Preparation method of lactide

A lactide and lactic acid technology, applied in the direction of organic chemistry, can solve the problems of high synthesis cost, increased production efficiency, disadvantages, etc., and achieve the effects of simple and environmentally friendly production process, less environmental pollution, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing lactide, which can be realized by those skilled in the art by referring to the content of this article and appropriately improving the process parameters. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they all belong to the protection scope of the present invention. The method and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the method and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

[0022] The invention provides a method for preparing lactide, comprising:

[0023] In the presence of H-beta molecular sieve, the lactic acid is heated and reacted under reduced pressure to obtain lactide; the ...

Embodiment 1

[0041] 2 grams of H-beta molecular sieve (SiO 2 :Al 2 o 3 Molar ratio 25:1), 2 grams of lactic acid (concentration 105%) were added to the reaction flask. The reaction flask was placed in an oil bath at a temperature of 130° C. and continuously stirred; at the same time, vacuum distillation was carried out. After 4 hours of reaction, no product distilled out of the reaction flask, and lactide was obtained in the condenser, and the lactide yield was 27%.

Embodiment 2

[0043]1 gram of H-beta molecular sieve (Si:Al molar ratio 12.5:1) and 4 grams of lactic acid (concentration 105%) were added to the reaction flask. The reaction bottle was kept stirring in an oil bath with a temperature of 120°C; at the same time, vacuum distillation was carried out with a vacuum degree of 300 Pa. After 4 hours of reaction, no product distilled out of the reaction bottle, and lactide was obtained in the condenser tube, and the lactide yield was 51 %.

