Patents

Literature

97results about How to "Overcoming craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined grouting construction process of reinforcing foundation

InactiveCN1487150AAddress controllabilityAddress reliabilitySoil preservationHigh pressurePressure grouting

The combined grouting construction process of reinforcing foundation includes the following steps: drilling grouting hole; establishing hole top grouting apparatus; high pressure rotary spraying clear water to expand hole; high pressure rotary spraying mortar and static pressure grouting. The present invention combines static pressure grouting technology and high pressure rotary spraying grouting technology with different advantages, so as to reach maximum application range, optimized reinforcing effect, and successive and safe reinforcement.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

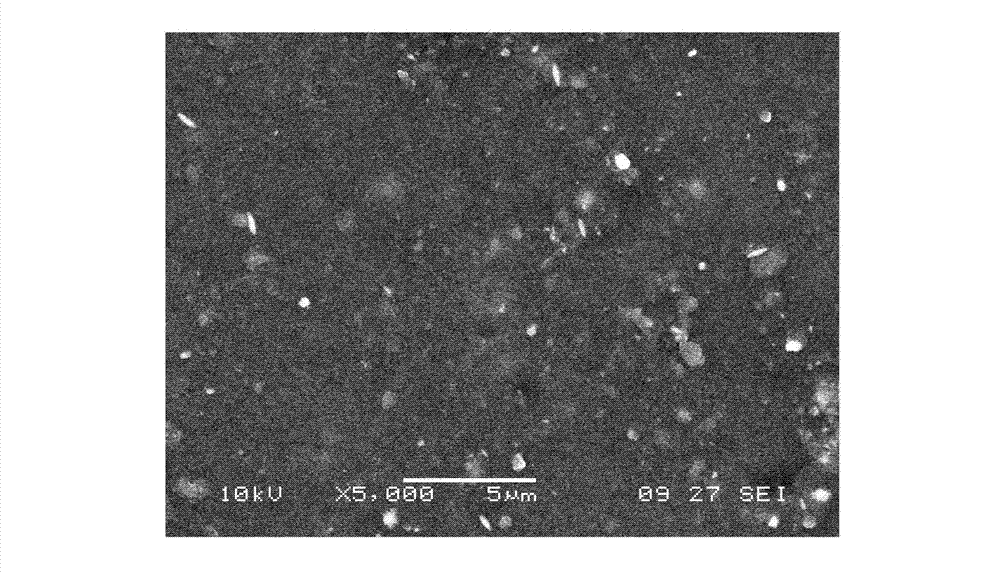

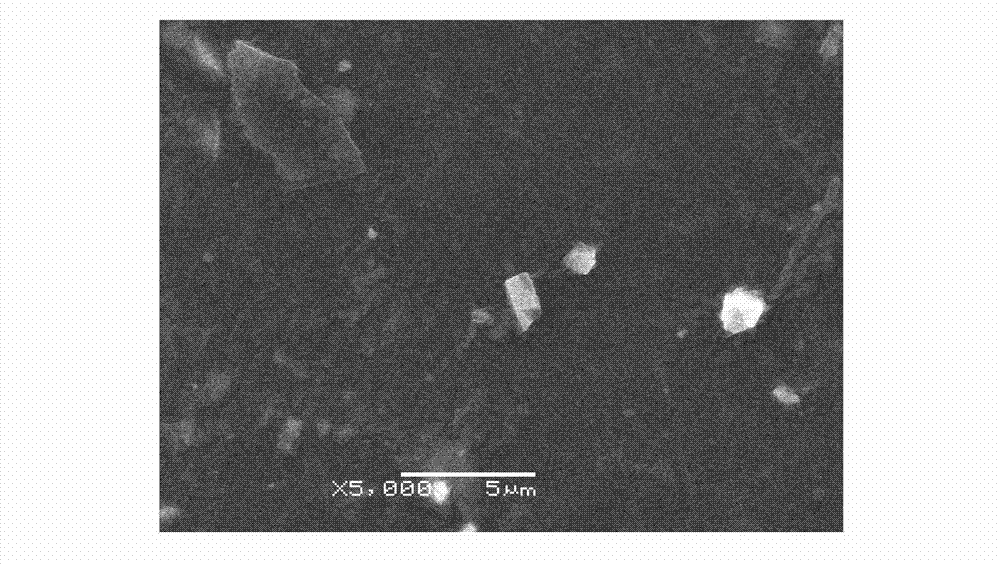

Manufacturing method of inorganic particle filled polyimide film

InactiveCN101805517AUniform and stable dispersionOvercoming dispersionGrain treatmentsOrganic solventInorganic particle

The invention discloses a manufacturing method of an inorganic particle filled polyimide film, in particular to a manufacturing method of an inorganic particle filled polyimide film which adopts a small-sized grinding ball as a grinding medium and also adopts a grinding machine to uniformly and stably disperse inorganic particles into an organic solvent, thereby improving the transparency and mechanical properties of the film. The manufacturing method comprises the following steps: adding a grinding ball with the diameter no more than 6mm into the grinding bucket of a grinding machine with a moving medium, and adding and grinding part of organic solvent, inorganic particles and surfactant until the inorganic particles are uniformly dispersed in the organic solvent, thereby obtaining inorganic particle / organic solvent suspension; adding the inorganic particle / organic solvent suspension, the remaining organic solvent and diamine and dianhydride with identical molar numbers into a reactor, and preparing inorganic particle / polyamic acid solution suspensoid in a conventional method; and preparing the inorganic particle filled polyimide film with the inorganic particle / polyamic acid solution suspensoid according to the production process of the conventional flow casting method. The film has the advantages of good transparency and excellent mechanical properties.

Owner:天津恒通时代电工材料科技有限公司 +1

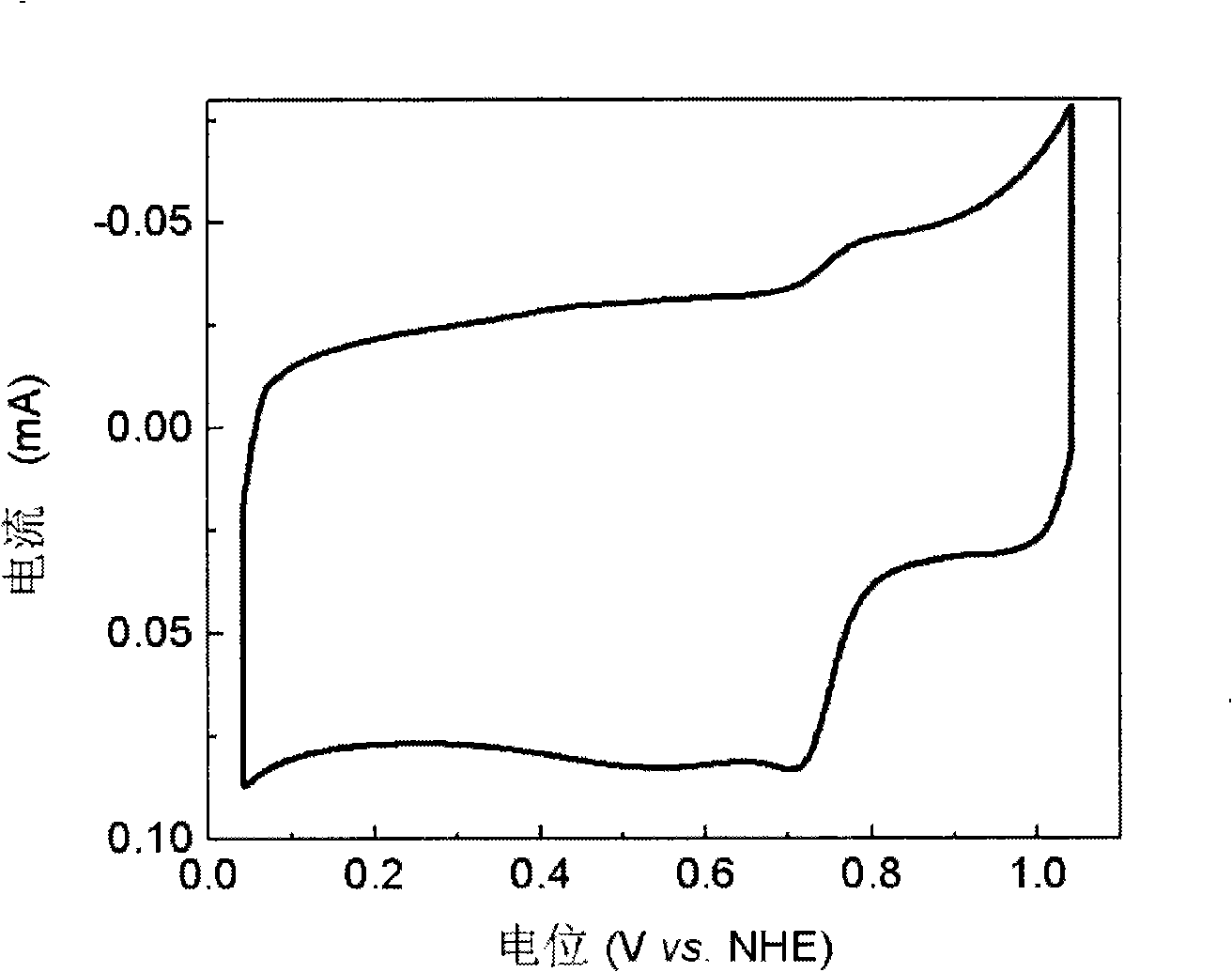

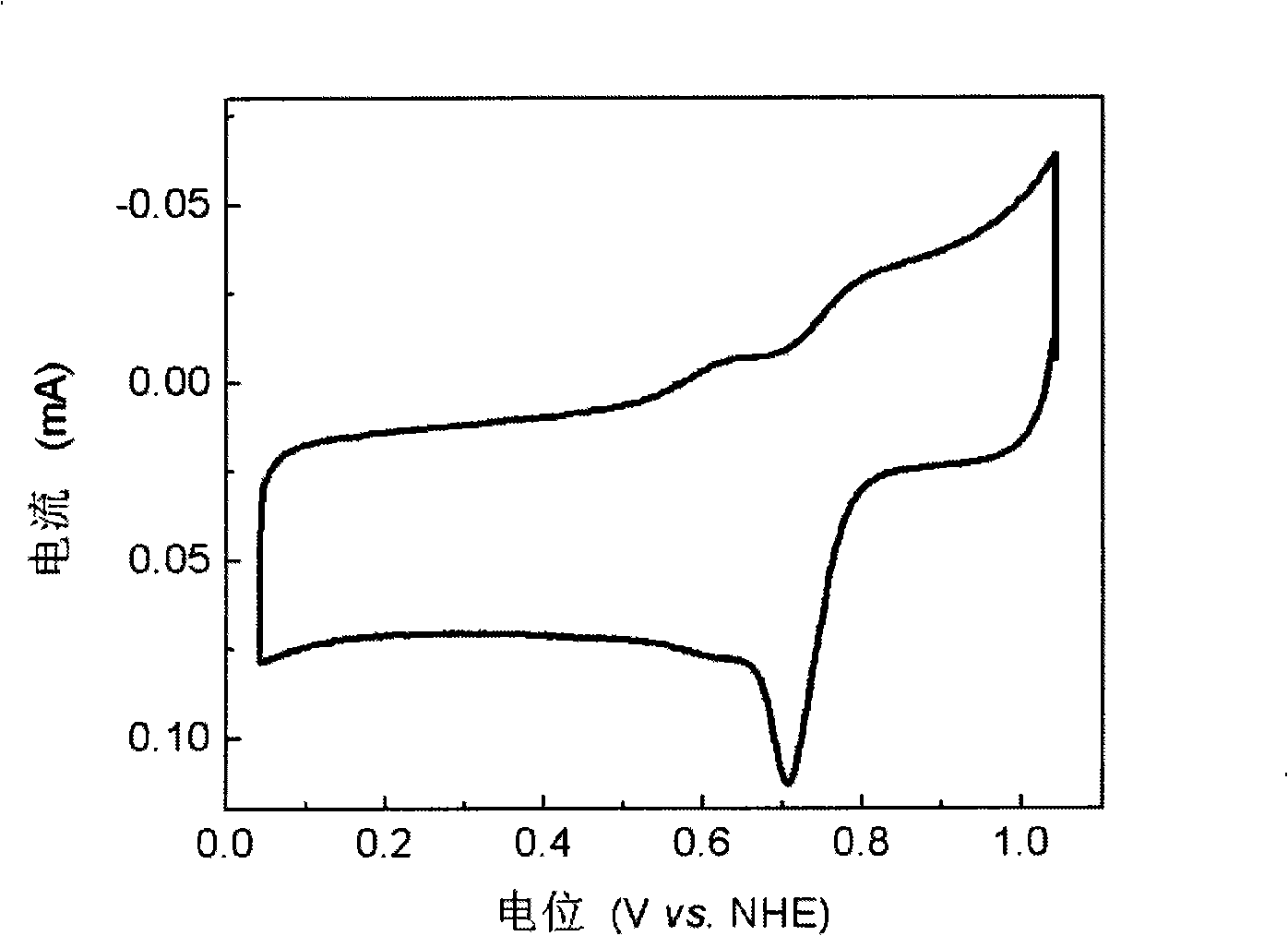

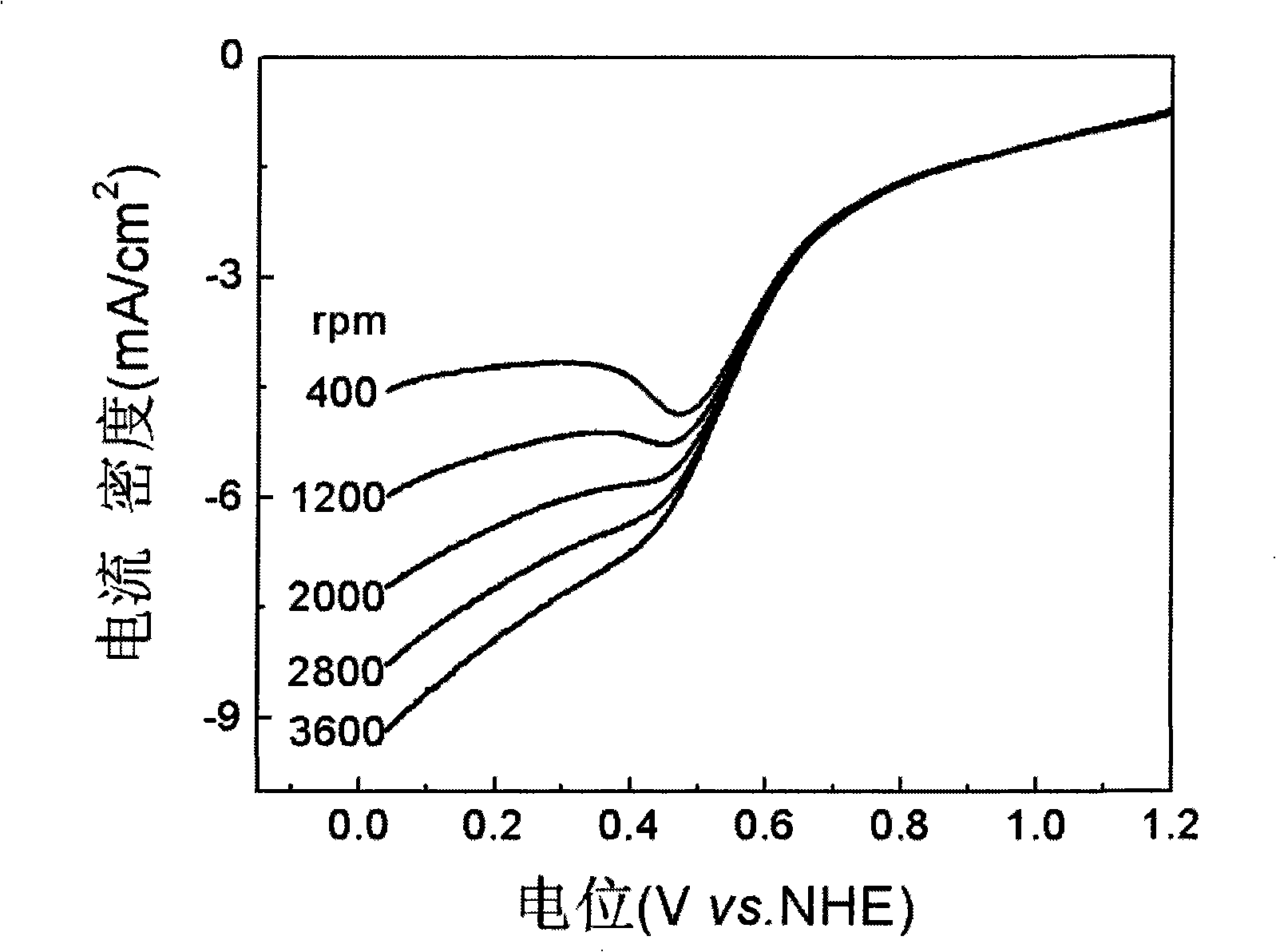

Oxygen reduction catalyst for fuel cell and preparation method thereof

InactiveCN101306385AOvercome costsOvercoming craftOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesPorphyrinPhthalocyanine

The invention discloses a fuel battery used oxygen reduction catalyst and the preparation method thereof, and relates to a loaded catalyst which is composed of a transition metal chelate and a carbon black carrier, wherein, the transition metal chelate is prepared through the reaction of transition metal salt and diethylene triamine. MN3 structure is included in the molecule of the transition metal chelate (M is transition metal and N is nitrogen atom), and an active site is provided for catalyzing the oxygen reduction reaction. The catalyst takes the diethylene triamine with low cost as the raw material; overcomes the problems of the traditional oxygen reduction catalyst of the macrocyclic compound, such as metalloporphyrin and metal phthalocyanine, that the cost of the raw materials is high, and the traditional oxygen reduction catalyst is not suitable for the large scale production industrial production; and has the advantages of simple preparation technology, mild condition, secure process, low cost, and so on. The catalytic performance of the catalyst is equivalent to the oxygen reduction of the metalloporphyrin, the catalytic has good anti carbinol oxygenic property, and can be applied to the oxygen reduction reaction of the cathode of the battery.

