Patents

Literature

98results about How to "Even distribution of elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

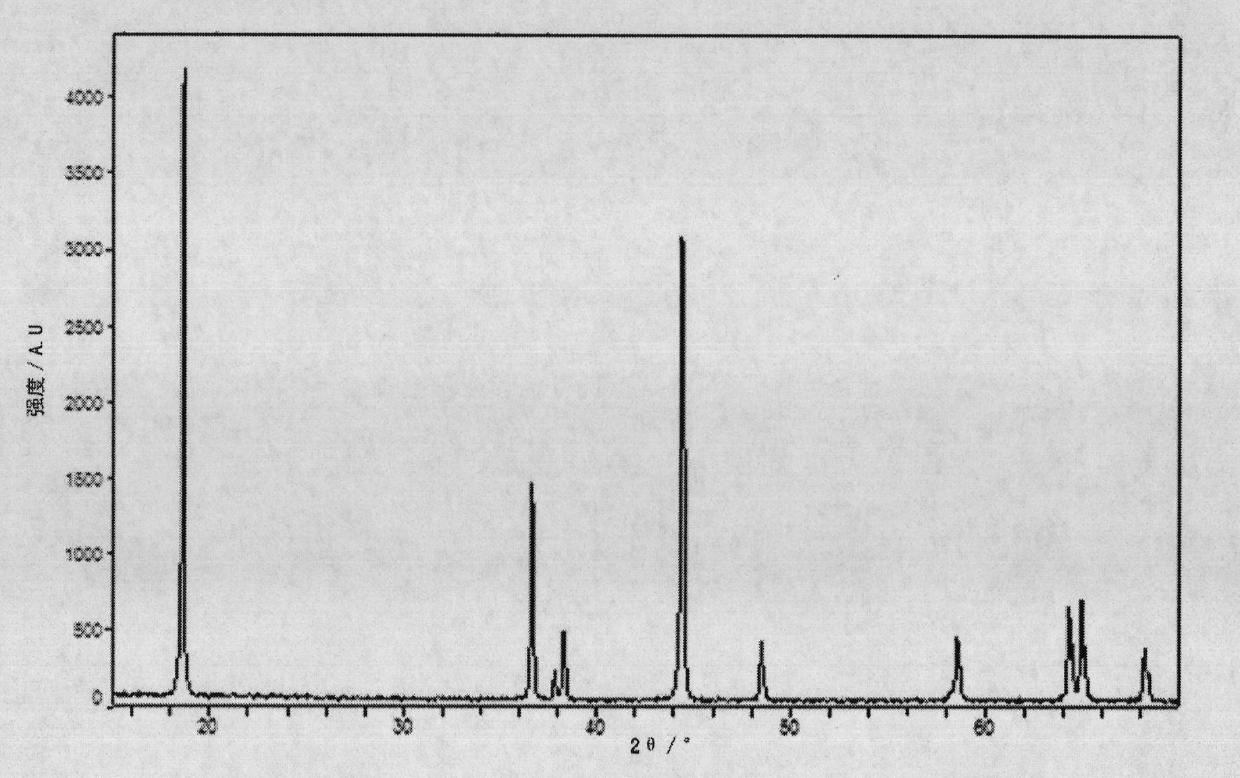

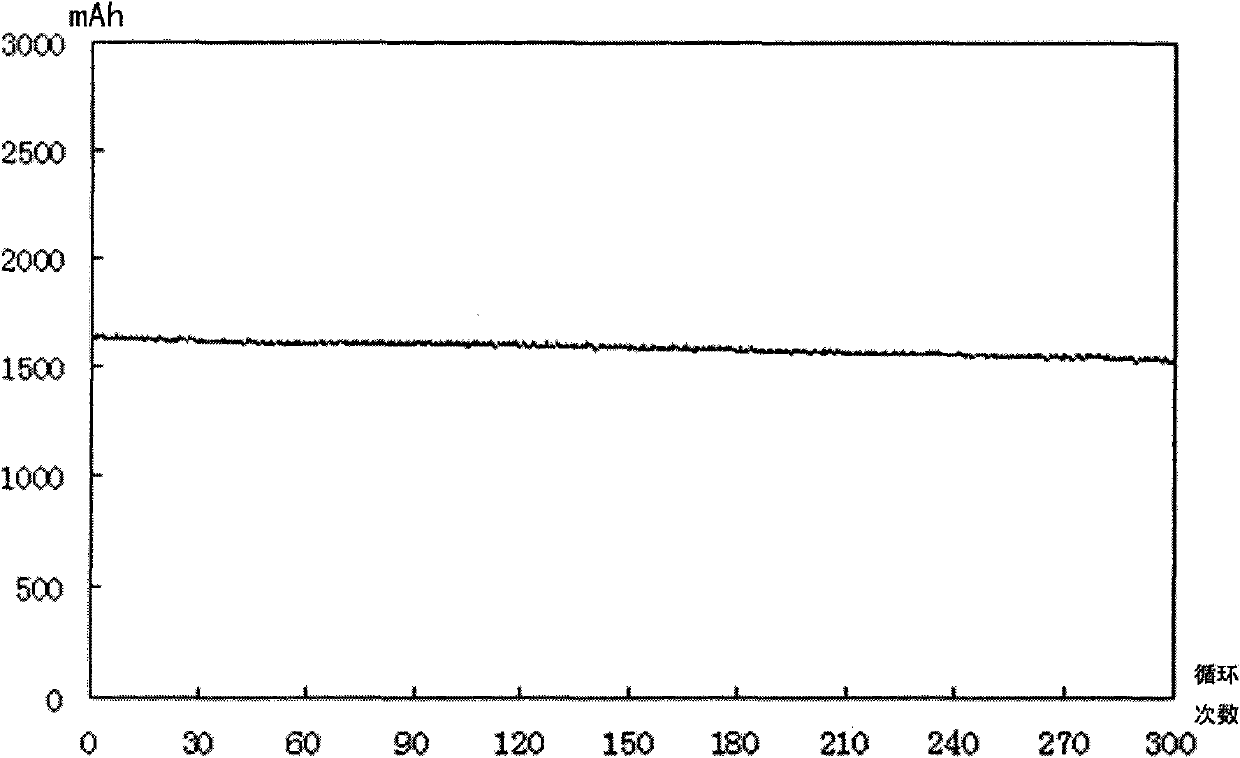

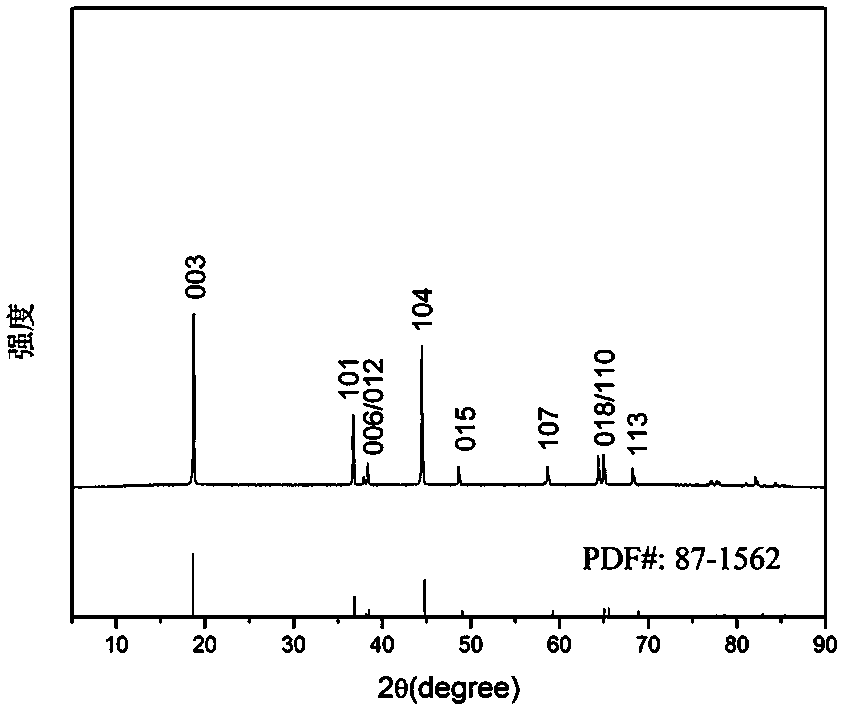

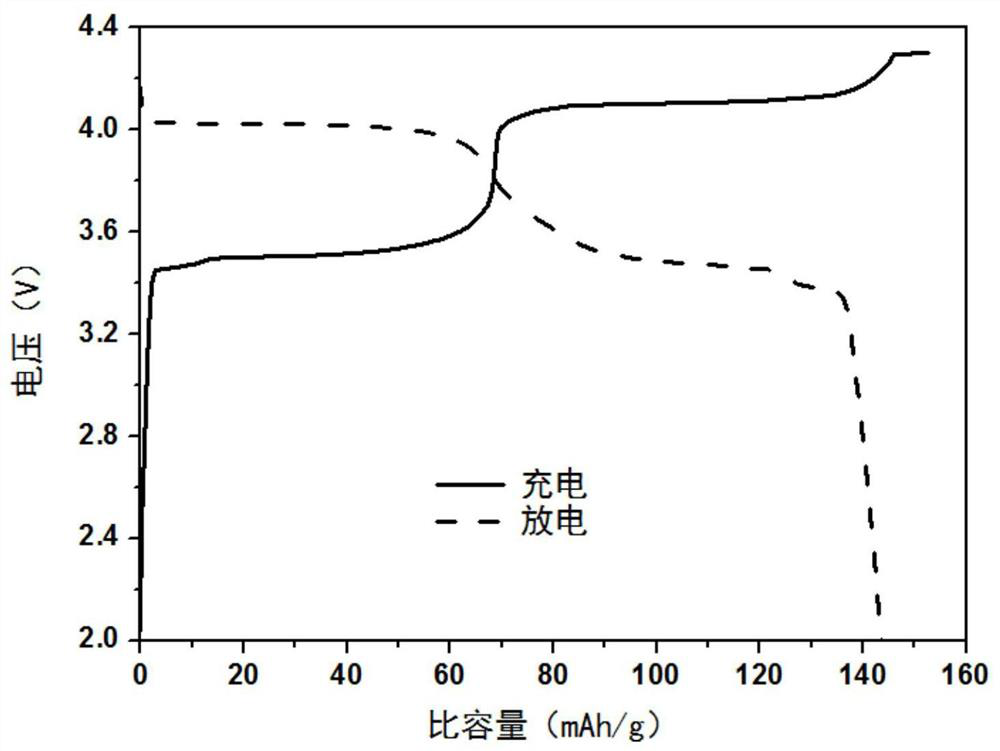

Lithium ion battery cathode material, preparation method and lithium ion battery

ActiveCN105449169AImprove storage effectEven distribution of elementsCell electrodesSecondary cellsPhysical chemistrySingle crystal

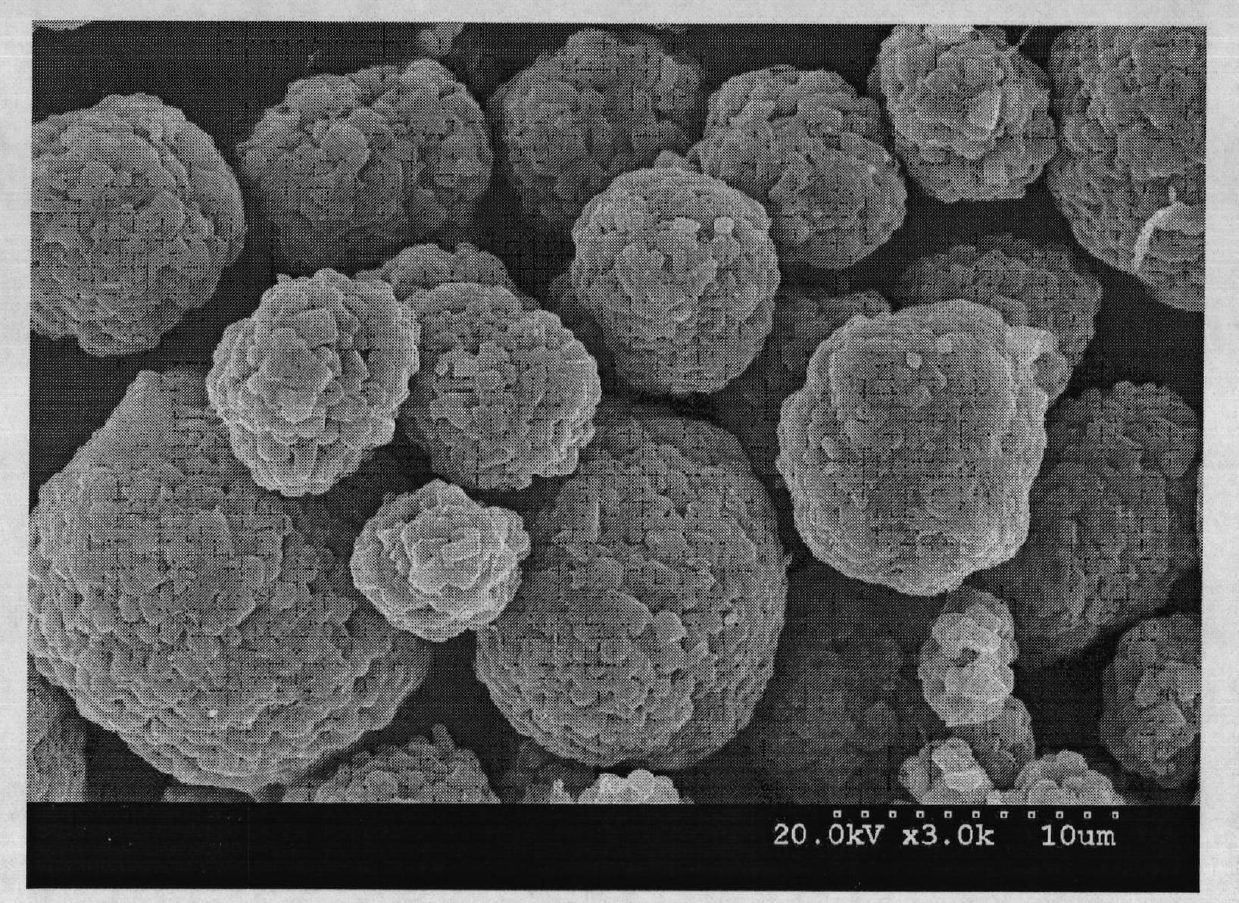

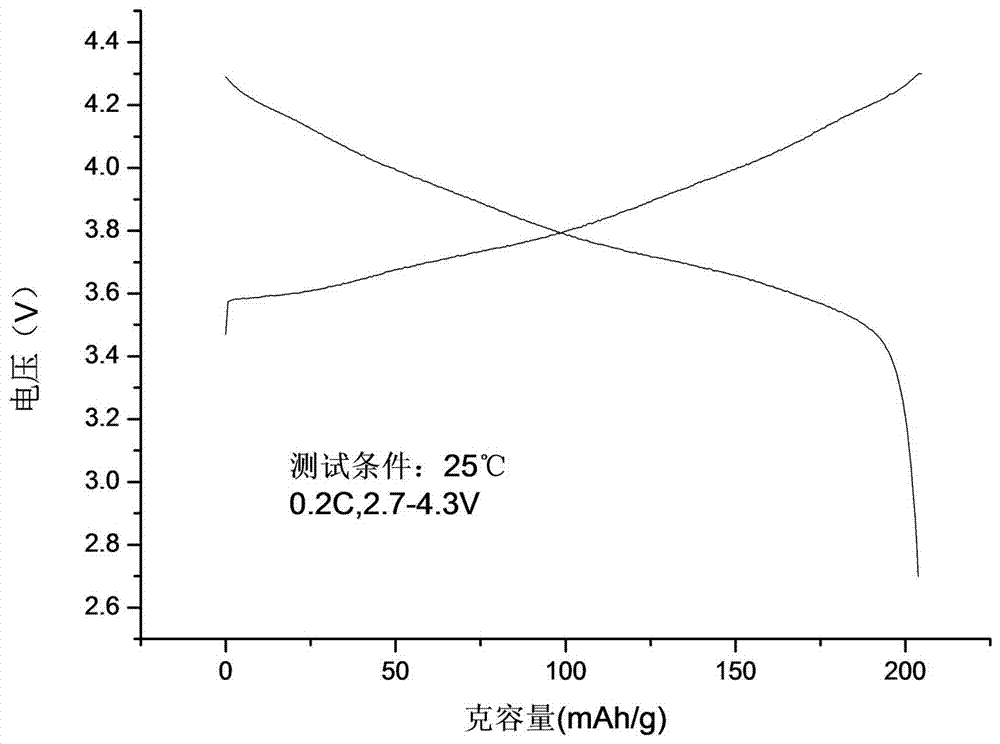

The invention provides a preparation method of a lithium ion battery cathode material. The prepared lithium ion battery cathode material has good pseudo-single crystal form by utilizing pressure-boiling crystal at certain temperature. The preparation method is simple in technology and easy in control. The general formula of the lithium ion battery cathode material prepared by the preparation method is expressed as Li (NixCo1-x-yMny) O2, wherein x is more than or equal to 0.34 and is less than or equal to 0.68, y is more than or equal to 0.15 and is less than or equal to 0.31, x +y is more than 0 and is less than 1. The invention also provides a lithium ion battery containing the lithium ion battery cathode material.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

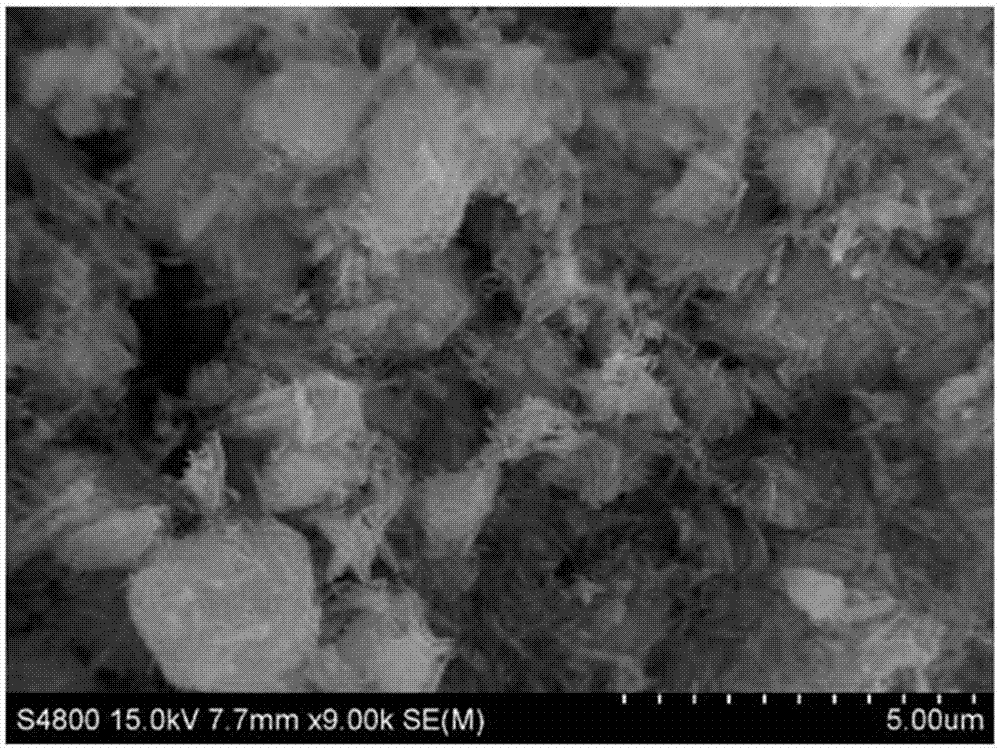

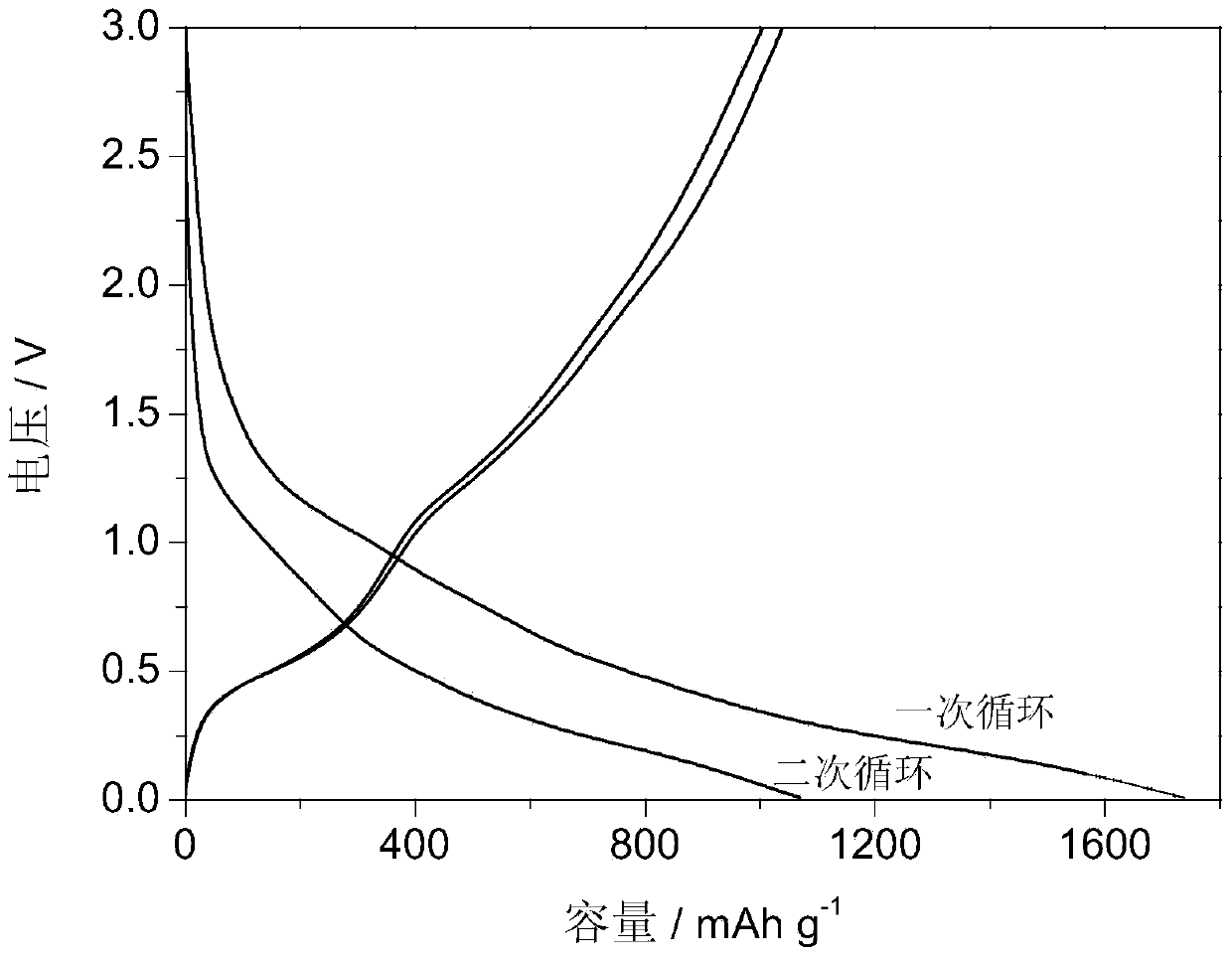

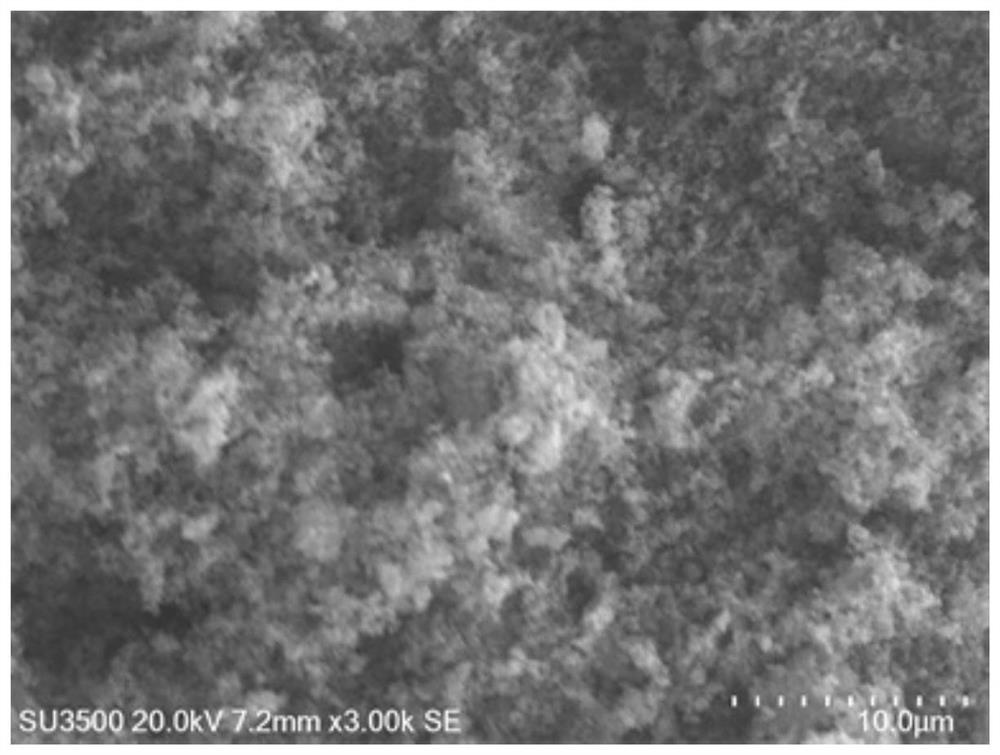

Method for synthesizing lithium ion battery negative electrode material according to mechanochemical method

