Patents

Literature

39results about How to "Good solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

A kind of plastic mold steel and its manufacturing method

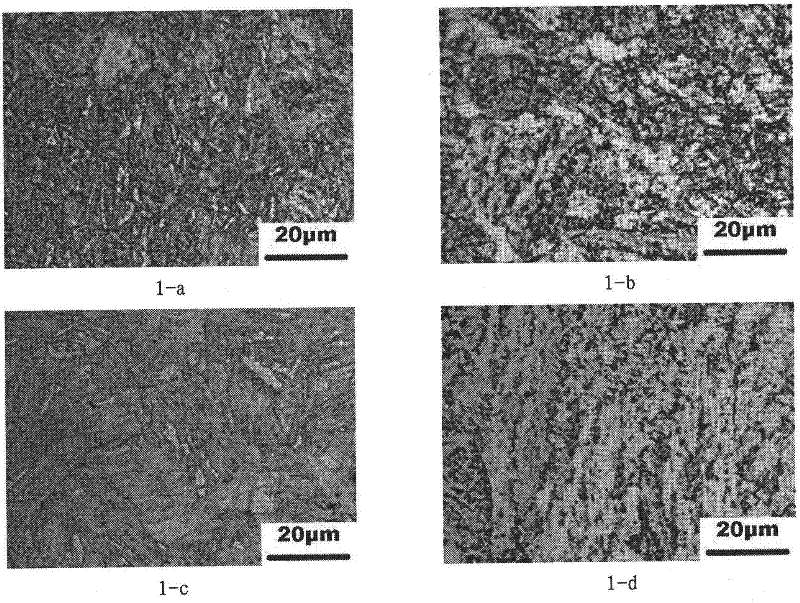

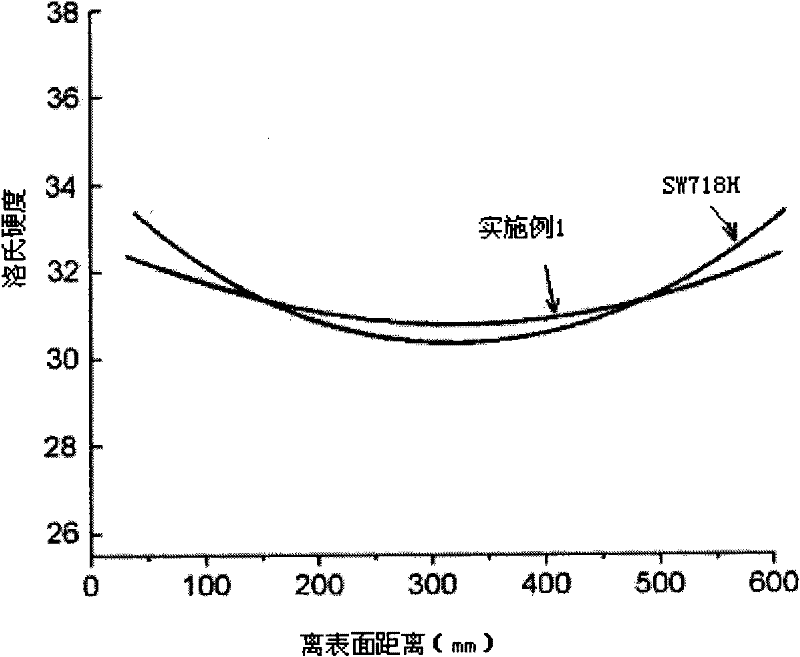

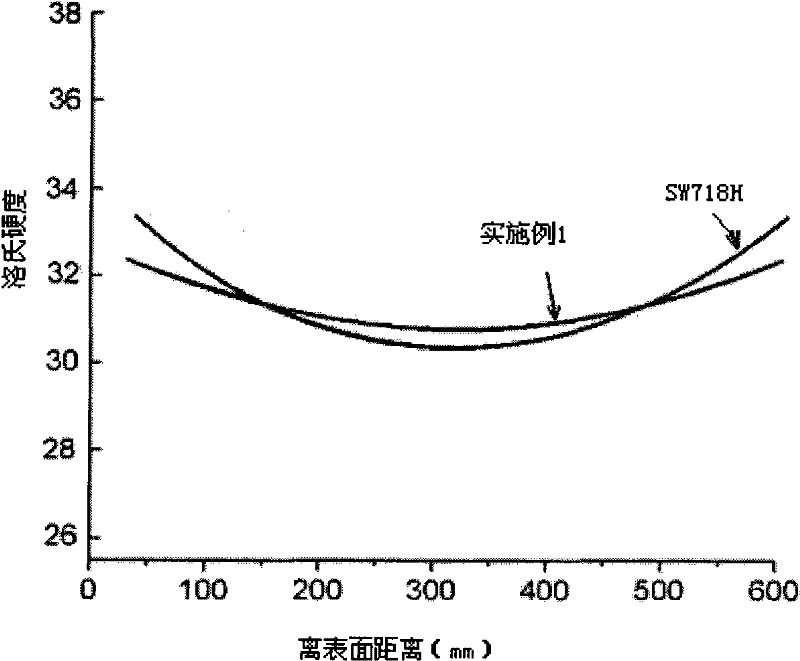

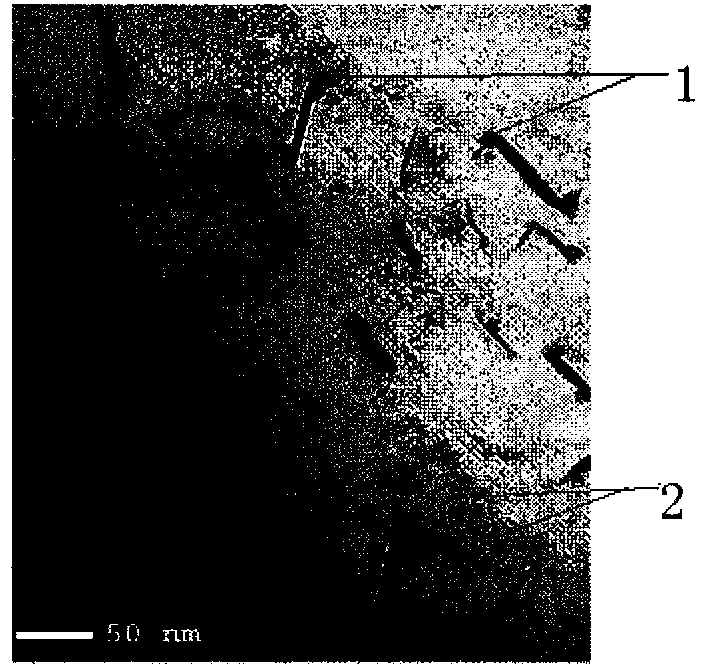

The invention discloses a plastic mold steel which comprises the following chemical components in percentage by weight: 0.25-0.29% of C, 1.30-1.50% of Mn, 0.40-0.60% of Si, 1.20-1.50% of Cr, 0.40-0.50% of Mo, 0.02-0.05% of Nb, less than or equal to 0.15% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.012% of N and the balance of iron and inevitable impurities. In the manufacture method of the plastic mold steel, a quenching and tempering heat treatment process is not used, and direct air cooling after forging is carried out, thus prehardened plastic mold steel with thickness above 600 mm and uniform hardness from core to surface is manufactured. According to the plastic mold steel disclosed by the invention, the limit that the existing non-quenched and tempered mold steel has thickness smaller than 400 mm is overcome, and the requirements of mold industries on low-cost high-quality large-sized prehardened plastic mold steel are reached.

Owner:宝武特种冶金有限公司

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

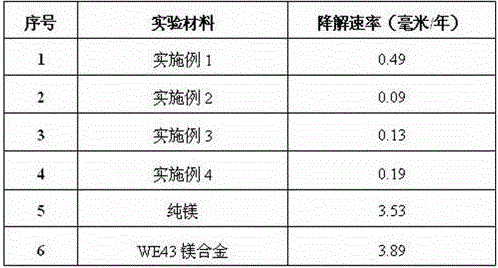

Rare earth-contained heat-resistant magnesium alloy and preparation method thereof

ActiveCN103421999AImprove mechanical propertiesGood mechanical propertiesRare earthUltimate tensile strength

The invention discloses a rare earth-contained heat-resistant magnesium alloy and a preparation method thereof, belongs to the technical field of magnesium alloy preparation. The heat-resistant magnesium alloy disclosed by the invention comprises the following materials by weight: 2 to 8 percent of Sm, 0.5 to 6 percent of Gd, 0.1 to 2 percent of Zn, 0.1 to 1.5 percent of Zr, and Mg and inevitable impurity elements in balancing amount, wherein the total weight of the impurity elements is equal to or smaller than 0.02 percent. By adding ally elements (Sm, Gd and Zn) to replace Y and Nd of WE series alloies, and adjusting corresponding heat treatment processes to ensure that the prepared magnesium alloy has excellent indoor temperature intensity, high-temperature strength and plasticity, the indoor temperature intensity, high-temperature strength and plasticity of the magnesium alloy prepared according to the preparation method are more excellent than those of the conventional WE series commercial magnesium alloies; the preparation method of the magnesium alloy prepared according to the preparation method is lower than that of the conventional WE series commercial magnesium alloies. The process is simple; industrialized application is facilitated.

Owner:CENT SOUTH UNIV

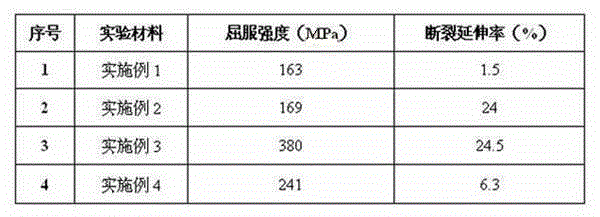

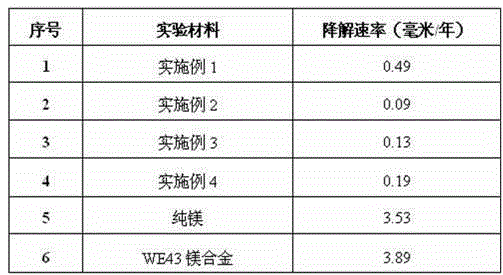

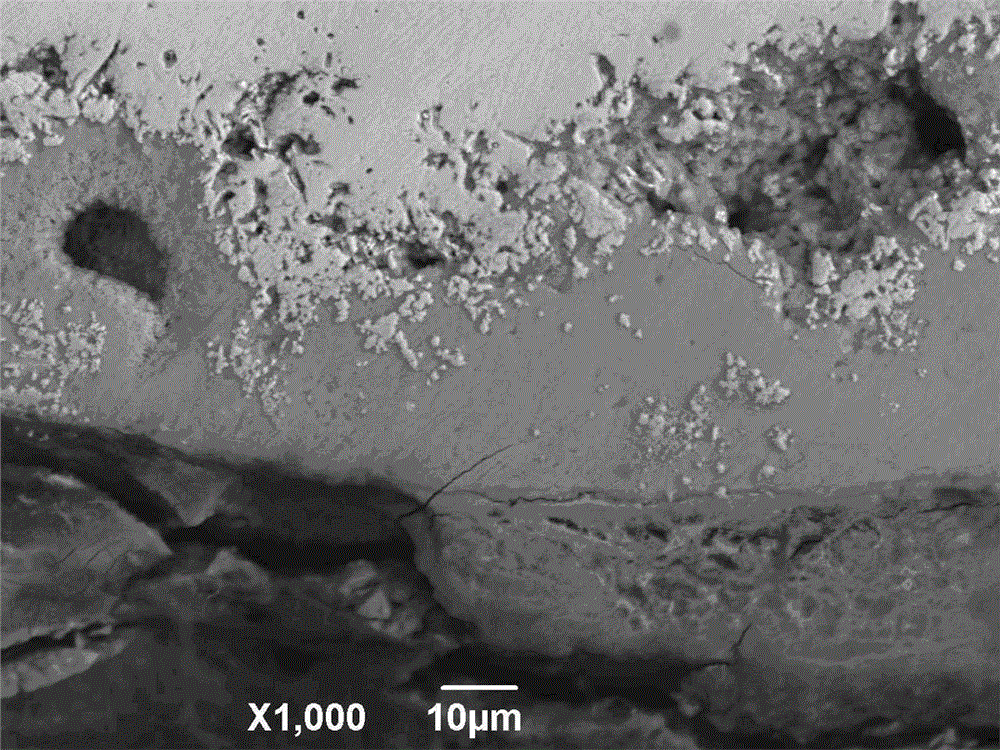

Degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for human body and application thereof

ActiveCN104689378ALow costImprove corrosion resistanceSuture equipmentsProsthesisAdditive ingredientZinc alloys

The invention provides a degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for a human body and application thereof and relates to the field of medical implant materials. The zinc alloy contains a Zn element, a Fe element and an X element, wherein the X element is at least one of Mg, Ca and Sr, the mass percent of Zn element is 89.92-99.997%, the mass percent of Fe element is 0.002-10%, and the mass percent of X element is 0.001-0.08%. According to the zinc alloy provided by the invention, the cost of added materials is low, degradation products of all ingredients of a prepared alloy material can be degraded through human body metabolism, the corrosion resistance is far higher than that of a magnesium alloy, the degradation rate is greatly lowered, a longer-time mechanical support can be provided, and the strength and toughness of the alloy material are good.

