Patents

Literature

121results about How to "Reduce punching force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

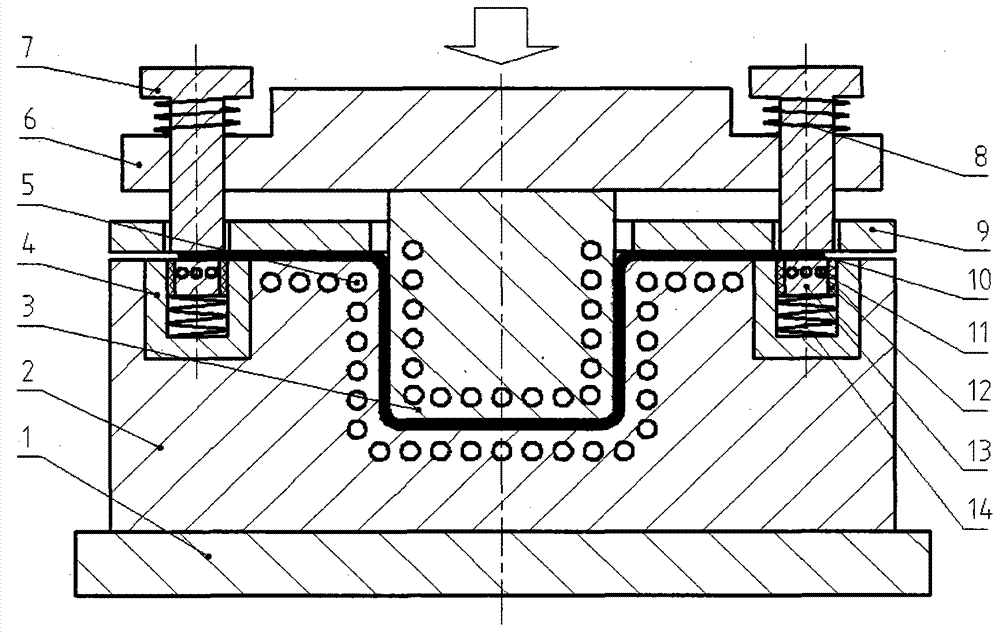

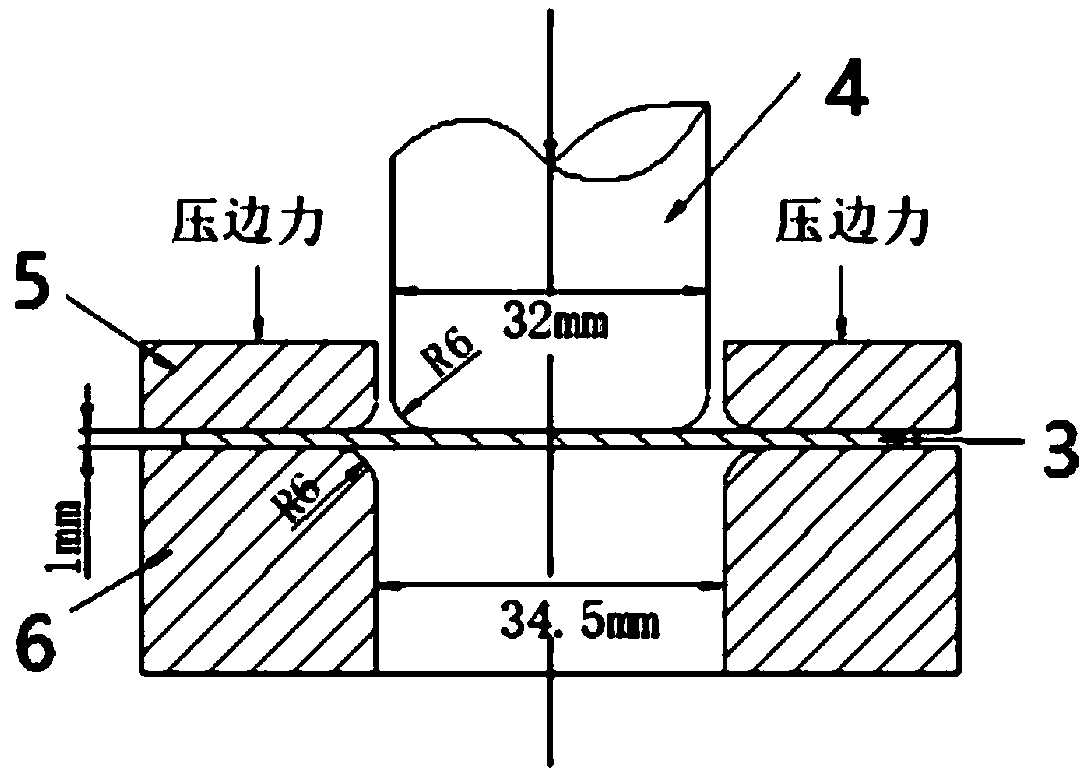

Hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel

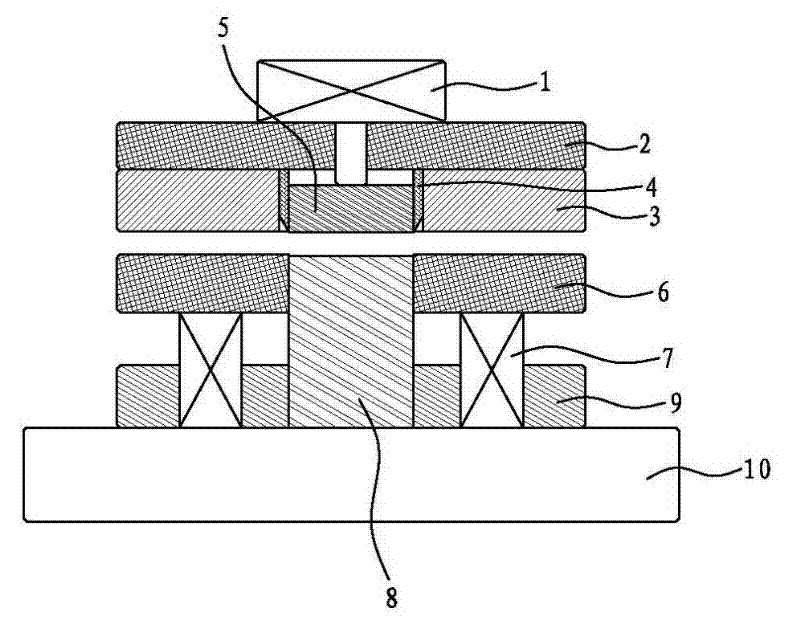

The invention provides a hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel. By means of the composite mould, blanking is composited in a hot stamping process, and trimming and punching are performed on sheet metal at a temperature higher than a martensite formation temperature. The hot stamping and warm blanking composite forming technology comprises the following processes of putting the sheet metal of the ultrahigh-strength steel heated to achieve complete austenitizing into the composite mould, performing stamping forming and then performing cooling and quenching; heating sheet metal needing blanking locally, keeping a warm state, performing warm blanking after completion of forming, and performing cooling further in a pressure maintaining mode. The hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel effectively solves the problems of poor quality, low precision, high cost and long period of holes trimmed and punched in the later period of the ultrahigh-strength steel and has great practical significance in production practice.