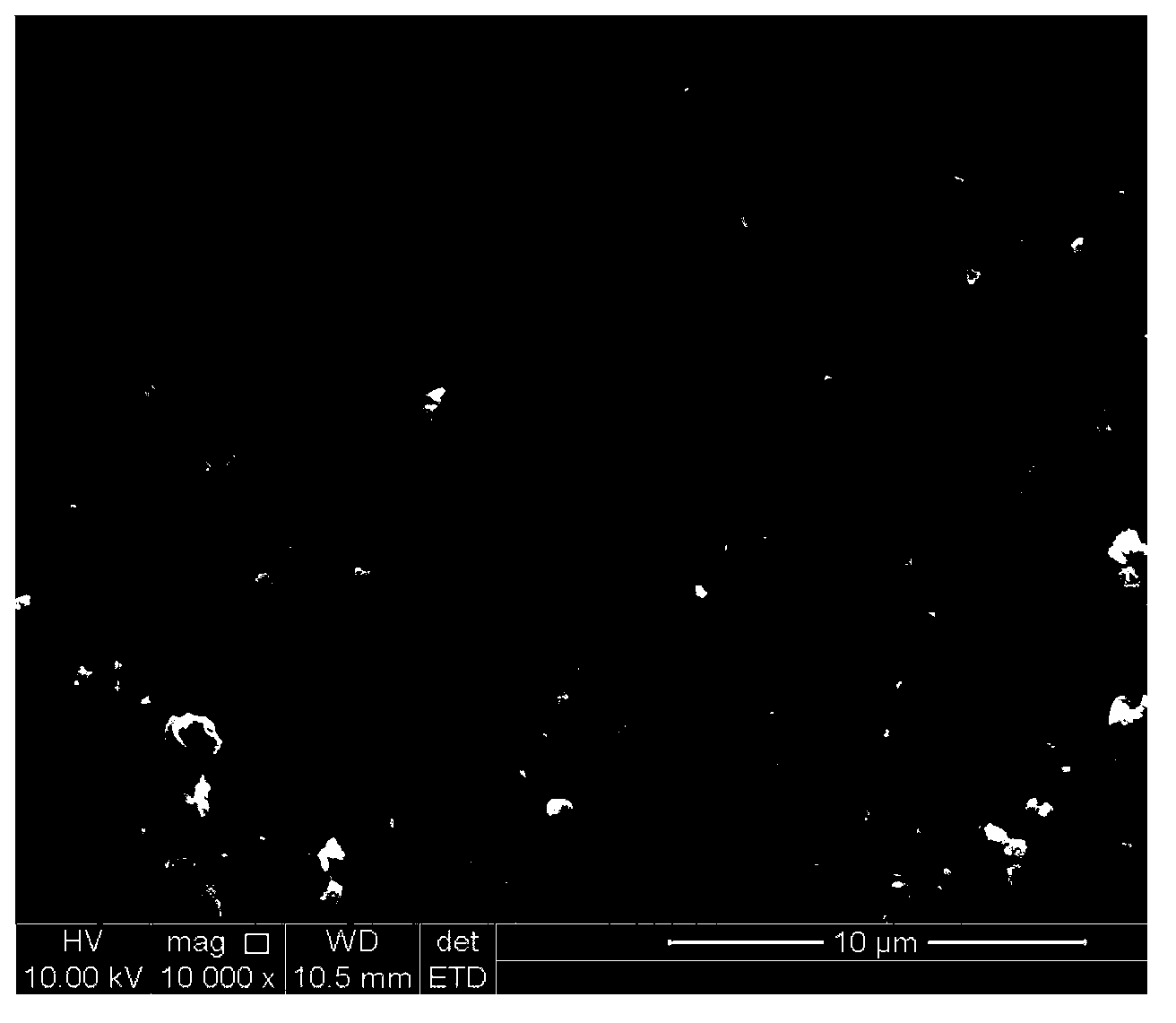

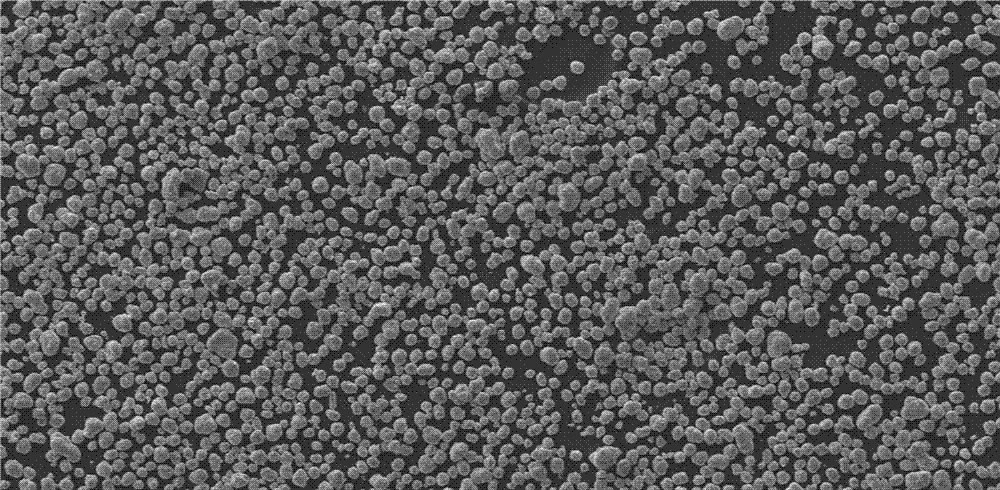

ActiveCN103606661ASmall particle sizeThe synthesis process is simpleMaterial nanotechnologyCell electrodesSlurryLithium-ion battery

The invention provides a method for synthesizing a lithium ion battery negative electrode material according to a mechanochemical method. The method comprises the following steps of proportioning raw materials in a certain mass ratio, wherein the raw materials include graphite oxide and relatively cheap micron-sized metal powder; carrying out wet ball milling to obtain slurry; naturally drying the slurry; and roasting at medium and low temperature for a short time, thus obtaining the negative electrode material. The method is simple in process, meets the environment requirement, and can be applied to industrial production. According to the prepared negative electrode material, nano-sized particles, high metallic oxide load and good properties can be achieved, and the prepared material is suitable for being used as the battery negative electrode material.

Owner:NANJING UNIV OF TECH

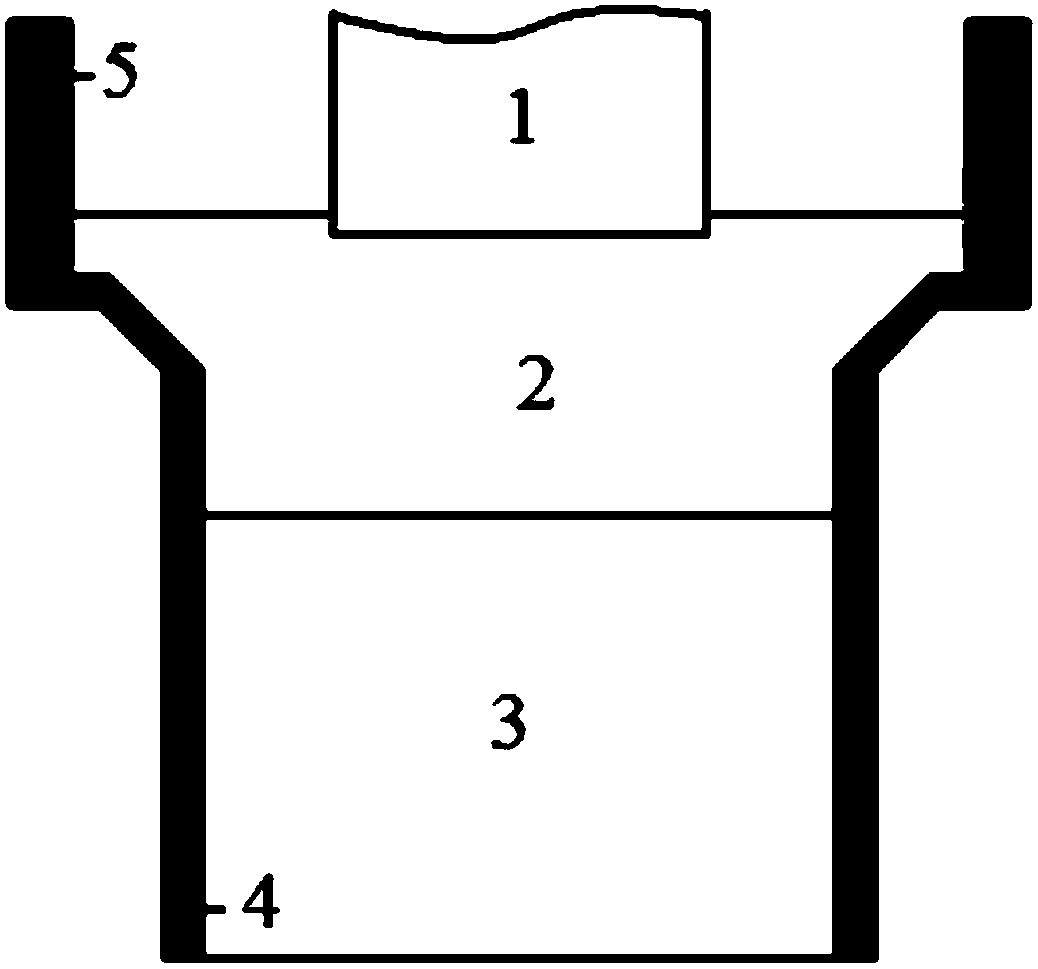

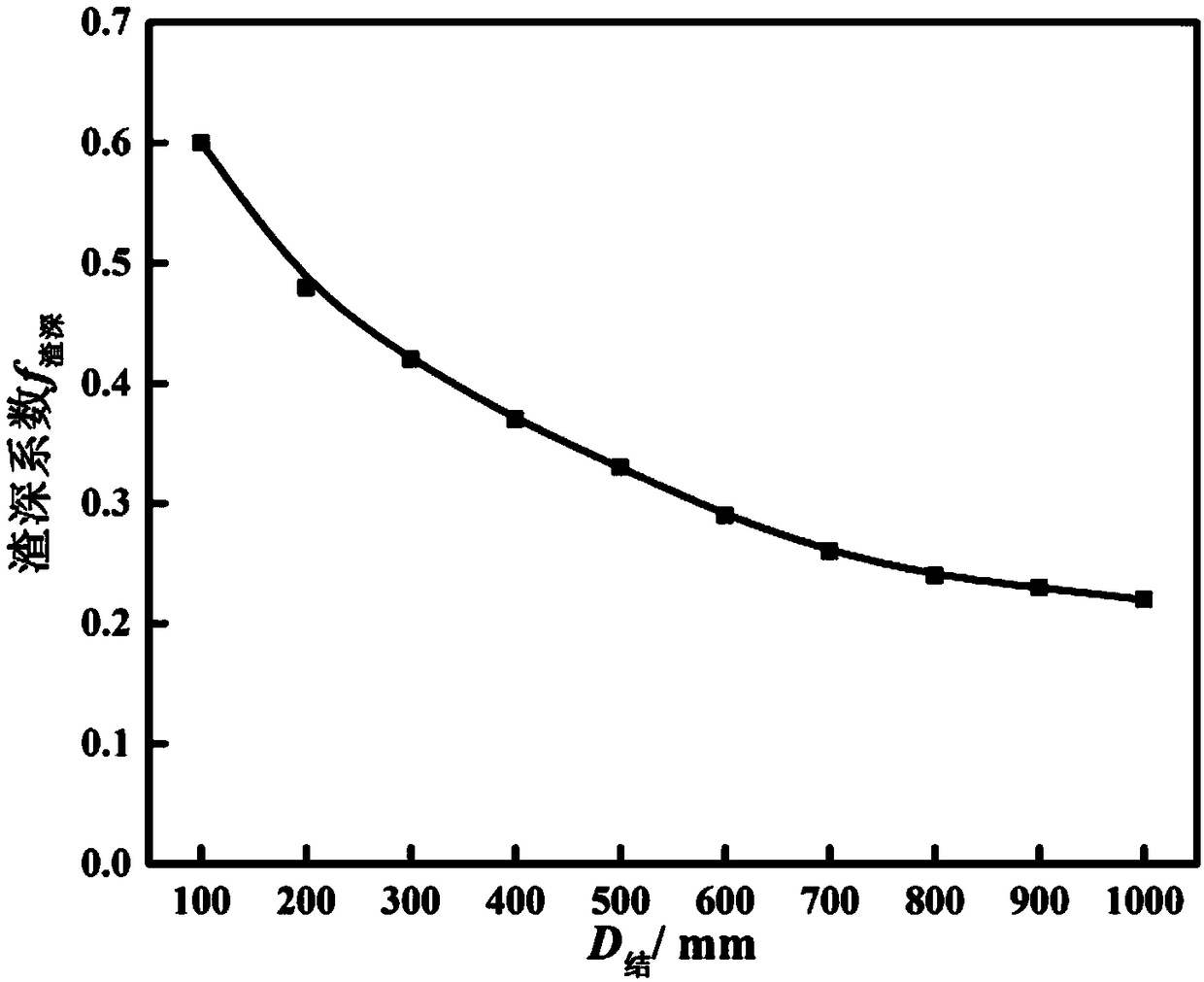

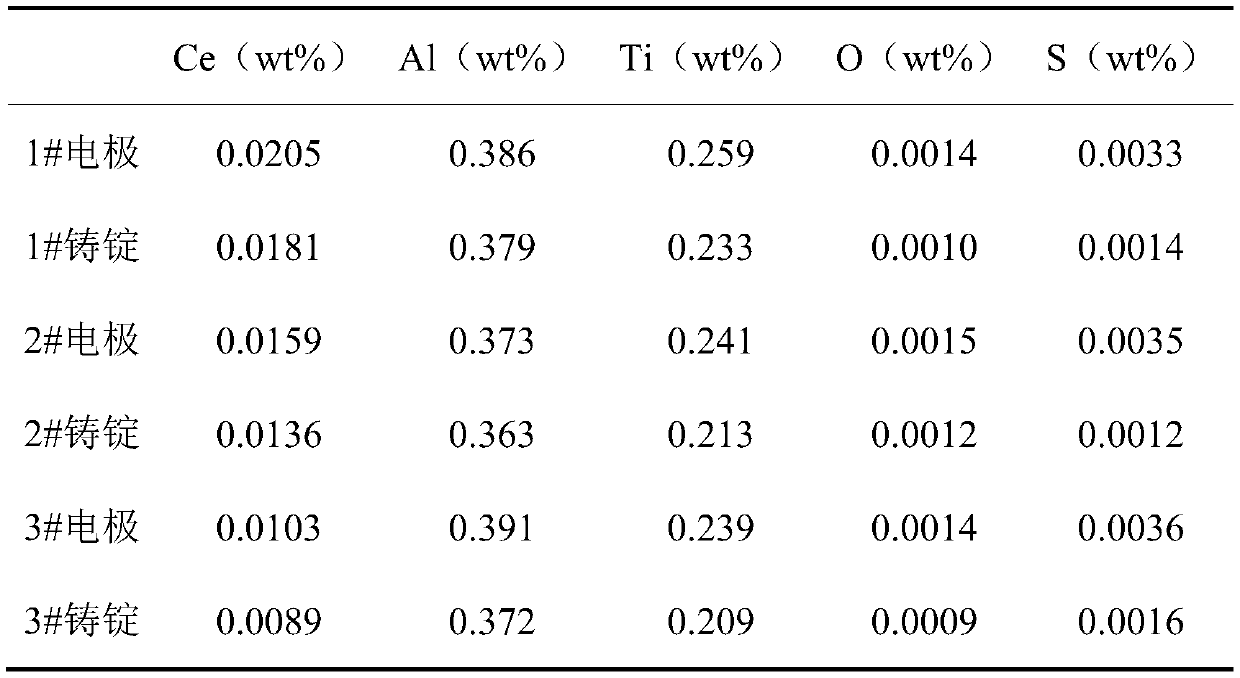

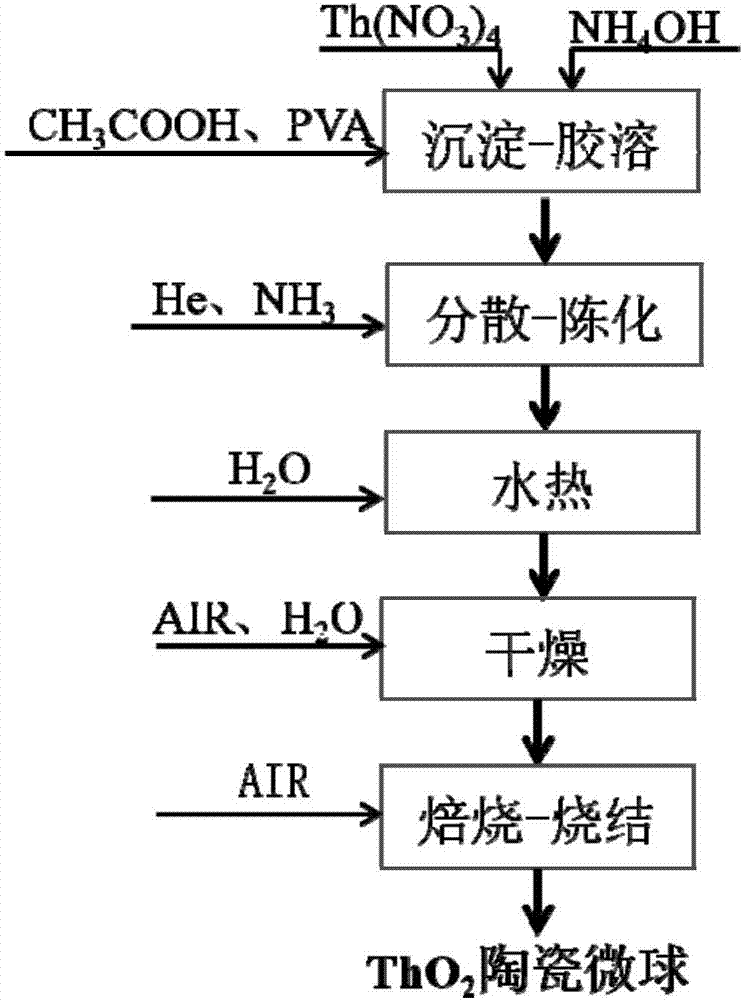

Slag system for smelting GH984G nickel base alloys and application method thereof

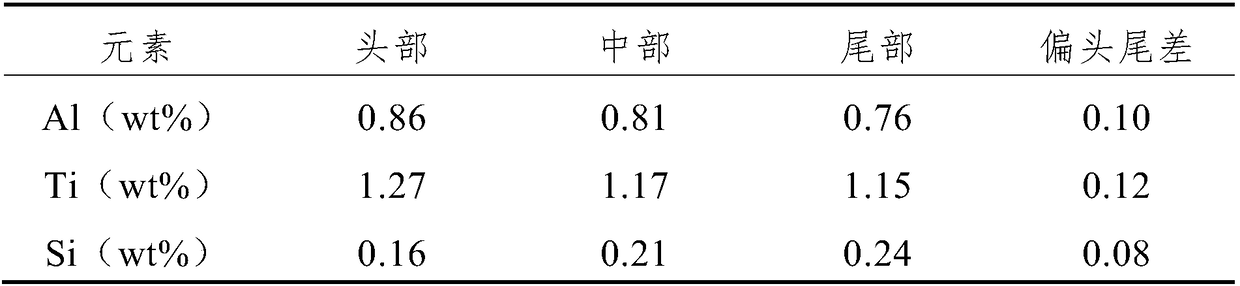

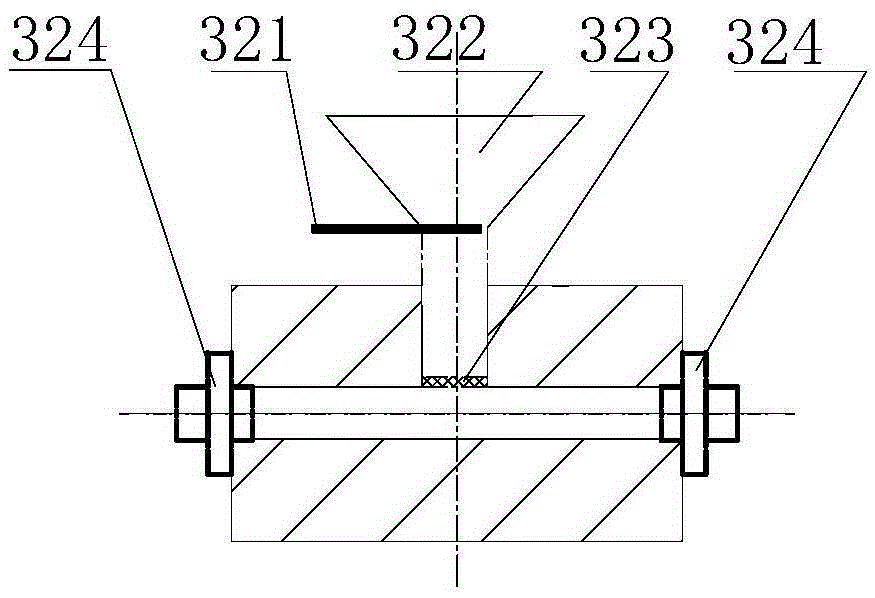

The invention relates to a slag system for smelting GH984G nickel base alloys and an application method thereof. The slag system comprises the following components in percentage by weight: 25-30% of CaO, 20-25% of Al2O3, 2-5% of MgO, 4-7% of TiO2, 1-3% of SiO2 and the balance of CaF2. The slag system is suitable for smelting GH984G high-temperature alloys through remelting of T-shaped crystallizeringot extracting electroslag. The slag system can preferably solve the problems of nonuniform distribution of easy-oxidized elements at the heads and the tails of ingots in the process of smelting the GH984G high-temperature alloys through remelting of the ingot extracting electroslag and weaker surface quality of ingots.