Owner:SHANGHAI JIAO TONG UNIV

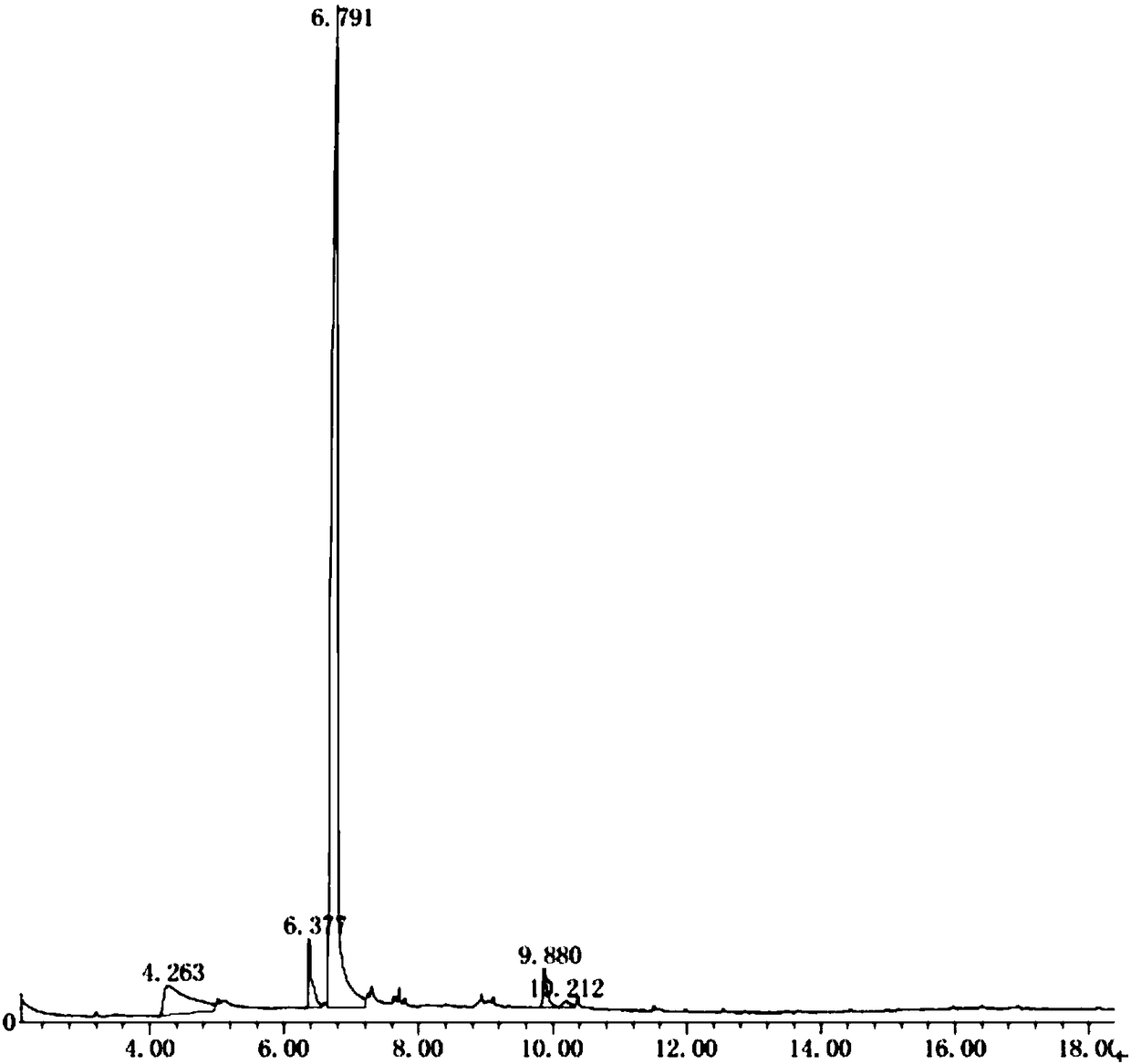

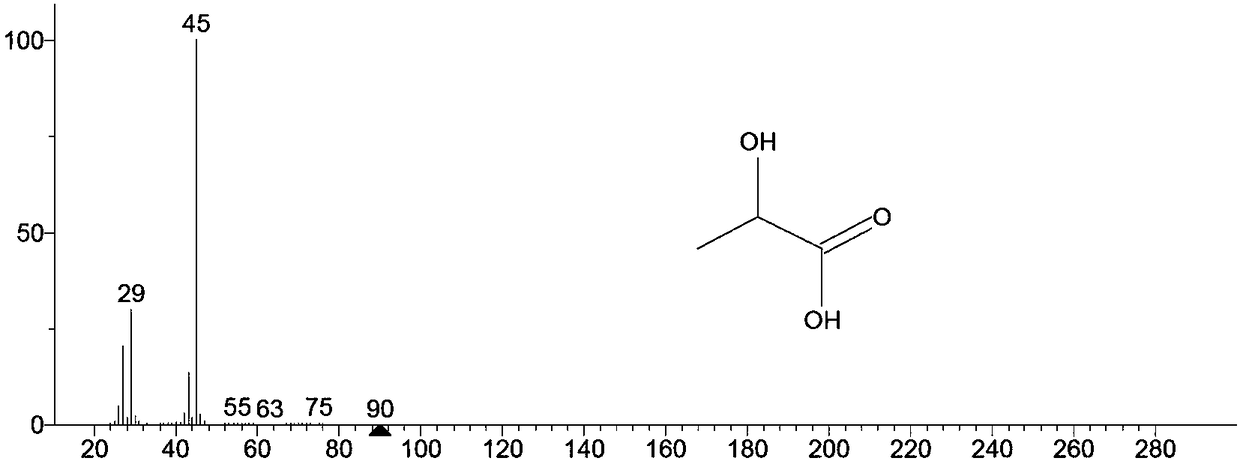

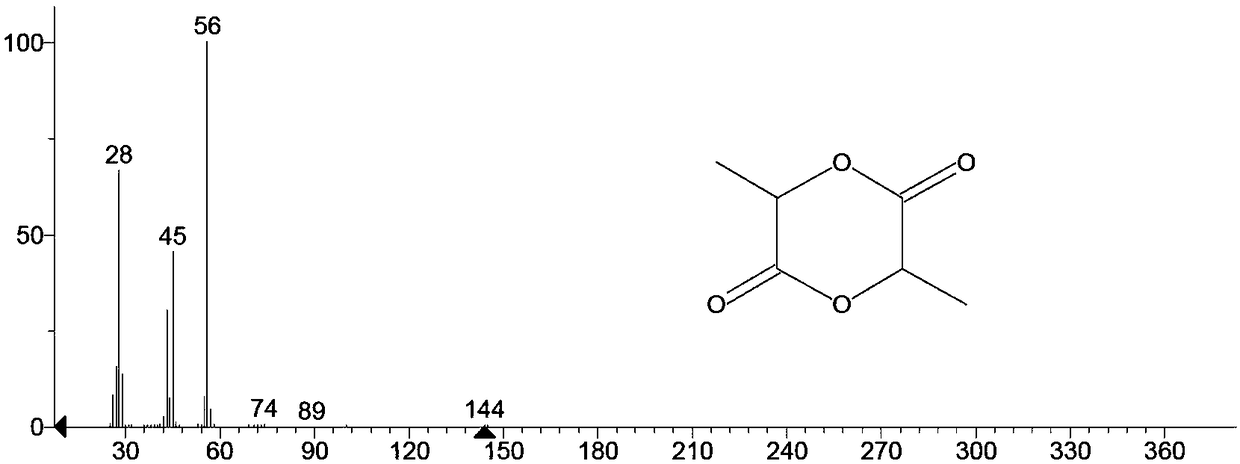

Preparation method of lactide

The invention provides a preparation method of lactide. The method comprises the following step: lactic acid is subjected to a heating reaction under reduced pressure in presence of an H-beta molecular sieve, and lactide is obtained, wherein the reaction pressure is 50-1500 Pa. With adoption of the method adopting vacuum and heating, lactic acid reaction is catalyzed by the H-beta molecular sieve,synthesis of lactide from lactic acid is finished directly, lactide with high optical purity (higher than 96%) is obtained, and the defects of long technological process and high reaction temperaturecaused by the that that oligomerization and high-temperature pyrolysis are needed in the conventional lactide are overcome. No organic solvent is used in the whole preparation process, only wastewater is produced during preparation, and little environmental pollution is caused; the reaction temperature is low, repeated catalysis is realized through hydrolysis of a lactic acid oligomer, the H-betamolecular sieve can be recycled, and the preparation process is simple and environmentally friendly and has potential large-scale application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

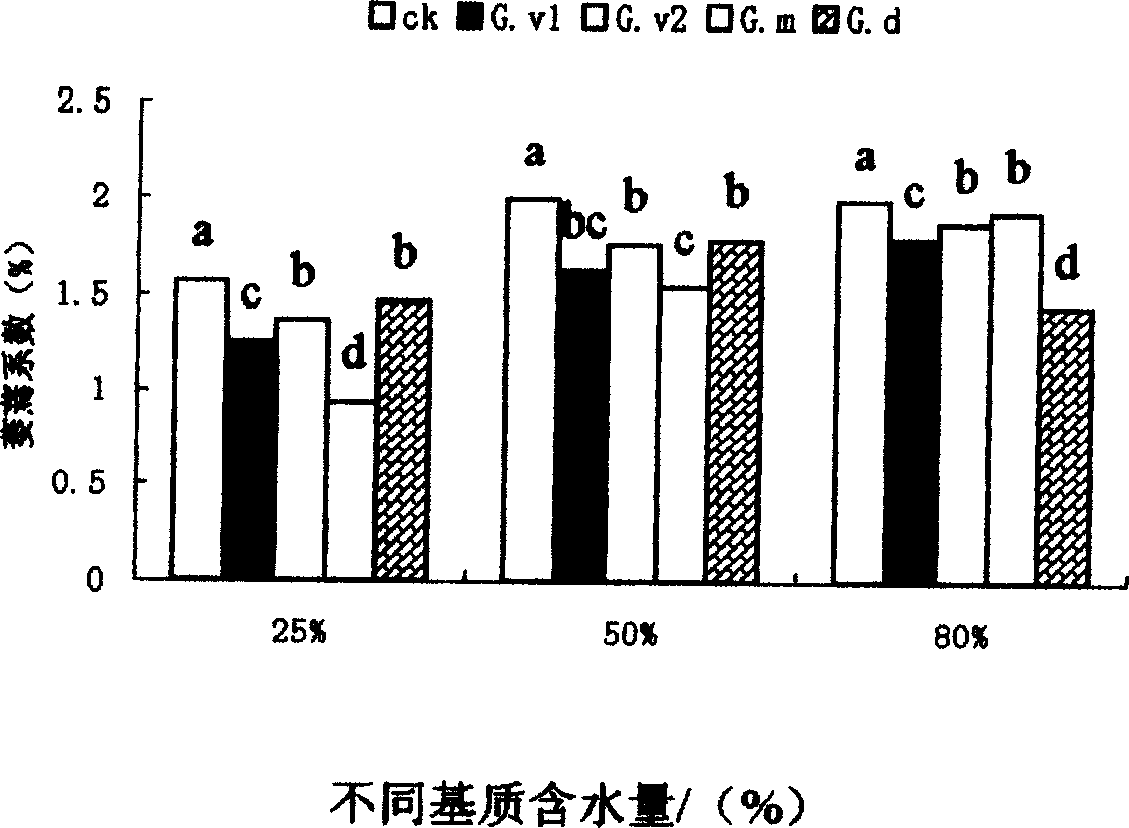

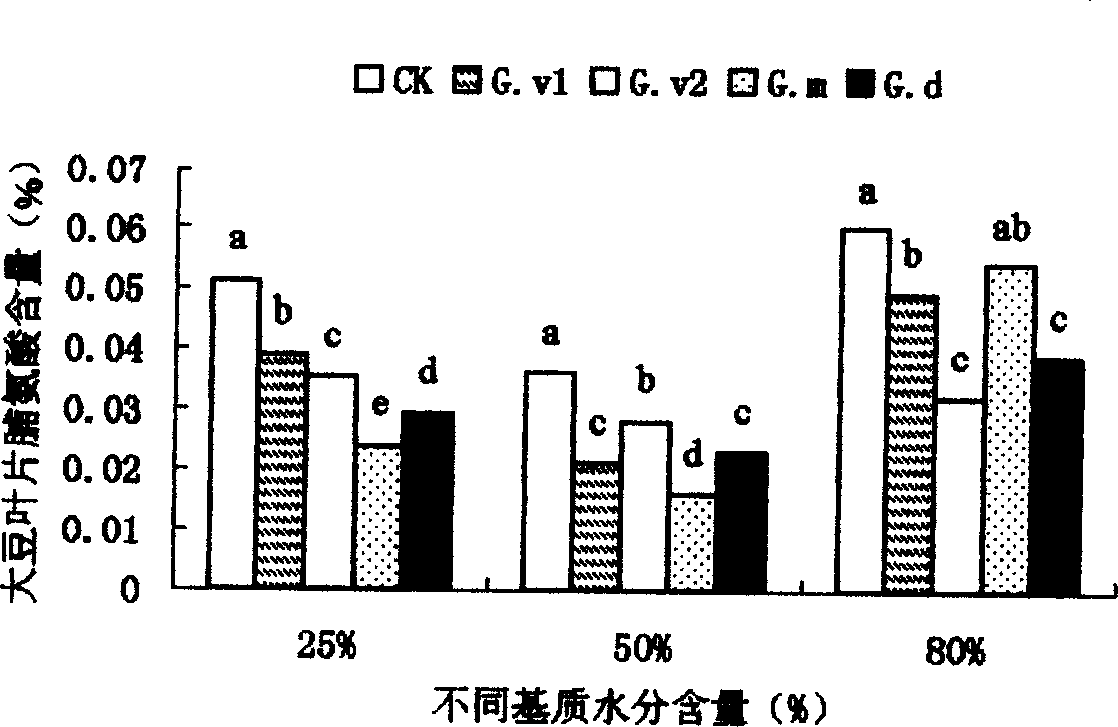

Efficient drought-resisting and high phoshpate-tolerant nutritious bush mycorrhizal fungus and its production process

InactiveCN1548524APromotes nutrient absorptionImprove drought resistanceFungiSymbiotic/parasitic combinationsHigh phosphateBiotechnology

The present invention relates to Glomus mosseae 93-6 as one kind of efficient drought-resisting and high phosphate-tolerant nutrients bush mycorrhizal fungus and its production process. The Glomus mosseae preparation is prepared with kaoliang as host plant, mixture of zeolite and sand as culture medium. The dried preparation contains 40-65 spores in each ml. Glomus mosseae may be grown in various kinds of plants to improve nutrients absorption, raise drought resistance and promote growth of plant. Test shows that the present invention has excellent seedling strengthening and yield increasing effect on straw berry, rice, water melon and other crops.

Owner:北京市农林科学院植物营养与资源研究所 +1

Method for separating and extracting cholesterol in lanolin alcohol

InactiveCN101817859AAvoid disadvantages such as being vulnerable to damageLight colorSteroidsLanosterolDistillation

The invention relates to a method for separating and extracting cholesterol in lanolin alcohol, which comprises the following steps: carrying out molecular distillation on lanolin alcohol, collecting the light-phase fraction which is refined lanolin alcohol, heating the refined lanolin alcohol in a mixed solvent of methanol and acetone until the refined lanolin alcohol is completely dissolved, and cooling to cooling temperature, wherein the remainder of the filtrate after reduced pressure distillation is the primary concentrate of cholesterol; heating to dissolve the primary concentrate of cholesterol in acetone, cooling to precipitate, filtering, and carrying out reduced pressure distillation on the filtrate to recover the solvent, wherein the balance is the secondary concentrate of cholesterol; heating to dissolve the secondary concentrate of cholesterol in an alcohol solvent, cooling to cooling temperature, keeping the temperature for 6-12 hours, and vacuum-filtering to obtain the white acerose cholesterol crude product; and recrystallizing the cholesterol crude product through a methanol-acetone mixed solvent to obtain the refined cholesterol product. The refined cholesterol product selectively recrystallizes through the solvent to obtain the byproduct lanosterol accounting for 63-70% and the cholesterol product of which the purity is more than 90%.

