mo, less than or equal to 0.010% of P, less than or equal to0.008% of S, less than or equal to 0.004% of V, less than or equal to 0.0025% of Ti, less than or equal to 0.0003% of B, less than or equal to 0.0009% of O, less than or equal to 0.0080% of N, less than or equal to 0.00012% of H and the balance Fe. According to the Cr54 steel, carbon equivalent, a cold crack sensitivity coefficient and a hot crack sensitivity coefficient are introduced, so that the excellent welding performance of the Cr54 steel is ensured, and the cold and hot brittleness resistance is improved; and the surface quality of the steel is improved by adopting an innovative process, the rejection rate is reduced, and the effective cost is increased less.

Owner:XINING SPECIAL STEEL +1

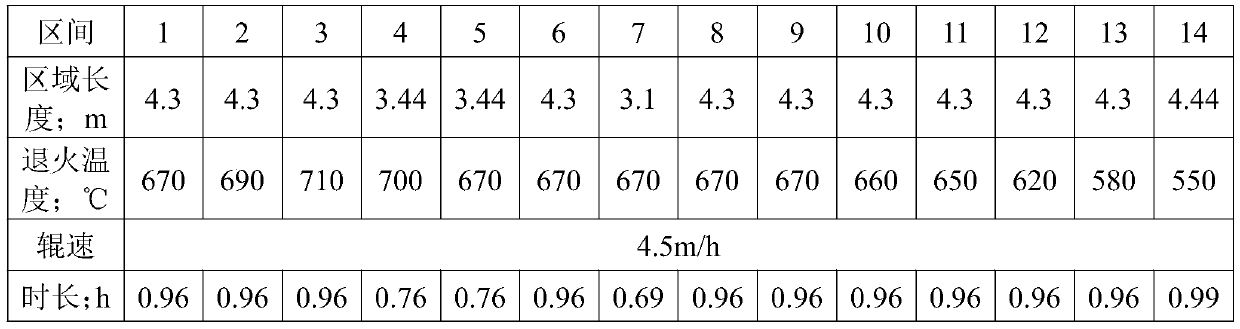

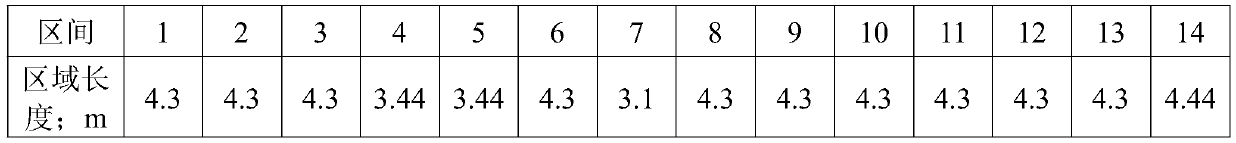

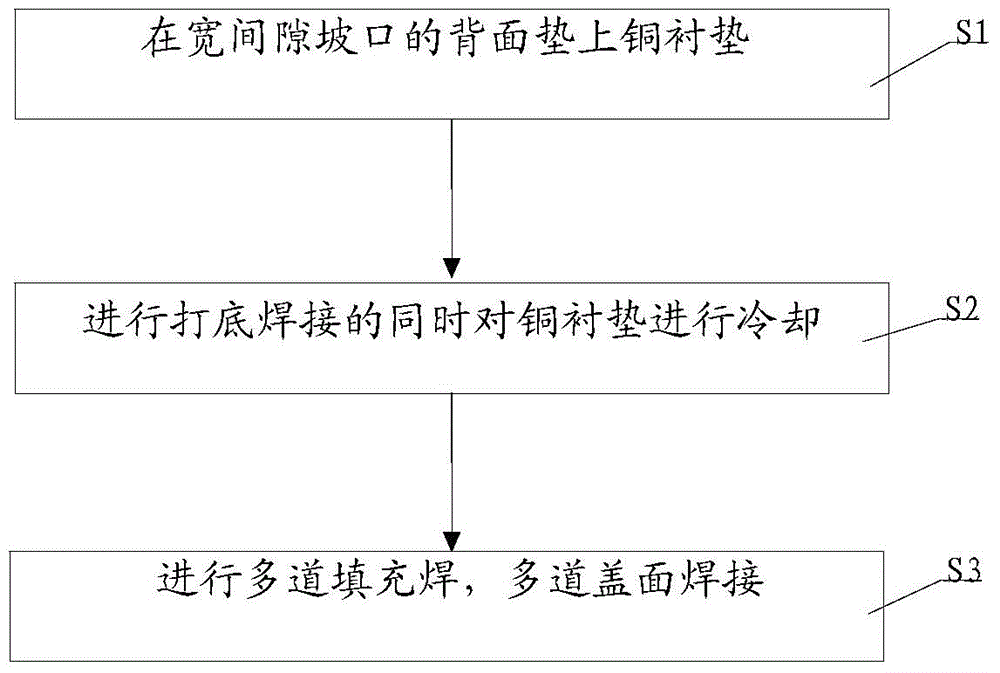

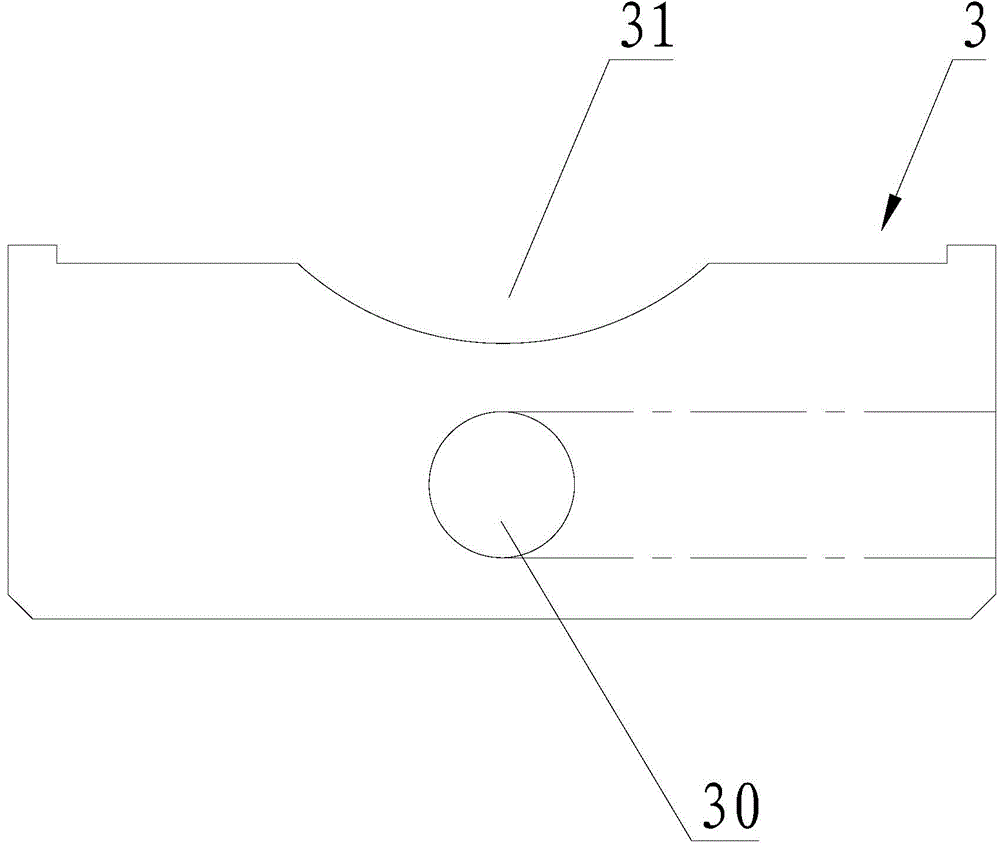

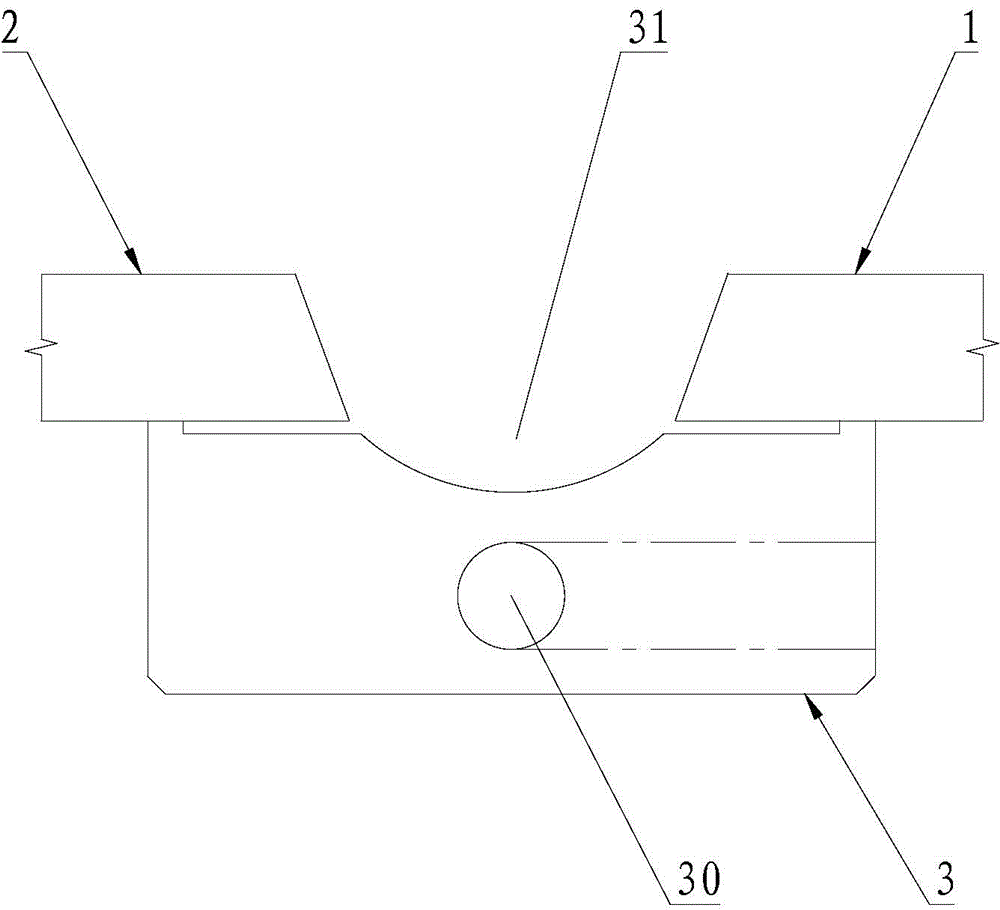

Wide-gap square butt joint welding technology and welding structure

ActiveCN104526112AFine and uniform grainReduce the degree of segregationWelding/cutting auxillary devicesArc welding apparatusTest sampleButt joint

The invention relates to a wide-gap square butt joint welding technology and welding structure. A copper liner is adopted to replace a ceramic liner, and the problem that ceramic is molten and stirred to generate slag inclusion is avoided. In the backing weld process, the copper liner is cooled, a weld joint is fast cooled and formed, meanwhile, a weld connector is prevented from generating an overheated structure, the segregation degree is effectively reduced, and the mechanical performance of the weld connector is improved. A solid welding wire is used for backing weld, and weld cracks are not prone to being generated. A contrast test shows that when a gap is 12 mm, the ceramic