Owner:XIAN ADVANCED MEDICAL TECH

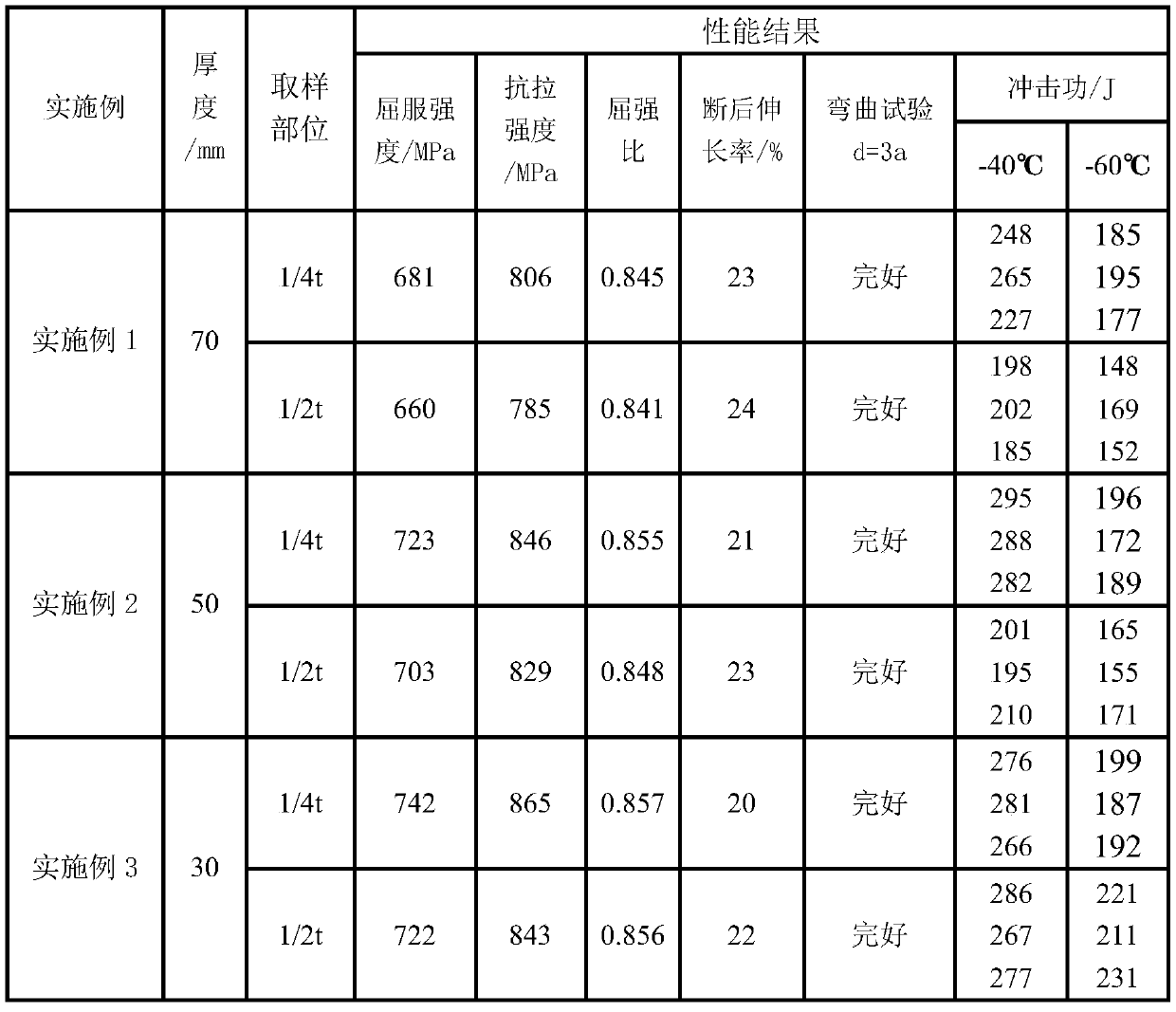

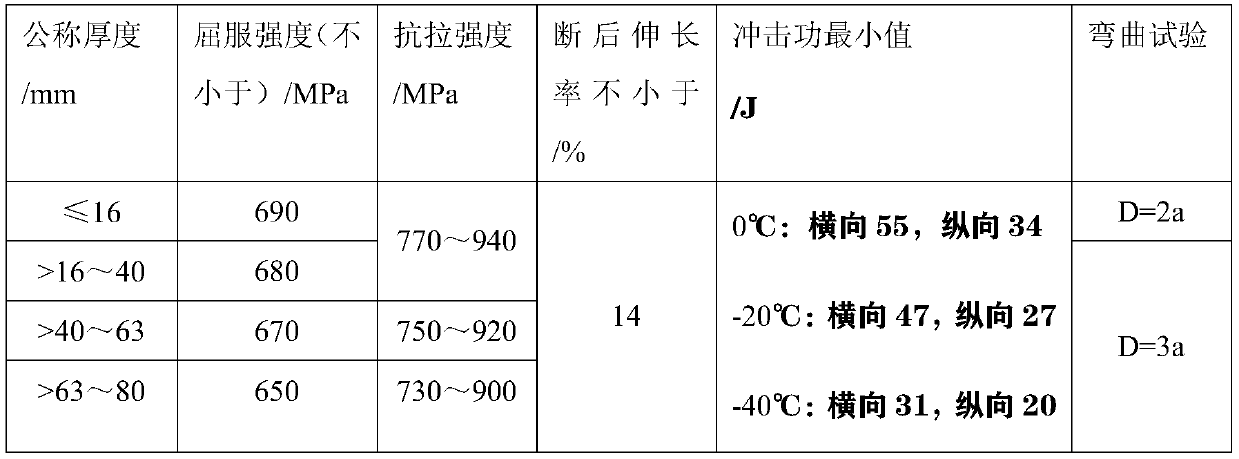

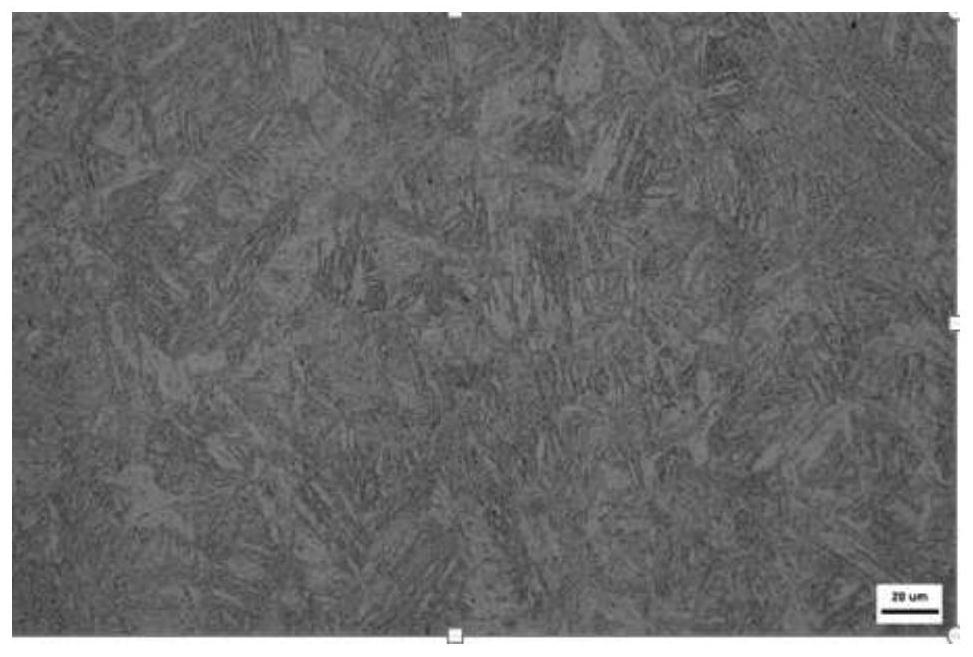

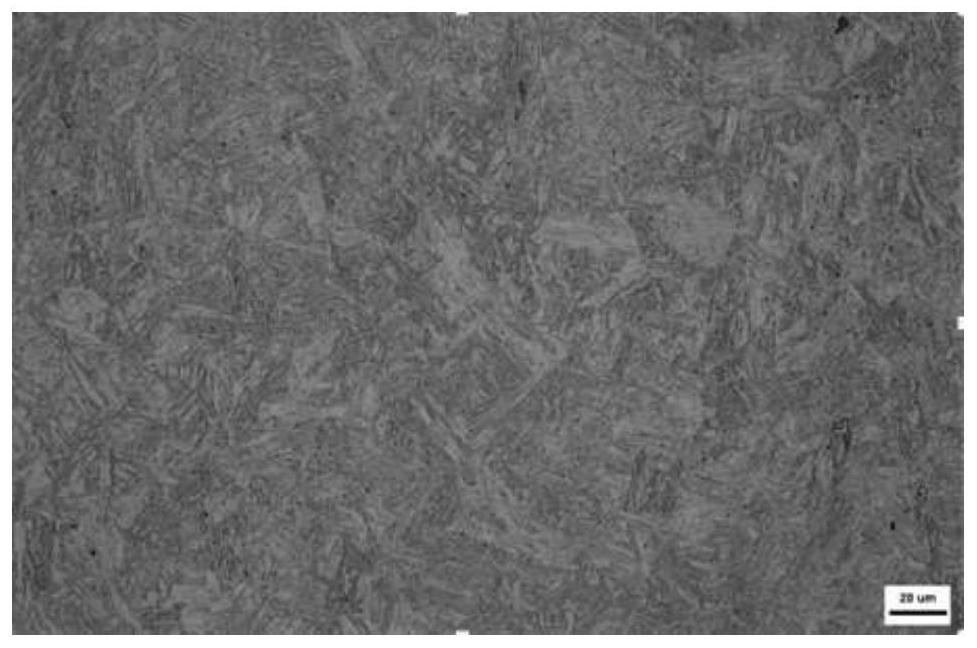

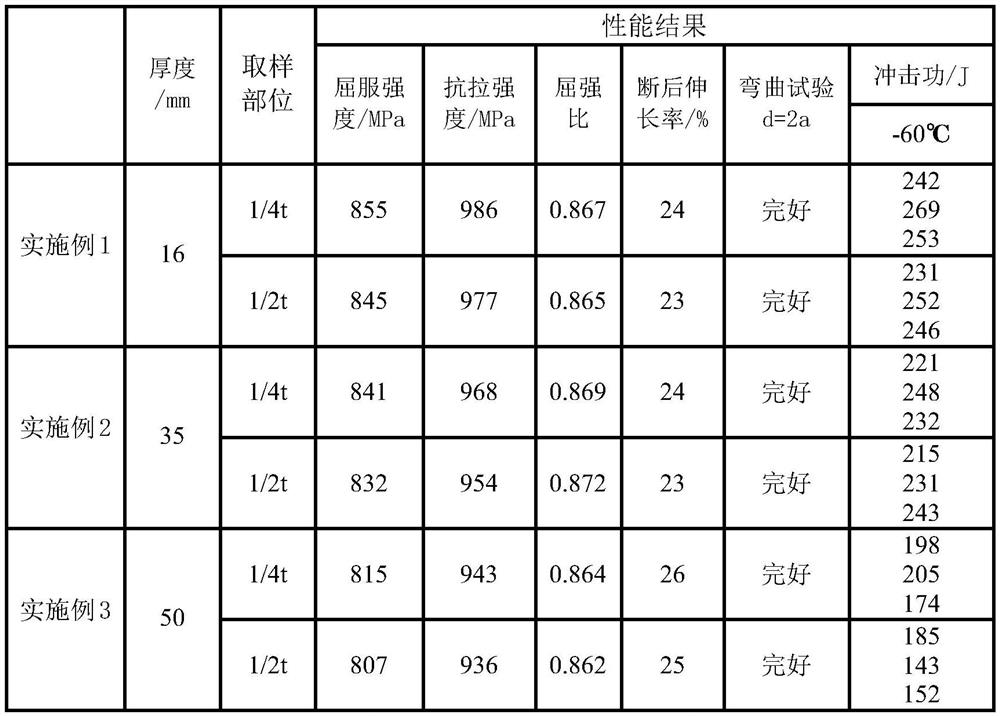

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

The invention discloses 690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and a manufacturing method, and relates to the technical field of steel smelting. Thesteel comprises the following chemical components of, in percentage by mass, 0.05%-0.10% of C, 4.1%-4.7% of Mn, 0.15%-0.4% of Si, less than or equal to 0.010% of P, less than or equal to 0.003% of S,0.01%-0.05% of Ti, less than or equal to 0.6% of Ni + Cr + Mo, and the balance Fe and inevitable impurities. The requirements of ultra-high strength steel safety performance and construction cost in acomplex environment in the field of engineering machinery can be met.

Owner:NANJING IRON & STEEL CO LTD

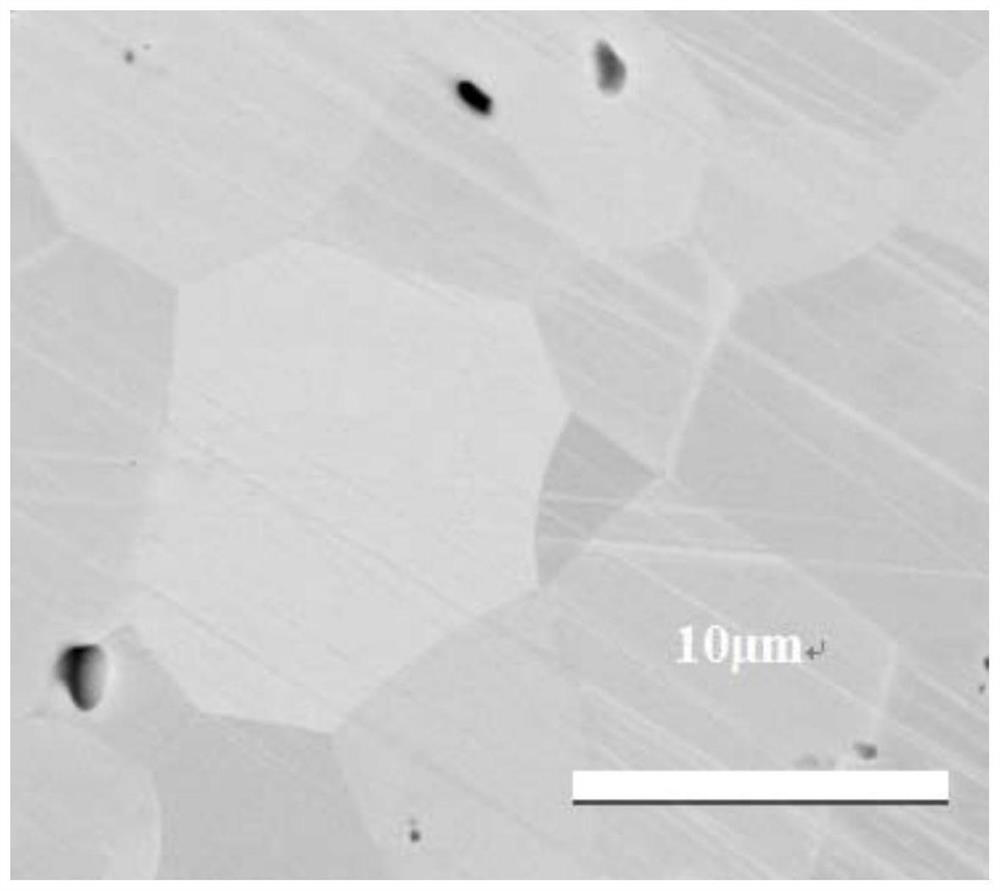

Ultrahigh steel Q960E thick plate and manufacturing method

The invention discloses an ultrahigh steel Q960E thick plate, and relates to the field of ultrahigh-strength steel thick plate producing and manufacturing. The ultrahigh steel Q960E thick plate comprises chemical components including, by mass percent, 0.15%-0.18% of C, 0.20%-0.50% of Si, 0.80%-1.30% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.003% of S, 0.30%-0.50% of Cr, 0.40%-0.60% of Mo, 0.80%-1.0% of Ni, 0.008%-0.030% of Ti, 0.015%-0.050% of Nb, 0.0008%-0.0025% of B and the balance Fe and inevitable impurities. The medium-high carbon and alloying component design is adopted, controlled rolling and offline heat treatment methods are adopted for assistance, and the ultrahigh-strength steel thick plate with the thickness being 90 mm is provided.