Owner:TIANJIN UNIV

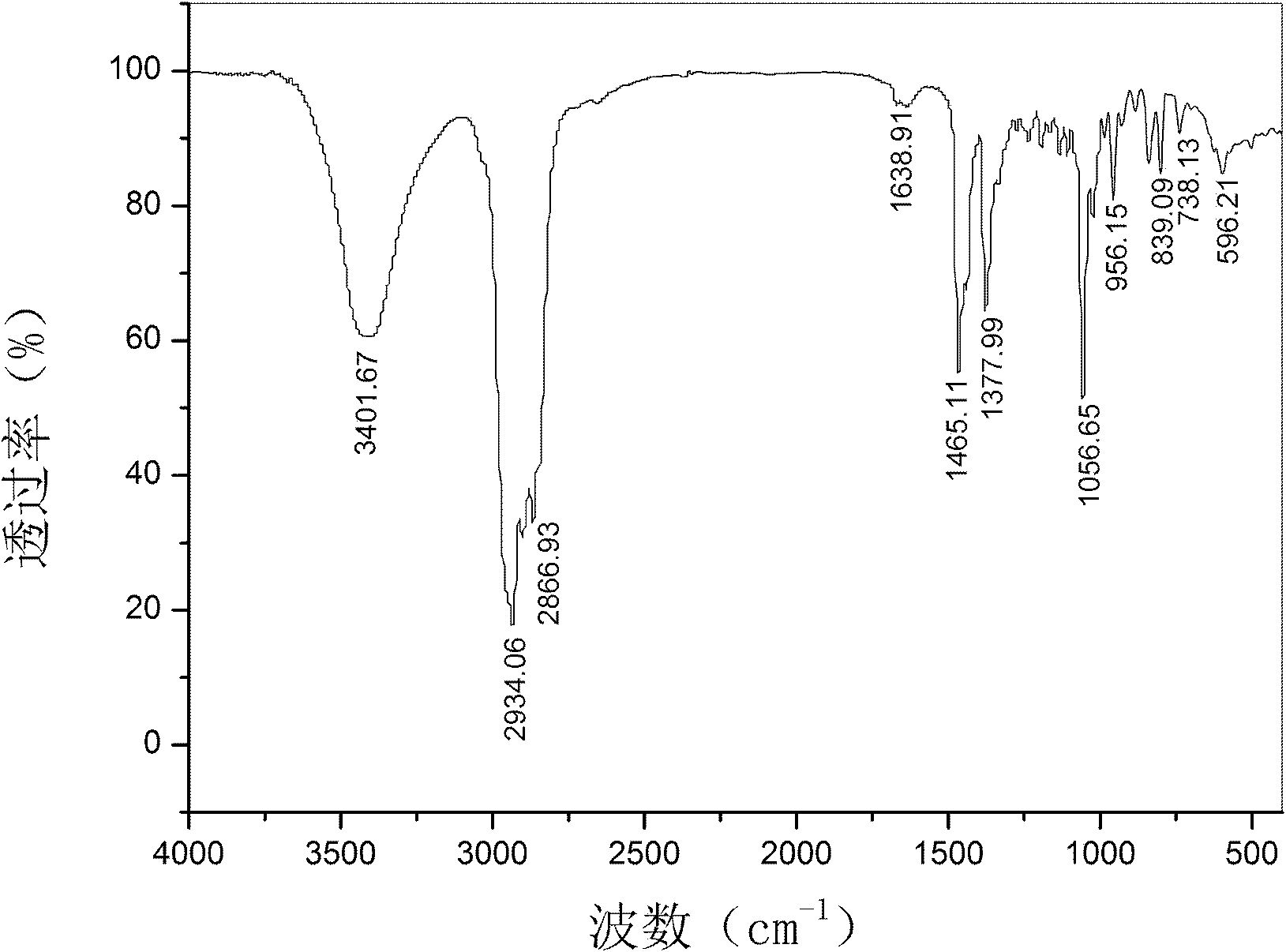

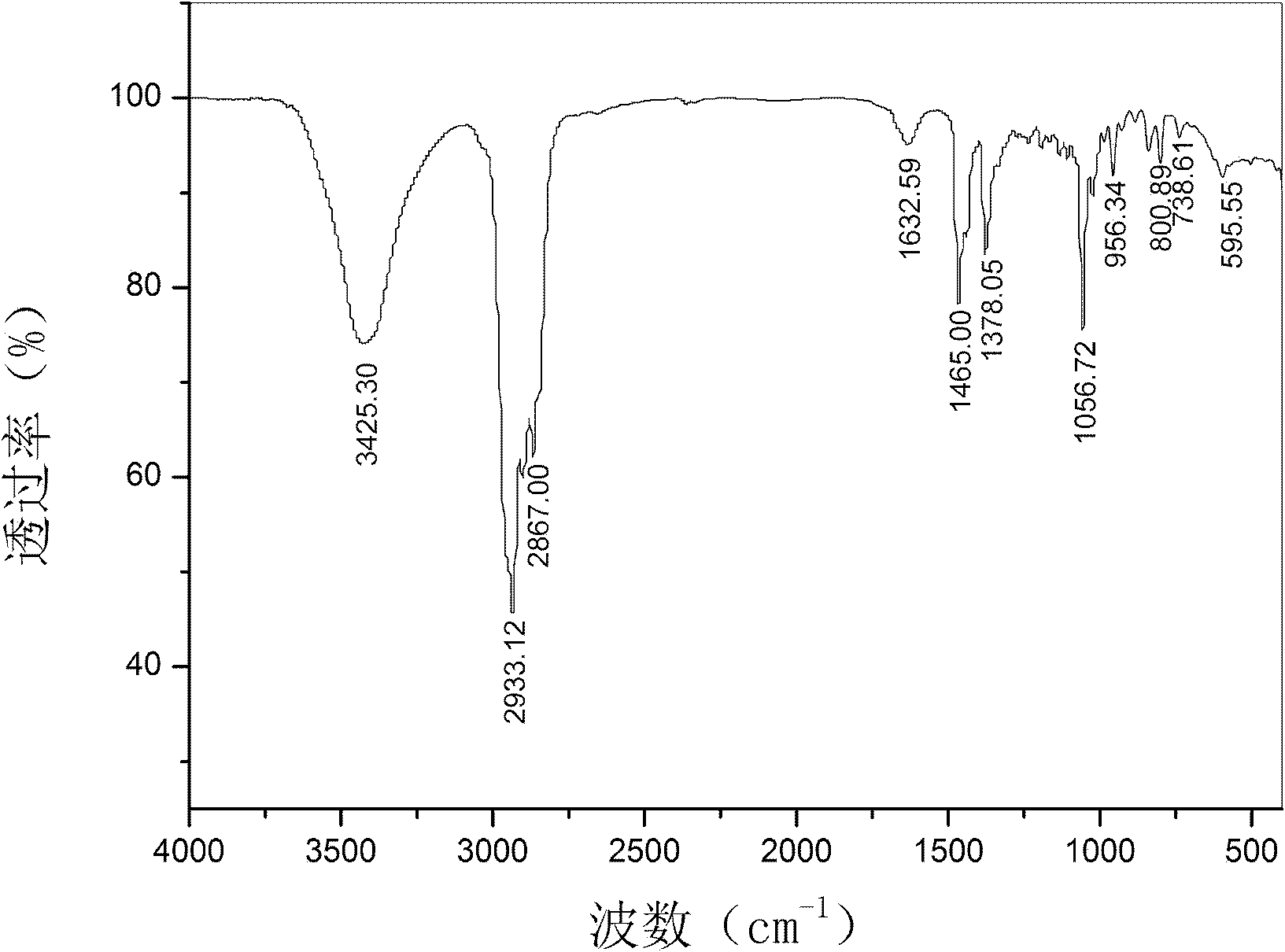

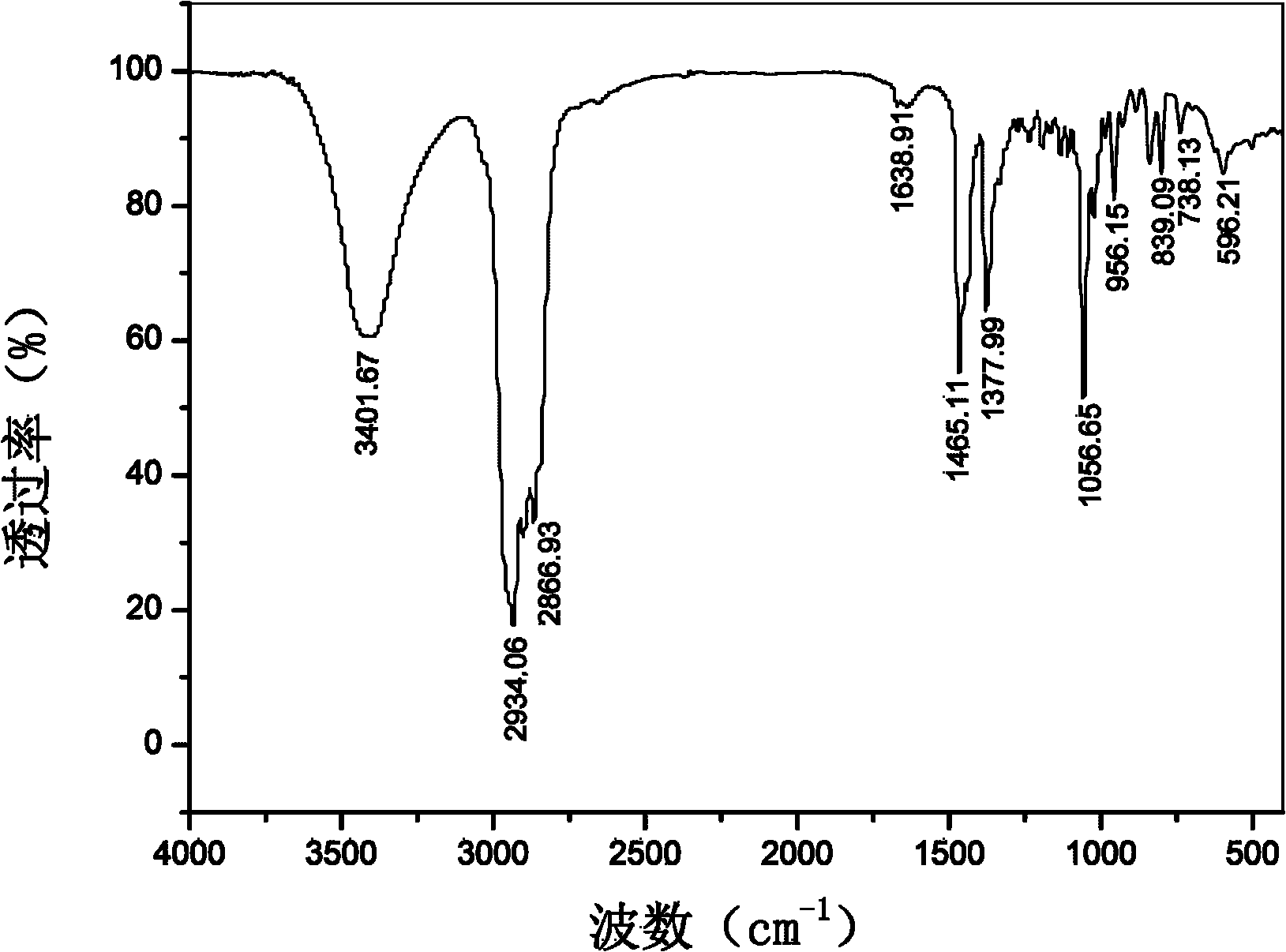

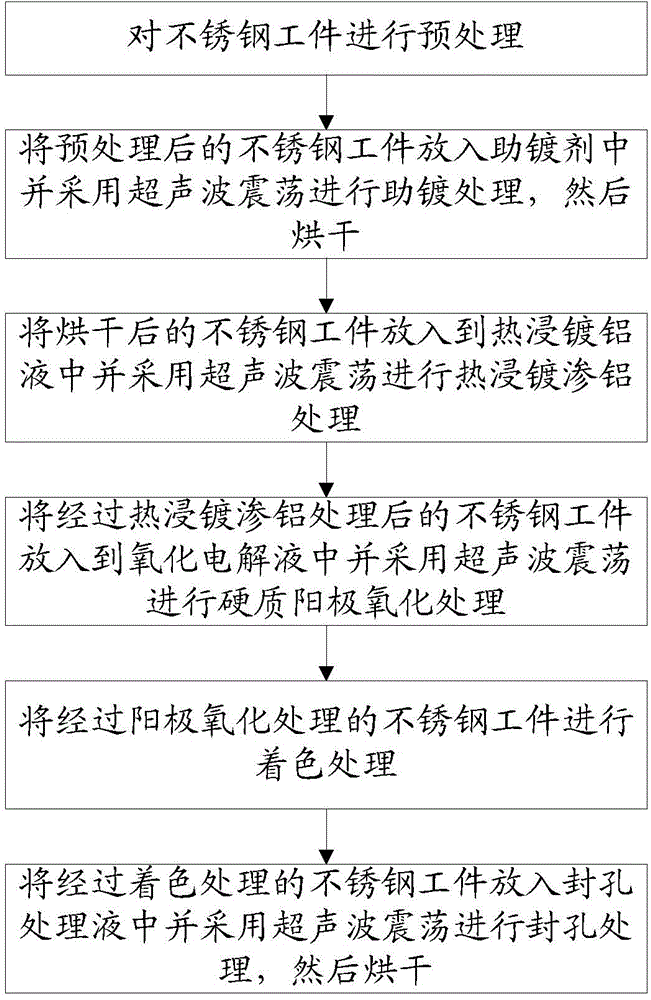

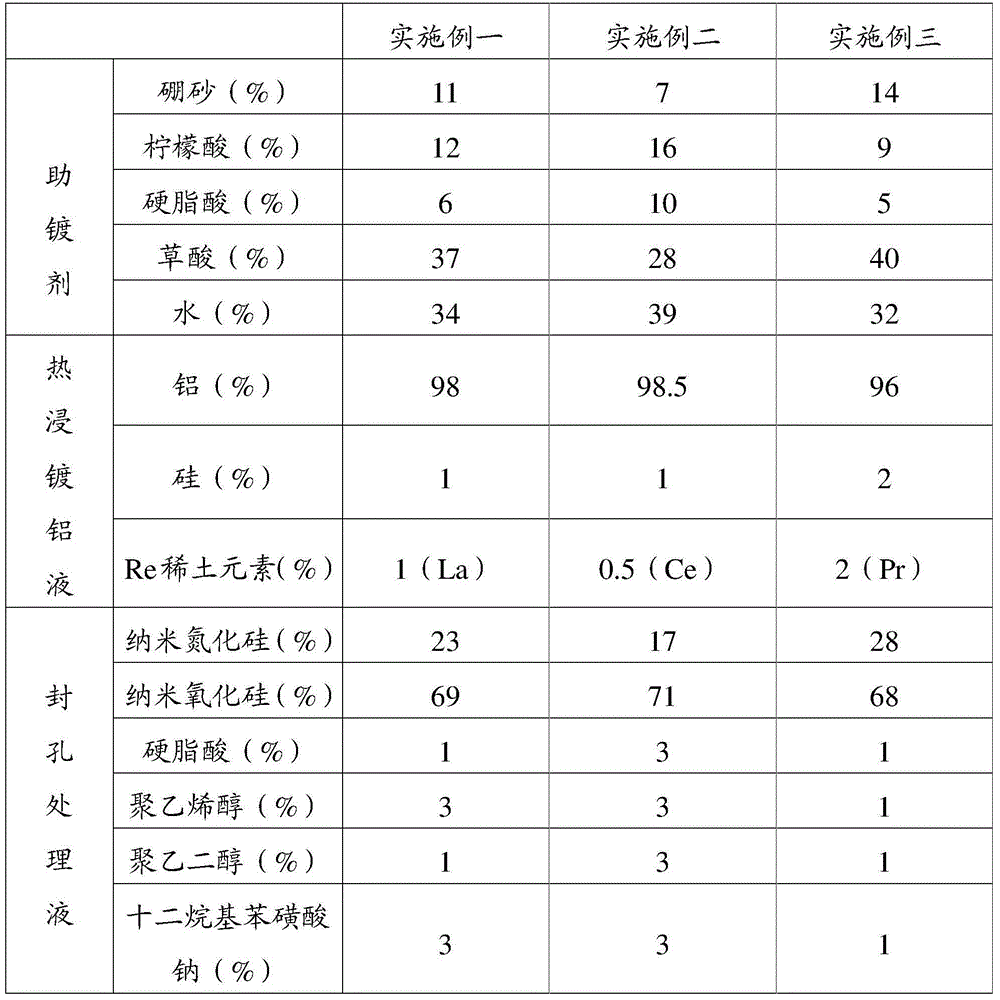

Stainless steel surface treatment method and stainless steel watch shell

ActiveCN105274519AFully processedQuality improvementHot-dipping/immersion processesAnodisationAnodizingPre treatment

The invention discloses a stainless steel surface treatment method and a stainless steel watch shell. The stainless steel surface treatment method includes the following steps that S1, pretreatment is conducted on a stainless steel workpiece; S2, the stainless steel workpiece is put into a plating assistant agent, and plating assistant treatment is conducted through ultrasonic oscillation; S3, the stainless steel workpiece is put into hot-dip aluminum plating liquid, and hot-dip plating and aluminizing treatment is conducted through ultrasonic oscillation; S4, the stainless steel workpiece is put into oxidization electrolyte, and hard anodizing treatment is conducted through ultrasonic oscillation; S5, color coated treatment is conducted on the stainless steel workpiece; and S6, the stainless steel workpiece is put into hole sealing treatment liquid, hole sealing treatment is conducted through ultrasonic oscillation, and then the stainless steel workpiece is dried. By means of the stainless steel surface treatment method, the defects that by means of an existing ion plating method, the bonding force of an aluminum plating layer and a stainless steel base body is poor, and if base transition layer film coating is adopted, the process cost is increased, and high process cost caused by the fact that time is seriously consumed due to ion plating of thick films are overcome.