Owner:NORTHEASTERN UNIV

Sample preparation method of material containing silicon carbide used for x-ray spectrometric analysis

ActiveCN101008593AEven distribution of elementsParticle effect noMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceOxygen

This invention relates to one sampling method for X ray spectrum analysis of carbon silicon materials, which comprises the following steps: processing mixture of oxygen agent; processing fuse hanging bottom foil pot; pulling the mixture carbon silicon anti-fire materials sample ad mixture oxygen agent into the pot; putting the pot onto high temperature chamber for heating of oxidation in low temperature to process the glass rollers for the spectrum analysis for X ray.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing titanium dioxide and graphene dual-layer co-coated core-shell-structured positive electrode material of lithium-sulfur battery by one-step method

ActiveCN106876673AEvenly distributedImprove electronic conductivityMaterial nanotechnologyCell electrodesCvd grapheneChemical bond

The invention discloses a method for preparing a titanium dioxide and graphene dual-layer co-coated core-shell-structured positive electrode material of a lithium-sulfur battery by a one-step method, relates to a preparation method for the positive electrode material of the lithium-sulfur battery, and aims to solve the technical problems of a complex preparation method of a graphene-coated sulfur material and limitation in limiting a shuttle effect of polysulfide of the existing positive electrode material of the lithium-sulfur battery. The preparation method comprises the steps of 1, preparing graphene oxide paste; and 2, performing mixing and ball milling, freezing and reducing, and vacuum drying. According to the method, titanium dioxide is added to an electrode material, so that diffusion and dissolving of polysulfide can be effectively limited through chemical bonds of titanium dioxide and polysulfide; however, the conventional hydrothermal method and chemical vapor deposition method and the like cannot facilitate industrial production of the material; and the hydrophilic nanometer titanium dioxide is adopted by the method, and the material is prepared by the simple process of ball milling, so that possibility is provided for industrial production.

Owner:HARBIN INST OF TECH

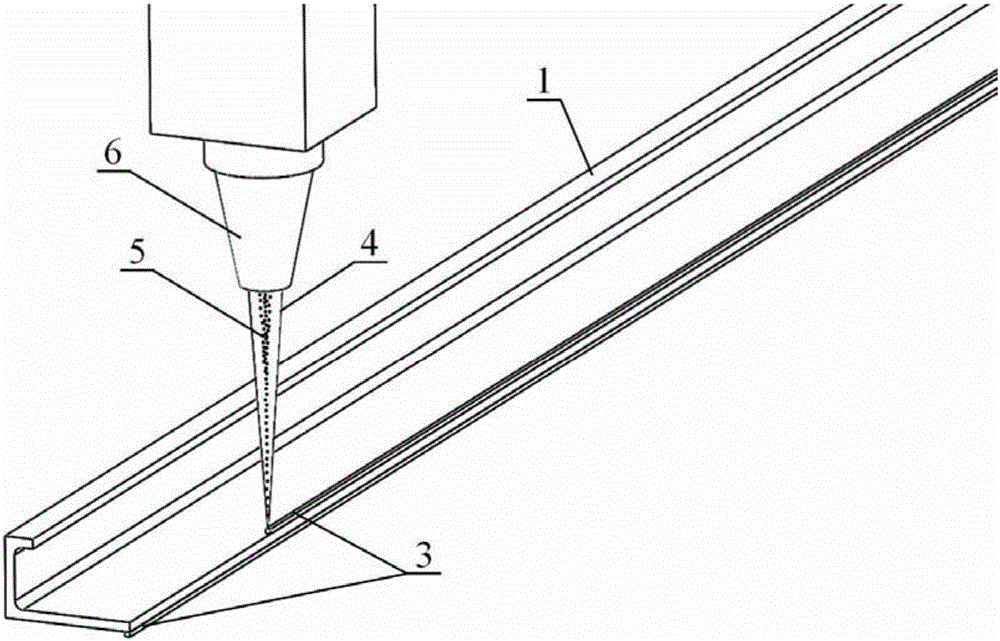

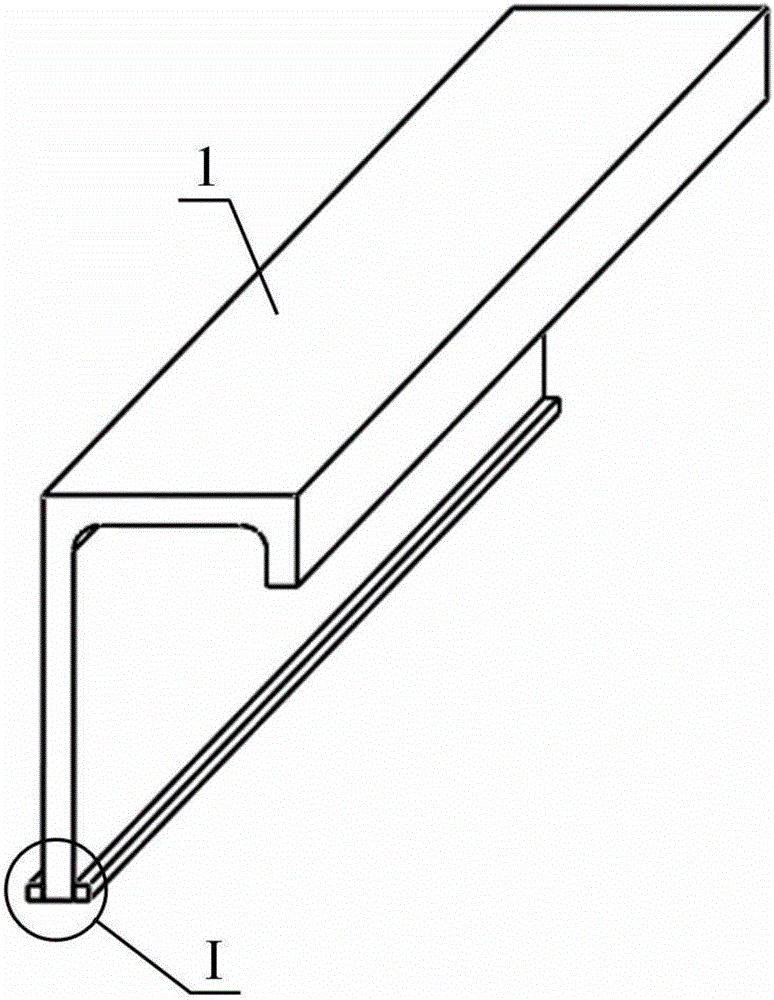

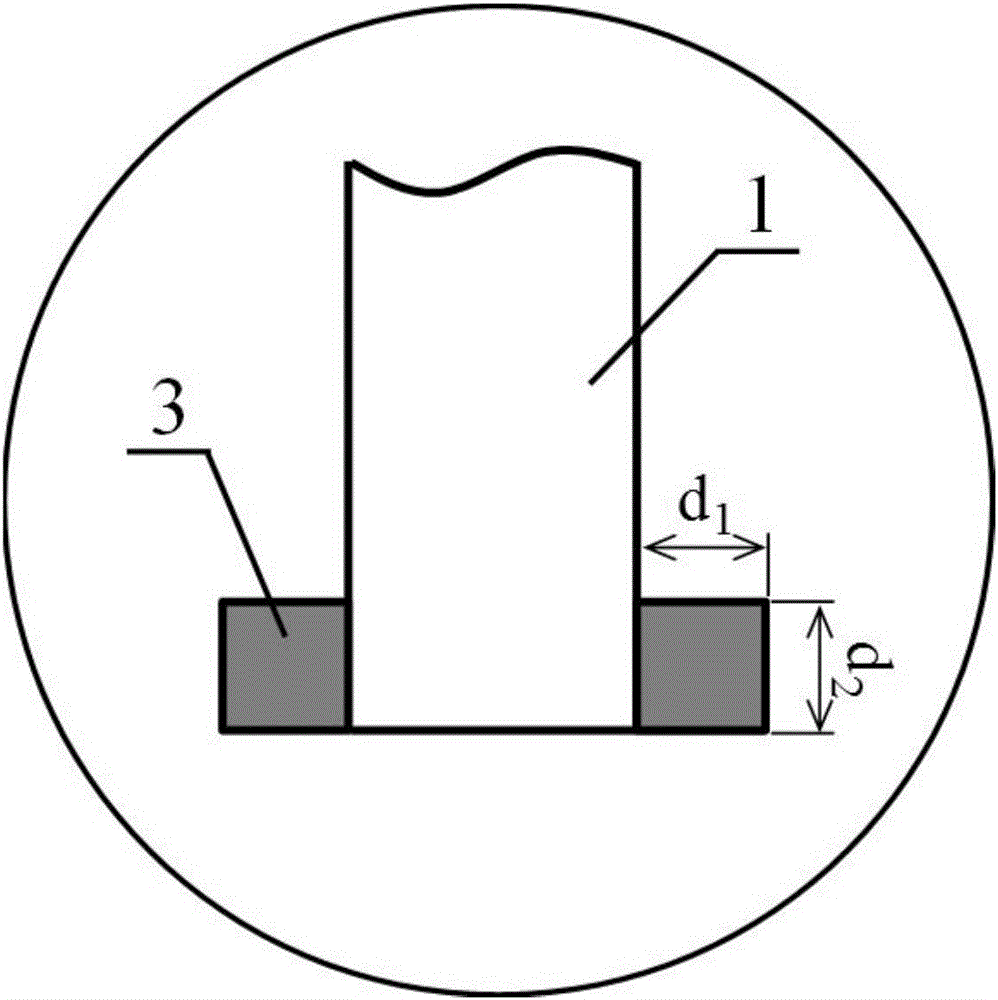

3D additive-manufacturing bilateral laser welding method for T-shaped structure

ActiveCN105710536AImprove mechanical propertiesEvenly regulatedLaser beam welding apparatusMelting tankAlloy

Owner:HARBIN INST OF TECH

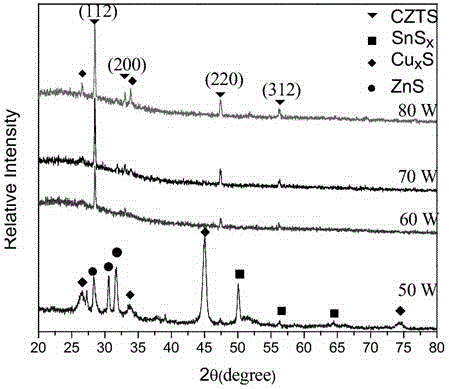

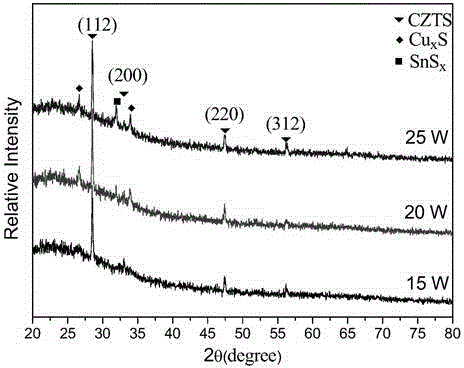

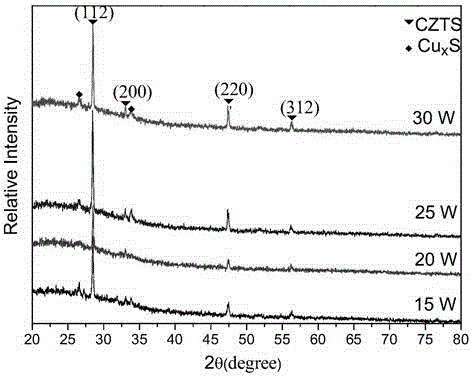

Sulfide target cosputtering preparation method of CZTSSe film and product thereof

InactiveCN104947050AVulcanization step omittedEven distribution of elementsFinal product manufactureVacuum evaporation coatingVulcanizationCZTS

The invention relates to a sulfide target cosputtering preparation method of a CZTSSe film and a product thereof. The cosputtering preparation method of a copper-zinc-tin-sulfur-selenium (Cu2ZnSn(SSe)4, CZTSSe for short) film absorption layer comprises the following steps: (1) preparing a Cu-Zn-Sn-S precursor prefabricated film on a soda-lime glass substrate by using a sulfide target by a cosputtering technique; (2) carrying out direct vulcanization-free high-temperature annealing treatment on the Cu-Zn-Sn-S precursor prefabricated film obtained by cosputtering to prepare a copper-zinc-tin-sulfur (Cu2ZnSnS4, CZTS for short) film absorption layer; and (3) preparing the Cu-Zn-Sn-S precursor prefabricated film by using the optimized preparation scheme in the step (2), and preparing the CZTSSe film absorption layer by using a solid selenium source (Se powder) selenizing annealing technique. The product CZTS / CZTSSe film has higher photoabsorption coefficient, and is an ideal film solar cell material.

Owner:INNER MONGOLIA UNIVERSITY

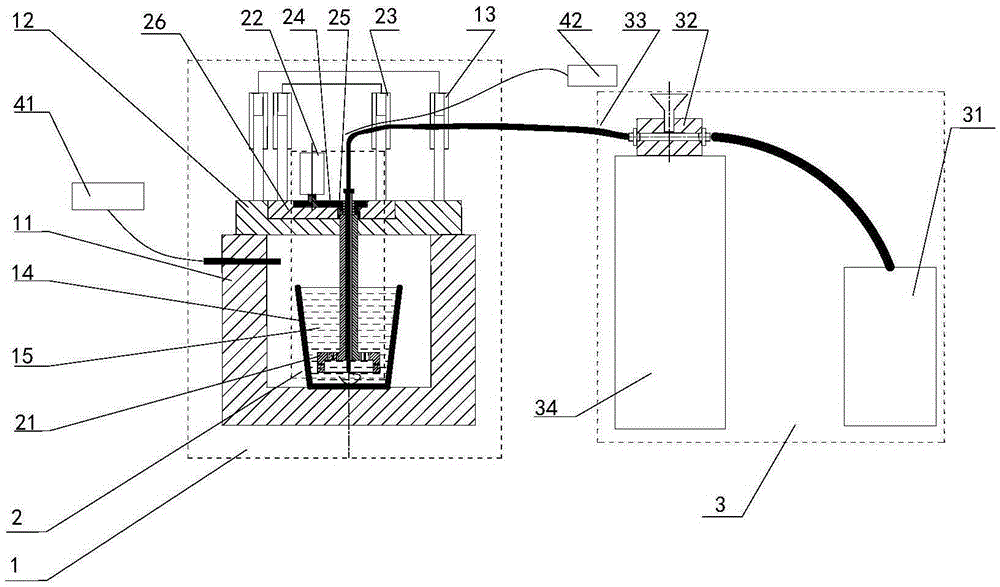

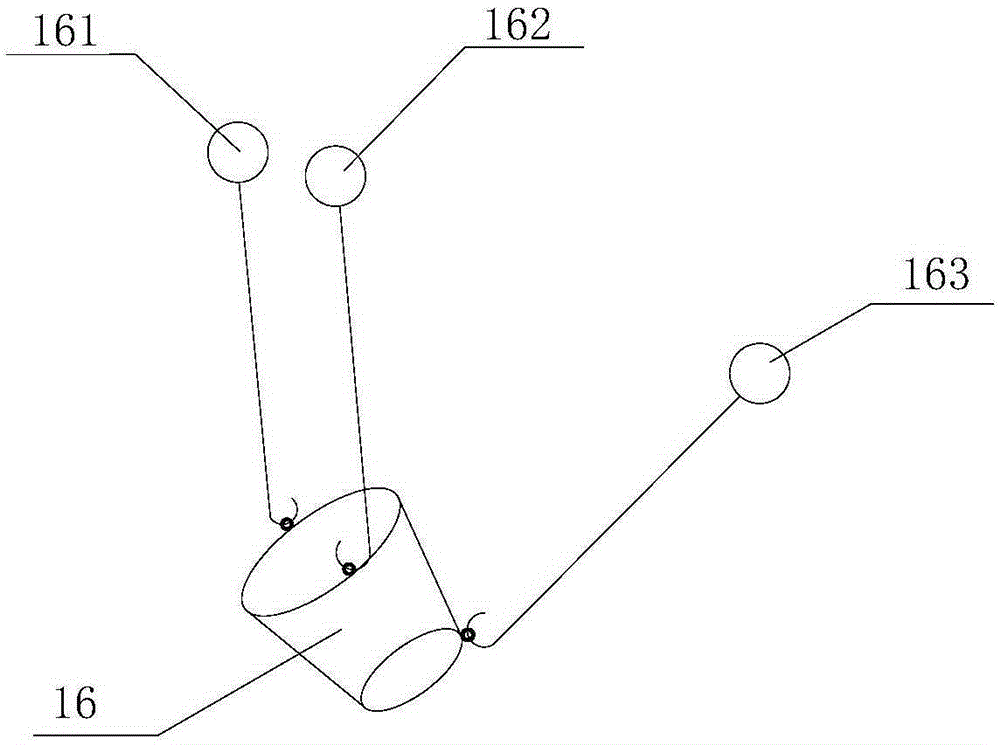

Aluminium alloy smelting device

The invention provides an aluminium alloy smelting device which comprises a smelting mechanism, a stirring mechanism, a conveying mechanism and a temperature control mechanism, wherein the smelting mechanism comprises a resistance type crucible smelting furnace, a furnace lid located above the smelting furnace, a first hydraulic cylinder connected with the furnace lid and a graphite crucible located in the smelting furnace; aluminum liquid is contained in the crucible; the stirring mechanism comprises a graphite bell jar; the top end of the graphite bell jar is connected with a motor through a connector and a transmission system which are located on a mounting plate; a second hydraulic cylinder is arranged on the mounting plate; the conveying mechanism comprises an air compressor and a conveying pipe; a feeding tank is mounted between the air compressor and the conveying pipe; the tail end of the conveying pipe is connected with a through hole in the graphite bell jar; the temperature control mechanism comprises an internal thermocouple and an external thermocouple; the internal thermocouple penetrates through the resistance type crucible smelting furnace and is communicated with the interior of the furnace; and the external thermocouple passes through the interior of the graphite bell jar and is connected with the aluminum liquid. Through the design and use of the structure, the stability of ingot quality can be guaranteed, so that the stability and reliability of later-period experiment data are guaranteed.

Owner:YINBANG CLAD MATERIAL

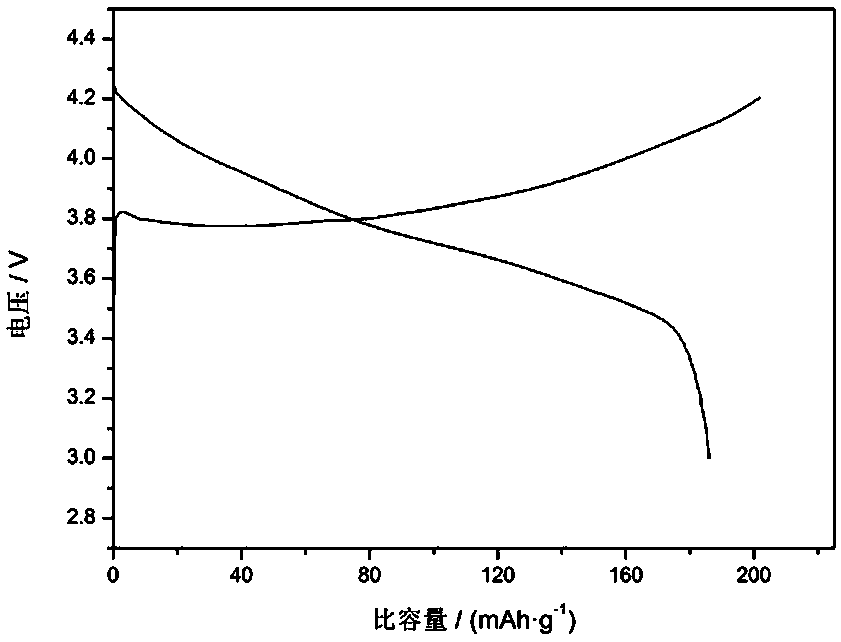

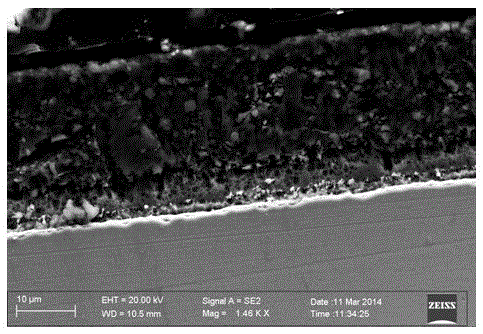

Composite cathode material for lithium ion battery and preparation method thereof

ActiveCN102569765AImprove cycle lifeReduce the impactCell electrodesComposite cathodeLithium-ion battery

The invention relates to a composite cathode material for a lithium ion battery and a preparation method of the composite cathode material. The composite cathode material has a chemical formula: Li a Ni x Co y Mn 1-x-y O2 (b)MO, wherein the b / a is greater than or equal to 0.005 but is smaller than or equal to 0.1. The preparation method comprises the steps that: 1, hydroxide is coated on the surface of a multi-element material of Li a Ni x Co y Mn 1-x-y O2 through a wet process; and 2, the composite cathode material of Li a Ni x Co y Mn 1-x-y O2 (b)MO is prepared through high-temperature calcinations, wherein the b / a is greater than or equal to 0.005 but is smaller than or equal to 0.1. The composite cathode material and the preparation process have the advantages that the element distribution of the material is uniform, the surface metal oxide exists, the direct contact of the composite cathode material with electrolyte is avoided, the worsening reaction is reduced, and the cycle service life of the battery is effectively prolonged.

