Patents

Literature

408results about How to "Production process is environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lutein ester microcapsule powder and preparation method thereof

ActiveCN102389108AInstant highGood self-emulsifying performanceFood preparationAntioxidantFiller Excipient

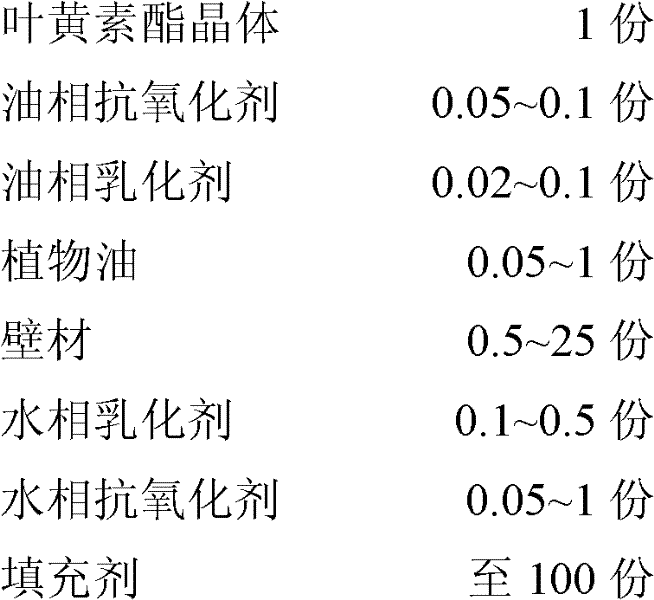

The invention discloses lutein ester microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of: preparing an oil phase solution and a water phase solution respectively, and mixing and emulsifying the oil phase solution and the water phase solution; and non-water raw materials comprise the following components in part by weight: 1 part of lutein ester crystal, 0.05 to 0.1 part of oil phase antioxidant, 0.02 to 0.1 part of oil phase emulsifying agent, 0.05 to 1 part of plant oil, 0.5 to 25 parts of wall material, 0.1 to 0.5 part of water phaseemulsifying agent, 0.05 to 1 part of water phase antioxidant, and the balance of filler. In the preparation method for the lutein ester microcapsule powder, the oil-soluble lutein ester is fully dispersed in cold water in the form of sub nanometer particles, and the product can be self-emulsified in water, and is good in instant capacity and self-emulsification capacity, and high in stability, and has uniform and durable color; and the phenomena of oil floating, precipitation, adhesion to a bottle wall and the like are avoided during application. Organic solvents are not introduced in the powder, so solvent residues are avoided in the product. The production process is environment-friendly, simple and practicable, expensive equipment is not needed, and the microcapsule powder can be industrially produced easily and conveniently.

Owner:INNOBIO CORP LTD

Method for preparing titanium white

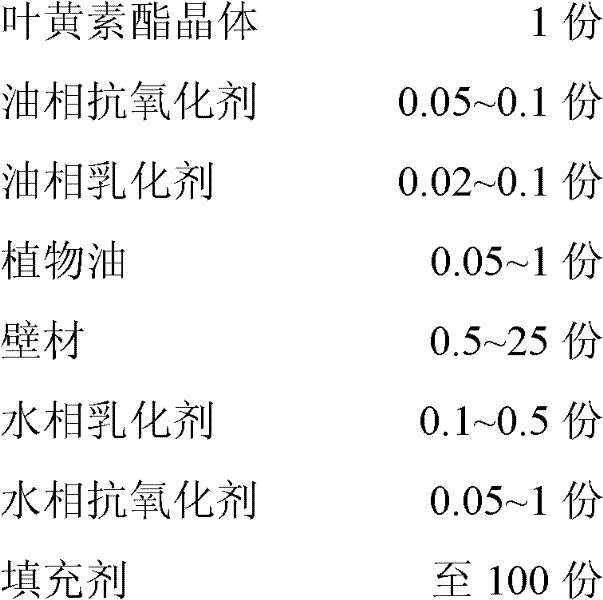

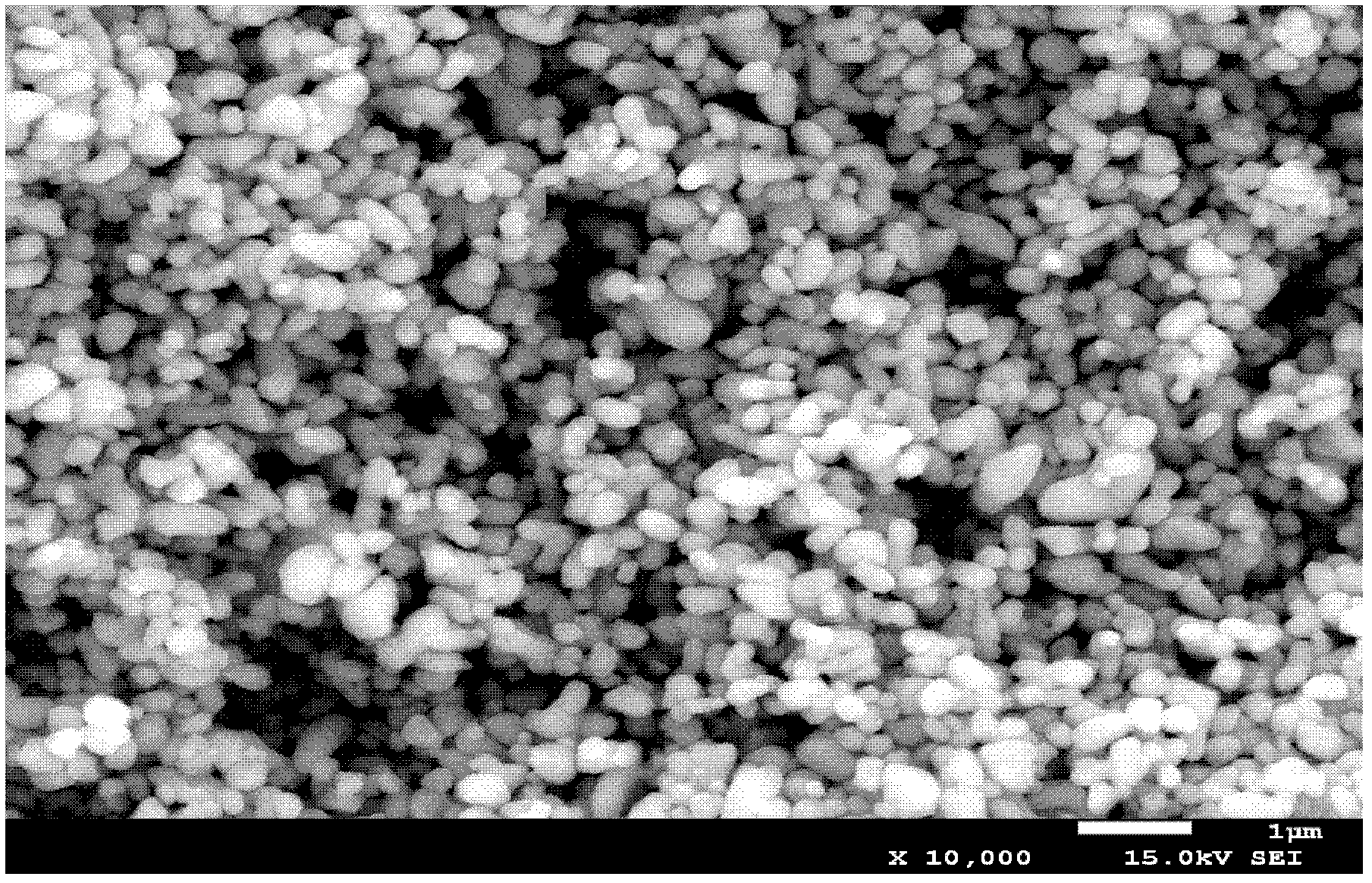

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

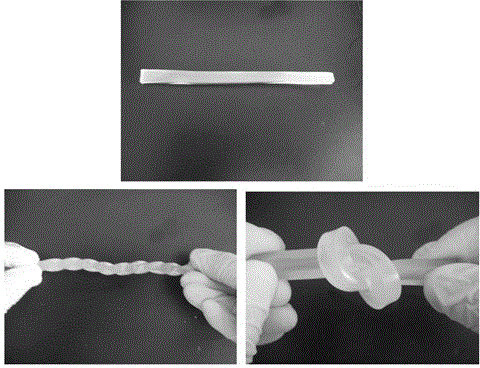

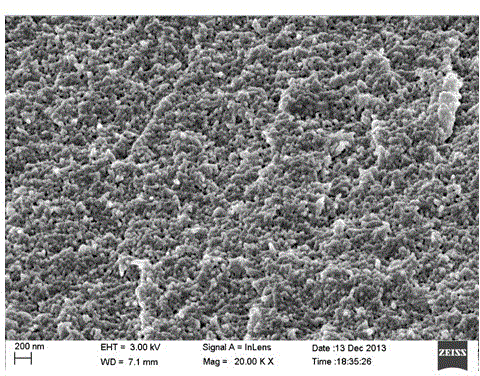

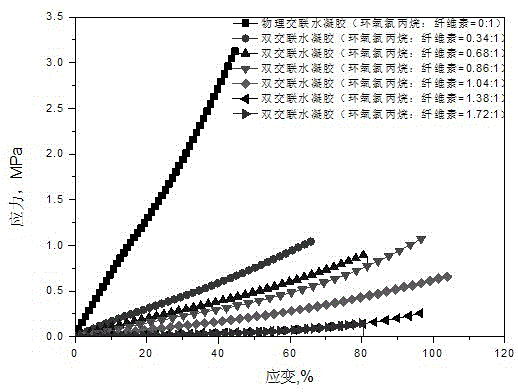

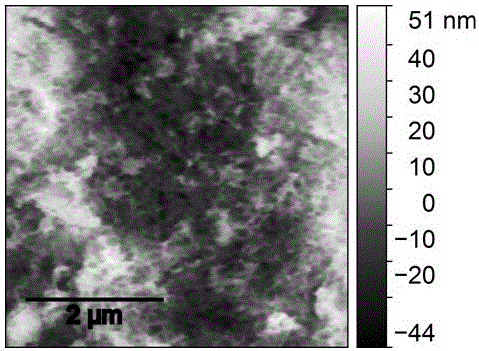

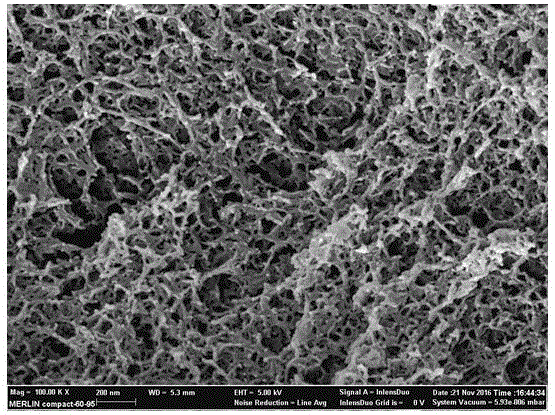

Chemical and physical crosslinking based dual-network cellulose gel system material

The invention discloses a chemical and physical crosslinking based dual-network cellulose gel system material. The material comprises aquogel, aerogel and bioplastics, wherein a quantitative crosslinking agent is added to a cellulose solution and stirred to form partial chemical crosslinking cellulose gel, the gel is placed in a cellulose nonsolvent for physical crosslinking, and dual-network cellulose gel is obtained after washing. The dual-network cellulose aerogel is prepared by drying dual-network cellulose aquogel, and then is subjected to heat treatment at the temperature of higher than 150 DEG C, and carbon aerogel is obtained; dual-network cellulose aquogel or aerogel is subjected to hot pressing, and dual-network cellulose bioplastics are prepared. The prepared dual-network cellulose material has the advantages of good mechanical property, large specific surface area, high elongation at break and the like, can be easily processed into formed products with various forms such as a fiber form, a sheet form, a particle form, a thin film form, a cylinder form and the like.

Owner:WUHAN UNIV

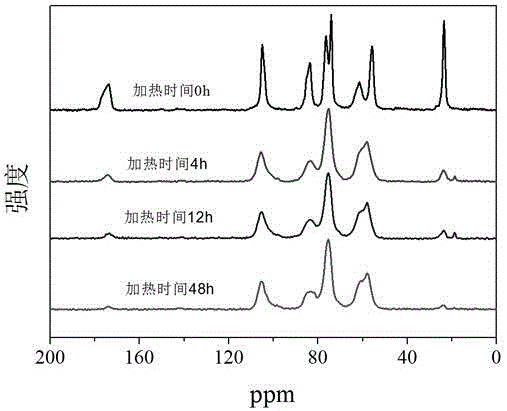

Preparation method of chitosan gel series material

ActiveCN106800662AReduce energy consumptionConducive to environmental protection and operator healthSolventCrosslinked chitosan

The invention discloses a method for preparing a chitosan gel series material directly by using chitin. The material is prepared from hydrogel and aerogel. The method comprises the steps of dissolving the chitin into a solvent of alkali-urea, and heating in a sealing way for realizing homogeneous phase deacetylation of the chitin so as to obtain chitosan alkaline gel; removing alkali liquor urea in the chitosan alkaline gel by using a non-solvent replacement method, and then obtaining physically crosslinked chitosan hydrogel; adding a chemical cross-linking agent into a chitin solution, stirring and then heating to obtain partially crosslinked chitosan alkaline gel; removing alkali liquor urea in the chitosan alkaline gel by using a solvent replacement method, and then obtaining physically and chemically bi-crosslinked chitosan hydrogel; drying to remove the solvent in the chitosan hydrogel and chitosan organic gel so as to obtain chitosan aerogel. The chitosan is derived from the chitin in the natural world and has excellent biocompatibility and biodegradability; therefore, the chitosan gel series material has great application prospect in the field of bio-medical treatment.