Owner:ZHUHAI ROSSINI WATCH IND

Cross-linked polypropylene composite material and preparation method thereof

InactiveCN102070837AOvercome warm waterOvercoming craftPlastic/resin/waxes insulatorsPolypropylene compositesPolymer science

The invention discloses a cross-linked polypropylene composite material. The cross-linked polypropylene composite material is prepared by mixing polypropylene, an initiator, a cross-linking agent, a self-cross-linking promoter, a catalyst, a primary antioxidant, an auxiliary antioxidant and other processing aids according to a certain proportion. A preparation method of the cross-linked polypropylene composite material comprises the following steps of: weighing other components except the self-cross-linking promoter and the cross-linking catalyst according to the proportion first, fully mixing in a mixing kettle, and then adding into a twin-screw extruder from a feeding port; and adding the self-cross-linking promoter and the cross-linking catalyst into the twin-screw extruder from a side port of a screw, and then extruding and pelleting to obtain the cross-linked polypropylene composite material, wherein the adding of the self-cross-linking promoter from the side port of the screw is delayed, so that silane is grafted on polypropylene first and then reacts with the self-cross-linking promoter to form preliminary cross-linked polypropylene. The invention has the advantages of overcoming a warm water or steam cross-linking process in the conventional silane cross-linked polypropylene, realizing one-step continuous production, meeting the requirement of injection molding, and solving the problem that the subsequent processing cannot be performed by a radiation cross-linking method, along with excellent mechanical property.

Owner:KINGFA SCI & TECH CO LTD +2

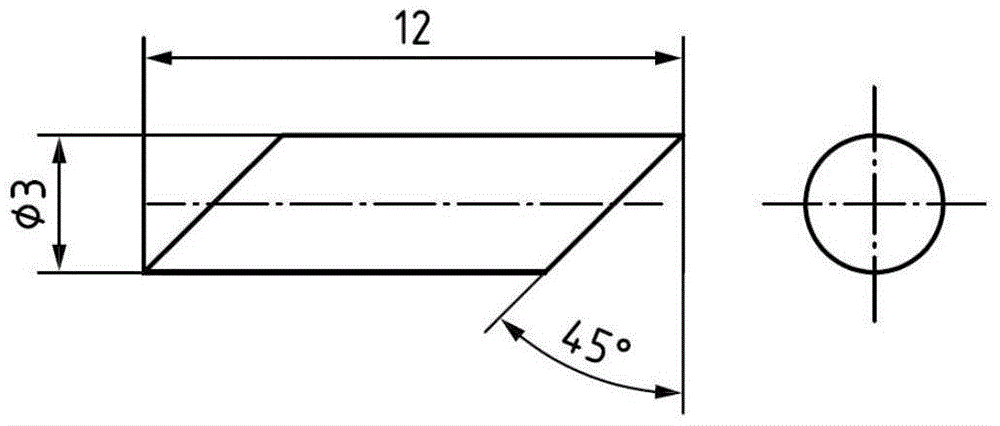

MEMS (Micro-Electro-Mechanical Systems) processing technique-based cylindrical capacitive sensor

InactiveCN102607394AReduce edge effectsHigh measurement accuracyDecorative surface effectsUsing electrical meansCapacitanceCopper electrode

The invention discloses an MEMS processing technique-based cylindrical capacitive sensor. The MEMS processing technique-based cylindrical capacitive sensor comprises a rotary spindle electrode and a cylindrical fixed electrode coaxially mounted on the outside of the rotary spindle electrode; in the rotary spindle electrode, a first insulating layer, a copper spindle electrode and a second insulating layer outwardly and sequentially wrap the outer cylindrical surface of a spindle; and in the cylindrical fixed electrode, a third insulating layer, an equipotential protective ring, a fourth insulating layer and four arc-shaped electrodes equidistantly embedded in the inner circle of the fourth insulating layer are inwardly and sequentially wrapped in the cylindrical hole of an electrode base. The MEMS processing technique can be adopted to process the electrodes to be ultrathin, the complex processing and assembly process of the main conventional method in producing the cylindrical capacitive sensor can be overcome, the size of the sensor is reduced, moreover, the edge effect of the sensor can be inhibited as well, and the cylindrical capacitive sensor is suitable for monitoring the rotation error of the spindle. Due to the technique, the miniaturized cylindrical capacitive sensor can be easily produced, and the sensor can also be easily produced in batches.

Owner:ZHEJIANG UNIV

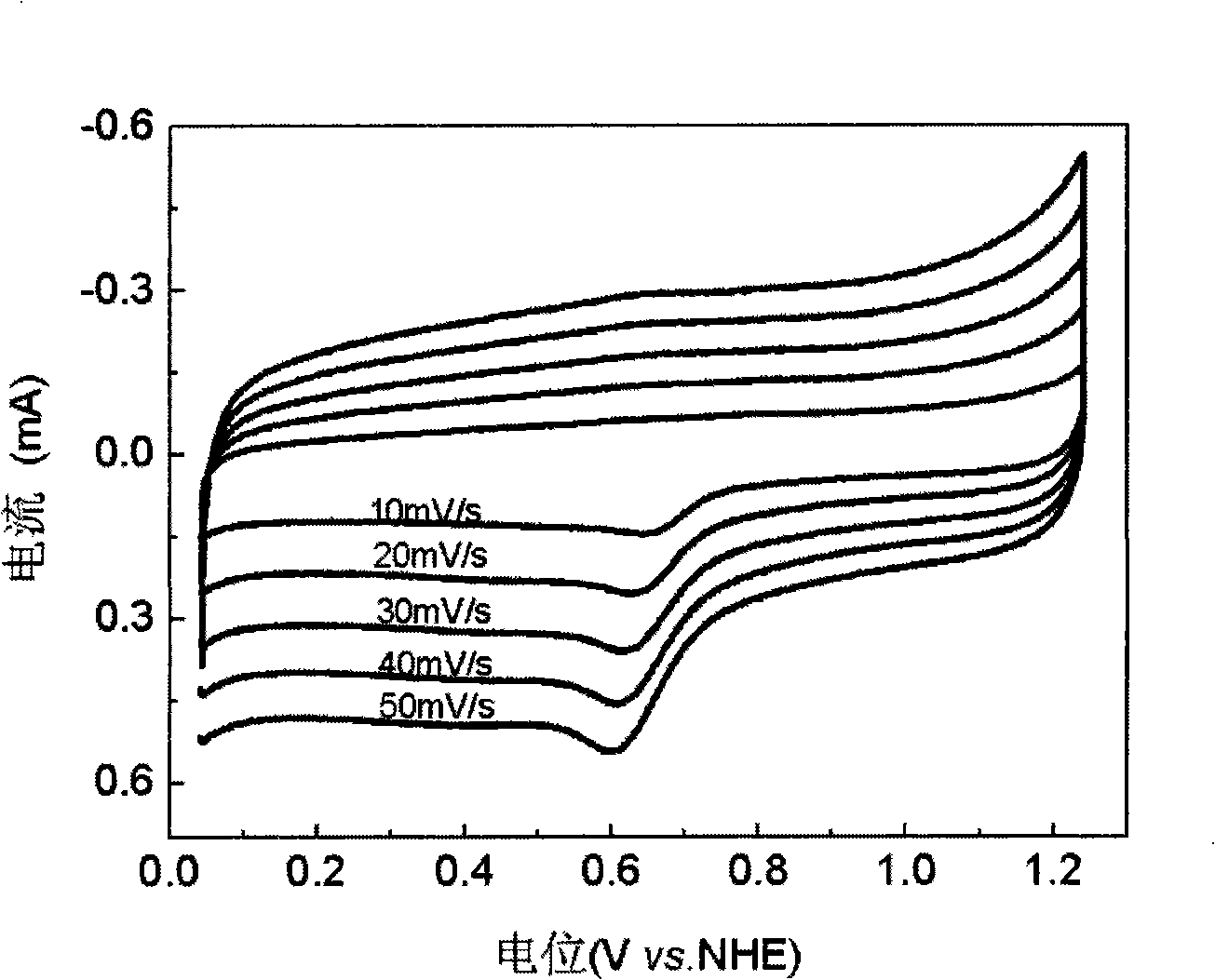

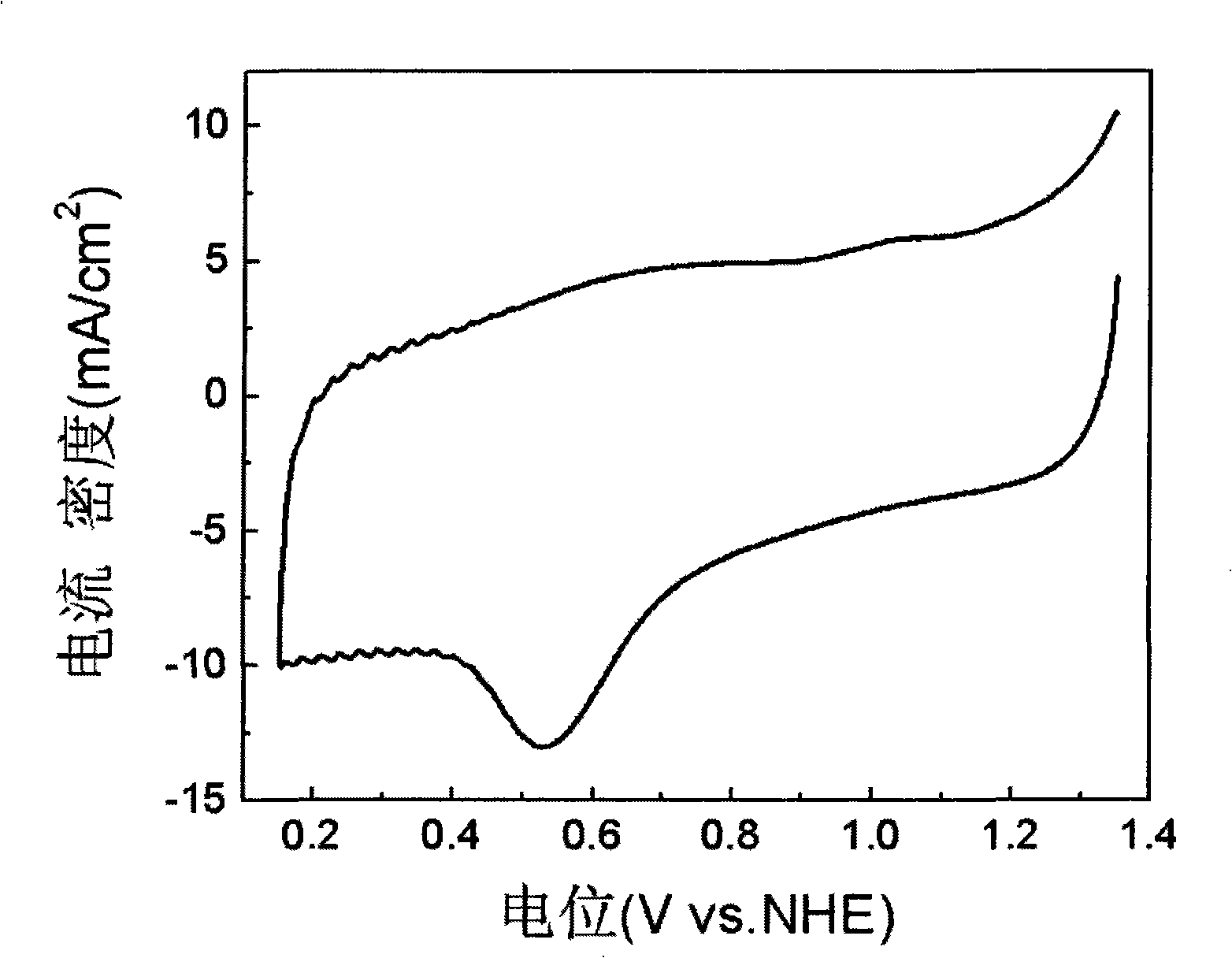

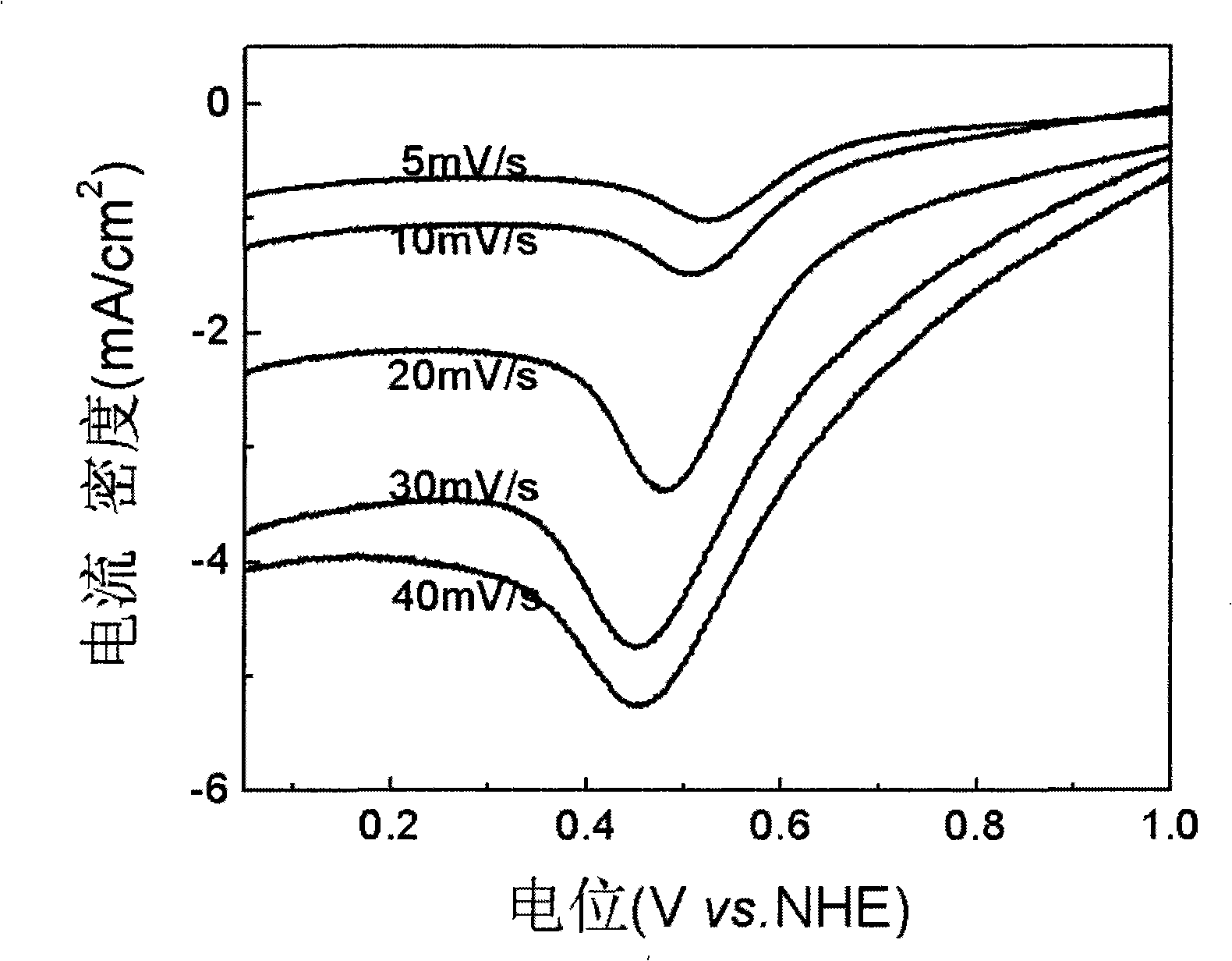

Oxygen reduction electrocatalyst and preparation thereof

InactiveCN101259437AReduce manufacturing costOvercome costsCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsAlcohol fuelPorphyrin

The invention discloses an oxygen reduction electrocatalyst and a preparation method thereof, which is a load type catalyst and consists of a transition metal triethylene tetramine chelate complex and a carbon black carrier; wherein, the transition metal triethylene tetramine chelate complex is obtained by the reaction of transition metal-salt and triethylene tetramine. The oxygen reduction electrocatalyst of the invention uses the triethylene tetramine having simple structure and low cost, which overcomes the defects of traditionally used macrocyclic compound porphyrin and Phthalocyanine and derivatives thereof and has simple preparation technique, low cost, friendly environment and a better catalytic activity; a oxygen reduction peak potential is 0.6745 (vs. NHE) and a oxygen reduction peak current is 1.493mA / m<2>; stability is relatively high, and oxygen reduction catalytic performance is not obviously reduced after recycling for 24 hours. The oxygen reduction electrocatalyst of the invention can be applied to the fields of proton exchange membrane fuel batteries, direct alcohol fuel cells, and cathode materials of metal-air battery, etc.