Owner:HENAN KELONG NEW ENERGY CO LTD

Method for preparing ternary cathode material NCA of lithium ion battery

InactiveCN107732235AReduce wasteEven distribution of elementsSecondary cellsPositive electrodesNickel saltLithium-ion battery

Owner:福建金山锂科新材料有限公司

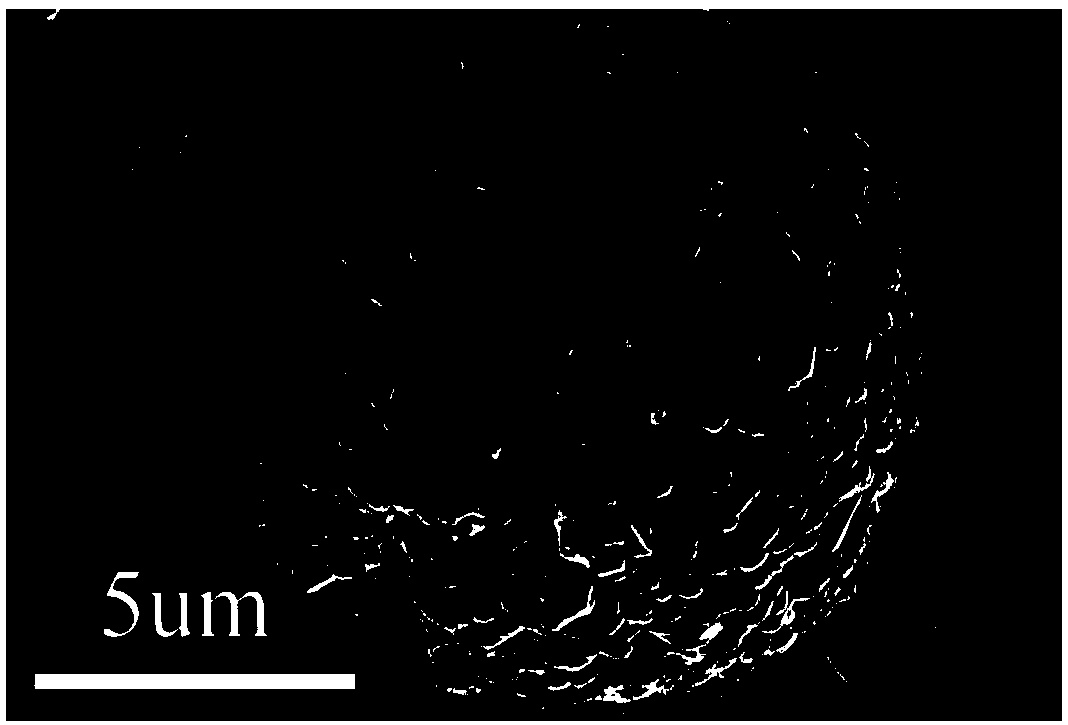

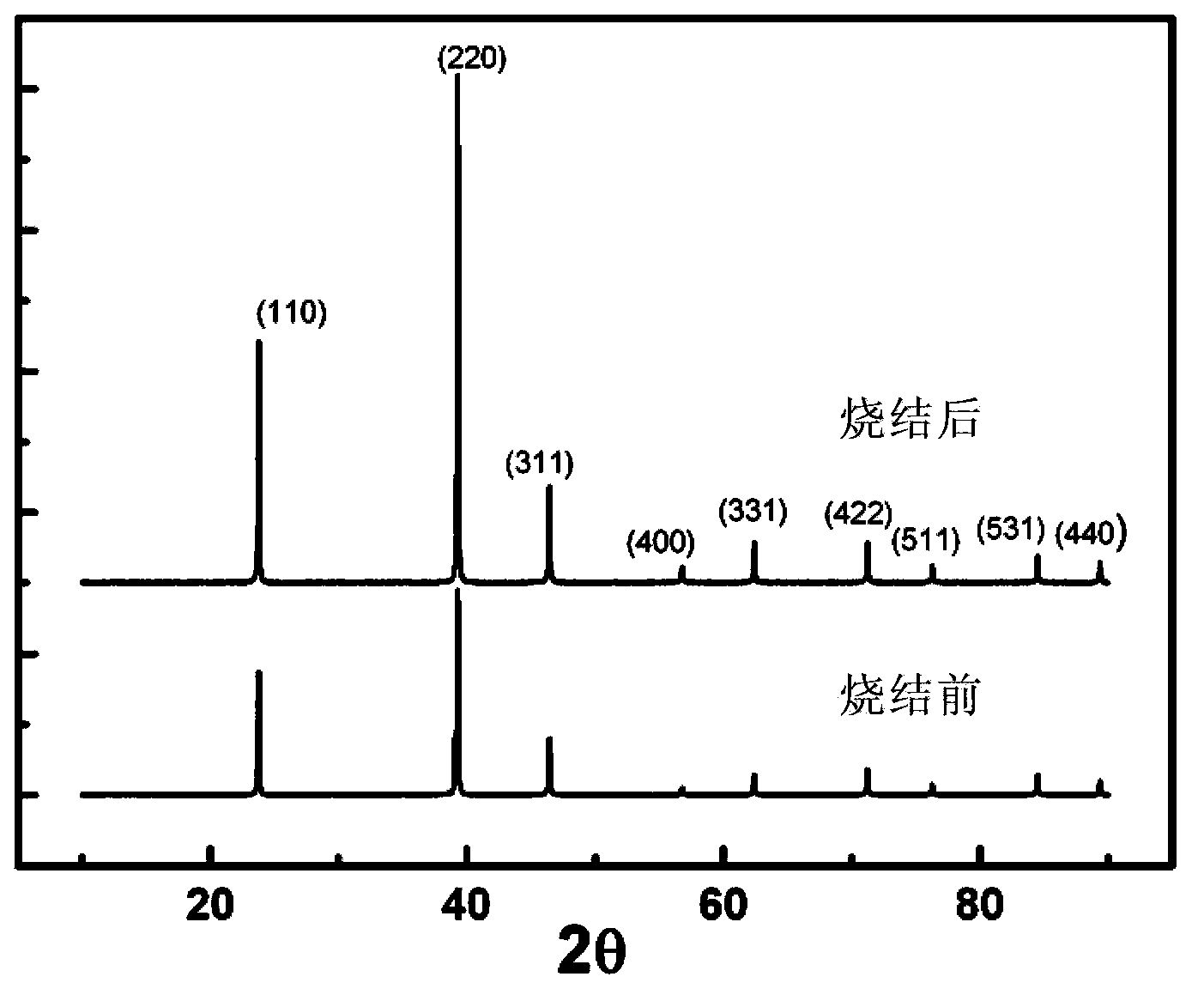

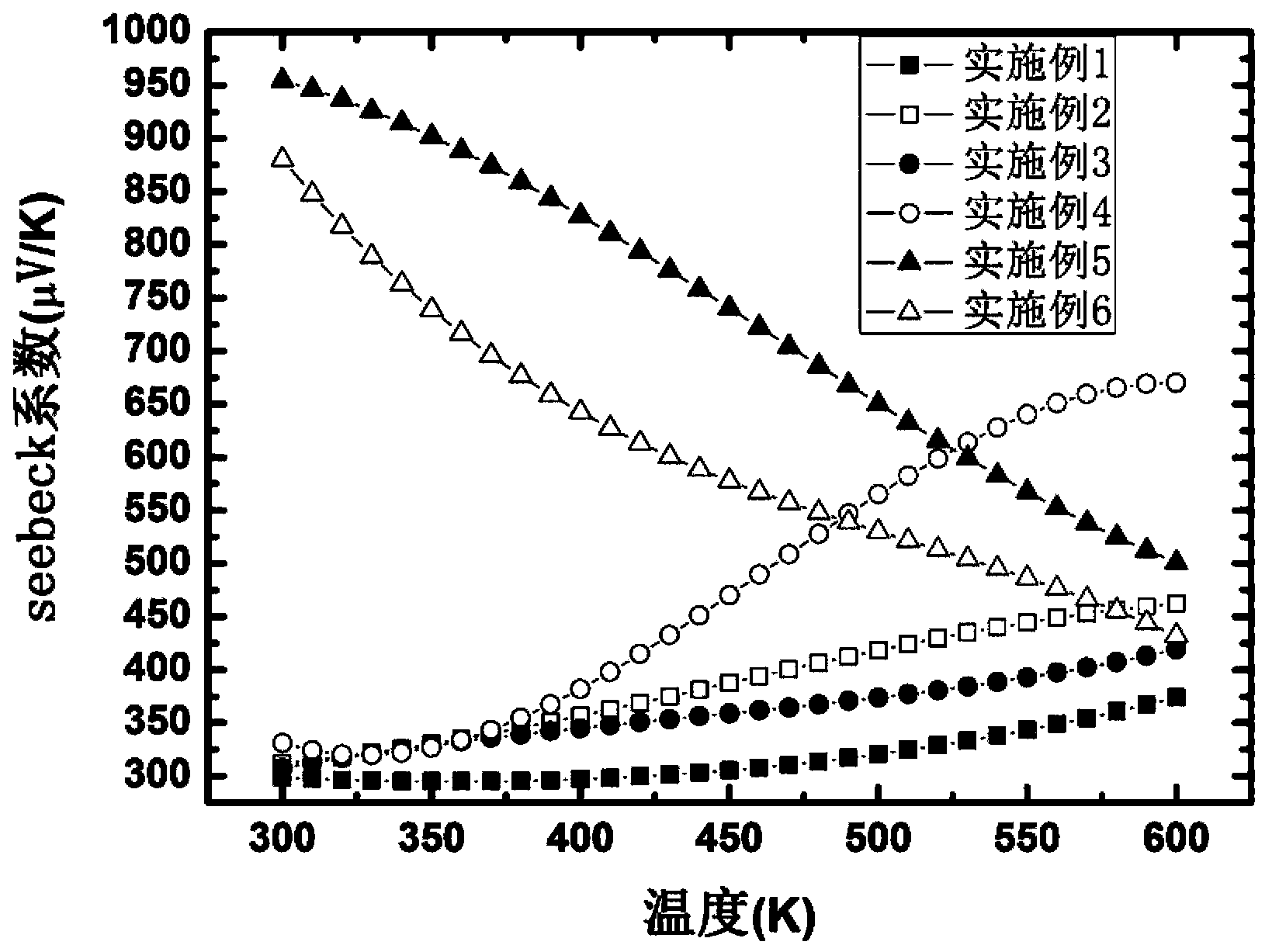

Novel Cd-Te based thermoelectric material and preparation method thereof

ActiveCN103396122AEven distribution of elementsSimple preparation processThermoelectric device junction materialsHalogenChemical compound

The invention provides a novel Cd-Te based thermoelectric material and a preparation method thereof. The Cd-Te matrix of the Cd-Te based thermoelectric material is doped with a halogen and / or a positive-trivalent metal element, and / or compounded with a conductive simple substance or a conductive compound or a combination of the conductive simple substance and the conductive compound. The preparation method comprises the following steps: heating Te, Cd, the doped raw material and / or the composite raw material under a vacuum high temperature condition to obtain a mixture, cooling the mixture, grinding the mixture to form powder, and sintering the powder to obtain the thermoelectric material. The novel thermoelectric material provided in the invention for the first time has the advantages of uniform element distribution, bulkiness, polycrystal, simple preparation technology and short preparation time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nickel/cobalt-rich high-entropy ceramic positive electrode material for lithium ion battery and preparation method thereof

ActiveCN112331840AEven distribution of elementsImprove performanceCell electrodesSecondary cellsComposite materialAqueous solution

The invention belongs to the field of new energy materials, and particularly relates to a nickel / cobalt-rich high-entropy ceramic positive electrode material for a lithium ion battery and a preparation method thereof. The chemical formula of the nickel-cobalt-rich high-entropy ceramic positive electrode material is LiNixCoyA(1-x-y) / nB(1-x-y) / nC(1-x-y) / nD(1-x-y) / n...O2, wherein 0.4 < = x < = 0.8 and 0.1 < = y < = 0.3, and the proportion is the ratio of the amount of substance; the A, B, C and D are selected from Mn, Zn, Mg and Al, and the n is 3 or 4. A preparation method comprises the following steps: (1) preparing a metal salt aqueous solution in proportion, adding the metal salt aqueous solution, a complexing agent and alkali into a reaction container in a certain proportion, controllingthe pH value to be constant to obtain a precipitate, and washing the precipitate to obtain a product precursor; (2) mixing and roasting the precursor and a lithium salt to finally obtain a positive electrode material. The nickel / cobalt-rich high-entropy system can effectively improve the performance of the positive electrode material.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

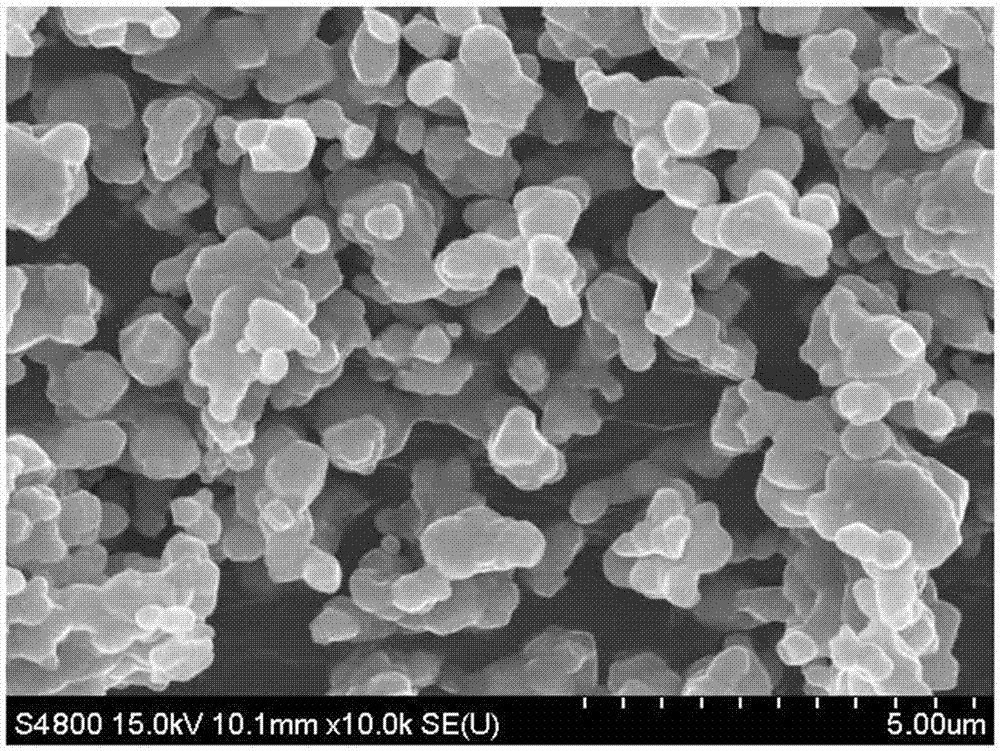

Preparing method for precursor of lithium ionic cell positive material

InactiveCN101284683AGood physical appearanceEvenly distributedCell electrodesManganese oxides/hydroxidesChemical measurementMetal

A method for preparing the precursor of the anode material for a lithium battery is characterized in that the preparation process comprises the steps of preparing a metal salt solution with the total metal ion concentration of 0.1 to 3mol / L according to the stoichiometric proportion of corresponding metal salts and the prepared precursor composite hydroxid; adding a sodium hydroxide solution with the concentration of 0.1 to 5mol / L to the metal salt solution; and reacting under the condition of inert gases to obtain the precursor composite hydroxid. The protection by the inert gases effectively prevents the oxidation of Mn and the generation of Alpha type hydrous hydroxide, so as to prepare the pure phase composite hydroxid precursor with the Beta-Ni(OH)2 type structure. The precursor has evenly distributed elements, good electrochemical activity and is favorable for preparing high-performance anode materials.

Owner:JINCHUAN GROUP LIMITED

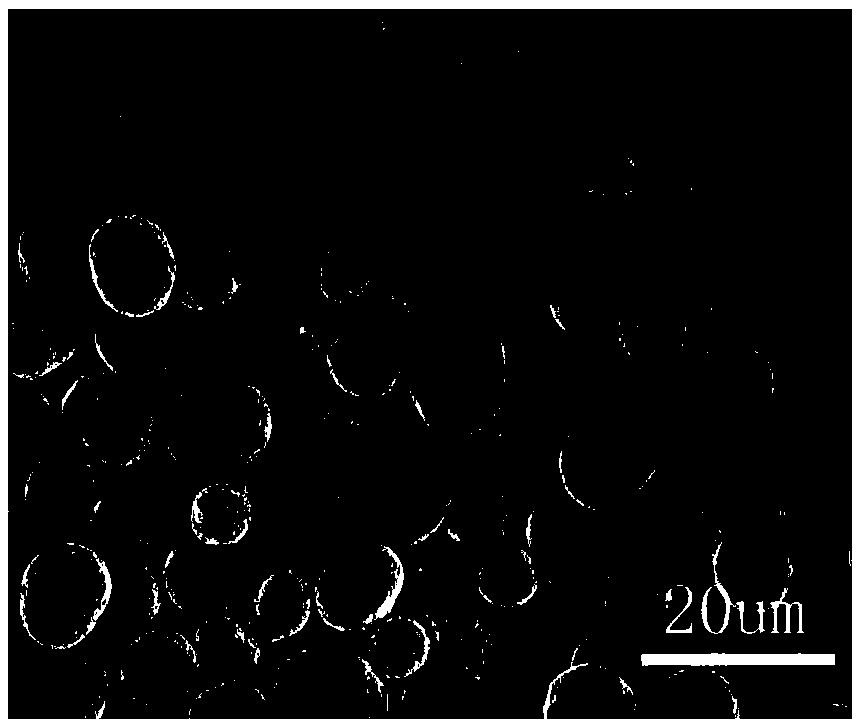

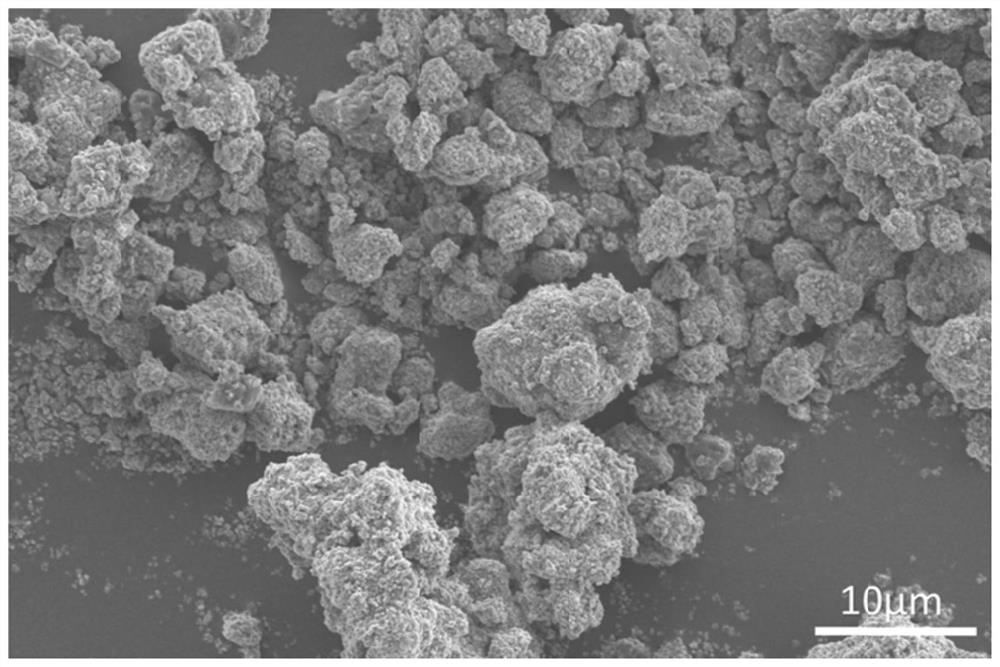

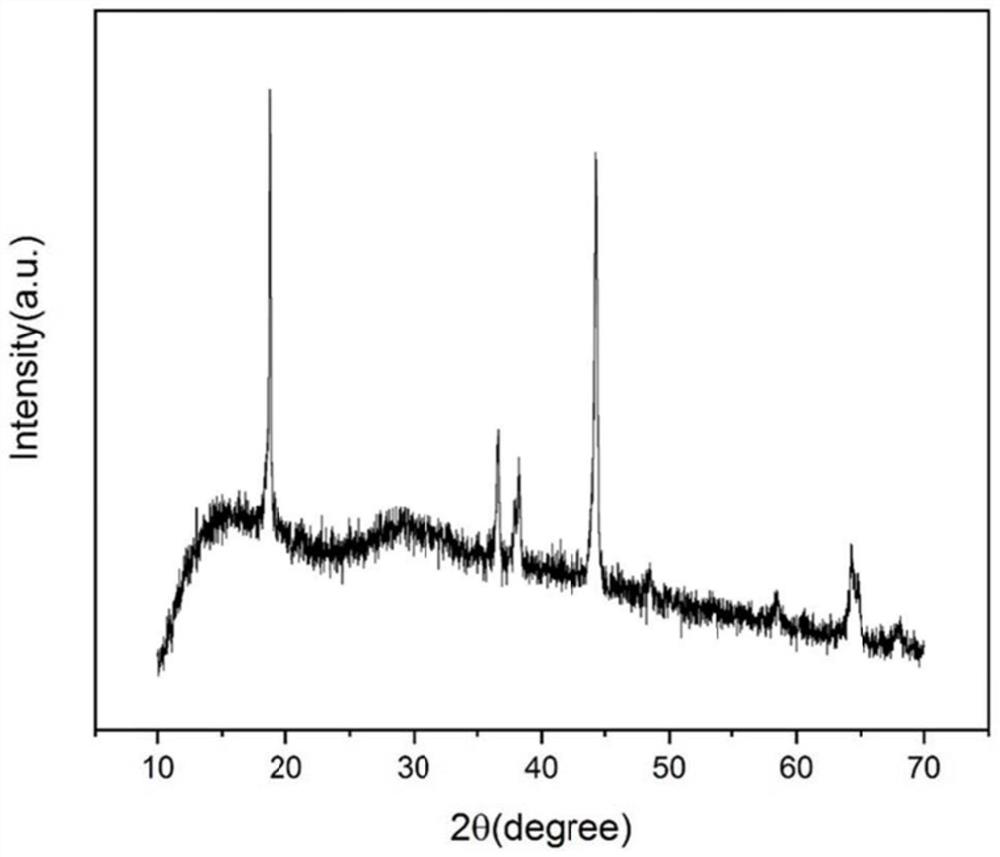

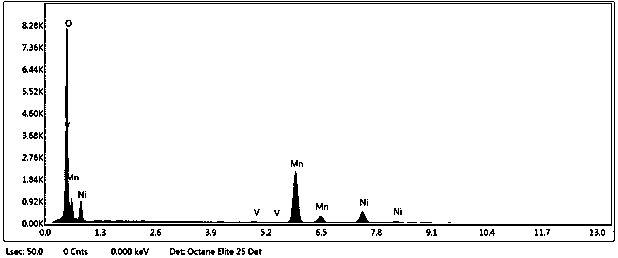

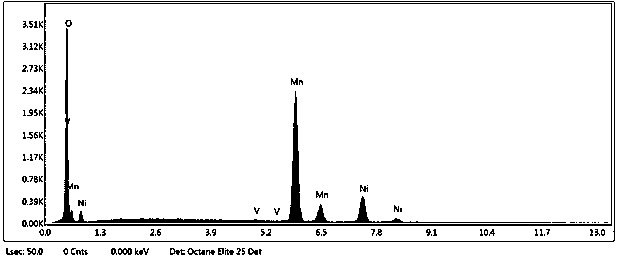

Vanadium-doped nickel-manganese composite hydroxide and preparation method thereof