Owner:WUHAN UNIV

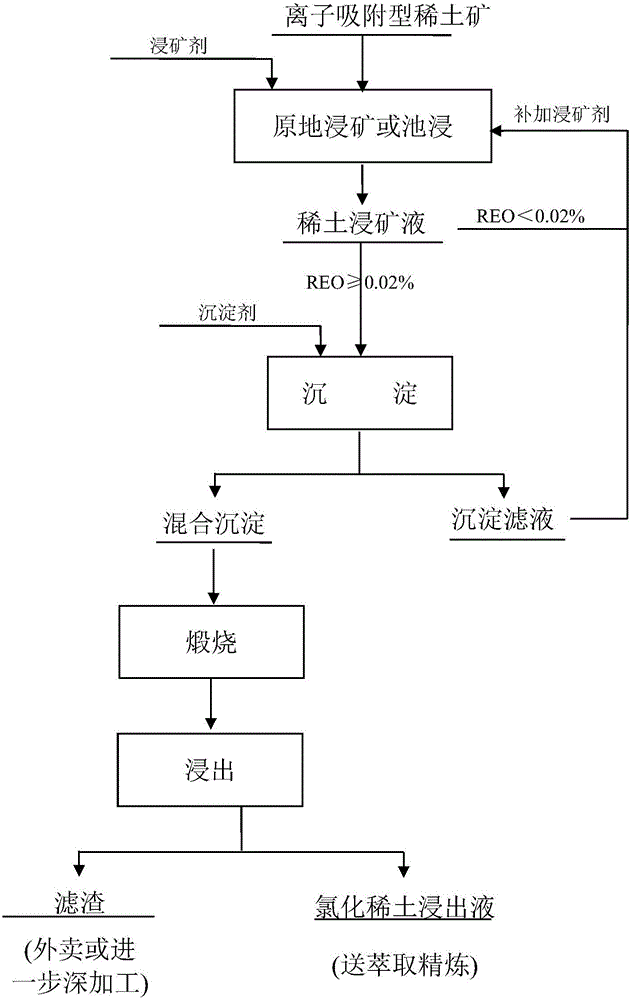

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

ActiveCN105803226AEfficient separationAchieve purificationProcess efficiency improvementAluminum canRare earth

The invention relates to a method for extracting rare earth and aluminum from ion adsorption type rare earth ores. The method includes the steps that (1), ore leaching is performed, wherein an ore leaching agent is added for in-situ ore leaching or pond leaching, and rare earth ore leaching liquid with the rare earth concentration higher than 0.02% is obtained; (2), precipitation is performed, wherein solid and liquid separation is performed after a precipitation agent is added into the rare earth ore leaching liquid for precipitation, and precipitated filter liquor and mixed precipitate containing rare earth and aluminum are obtained; (3), calcination is performed, wherein the mixed precipitate containing rare earth and aluminum is calcinated, and calcinated products containing rare earth oxide and alpha-aluminum oxide are obtained; and (4), leaching out is performed, wherein solid and liquid separation is performed after a chlorination leaching agent is added into the calcinated products containing rare earth oxide and alpha-aluminum oxide for leaching out, chlorinated rare earth leaching-out liquid and filter residues containing alpha-aluminum oxide are obtained, rare earth oxide is extracted from the chlorinated rare earth leaching-out liquid, and aluminum oxide fine products are extracted from the filter residues containing alpha-aluminum oxide. The method is simple in technology, precipitation is directly performed without impurity removal, and by means of the dissolution property difference of the calcinated products in an acid environment, the rare earth and the aluminum can be separated and recycled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

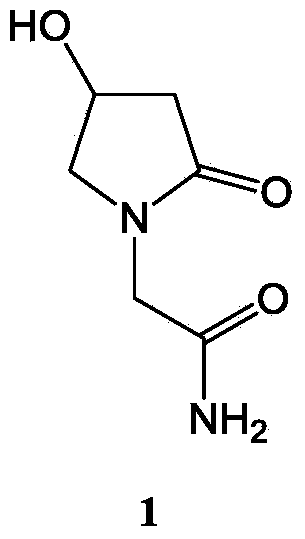

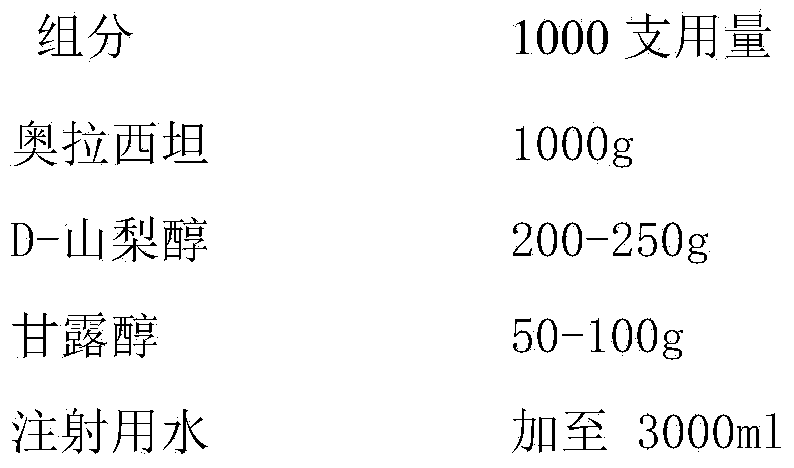

Oxiracetam freeze-drying preparation for injection and preparation method thereof

ActiveCN103446067AStable in natureLong validity periodOrganic active ingredientsPowder deliveryFreeze-dryingImpurity

The invention relates to an oxiracetam freeze-drying preparation for injection and a preparation method thereof, belonging to the technical field of medicines. The freeze-drying preparation is a crystal form compound formed by oxiracetam, D-sorbitol and mannitol in a weight ratio of 1: (0.2-0.25): (0.05-0.1). The oxiracetam freeze-drying preparation has the beneficial effects that the production cycle is shortened by about 20 hours, the rate of finished products is increased by above 99%, the phenomena such as the upward shifting and the eruption of the product are avoided, medicine molecules are constrained in crystal lattices, the water content is extremely low and can be controlled below 0.1%, the preparation is difficult to degrade and has relatively good stability, the period of validity is up to 36 months, the impurity content is greatly reduced, the single maximum impurity is less than 0.1%, and the total impurities are less than 0.5%; no organic solvents are involved in the production process, the energy consumption and the cost are substantially reduced, and the technology has environmentally-friendly effect and is suitable for large-scale industrialization production. Compared with the prior art, the oxiracetam freeze-drying preparation provided by the invention has obviously improved curative effect and is suitable for clinical application.

Owner:CSPC OUYI PHARM CO LTD

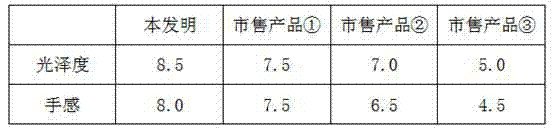

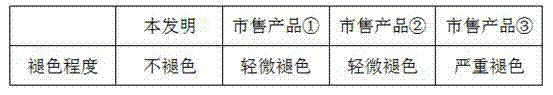

Environment-friendly leather cleaning care agent and preparation method thereof

InactiveCN103966031AEffective anti-fouling and waterproofReduce surface tensionOrganic detergent compounding agentsSurface-active detergent compositionsOil emulsionOrganosolv

The invention relates to an environment-friendly leather cleaning care agent and a preparation method thereof. Leather cleaning supplies sold at present markets are single in function and finite in detergency, easily cause leather fiber hardening and hard handfeel, and contain components which easily pollute the environment. The environment-friendly leather cleaning care agent is prepared by mixing fatty alcohol-polyoxyethylene ether, alkyl glycoside, silicone latex, silicon oil emulsion, sodium citrate, glycerin, Kathon, essence and water, wherein the fatty alcohol-polyoxyethylene ether serving as an anionic surfactant and the alkyl glycoside serving as a nonionic surfactant are used as decontamination components. The environment-friendly leather cleaning care agent disclosed by the invention is anti-fouling and waterproof, enables leather to be soft and smooth, assists in resisting leather ageing and surface drying and cracking, and has good biodegradability and a good moisturizing effect; the leather cleaning care agent does not contain organic solvents, so that the production process is environment-friendly; the leather cleaning care agent has a mildew-proof and bacteriostatic effect.