Owner:SHANGHAI JIAO TONG UNIV

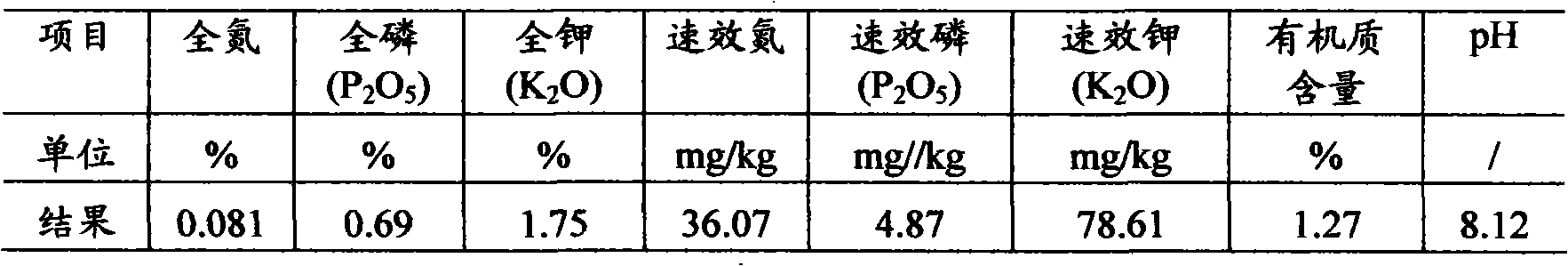

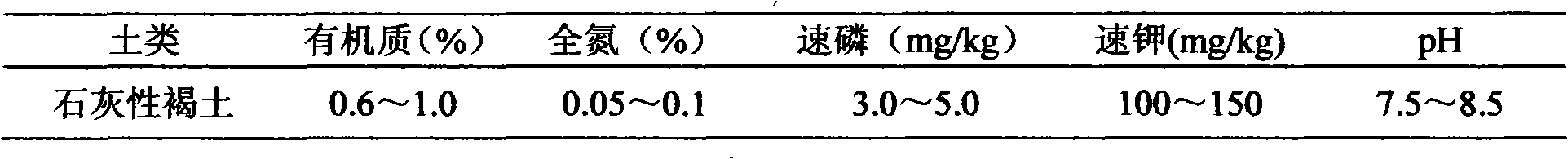

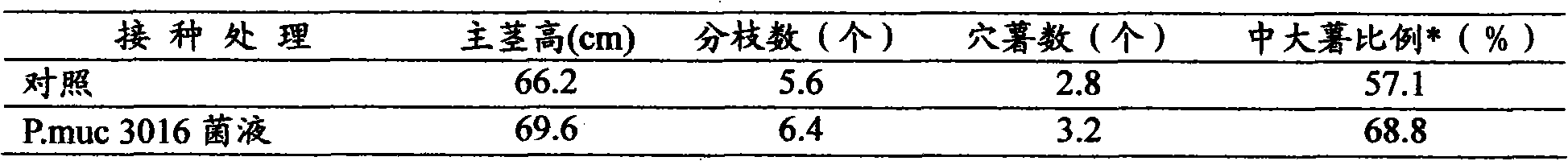

Bacillus mucilaginosus and culture method and culture medium thereof

InactiveCN101967456AOvercoming craftOvercoming complexityBacteriaMicroorganism based processesBiotechnologyDipotassium hydrogen phosphate

The invention relates to a kind of Bacillus mucilaginosus and a culture method and culture medium thereof, belonging to the microbiological technical field. The Bacillus mucilaginosus P.muc3016 has the functions of nitrogen fixation, phosphorus-dissolving and potassium-releasing and belongs to the Paenibacillus group. The batch fermentation method is adopted to ferment and culture the Bacillus mucilaginosus and the concentrations of carbon source and dissolved oxygen are monitored and regulated. The culture medium contains carbon source, soybean meal powder, ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, calcium sulfate and calcium carbonate, and the pH value of the culture medium is 7.5-7.0. The Bacillus mucilaginosus of the invention has three functions of nitrogen fixation, phosphorus-dissolving and potassium-releasing simultaneously, has higher function activity and can obviously increase the crop yield; and by adopting the culture method and culture medium of the invention, the fermentation density can be increased and the fermentation time can be shortened.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

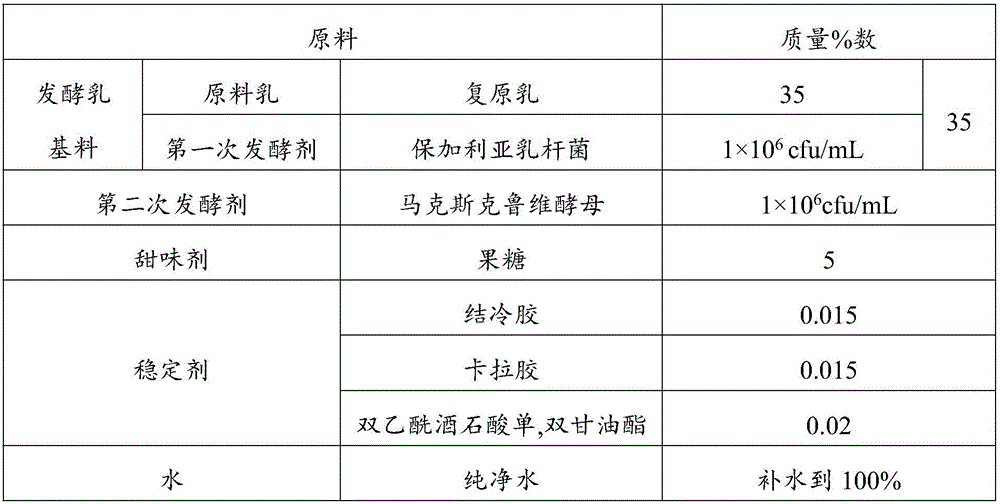

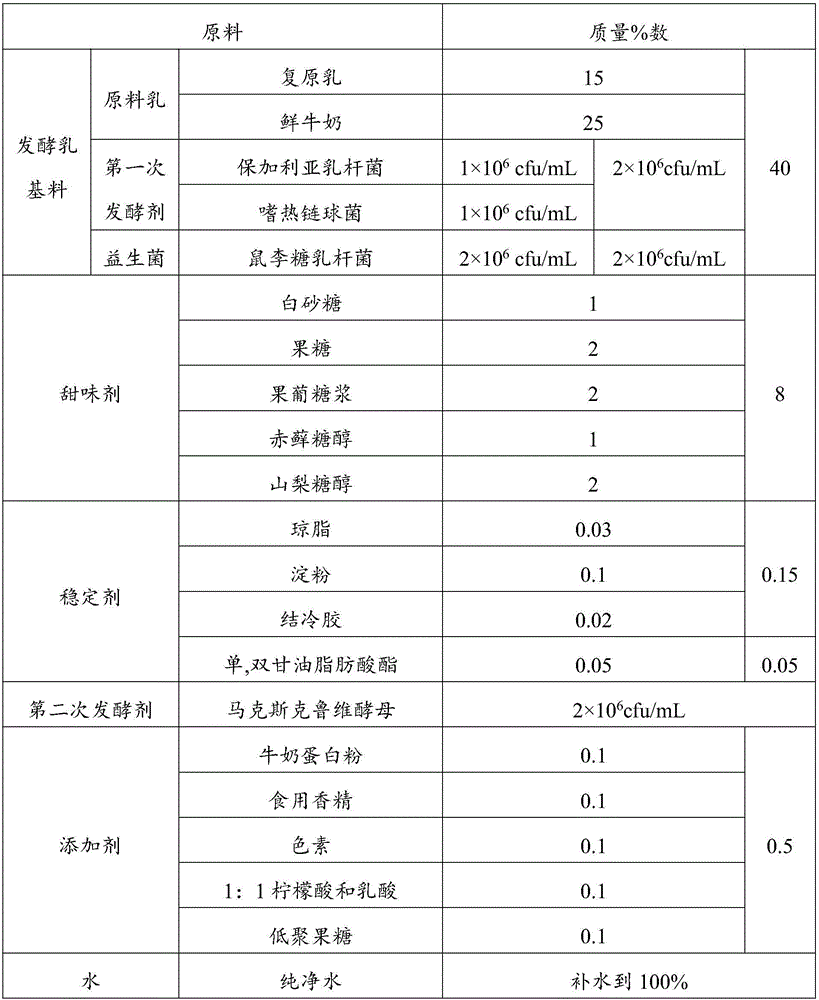

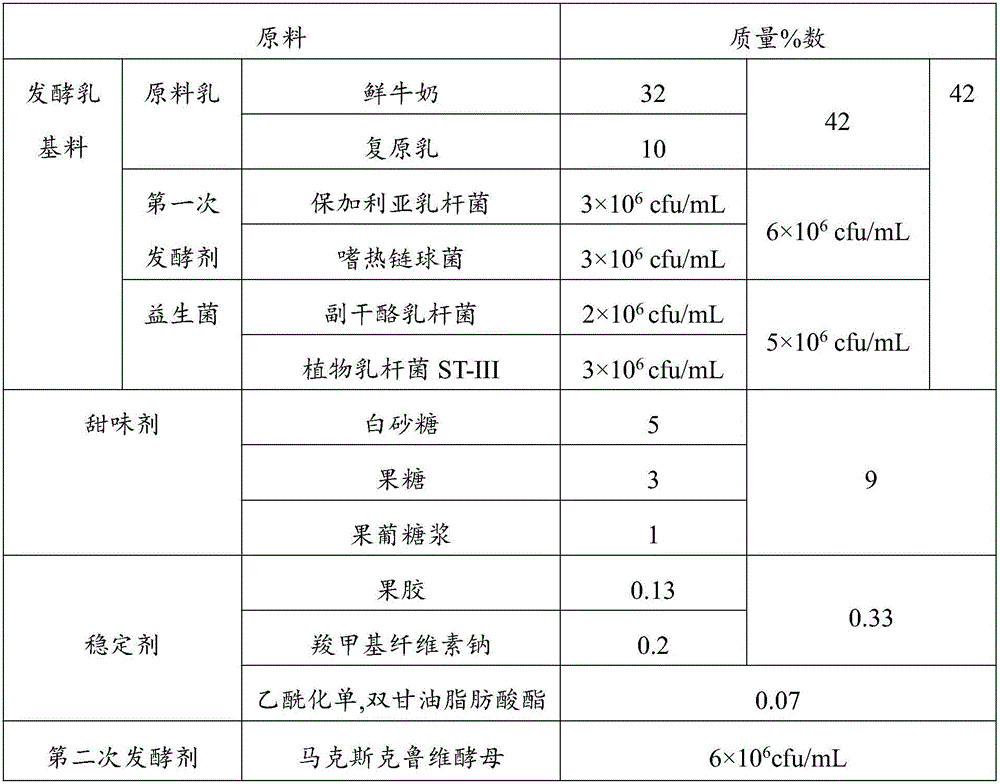

Raw material composition of fermented milk beverage, as well as fermented milk beverage and preparation method thereof

The invention discloses a raw material composition of a fermented milk beverage. The raw material composition comprises the following raw materials in percentage by mass: 35-60% of a fermented milk base material, 0.05-1% of a stabilizing agent, 5-15% of a sweetening agent and the balance of water, wherein the fermented milk base material is prepared through fermentation of raw material milk and lactic acid bacteria, and the stabilizing agent comprises the following components of (a) one, or two or more of sodium carboxymethyl cellulose, propylene glycol alginate, pectin, agar, starch, carrageenin and gellan gum; and (b) one, or two or more of mono(di)glycerin fatty acid ester, acetylated mono(di)glycerin fatty acid ester, and diacetyl tartaric acid ester of mono(di)glycerides. The raw material composition of the fermented milk beverage provided by the technical scheme of the invention is used as a raw material, and kluyveromyces lactis (kluyveromyces lactis) is added for fermentation, so that a gas-containing fermented milk beverage is made. The fermented milk beverage is subjected to secondary fermentation of lactic acid bacteria and microzymes, contains gas produced by natural fermentation, and is high in irritating mouth feel, unique in flavor, and good in stability.

Owner:BRIGHT DAIRY & FOOD

Split die vacuum bag-autoclave forming method of irregular composite material

To solve the problems in the prior art that the surface quality and the shape of a non-adhered die plane need to be completed and accomplished through processes of mechanical machining, polishing, painting and the like in the vacuum bag-autoclave forming process, the invention provides a split die vacuum bag-autoclave forming method of irregular composite materials. A lower die and an upper die are manufactured according to the appearance size and the shape of a composite material part to be formed; a raw rubber sheet layer is paved on the split plane of the upper die and the lower die; and the thickness of the raw rubber layer meets the requirement that the sum of the rubber thickness of the vulcanized raw rubber and the height of the forming chamber of the die is equal to the thickness of the composite material part to be formed. The method has the beneficial technical effects that advantages that the vacuum bag-autoclave forming process is high in density and uniform in distribution and the die forming process is accurate in appearance size and shape are both considered.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