Owner:JILIN UNIV

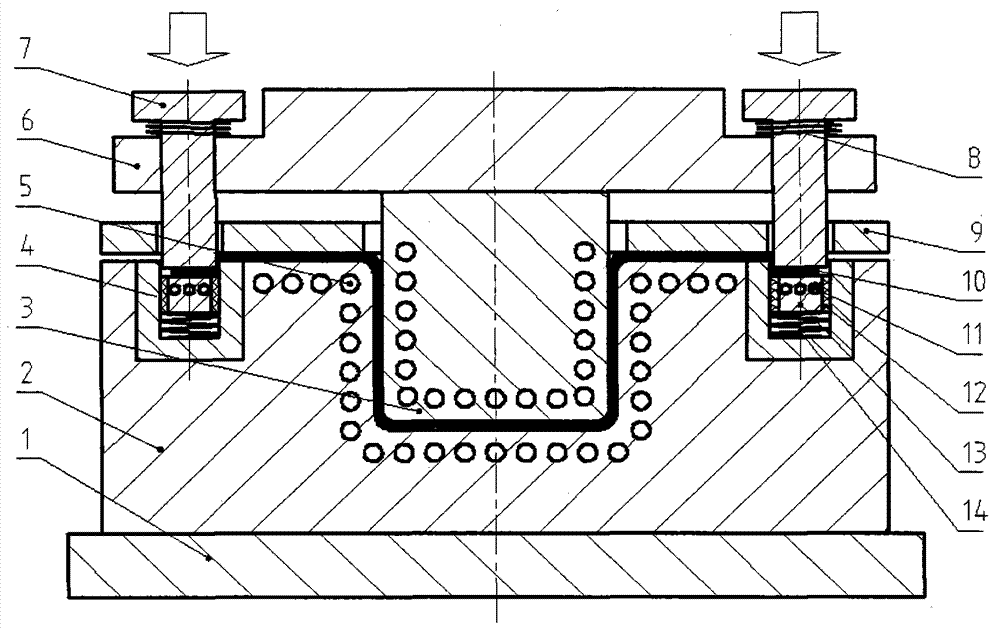

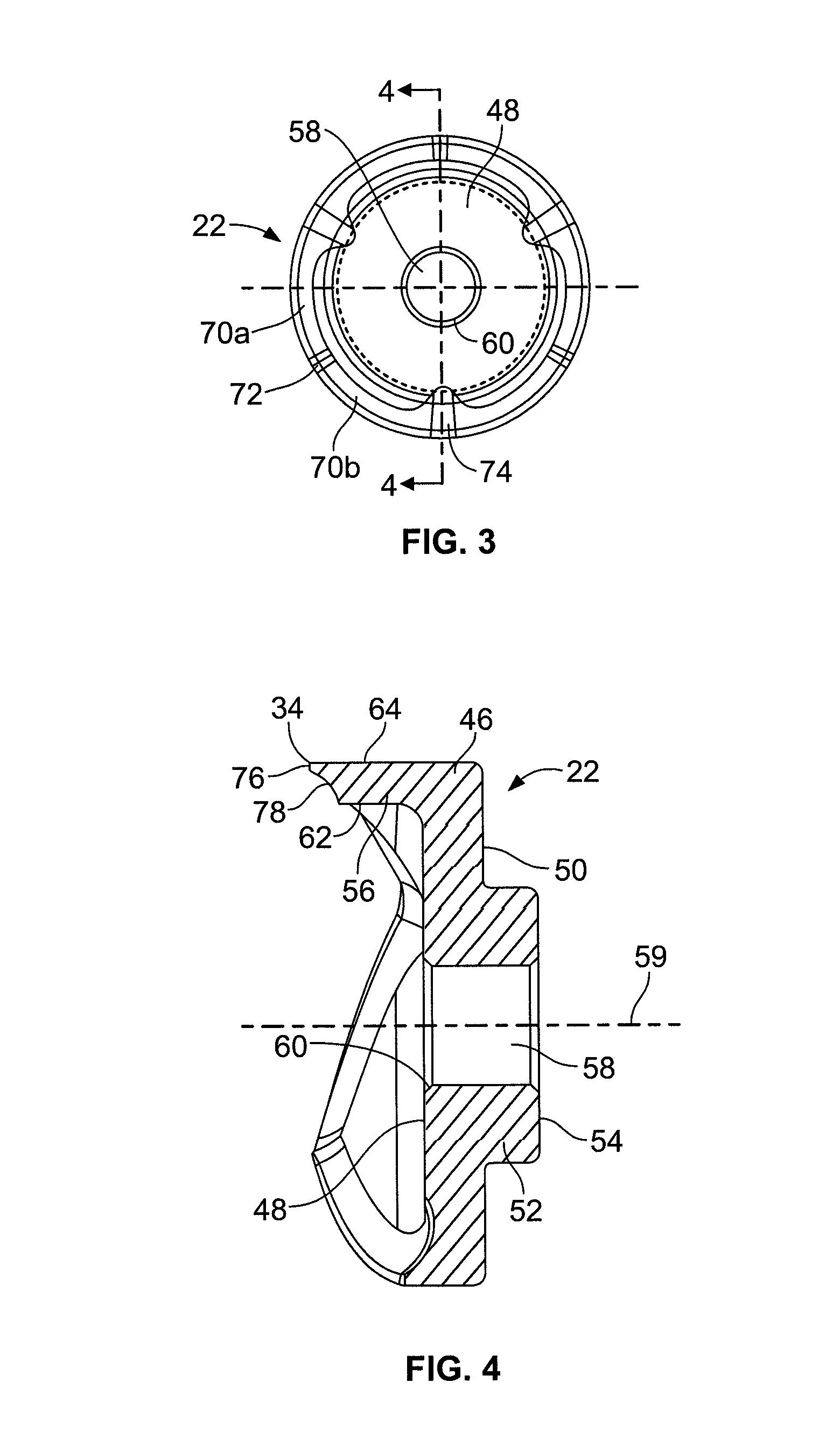

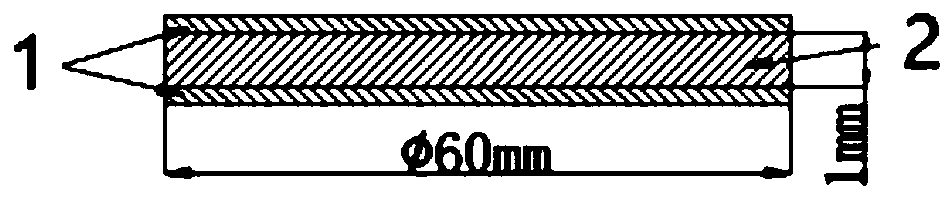

Sleeve for a punch assembly

ActiveUS8904911B2Improve rigidityReduce deflectionPerforating toolsMetal working apparatusPunchingPilot hole

A punch assembly includes a punch, a sleeve, a draw stud and a die. The sleeve adds rigidity to the draw stud, thereby reducing elastic deflection of the draw stud, reducing bending moment on the draw stud, reducing punching force, and extending the punch, draw stud and die fatigue life. The sleeve also aids in axial alignment of the punch, die and workpiece with a pilot hole drilled through a workpiece.