Owner:于文 +1

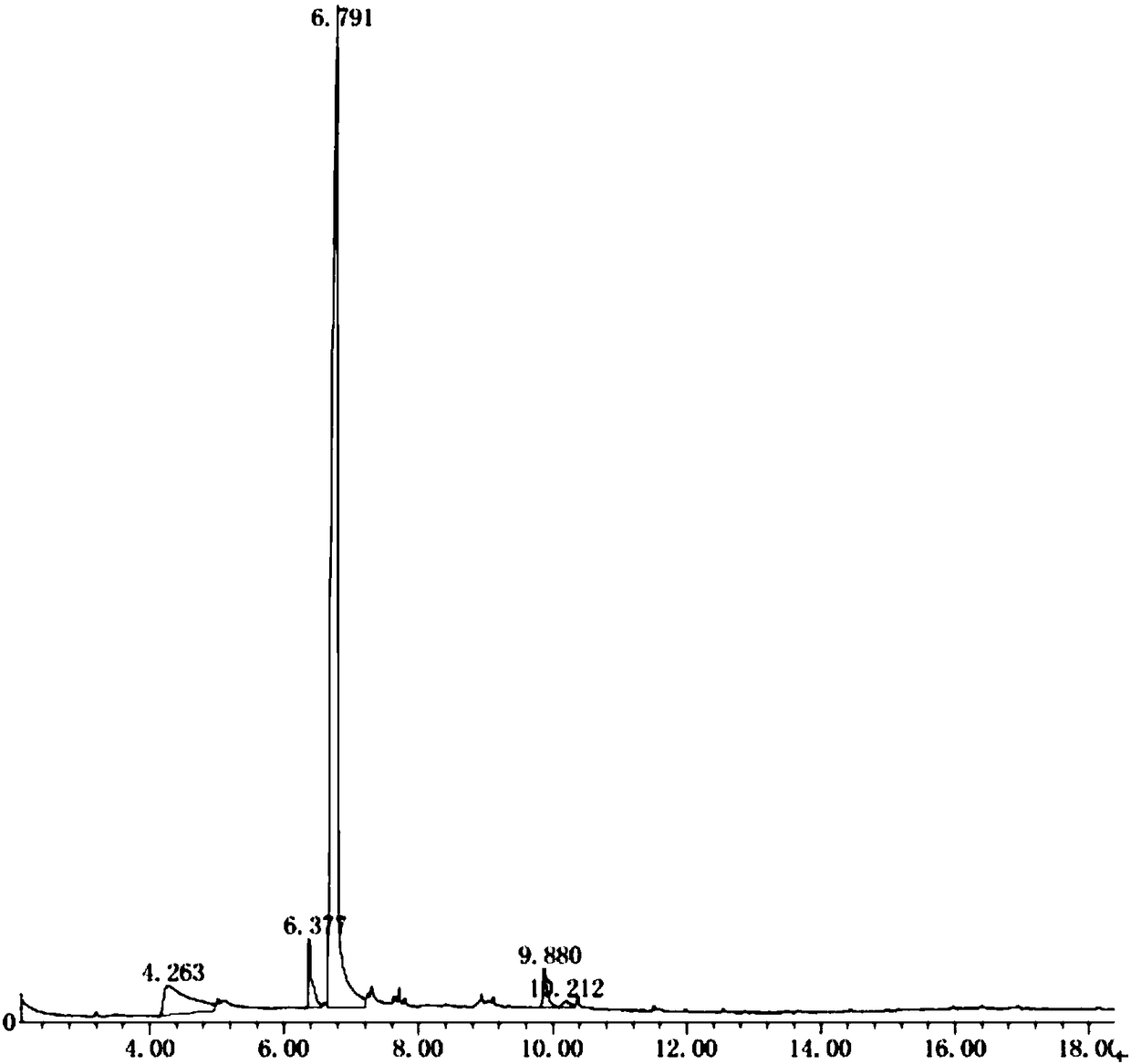

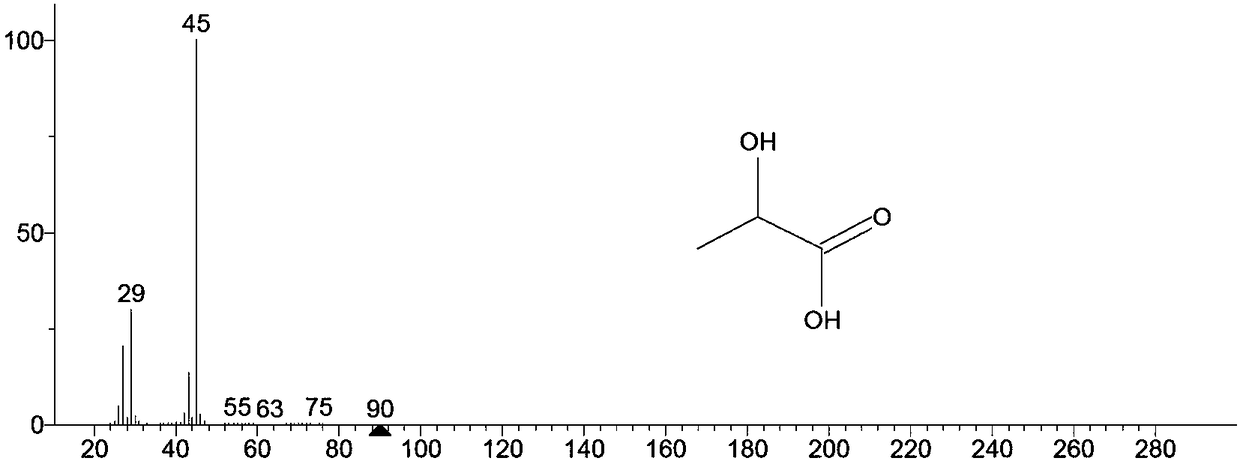

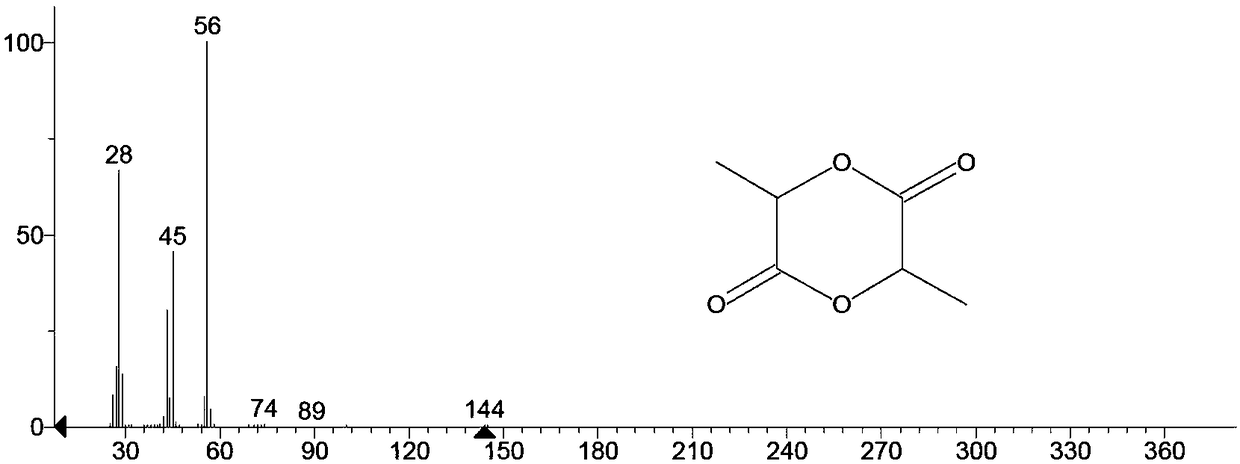

Preparation method of lactide

The invention provides a preparation method of lactide. The method comprises the following step: lactic acid is subjected to a heating reaction under reduced pressure in presence of an H-beta molecular sieve, and lactide is obtained, wherein the reaction pressure is 50-1500 Pa. With adoption of the method adopting vacuum and heating, lactic acid reaction is catalyzed by the H-beta molecular sieve,synthesis of lactide from lactic acid is finished directly, lactide with high optical purity (higher than 96%) is obtained, and the defects of long technological process and high reaction temperaturecaused by the that that oligomerization and high-temperature pyrolysis are needed in the conventional lactide are overcome. No organic solvent is used in the whole preparation process, only wastewater is produced during preparation, and little environmental pollution is caused; the reaction temperature is low, repeated catalysis is realized through hydrolysis of a lactic acid oligomer, the H-betamolecular sieve can be recycled, and the preparation process is simple and environmentally friendly and has potential large-scale application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

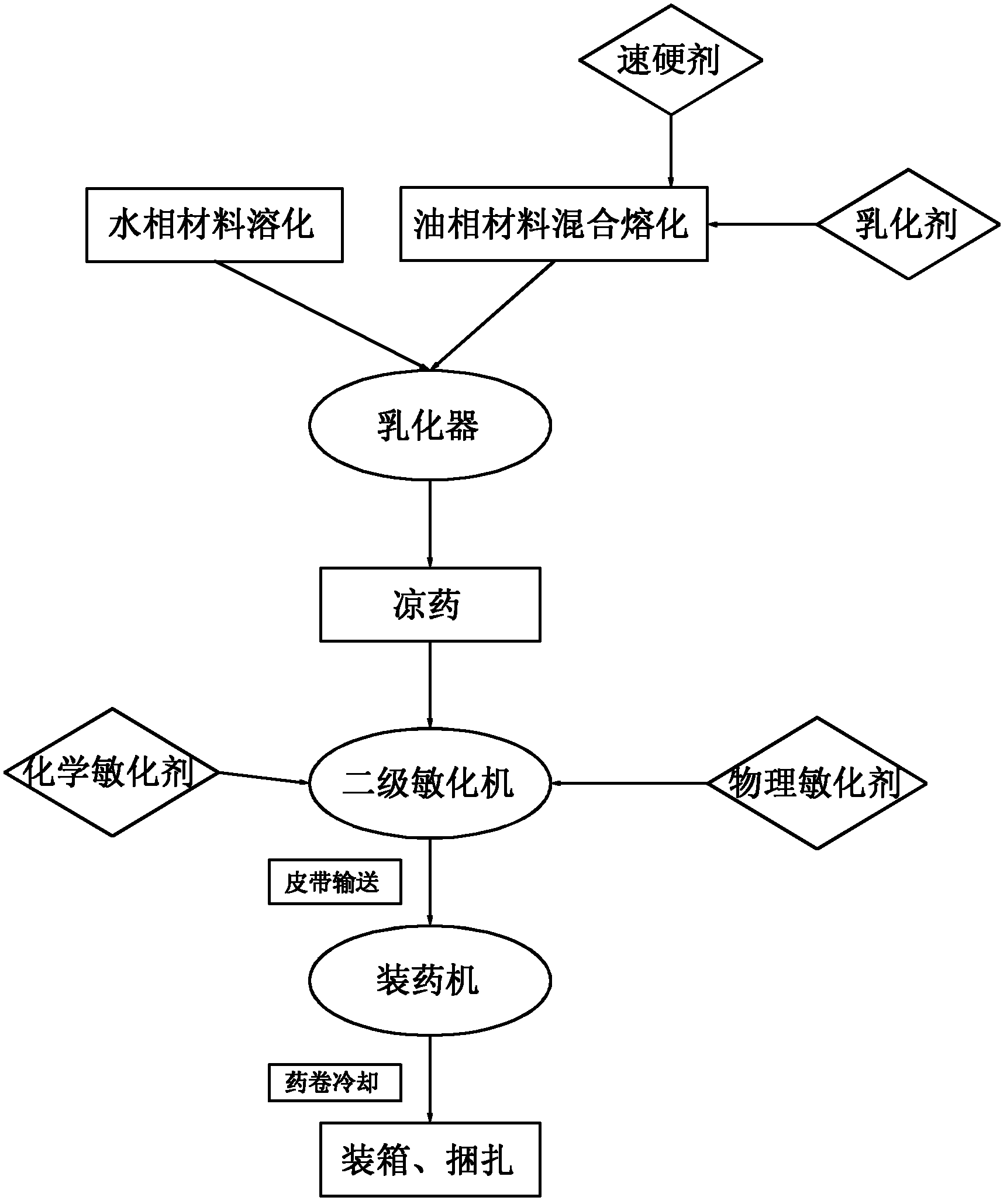

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Shoe and sock anti-bacterium and odor eliminating agent and preparation method thereof

InactiveCN105875621AStrong ability to kill bacteriaChemically stableBiocideDead animal preservationSolventPhenol

The invention relates to a shoe and sock anti-bacterium and odor eliminating agent and a preparation method thereof. The existing product for eliminating odor of shoes and socks sold in the market has the defects that the odor eliminating function is weakened after the use for a period of time; the bacterium growth and breeding cannot be effectively inhibited; or even some formulas contain nonyl phenol type substances with poor biological degradability, so that the environment pollution can be easily caused. A product comprises a solvent, an antibacterial agent, an odor eliminating agent, a mildewproof agent, deionized water, essence and pigments; the materials are mixed and prepared; two efficacies of anti-bacterium and odor elimination are achieved; the defects in the prior art are overcome; the shoe and sock anti-bacterium and odor eliminating agent is mild and inirritative; the shoe and sock contamination is avoided; safety and environment protection are realized; the use is convenient.

Owner:于文 +1

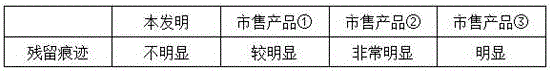

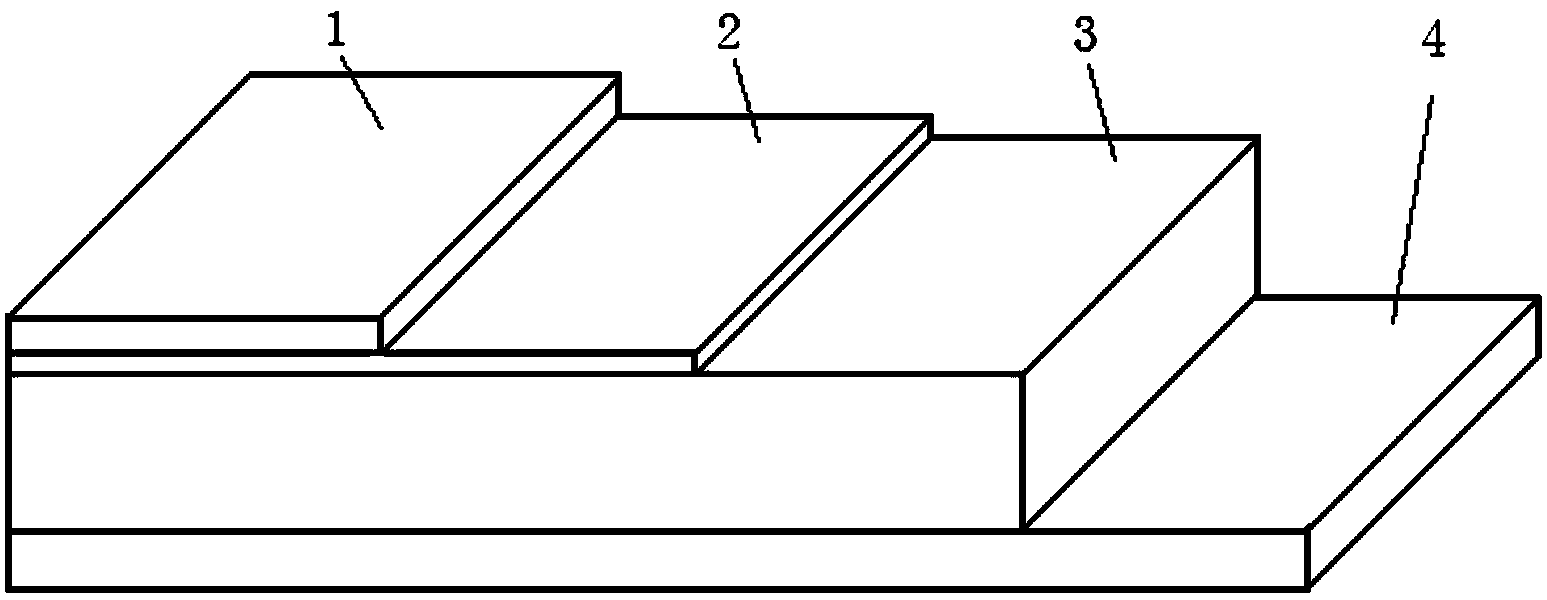

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

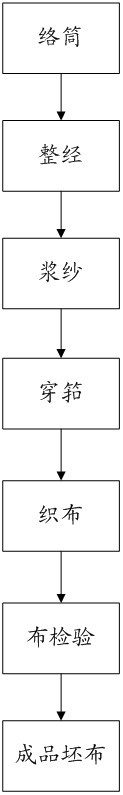

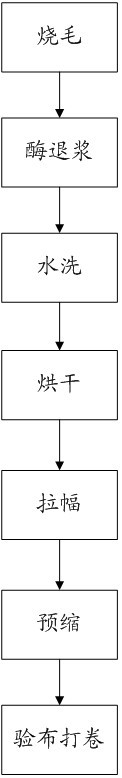

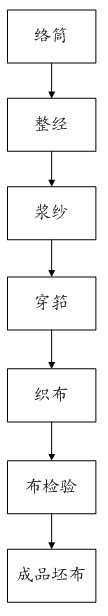

Textile and production process thereof

ActiveCN102605511AWith thermoregulationAnti-allergicSingeingDry-cleaning apparatus for textilesAntibiosisAllergy prevention

The invention discloses a textile. A plain-weave or diagonal-weave organization unit is interwoven by warps and wefts, the warps are made of colored cotton, the wefts are made of natural colored hemp, the warps and the wefts of the plain-weave or diagonal-weave organization unit are arranged vertically in a layered manner, and the ratio of the warps to the wefts is 5:3. The production process of the textile includes weaving process and finishing process. The warps and the wefts of the textile are properly matched vertically in the layered manner, and mutually make good for deficiency so as to realize perfect combination of appearance and hand feeling. In addition, the textile has functions of temperature regulation, allergy prevention, static elasticity prevention and antibiosis. The production process includes the pure physical finishing process, chemical preparation is omitted, pollution is reduced, and the production process is environment-friendly.