liner is adopted for single-face CO2 welding, the formed surface of the weld joint on the back face is wide, backing thickness is increased, the weld joint is overheated, reinforcement height is large, forming deteriorates, the liner is prone to falling off, and impact toughness is reduced severely; through the wide-gap square butt joint welding technology, the weld joint is formed attractively and is golden, a backing weld channel on a macro-test sample is small and even in grain, and a welding technology test displays that all indexes of the mechanical performance of the whole weld connector meet the requirement of EH36 steel plates.

Owner:FUJIAN MAWEI SHIPBUILDING

Modified China fir composite wood

InactiveCN108098950AGood dimensional stabilityReduced impact toughnessPressure impregnationWood impregnation detailsPerformance indexComposite lumber

The invention provides modified China fir composite wood. The composite material has better dimensional stability. Impact toughness of modified China fir is reduced slightly, while other main mechanical performance indexes such as bending strength, bending elasticity modulus, parallel-to-grain compressive strength, hardness and the like are all increased. Fast growing China fir wood is treated with an aluminium sulfate solution and a water glass solution in sequence in experiments in order to improve properties of the fast growing China fir wood. Aluminium ions immersed into the wood are boundwith silicate ions, aluminium sulfate precipitates are generated in wood microfiber gaps and cells of tracheids (or fiber), so that the wood is filled with a large amount of inorganic matter, and theChina fir inorganic composite wood is obtained. Dimensional stability of the inorganic composite wood is improved substantially, anti-shrinkage coefficient can reach 34.21, and stability coefficientreaches 80% or higher.

