A high-entropy intermetallic compound with high strength and wide temperature range wear resistance

An intermetallic compound, wide temperature range technology, applied in the field of high-strength wear-resistant alloy materials, can solve the problems of room temperature yield strength difficult to break 1.5GPa, brittle intermetallic phase precipitation in large quantities, wear resistance difficult to maintain and other problems, to achieve good High temperature softening resistance, enlarged lattice distortion effect, high performance reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

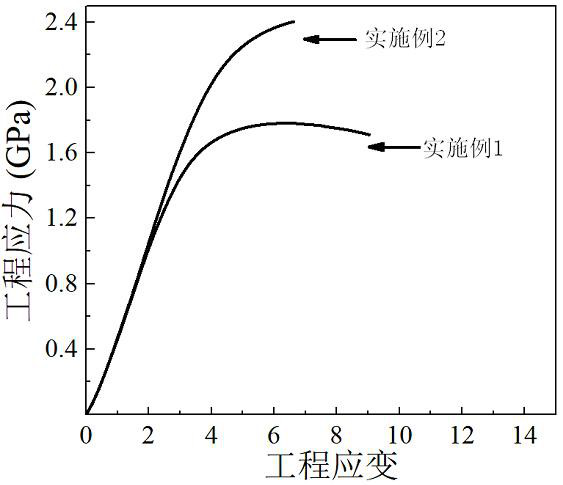

Embodiment 1

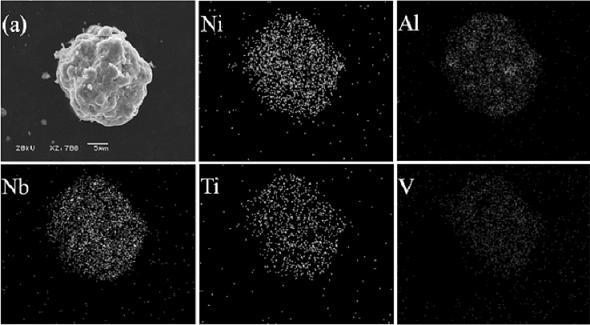

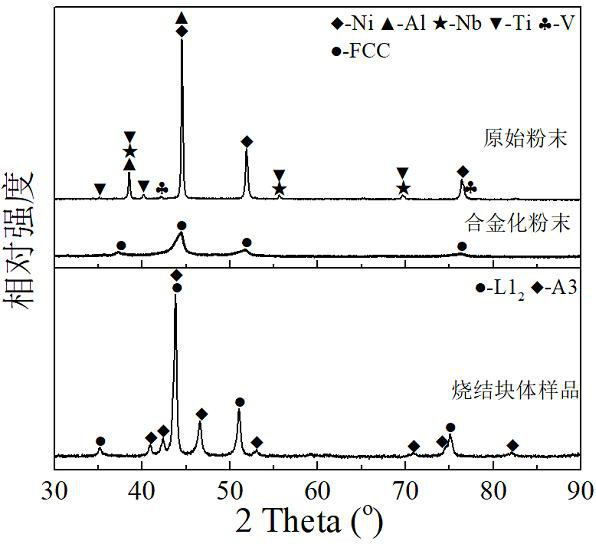

[0036] Example 1 Preparation of Ni 0.75 (Al 1 / 4 Nb 1 / 4 Ti 1 / 4 V 1 / 4 ) 0.25 High entropy intermetallic compounds:

[0037] According to the ratio shown in Table 1, use an electronic balance to weigh the original metal powder and put it into a cemented carbide tank, and perform a mechanical alloying process through a high-energy ball mill, as follows:

[0038] (1) Mixing: Put Ni powder, Al powder, Ti powder, Nb powder and V powder into the cemented carbide tank equipped with the high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and place them in the argon In an air atmosphere, the mixture was mixed for 8 h under the conditions of a ball-to-material ratio of 2:1 and a rotational speed of 150 r / min to obtain uniformly mixed initial element powders;

[0039] (2) Alloying: put the uniformly mixed initial element powder into a high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and...

Embodiment 2

[0049] Example 2 Preparation of Ni 0.5 (Al 1 / 4 Nb 1 / 4 Ti 1 / 4 V 1 / 4 ) 0.5 High entropy intermetallic compounds:

[0050] According to the ratio shown in Table 2, use an electronic balance to weigh the original metal powder and put it into a cemented carbide tank, and carry out the mechanical alloying process through a high-energy ball mill, as follows:

[0051] (1) Mixing: Put Ni powder, Al powder, Ti powder, Nb powder and V powder into the cemented carbide tank equipped with the high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and place them in the argon In an air atmosphere, mix for 10 hours under the conditions of a ball-to-material ratio of 1.5:1 and a rotational speed of 150r / min to obtain uniformly mixed initial element powders;

[0052] (2) Alloying: put the uniformly mixed initial element powder into a high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and use absol...

Embodiment 3

[0061] Example 3 Preparation of Ni 0.7 (Al 1 / 4 Nb 1 / 4 Ti 1 / 4 V 1 / 4 ) 0.3 High entropy intermetallic compounds:

[0062] According to the ratio shown in Table 3, use an electronic balance to weigh the original metal powder and put it into a cemented carbide tank, and perform a mechanical alloying process through a high-energy ball mill, as follows:

[0063] (1) Mixing: Put Ni powder, Al powder, Ti powder, Nb powder and V powder into the cemented carbide tank equipped with the high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and place them in the argon In an air atmosphere, mix for 5 h under the conditions of a ball-to-material ratio of 1:1 and a rotational speed of 100 r / min to obtain uniformly mixed initial element powders;

[0064] (2) Alloying: put the uniformly mixed initial element powder into a high-energy ball mill, use cemented carbide balls with a diameter of 3-10 mm as the grinding balls, and use absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com