Owner:JIANGSU MENGLAN GROUP

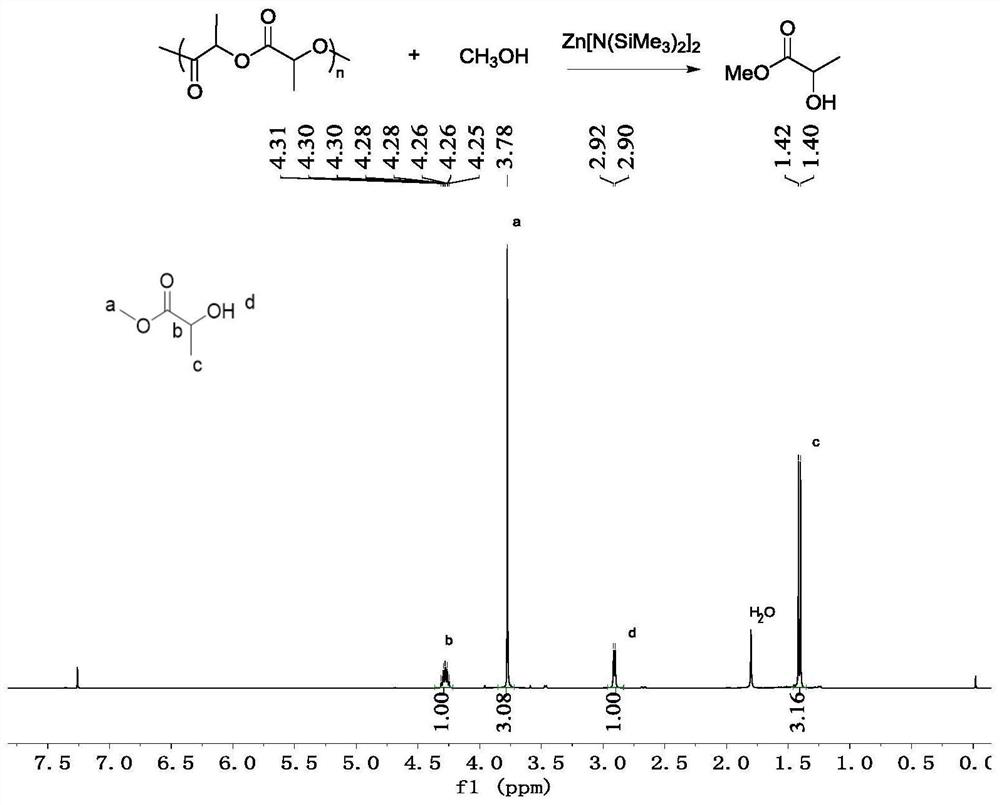

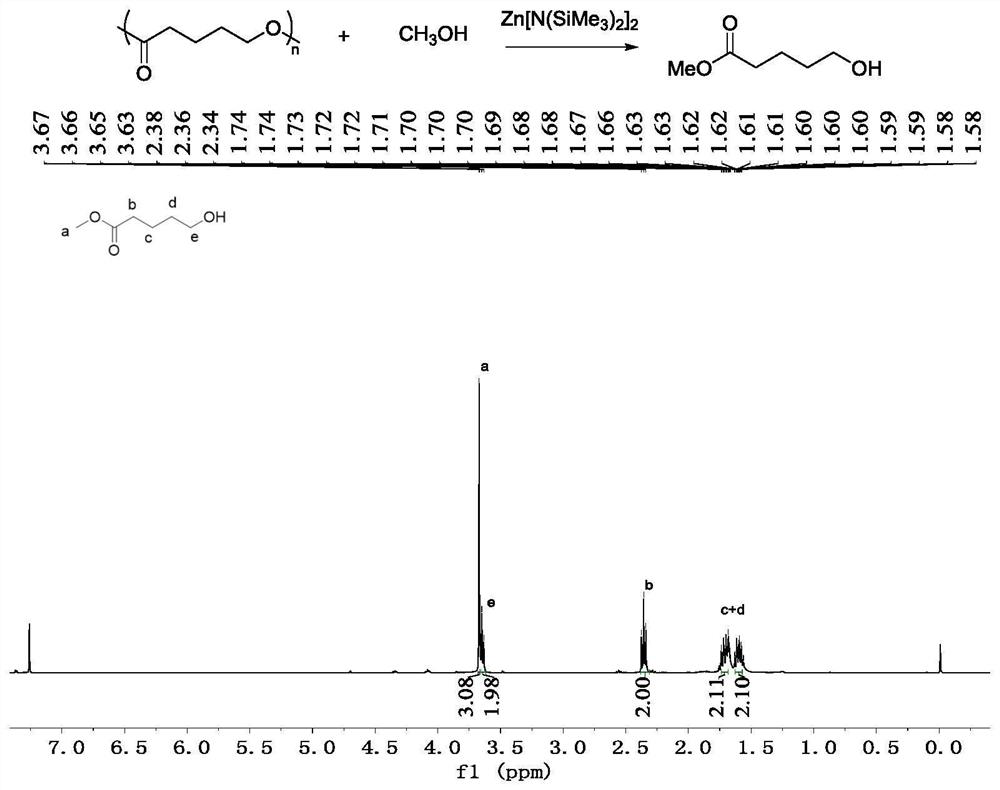

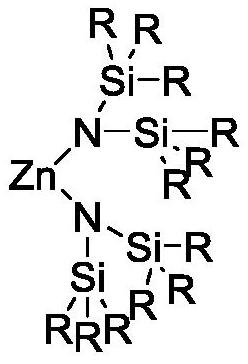

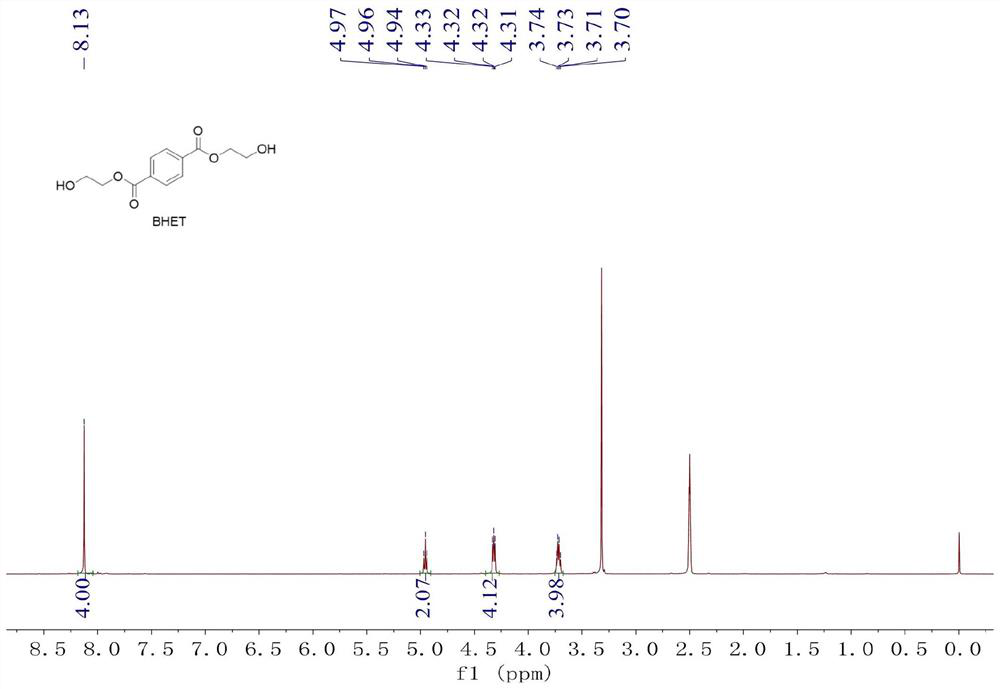

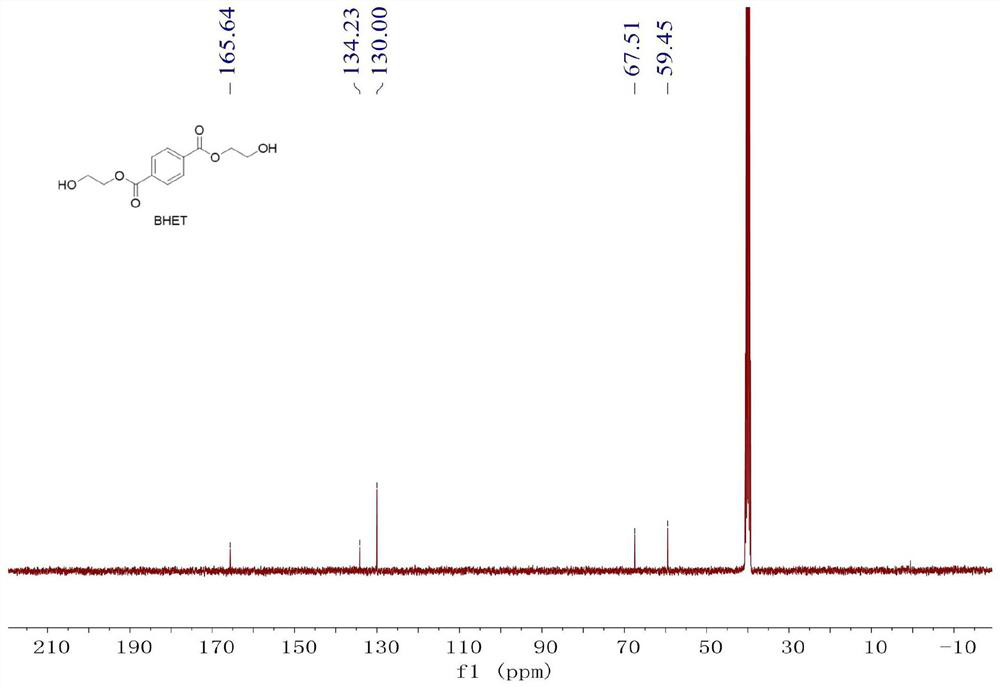

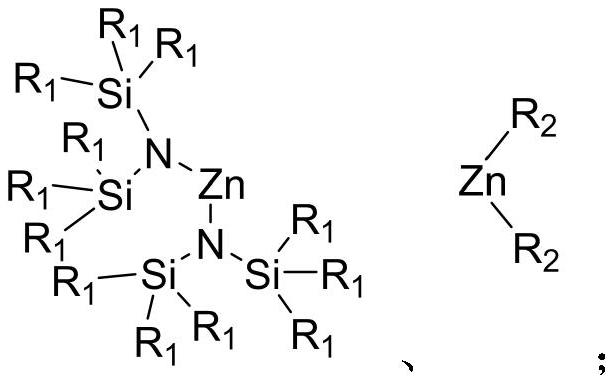

Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

ActiveCN112076790AAchieve reuseRealize secondary usePreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterTrans esterification

The invention discloses a zinc catalyst applicable to controllable depolymerization of a polyester material and a catalytic method thereof, and belongs to the technical field of polyester depolymerization. The problems that an existing zinc catalyst used for alcoholysis of waste polyester materials needs to synthesize complex ligands, and the number of synthesis steps is increased are solved. Thecatalyst adopted by the invention is a bis(hexaalkyldisilazane)zinc catalyst with a simple structure, and under the participation of an alcohol compound, the polyester material can be depolymerized into small organic molecules under mild conditions through the transesterification reaction catalyzed by the catalyst, so that the reutilization of waste polyester is realized. The zinc catalyst is adopted to catalyze polyester depolymerization, metal zinc is non-toxic, colorless, cheap and easy to obtain and serves as one of the microelements of a human body, biocompatibility is good, and the production process is more environmentally friendly; the catalyst is simple in structure, few in synthesis steps and more economical in production cost. The catalyst has very good universality, and has a very good depolymerization effect on various polyester materials with different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