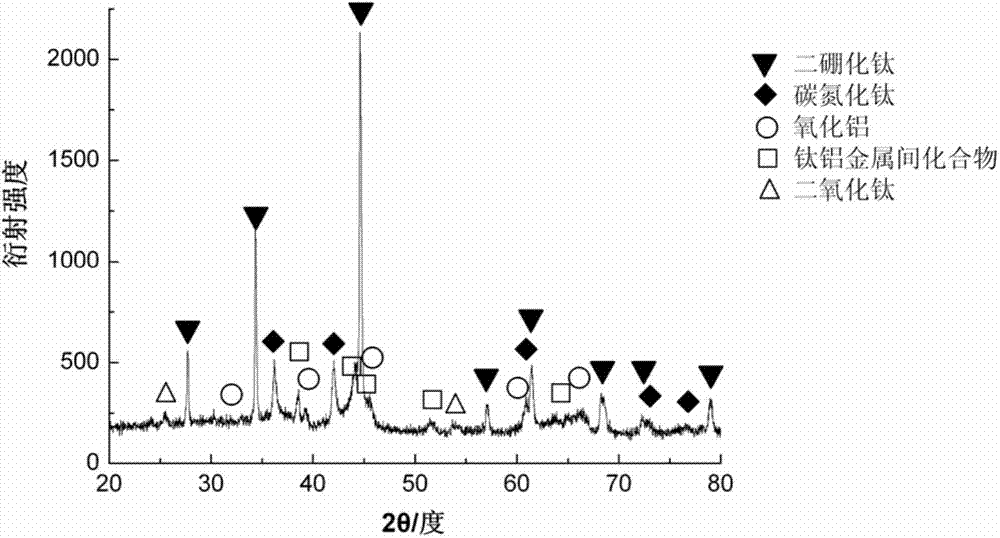

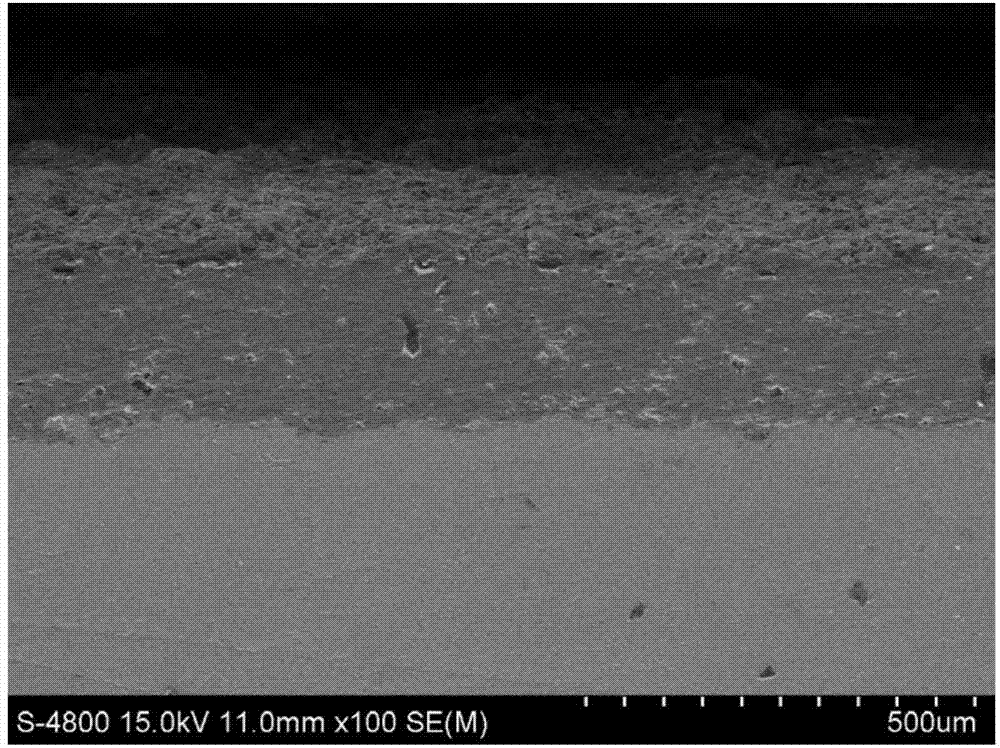

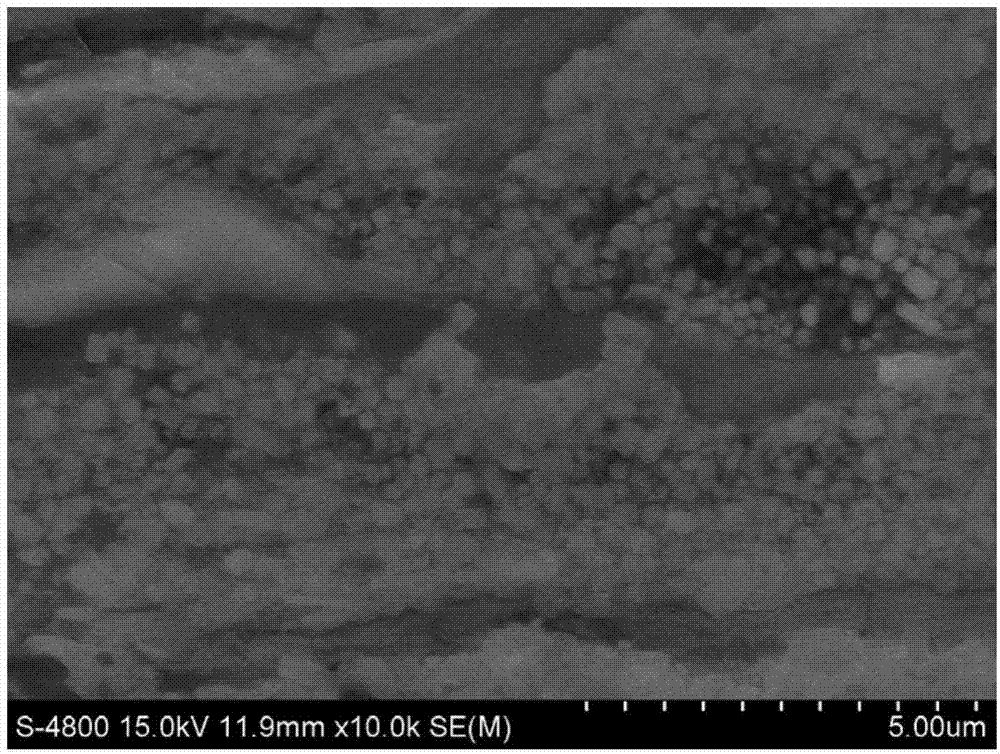

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

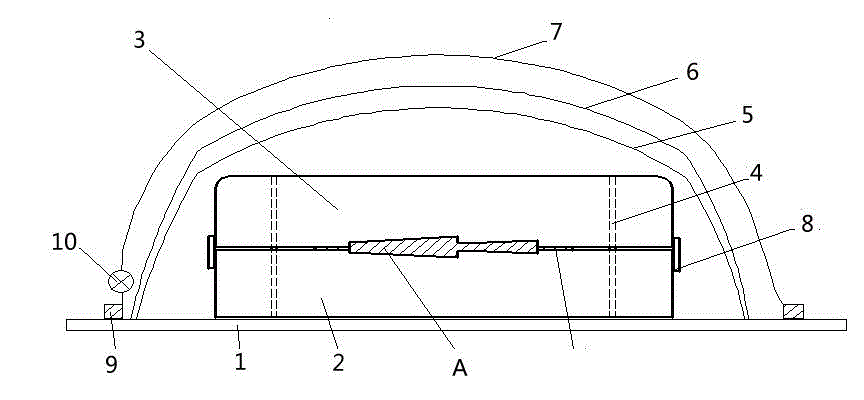

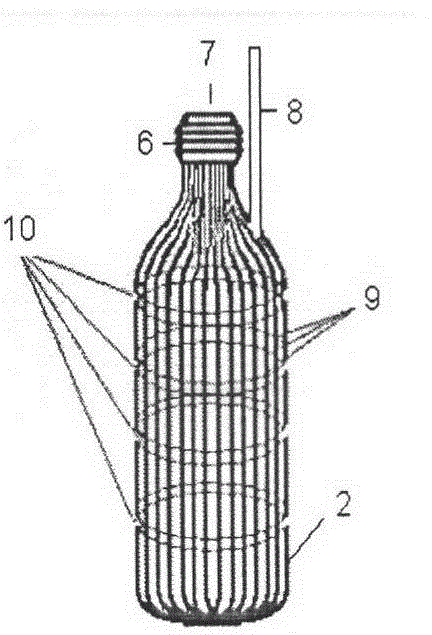

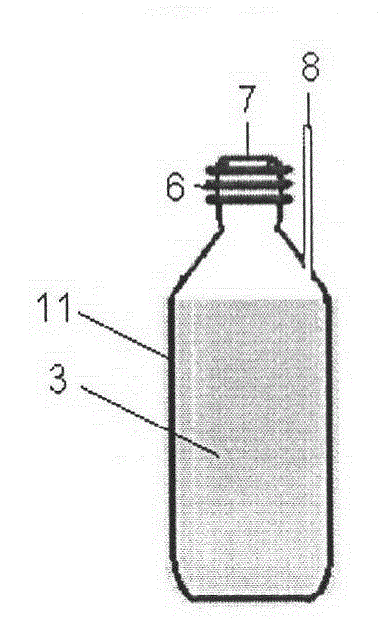

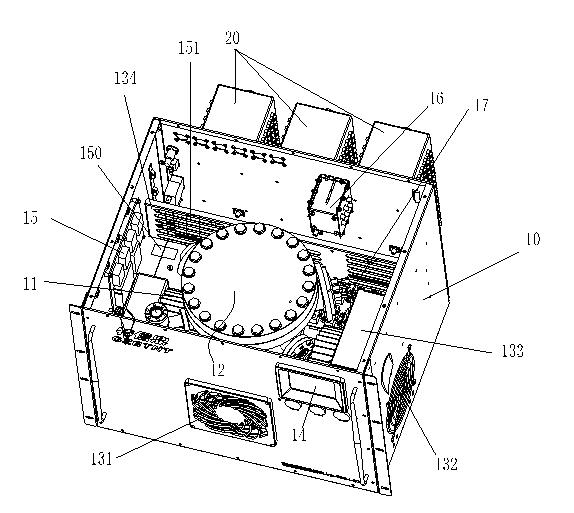

Seeping micro-irrigation container and preparation method thereof

InactiveCN102742489AAntibacterialRodent-proofWatering devicesSynthetic resin layered productsThermoplasticCapillary network

The invention relates to a seeping micro-irrigation container and a preparation method thereof. The container is made of a micro-irrigation material with a capillary water seeping function, has a three-dimensional network capillary water seeping structure of inorganic particles and thermoplastic plastics, and has a power-free self-adaptation, continuous and balanced seeping function. According to water potential of soil contacted with the container, water can seep outwards automatically through the capillary network structure inside the container or stop seeping outwards. The container further comprises a gel protective layer (11). The container has good water seeping capacity, can prevent blocking, bacteria and rats, can be used as a mini reservoir independently, can also be connected with a pipeline system, and forms a power-free self-adaptation, continuous and balanced seeping micro-irrigation system.

Owner:深圳市金麦田网络技术有限公司

Method for recycling waste lithium ion battery positive electrode material

InactiveCN108285977AOvercome energy consumptionOvercoming craftWaste accumulators reclaimingProcess efficiency improvementWater bathsElectrical battery

The invention relates to a method for recycling a waste lithium ion battery positive electrode material. According to the technical scheme, a waste lithium ion battery undergoes discharging, disassembling and crushing to obtain a positive pole piece; an organic acid solution with the concentration being 0.1-3.0 mol / L and a hydrogen peroxide solution with the concentration being 30 wt% are mixed toobtain a mixed solution, wherein the mass concentration of the hydrogen peroxide in the mixed solution is 0.5-10%; according to the solid-liquid ratio of the positive pole piece to the mixed solutionbeing 10-80 g / L, the positive pole piece is added into the mixed solution, stirring is carried out for 10-120 minutes under a water bath condition of 30-90 DEG C to obtain a mixture; the mixture is filtered to obtain filtrate containing valuable metal ions; the filtrate is baked at 50-200 DEG C for 8-24 hours, and a precursor for preparing the positive electrode material of the lithium ion battery is obtained. The method has the characteristics of being simple in process, low in energy consumption, short in process, low in reagent consumption, low in recovery cost and free of secondary pollution.

Owner:WUHAN UNIV OF SCI & TECH

Process for extracting proanthocyanidin from grape seed by super critical carbon dioxide

The supercritical CO2 process of extracting proanthocyanidin from grape seed includes the following steps: adding anhydrous ethyl alcohol as entrainer and grape seed after being supercritical deoiled in certain ratio into extracting kettle for extraction at 35-55 deg.c and 30-50 MPa; soaking statically for 30-90 min; adding entrainer continuously in certain ratio and discharging dynamically; twice separating the extracted solvent to obtain proanthocyanidin containing solvent; and evaporating the solvent to obtain proanthocyanidin product. The process of the present invention has reduced entrainer consumption, short production period, high yield and high proanthocyanidin content in the product.

Owner:TIANJIN UNIV

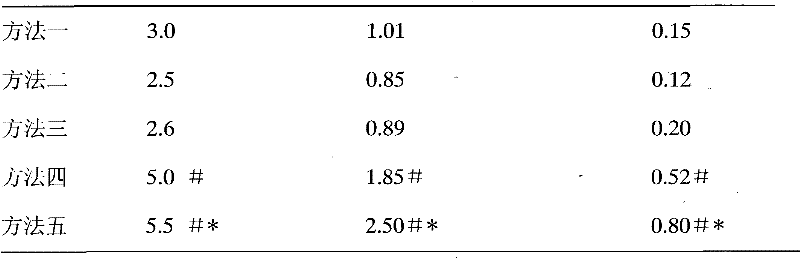

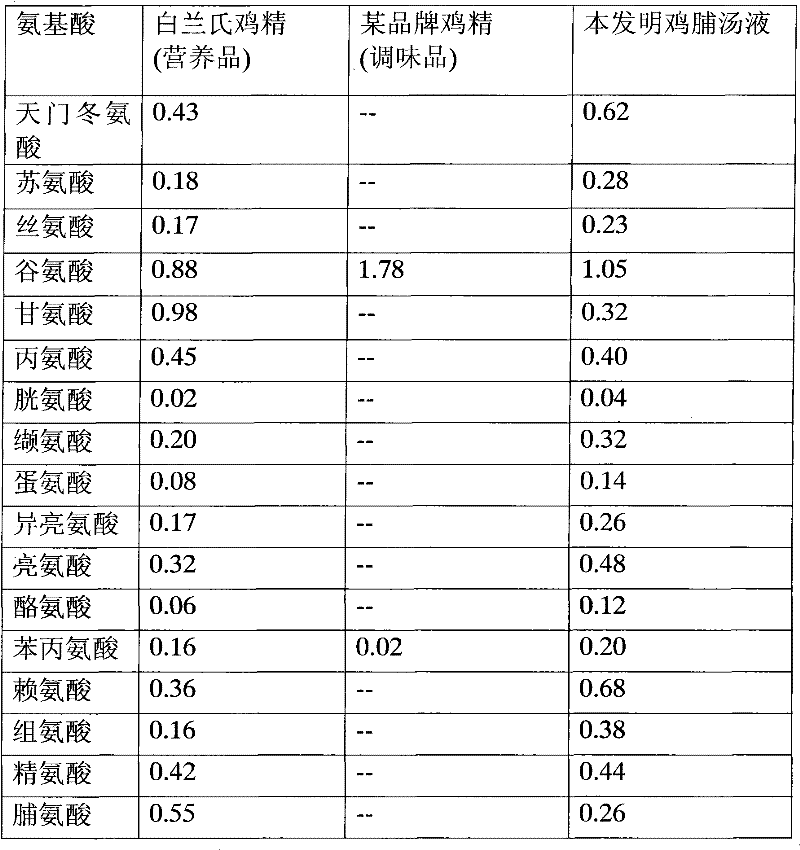

Preparation method and application of chicken soup beverage

InactiveCN102224957AOvercome the disadvantage of less dissolutionPreserve the flavorFood preparationEssential amino acidFood flavor

The invention discloses a chicken soup beverage and a preparation method thereof. A formula for preparing the chicken soup beverage comprises, by weight, 500-5000 parts of purified water, 100-500 parts of chicken chest meat, 5-50 parts of dried or fresh fruit, 2-10 parts of salt, 5-50 parts of dried or fresh vegetable, 2-20 parts of dried or fresh marine product and a proper amount of spices. Theprepared chicken soup beverage does not contain non-natural foodstuff additives, has 0.1%-10%(m / m) of protein, a plurality of essential and non-essential amino acids for human body, 0.01%-0.5%(m / m) of fat and no fishy smell or foreign flavor, and can be drunk at normal temperature or heated for drinking. The prepared chicken soup beverage can also be applied to flavorings and health food.

Owner:潘娜

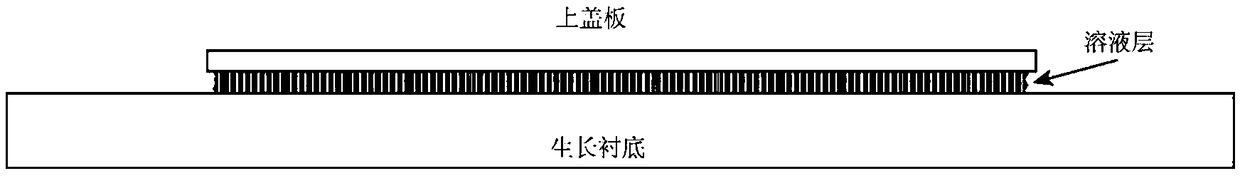

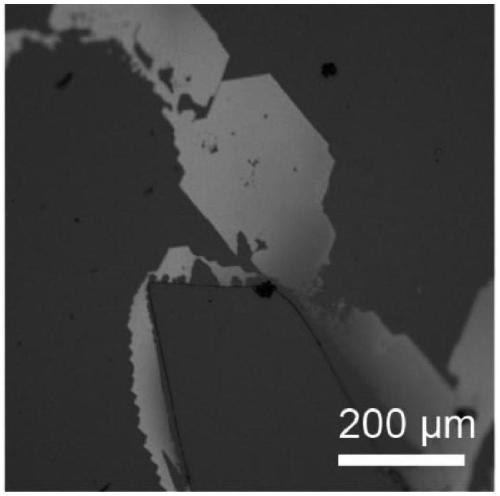

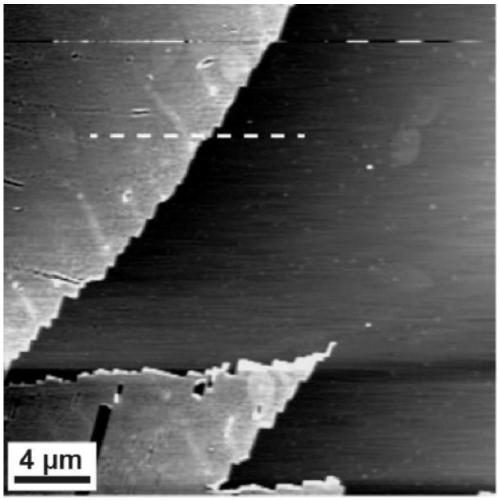

Space limited growing method of two-dimensional hybrid perovskite crystal

InactiveCN109355708AOvercoming craftOvercome many shortcomings such as expensive equipmentPolycrystalline material growthFrom normal temperature solutionsVertical planeGas phase

The invention discloses a space limited growing method of a two-dimensional hybrid perovskite crystal. A crystal growing region is formed by using two pieces of upper and lower substrates, the growingregion is filled with a crystal growing solution, the growing of the perovskite crystal in a two-dimensional plane is restricted by using the growing solution in the region to inhibit the growing ofthe crystal outside a vertical plane, and therefore a large-size, high-quality two-dimensional hybrid perovskite crystal is obtained on the surfaces of the substrates. On the other hand, an oleic acidsurface modifier or a surface modifier similar to oleic acid are added to the crystal growing solution, and the surface modifier attaches to the surface of the crystal to further limit the growing ofthe crystal outside the two-dimensional plane. By means of the method, the defects of smaller size of the two-dimensional hybrid perovskite crystal growing through a traditional solution method, complicated procedures and expensive equipment of the two-dimensional hybrid perovskite crystal growing through a gas phase condensing method and the like can be overcome.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

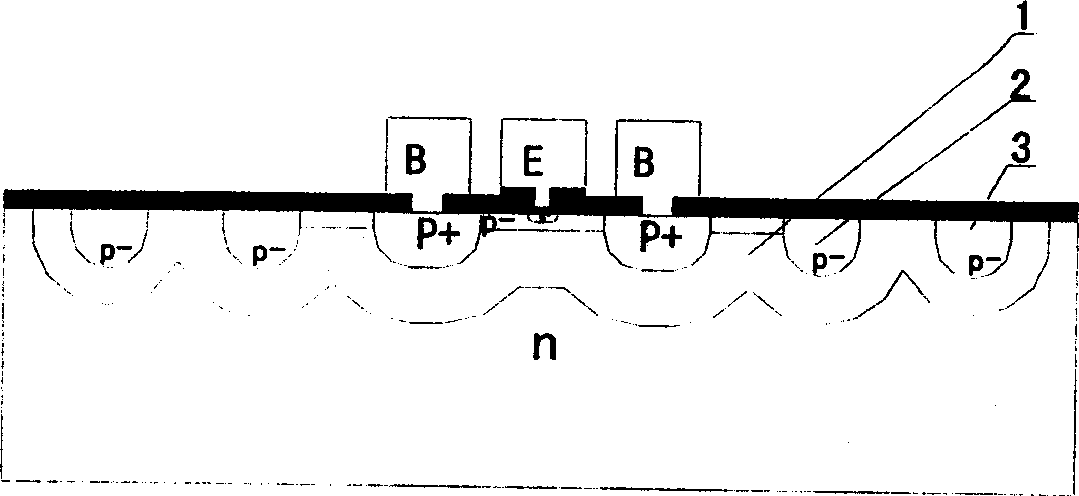

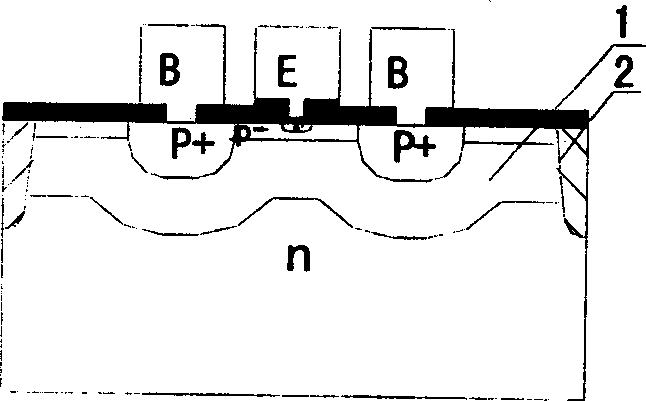

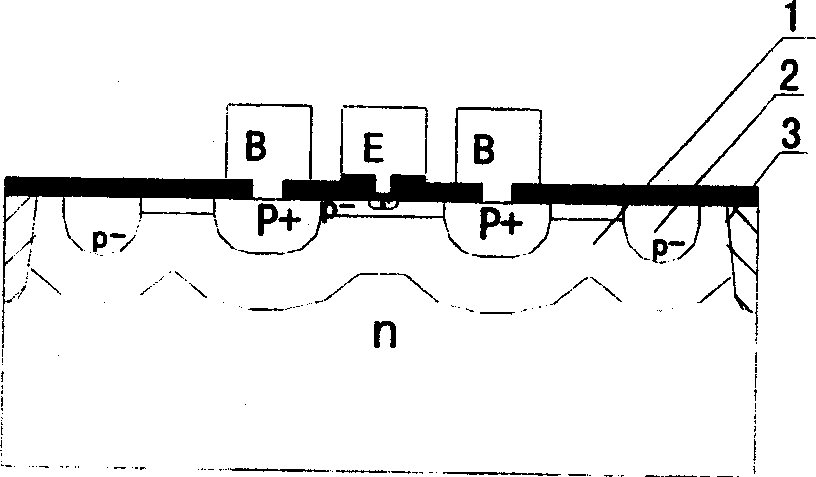

Semiconductor platform technology

InactiveCN1794432AHigh collector junction breakdown voltageLower junction capacitanceSemiconductor/solid-state device manufacturingCapacitanceMicrowave

This invention relates to a platform technology of semiconductors combining advantages of the plane and mesa technologies to diffuse a deep junction at the edge of the PN junction to let it have a most possible high break-over voltage and erode silicon in the width sphere of an exhaust region of the outside of said junction to form a mesa structure, which can bear rather high break-over voltage to block the further expansion of the exhaust areas and reduce the capacitance of the PN junction, so the total break-over voltage of the collector junction of the transistor is increased due to the sum voltage shared by the mesa and the PN junction.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Nisin extraction method

InactiveCN102304172AOvercoming craftOvercome purityPeptide preparation methodsDepsipeptidesBiotechnologyOrganic solvent

The invention relates to a nisin extraction method which is characterized by comprising the following steps: (1) adjusting the pH value of a nisin fermentation concentrated solution to 1.7-3.0, and mixing the nisin fermentation concentrated solution with a water-microsoluble organic solvent or water-insoluble organic solvent, wherein the organic solvent is any one of dichloromethane, n-butyl alcohol, ethyl acetate and carbon tetrachloride, or a combination of any two; and (2) stirring, standing, carrying out solid-phase separation to obtain a nisin wet cake, and drying while depressurizing invacuum to obtain the nisin product. The invention has the following main advantage: the nisin is precipitated by means of the organic solvent, thereby overcoming the defects of the existing process such as high salt content and low product purity, and ensuring that the product purity of nisin is higher than 50%. The method is safe, convenient, practical and low in cost.

