Lithium ion battery cathode material, preparation method and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of easily broken material particles, long production process, and long production cycle, so as to achieve uniform distribution of elements and improve storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a kind of preparation method of lithium ion battery cathode material, comprises the following steps:

[0036] (1) Dissolving nickel salt, cobalt salt and manganese salt in a solvent to make solution A;

[0037] (2) Add the precipitant to solution A to obtain solution B;

[0038] (3) Transfer solution B to a reaction kettle for autoclave crystallization at a temperature ranging from 70 to 240°C to obtain a co-precipitate;

[0039] (4) Separating the co-precipitate from solid to liquid to obtain the precursor;

[0040] (5) Mix the precursor with the lithium salt and perform a solid-state reaction to obtain a lithium-ion battery cathode material containing nickel, cobalt, and manganese.

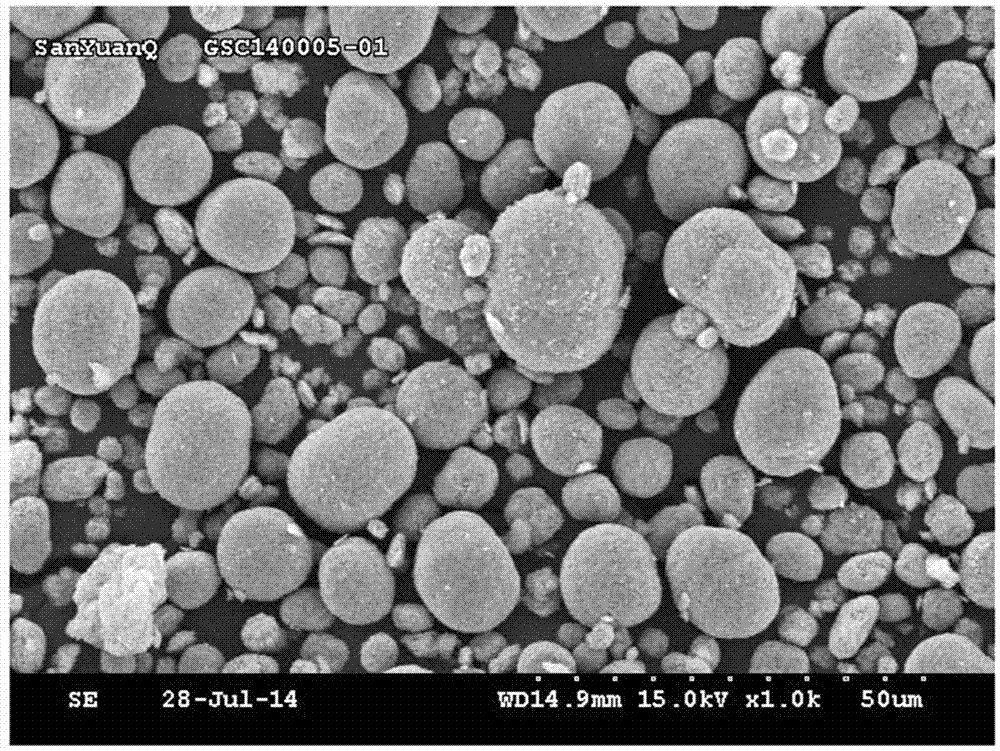

[0041] The invention provides a medium-temperature pressure-cooking crystal preparation method at 70-240°C, which is beneficial to the formation and control of special morphology. At the same time, the reaction system is carried out in a closed reaction k...