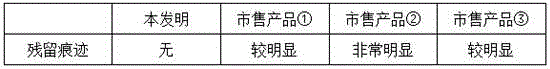

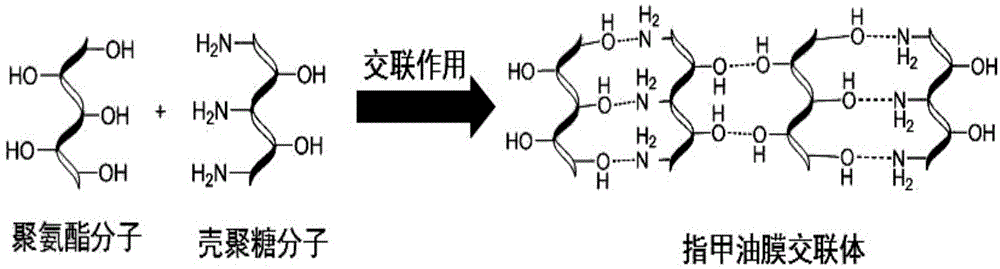

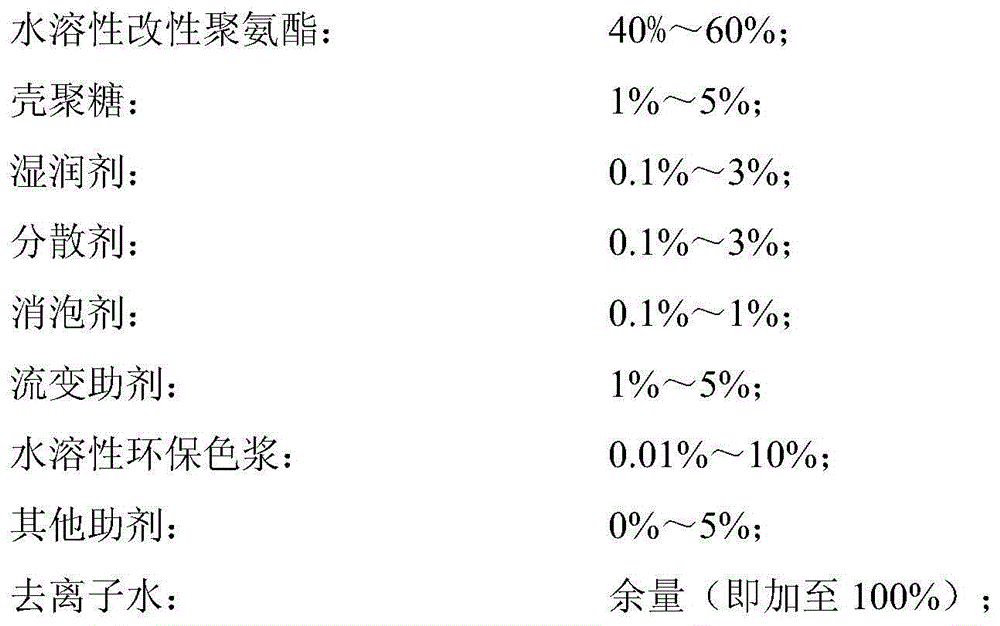

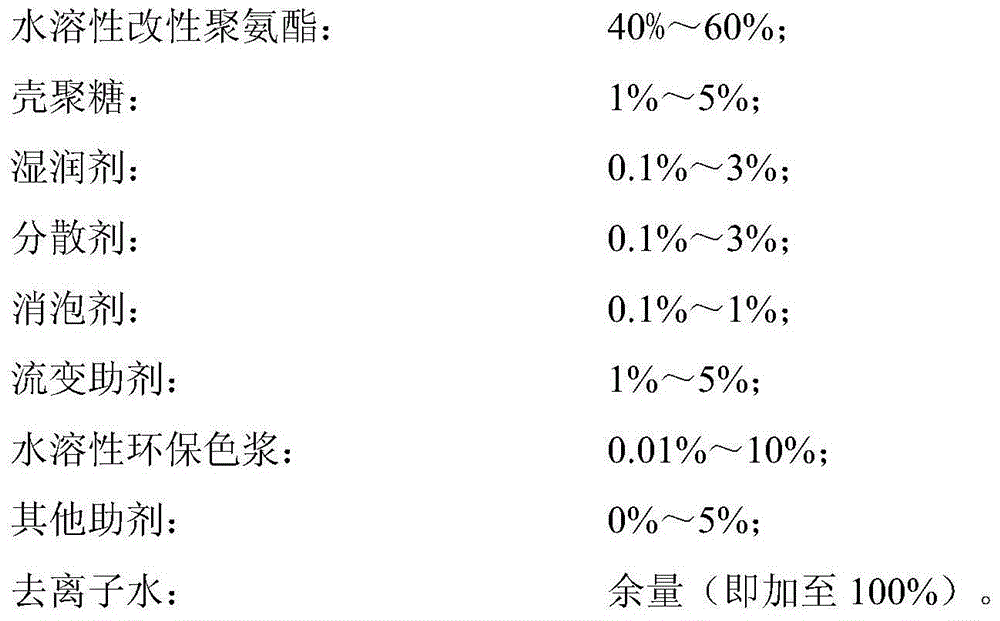

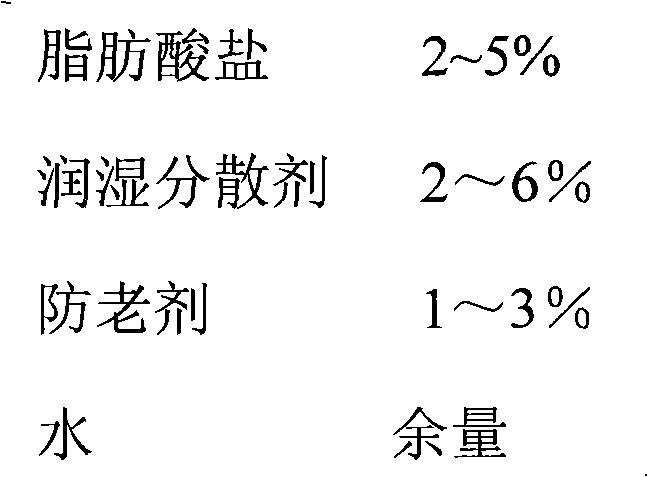

Strippable water-based non-irritation nail polish

InactiveCN104434568AProduction process is environmentally friendlyGood chemical propertiesCosmetic preparationsToilet preparationsWater basedIrritation

The invention relates to the field of synthetic production of cosmetics and aims to provide strippable water-based non-irritation nail polish. The strippable water-based non-irritation nail polish comprises deionized water, water-soluble modified polyurethane, chitosan, a wetting agent, a dispersing agent, an antifoaming agent, a rheological agent, water-soluble environment-friendly color paste and other additives. Water is used as a solvent, and no or only a small amount of absolute ethyl alcohol is added to be used as an additive, so that the nail polish has no paint smell of traditional oil-soluble nail polish or alcohol smell of alcohol-soluble nail polish and contains no alkali-associative thickener, and the whole nail polish system is neutral and causes no damage to the skin, nails and clothes.

Owner:毛红兵 +1

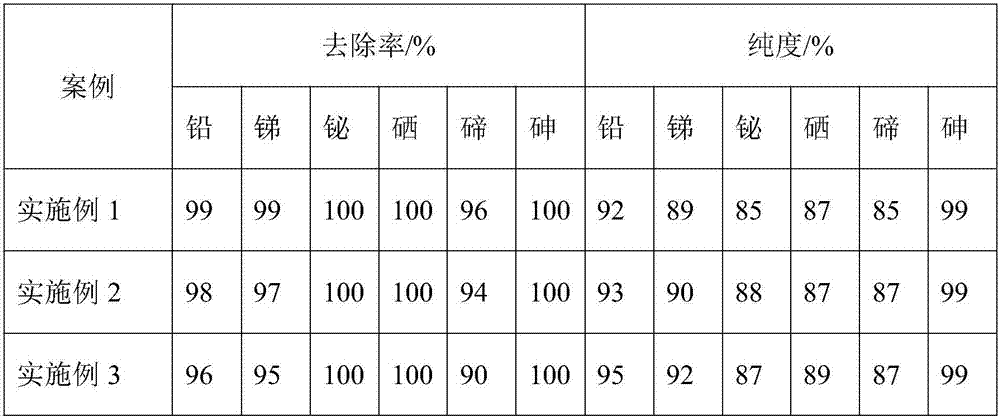

Method for removing lead, antimony, bismuth, selenium, tellurium and arsenic from copper anode slime by vacuum reduction

InactiveCN107217145AIncrease contentAvoid pollutionProcess efficiency improvementElemental selenium/telluriumAntimonySulfur dioxide

The invention relates to the technical field of metal smelting, and discloses a method for removing lead, antimony, bismuth, selenium, tellurium and arsenic from copper anode slime by vacuum reduction. The method comprises the steps: S1, after drying and dispersing the copper anode slime, uniformly mixing the copper anode slime with a solid reducer; in a vacuum furnace, electrically heating to reduce and distill out lead, antimony, bismuth, selenium, tellurium and arsenic vaporized materials, and thus leaving over residues containing gold, silver and copper; S2, introducing smoke dust into a multistage condenser group, controlling the temperature gradient of the multistage condenser group, thus condensing lead, antimony, bismuth, selenium, tellurium and arsenic in the smoke dust in different condensers, and respectively obtaining lead, antimony, bismuth, selenium, tellurium and arsenic. The method adopts vacuum distillation and fractional condensation for the copper anode slime to separate lead, antimony, bismuth, selenium, tellurium and arsenic, therefore the removal rate is high, and the purity of recovered materials is high. Moreover, the process is simple, no sulfur dioxide is discharged, and the environment is not polluted..

Owner:郴州万墨环保科技有限公司

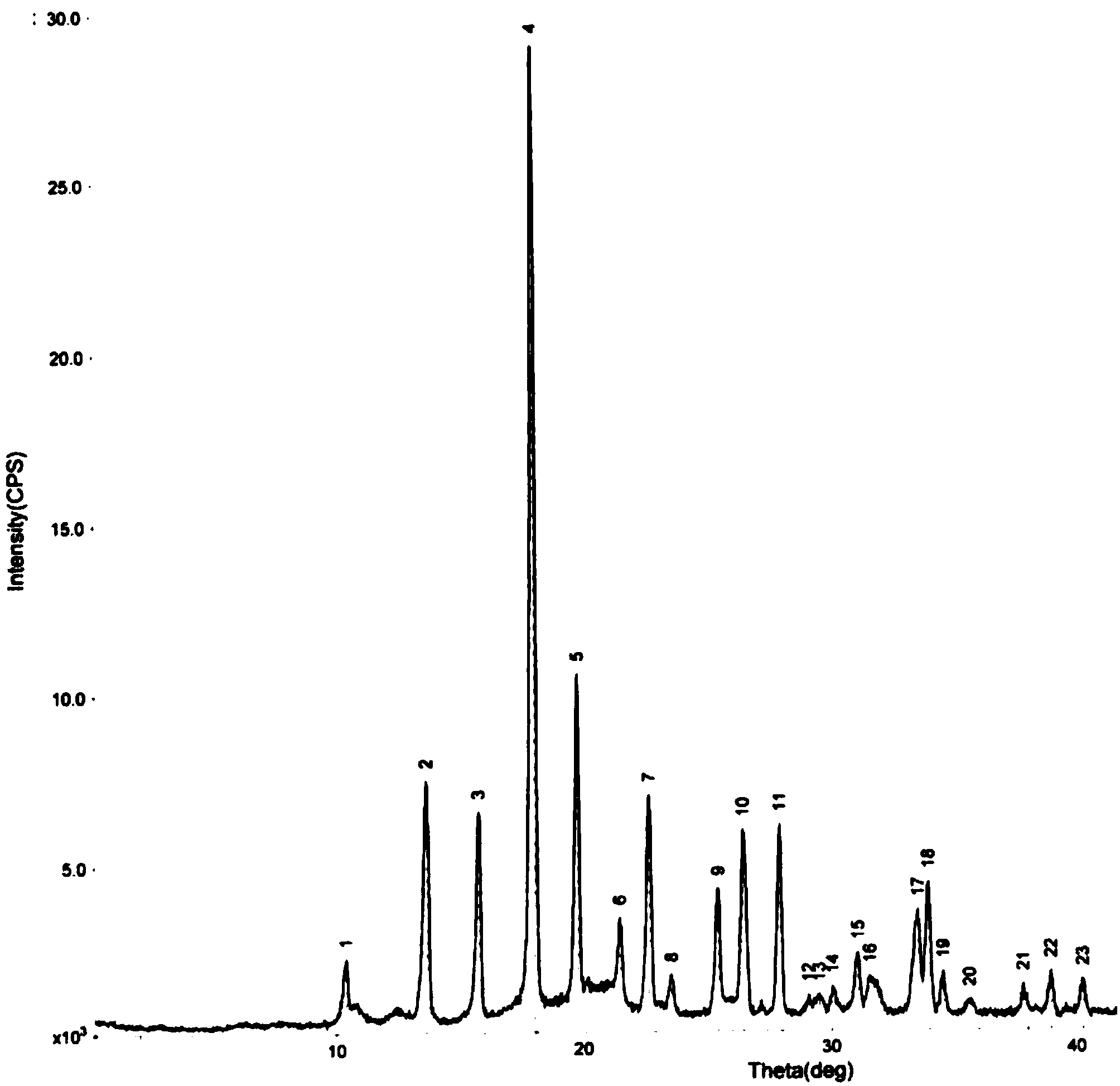

Preparation method of highly dispersed graphene oxide quantum dots

The invention provides a preparation method of highly dispersed graphene oxide quantum dots. According to the technical scheme of the invention, one or more components, selected from coking coal, bituminous coal, brown coal, peat and anthracite, is / are adopted as raw materials. The raw materials are subjected to oxidation, separation and lyophilization to obtain light-yellow graphene oxide quantum dots. The preparation method is low in production cost, simple in process, green and environment-friendly. Obtained graphene oxide quantum dots are controllable in size, good in fluorescence effect, excellent in monodispersity and good in water solubility. The prepared highly dispersed graphene oxide quantum dots have a very large application prospect in the fields of photoelectric materials, device preparation, biological images, display screens, drug carriers, solar cells, anti-counterfeiting coatings, novel semiconductor devices and the like.