Owner:NANJING IRON & STEEL CO LTD

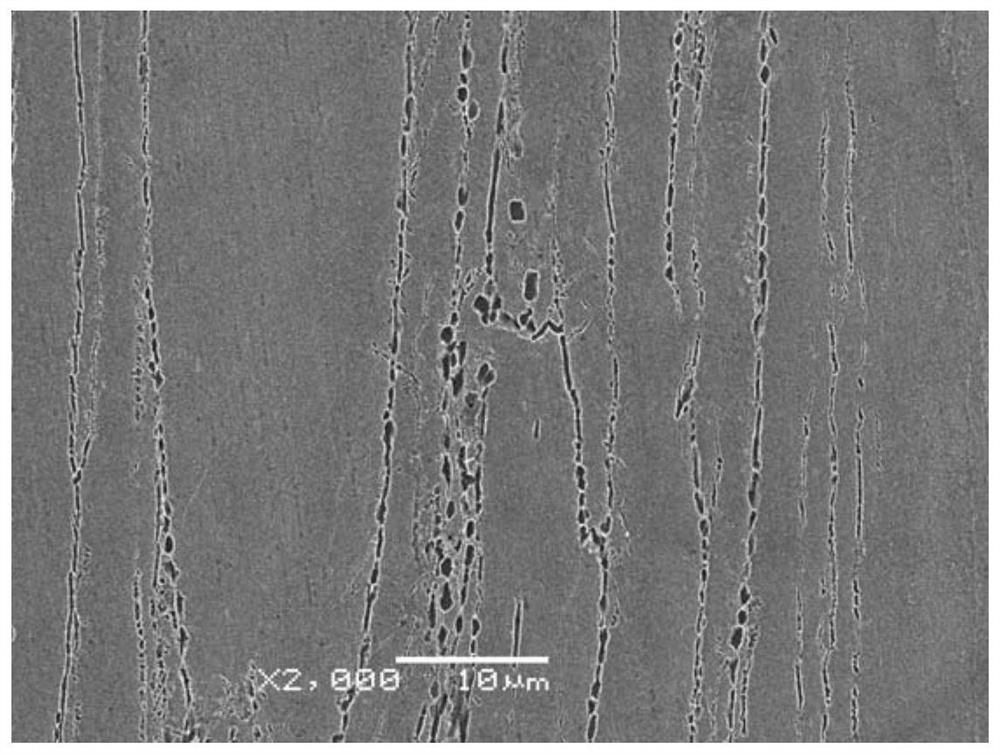

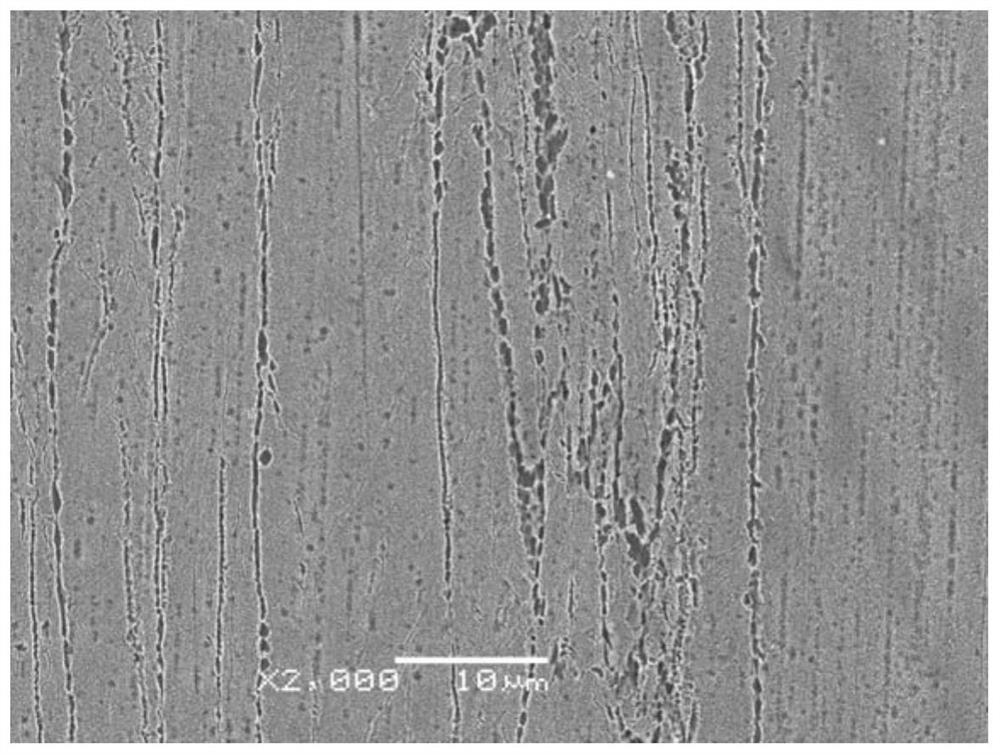

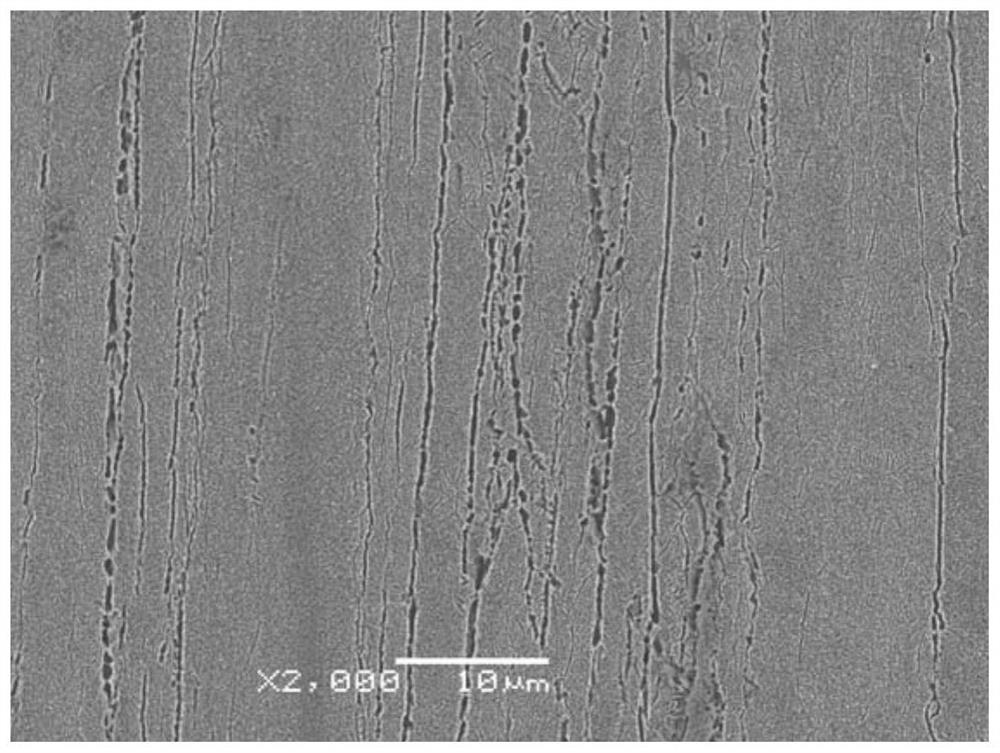

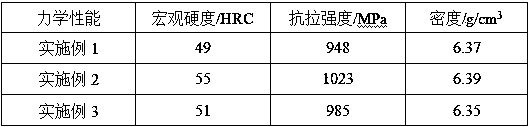

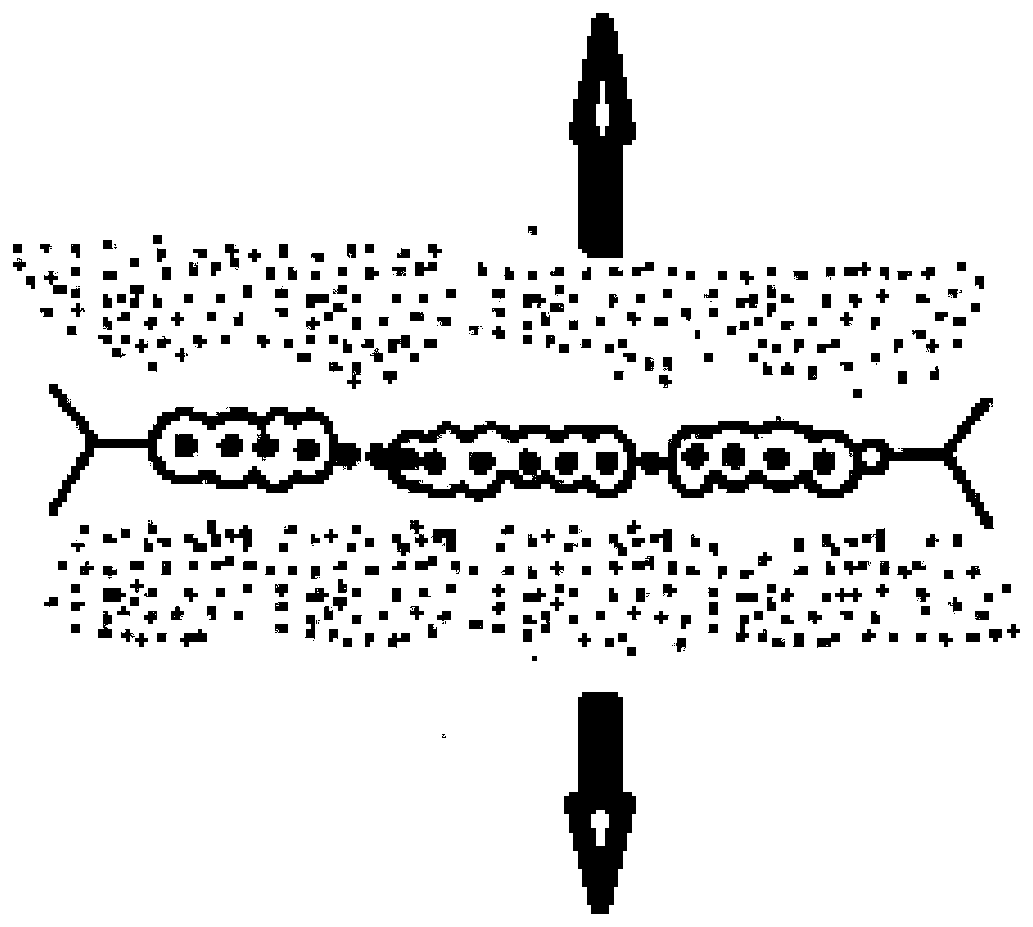

Material of stirring head for friction stir welding and preparation method thereof

ActiveCN110102869AOptimize ball milling processSintering changeNon-electric welding apparatusFriction stir weldingFriction welding

The invention discloses a material of a stirring head for friction stir welding and a preparation method thereof, and relates to the technical field of the friction stir welding. The material of the stirring head is prepared from W, 10%-20% by weight of Re and 0.3%-1.0% by weight of ZrC. By adding the nano ZrC into the material of the stirring head, the cost can be effectively reduced on the basisof ensuring the mechanical property and the high-temperature wear resistance of the material. According to the preparation method, it is ensured that the added ZrC material can exist in a nanometer form, and stress concentration can be effectively avoided due to good high-temperature stability of the ZrC material.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

High-strength and heat-resisting rare earth aluminum alloy and preparing method thereof

InactiveCN111763861APoor high temperature performanceGood mechanical properties at room temperatureMaterials sciencePlastic property

The invention relates to a high-strength and heat-resisting rare earth aluminum alloy containing rare earth samarium and a preparing method of the high-strength and heat-resisting rare earth aluminumalloy and belongs to the technical field of alloys. The aluminum alloy comprises the following components including, by mass percent, 5%-6% of Zn, 2%-3% of Mg, 1%-2% of Cu, 0.1%-0.2% of Sm and the balance Al and inevitable impurities. Various second phases, uniform and fine microstructures and weak base plane textures are evenly distributed in the alloy, and therefore the alloy can have high strength and high plasticity. The invention further discloses a preparing method of the high-strength and heat-resisting rare earth aluminum alloy material, nano-order and micron-order second phases and grains with the size being relatively fine are evenly distributed in the tissue of the prepared aluminum alloy, and the mechanical performance of the aluminum alloy is obviously improved.

