Raw material composition of fermented milk beverage, as well as fermented milk beverage and preparation method thereof

A technology for fermented milk beverages and raw material compositions, applied in dairy products, milk preparations, applications, etc., can solve the problems of insufficient killing of microorganisms, easy reproduction of harmful microorganisms, etc., and achieves unique flavor, low equipment requirements, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] One preferred preparation method of the fermented milk base comprises the following steps: homogenizing raw milk, sterilizing, cooling, adding lactic acid bacteria, and fermenting to obtain the fermented milk base.

[0042] The aforementioned raw milk includes one or both of fresh milk and reconstituted milk. Preferably it is a mixture of fresh milk and reconstituted milk; the best is fresh milk.

[0043] In the method for preparing fermented milk base material, the homogenization of raw milk preferably includes primary homogenization, more preferably primary homogenization and secondary homogenization. The homogeneous temperature is preferably 54-66°C, more preferably 57-62°C, most preferably 60°C. When two-stage homogenization is included, the total pressure of the first-stage homogeneous pressure and the second-stage homogeneous pressure is preferably 15-25 MPa, more preferably 18-22 MPa, most preferably 20 MPa.

[0044] The raw milk can be sterilized at 90-95°C fo...

Embodiment 1

[0069] 1. Proportion

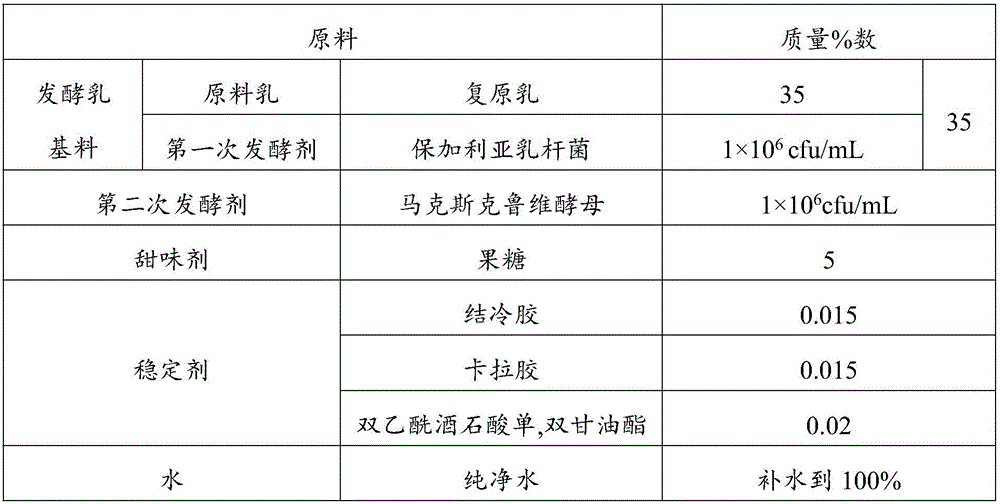

[0070] Table 1

[0071]

[0072] 2. Method

[0073] (1) Homogenize the raw milk at 54°C, 15Mpa, sterilize at 90°C for 5 minutes, cool to 35°C, add the first starter as shown in Table 1, and ferment to an acidity of 70°T to obtain a fermented milk base , turned over and cooled to 2°C for temporary storage.

[0074](2) Stir and mix the sweetener, stabilizer and water at 60°C for 10 minutes according to the ratio in Table 1, cool to 2°C, add the fermented milk base material obtained in (1), stir and mix for 10 minutes, 15Mpa 54°C- Grade homogeneous, sterilized at 90°C for 5 minutes, cooled to 25°C to obtain a mixture;

[0075] (3) Add the second starter to the mixture according to the ratio in Table 1, fill it, and ferment it at 25°C for 24 hours, then sterilize it again in a sterilizer at 85°C for 30 minutes, and cool it to room temperature through a cooling tunnel to obtain a fermented milk drink.

[0076] After testing, mold, yeast, Escherichia c...