Owner:哈尔滨正灏建筑设备安装工程有限公司

Automobile transmission gear and heat treatment process thereof

ActiveCN106224492ALight in massImprove structural strengthNon-macromolecular adhesive additivesFilm/foil adhesivesMagnesiumOxide

The invention relates to an automobile transmission gear. Constituents of the automobile transmission gear comprise C, Cr, Si, Mn, Zn, Cu, Ag, Au, Pt, Ni, W, Mo, Nd, Ce, Eu, Lu, Ti, Als, S, P, N, talcum powder, magnesium oxide and the balance Fe. Anti-rust performance and abrasion resistance of the automobile transmission gear are improved, and meanwhile, impact toughness and fatigue strength of the gear are not reduced; in addition, the service life of the automobile transmission gear can be prolonged; and meanwhile, the automobile transmission gear can have the antistatic property, the heat absorption and insulation properties and surface water repellency.

Owner:SUZHOU LIDE PRECISION IND

Turbine blade capable of improving thermal cracking resistance and production process thereof

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

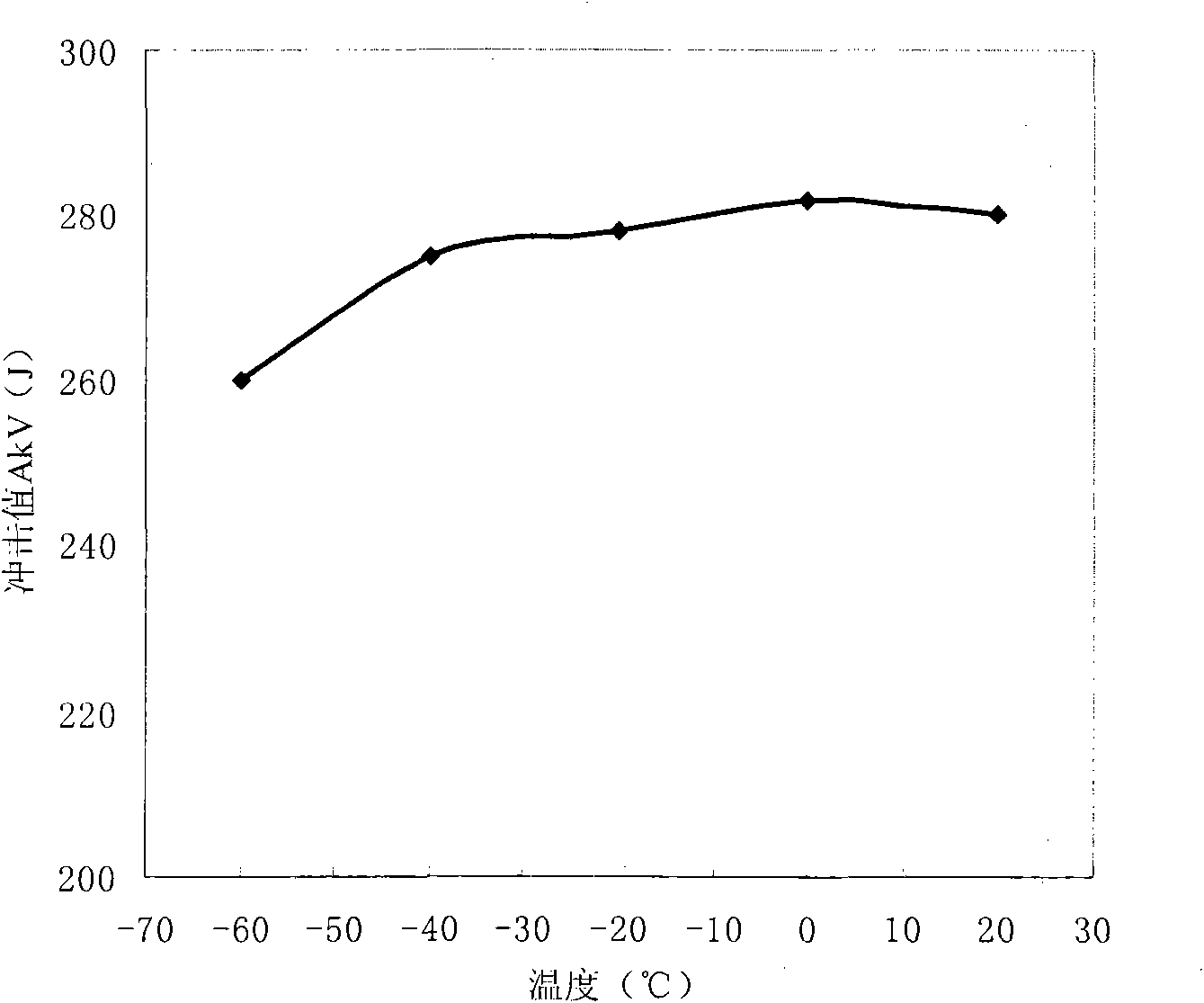

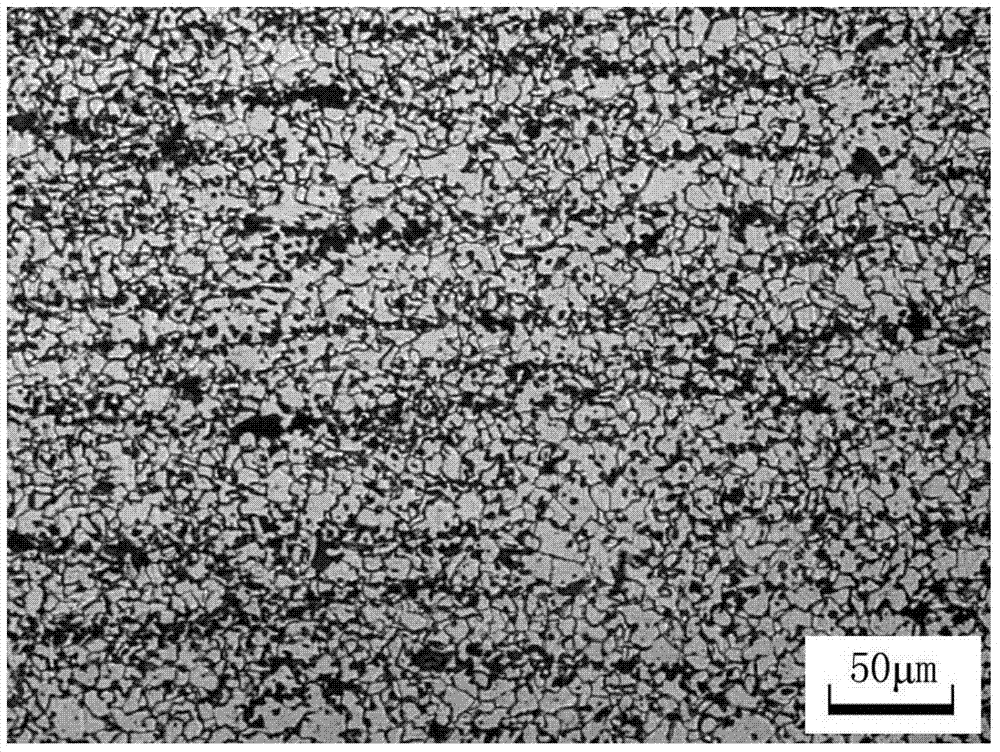

