Preparation method of titanium boride based inorganic composite coating

An inorganic composite material, titanium boride technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of high raw material cost, easy cracking of the coating, complicated preparation process, etc., to overcome the particle shape Irregularity, overcoming the effects of high cost of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

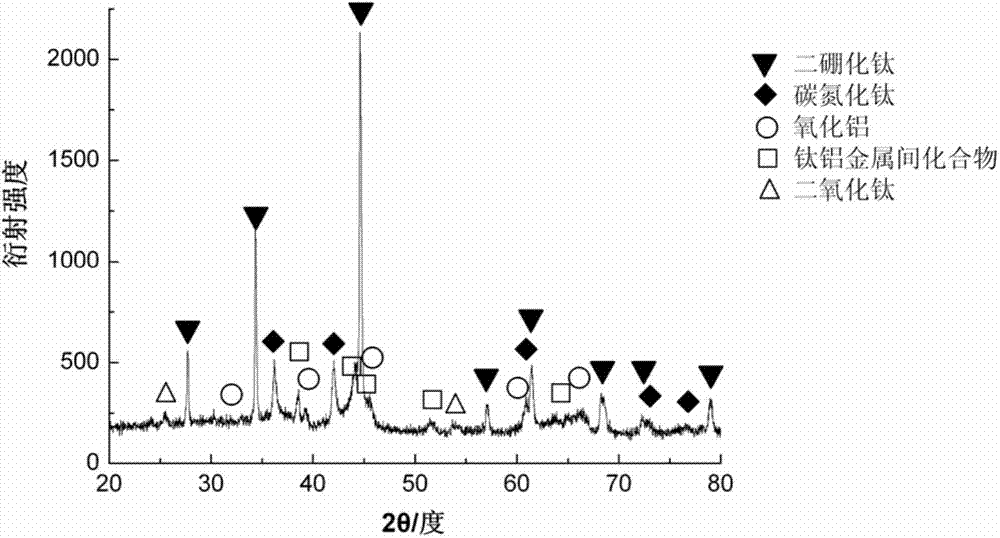

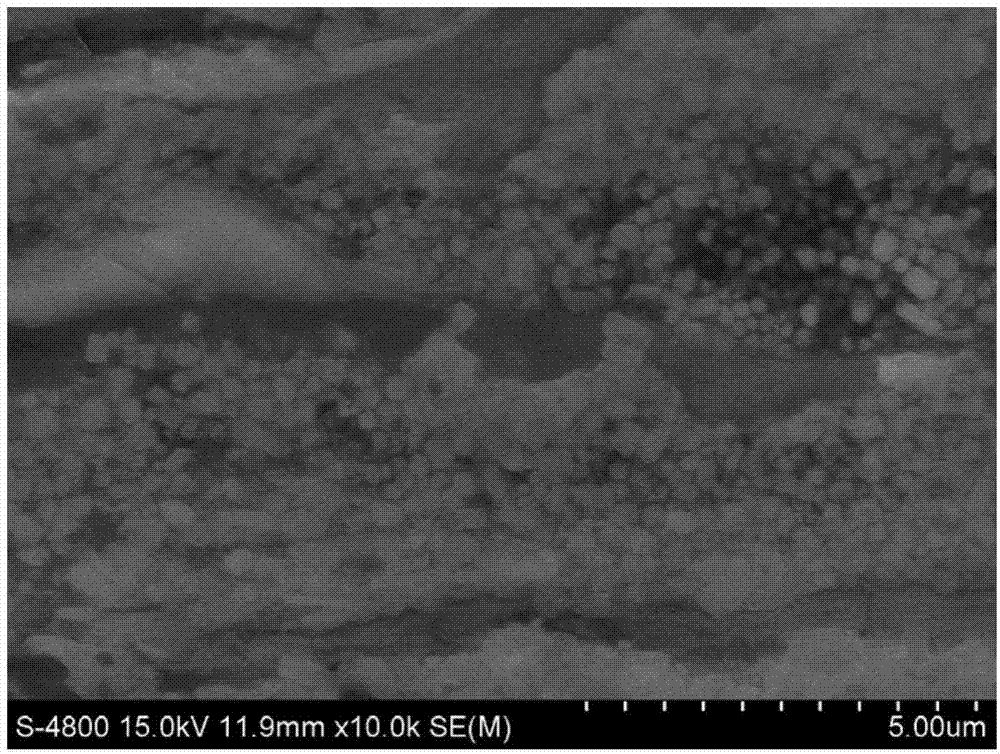

[0046] First step, formulating TiO for thermal spraying 2 / B 4 C / Al composite powder;