Owner:YANTAI NANSHAN UNIV

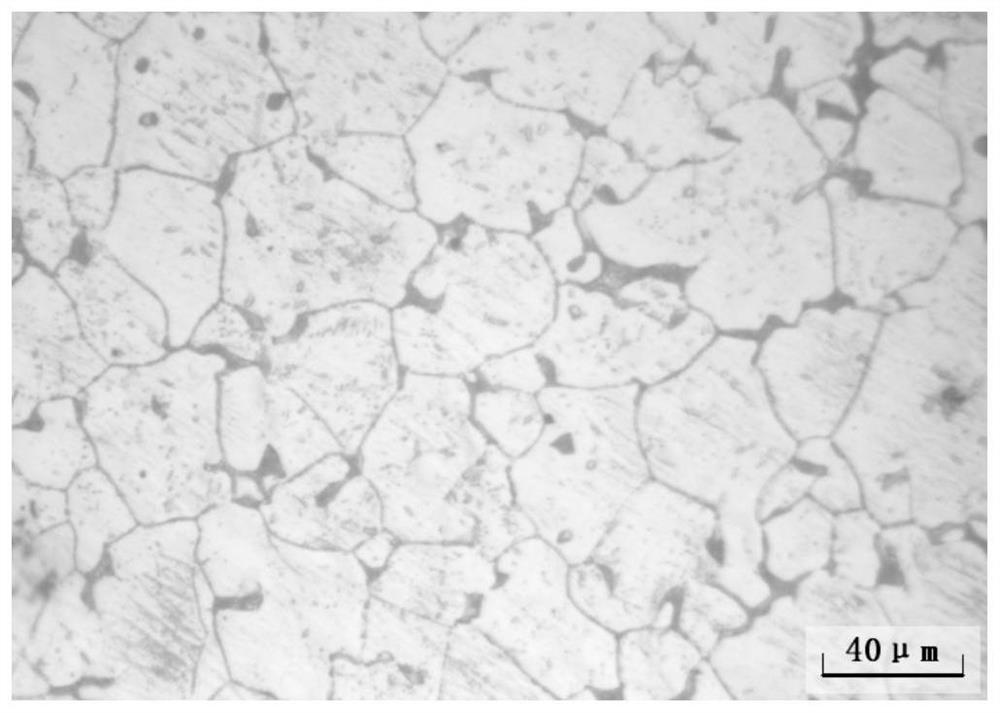

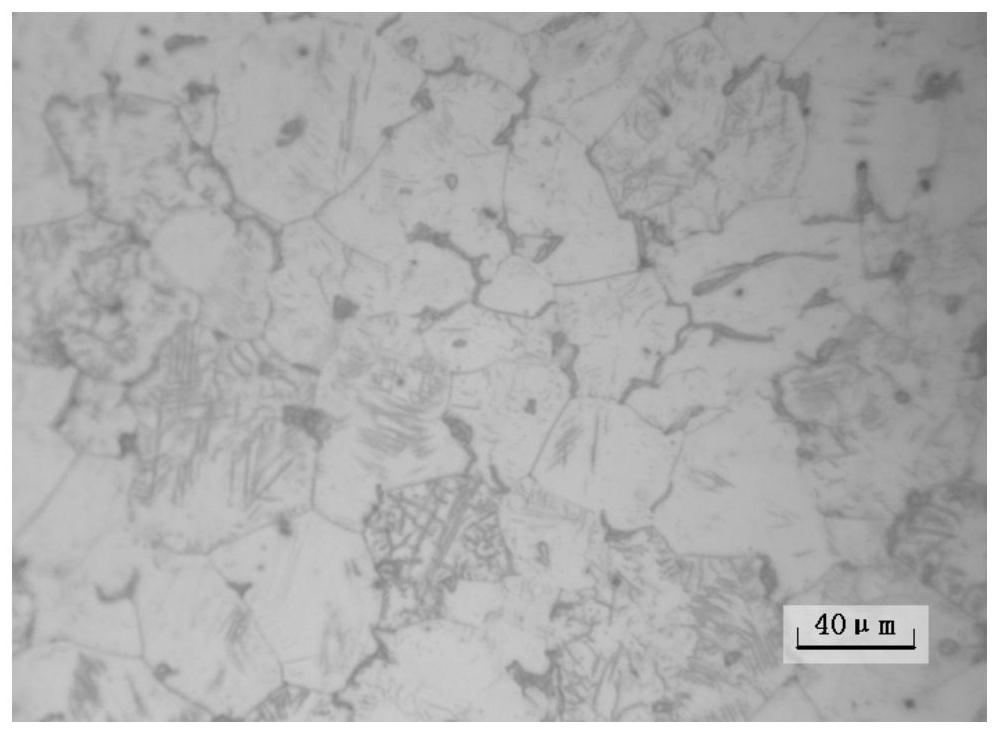

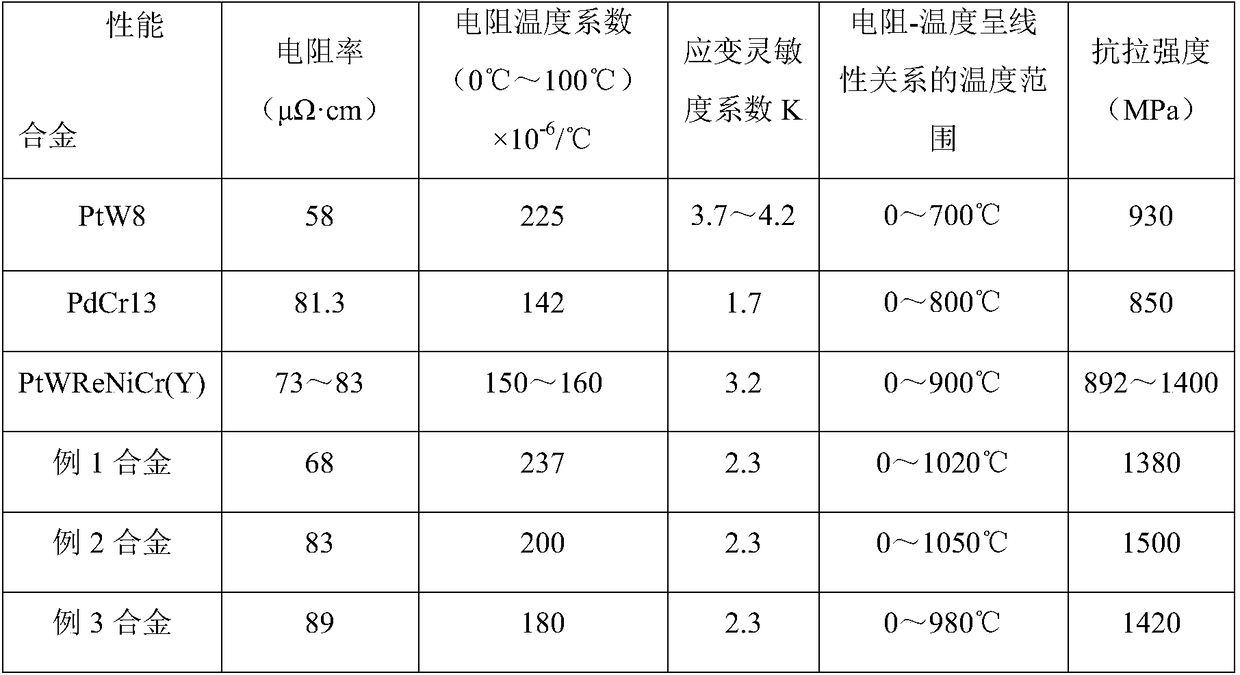

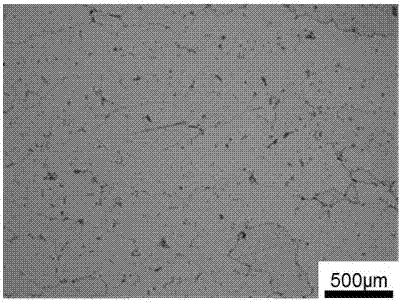

Novel platinum-based high-temperature resistance strain alloy and preparation method thereof

ActiveCN108179303AStable mechanical propertiesImprove electrical performancePetrochemicalOxidation resistant

The invention discloses novel platinum-based high-temperature resistance strain alloy and a preparation method thereof. The alloy is prepared from the following chemical components in percentage by mass: 15 to 40 percent of Rh, 4 to 10 percent of Mo, 2 to 8 percent of Re, 0.5 to 3 percent of Cr, and the balance of Pt. The alloy can also be added with 0 to 2 percent of M (M is at least one of Ni, Zr, Y and Sc). A finish product is prepared by adopting the processes of preparing an alloy ingot in a high-frequency induction smelting furnace, hammer cogging at a high temperature, performing stableheat treatment and the like. The alloy material has high tensile strength and electrical resistivity, low resistance temperature coefficient, excellent high-temperature mechanical properties and oxidation resistance, and resistance-temperature characteristic is linear in the temperature range of 0 to 1,050 DEG C, the novel platinum-based high-temperature resistance strain alloy can be widely applied to the stress-strain test of a hot end component at over 1,000 DEG C in the fields, such as spaceflight, aviation, heavy machinery, petrochemical industry and nuclear industry, and ensures the safety and reliability of an operating system.