Embodiment 2

[0078] 1. Proportion

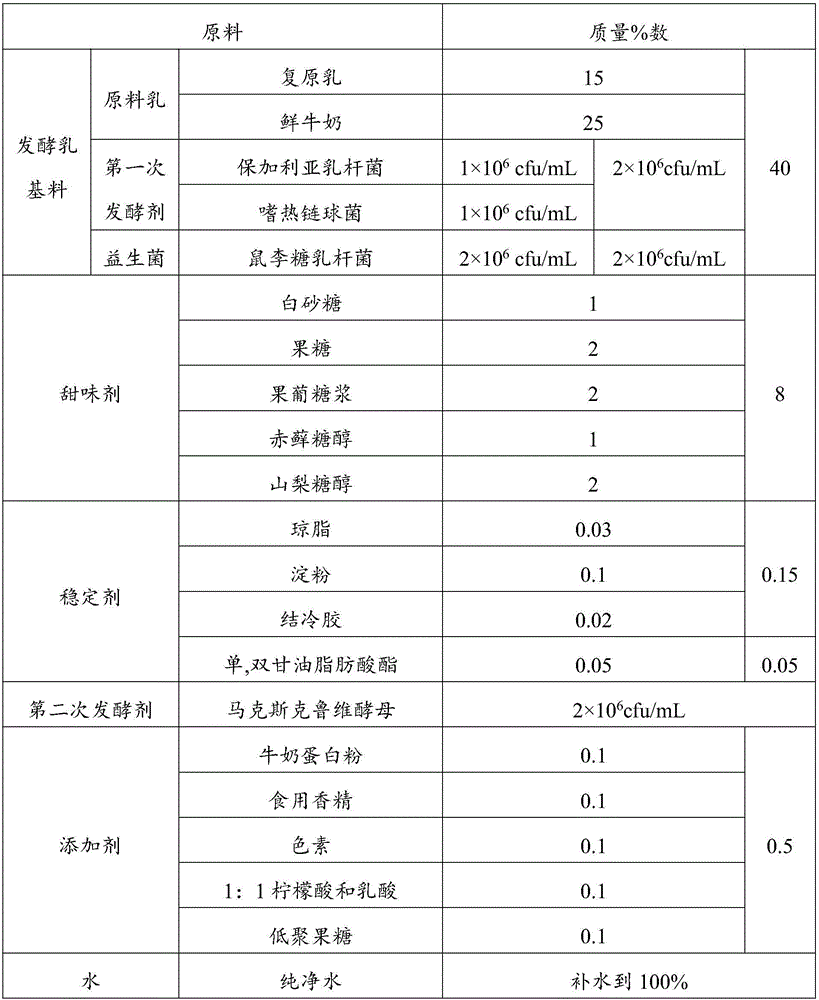

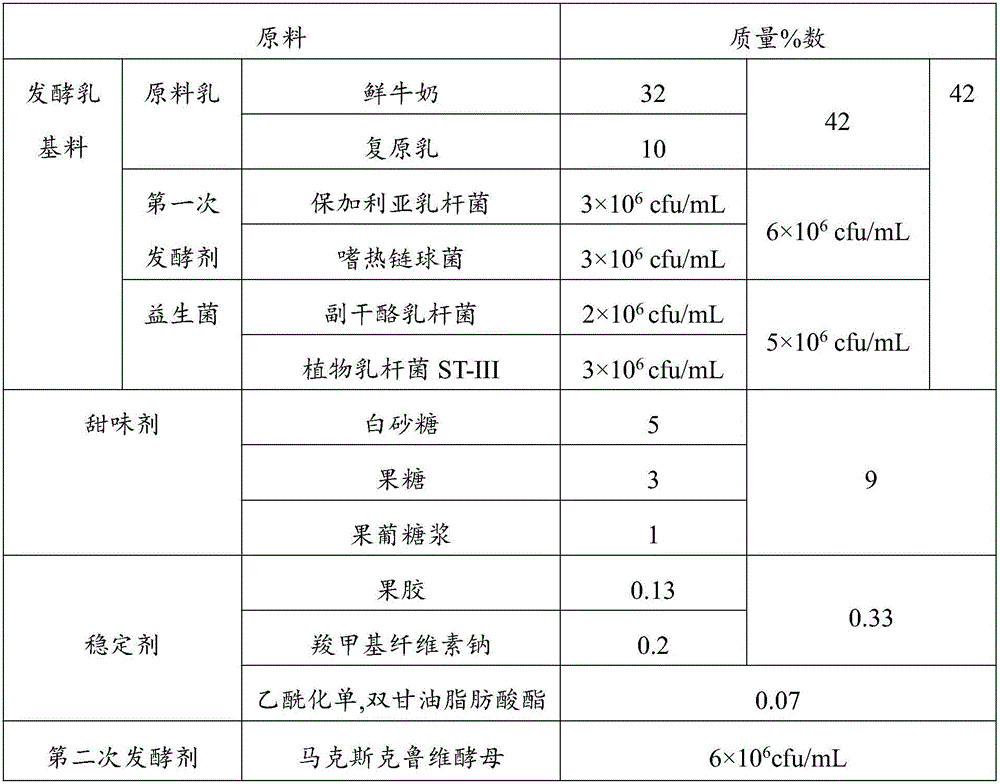

[0079] Table 2

[0080]

[0081] 2. Method

[0082] (1) Homogenize the raw milk at 55°C, 18Mpa, sterilize at 91°C for 5 minutes, cool to 37°C, add the first starter and probiotics as shown in Table 2, and ferment to an acidity of 85°T to obtain a fermented For the milk base material, turn over the tank and cool to 5°C for temporary storage.

[0083] (2) Stir and mix the sweetener, stabilizer, additive and water according to the ratio in Table 2 at 62°C for 15 minutes, cool to 5°C, add the fermented milk base obtained in (1), stir and mix for 15 minutes, 18Mpa first-level homogeneous, sterilized at 91°C for 5 minutes, cooled to 25°C to obtain a mixed solution;

[0084] (3) Add the second starter to the mixture according to the ratio in Table 2, fill it, and ferment it at 25°C for 36 hours, then sterilize it again in a sterilizer at 90°C for 25 minutes, and cool it to room temperature through a cooling tunnel to obtain a fermented milk drink.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com