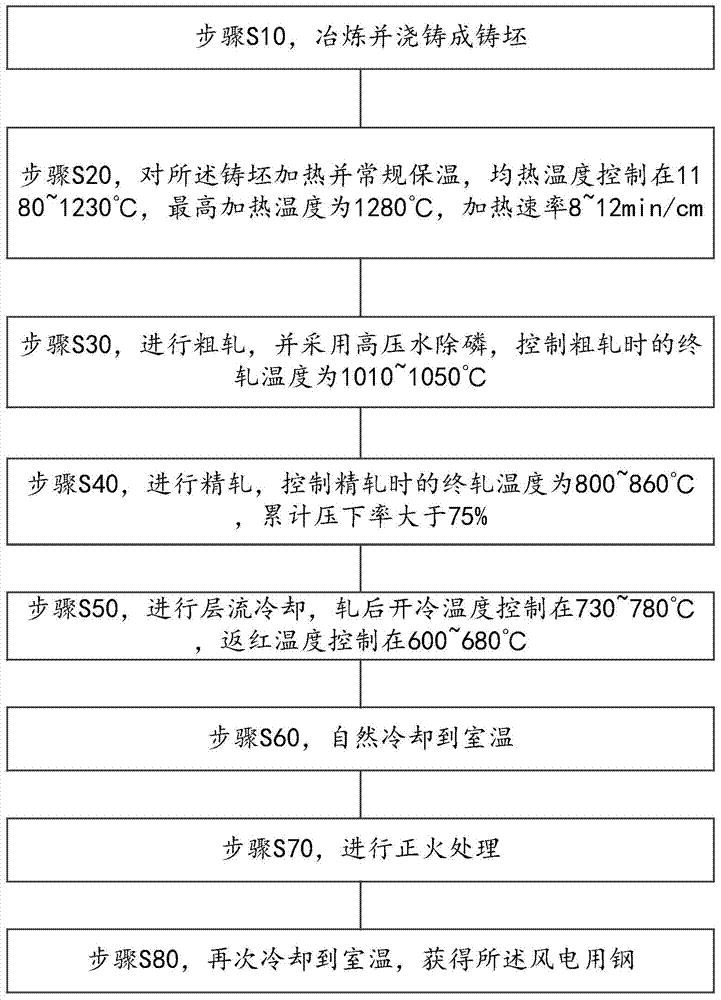

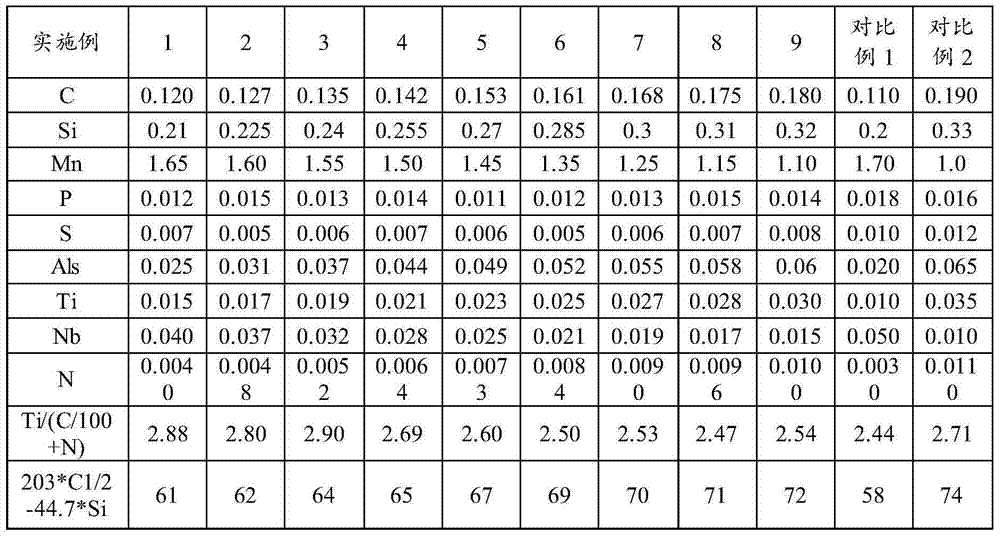

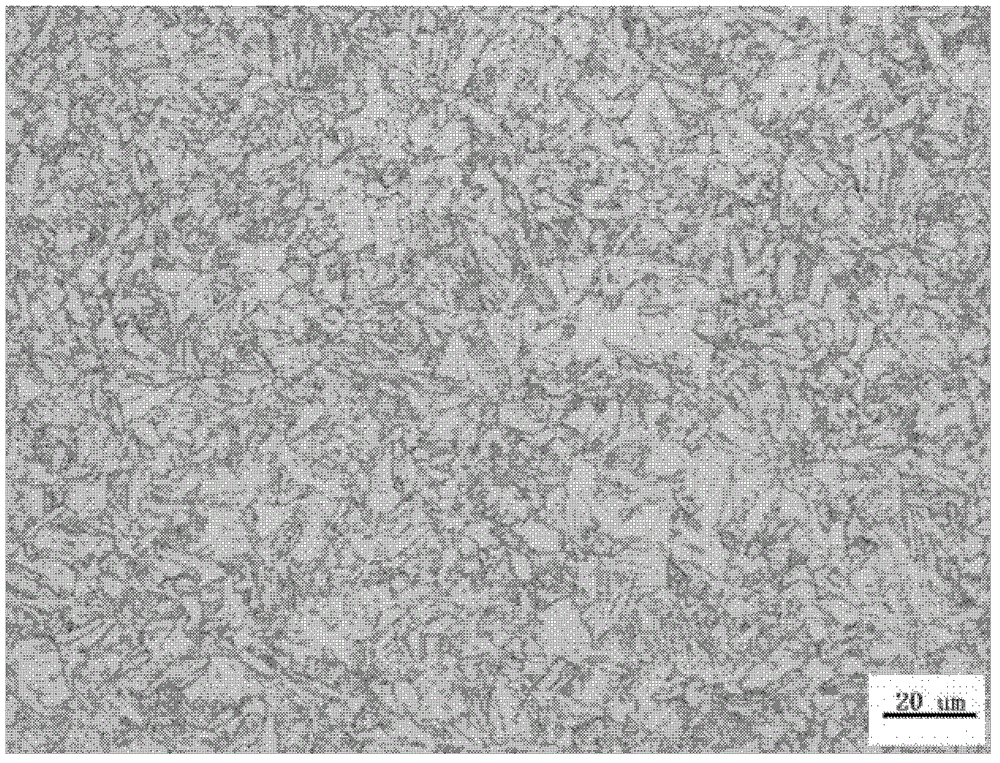

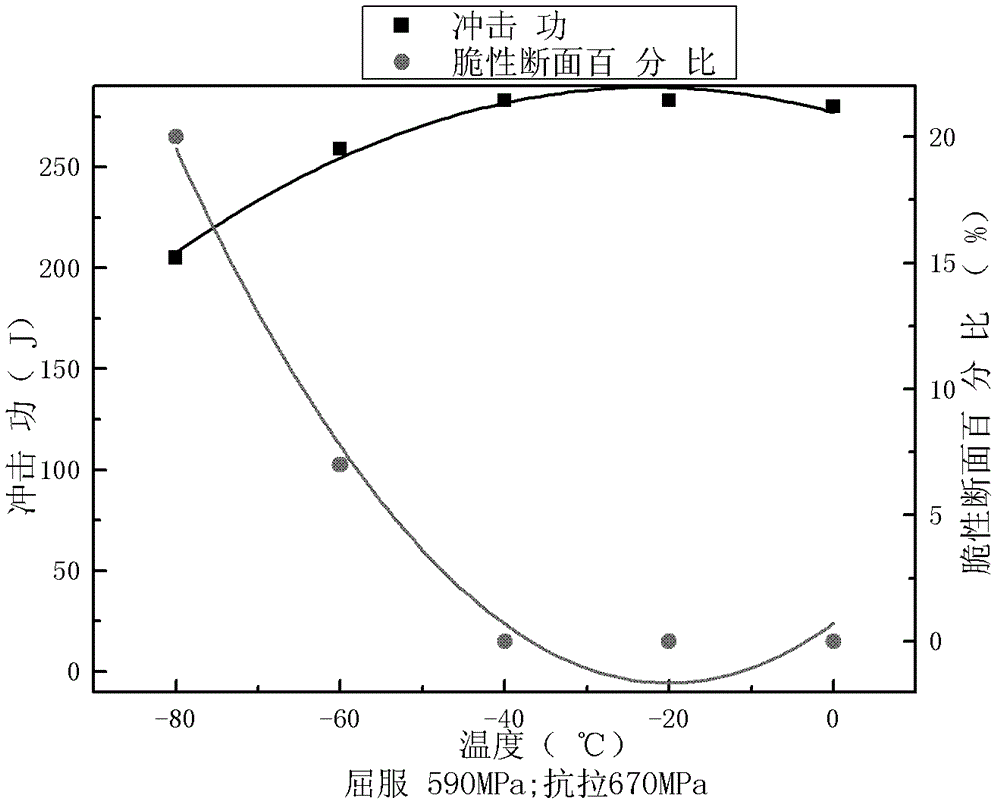

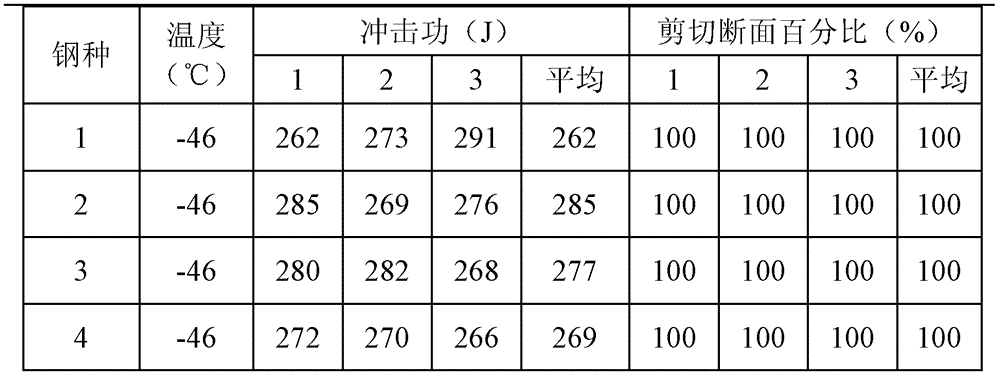

Normalized steel plate for wind power, and production method thereof

The invention discloses a normalized steel plate for wind power, and a production method thereof. The yield strength, the tensile strength, the elongation percentage A, the -40DEG C impact energy and the -60DEG C impact energy of the normalized steel plate for wind power are not lower than 370MPa, 500-650MPa, not lower than 30%, not lower than 250J and not lower than 200J respectively. The steel plate comprises, by mass, 0.12-0.18% of C, 0.21-0.32% of Si, 1.10-1.65% of Mn, 0.015% or less of P, 0.008% or less of S, 0.015-0.040% of Nb, 0.015-0.03% of Ti, 0.025-0.06% of Als, 0.004-0.010% of N, and the balance of Fe and inevitable impurities; and 203*C<1 / 2>-44.7*Si is not lower than 61 and not greater than 72, and Ti / (C / 100+N) is in a range of 2.47-2.69 or 2.88-2.90. Nb and Ti alloy is used in the steel plate, so alloy cost of the steel plate is reduced, the low temperature performances of