Owner:SINO PLATINUM METALS CO LTD

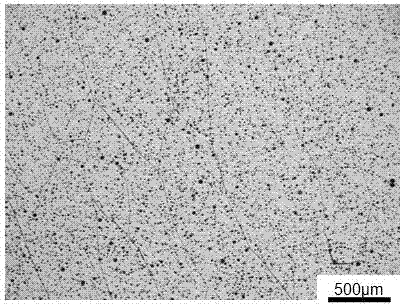

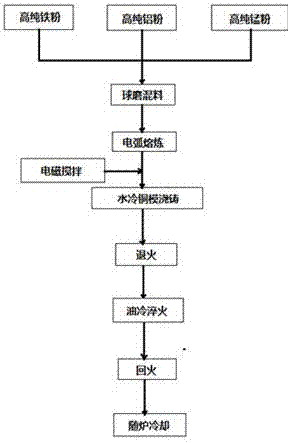

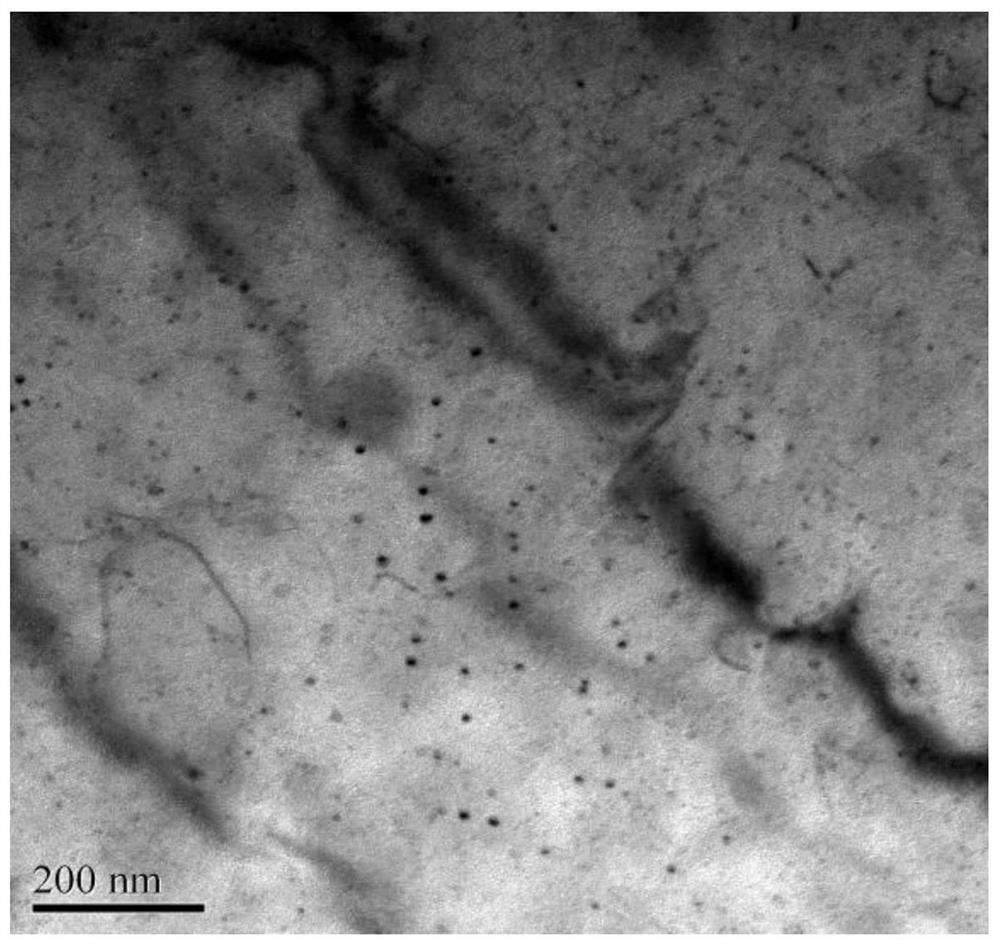

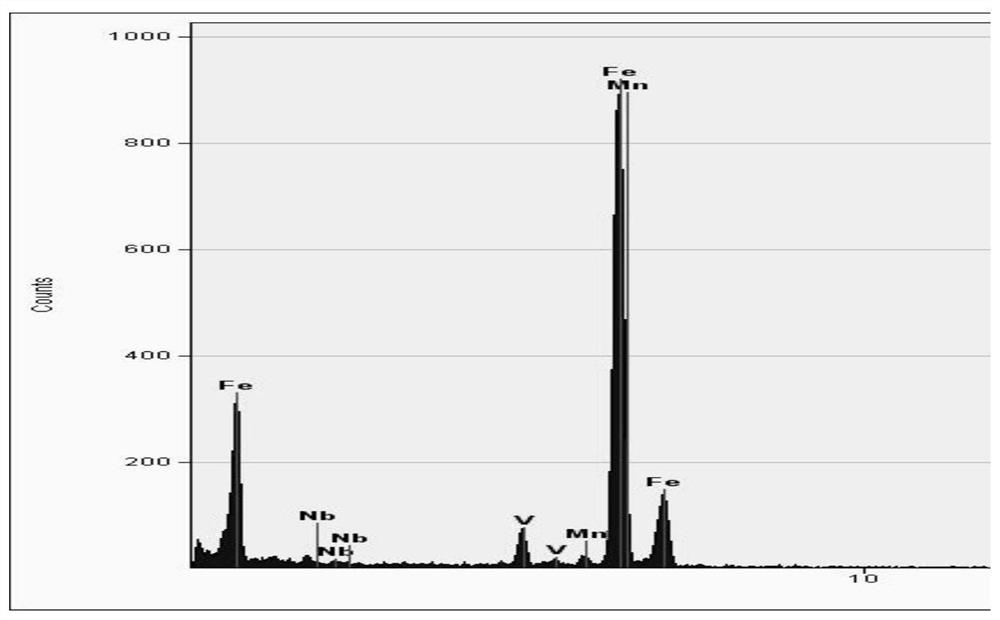

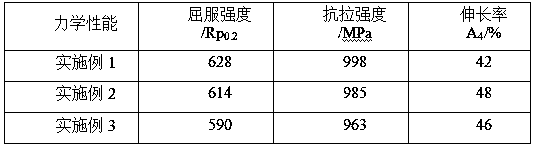

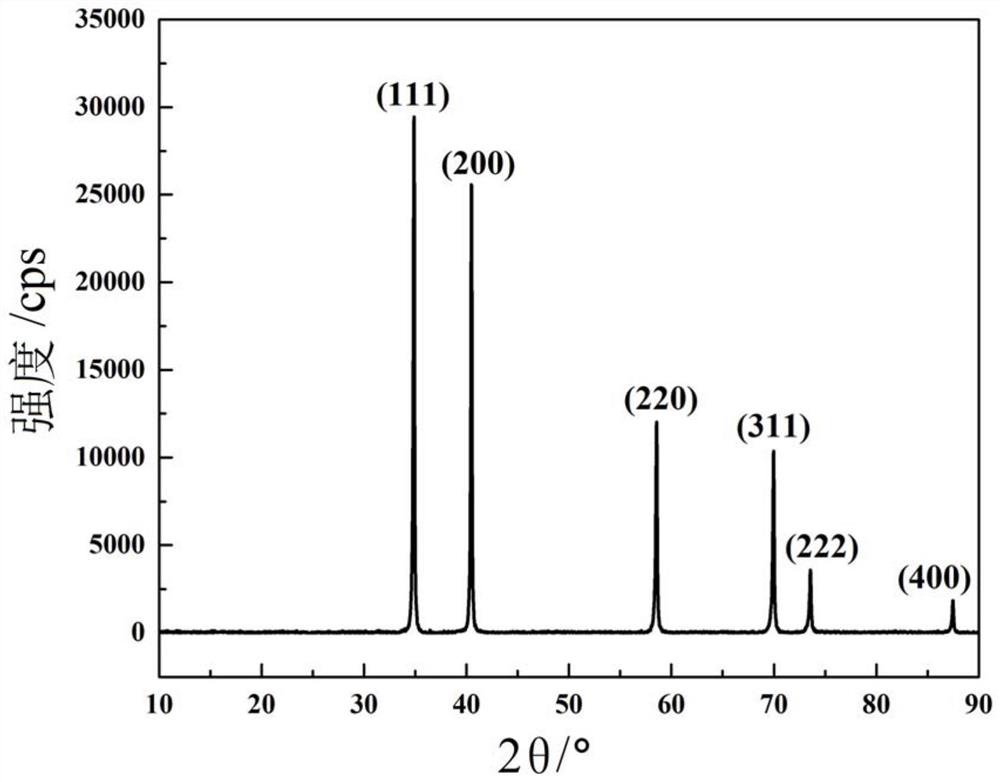

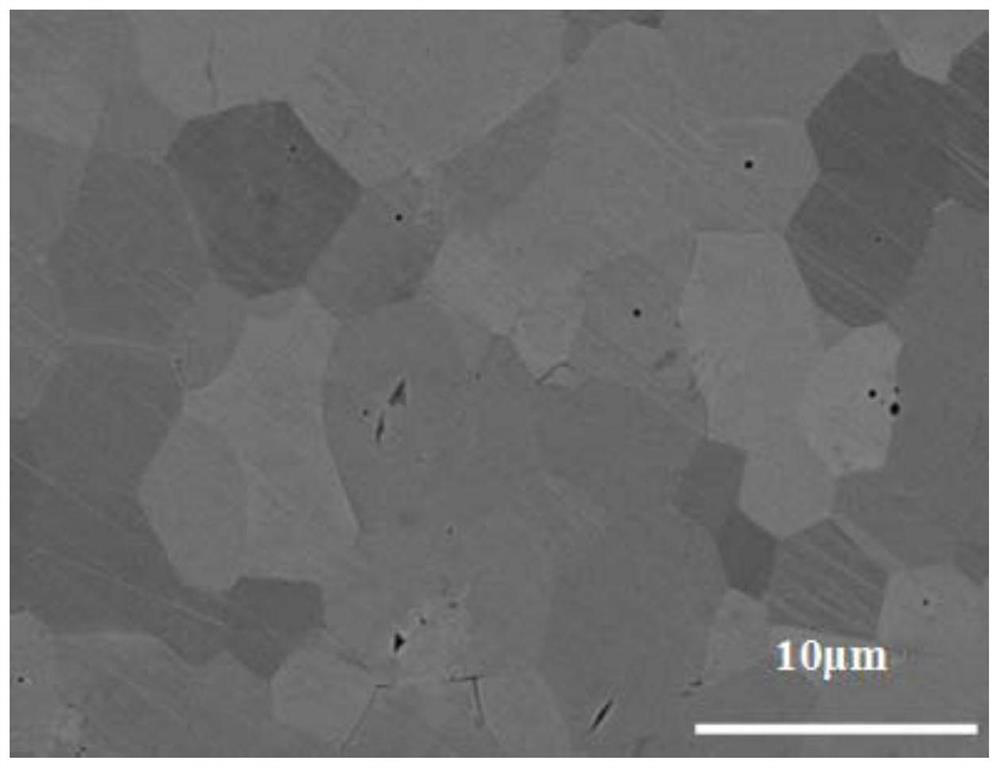

Preparation method for Fe-Mn-Al alloy

The invention relates to a preparation method for Fe-Mn-Al alloy, and belongs to the technical field of lightweight and high strength alloy preparation. The preparation method comprises the steps that by weight, 12.0-14.0% of Al, 18.0-30.0% of Mn and the balance Fe are mixed evenly and proportionally; mixed powder is subjected to tabletting and then is smelted under the protection of inert gas, melts are continuously stirred in the smelting process, and when the temperature of alloy melts reaches 1520-1550 DEG C, a water-cooling copper mold is adopted to cast a sample; the obtained sample is subjected to heat preservation at the 1000 DEG C for 2-3 hours under the protection of inert gas and then subjected to oil quenching, alloy after oil quenching continues to be heated to 550-650 DEG C at the atmosphere of inert gas and subjected to tempering treatment, after heat preservation is conducted for 2-4 hours, the alloy is cooled to the indoor temperature along with a furnace, and the Fe-Mn-Al lightweight and high strength alloy is obtained. The method is relatively simple and reliable, and the prepared Fe-Mn-Al alloy is high in strength, light, good in oxidation resistance and good in corrosion resistance.

Owner:陕西华领新材料科技股份有限公司

635MPa-grade high-strength anti-seismic steel bar and preparation method thereof

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to a 635MPa-grade high-strength anti-seismic steel bar and a preparation method thereof. Steel in a steel bar comprises the following chemical components in percentage by weight: 0.24-0.29 percent of C, 0.70-0.80 percent of Si, 1.50-1.60 percent of Mn, less thanor equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.100-0.160 percent of V, 0.010-0.030 percent of Nb and the balance of Fe and inevitable impurity elements. The 635MPa-gradehigh-strength anti-seismic steel bar with high strength and high plasticity is produced by adopting a high-C, Si and Mn component design and a V and Nb combined microalloying manner under the condition of existing process equipment of a production plant and combining steelmaking and steel rolling processes, is stable in performance and good in comprehensive mechanical property, and has yield strength greater than or equal to 635MPa, tensile strength greater than or equal to 795MPa, percentage elongation after fracture greater than or equal to 15%, total elongation under maximal force greater than or equal to 9.0%, the strength-to-yield ratio greater than or equal to 1.25 and the yield-to-yield ratiogreater than or equal to 1.30, good anti-seismic performance is achieved, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

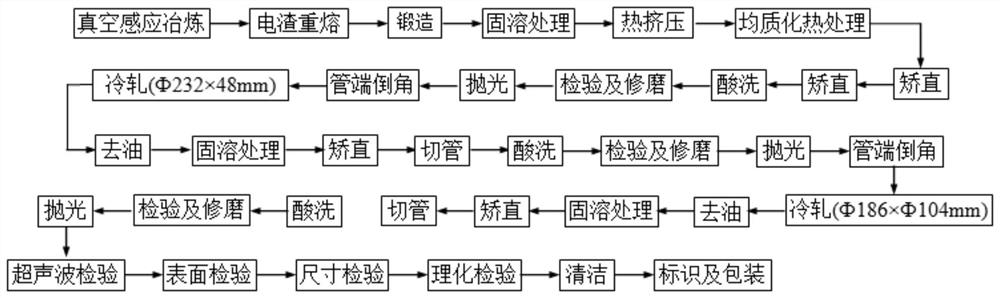

Alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and manufacturing method

ActiveCN111876690AHigh strengthImprove corrosion resistanceNuclear energy generationNuclear reaction controlChemical compositionNichrome

The invention discloses an alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and a manufacturing method, and relates to iron-nickel-chromium alloy seamless tubes. Thealloy movable conduit comprises the following chemical components including, by mass, 0.04%-0.09% of C, 1.2%-1.8% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 0.20% of Si, 15.0%-17.0% of Cr, 35.0%-37.0% of Ni, 3.0%-3.5% of Mo, not more than 0.05% of Cu, not more than 0.05% of Y, not more than 0.002% of B, not more than 0.05% of Zr, not more than 0.1% of Al, not more than 0.2% of W, not more than 0.03% of N, not more than 0.025% of Co, not more than 0.006% of As, not more than 0.005% of Sb, not more than 0.005% of Bi, not more than 0.006% of Sn, not more than 0.006% of Pb, not more than 0.015% of the sum of As, Sb, Bi, Sn and Pb and the balance Fe and trace elements. The alloy movable conduit has the good structure and mechanical properties, corrosion resistance, dimensional precision and surface quality, and the use requirements of a sodium-cooled fast reactor are met.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