Owner:CHONGQING UNIV

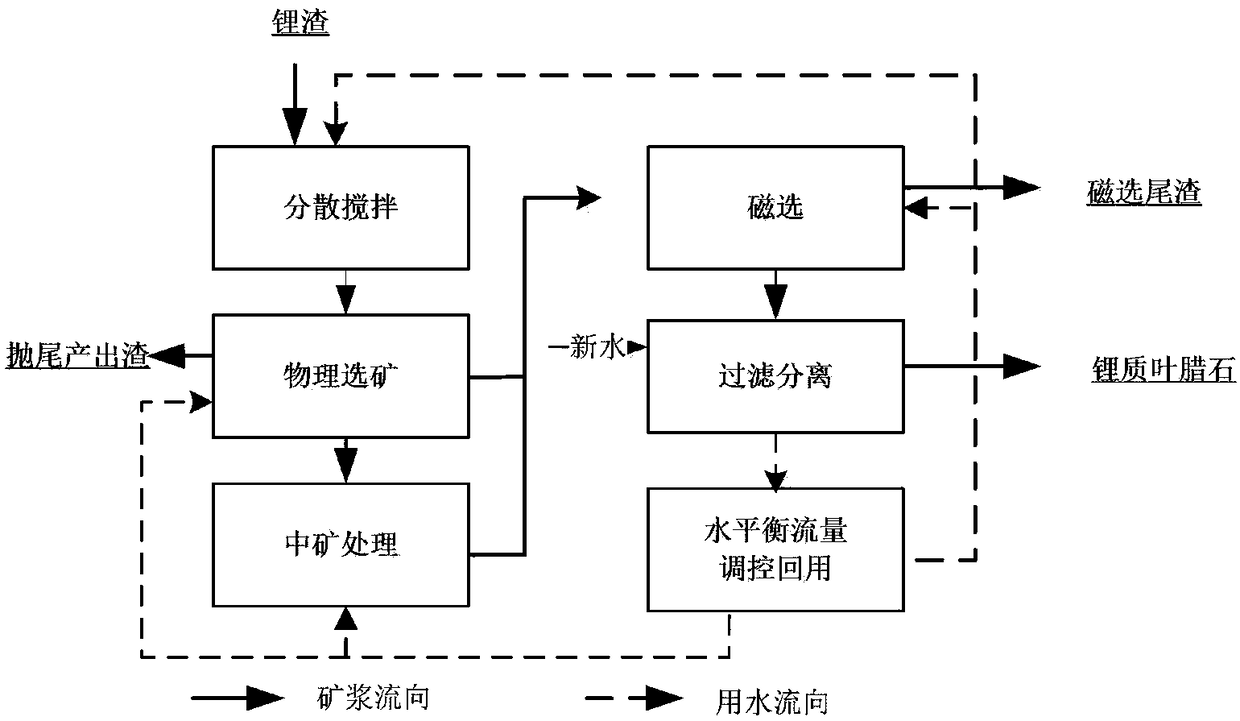

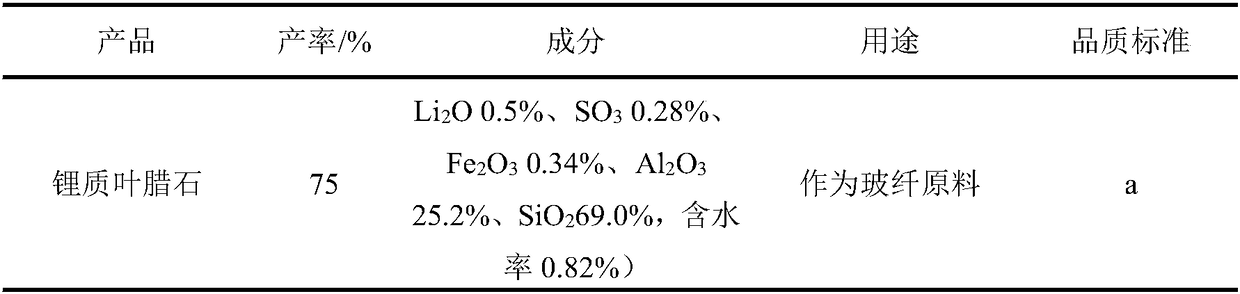

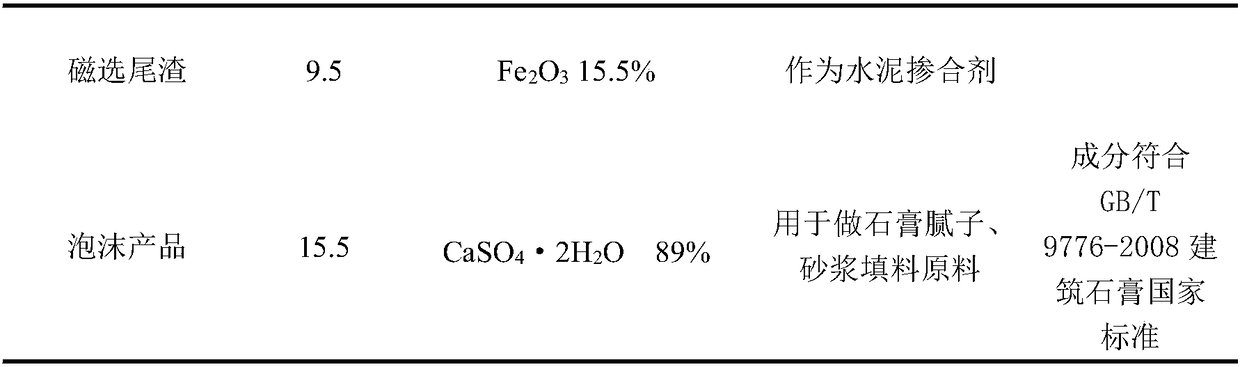

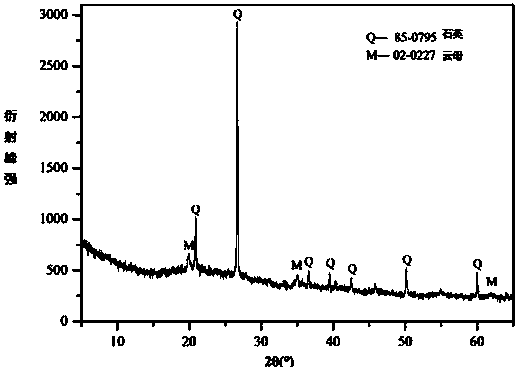

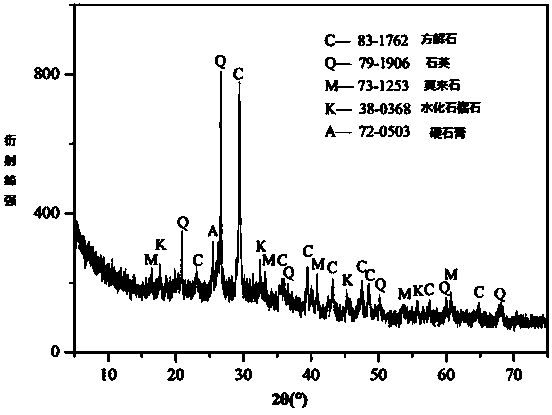

High-valued comprehensive utilization method of lithium slag

The invention provides a high-valued comprehensive utilization method of lithium slag, in particular to mineral waste residues obtained by lithium extraction of spodumene by a sulfuric acid method. The high-valued comprehensive utilization method comprises the following steps: firstly, carrying out size mixing and stirring on the lithium slag and enabling sulfate mineral in the lithium slag to bein a dispersed suspension state; secondly, carrying out desulfurizing treatment on a product obtained in the first step by using a physical ore dressing mode to obtain desulfurized slurry and tailingdiscarding produced slag and enabling the sulfur content of slag phase in the desulfurized slurry to be smaller than or equal to 0.5 percent; thirdly, under the condition that the magnetic field strength is 0.5 to 2.0T, carrying out magnetic separation on the desulfurized slurry obtained in the second step to obtain magnetic separation slurry and magnetic separation tailings and reducing the content of ferric oxide in the magnetic separation slurry to be smaller than or equal to 0.05 percent; then concentrating, filtering and drying the obtained magnetic separation slurry to obtain a pyrophyllite raw material for glass fibers. The treatment method of the lithium slag, disclosed by the invention, has the advantages of greenness and environmental protection, obvious economic benefits and capability of realizing the leap of high-valued recycling of the lithium slag.

Owner:TIANQI XINLONG CO LTD

Method for preparing cyclic sulfate by directly oxidizing hydrogen peroxide

PendingCN111909129ALess impuritiesHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The method comprises the following steps: dropwise adding hydrogen peroxide into a mixture of cyclic sulfite, an organic solvent and a solid catalyst to carry out catalytic oxidation reaction, filtering out the solid catalyst after the reaction is finished, standing filtrate for layering, taking an organic layer, and performing distilling and concentrating to obtain a cyclic sulfate product. Cheaphydrogen peroxide is used for directly catalyzing and oxidizing cyclic sulfite to prepare cyclic sulfate, so that on one hand, the reaction is mild and easy to control, and the reaction conversion rate is high; on the other hand, no waste salt is generated, the evaporation capacity of water is small, energy consumption is low, generated waste water is little, and the production process is more environmentally friendly; the used solid catalyst contains an active component, an active auxiliary agent and an oxide carrier, and can be recycled, so that the consumption of noble metals is reduced, and the production cost is greatly reduced; the cyclic sulfate prepared by the method is few in impurities, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM +1

Nano calcium carbonate and styrene-butadiene rubber composition and preparation method thereof

The invention discloses a nano calcium carbonate and styrene-butadiene rubber composition and a preparation method thereof. The weight of styrene-butadiene rubber is 20 to 40 percent of that of calcium carbonate. The product provided by the invention is the nano calcium carbonate and styrene-butadiene rubber composition with small particle sizes and uniformly distributed granularity; and the composition can remarkably improve the dispersibility of the nano calcium carbonate in the rubber, realize the nano-scale dispersion of the nano calcium carbonate in the rubber system, enhance the functional reinforcement function of the nano calcium carbonate, simultaneously further simplify a process flow, save the steps of drying, crushing and the like in a nano calcium carbonate powder preparation process, and avoid energy consumption and dust pollutions caused by the steps of drying, crushing and the like.

Owner:建德华明科技有限公司

Accumulator electrode with internal particle movable and producing process thereof

InactiveCN101335342AFully automatedProduction process is environmentally friendlyElectrode manufacturing processesElectricityFast charging

The invention relates to a battery electrode with movable internal particles and a preparation method thereof, and pertains to the technical field of the battery electrode. The battery electrode is characterized in that the battery electrode comprises an electrode frame which is arranged in the battery body, movable electrode particles are piled in the electrode frame, the electrode particles are negative particles or positive particles made of solid electrode material, the electrode frame has net-shaped structure and is connectively provided with an input pipeline and an output pipeline which extend out of the battery body, and the electrode frame is connectively provided with an electrode post head. The battery electrode with movable internal particles and the preparation method thereof break through the traditional model in which the battery electrode is fixed in the battery. The electrode particles of the battery electrode can be input into or output from the battery body, can be charged in the battery body and also can be moved out of the battery body to carry out charging and maintenance. The battery electrode has the advantages that the manufacturing automatization of the battery electrode can be realized; the volume and the weight of the battery are reduced; the use performance of the battery is improved; and fast charge is achieved.