the steel plate are enhanced, the yield strength is high, and the technical problems of high alloy cost, poor low temperature performances and small normalized yield strength of steel plates for wind power in the prior art are solved.

Owner:武汉钢铁有限公司

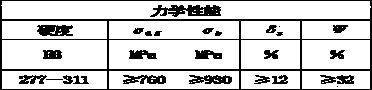

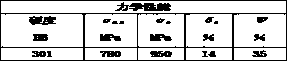

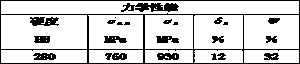

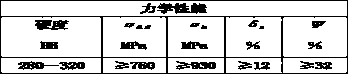

Cast steel materials

ActiveCN1970816AReduced impact toughnessImprove hardenabilityHeat treatment process controlUltimate tensile strengthSteel casting

The invention discloses a making method of cast-steel material, which comprises the following steps: allocating raw material with 0.2-0.29% C, 0.4-0.6% Si, 0.8-1.1% Mn, 0.35-0.5% Cr, not more than 0.15% Ni, not more than 0.20% Mo, not more than 0.040% S and not more than 0.040% P; casting once at 920+-10 deg.c; insulating 2h; cooling; heating to 880 deg.c; insulating 1h; quenching to indoor temperature; tempering at 580+-10 deg.c; insulating 2h; cooling to 350 deg.c; discharging. The cast steel (ZG30Cr06A) possesses excellent strength, which improves plasticity and impacting flexibility.