A human-degradable, corrosion-resistant, high-strength-tough Zn‐Fe‐X zinc alloy and its application

ActiveCN104689378BLow costImprove corrosion resistanceSuture equipmentsProsthesisZinc alloysUltimate tensile strength

A corrosion-resistant, high strength and ductility Zn-Fe-X zinc alloy and applications thereof in medical implant materials. The zinc alloy comprises elements Zn, Fe, and X, where the element X is at least one among Mg, Ca, and Sr, the mass percentage of element Zn is: 89.92-99.997%, the mass percentage of element Fe is: 0.002-10%, and the mass percentage of element X is: 0.001-0.08%.

Owner:XIAN ADVANCED MEDICAL TECH

Near-beta type titanium alloy with good matching of strength and plasticity and preparation method thereof

The invention discloses a near-beta type titanium alloy with good matching of strength and plasticity and a preparation method thereof, and belongs to the field of titanium alloys. According to the preparation method, medium-sized crystal grains in the sintered alloy are crushed and refined after upsetting, drawing and cogging in a single-phase region. Then a rolled bar is subjected to one-step quasi-beta bar rolling at a phase transformation point by utilizing a relatively high phase transformation point caused by high oxygen content of the alloy, crystal grains are crushed again, and a coordinated structure of non-uniform crystal grains and a multi-stage layered second phase is realized by virtue of dynamic precipitation and partial recrystallization of the second phase under the actionof thermal coupling. Non-uniform mixed crystals comprise ultrafine beta crystal grains and coarse beta crystal grains, and the multi-stage layered second phase comprises a layered primary alpha phase,a strip-shaped grain boundary alpha phase and a beta transformation structure. After short-time heat treatment, the non-uniform mixed crystal structure is reserved, the multi-stage layered second phase is increased from ternary to quaternary through the separated fine-needle-shaped alpha phase, and the alloy maintains good plasticity while having high strength.

Owner:CHANGAN UNIV

Powder metallurgy preparation method of Fe-Mn-Al series alloy

The invention relates to a powder metallurgy preparation method of a Fe-Mn-Al series alloy, and belongs to the technical field of powder metallurgy preparation. The powder metallurgy preparation method comprises the steps that firstly aluminum powder, manganese powder and iron powder are evenly mixed to obtain Fe-Mn-Al mixed powder; under the protection of argon, the obtained Fe-Mn-Al mixed powderis smelted to be qualified alloy liquid, then the alloy liquid is injected into a tundish located above an atomizing nozzle, the alloy liquid flows out from a leakage hole in the bottom of the tundish and encounters high-speed argon airflow with the pressure being 6 MPa to be atomized to be small droplets when passing through an HK-03 type annular hole nozzle, the atomized droplets are rapidly solidified in a closed atomizing cylinder to be Fe-Mn-Al alloy powder, and the Fe-Mn-Al alloy powder passes through a label screen which is 100 meshes; and the obtained Fe-Mn-Al alloy powder is subjected to pressing forming, in the hydrogen environment, temperature is improved to 800-1200 DEG C and sintering is conducted for 4-8 h, after sintering is completed, furnace cooling is conducted till thetemperature reaches the room temperature, and a block-shaped Fe-Mn-Al alloy is obtained. According to the powder metallurgy preparation method, the corrosion resistance, the specific strength, the high-temperature oxidation resistance and the like of the obtained Fe-Mn-Al alloy are greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

