Cast aluminum alloy with high thermal conductivity and preparation method thereof

A technology of casting aluminum alloy and high thermal conductivity, applied in the field of metal materials, can solve problems such as thermal conductivity gap, and achieve the effect of reducing energy consumption, good performance and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

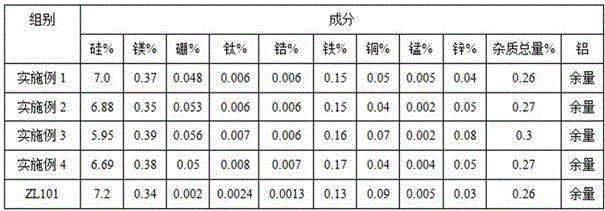

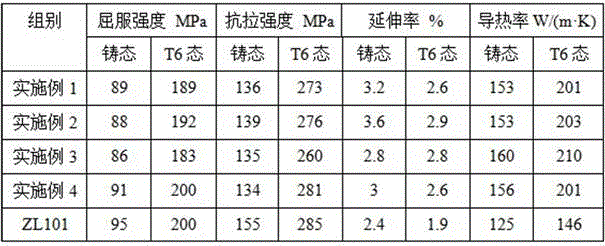

Examples

preparation example Construction

[0024] A method for preparing cast aluminum alloy with high thermal conductivity, comprising the following steps:

[0025] 1) Use a natural gas reflection melting furnace for melting, first melt the pure aluminum ingot, when the temperature of the pure aluminum liquid reaches 800-850°C, then add pure silicon, after the silicon is melted, then add the remaining intermediate alloy, after the melting is complete , stand still, and finally add magnesium. After the melting is complete, analyze the composition of the alloy melt before the furnace to detect the composition content of the alloy melt, and reach the qualified range by feeding or diluting the melt with unqualified composition content;

[0026] 2) Lower the temperature of the alloy melt with qualified composition to 730-750°C, blow the modificant boron oxide powder into the melt through inert gas, then continue to degas and remove slag with inert gas, and then carry out the component analysis before the furnace. After pou...

Embodiment 1

[0034] 1) Use a 5-ton natural gas reflective melting furnace for smelting. During the smelting process, first melt 2700Kg of pure aluminum ingots. When the temperature of the pure aluminum liquid reaches 830°C, add 210Kg of pure silicon. After the silicon is melted, add the remaining Intermediate alloys, namely 50Kg Al-3B, 3.6Kg Al-5Ti, 1.8Kg Al-10Zr, after the melting is complete, keep warm for 10 minutes, and finally add 12Kg magnesium. ;

[0035] 2) Lower the temperature of the alloy melt with qualified composition to 740°C, blow into the melt through nitrogen with a pressure of 0.2MPa and blow into the melt the weight of all substances and 0.04% of the modifier boron oxide powder, and then continue to degas with nitrogen Slag for 10 minutes, and then analyze the components before the furnace, and pour water to cast after passing the test.

Embodiment 2

[0037] 1) Use a 5-ton natural gas reflective melting furnace for melting. During the melting process, first melt 2700Kg of pure aluminum ingots. When the temperature of the pure aluminum liquid reaches 800°C, add 206Kg of pure silicon. After the silicon is melted, add the remaining Intermediate alloys, namely 50Kg Al-3B, 3.6Kg Al-5Ti, 1.8Kg Al-10Zr, after the melting is complete, keep warm for 15 minutes, and finally add 11Kg of magnesium. After the melting is complete, analyze the composition of the alloy melt before the furnace ;

[0038] 2) Lower the temperature of the alloy melt with qualified composition to 750°C, blow into the melt through nitrogen with a pressure of 0.4MPa and blow into the melt the weight of all material weight and 0.03% modifier boron oxide powder, and then continue to degas with nitrogen Slag for 10 minutes, then carry out the composition before the furnace, pour water and cast after passing the test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com