[0047] Al powder with a particle size range of 1 micron to 5 microns, TiO with a particle size range of 0.001 micron to 0.1 micron 2 Powder and B with a particle size ranging from 0.5 microns to 5 microns 4 C powder is evenly mixed into a mixture powder, wherein the weight percentage of Al powder is 27%, TiO 2 The weight percentage of powder is 59%, B 4 The weight percent of C powder is 14%, and then uniformly mixed into polyvinyl alcohol with a weight ratio of material powder: binder = 100:1, thus being formulated into TiO2 for thermal spraying. 2 / B 4 C / Al composite powder;

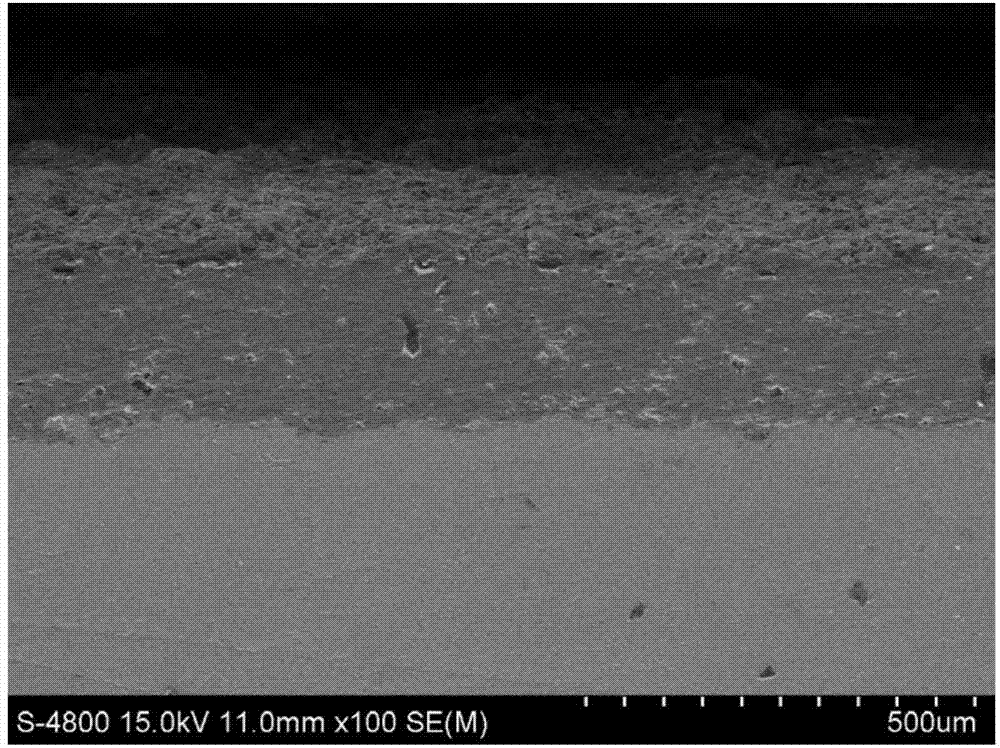

[0048] The second step is to spray a layer of alloy primer on the surface of the metal workpiece to be coated

[0049] Shot peening is performed on the surface of the Q235 steel workpiece to be coated first, and then a layer of Ni-Al alloy bottom layer is sprayed on the surface of the Q235 steel workpiece afte...

Embodiment 2

[0056] First step, formulating TiO for thermal spraying 2 / B 4 C / Al composite powder;

[0057] Al powder with a particle size range of 1 micron to 10 microns, TiO with a particle size range of 0.001 micron to 0.1 micron 2 Powder and B with particle size ranging from 0.001 micron to 0.5 micron 4 C powder is evenly mixed into a mixture powder, wherein the weight percentage of Al powder is 27%, TiO 2 The weight percentage of powder is 59%, B 4 The weight percent of C powder is 14%, and then uniformly mixed into the methyl cellulose with a weight ratio of material powder: binder = 100:0.8, thus being formulated into TiO for thermal spraying 2 / B 4 C / Al composite powder;

[0058] The second step is to spray a layer of alloy primer on the surface of the metal workpiece to be coated

[0059] Shot peening is performed on the surface of the 45 steel workpiece to be coated first, and then a layer of Fe-Al alloy bottom layer is sprayed on the surface of the 45 steel workpiece afte...

Embodiment 3

[0063] Except that the metal workpiece to be coated is a Q195 steel workpiece, the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com