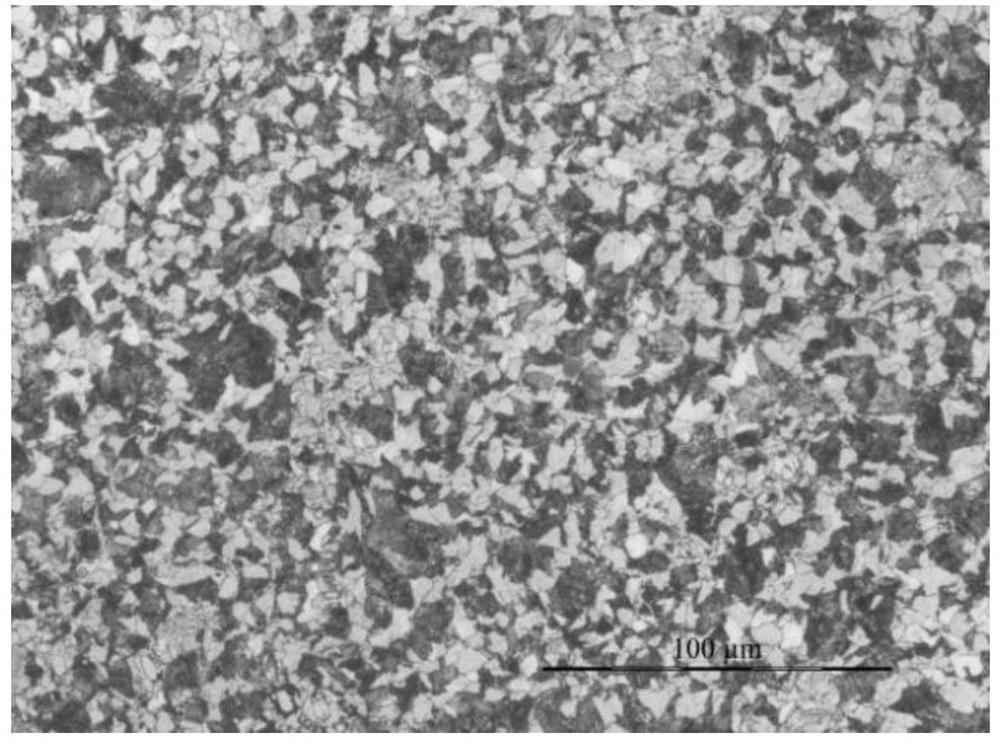

Equiaxial high-strength zirconium alloy and preparation method thereof

The invention provides an equiaxial high-strength zirconium alloy and a preparation method thereof, and belongs to the technical field of alloys. The equiaxial high-strength zirconium alloy comprises strengthening elements and the balance Zr; on the basis of the mass of the equiaxial high-strength zirconium alloy, the strengthening elements comprise 0.1%-3% of Sn and 0.5%-4.5% of Hf; and the equiaxial high-strength zirconium alloy is composed of a phase including equiaxial alpha grains. The zirconium alloy contains a certain amount of Sn element, the Sn element can enter a Zr matrix, so that replacement solid solution strengthening is realized; when the content of the Sn element is relatively high, the excessive Sn element can generate Zr4Sn second-phase particles, so that a second-phase strengthening effect is achieved; Hf further has a solid solution strengthening effect; all the elements are matched, so that the zirconium alloy has high strength; and Ti is continuously added on the basis of the strengthening elements, Ti and Zr can form an infinite solid solution, and the strength of the zirconium alloy can be further improved.

Owner:YANSHAN UNIV

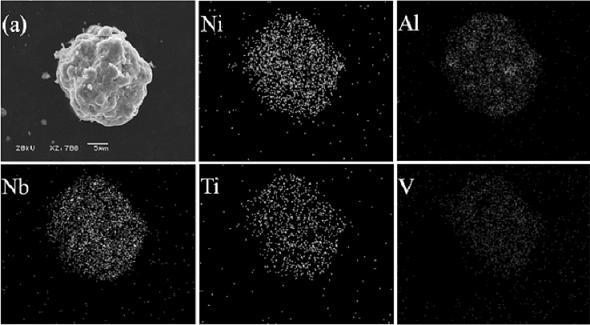

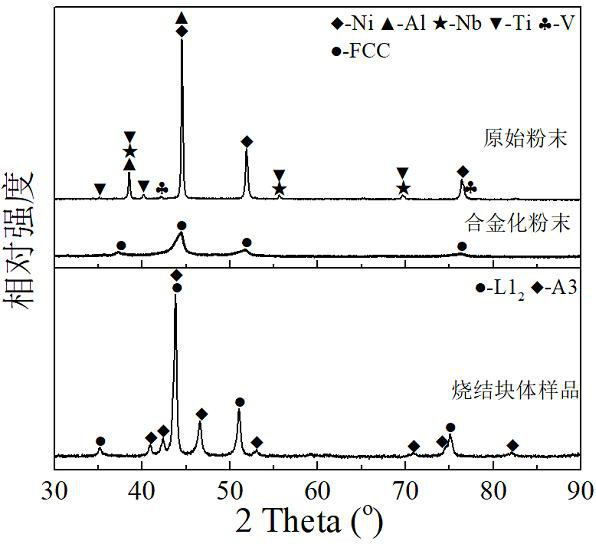

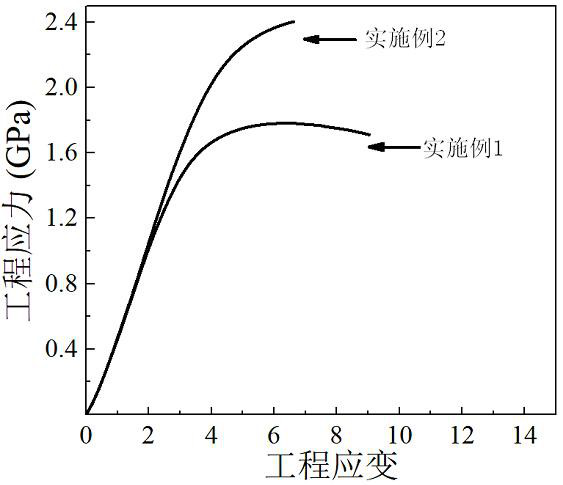

Powder metallurgy preparation method for Ni-Cr-Al-Fe high-temperature alloy

The invention discloses a powder metallurgy preparation method for a Ni-Cr-Al-Fe high-temperature alloy, and belongs to the technical field of high-temperature alloys. According to the powder metallurgy preparation method, Ni-Cr-Al-Fe alloyed powder is obtained through a gas atomization method, a nano-powder body is extruded into blocks, sintering is conducted in the hydrogen environment through avacuum double-tube heating furnace, thus Ni-Cr-Al-Fe alloying is achieved again, and the Ni-Cr-Al-Fe blocky alloy is obtained. During sintering, oxidation of powder is effectively reduced through using of reductive gas, generating of other oxide impurities is reduced, the grains of the Ni-Cr-Al-Fe high-temperature alloy prepared through a nanotechnology are refined, meanwhile, chemical propertiessuch as corrosion resistance, specific strength and high-temperature oxygen resistance of the Ni-Cr-Al-Fe high-temperature alloy are greatly improved, and the application requirements of gas turbinescan be met.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of Ni-Cr-Al-Fe-series high-temperature alloy

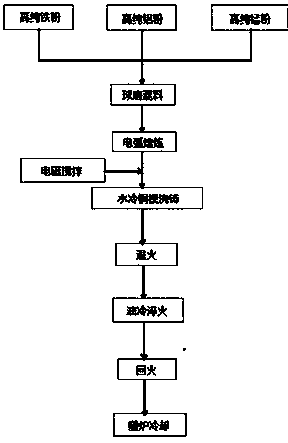

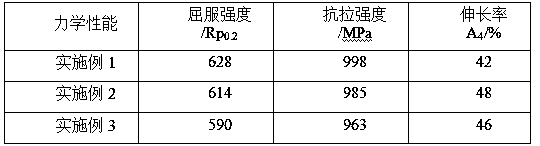

The invention discloses a preparation method of a Ni-Cr-Al-Fe-series high-temperature alloy, and belongs to the technical field of a high-temperature alloy. The method comprises: uniformly mixing ironpowder, chromium powder, aluminium powder and nickel powder via ball milling to obtain a mixed material; in a condition with the pressure in a range of 20-50 MPa, performing sheeting moulding on themixed material to obtain a metal sheet, putting the metal sheet in a vacuum electric arc melting furnace, in a condition with an argon protection atmosphere and electromagnetic stirring, performing electric arc melting till the temperature of the alloy solution is 1540-1560 DEG C, and performing water-cooling copper-formed mold casting to obtain an alloy A; and putting the alloy A in an argon atmosphere, performing thermal insulation at 1200-1250 DEG C for 0.5-1.5 h, performing oil hardening, putting the obtained product in an argon atmosphere, performing heating till the temperature reaches 550-650 DEG C, performing tempering treatment for 3-6 h, and cooling the furnace to the room temperature to obtain the Ni-Cr-Al-Fe-series high-temperature alloy. The prepared Ni-Cr-Al-Fe-series high-temperature alloy is high in tensile strength, elongation percentage and yield strength and can meet the application requirement of a gas turbine.

Owner:KUNMING UNIV OF SCI & TECH

A kind of superhard five-component transition metal carbide single-phase high-entropy ceramic material and preparation method thereof

ActiveCN110194667BRegulating the densification processCalcination temperature is lowTransition metal carbidesOxygen contamination

Owner:HARBIN INST OF TECH

Flux core, preparation method of flux core, flux-cored wire and welding method

ActiveCN112872651ALower transition temperatureIncrease subcoolingWelding/cutting media/materialsSoldering mediaManganeseCobalt

The invention discloses a flux core, a preparation method of the flux core, a flux-cored wire and a welding method. The flux core is prepared from the components including, by mass, 18%-24% of metallic nickel, 14%-20% of metallic chromium, 0.8%-1.4% of metallic manganese, 1.7%-2.2% of metallic molybdenum, 1.7%-2.6% of metallic cobalt, 0.2%-0.5% of metallic vanadium, 0.4%-0.9% of silicon and the balance iron. According to the flux-cored wire, the connection quality of CB2 heat-resistant steel is improved, automatic welding can be achieved, and the production efficiency is high.

Owner:HUANENG POWER INT INC +1

Medium carbon ferromanganese medium-thick steel for 800MPa engineering machinery and manufacturing method of medium carbon ferromanganese medium-thick steel

The invention discloses medium carbon ferromanganese medium-thick steel for 800MPa engineering machinery and a manufacturing method of the medium carbon ferromanganese medium-thick steel, and relatesto the technical field of iron and steel smelting. The medium carbon ferromanganese medium-thick steel comprises the chemical components in percentage by mass of 0.05%-0.08% of C, 4.8%-5.8% of Mn, 0.10%-0.35% of Si, P being smaller than or equal to 0.010%, S being smaller than or equal to 0.003%, 0.01%-0.05% of Ti, 0.7%-1.2% of Ni+Cr+Mo, and balance Fe and inevitable impurities. The medium carbonferromanganese medium-thick steel can have excellent core mechanical properties than common 800MPa high-intensity structural steel, and requirements for extra-high-intensity steel safety performance and low manufacturing cost in the engineering machinery trade under complete adverse environment, can be met.

Owner:NANJING IRON & STEEL CO LTD

A kind of preparation method of fe-mn-al alloy

The invention relates to a preparation method for Fe-Mn-Al alloy, and belongs to the technical field of lightweight and high strength alloy preparation. The preparation method comprises the steps that by weight, 12.0-14.0% of Al, 18.0-30.0% of Mn and the balance Fe are mixed evenly and proportionally; mixed powder is subjected to tabletting and then is smelted under the protection of inert gas, melts are continuously stirred in the smelting process, and when the temperature of alloy melts reaches 1520-1550 DEG C, a water-cooling copper mold is adopted to cast a sample; the obtained sample is subjected to heat preservation at the 1000 DEG C for 2-3 hours under the protection of inert gas and then subjected to oil quenching, alloy after oil quenching continues to be heated to 550-650 DEG C at the atmosphere of inert gas and subjected to tempering treatment, after heat preservation is conducted for 2-4 hours, the alloy is cooled to the indoor temperature along with a furnace, and the Fe-Mn-Al lightweight and high strength alloy is obtained. The method is relatively simple and reliable, and the prepared Fe-Mn-Al alloy is high in strength, light, good in oxidation resistance and good in corrosion resistance.

Owner:陕西华领新材料科技股份有限公司

A kind of low-temperature resistant micro-alloyed steel and its production process

Owner:CENT IRON & STEEL RES INST +1

A kind of preparation method of ni-cr-al-fe series superalloy

The invention discloses a preparation method of a Ni-Cr-Al-Fe-series high-temperature alloy, and belongs to the technical field of a high-temperature alloy. The method comprises: uniformly mixing ironpowder, chromium powder, aluminium powder and nickel powder via ball milling to obtain a mixed material; in a condition with the pressure in a range of 20-50 MPa, performing sheeting moulding on themixed material to obtain a metal sheet, putting the metal sheet in a vacuum electric arc melting furnace, in a condition with an argon protection atmosphere and electromagnetic stirring, performing electric arc melting till the temperature of the alloy solution is 1540-1560 DEG C, and performing water-cooling copper-formed mold casting to obtain an alloy A; and putting the alloy A in an argon atmosphere, performing thermal insulation at 1200-1250 DEG C for 0.5-1.5 h, performing oil hardening, putting the obtained product in an argon atmosphere, performing heating till the temperature reaches 550-650 DEG C, performing tempering treatment for 3-6 h, and cooling the furnace to the room temperature to obtain the Ni-Cr-Al-Fe-series high-temperature alloy. The prepared Ni-Cr-Al-Fe-series high-temperature alloy is high in tensile strength, elongation percentage and yield strength and can meet the application requirement of a gas turbine.