Owner:GREENLEE TEXTRON

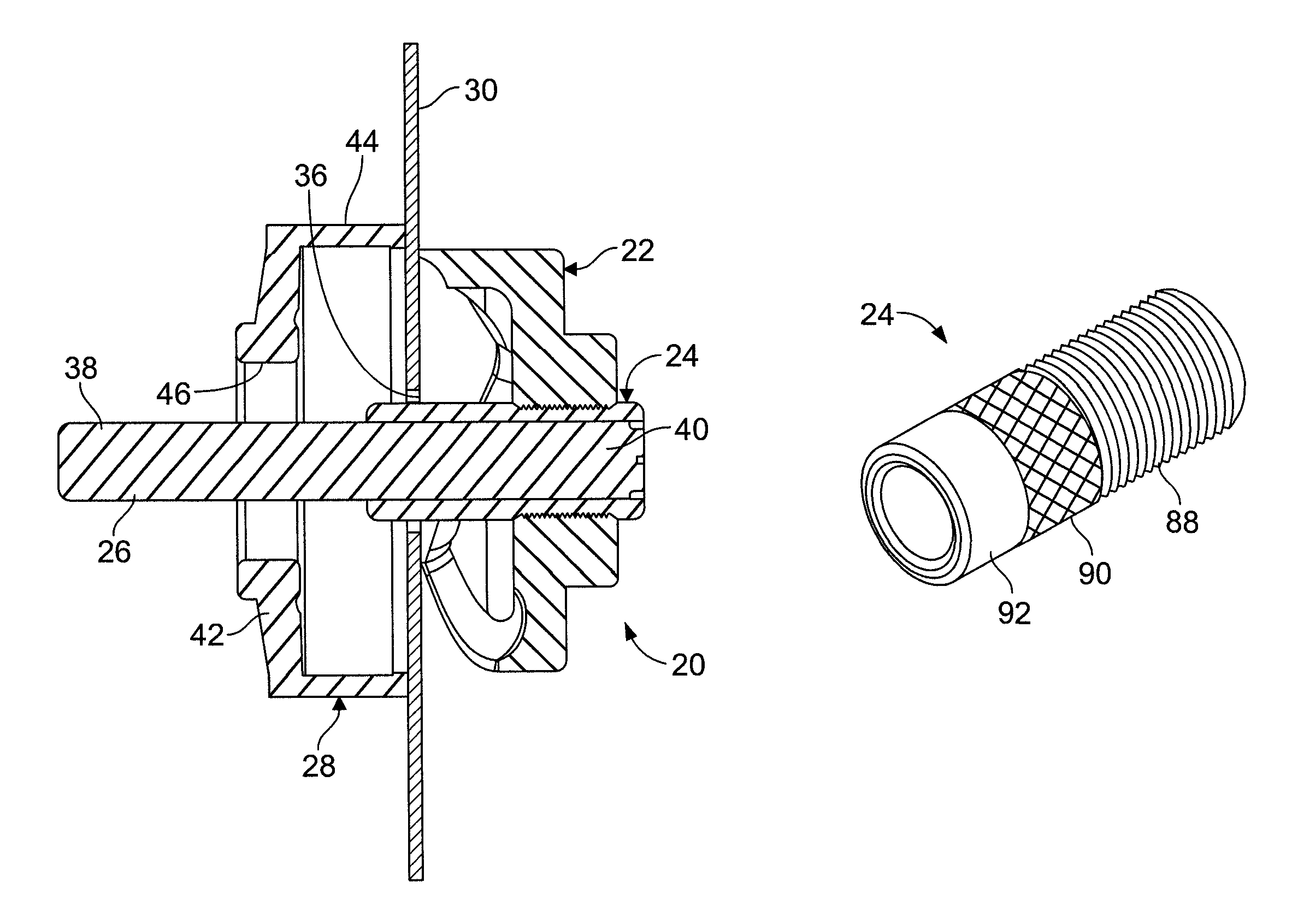