Owner:郑州煤机格林材料科技有限公司

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

X80 steel grade anti-corrosion low-temperature seamless line pipe

The invention provides an X80 steel grade anti-corrosion low-temperature seamless line pipe which comprises the following components in percentage by weight: 0.08 to 0.14 percent of C, 0.20 to 0.35 percent of Si, 1.10 to 1.40 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.20 percent of Mo, 0.020 to 0.060 percent of Al, 0.02 to 0.05 percent of Nb, 0.05 to 0.10 percent of V, 0.10 to 0.20 percent of Cu, 0.10 to 0.20 percent of Ni, less than or equal to 0.015 percent of Ti, less than or equal to 0.15 percent of Cr, 0.0015 to 0.0060 percent of Ca, less than or equal to 0.0005 percent of B, less than or equal to 0.012 percent of N, less than or equal to 0.43 percent of CEV, less than or equal to 0.23 percent of Pcm and trace amount of ferrum and impurity elements. The line pipe has the rigidity of less than or equal to 250 HV10 and grain size of more than or equal to 8 levels, and passes tests of hydrogen induced cracking (HIC) and sulfide stress corrosion (SSC) corrosion tests at the ductile-brittle transition temperature of below -60 DEG C. The line pipe has the advantages that the integral tissue of a pipe body is uniform,the equivalent carbon content is less than the that of the requirement of the American petroleum institute (API) 5L standard, the welding performance is high, the low-temperature toughness and anti-corrosion performance are excellent, the cost is low, and the requirement of users on the X80 steel grade seamless line pipe can be met completely.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Welding wire for submerged arc welding of high-manganese low-temperature steel and welding method

ActiveCN109623198AReduce welding costsLow costArc welding apparatusWelding/cutting media/materialsChemical compositionManganese

The invention discloses a welding wire for submerged arc welding of high-manganese low-temperature steel and a welding method, and relates to the technical field of welding. The welding wire is prepared from the following chemical components according to mass percent: 0.2% to 0.4% of C, 12% to 15% of Mn, 16% to 20% of Ni, 2% to 5% of Cr, less than or equal to 0.004% of P, less than or equal to 0.002% of S and the balance of Fe and inevitable impurities. The manganese-nickel composition design adopted by the welding wire has good compatibility with high-manganese low-temperature steel base metal and is suitable for a conventional welding wire manufacturing method, the composition is simple, weld metal formed by the welding wire has good impact toughness at low temperature of -196 DEG C, andthe welding requirement of the high-manganese low-temperature steel for constructing equipment like a liquefied natural gas storage tank is preferably met.

Owner:NANJING IRON & STEEL CO LTD

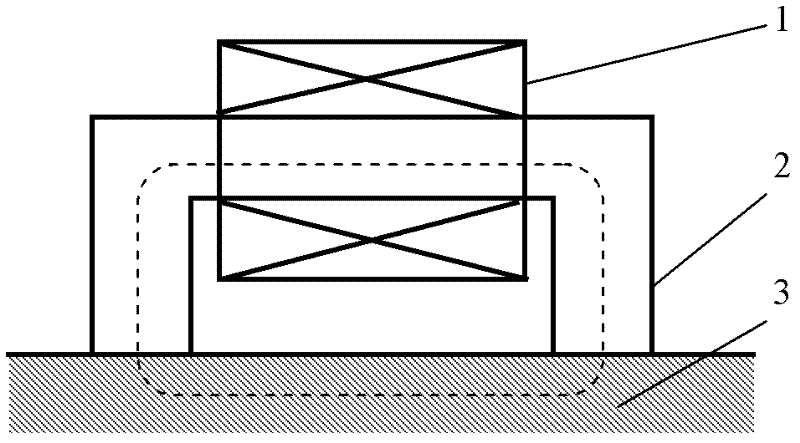

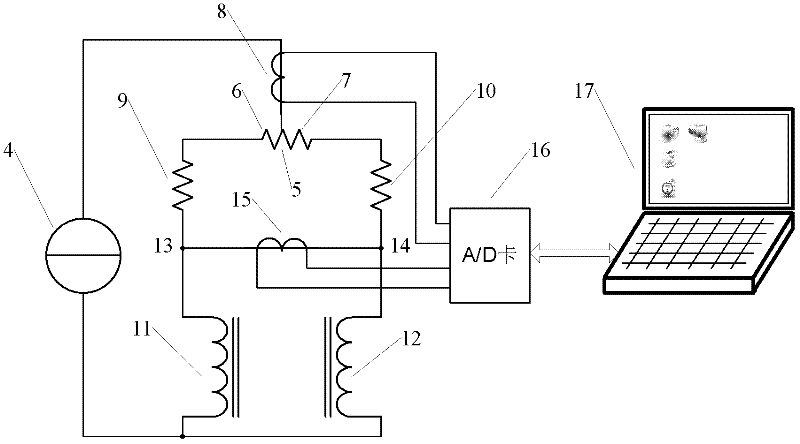

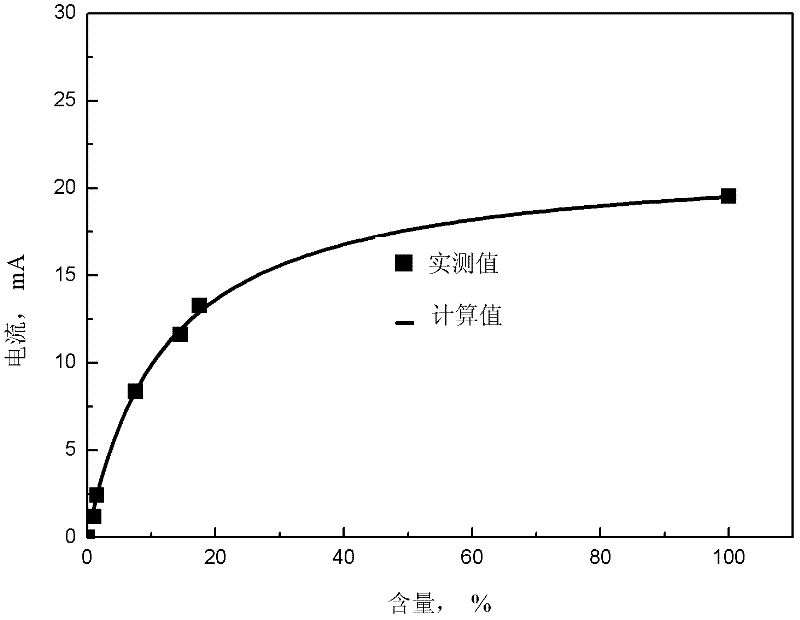

Electromagnetic on-line detection method of retained austenite of rolling bearing

InactiveCN102507723AQuick checkReduced impact toughnessMaterial magnetic variablesData acquisitionAlternating current

The invention discloses an electromagnetic on-line detection method of retained austenite of a rolling bearing. The electromagnetic on-line detection method comprises the steps that: (1) an alternating current bridge type circuit is established to build an equivalent circuit of a magnetic loop; (2) a constant current source provides exciting current signals; (3) the constant current source inputs the exciting current to an excitation loop; (4) resistors, a reference probe and a measuring probe compose four arms of the alternating current bridge type circuit, and the reference probe and the measuring probe detect a material to be detected; (5) the resistors are connected with a mutual inductor to send output current signals to a data acquisition card and then to a computer; (6) another mutual inductor is connected between the reference probe and the measuring probe to send unbalanced current signals to the data acquisition card and then to the computer; and (7) the computer adjust the alternating current bridge type circuit to a maximum sensitivity according to the input exciting current, and the unbalanced current signal calculates content of the residual austenite of the detected piece. The electromagnetic on-line detection method, disclosed by the invention, has the advantages of high sensitivity, good repeatability, convenient operation and fast detection speed, is relatively well matched with a result of an X-ray method and is suitable for on-line detection and popularized use.