Owner:KUNMING UNIV OF SCI & TECH

A kind of aluminum alloy material and laser 3D printing aluminum alloy component based on the material

ActiveCN112620649BImprove corrosion resistanceImprove mechanical propertiesAdditive manufacturing apparatusHeat stabilityLaser additive manufacturing

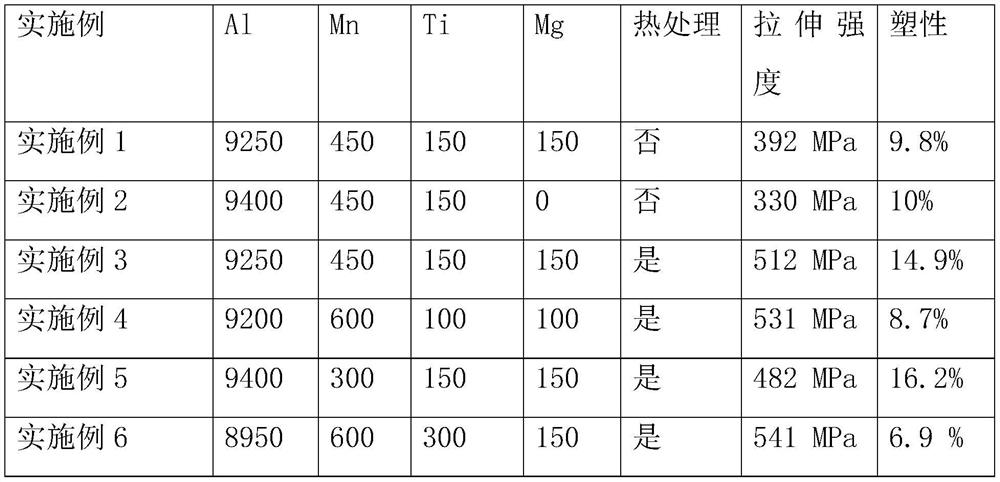

The invention belongs to the field of laser additive manufacturing, and in particular relates to an aluminum alloy material and a laser 3D printed aluminum alloy component based on the material. The preparation method of the aluminum alloy material of the present invention comprises the following steps: (s1) uniformly mixing Al, Mn, and Ti to obtain a mixture, in parts by mass, the Mn content is 1-8 parts, and the Ti content is 1-8 parts 6 parts, the content of Al is 84-98 parts; (s2) After melting the mixture, the aluminum alloy powder is obtained by gas atomization, and dried to obtain the aluminum alloy material. The invention adds Mn and Ti elements, so that the processing performance and mechanical properties of the deformed aluminum alloy that are not suitable for the laser 3D printing process are significantly improved, and the developed alloy has extremely high thermal stability, and can use very simple heat treatment To relieve the residual stress generated during the 3D printing process.

Owner:HUAZHONG UNIV OF SCI & TECH

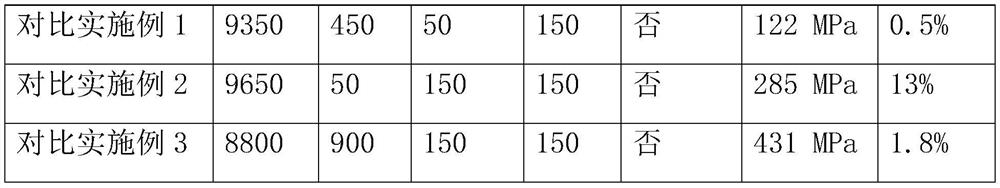

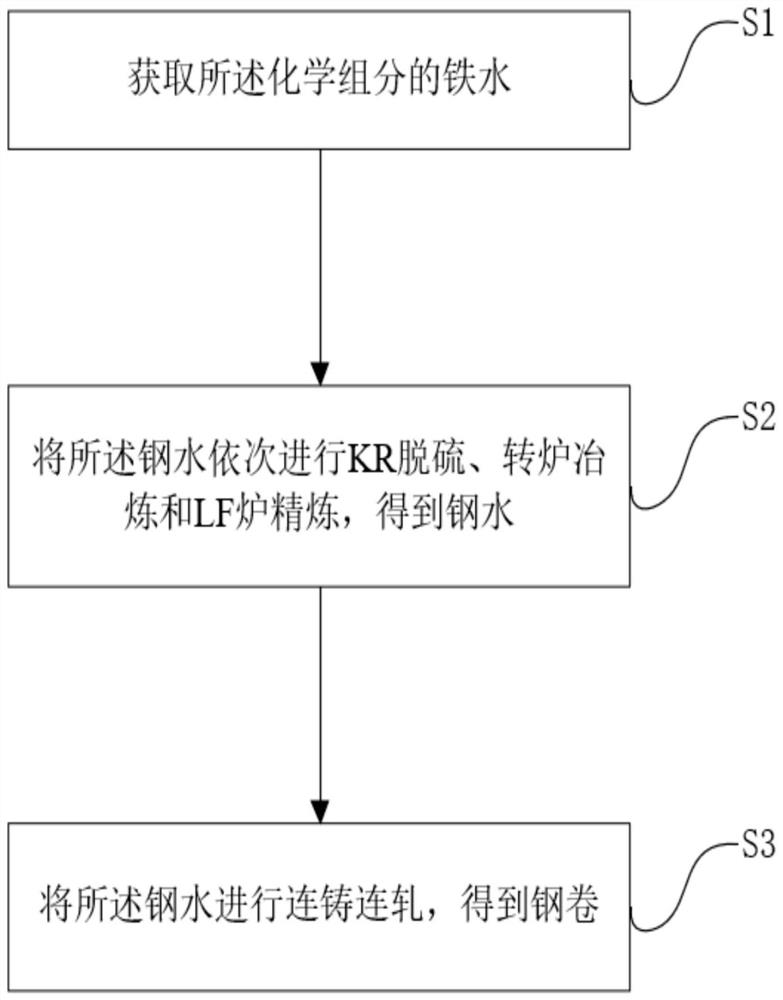

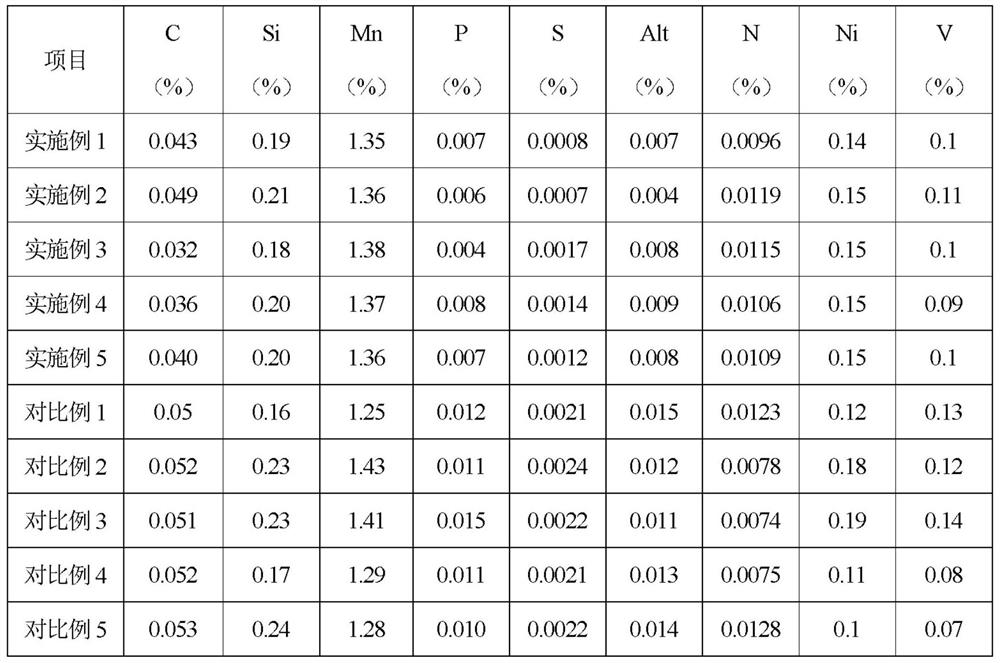

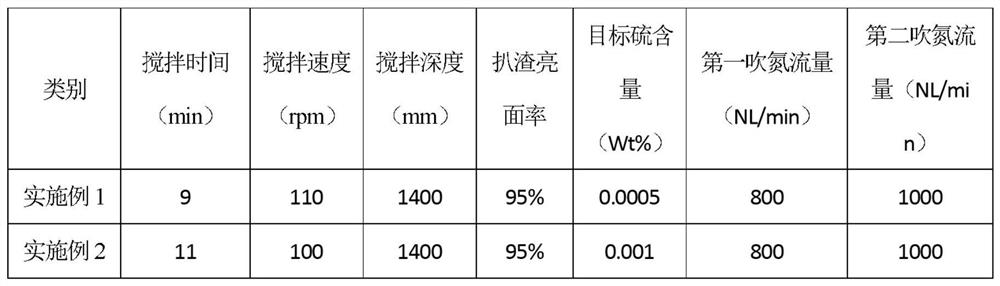

Low-carbon low-phosphorus low-aluminum high-nitrogen ultralow-sulfur steel and preparation method thereof

ActiveCN114381659AGood solid solution strengtheningIncreased potencyManufacturing convertersProcess efficiency improvementMaterials scienceAluminum high

The invention relates to the technical field of metallurgy, in particular to low-carbon, low-phosphorus, low-aluminum, high-nitrogen and ultralow-sulfur steel and a preparation method thereof.The low-carbon, low-phosphorus, low-aluminum, high-nitrogen and ultralow-sulfur steel comprises C, Si, Mn, P, S, Alt, N, Ni, V and the balance Fe and inevitable impurities; the method comprises the steps that molten iron of the low-carbon, low-phosphorus, low-aluminum, high-nitrogen and ultralow-sulfur steel is obtained; the molten steel is sequentially subjected to KR desulfurization, converter smelting and LF furnace refining, and molten steel is obtained; the molten steel is subjected to continuous casting and rolling, and a steel coil is obtained; by controlling the chemical components of the low-carbon, low-phosphorus, low-aluminum, high-nitrogen and ultralow-sulfur steel, the stability of the components in the steel grade is realized, and the toughness and plasticity of the steel are improved; and by controlling the processes of KR desulfurization, converter smelting and LF furnace refining, the cleanliness of the molten steel is improved, and the stability of the content of each component is maintained.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A high-entropy intermetallic compound with high strength and wide temperature range wear resistance

ActiveCN113774265BExtended lattice distortion effectsGood solid solution strengtheningChemical compositionNew energy

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of 3003 aluminum alloy for the core material of aluminum alloy radiator water pipe

The invention provides a 3003 aluminum alloy for a core material of an aluminum-alloy radiator water tube. The 3003 aluminum alloy can be used for effectively improving soldered yield strength of the radiator water tube and prolonging the service life of the radiator. The 3003 aluminum alloy is characterized by comprising the following materials (based on 100 total mass parts): not more than 0.6 part of magnesium (Si), not more than 0.7 part of iron (Fe), 0.2-0.45 part of copper (Cu), 1-1.5 parts of magnesium (Mn), 0.1-0.35 part of magnesium (Mg), not more than 0.1 part of zinc (Zn), and the balance of aluminum (Al) and inevitable impurity elements.

Owner:YINBANG CLAD MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com