InactiveCN110943212ALess impuritiesImprove cycle performanceCell electrodesSecondary cellsManganesePhysical chemistry

The invention relates to a vanadium-doped nickel-manganese composite hydroxide and a preparation method thereof. The vanadium-doped nickel-manganese composite hydroxide is represented by a general formula Ni < x > Mn < 1-x > Vz (OH) < 2 + a >, wherein x is greater than or equal to 0.1 and less than or equal to 0.9, 0.001 < = z < = 0.01; wherein a is more than or equal to 0.005 and less than or equal to 0.05, the microstructure is determined to be sphere-like by an analytical scanning electron microscope method, the D50 is determined to be 3.0-16.0 mu m by a particle size analysis laser diffraction method, and the specific surface area is determined to be 4.0-13.0 m < 2 > / g by a gas adsorption BET method; the vanadium element is introduced to stabilize the structure of the catalyst; according to the preparation method, atomic-scale mixing of nickel, manganese and vanadium elements is achieved, the obtained vanadium-doped nickel-manganese composite hydroxide has the advantages of being uniform in element distribution, good in sphericity degree and stable in crystal lattice, the problems that in the prior art, vanadium element doping is not uniform, and particles are prone to breakageare solved, and the safety, the cycle performance and the rate performance of the nickel-manganese positive electrode material are further improved.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Negative and positive ion co-doped monocrystal-like ternary positive electrode material and preparation method thereof

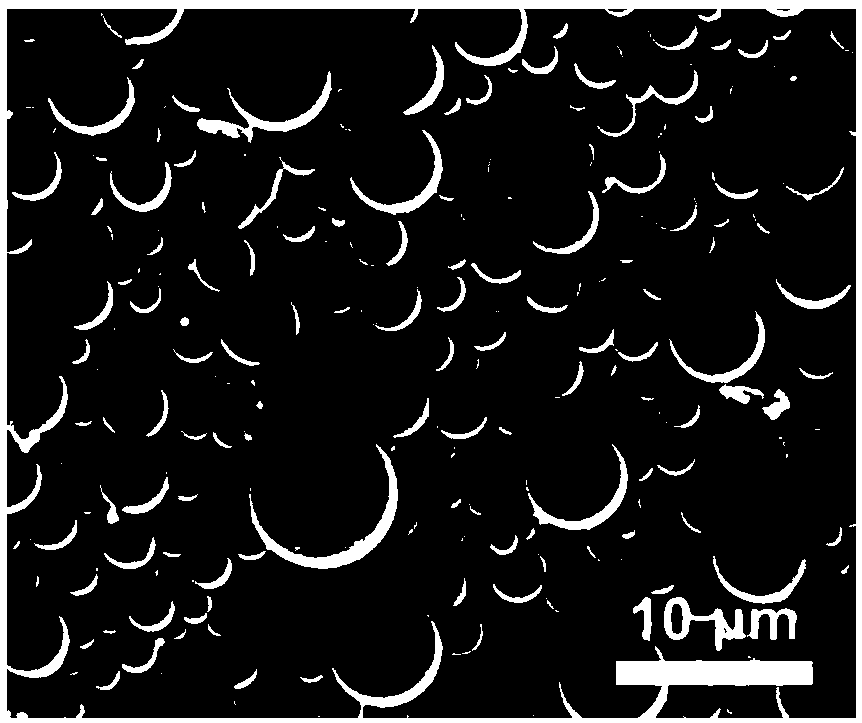

ActiveCN110289415AEven distribution of elementsReduce the degree of cation mixingSecondary cellsPositive electrodesSol-gelCyclic stability

The invention discloses a negative and positive ion co-doped monocrystal-like ternary positive electrode material and a preparation method thereof. The general formula of the negative and positive ion co-doped monocrystal-like ternary positive electrode material is LiNi<0.8-x>Co0.15Al0.05MxO<2-y>Vy, wherein 0.01<=x<=0.03, 0.01<=y<=0.04, M is one of Zn, Mg and Cu elements, and V is one of F, Br and Cl elements. The preparation method comprises the following steps: firstly, preparing a precursor of a cationic M-doped ternary positive electrode material by adopting a sol-gel method, then carrying out the ball-milling and uniform mixing of the precursor with lithium salt (lithium salt for providing lithium element), and carrying out high-temperature roasting to obtain the negative and positive ion co-doped monocrystal-like ternary positive electrode material. The ternary positive electrode material of the lithium ion battery prepared by the invention has the advantages of fine and uniform particles, low specific surface area, low cationic mixing degree, good crystallinity, good cycling stability and good initial coulombic efficiency.

Owner:FUZHOU UNIVERSITY

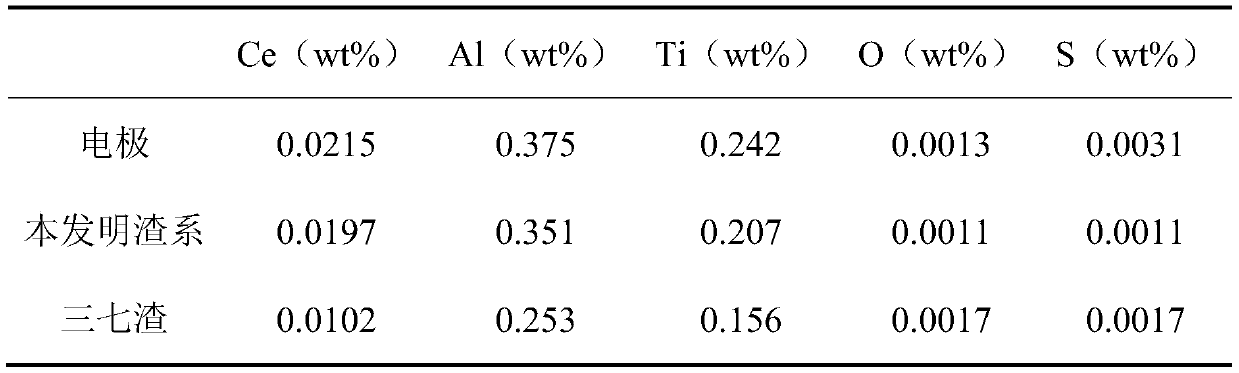

Slag system for smelting GH3625 nickel-base alloy containing rare earth Ce and electroslag remelting smelting method thereof

The invention relates to a slag system for smelting a GH3625 nickel-base alloy containing rare earth Ce and an electroslag remelting smelting method thereof. The slag system comprises, by weight, 20-25% of CaO, 17-21% of Al2O3, 5-7% of NaF, 3-5% of MgO, 1-2% of TiO2, 4-6% of CeO2, 1-2% of SiO2, and the balance CaF2. The slag system is suitable for electroslag remelting smelting of the GH3625 alloycontaining rare earth, and the problem of Ce, Al and Ti burning loss in the process of electroslag remelting smelting of the GH3625 alloy containing Ce can be well solved.

Owner:上海一郎合金材料有限公司

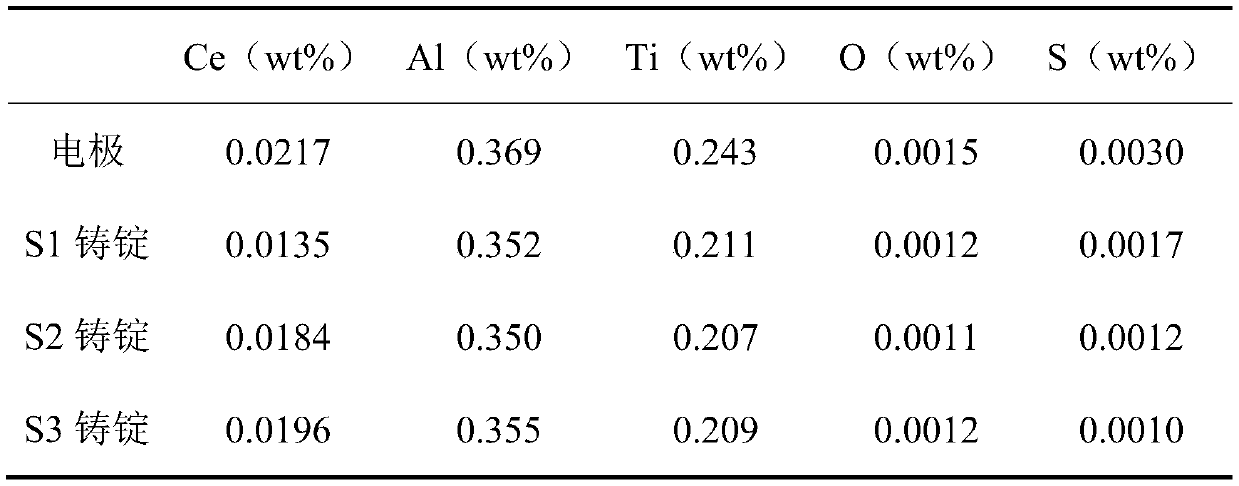

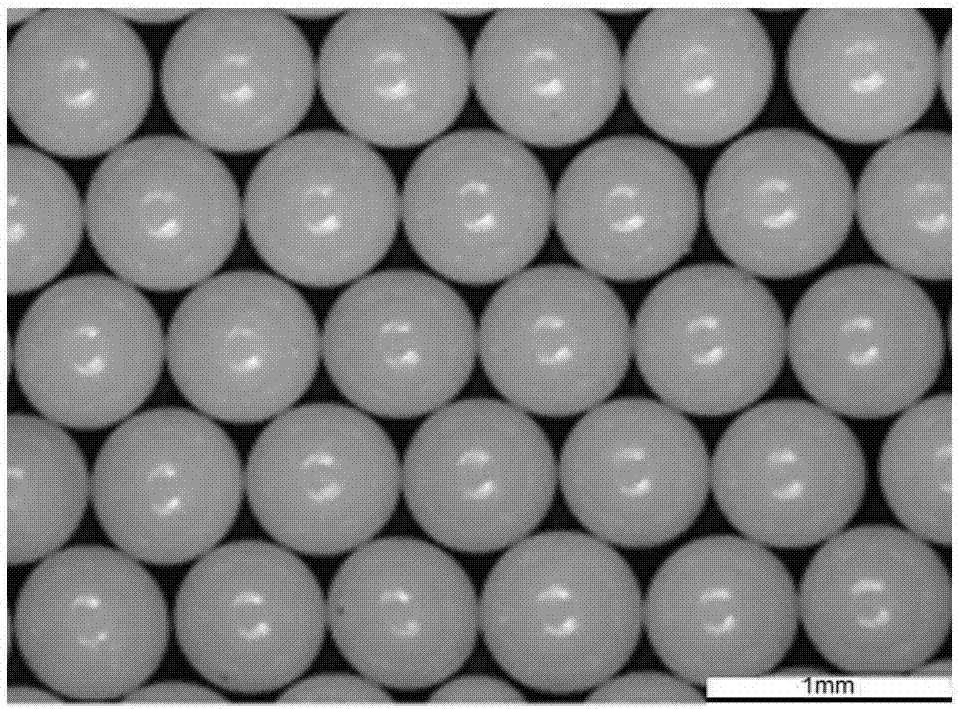

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for measuring content of heavy metal in soil by hand-held X-ray fluorescence spectrometer

InactiveCN107179329AShort analysis timeEven distribution of elementsMaterial analysis using wave/particle radiationPhysicsCalibration curve

The invention relates to a method for measuring the content of heavy metal in soil by a hand-held X-ray fluorescence spectrometer. The method comprises the following steps: 1) take an appropriate quantity of a soil standard sample and a to-be-tested soil sample, then drying the soil standard sample and to-be-tested soil sample, and pressing the dry soil standard sample and to-be-tested soil sample under 32-35 t for 32-35 s to obtain the soil standard sample and the to-be-tested soil sample; 2) drawing a calibration curve according to the linear relationship between strength and content; 3) opening the hand-held X-ray fluorescence spectrometer, preheating the hand-held X-ray fluorescence spectrometer for 20-25 min, then testing the soil standard sample and the to-be-tested soil sample, and comparing a result with the calibration curve to obtain the content of the heavy metal in the to-be-tested soil sample. The method has the advantages that the method is simple, operation is easy, analysis time is greatly shortened, the measurement result is accurate, and precision is high.

Owner:SUZHOU LANSCI INSTR

Non-layered two-dimensional PbSe crystal material and preparation method thereof

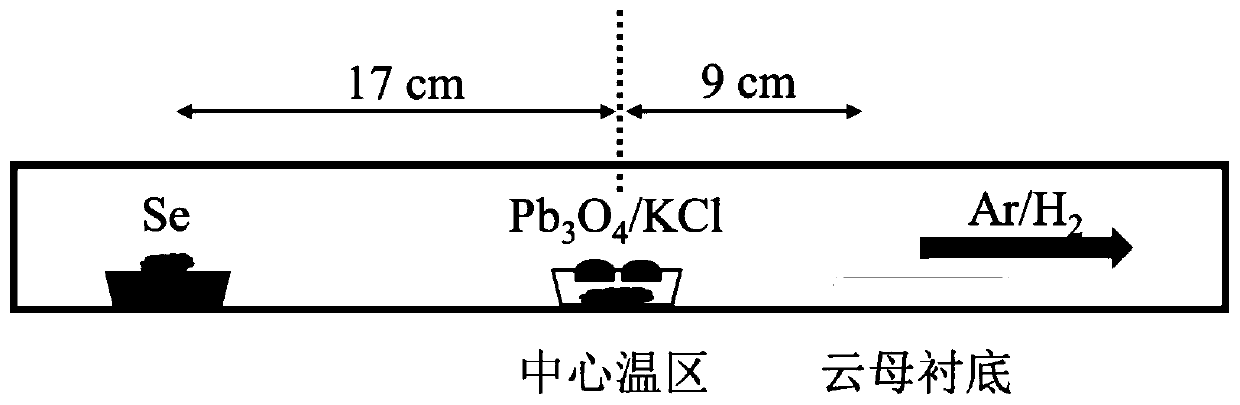

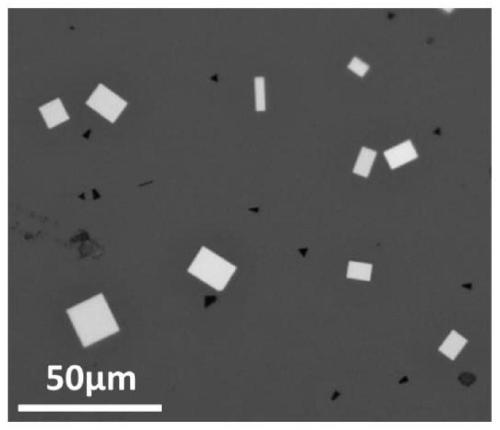

ActiveCN111304747ALow reaction temperatureUniform responsePolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsPhysical chemistry

The invention belongs to the field of nanometer semiconductor materials, and discloses a non-layered two-dimensional PbSe crystal material and a preparation method thereof. The preparation method comprises the following steps: (a) selecting a reaction container, marking the reaction container as an upstream region, a central region and a downstream region, selecting Se powder as a selenium source,and placing the Se powder in the upstream region; (b) selecting Pb3O4 as a lead source, mixing the Pb3O4 with potassium chloride so as to obtain a precursor, then placing the precursor in the centralregion, and selecting mica as a growth substrate to be placed in the downstream region; and (c) introducing argon into the reaction container as carrier gas, introducing hydrogen as reaction gas, andcarrying out a reaction under heating so as to obtain the non-layered two-dimensional PbSe crystal material on the mica substrate. The invention also discloses a product prepared by using the method.The method provided by the invention meets the preparation requirements of large-batch two-dimensional nanometer PbSe crystal materials; a product crystal has the advantages of smooth and clean surface, uniform morphology, uniform element distribution, rich and cheap raw materials, simple preparation, and convenience in popularization and large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

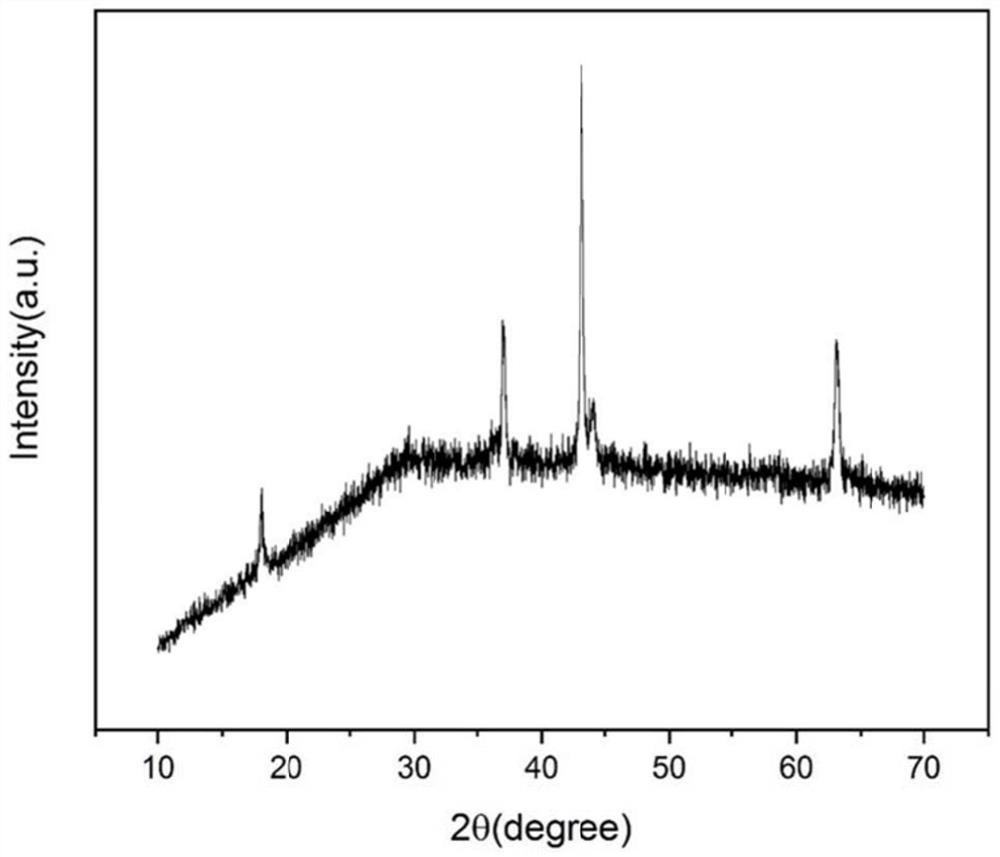

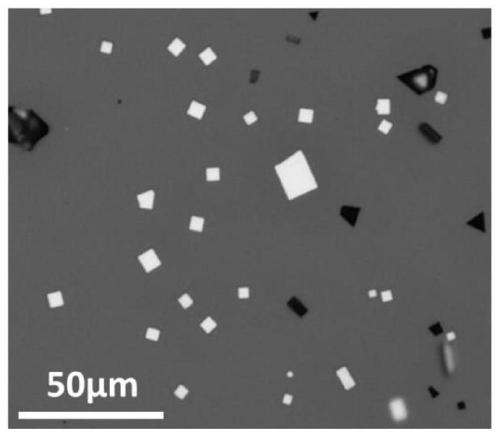

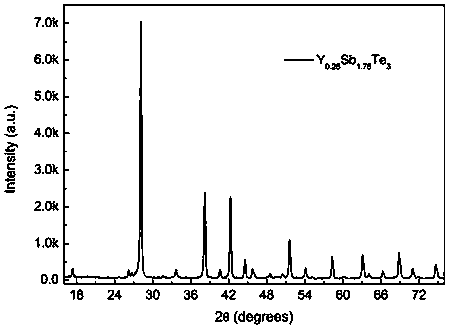

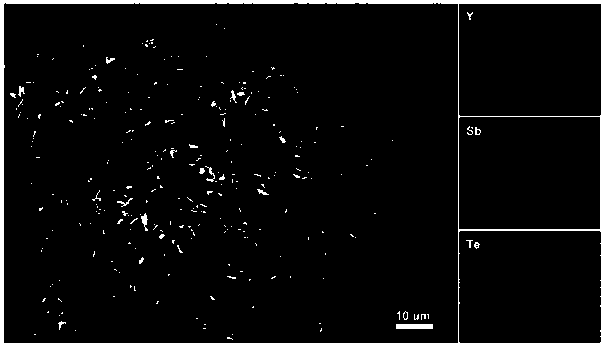

Preparation method of yttrium-doped antimony telluride phase changing material

ActiveCN108389960ARaw materials are cheap and easy to getSimple processElectrical apparatusThermal insulationSolvent

The invention provides a preparation method of an yttrium-doped antimony telluride phase changing material. The preparation method of the yttrium-doped antimony telluride phase changing material Y<x>Sb<2-x>Te<3> comprises the steps of 1) enabling raw materials Y(NO<3>)<3>.6H<2>O, SbCl<3> and TeO<2> to be dissolved into a mixed solvent of dilute ammonia water and absolute ethyl alcohol to obtain aprecursor, wherein the molar ratio of Y(NO<3>)<3>.6H<2>O to SbCl<3> to TeO<2> is x: 2-x: 3 (x is greater than or equal to 0 and less than or equal to 0.33); 2) transferring the precursor obtained in the step 1) into a reaction kettle, adding NaBH<4>, next, heating to 160-200 DEG C, performing thermal insulation for 18-24h, then cooling to the room temperature, and next, separating out precipitates; and 3) performing alternate washing and filtering on the precipitates by deionized water and ethyl alcohol and then carrying out vacuum constant temperature drying to obtain the yttrium-doped antimony telluride phase changing material. The preparation method disclosed in the invention has the characteristics of low cost of raw materials, simple process, low equipment cost, safety and no pollution and the like; and the prepared phase change material is small in granularity, high in purity and uniform in element distribution.