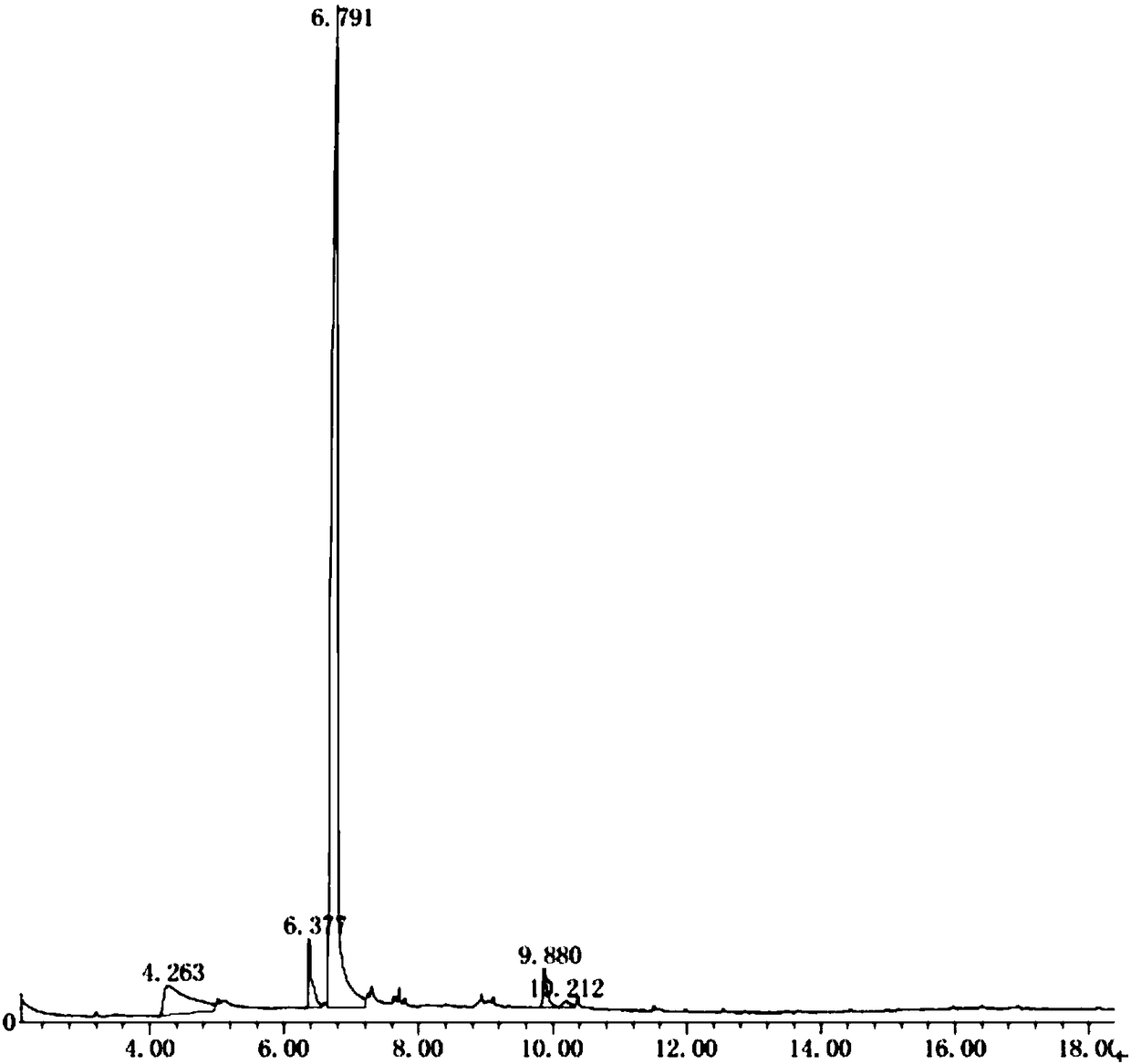

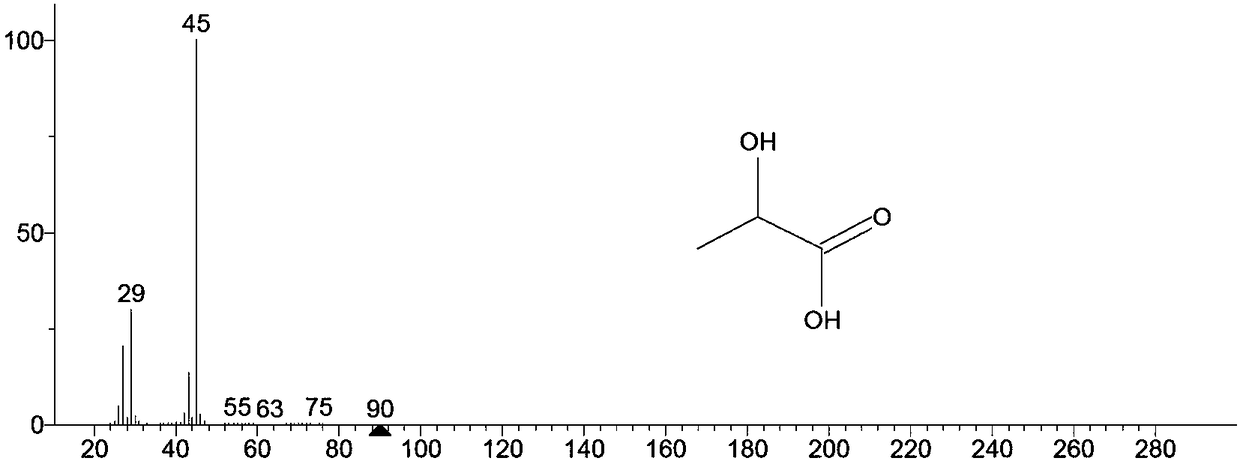

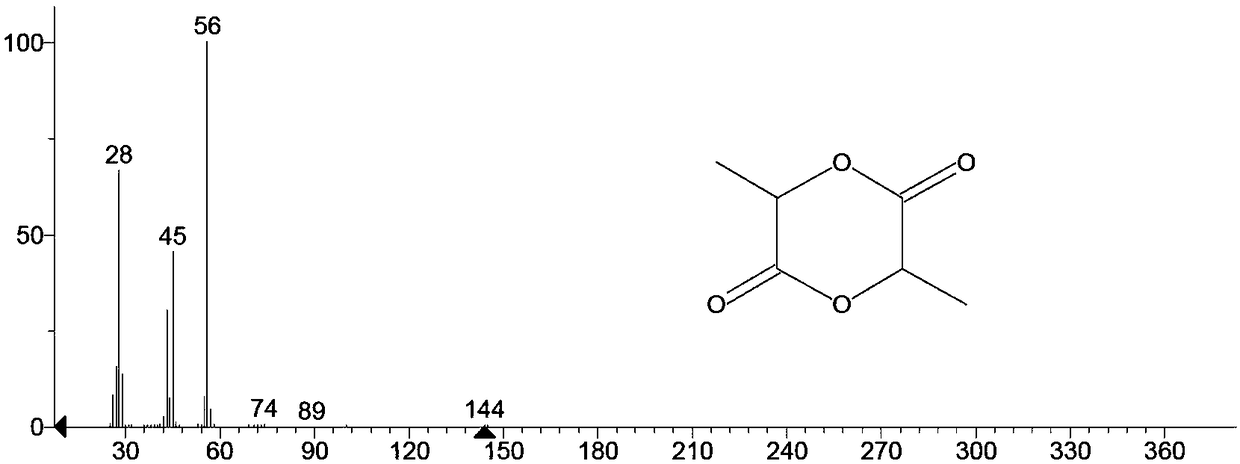

[0044] The result is as figure 1 as shown, figure 1 GC-MS figure for the lactide prepared in Example 2 of the present invention; figure 2 The mass spectrum of lactic acid at a retention time of 4.263 minutes in the GC-MS diagram of lactide prepared in Example 2 of the present invention; image 3 The mass spectrum of racemic lactide at the retention time of 6.377 minutes in the GC-MS chart of the lactide prepared in Example 2 of the present invention; Figure 4 It is the mass spectrum of L-lactide with a ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com