Preparation method and application of modified carbon nanotube

A technology of carbon nanotubes and nanotubes, which is applied in the field of preparation of modified carbon nanotubes, can solve the problems of heat conduction materials that are difficult to achieve heat conduction, poor thermal conductivity, uneven dispersion, etc., and achieve excellent mechanical properties, excellent thermal conductivity and The effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

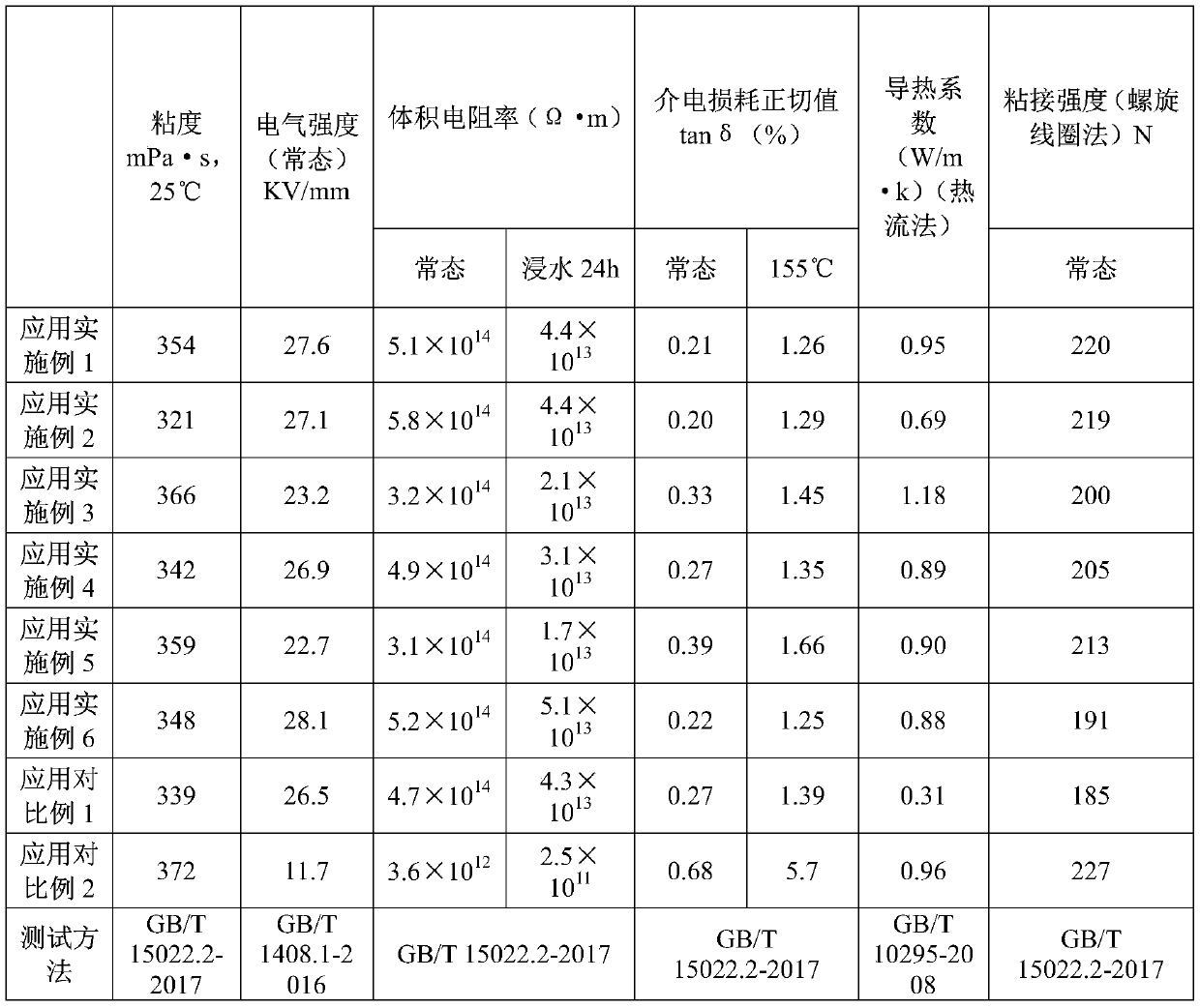

Examples

Embodiment 1

[0030] The preparation of embodiment 1 modified carbon nanotubes

[0031] (1) Prepare surface carboxylated carbon nanotubes; add 1 part of multi-walled carbon nanotubes to 90 parts of concentrated sulfuric acid for ultrasonic dispersion for 30 minutes, then add 30 parts of nitric acid to this solution, and stir in an oil bath at 110 ° C 6 hours. After the reaction is completed, pour this solution into 1000 parts of water to obtain a yellow-brown solution, then centrifuge this solution at a speed of 10000 r / min, wash the product with water and continue centrifuging three times to obtain surface carboxylated carbon nanotubes;

[0032] (2) 10 parts of surface carboxylated carbon nanotubes prepared in step (1) are added to a mixed solution of 50 parts of water and 50 parts of ethanol, and 5 parts of ethyl orthosilicate and 5 parts of vinyltriethoxysilane Mix, and prepare 10 parts ammonia. Put the surface carboxylated carbon nanotube solution into an oil bath at 35°C and stir, sl...

Embodiment 2

[0033] The preparation of embodiment 2 modified carbon nanotubes

[0034](1) Prepare surface carboxylated carbon nanotubes; add 1 part of multi-walled carbon nanotubes to 90 parts of concentrated sulfuric acid for ultrasonic dispersion for 30 minutes, then add 35 parts of nitric acid to this solution, and stir in an oil bath at 115 ° C After 6 hours, after the reaction was completed, pour this solution into 1000 parts of water to obtain a yellow-brown solution, then centrifuge this solution at a speed of 10000r / min, wash the product with water and continue centrifuging three times to obtain surface carboxylated carbon nanotube;

[0035] (2) 10 parts of surface carboxylated carbon nanotubes prepared in step (1) are added to a mixed solution of 50 parts of water and 50 parts of ethanol, and 2.5 parts of ethyl orthosilicate and 7.5 parts of vinyltriethoxysilane Mix, and prepare 10 parts ammonia. Put the surface carboxylated carbon nanotube solution in a 40°C oil bath and stir, ...

Embodiment 3

[0036] The preparation of embodiment 3 modified carbon nanotubes

[0037] (1) Prepare surface carboxylated carbon nanotubes; add 1 part of multi-walled carbon nanotubes to 90 parts of concentrated sulfuric acid for ultrasonic dispersion for 30 minutes, then add 30 parts of nitric acid to this solution, and stir in an oil bath at 110 ° C 6 hours. After the reaction is completed, pour this solution into 1000 parts of water to obtain a yellow-brown solution, then centrifuge this solution at a speed of 10000 r / min, wash the product with water and continue centrifuging three times to obtain surface carboxylated carbon nanotubes;

[0038] (2) 10 parts of surface carboxylated carbon nanotubes prepared in step (1) are added to a mixed solution of 50 parts of water and 50 parts of ethanol, and 7.5 parts of ethyl orthosilicate and 2.5 parts of vinyltriethoxysilane Mix, and prepare 10 parts ammonia. Put the surface carboxylated carbon nanotube solution into an oil bath at 35°C and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com