Owner:BEIHANG UNIV

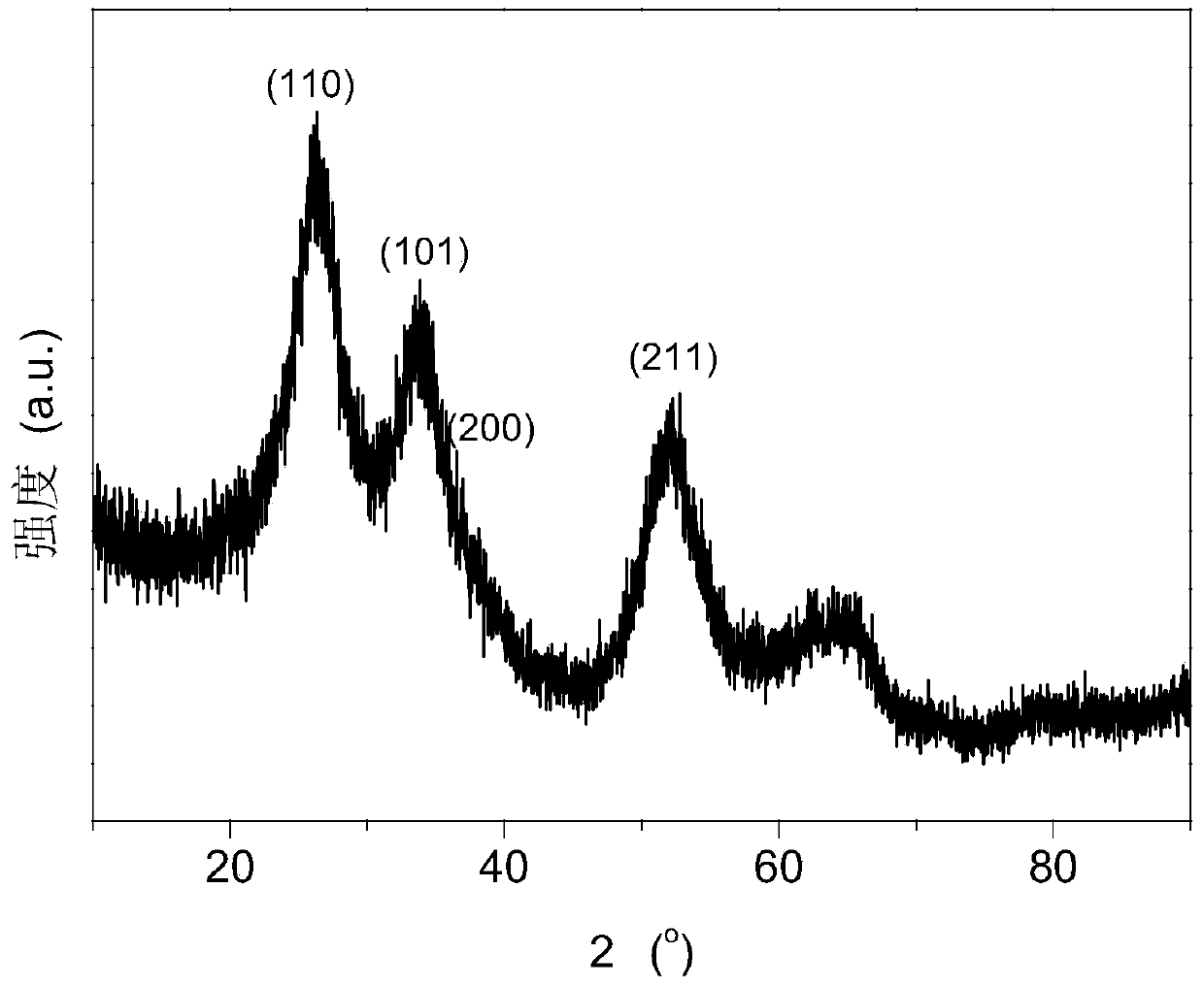

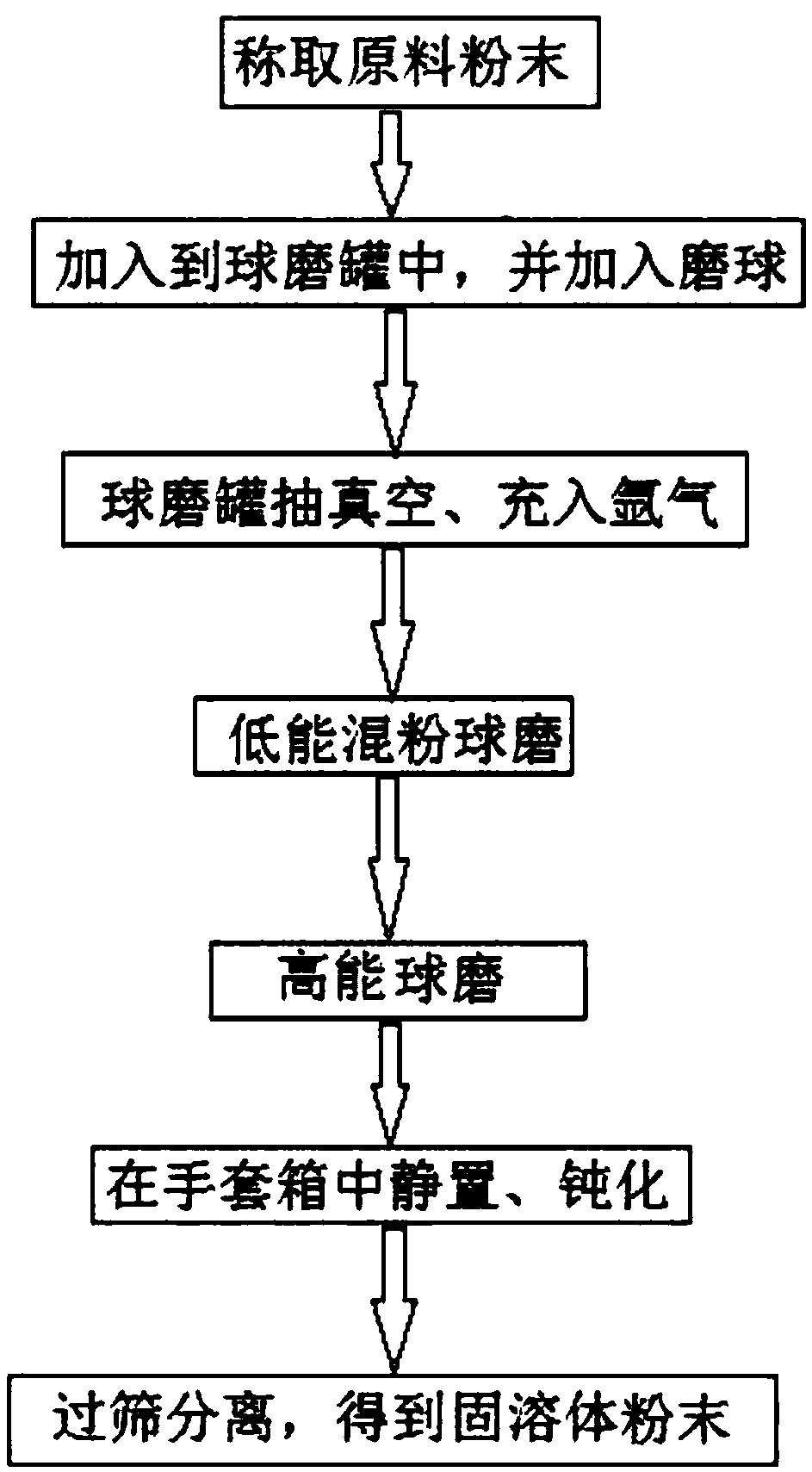

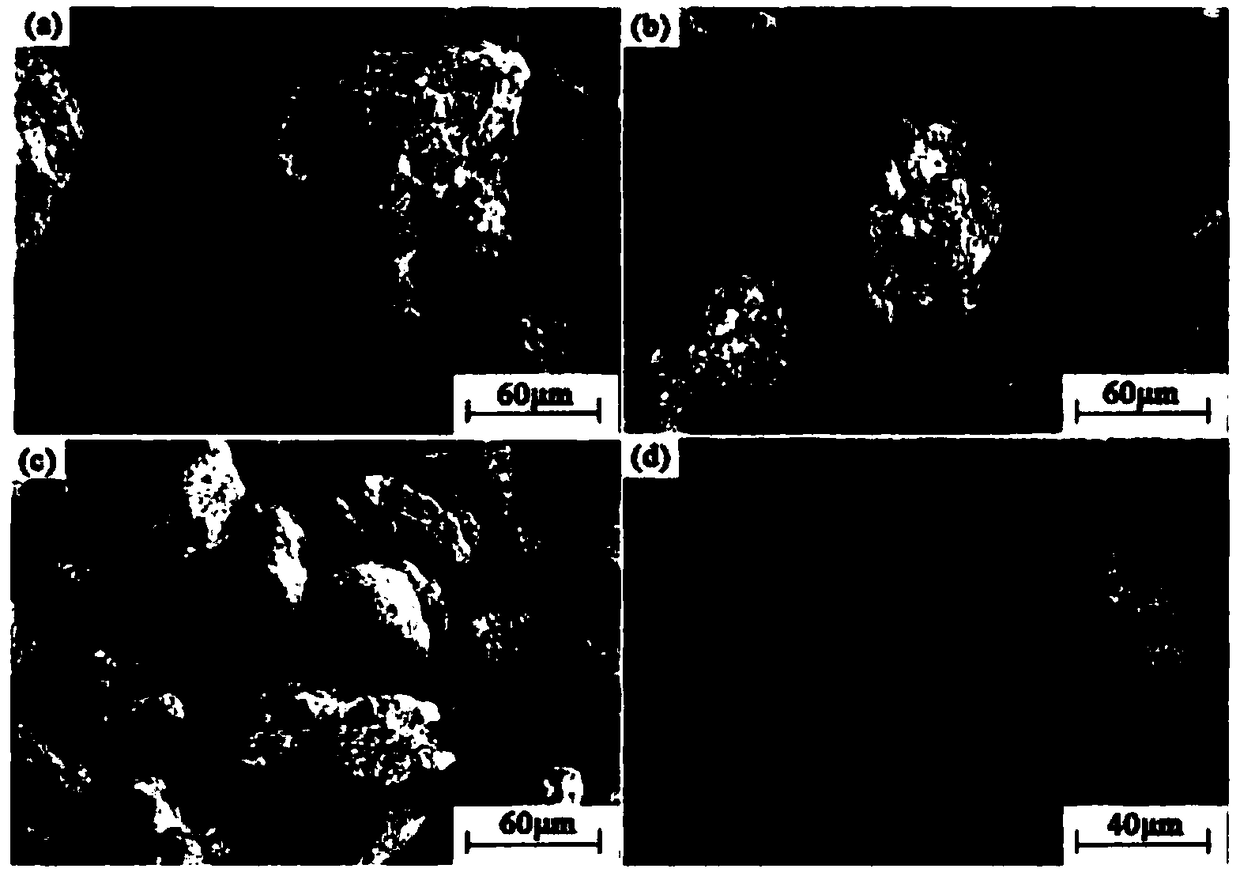

Mechanical alloying preparation method of Ti-22Al-25Nb (at.%) solid solution

ActiveCN108465819AAvoid burnsAvoid problems such as component segregationTransportation and packagingMetal-working apparatusMaterials preparationAl powder

The invention belongs to the technical field of material preparation, and particularly relates to a mechanical alloying preparation method of a Ti-22Al-25Nb (at.%) solid solution. The method comprisesthe following steps that S1, weighing is carried out according to the element ratio of the solid solution, wherein Ti powder, Al powder and Nb powder are weighted according to the atomic ratio of 53: 22 : 25 ; S2, the weighed three kinds of element powder are added into a ball milling tank, and stainless steel grinding balls are added according to a ball material ratio of 6 : 1 to 9 : 1; S3, theball milling tank is vacuumized, and then is filled with argon; S4, the ball milling tank is placed on a ball mill for low-energy mixed powder ball milling; S5, the ball milling tank performs high-energy ball milling on the ball mill; S6, the ball milling tank is allowed to be subject to standing for 24 hours in an argon glove box, then an upper cover of the ball milling tank is opened for passivation, and the passivation time is not less than 24 hours; and S7, the powder and the grinding balls are sieved and separated in the argon glove box to obtain Ti-22Al-25Nb (at.%) solid solution powder. According to the method, no process control agent is added so that the pollution to the powder can be prevented, and the mechanical alloying efficiency can be improved.

Owner:YANSHAN UNIV

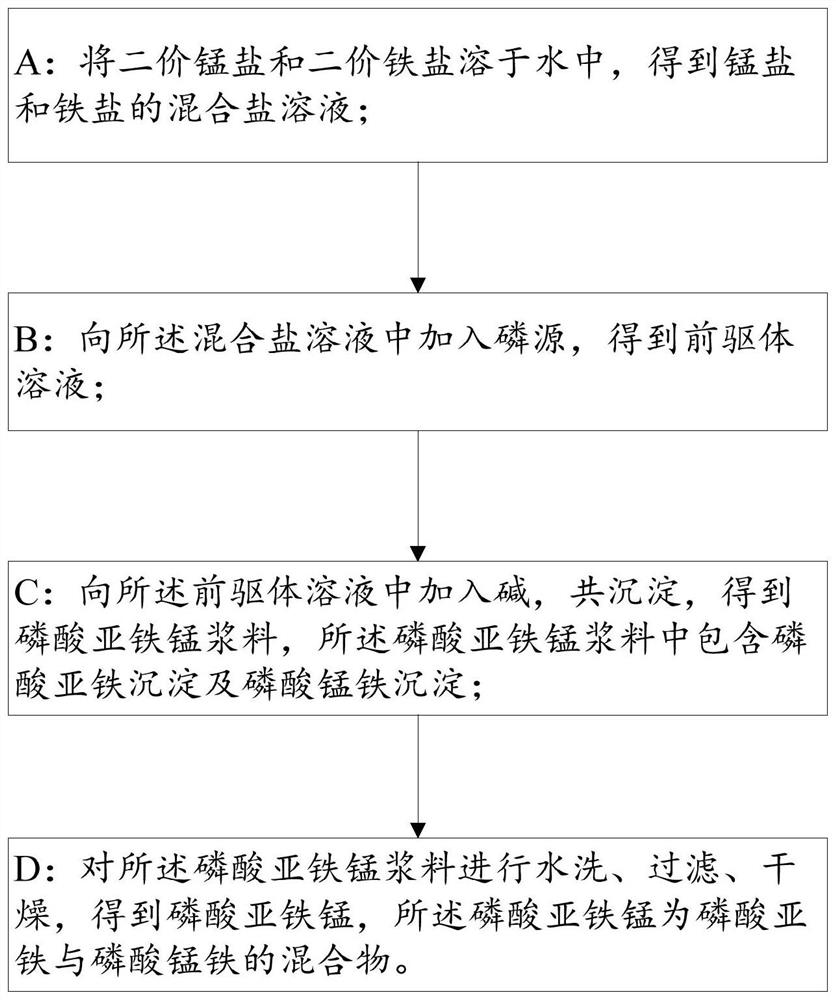

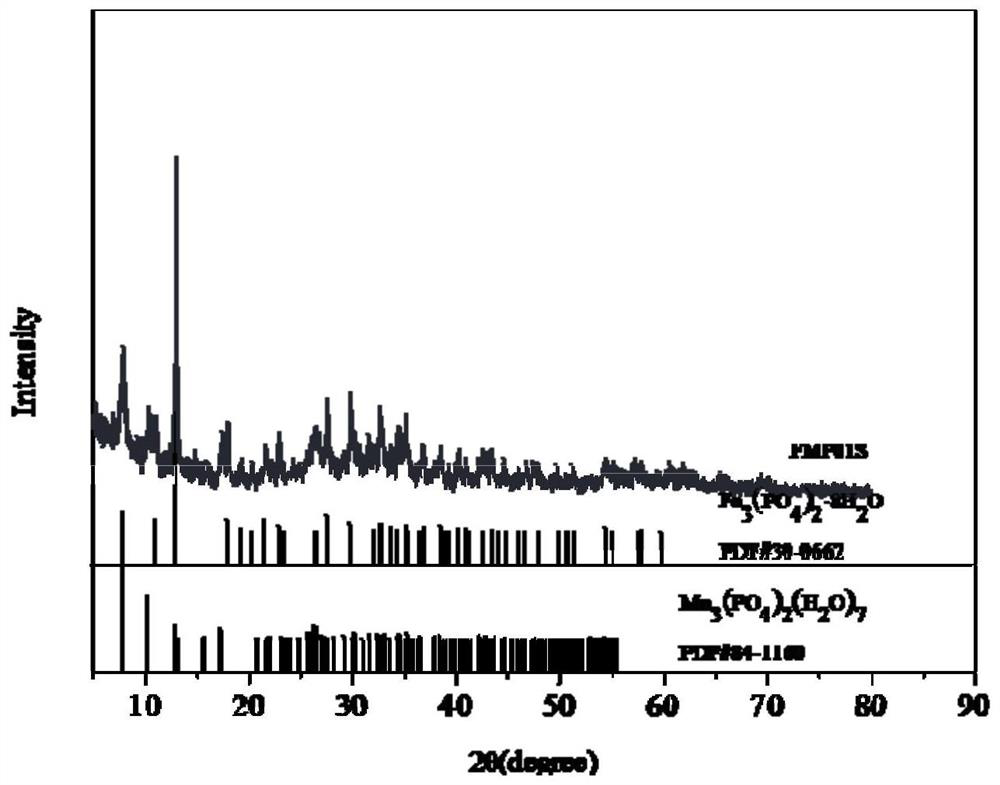

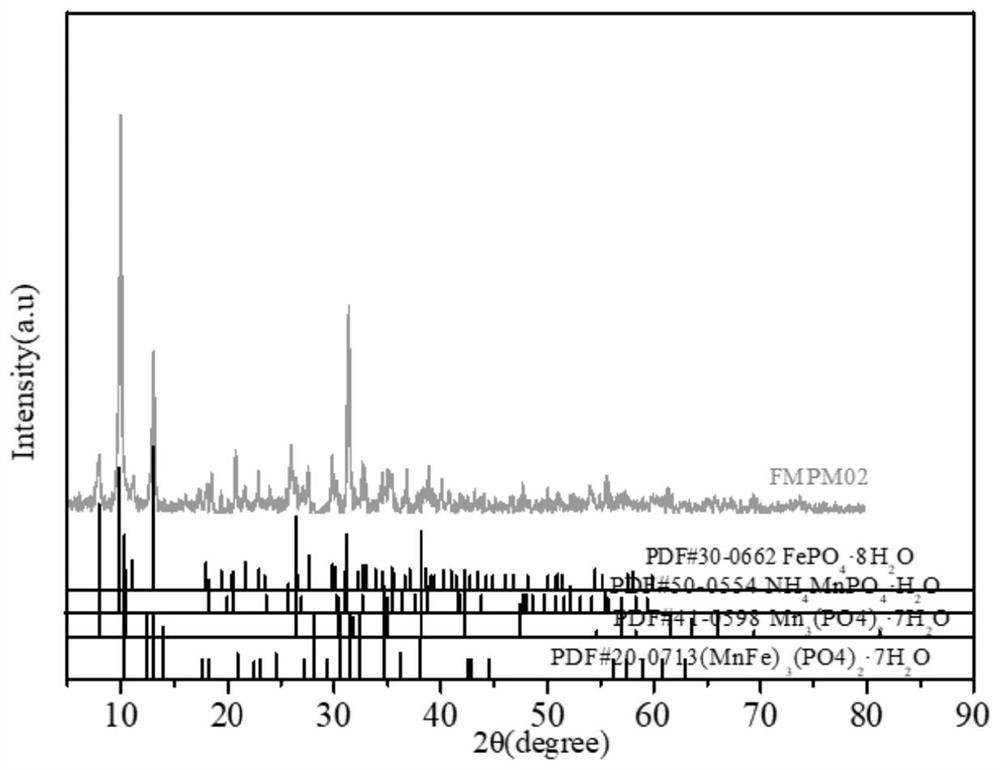

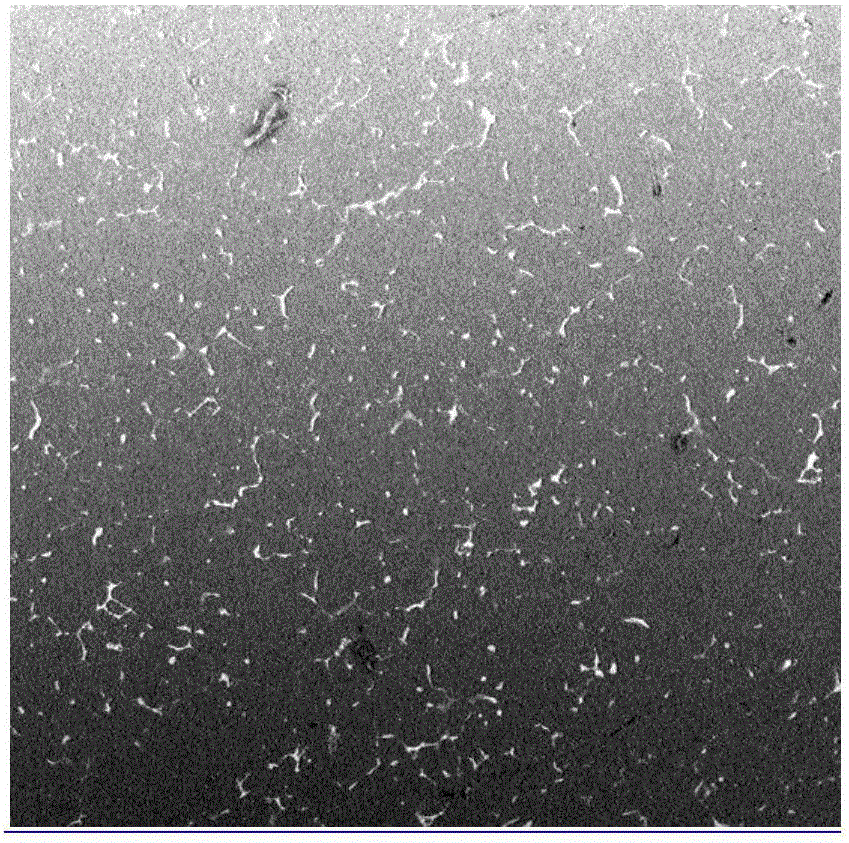

Manganese ferrous phosphate as well as preparation method and application thereof

ActiveCN114057177AStable ratioEven distribution of elementsCell electrodesPhosphorus compoundsPhosphateNitrogen gas

The invention discloses manganese ferrous phosphate and a preparation method and application thereof, wherein the preparation method comprises the following steps: dissolving divalent manganese salt and divalent iron salt in water to obtain a mixed salt solution of manganese salt and iron salt; adding a phosphorus source into the mixed salt solution to obtain a precursor solution; adding alkali into the precursor solution for co-precipitation to prepare ferrous phosphate manganese slurry, which contains ferrous phosphate precipitates and ferromanganese phosphate precipitates; and washing, filtering and drying the manganese ferrous phosphate slurry to obtain manganese ferrous phosphate. According to the preparation method of the manganese ferrous phosphate, nitrogen does not need to be introduced, so that nitrogen oxide waste gas cannot be generated, and environmental pollution cannot be caused. Besides, the proportion of iron, phosphorus and manganese in the manganese ferrous phosphate prepared by the preparation method of the manganese ferrous phosphate is stable, the impurity content is low, and the requirements of a lithium iron manganese phosphate positive electrode material on a precursor raw material can be met.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

Method for refining grain capable of dissolving aluminum alloy material

A method for refining a grain capable of dissolving an aluminum alloy material includes the steps of adding an aluminum ingot into an induction heater, obtaining molten aluminum by rising the temperature and fusing, sequentially adding a pre-prepared function alloy, a pre-prepared reinforced alloy, a pre-prepared cryogenic alloy and a pre-prepared activated alloy, fully mixing and conducting hot insulation, obtaining a solution provided with macroscopic and uniform properties, adding a defoaming agent and conducting deslagging process, placing a preheated mould in an oscillating magnetic field, molding and obtaining a casting by conducting mechanical vibration and adopting an external magnetic field with certain magnetic induction intensity, conducting heat treatment after rapid cooling of the casting, and processing the casting into a standard component needed in an experiment. The method for refining the grain capable of dissolving the aluminum alloy material has the characteristics that the strength of the material is improved to meet the requirement for the strength of practical applications.