Embodiment 1

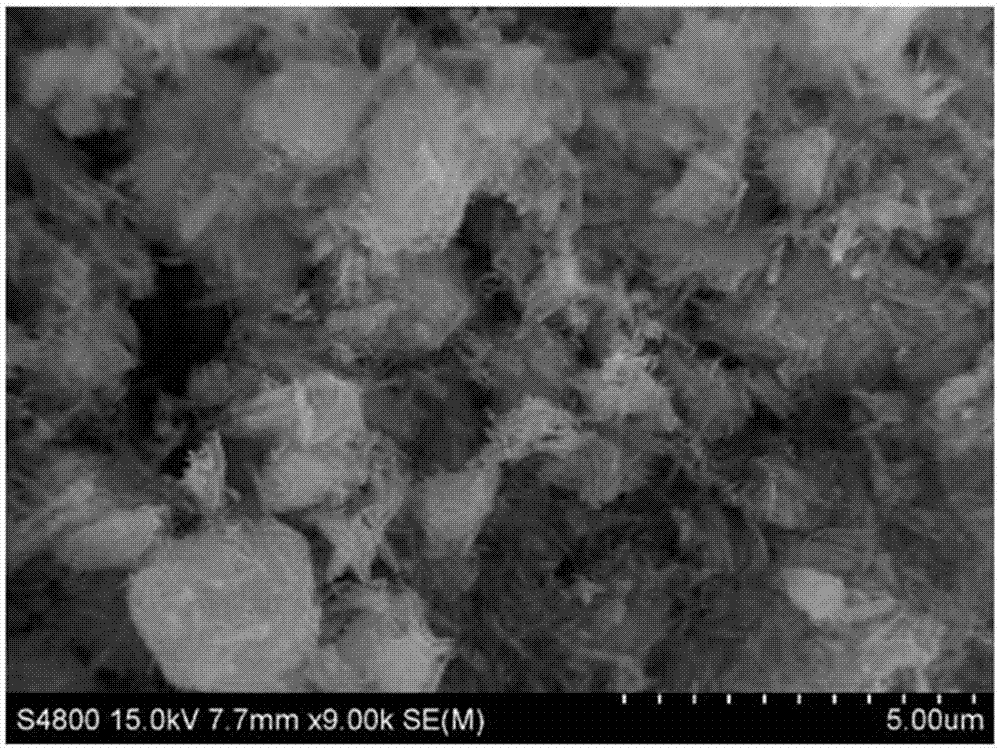

[0071] Add 6mmol of nickel acetate, 2mmol of cobalt acetate, and 2mmol of manganese acetate into a mixture of 30ml of deionized water and 70ml of ethylene glycol in the ratio of Ni:Co:Mn=0.6:0.2:0.2 and stir to dissolve, and then add 2mmol of PEG400 , to obtain solution A. At room temperature, add 10 mmol dimethyl oxalate to solution A while stirring, and then add 1 g of PVP to dissolve completely to obtain solution B. Solution B was transferred to the reactor, the reaction temperature was 200°C, the reaction pressure was 3MPa, and the reaction time was 24h. After cooling down naturally, the reaction product was suction filtered and washed with deionized water and ethanol respectively. The filtered product was dried in vacuum at 80° C. to obtain an oxalate precursor. The above-mentioned oxalate precursor is placed in a muffle furnace and heated to 500° C. for pre-calcination to obtain an oxide precursor. The oxide precursor and lithium carbonate were fully mixed in a molar r...

Embodiment 2

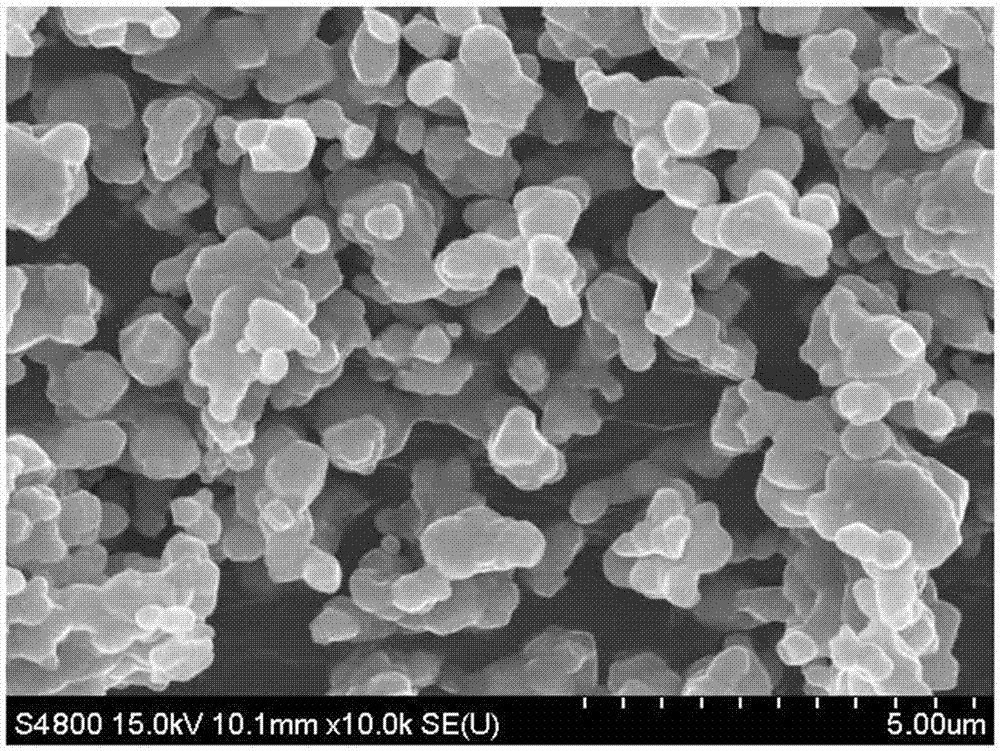

[0073] Add 6.8mmol of nickel acetate, 1.5mmol of cobalt acetate, and 1.7mmol of manganese acetate into a mixture of 30ml of deionized water and 70ml of ethylene glycol in the ratio of Ni:Co:Mn=0.68:0.15:0.17 and stir to dissolve. 1.5 mmol of PEG400 to obtain solution A. At room temperature, add 10 mmol dimethyl oxalate to solution A while stirring, and obtain solution B after complete dissolution. Solution B is transferred in the reactor, and reaction temperature is 180 ℃, and reaction pressure is 6MPa, and reaction time is 12h, and after cooling down naturally, reaction product is sucked and washed with deionized water and ethanol respectively. The filtered product was dried in vacuum at 80° C. to obtain an oxalate precursor. The above-mentioned dried product was placed in a muffle furnace and the temperature was raised to 500° C. for pre-calcination to obtain an oxide precursor. The oxide precursor and lithium hydroxide were fully mixed in a molar ratio of 1:1.02, solid-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com