Processing method for tea flowers

A processing method and a tea tree flower technology are applied in the processing field of tea tree flowers, which can solve the problems of destroying the chemical bonds of tea tree flowers, high water content of tea tree flowers, long steam-heating steaming and killing time, etc. full shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

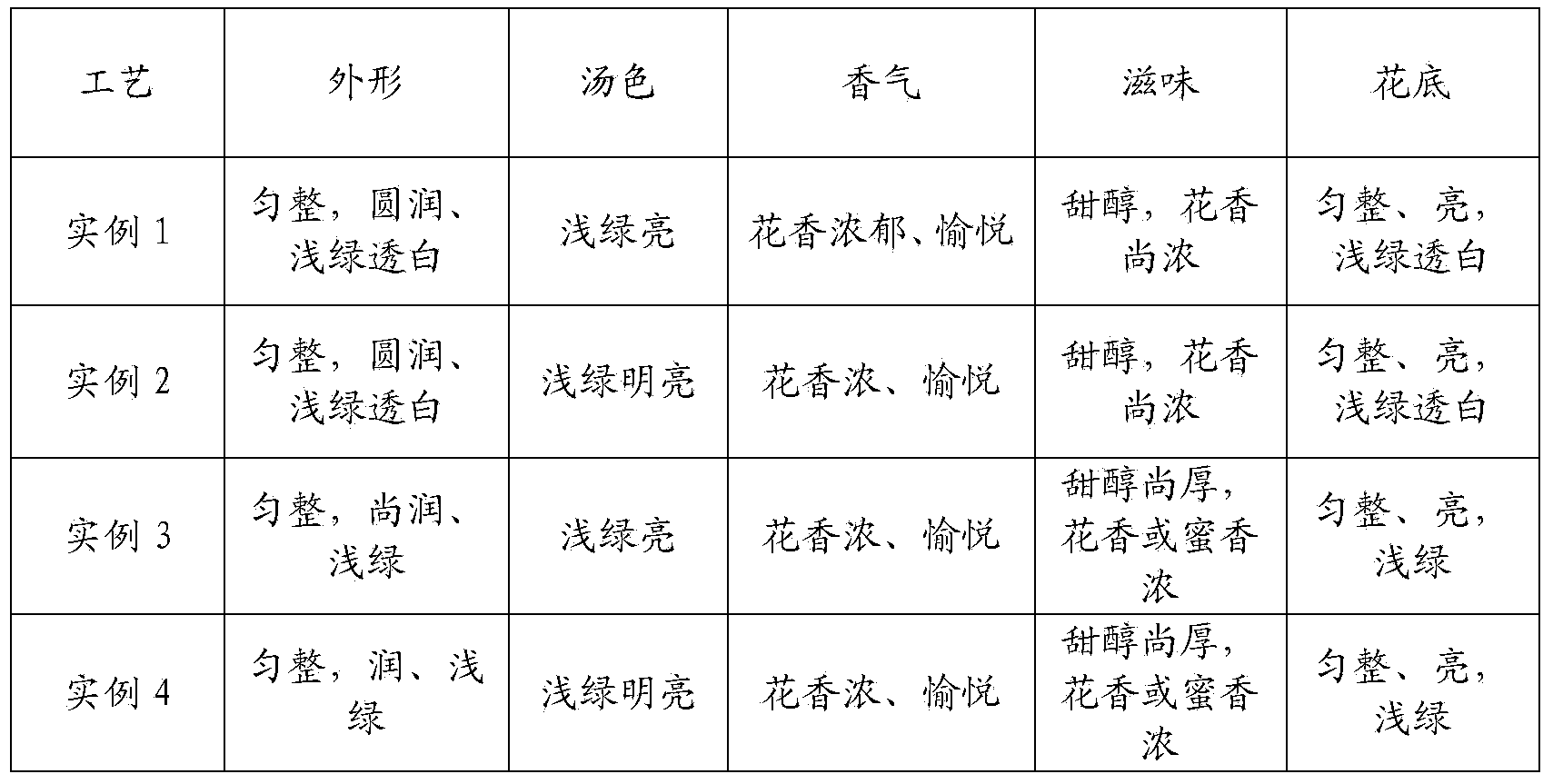

Examples

Embodiment 1

[0020] Pick the tea tree flowers in the bud stage after the dew has dried up. The residual flowers and rotten flowers are not picked. Spread them on a clean water sieve, bamboo mat, or wooden board with a thickness of 2-3cm, and naturally wither indoors at 25-30°C for 4-6 hours. Evenly spread a single layer of tea tree flowers on the conveyor belt of a tea microwave curing machine with a microwave frequency of 2450±10MHz and a power of 6KW (produced and commercially available by Nanjing Aorun Microwave Technology Co., Ltd.), and adjust the continuously variable speed regulator to F=8 , the transmission speed is 0.76 m / min, and the greening time is 3 minutes and 40 seconds. After the microwave curing, the water content of the tea tree tea reaches 45%. Dehydration and drying in the tea roaster, drying temperature 90-95°C, drying time 1 hour, naturally cool to 20-30°C, then bake at 85°C for 2 hours, take out when the water content is lower than 6%, spread and cool to 20 After ~30...

Embodiment 2

[0022] Pick the tea tree flowers in the bud stage after the dew has dried up. The residual flowers and rotten flowers are not picked. Spread them on a clean water sieve, bamboo mat, or wooden board with a thickness of 2-3cm, and naturally wither indoors at 25-30°C for 4-6 hours. Evenly spread a single layer of tea tree flowers on the conveyor belt of a tea microwave curing machine with a microwave frequency of 2450±10MHz and a power of 6KW (produced and commercially available by Nanjing Aorun Microwave Technology Co., Ltd.), and adjust the continuously variable speed regulator to F=9 , the transmission speed is 0.83 m / min, and the greening time is 3 minutes and 20 seconds. After the microwave curing, the water content of the tea tree tea reaches 50%. Dehydration and drying in the tea roaster, drying temperature 90-95°C, drying time 1.5 hours, natural cooling to 20-30°C and then drying at 85°C for 2 hours, take out when the water content is lower than 6%, spread and cool to Aft...

Embodiment 3

[0024] Pick the tea tree flowers in the opening stage after the dew has dried up. The residual flowers and rotten flowers are not picked. Spread them on a clean water sieve, bamboo mat, or wooden board with a thickness of 2 to 3 cm. Naturally wither indoors at 25 to 30 ° C for 4 to 6 hours. Evenly spread a single layer of tea tree flowers on the conveyor belt of a tea microwave curing machine with a microwave frequency of 2450±10MHz and a power of 6KW (produced and commercially available by Nanjing Aorun Microwave Technology Co., Ltd.), and adjust the continuously variable speed regulator to F=10 , the transmission speed is 0.90 m / min, and the greening time is 3 minutes and 5 seconds. After the microwave curing, the water content of the tea tree tea reaches 45%, and the tea tree flowers after cooling to 20-30°C are spread in a single layer on the tray, and placed Dehydrate and dry in the tea roaster, drying temperature 85-90°C, drying time 0.5 hours, naturally cool to 20-30°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com