Owner:XI AN JIAOTONG UNIV

Preparation method of cold work die steel material

The invention discloses a preparation method of a cold work die steel material. The preparation method comprises steps of fusion, oxidation, detection and adjustment of alloy composition, refining, casting and heat treatment. The cold work die steel material comprises following chemical elements, by weight, 0.8 to 0.9 portion of carbon, 1.1 to 1.3 portions of silicon, 2.1 to 2.3 portions of manganese, 0.8 to 0.9 portion of molybdenum, 0.1 to 0.15 portion of nickel, 0.6 to 0.7 portion of titanium, 1.1 to 1.2 portions of chromium, 0.3 to 0.4 portion of aluminium, 1 to 2 portions of Hf, 0.06 to 0.08 portion of Nb, 2.5 to 2.8 portions of Bi, 0.03 to 0.05 portion of Sb, S less than 0.03 portion, P less than 0.03 portion, and the balance iron. According to the cold work die steel material, molybdenum, nickel and chromium alloy elements are capable of stabilizing pearlite; aluminium is capable of increasing heat resistance of the cold work die steel material, and promoting fusion of graphitized alloy elements of all stages into the cold work die steel material significantly; and useful actions of molybdenum, nickel and chromium are maintained by adjustment of alloy composition. Cracking of the cold work die steel material is difficult to happen, and the cold work die steel material is capable of reducing impact toughness.

Owner:CHUZHOU XINLONG ELECTROMECHANICAL

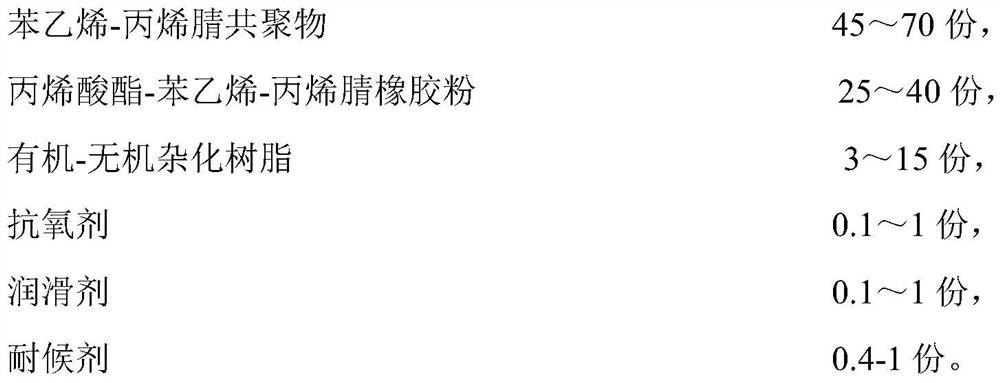

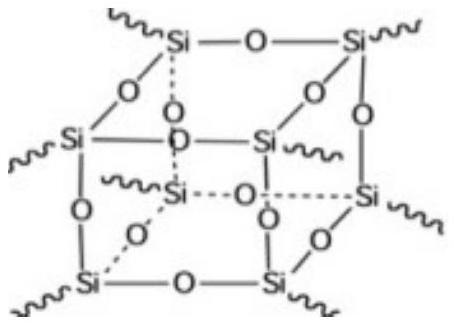

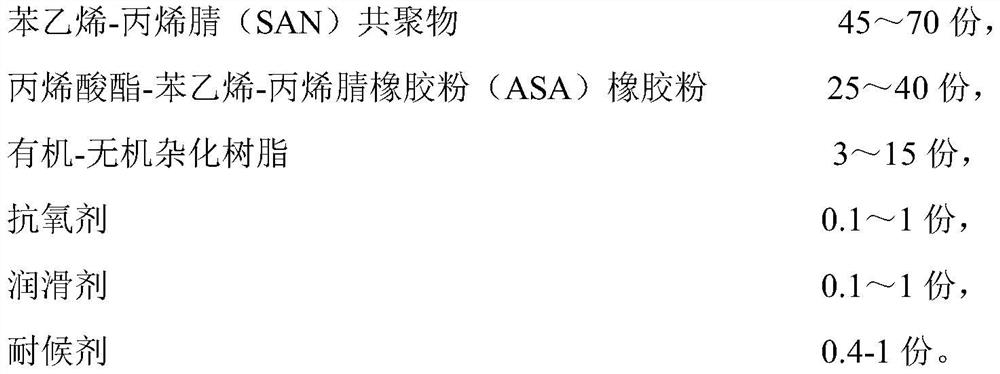

ASA resin suitable for automobile millimeter-wave radar and preparation method thereof

ActiveCN111875898AMaintain weather resistance and impact toughnessSimple methodComposite materialWeather resistance

The invention relates to ASA resin suitable for an automobile millimeter-wave radar and a preparation method of the ASA resin. The ASA resin comprises the following components in parts by weight: 45-70 parts of styrene-acrylonitrile (SAN) copolymer, 25-40 parts of acrylate styrene-acrylonitrile rubber powder (ASA) powder, 3-15 parts of organic-inorganic hybrid resin, 0.1-1 part of antioxidant, 0.1-1 part of lubricant and 0.4-1 part of weather-resistant agent. The preparation method comprises the following steps: adding all the components into a mixing stirrer for mixing the components; and feeding the obtained mixture into a twin-screw extruder through a weightless feeding machine, and carrying out blending granulation to obtain the ASA resin suitable for the automobile millimeter-wave radar. By introducing the organic-inorganic hybrid resin, the dielectric constant of the ASA resin can be effectively reduced, millimeter wave radar wave absorption of the material can be effectively reduced, and meanwhile, the obtained ASA resin can keep good impact toughness and weather resistance and is suitable for automobile exterior trimming parts.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Welding wire of Ti62A alloy suitable for manned submersible and preparing method of welding wire