Owner:LUOYANG QIHONG BIOTECH

Production process for high-moisture-absorption polyester down-proof fabric used for home textiles

ActiveCN107099908AGood flexibilityImprove compactnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterFiber

The invention relates to a production process for a high-moisture-absorption polyester down-proof fabric used for home textiles. The production process includes the following steps that weaving is conducted, wherein polyester DTY silk serves as warp yarn, sea-island fibers serve as weft yarn, and weaving is conducted on a water-jet loom; the sea-island fibers refer to PET, the island refers to COPET, the on-loom warp density is 137-200 per inch, the weft density is 100-200 per inch, and a gray fabric is formed by weaving; one side of the fabric is brushed; refining and splitting are conducted, the brushed fabric is fed into an overflow dyeing machine, splitting is conducted in the overflow dyeing machine, and the softness and compactness of the fabric are improved; water washing and plastification are conducted, fluffing and setting are conducted, the fabric obtained after water washing and plastification is subjected to pad-roll processing with a polyester bulking agent before passing through a setting machine, and a finished fabric product is formed after being subjected to setting through the setting machine. The process does not require the high-count and high-density weaving process required by a traditional down-proof fabric, so that the gray fabric weaving production difficulty is low, at the same time, the disadvantages that the coated down-proof fabric production process requires coating operation and thus causes long production process, hard hand feeling and easy-to-fall-off coatings are overcome, and therefore the production process is more suitable for the down-proof fabric used for the home textiles.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation

ActiveCN103992200AExpand the range of industrial applicationsRich production methodsHydrocarbon by hydrogenationCalcium carbidePtru catalystHydrogenation reaction

The invention relates to a process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation. A process for producing methanol or dimethyl ether from coal-based or natural gas-based synthetic gas and further producing low-carbon olefins mainly comprising ethylene and propylene has the disadvantages of long process flow, complex process and large investment. The process method provided by the invention comprises the steps of drying and screening semi-coke, then mixing with lime powder, producing calcium carbide in a closed calcium carbide furnace and obtaining hydrogen from tail gas of the calcium carbide furnace through PSA; enabling obtained calcium carbide to react with water to produce acetylene gas; mixing acetylene gas with hydrogen according to a proportion, then compressing, entering an acetylene gas hydrogenation reactor, performing acetylene gas hydrogenation reaction under the action of a palladium-series silver-added additive catalyst, cooling the gas after reaction and then purifying through a rectification device to obtain ethylene gas. According to the ethylene production process provided by the invention, the supply-demand contradiction of semi-coke and calcium carbide can be relieved, the range of industrial applications of semi-coke and calcium carbide is expanded, the ethylene production method is enriched and the shortcomings of long process flow, high investment and large water demand of the existing ethylene production method are overcome.

Owner:榆林科大高新能源研究院有限公司

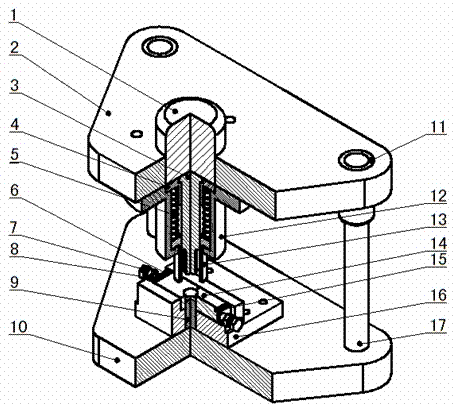

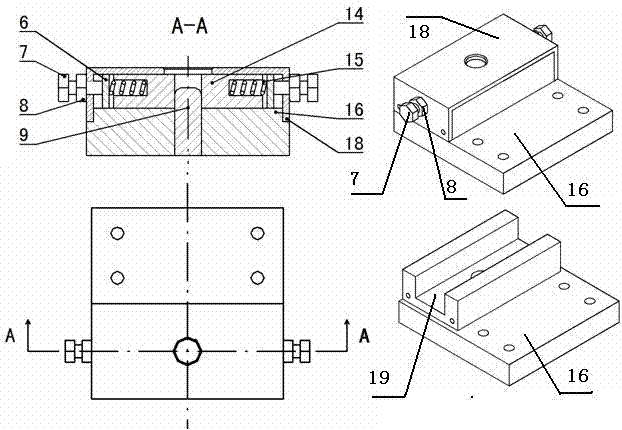

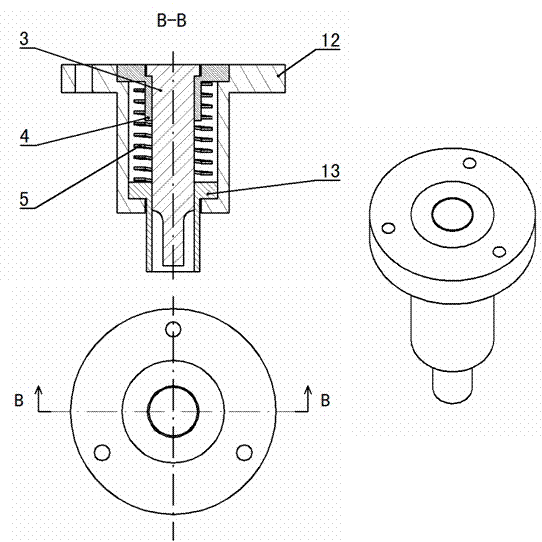

Combined type precision sheet metal stamping and riveting mould

InactiveCN102784841AImprove loading and unloading efficiencyReduce punching forceShaping toolsPunch pressMan-hour

The invention relates to a combined type precision sheet metal stamping and riveting mould, belonging to the field of pressed deformation connection and mould in mechanical engineering. The combined type precision sheet metal stamping and riveting mould comprises a guide device which comprises a postposed guide pillar and a guide sleeve, a precise upper mould and a precision lower mould to realize the precise stamping and riveting process so as to improve the loading and unloading efficiency of the sheet metal in the mould. The combined type precision sheet metal stamping and riveting mould can overcome the quality defects that riveting joints are asymmetric, riveting gaps appear in the riveting process, and that the riveting joints are easy to pull off and realizes a single-gate shearing-free stamping and riveting process; riveting joints with high strength, high rigidity, rotational symmetry and even stress can be formed; and the self-locking ability of the riveting joints is improved. The height increase of the riveting joint at the concave mould is small and the riveting joint at the concave mould is more attractive. The stamping force required by the convex mould is relatively small, so the combined type precision sheet metal stamping and riveting mould is suitable for a general punch press. The combined type precision sheet metal stamping and riveting mould is simple in structure and convenient to operate, saves installing and debugging man-hour, improves the labor productivity and thereby increases the economic benefit.

Owner:JIANGSU UNIV

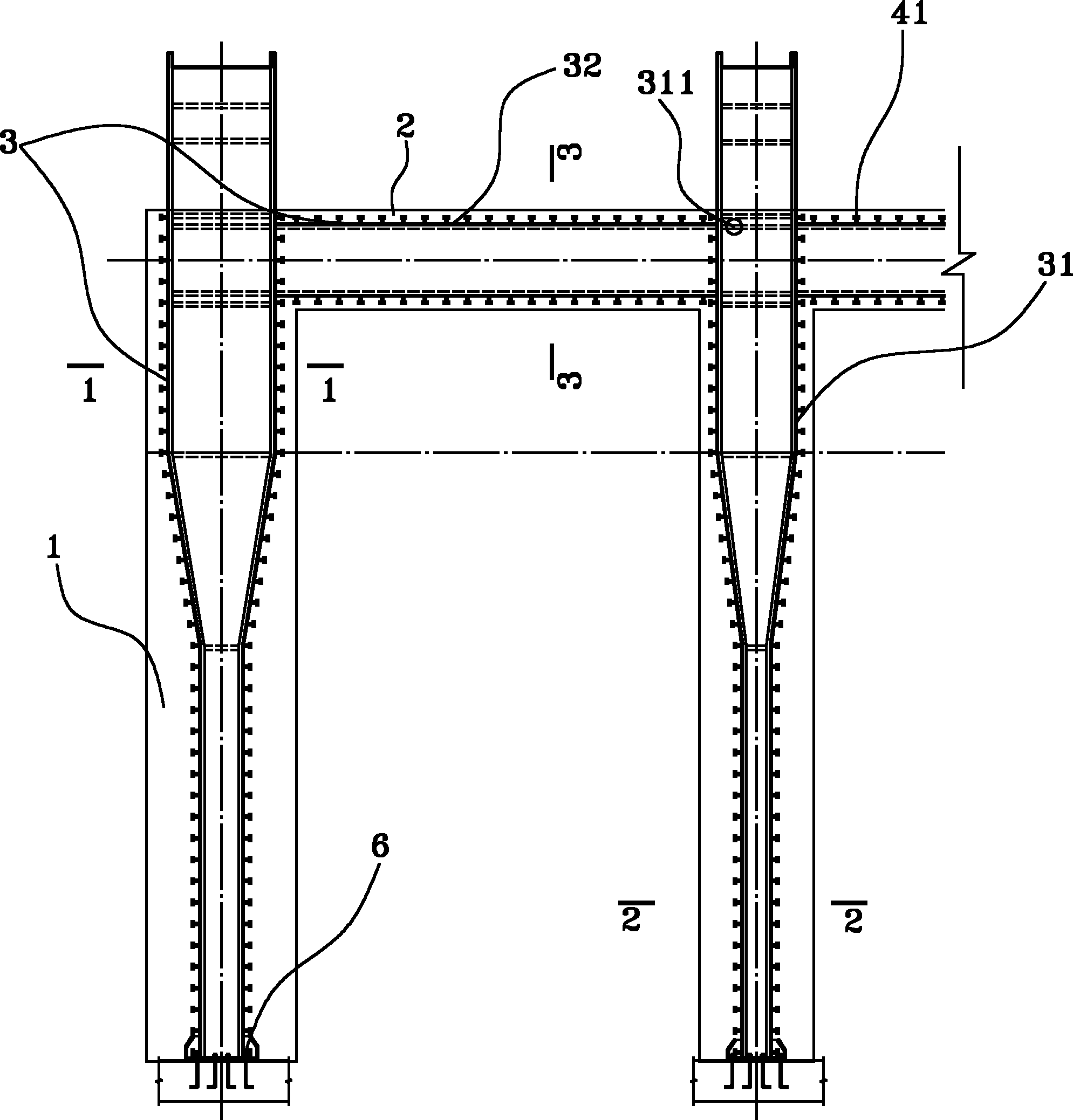

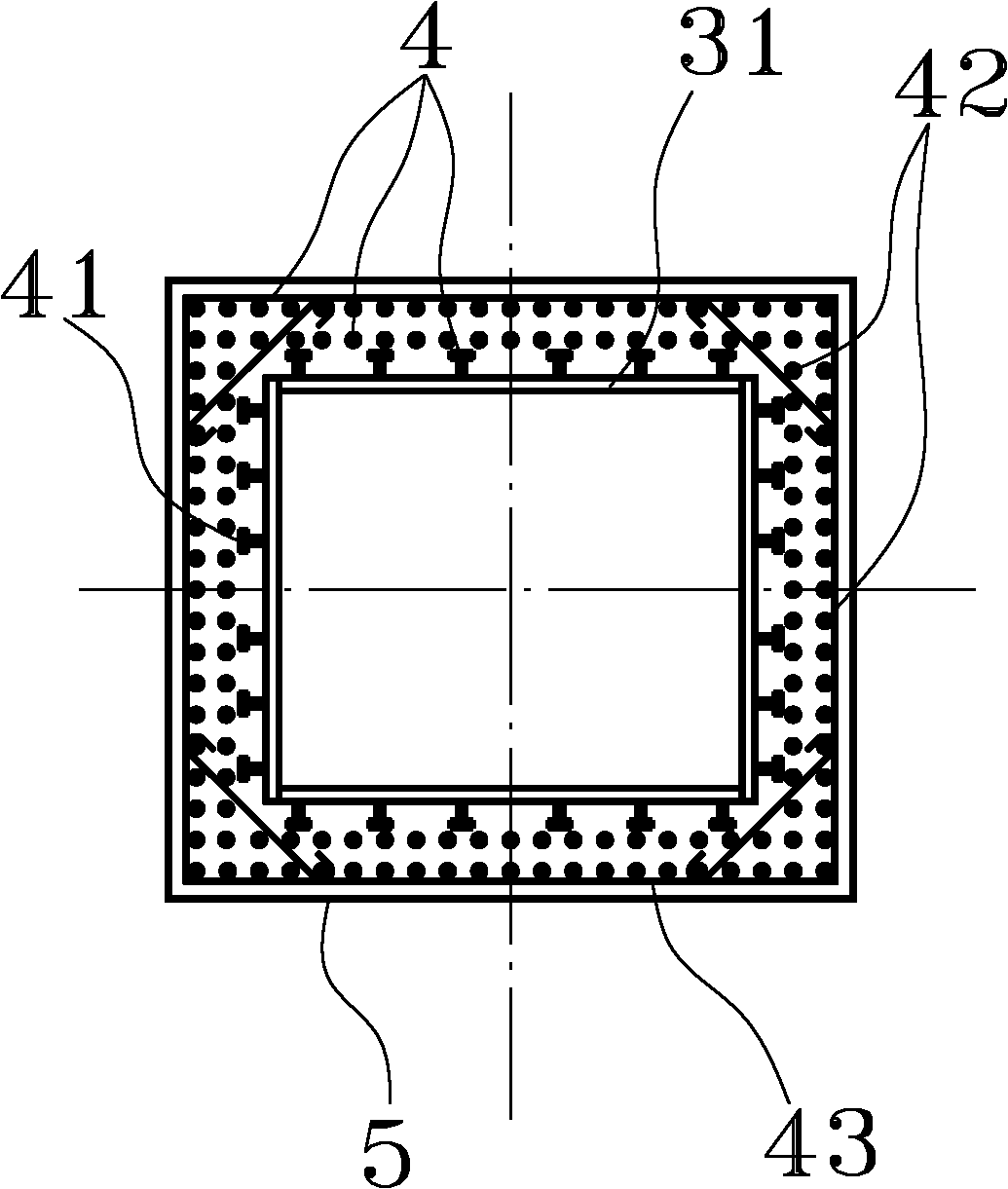

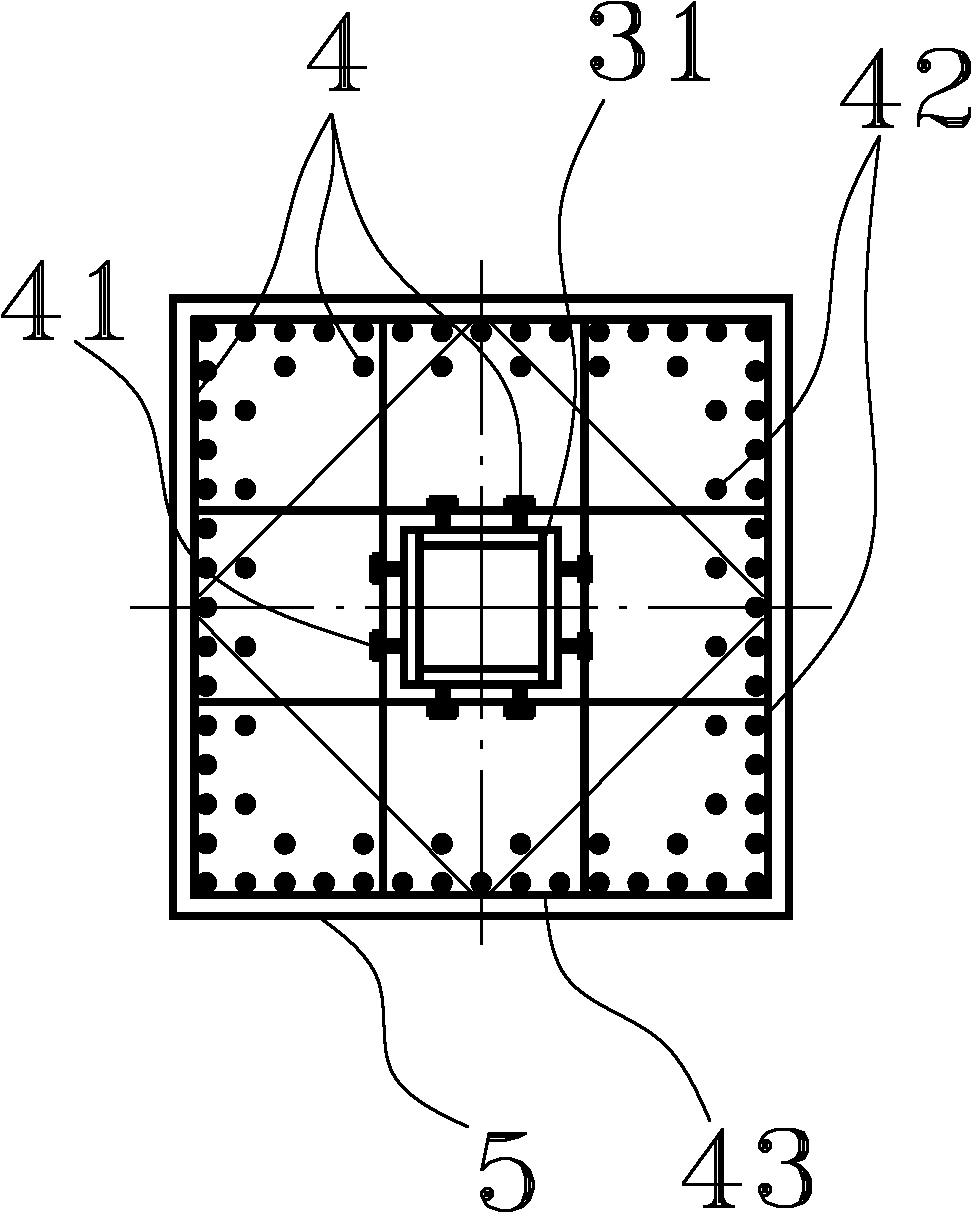

Construction method of steel reinforced concrete beam of large metallurgical industry plant