Owner:郑力

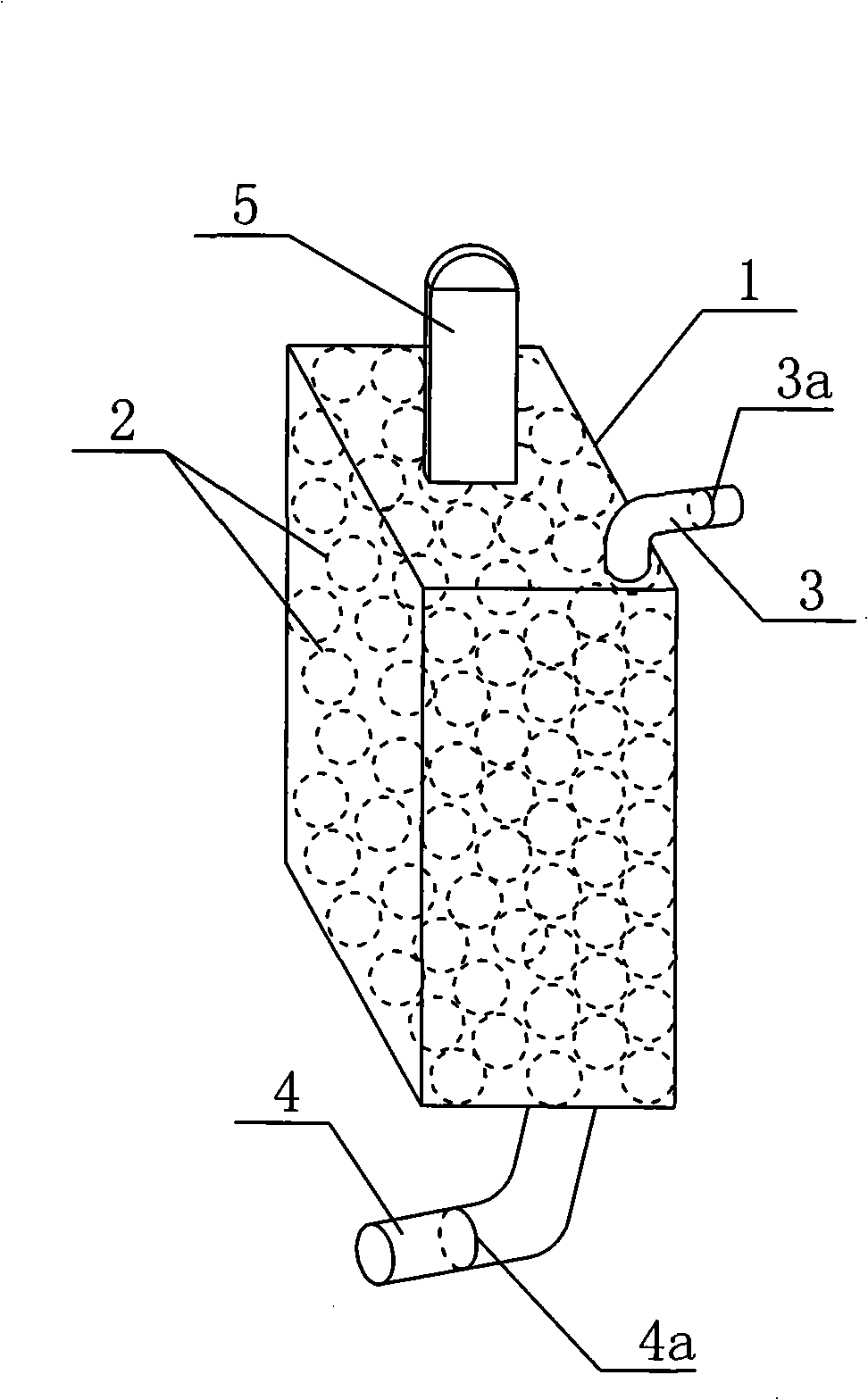

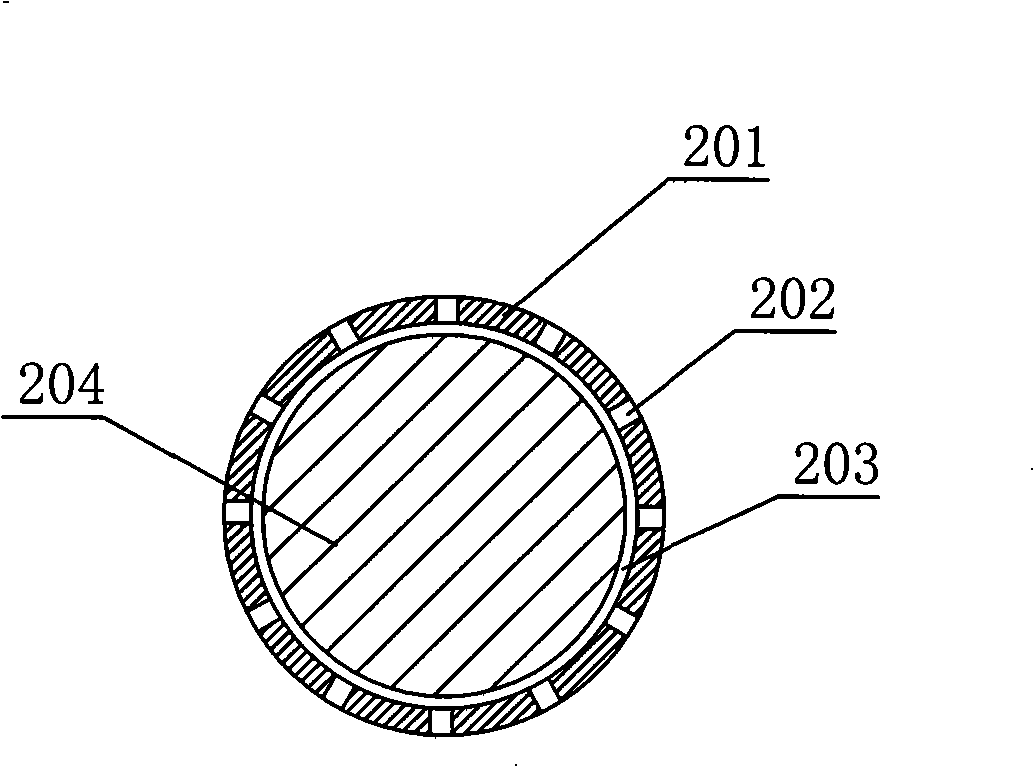

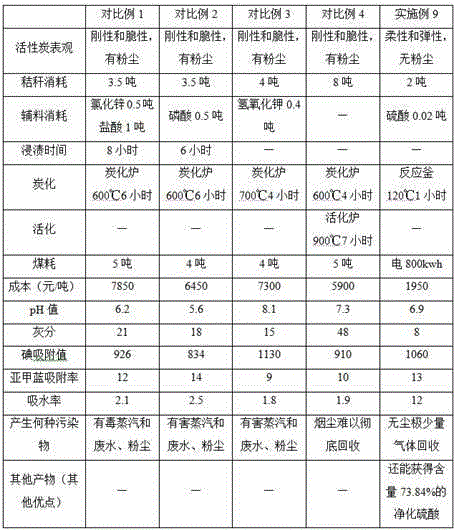

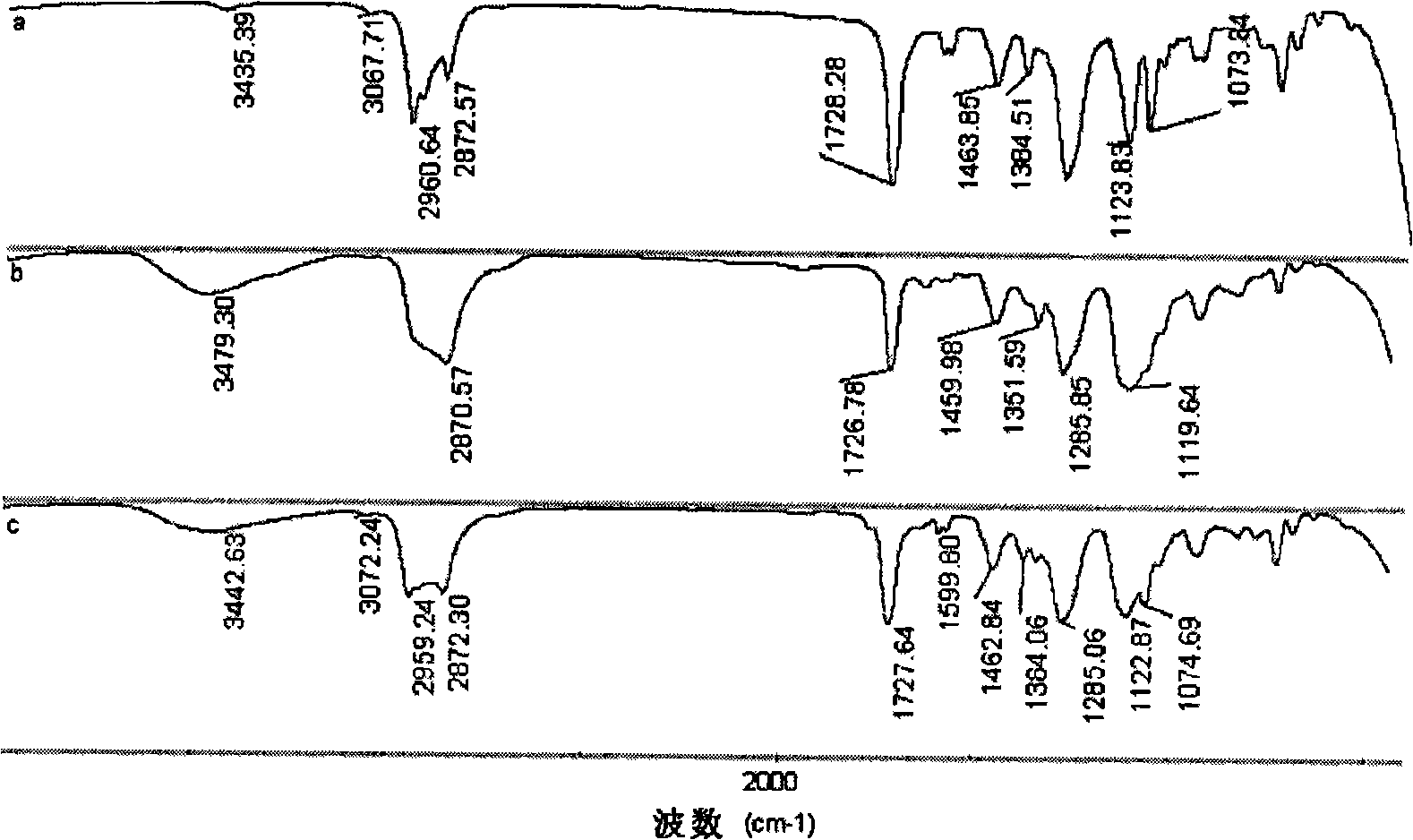

Method for directly preparing activated carbon in waste acid

ActiveCN105000558AProduction process is environmentally friendlyLow costFiltrationToxic industrial waste

The invention discloses a method for directly preparing activated carbon in waste acid. The method comprises the following steps: biomass raw materials or organic matter raw materials are smashed, the smashed biomass raw materials or organic matter raw materials are mixed with an acid solution, reaction is carried out under a certain temperature, and solid-liquid separation is carried out, so that a solid product and a filtrate are obtained; the solid product is repeatedly washed with water until a neutral property is achieved and sulfate ions do not exist, and suction filtration and drying are carried out, so that the activated carbon is obtained, and the filtrate is purified industrial sulfuric acid. According to the invention, high temperature is not required, the obtained activated carbon is dust-free activated carbon, and the obtained flexible and elastic activated carbon with high water absorbability can be widely applied to the industries of purification, decolorization, adsorption, filtration aiding, carriers, a conditioner and the like. The method is extremely wide in raw material applicability, can be used for purifying waste sulfuric acid, and can purify industrial waste acid into industrial-grade sulfuric acid.

Owner:赵常然

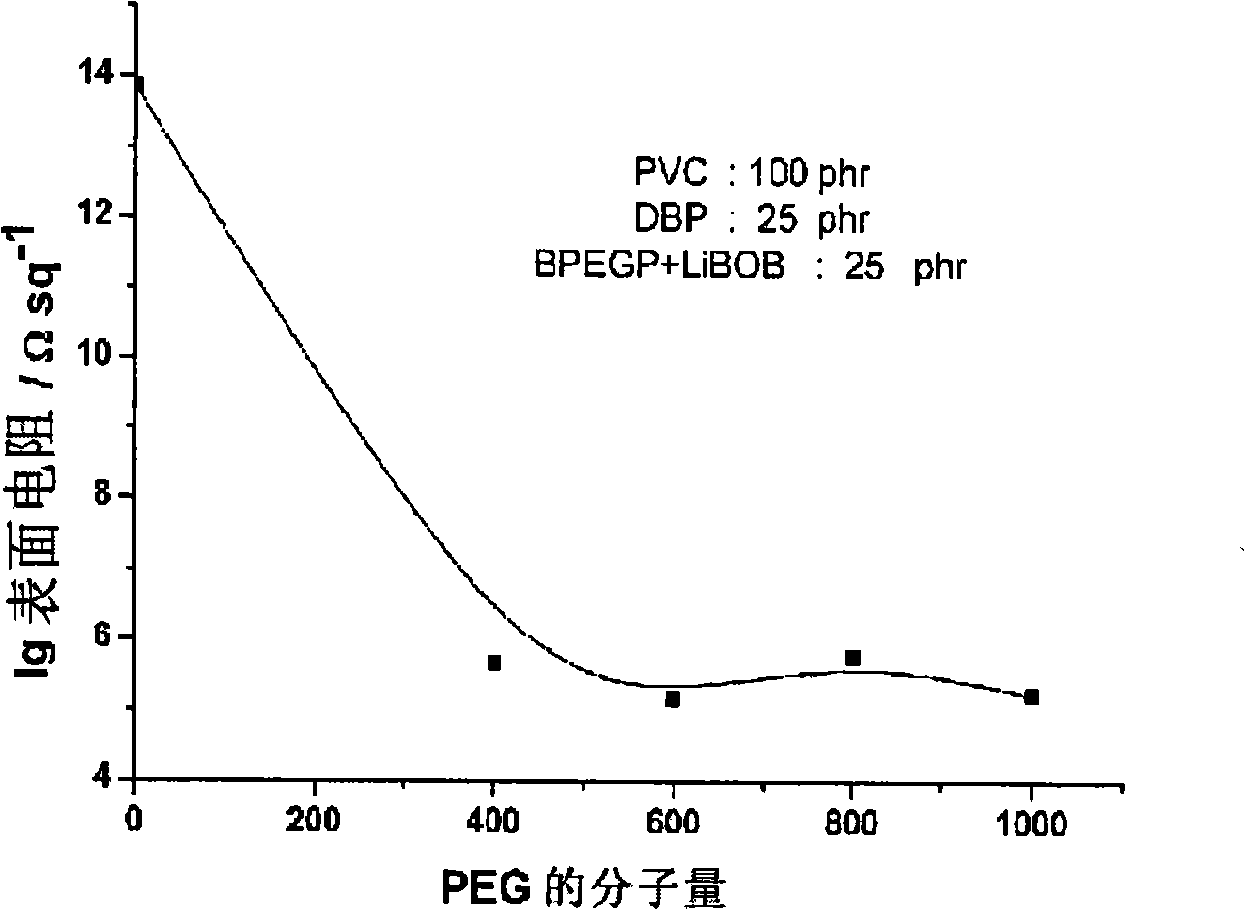

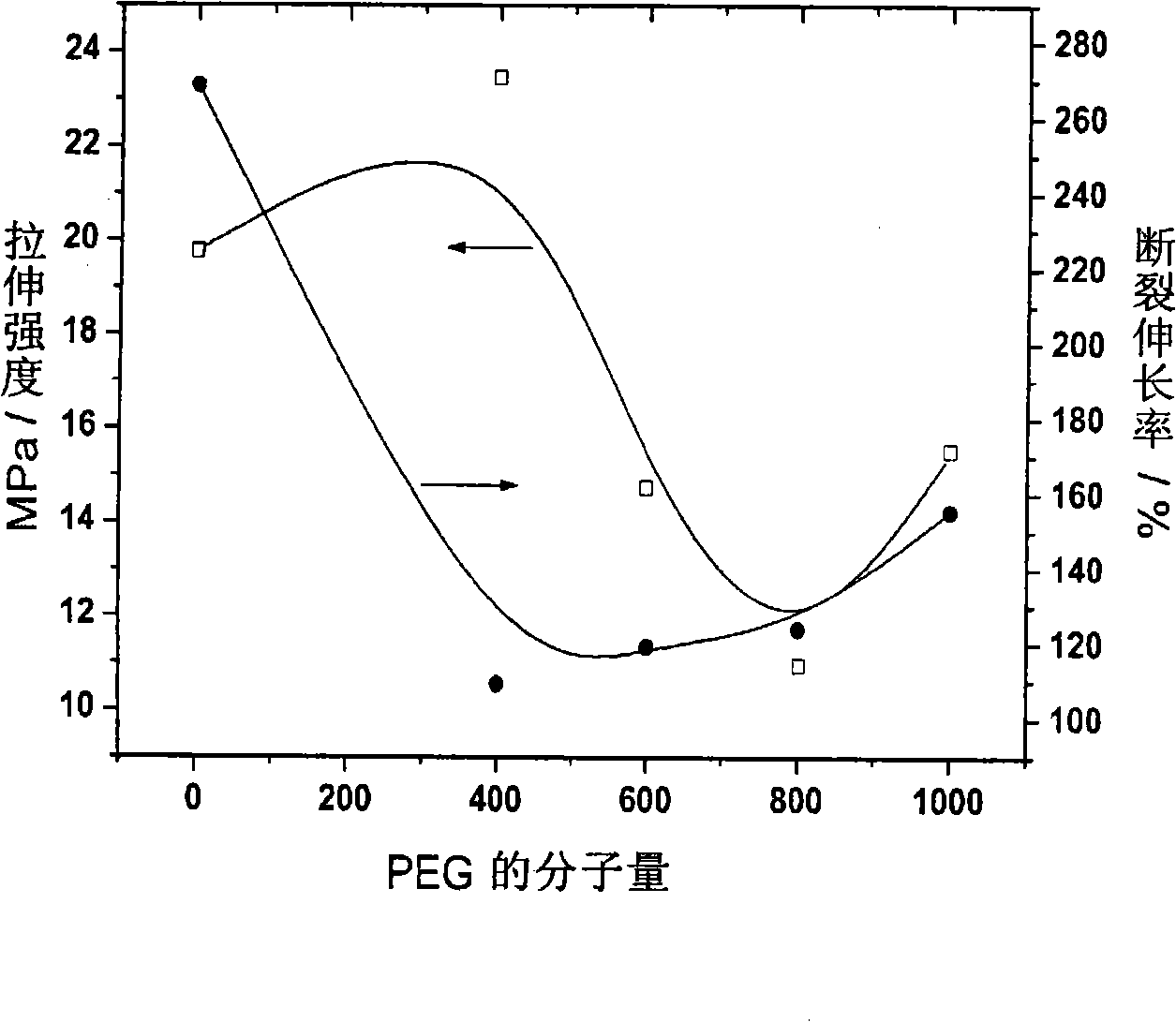

Method for preparing permanent antistatic agents

InactiveCN101358126AAdjustable molecular weightResponse conditions are relaxedOther chemical processesSolventLithium-ion battery

The present invention relates to a method for preparing a permanent antistatic agent. The method has the following characteristics: along with 0.1 to 5 mass portions of catalyst and 0 to 1000 mass portions of solvent, aromatic diester or aromatic diacid coupled with estolide compound thereof and ether alcohol compound are added into a reaction kettle provided with a thermometer, a stirrer and a reflux condenser according to a molar ratio of 1 : 1 to 2.5 to react under a temperature between 50 DEG C and 350 DEG C for one to twenty four hours, so that aromatic ester provided with a benzene ring and a polyether structure is synthesized; aromatic ether ester compound is obtained after the solvent and the unreacted monomers are removed; according to a mass ratio of 1 : 1 to 30, alkali metal salt and the compound are mixed so that the aromatic ether-ester permanent antistatic agent is produced. Even under a low humidity level, the aromatic ether-ester permanent antistatic agent can keep a good antistatic effect and can plasticize various polymer materials. The aromatic ether-ester permanent antistatic agent is used for the antistatic modification of general-purpose plastics and anti-corrosion, acid-and-alkali-resisting, anti-static and flame-retarding wind tubes, conveyer belts and gas-pumping-and-exhausting tubes used by coal mines, dust-free computer rooms, antistatic floorings, packages or lithium ion batteries.