ActiveCN111761258AWeight percent optimizationMeet the needs of special matching welding wireWelding/cutting media/materialsSoldering mediaAlloyVacuum annealing

The invention discloses a welding wire of Ti62A alloy suitable for a manned submersible and a preparing method of the welding wire. The welding wire is prepared from grade-zero sponge titanium, aluminum-vanadium intermediate alloy, aluminum-chromium intermediate alloy, aluminum-zirconium intermediate alloy, aluminum-molybdenum intermediate alloy and aluminum-stannum intermediate alloy. The components include, by weight percentage, 4.5-6.75% of Al, 0.5-1.5% of V, 0.3-1.75% of Cr, 1.5-2.5% of Zr, 1.5-3.0% of Mo, 0.5-2.0% of Sn and the balance Ti and inevitable impurities. Through pressing, assembly-welding, two times of smelting, cogging forging, free forging, rolling, wiredrawing, straightening, polishing, and vacuum annealing, the welding wire of the Ti62A alloy suitable for the manned submersible is obtained, wherein the performance of the welding wire meets the conditions that impact absorbing energy KV2 is larger than or equal to 20 J, the tensile strength Rm is larger than or equalto 1010 MPa, the welding wire is suitable for Ti62A alloy TIG welding, MIG welding, etc., and the requirements for matched welding wires special for the Ti62A alloy of domestic manned submersibles are met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

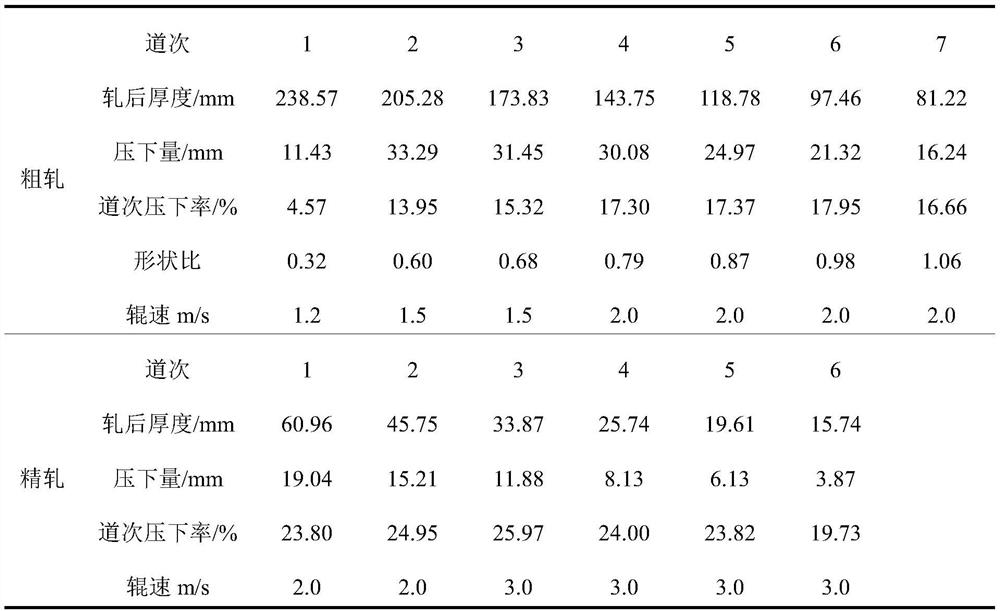

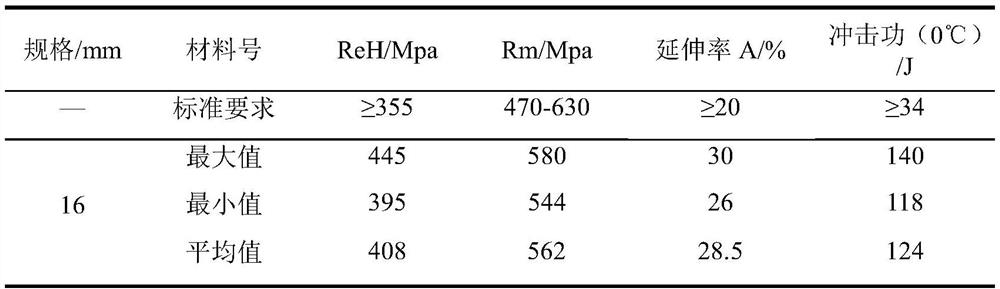

Low-cost production process for Q355C steel plate

The invention relates to low-cost production process for a Q355C steel plate. The Q355C steel plate comprises the following chemical components in percentage by mass: 0.11%-0.20% of C, not greater than 0.20%-0.45% of Si, 1.1%-1.6% of Mn, 0.015%-0.045% of Alt, not greater than 0.025% of P, not greater than 0.015% of S and the balance Fe; the internal quality of the steel plate is improved via converter smelting, reasonable end-point carbon content control, complete deoxygenation, white slag refining and soft blowing, calcium treatment, and continuous casting; and the internal quality of the steel plate is further improved through rough rolling and finish rolling two-phase controlled rolling, and reasonable allocation for rolling temperatures, speeds and passes. According to the low-cost production process for the Q355C steel plate, the impact toughness at 0 DEG C is improved by reducing a C content; expensive Nb and V are replaced by cheap micro-alloy element Al, so that the profit maximization is realized, and the impact toughness is further improved; and the Q355C steel plate is produced through a rolling process which is matched with the components, and the cost of a ton of steelcan be reduced by 50 yuan.

Owner:TIANJIN IRON & STEEL GRP

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

Solid core wire for gas protection welding of high manganese low temperature steel

ActiveCN109623202AReduce the content of expensive elements and alloy costsImprove performanceWelding/cutting media/materialsSoldering mediaLiquefied natural gasMetallic Nickel

The invention discloses a solid core wire for gas protection welding of high manganese low temperature steel. The solid core wire is characterized by comprising the following chemical composition in percentage by mass: 0.2-0.4% of C, 12-15% of Mn, 14-18% of Ni, 1.5-4.5% of Cr, 0.1-0.6% of Mo, 0.005-0.040% of Ti, no more than 0.004% of P, no more than 0.002% of S and the balance Fe and inevitable impurity elements. The solid core wire adopts the alloy design of composite manganese and nickel adding, the content of expensive elements such as nickel and the cost of alloy are reduced, the fact that the excessive amount of manganese forms excessive toxic manganese evaporation in the welding process is avoided, the use performance of the wire is improved, the weld metal formed by the solid corewire at low temperature of minus 196 DEG C has excellent impact toughness, and the welding requirements of the high manganese low temperature steel for the construction of liquefied natural gas storage tanks and other equipment are well met.

Owner:NANJING IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com