Process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation

A process method, calcium carbide gas technology, applied in the field of coal chemical industry, can solve the problems of small and medium-sized enterprises and areas lacking water, long technical process, complicated process, etc., to extend the product industry chain, overcome the long process process, and increase the number of enterprises effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

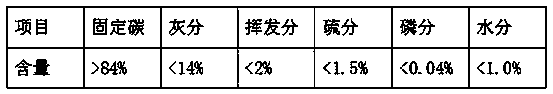

[0029] The main composition of the raw material semi-coke in this example is shown in the following table: (4000kg / h semi-coke, temperature 40°C)

[0030]

[0031] Step 1: Produce calcium carbide using a closed calcium carbide furnace production process:

[0032] After the semi-coke is dried and screened, the moisture content of the semi-coke is reduced to 1% by mass, and the particle size is controlled at 5-10mm; it is mixed with lime powder at a mass ratio of 0.65:1, and then enters a closed calcium carbide furnace for reaction , the calcium carbide furnace is cooled and purified for use; the tail gas of the calcium carbide furnace is obtained by pressure swing adsorption (PSA), and the remaining gas is returned to the closed calcium carbide furnace as fuel; the obtained calcium carbide is 5714.286kg / h.

[0033] Step 2: Calcium Calcium Gas Acquisition:

[0034] The calcium carbide obtained in step 1 and water are mixed in the calcium carbide generator at a mass ratio of ...

Embodiment 2

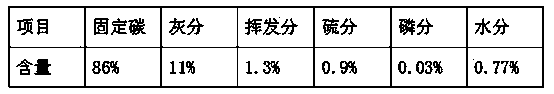

[0039] The main composition of the raw material semi-coke in this example is shown in the following table: (4000kg / h semi-coke, temperature 40°C)

[0040]

[0041] Step 1: Produce calcium carbide using a closed calcium carbide furnace production process:

[0042] After the semi-coke is dried and screened, the moisture content of the semi-coke is reduced to 1% by mass, and the particle size is controlled at 10-20mm; it is mixed with lime powder at a mass ratio of 0.65:1, and then enters a closed calcium carbide furnace for reaction , the calcium carbide furnace is cooled and purified for use; the tail gas of the calcium carbide furnace is obtained by pressure swing adsorption (PSA), and the remaining gas is returned to the closed calcium carbide furnace as fuel; the obtained calcium carbide is 6153.846kg / h.

[0043] Step 2: Calcium Calcium Gas Acquisition:

[0044] The calcium carbide obtained in step 1 and water are mixed in the calcium carbide generator at a mass ratio of...

Embodiment 3

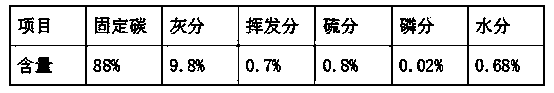

[0049] The main composition of the raw material semi-coke in this example is shown in the following table: (4000kg / h semi-coke, temperature 40°C)

[0050]

[0051] Step 1: Production of calcium carbide using a closed calcium carbide furnace production process:

[0052] After the semi-coke is dried and screened, the moisture content of the semi-coke is reduced to 1% by mass, and the particle size is controlled at 20-25mm; it is mixed with lime powder at a mass ratio of 0.65:1, and then enters a closed calcium carbide furnace for reaction , the carbide from the calcium carbide furnace is cooled and purified for use; the tail gas of the calcium carbide furnace is obtained by pressure swing adsorption (PSA), and the remaining gas is returned to the closed calcium carbide furnace as fuel; the obtained calcium carbide is 6666.667kg / h.

[0053] Step 2: Calcium Calcium Gas Acquisition:

[0054] The calcium carbide obtained in step 1 and water are mixed in the calcium carbide gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com