Owner:SICHUAN UNIV

Sludge autoclaved brick and preparation method thereof

The invention discloses a sludge autoclaved brick. The sludge autoclaved brick comprises the following raw material components in parts by weight: 20-60 parts of sludge dehydrated mud cakes, 11-25 parts of first fly ash, 0-10 parts of carbide slag or first lime, 22-39 parts of furnace slag and 1-6 parts of a reinforcing agent, wherein the sludge dehydrated mud cakes comprise the following raw material components in parts by weight: 33-66 parts of sludge, 15-33 parts of second fly ash, 15-33 parts of second lime and 1-5 parts of a coagulating agent. The autoclaved brick is prepared from industrial wastes as main raw materials, and is low in energy consumption, non-sintered, safe, healthy and stable for a long time. The invention also discloses a preparation method of the sludge autoclaved brick. According to the preparation method, the sludge water content is controlled in a mode of conditioning at first and then dehydrating to form the sludge dehydrated mud cakes, and the fly ash and the like are added to perform hydration reaction. The autoclaved brick prepared by the method can meet performance requirements of a standard brick, and the production process is simple, low in energy consumption and environment-friendly.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Method for preparing safe environment-friendly phenolic foam

InactiveCN102229706ALow thermal conductivityImprove thermal conductivityAlkaneSimple Organic Compounds

The invention discloses a method for preparing safe environment-friendly phenolic foam. The foam is prepared by a reaction after mixing the following ingredients: 100 weight portions of expandable phenolic resin, 8-15 weight portions of curing agent, 4-8 weight portions of surfactant and 20-50 weight portions of packing. The preparation method comprises the following steps: putting the ingredients in a reaction container in proportion, stirring with high speed, after mixing uniformly, transferring the ingredients to a preheated mould, foaming at the temperature of 60-80 DEG C and under the pressure of 15-40kg / cm<2>, cooling and demoulding. According to the method, because inflammable CFCs, low-carbon alkane and other lower-boiling organic compounds are not used as foaming agent, the production cost is reduced. The prepared phenolic foam has uniform quality, small aperture, low coefficient of thermal conductivity, and good thermal insulation performance, can be widely used in exterior wall, roofing, air-conditioning bellow and other thermal insulation materials, and improves thermal insulation performance and fireproof performance greatly.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Glue solution for copper-clad plate, composite based CEM-1 copper-clad plate, and preparation methods of glue solution and composite based CEM-1 copper-clad plate

ActiveCN106398110AImprove performanceWide range of usesSynthetic resin layered productsPaper/cardboard layered productsEpoxyOrganic solvent

The invention provides a glue solution for a copper-clad plate, a composite based CEM-1 copper-clad plate, and preparation methods of the glue solution and the composite based CEM-1 copper-clad plate. The glue solution for the copper-clad plate comprises the raw materials in parts by weight: 1200-2000 parts of epoxy soybean oil modified phenolic resin, 1200-2000 parts of epoxy resin, 150-250 parts of phenolic resin, 300-700 parts of a flame retardant, 250-350 parts of a curing agent, 1-5 parts of a curing accelerant, 50-150 parts of an inorganic filler and 100-300 parts of an organic solvent. On one hand, the epoxy soybean oil modified phenolic resin provided by the invention has the advantages of simple preparation process, good product performance and wide application; on the other hand, the glue solution for the copper-clad plate has the advantages of simple preparation process, good product performance, wide application and good permeability to wood pulp paper; what is noteworthy is that the composite based CEM-1 copper-clad plate provided by the invention has the advantages of simple preparation process, relatively good punching property, relatively good soldering resistance and good processing performance.

Owner:抚州市龙兴电子材料有限公司

Florfenicol water-soluble powder and preparation method thereof

InactiveCN106727334AGood water solubilitySimple production processAntibacterial agentsOrganic active ingredientsRoom temperatureWater soluble

The invention relates to florfenicol water-soluble powder and a preparation method thereof. The water-soluble powder is prepared from the following raw materials in parts by weight: 5-20 parts of florfenicol, 25-95 parts of water-soluble cyclodextrin polymer (CDP) and 5-19 parts of hydroxypropyl beta-cyclodextrin. The powder can be completely dissolved into water, the room-temperature solubility can reach 33.5% and the water solution is completely clear. The room-temperature solubility can reach 33.5% (335,000ppm), and the effective content of the florfenicol can reach 15% (150,000ppm), and is about 3300 times of state-recommended clinical dosage and much higher than that of an existing florfenicol composition.

Owner:SHANDONG BINZHOU ZHIYUAN BIO TECH CO LTD

Method for preparing shikimic acid from folium ginkgo extraction waste liquor

ActiveCN109593034AReasonable process designHigh purityCarboxylic compound separation/purificationOrganic solventHydrolysate

The invention relates to the field of extraction and purification of plant effective components, in particular to a method for preparing shikimic acid from folium ginkgo extraction waste liquor. The method comprises the following steps: carrying out enzymolysis on the folium ginkgo extraction waste liquor; and collecting an enzymatic hydrolysate, filtering by an organic membrane, carrying out adsorption elution by an anion exchange resin column, concentrating, crystallizing and drying. The method is simple to operate, economical and practical and proper to popularize, and does not need an organic solvent. Moreover, the obtained shikimic acid is high in purity and good in appearance condition, and the mass content is greater than 99%.

Owner:GUILIN NATURAL INGREDIENTS CORP

Method for retaining freshness of chilled fresh fish heads

ActiveCN102217668AReduce the initial bacterial countProduction process is environmentally friendlyMeat/fish preservation by coatingMeat/fish preservation using chemicalsChlorine dioxideElectrolysis

The invention provides a method for retaining freshness of chilled fresh fish heads, wherein freshwater fish heads are used as raw materials, and the freshness retaining of the fish heads is realized by virtue of sterilizing, coating, modified atmosphere packaging and other methods. The method comprises the main steps of: pre-treating: performing scaling, gill removing and cold-water cleaning on the fresh fish heads; sterilizing by electrolytic ozone water; draining; filling simulated gills; coating a compound fresh preserver; blowing to dry body surface water and sterilizing by using ultraviolet light; packaging under a modified atmosphere; and obtaining products. The main advantages of the method provided by the invention are as follows: (1) ginger is used for preparing the simulated gills and placed in gill covers, so that the function of assisting bacterial inhibition and fishy smell removal is achieved, the eye rims of the fish heads can be effectively prevented from sinking and the influence on the fish head appearances due to gill removal is eliminated; (2) the fish heads are sterilized by using the electrolytic ozone water and the ultraviolet light, so that the initial bacterial count of the raw materials is effectively decreased, and chlorine dioxide and preservative are not used so that the production technology is green and environment-friendly; and (3) the fish heads subjected to cold sterilization is coated with a green compound coating fresh preserver, so that the quality guarantee period of fish head products is effectively prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for catalytically degrading waste polyester material by using zinc catalyst

PendingCN113173856ASimple structureFew synthetic stepsOrganic compound preparationOrganic chemistry methodsPolyesterTrans esterification

The invention discloses a method for catalytically degrading a waste polyester material by using a zinc catalyst, belongs to the technical field of polyester degradation, and aims to solve the problems that an existing polyester waste chemical recovery catalyst is low in catalytic efficiency and low in material universality. According to the method disclosed by the invention, a zinc catalyst with a simple structure is adopted, and various polyester materials are depolymerized into small organic molecules through an ester exchange reaction catalyzed by the zinc catalyst under the participation of an alcohol compound, so that the recycling of the waste polyester is realized; and the method disclosed by the invention has good universality, and has a good depolymerization effect on polyester materials with various different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

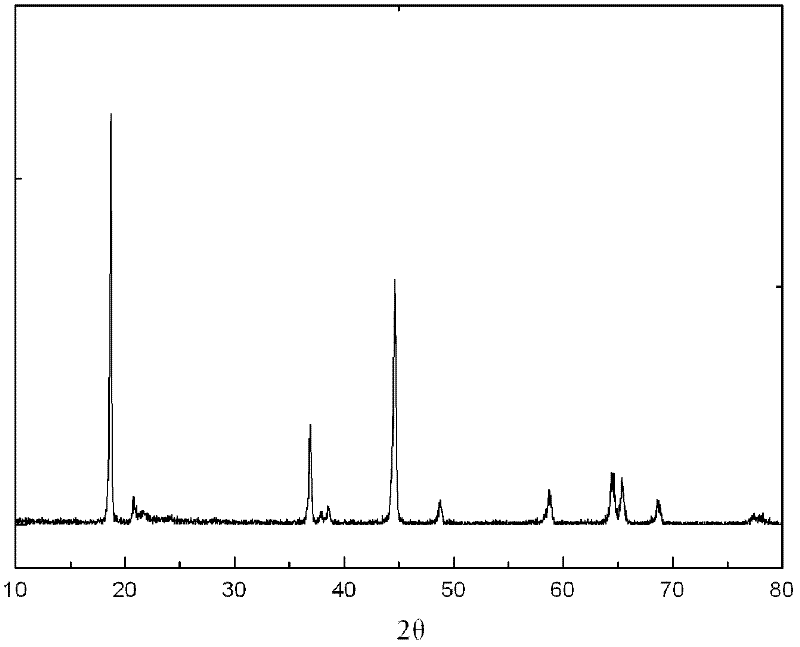

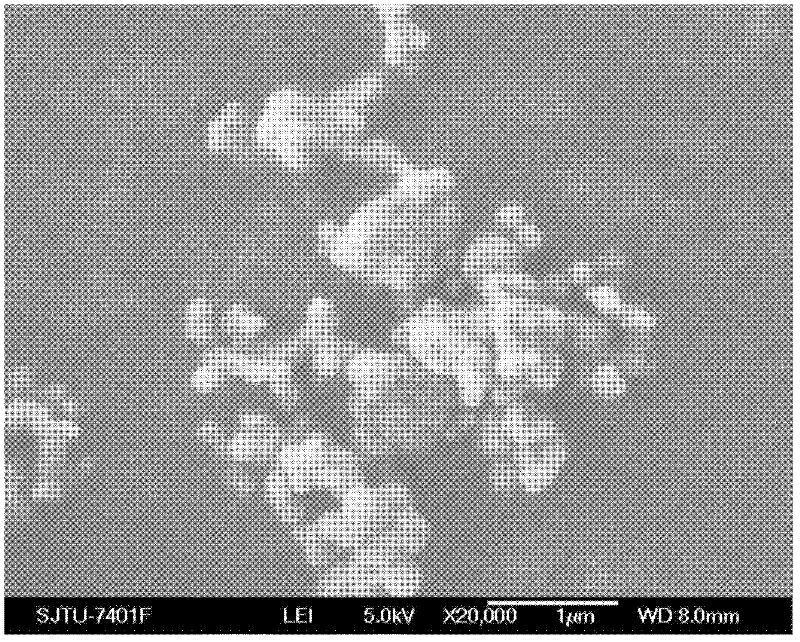

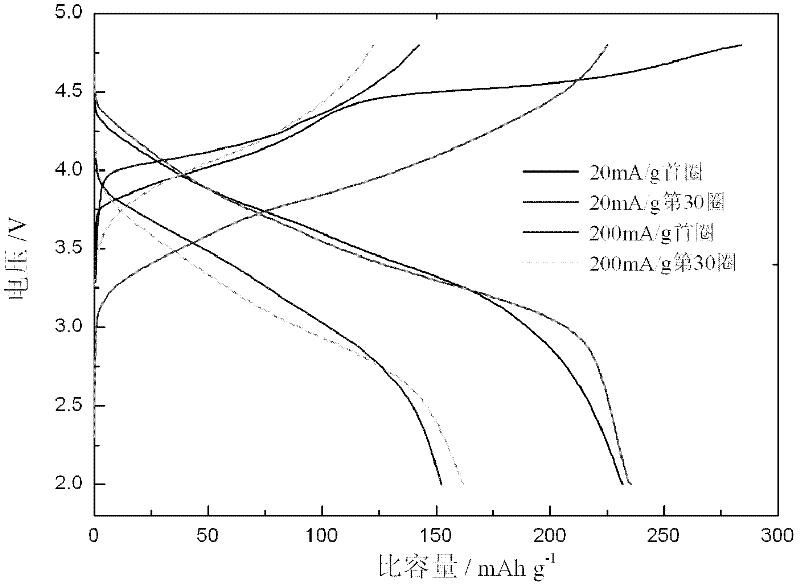

Preparation method of lithium abundant cathode material for lithium ion battery

InactiveCN102364732AShorten the diffusion pathGreen environmental particle sizeCell electrodesAir atmosphereNickel salt

The invention discloses a preparation method of a lithium abundant cathode material for a lithium ion battery. The preparation method comprises the following steps of: performing spray drying on manganese salt, cobalt salt, nickel salt and lithium salt which are dissolved in deionized water by a spray drying process to obtain precursor powder; and putting the precursor powder into a high temperature furnace, sintering under an air atmosphere, naturally cooling to room temperature, and thus obtaining a product, namely the lithium abundant cathode material Li[Ni2 / 5-xLixMn3 / 5-x / 2Cox / 2]O2 (x is more than 0 and less than 2 / 5). The lithium abundant cathode material prepared by the method has uniform particles with the average size of 200nm; and the cathode material of the lithium ion battery reflects extremely high discharging specific capacity, has the current charging / discharging density of 20mA / g and the initial-circle discharging capacity of 247mAh / g, and has the capacity retention rate of 99 percent after 10-time circulation. Compared with the conventional lithium abundant cathode material prepared by a co-precipitation method, the lithium abundant cathode material prepared by the method has a higher electrochemical property and high batch stability and is suitable for industrial mass production.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com