ActiveCN102182309AGuaranteed installation qualityGuarantee the quality of layoutBuilding material handlingReinforced concreteRebar

The invention discloses a construction method of a steel reinforced concrete beam of a large metallurgical industry plant, and belongs to the technical field of plant building construction production. The provided construction method of the steel reinforced concrete beam of the large metallurgical industry plant can ensure the manufacturing quality of the steel reinforced concrete beam. The construction method comprises the following steps of: arranging a steel skeleton, and adjusting the installation quality of a steel reinforced post by adjusting a shim plate and a wind cable; arranging a concrete steel rib outside the steel skeleton in an order of arranging the outer side of the steel reinforced post, arranging the outer side of the steel reinforced beam and finally arranging a concrete steel rib at the joint of the steel reinforced post and the steel reinforced beam; supporting a concrete cast template of the steel skeleton, and casting concrete inside and outside a steel reinforced post box body; finally, casting concrete on the steel reinforced beam by adopting a single-side feeding vibrating and single-side driving casting method, a two-side symmetrical layered feeding vibrating casting method and a middle feeding symmetrical driving vibrating casting method; and detaching the cast template after the strength of the concrete meets the design requirement, and curing the concrete.

Owner:CHINA 19TH METALLURGICAL CORP

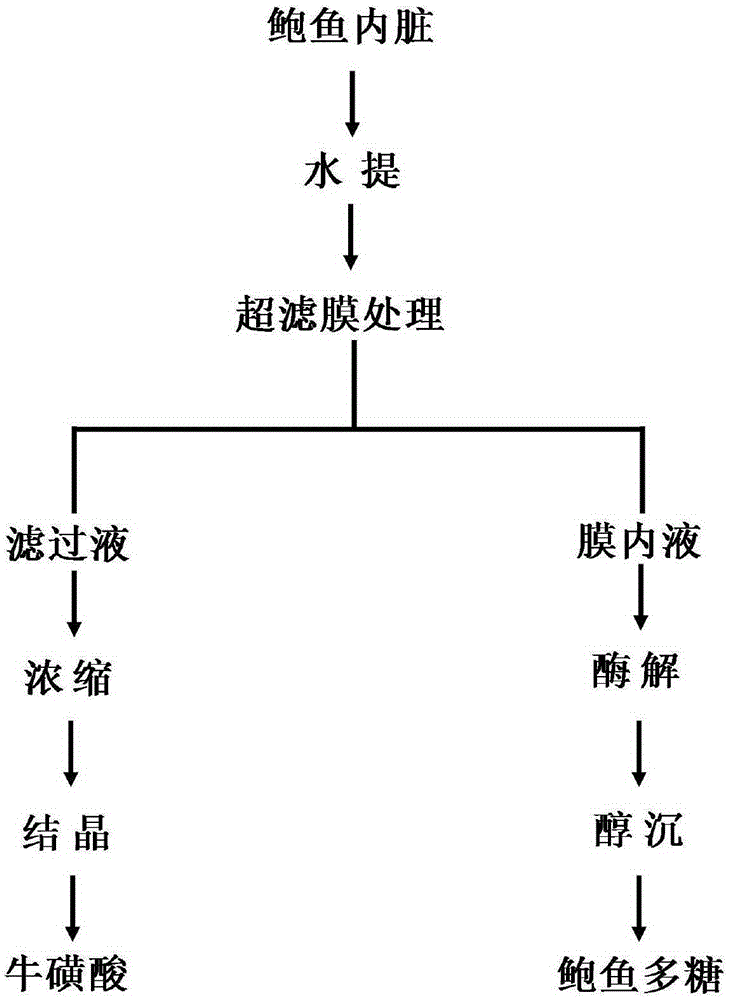

Method for extracting taurine and polysaccharides from abalone's viscera simultaneously

ActiveCN105272887AIncrease profitOvercoming craftOrganic chemistryOrganic compound preparationBiotechnologyUltrafiltration

The invention provides a method for extracting taurine and polysaccharides from abalone's viscera simultaneously. The method comprises following steps: waste collection of viscera produced in an abalone processing process; water extraction; Ultra-fol ultrafiltration membrane treatment; enzymolysis; ethanol precipitation; concentration; crystallization; acquisition of high-purity taurine crystals after recrystallization. The method overcomes the technical defect that the taurine and the polysaccharides cannot be extracted simultaneously from the abalone's viscera with the conventional method and adopts the technical scheme including water extraction, Ultra-fol ultrafiltration membrane treatment, enzymolysis, ethanol precipitation, concentration and crystallization to extract the taurine and the polysaccharides from abalone's viscera simultaneously, so that the utilization rate of the abalone resources is increased effectively. The method solves the problems of complicated process, higher cost and serious environmental pollution during preparation of natural taurine with a traditional ion exchange method, overcomes the defect of large ethyl alcohol consumption during preparation of the natural taurine with a conventional simple preparation method and solves the problems of complicated process and large consumption of a conventional method for preparing the polysaccharides from abalone.

Owner:JIMEI UNIV

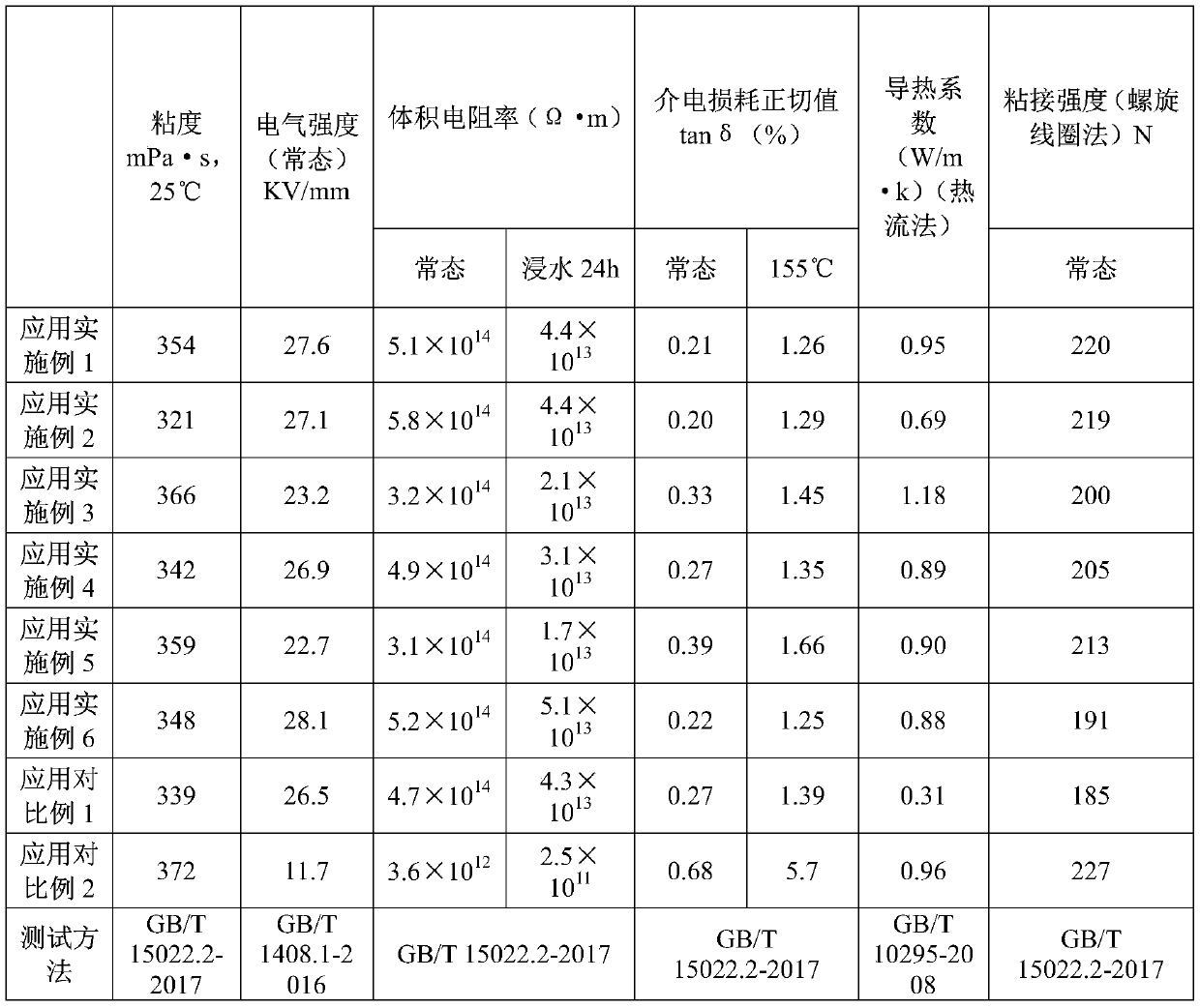

Preparation method and application of modified carbon nanotube

ActiveCN110921654AImprove thermal conductivityImprove insulation performanceCarbon compoundsCoatingsModified carbonSilicic acid

The invention discloses a preparation method and an application of a modified carbon nanotube. The preparation method comprises the steps: 1) preparing a surface-carboxylated carbon nanotube; 2) dissolving the surface-carboxylated carbon nanotube in a mixed solution of water and ethanol, then adding tetraethoxysilane, vinyltriethoxysilane and ammonia water, and carrying out a reaction to prepare the modified carbon nanotube with vinyl on the surface. The invention also discloses the application of the prepared modified carbon nanotube in a heat-conducting insulating material. The modified carbon nanotube prepared by the preparation method disclosed by the invention has the advantages of high thermal conductivity, low electric conductivity and good compatibility with organic matters, and isparticularly suitable for heat-conducting insulating paints.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

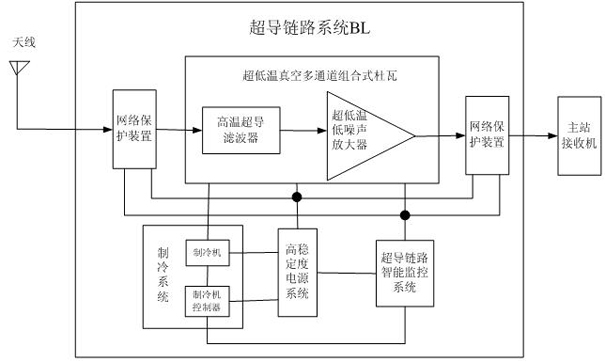

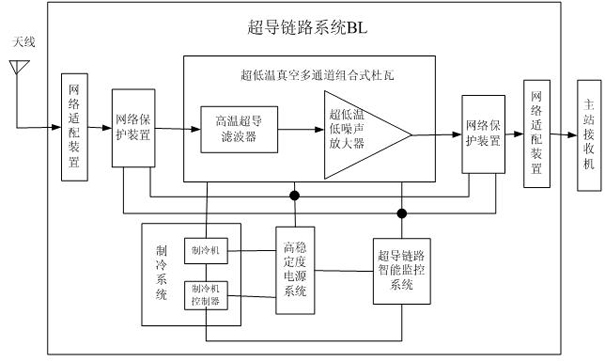

Superconducting link system

ActiveCN102026235AReduce the noise floorImprove performanceWireless communicationFrequency spectrumManufacturing technology

The invention discloses a superconducting link system, comprising a network adapter device, a network protector, an ultralow temperature vacuum multi-channel combined type Dewar, a high temperature superconduction wave filter, an ultralow temperature low-noise amplifier (LNA), a refrigerating system, a high-stability power supply system and an superconducting link intelligent monitoring system, wherein the high temperature superconduction wave filter and the ultralow temperature LNA are arranged in the ultralow temperature vacuum multi-channel combined type Dewar and operate in high vacuum environment with ultralow temperature and long-term holding pressure. In the superconducting link system, a brand new scientific overall structure design and a special manufacturing technology are adopted, thus the superconducting link system has extremely high out-band interference resisting capability and intermodulation interference reducing capacity, and can effectively reduce background noise of the system and improve gains for useful signals, thereby greatly enhancing the performance of a receiving link from an antenna to the output end of a receiver of a master station, greatly improving communication coverage, quality, capacity, user satisfaction, low-carbon and environmental-friendly network environment, and greatly increasing resource utilization rate of frequency spectrum and system equipment, return on investment, construction speed and the like.

Owner:广州特信网络技术有限公司

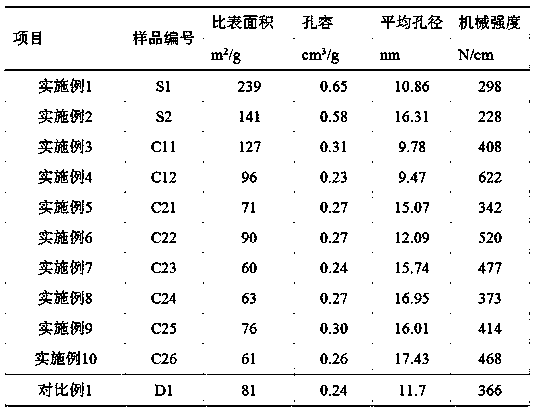

Preparation method of hydrofining catalyst with high mechanical strength

ActiveCN108671934AHigh mechanical strengthPromote formationMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentPhosphoric acidMetal salts

The invention discloses a preparation method of a hydrofining catalyst with high mechanical strength. The preparation method comprises the following steps: taking pseudo-boehmite and sesbania cannabina powder as raw materials; adding a nitric acid solution; then extrusion-molding, drying and carrying out three-section type roasting to obtain an aluminum oxide carrier; dissolving phosphoric acid and an organic additive into de-ionized water to prepare a solution; then adding the solution into a metal salt mixture; stirring, heating and refluxing to obtain an active component immersion solution;adding the obtained immersion solution into the aluminum oxide carrier; carrying out equal-volume immersion; then raising the temperature and drying to obtain the hydrofining catalyst. According to the preparation method disclosed by the invention, the catalyst with the high mechanical strength is prepared by adopting an immersion method and the organic additive is added in a preparation process;formation and distribution of a surface active center of the carrier can be optimized; the catalyst with the high mechanical strength can be obtained; meanwhile, relatively high catalytic activity ofthe catalyst can be ensured; the problem of a preparation technology in the prior art that a pore structure of the carrier is damaged or the catalyst is increased to improve the mechanical strength is overcome.

Owner:SINOCHEM QUANZHOU PETROCHEM CO LTD +1

Method for conducting chemical modification on nitrile butadiene rubber surface by using oxidation solution

The invention relates to a method for conducting chemical modification on a nitrile butadiene rubber surface by using an oxidation solution. The method includes the following steps: (1) surface processing: soaking nitrile butadiene rubber in a mixed solution containing 30-60% of sulfuric acid, 10-15% of potassium iodide and 5-10% of potassium bromide (mass percentage) for 3-7 days; and (2) drying processing: placing the nitrile butadiene rubber in a dry environment at the temperature of 100-110 DEG C for 1-2 hours. By conducting chemical modification on the nitrile butadiene rubber surface, a molecular structure of the nitrile butadiene rubber surface is changed so that polarity and hardness of the nitrile butadiene rubber surface are improved, mechanical performance, antifriction performance and abrasion resistance are improved, and service life of rubber products is greatly prolonged. The method is simple in process and low in cost.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com