Owner:SHAANXI UNIV OF SCI & TECH

Lithium iron manganese phosphate positive electrode material and preparation method thereof

InactiveCN112110433AImprove conductivityImprove crystal structureSecondary cellsPositive electrodesPhysical chemistryMaterials science

The invention provides a lithium iron manganese phosphate positive electrode material and a preparation method thereof, which belong to the technical field of lithium batteries. The problems of low gram volume, poor conductivity and the like of an existing lithium iron manganese phosphate material can be solved. The lithium iron manganese phosphate positive electrode material is characterized in that the chemical formula of a main body material is LiMn1-x-yFexMyPO4, x is larger than or equal to 0.1 and smaller than or equal to 0.5, y is larger than or equal to 0.002 and smaller than or equal to 0.02, meanwhile, carbon with the mass fraction being 0.5-3% is contained, and M is one or any combination of Mg, Ni, Co and Zn. A preparation method of a lithium iron manganese phosphate positive electrode material is characterized in that Mn1-x-yFexMyCO3 is prepared through a solution reaction, and then the lithium iron manganese phosphate material is obtained through a solid-phase reaction. The preparation method provided by the invention is rich and cheap in raw materials, simple and convenient in technological process and suitable for industrial production.

Owner:TIANNENG SAFT ENERGY JOINT CO

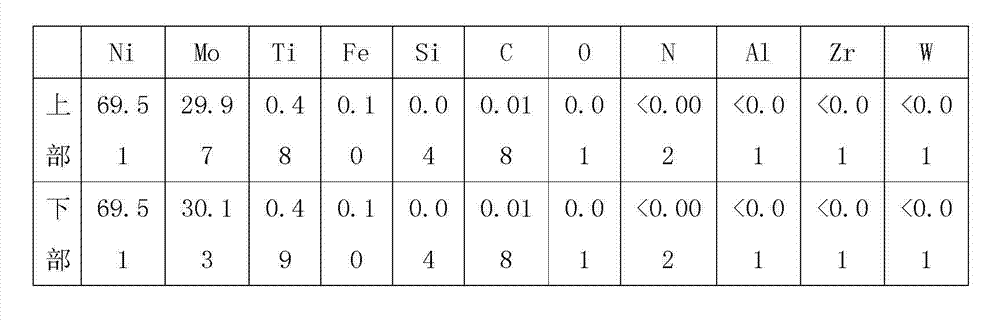

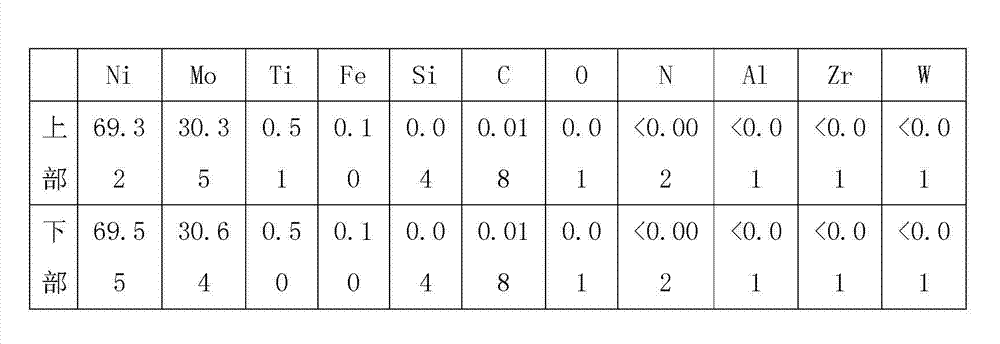

Nickel molybdenum titanium intermediate alloy and preparation method thereof

The invention relates to a nickel molybdenum titanium intermediate alloy. The alloy comprises the following components in percentage by weight: 68-72% of Ni, 28-32% of Mo, and 0.4-0.6% of Ti. A preparation method comprises the following steps of: firstly, calculating and weighing the required raw materials according to the components of the alloy; secondly, putting the raw materials into a crucible of a medium-frequency induction furnace, wherein the raw material of nickel and the raw material of molybdenum are in crossed placement, and the raw material of titanium is put at the gap of the two raw materials; thirdly, after low vacuum degree medium-frequency induction melting, casting into cylindrical ingots at 1300-1350 DEG C; fourthly, turning the cylindrical ingots into scraps. The added titanium element is conductive to overcoming the defect that the intermediate alloy is mingled with high-density molybdenum, the chemical components of the prepared nickel molybdenum titanium intermediate alloy are stable and uniform, the deviation of the main components is not more than 0.5%, and the preparation method is conductive to producing excellent titanium alloy ingots which are segregation-free and have no metallurgy mingling defect and comprise uniformly distributed elements of molybdenum and nickel.

Owner:宝钛特种金属有限公司

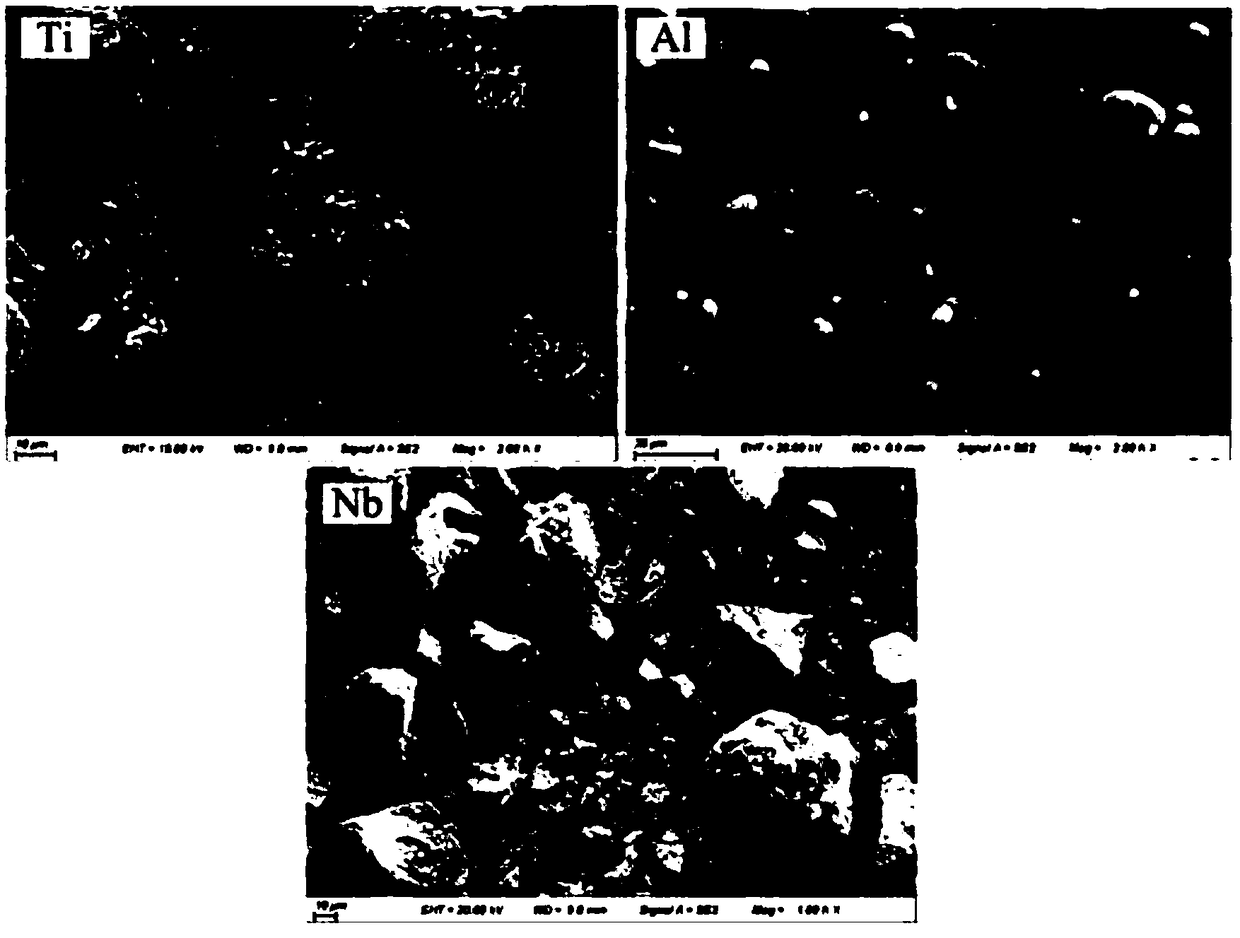

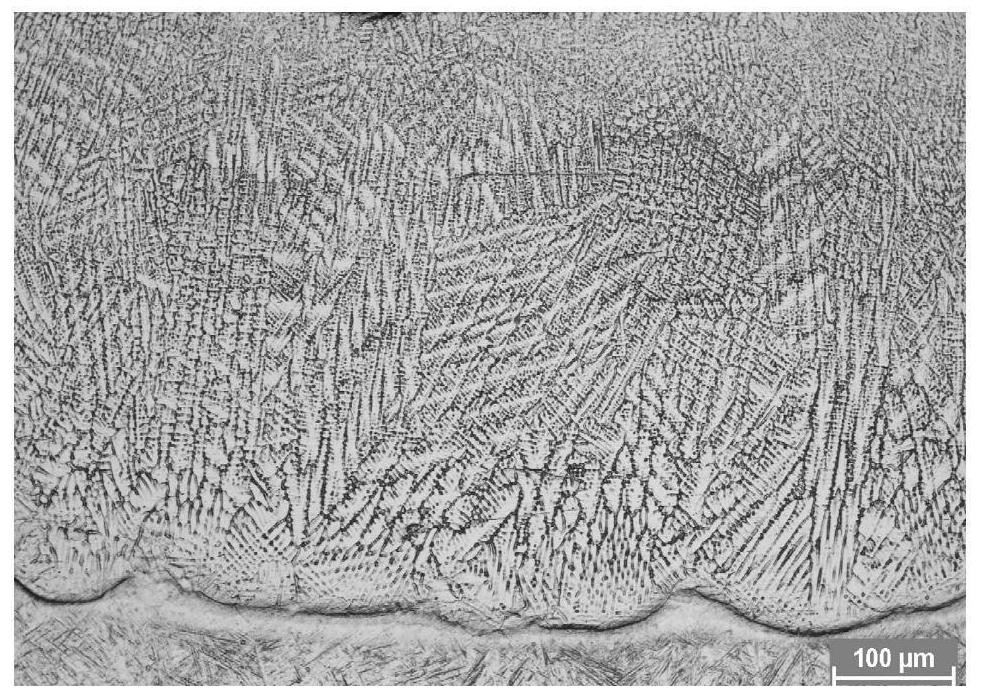

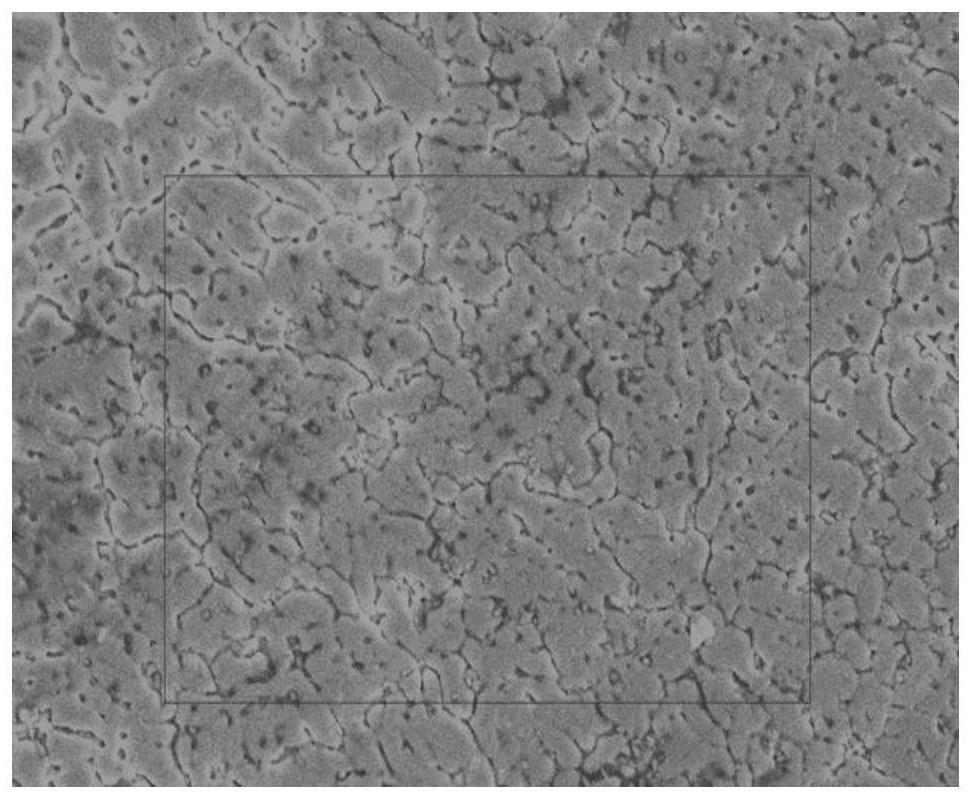

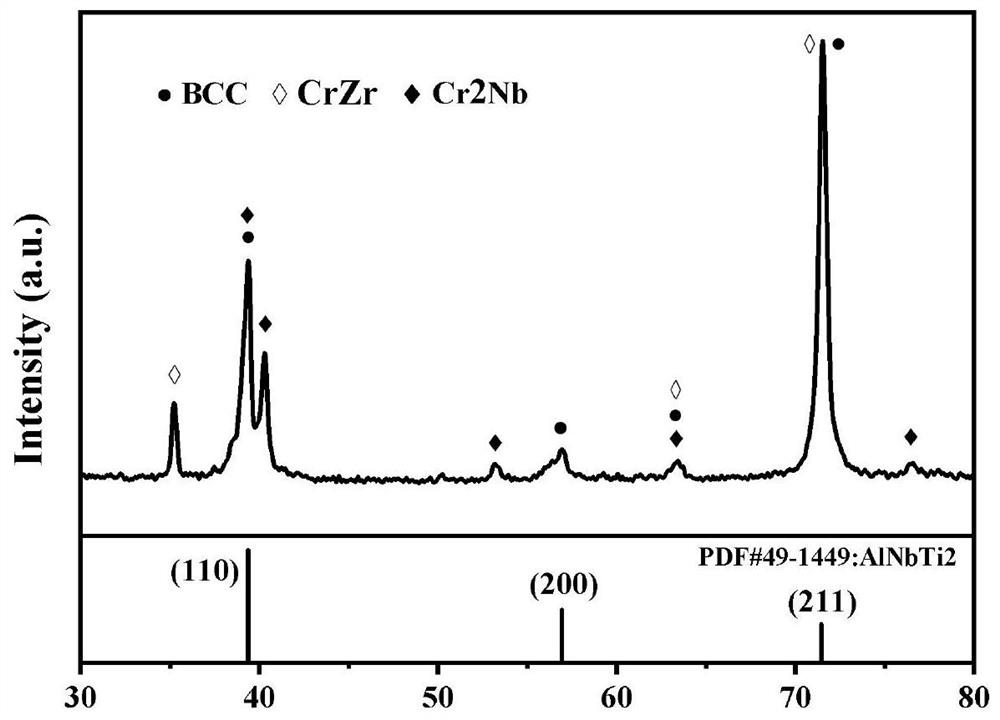

Preparation method of low-density refractory high-entropy alloy cladding layer for laser cladding

PendingCN114164425AImprove bindingGood macroscopic appearanceMetallic material coating processesMacroscopic scaleHigh entropy alloys

The invention discloses a preparation method of a low-density refractory high-entropy alloy cladding layer for laser cladding, the high-entropy alloy is composed of powder of six metal elements of Ti, Al, Mo, Nb, Cr and Zr, the high-entropy alloy is calculated according to the proportion, the mass of each component is accurately weighed, the components are fully and uniformly mixed by using a ball milling technology, the mixture is uniformly pressed on the surface of a base material, and the high-entropy alloy cladding layer is prepared. After drying, a cladding layer can be obtained through laser cladding processing, wherein a matrix material is TC4 (Ti6-Al4-V); after the high-entropy alloy powder is subjected to laser cladding, a cladding layer has good macroscopic morphology, has the characteristics of fine structure, no crack and high bonding strength between the cladding layer and a base material, and has relatively high microhardness. The high-entropy alloy shows a plurality of structure and performance characteristics different from those of traditional alloy, and belongs to the field of materials with academic value and aerospace application potential.

Owner:KUNMING UNIV OF SCI & TECH

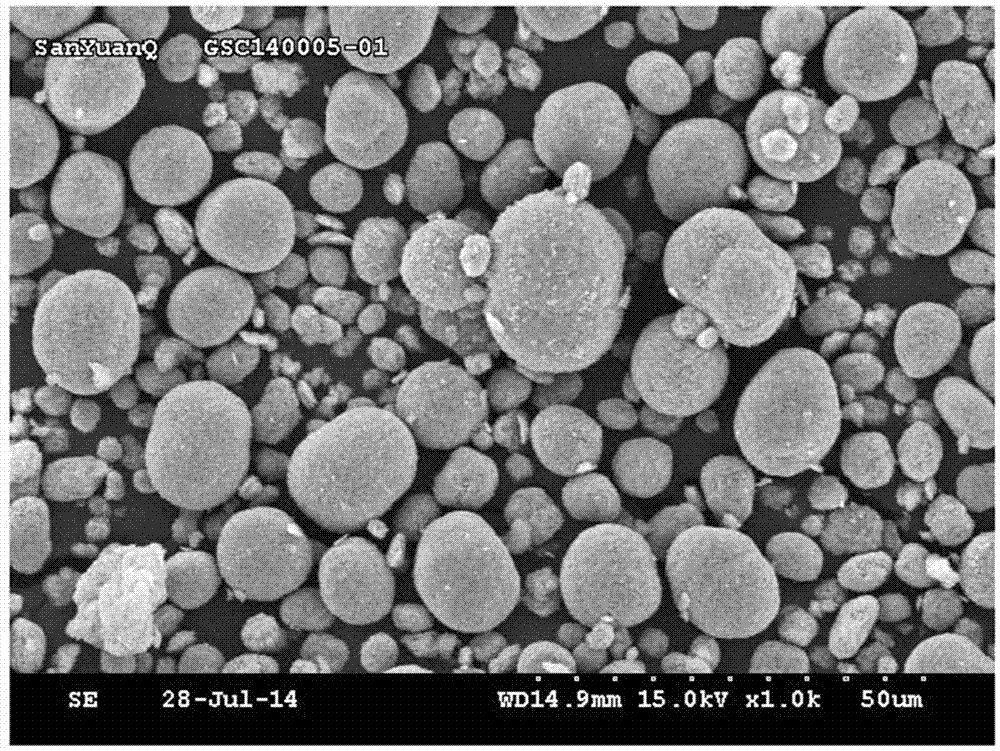

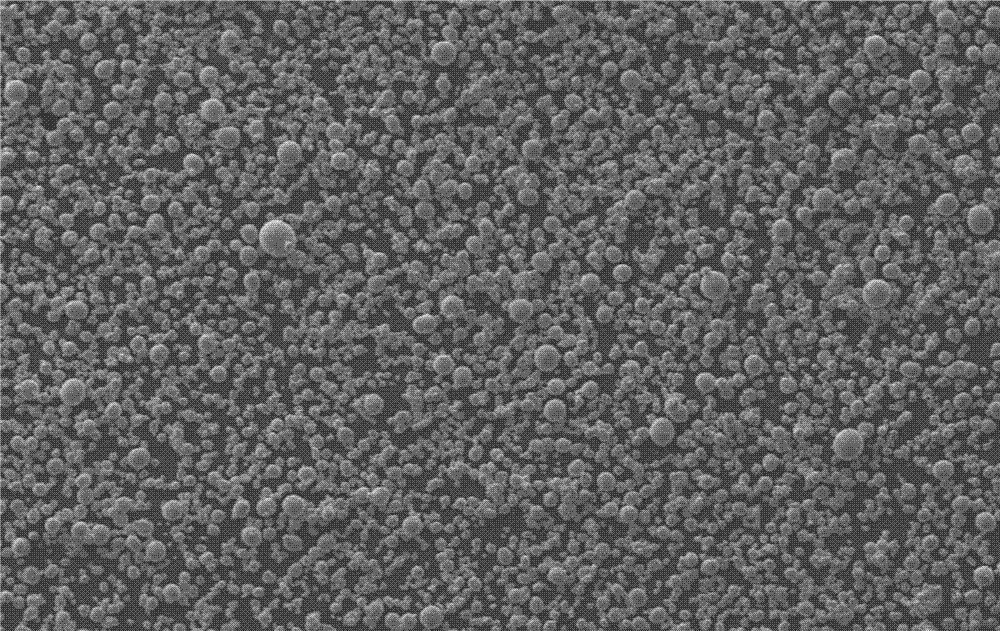

Preparation method of high-performance spherical lithium nickel cobalt aluminate anode material

InactiveCN107500366AEven distribution of elementsLow content of impurity elementsCell electrodesSecondary cellsSaline waterCobalt aluminate

The invention relates to a preparation method of a high-performance spherical lithium nickel cobalt aluminate anode material. The preparation method comprises the following steps: dissolving aluminum salt in a sodium hydroxide solution; preparing a nickel salt aqueous solution, a cobalt salt solution, acetylacetone, a nickel-cobalt salt complexing agent, an ammonia-water solution and a precipitator solution for later use; adding the solutions into a reaction kettle at the same time by controlling molar weights of aluminum, nickel and cobalt, and controlling a molar ratio of aluminum salt to the acetylacetone and a molar ratio of nickel and cobalt salt to the nickel-cobalt complexing agent; at 30 to 80 DEG C, keeping the reaction for 20 to 80 hours, and performing aging reaction for 10 to 20 hours; centrifugally filtering reaction liquid, thus obtaining a preliminary filter cake, adding the preliminary filter cake into a sodium carbonate solution for stirring and washing, then performing centrifugal filtering, thus obtaining a secondary filter cake, then repeatedly washing and filtering the secondary filter cake with distilled water till the pH of filtrate is smaller than 9, and obtaining a final filter cake; drying the final filter cake, thus obtaining a precursor; mixing the precursor with lithium, sintering the precursor in a rotary sintering furnace under the existence of oxygen, thus obtaining the lithium nickel cobalt aluminate anode material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

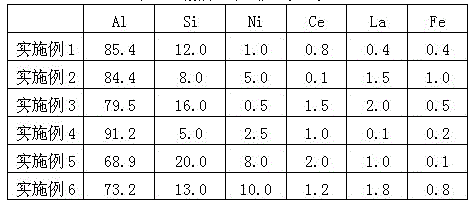

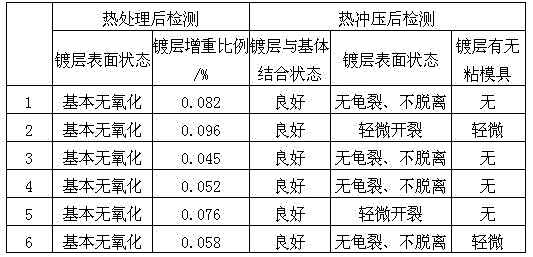

Anti-high temperature oxidation coating material and hot dipping process for hot stamping steel

ActiveCN103952653BRefined grain sizeGood high temperature oxidation resistanceHot-dipping/immersion processesHot stampingRare-earth element

The invention discloses a high-temperature-oxidization-resistant coating material for hot-stamped formed steel and a hot-dipping plating technology. A plating solution comprises the following components in percentage by mass: 5.0-20.0% of Si, 0.5-10.0% of Ni, 0.1-12.0% of Ce, 0.1-2.0% of La, not more than 1.0% of Fe, and the balance of Al and inevitable impurities. According to the coating material, the grain size of the texture can be effectively refined by adding rare earth and other elements in the plating solution; the coating is an Al-Si-Ni-rare earth material, Al and Si elements are main components of the coating and are combined with ferrum to generate a ferro-silicon-aluminum phase and further improve the oxidization resistance capability, the melting point of aluminum silicon can be further improved by Ni, and the grain size of the coating can be refined through the rare earth elements; therefore, the coating has the characteristics that the high-temperature oxidization resistance performance is excellent, the surface is difficult to crack after hot-stamped forming, and the coating is not adhered to a mold. Elements in the coating obtained by adopting the technology are uniformly distributed and organized with high density, are closely combined with a substrate, thus having high high-temperature oxidization resistance performance; during heating process, the high-temperature-oxidization-resistant coating material does not stick a furnace bottom roll, a steel substrate and a stamping mold can be better protected.

Owner:HEBEI IRON AND STEEL

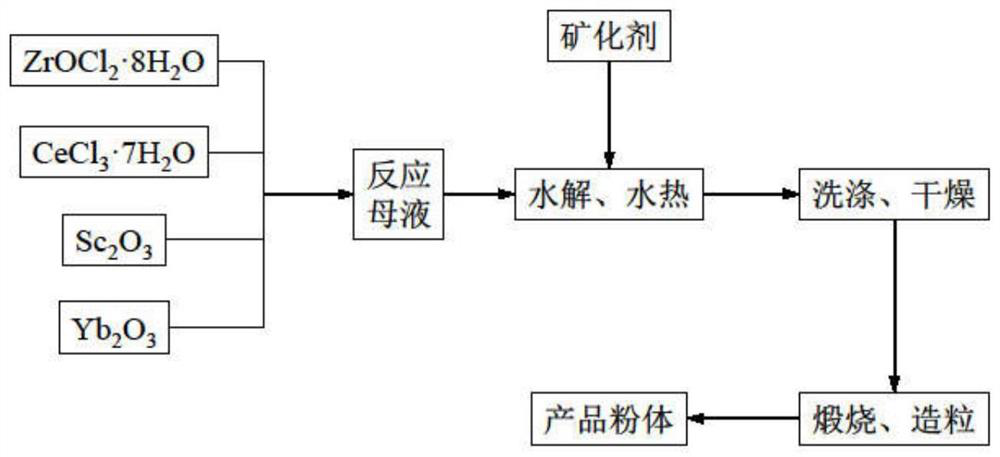

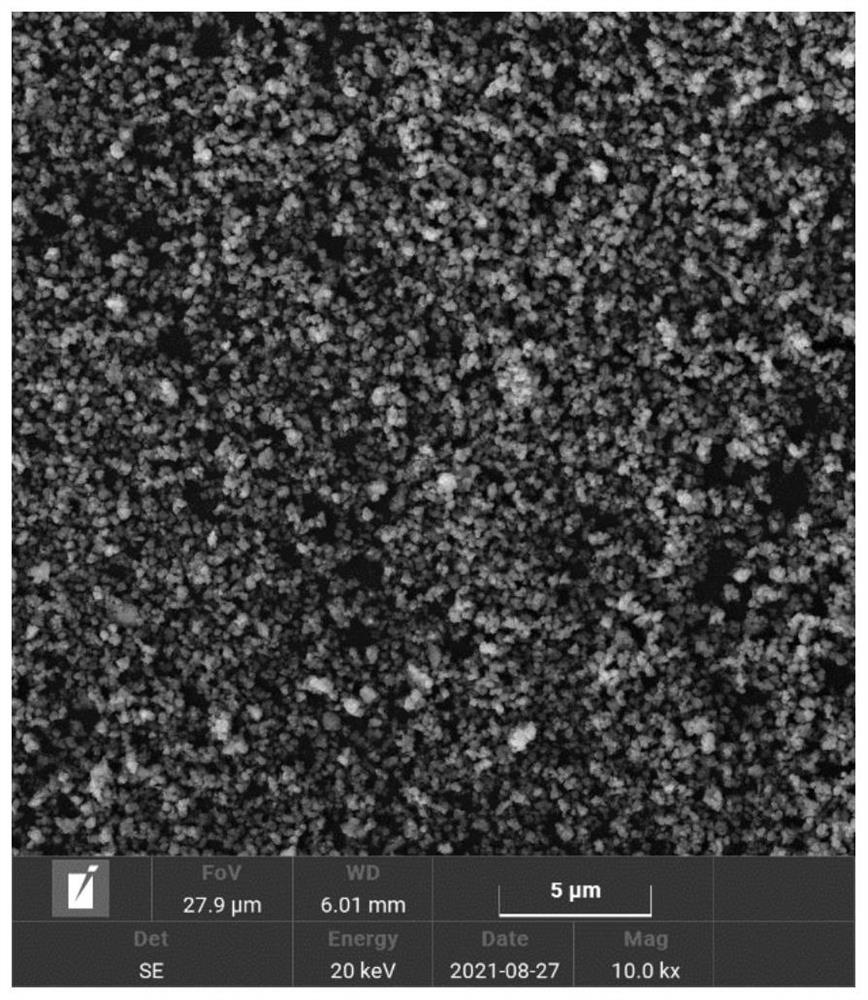

Hydrolysis-hydrothermal method for preparing scandium-cerium-ytterbium-doped zirconium oxide ultrafine powder

The invention belongs to the technical field of nano material preparation, and discloses a hydrolysis-hydrothermal method for preparing scandium-cerium-ytterbium doped zirconium oxide ultrafine powder. The method comprises the following steps: firstly, preparing a reaction mother solution containing zirconium, cerium, scandium and ytterbium elements, and then heating the reaction mother solution to 100-104 DEG C for hydrolysis reaction to obtain milk white hydrolysis slurry; cooling to 50-70 DEG C, adding ammonia water to adjust the pH value to 3.6-4, then adding a mineralizer, heating to 90-100 DEG C, carrying out a hydrothermal reaction, and washing and drying a product to obtain coarse powder; and successively carrying out two-step calcination on the obtained coarse powder at 600-800 DEG C and 900-1100 DEG C, crushing and granulating to obtain the scandium-cerium-ytterbium doped zirconium oxide ultrafine powder. The powder obtained by adopting the preparation method disclosed by the invention is uniform in particle size, uniform in element distribution and stable in physicochemical property. And the process flow is simple, the hydrothermal hydrolysis process is easy to directly observe, the process is controllable, and the method is suitable for large-scale industrial production.

Owner:FIRST RARE MATERIALS CO LTD

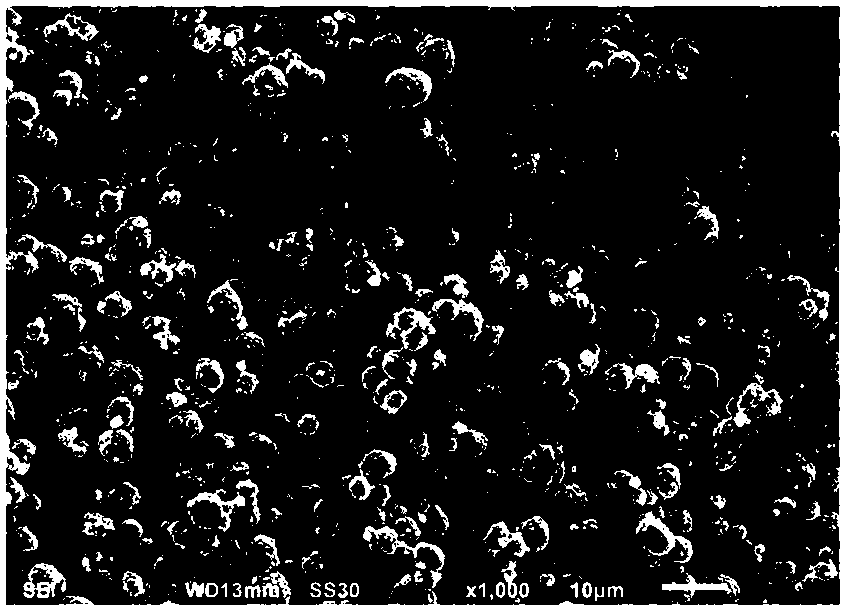

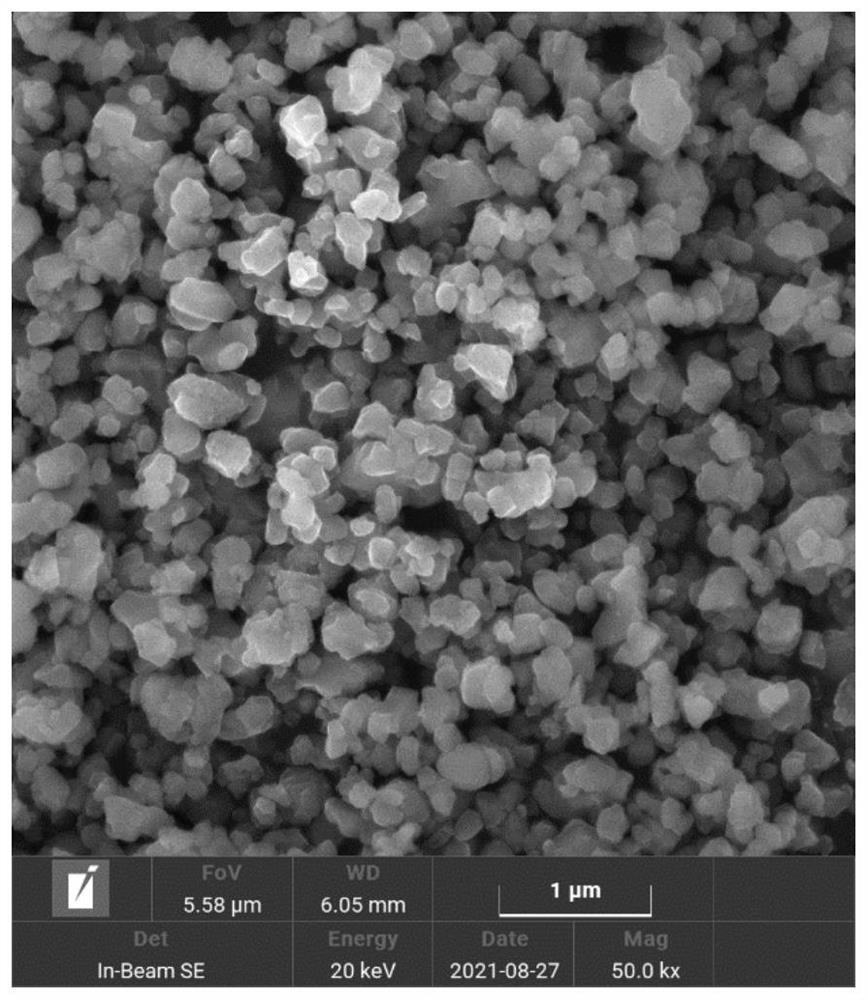

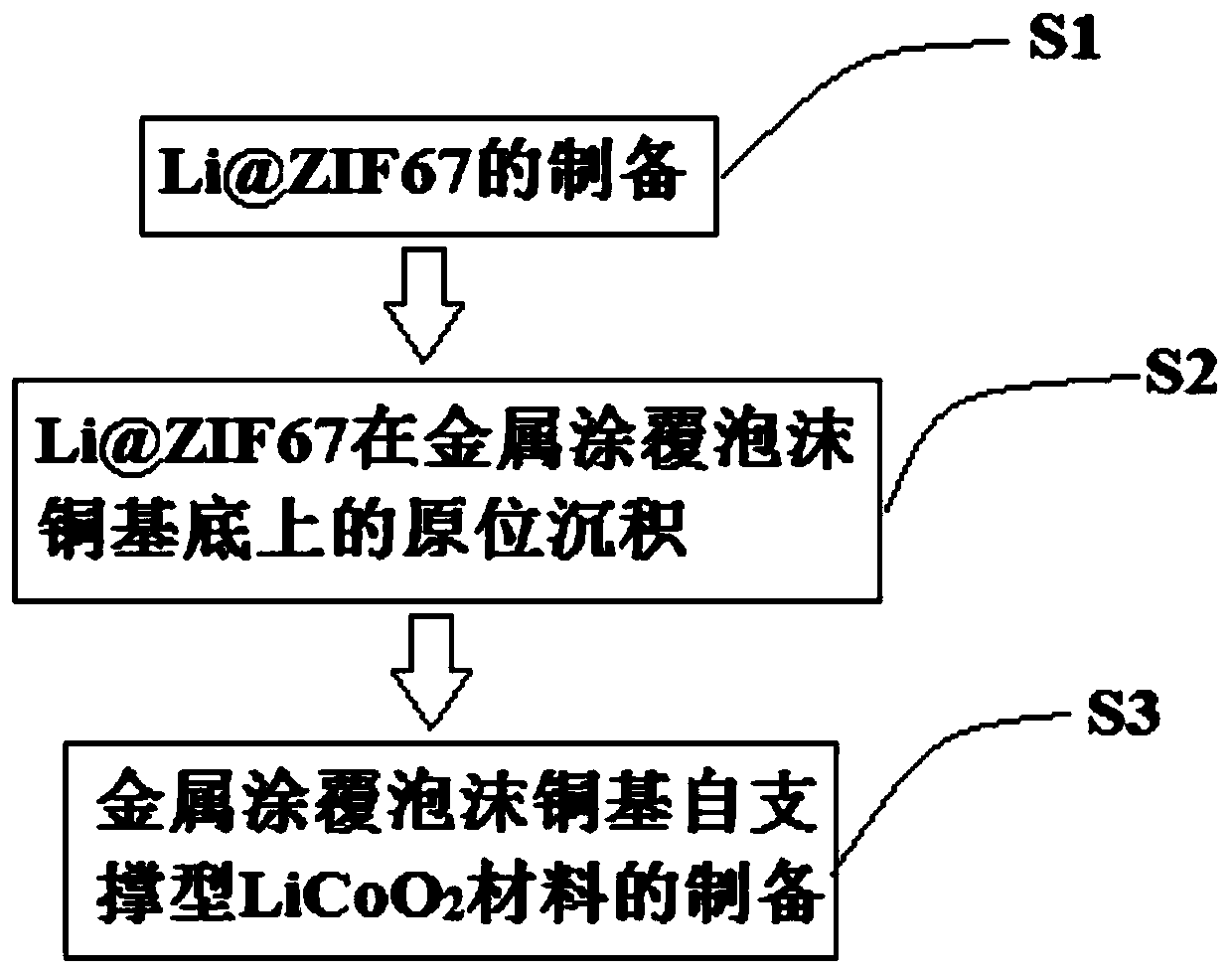

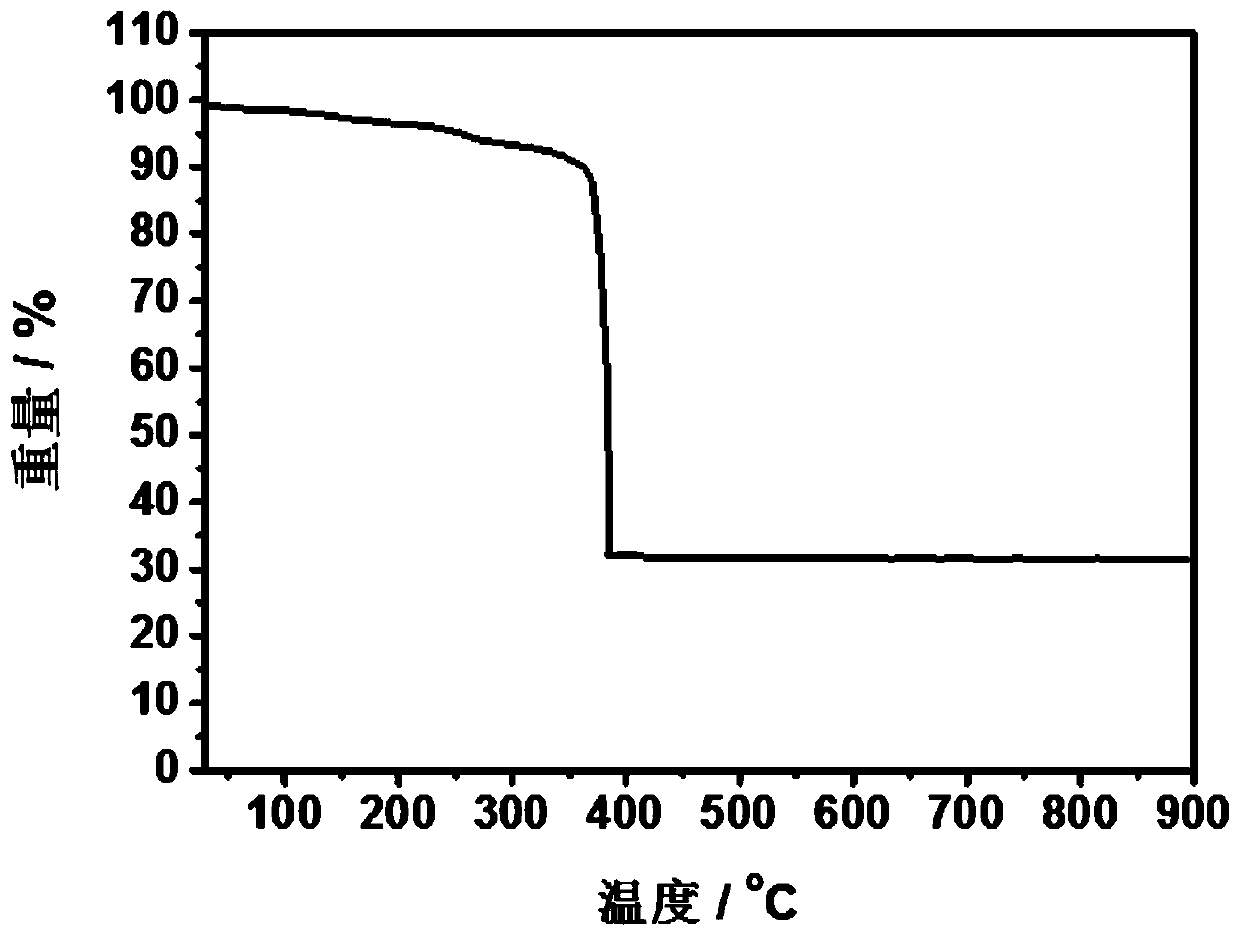

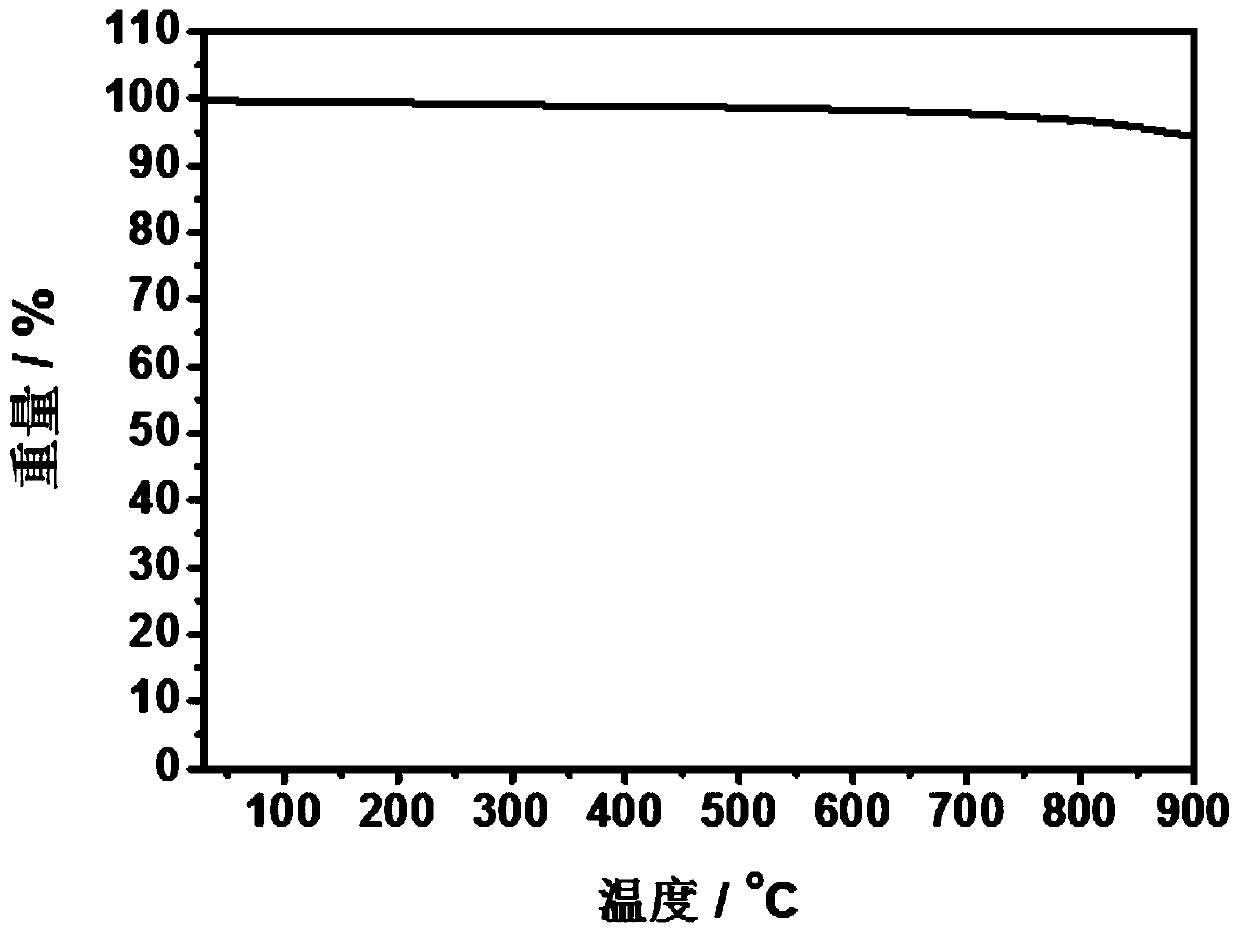

Metal-coated foamy copper-based self-supporting lithium cobalt oxide electrode material and manufacturing method thereof

ActiveCN110718689AEven distribution of elementsHigh crystallinitySecondary cellsPositive electrodesBattery cellMaterials science

The invention relates to a metal-coated foamy copper-based self-supporting lithium cobalt oxide electrode material and a manufacturing method thereof. The manufacturing method of the lithium cobalt oxide electrode material comprises the following steps of S1, preparing Li@ZIF67; S2, carrying out in-situ deposition of Li@ZIF67 on a metal-coated foamy copper substrate; and S3, manufacturing a metal-coated foamy copper-based self-supporting LiCoO2 material. The metal-coated foamy copper substrate of the invention is an important path for charge transmission and storage and is an excellent substrate for supporting an active material. Based on advantages of the ZIF67 precursor and a three-dimensional substrate structure, a metal-coated foamy copper-based self-supporting LiCoO2 material electrode manufactured by the manufacturing method has a large reversible capacity, a high porosity, an excellent rate capability and remarkable cycling stability. And due to remarkable electrochemical performance, the manufacturing method of the metal-coated foamy copper-based self-supporting LiCoO2 material of a nano polyhedron structure can also provide guidance for manufacturing of a leading-edge high-performance flexible lithium ion battery positive electrode material.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com