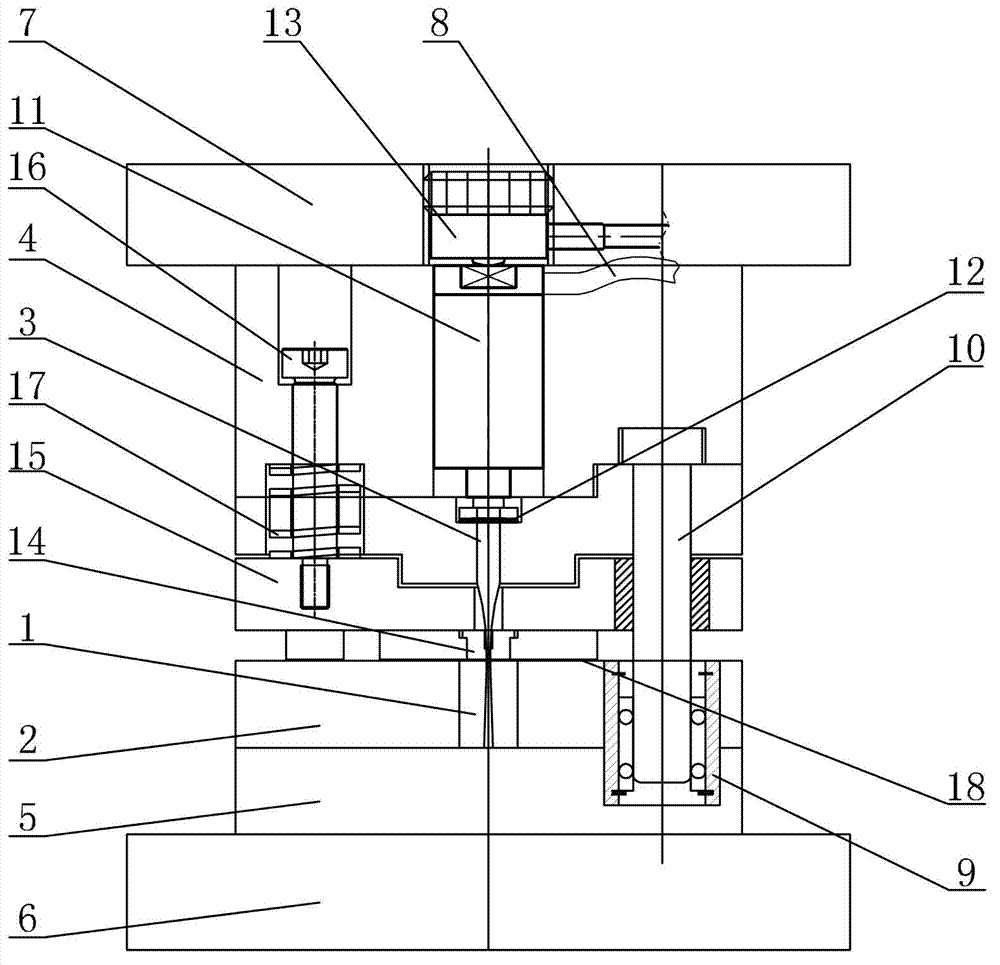

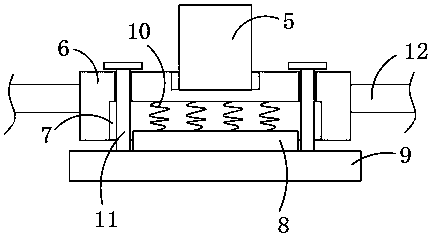

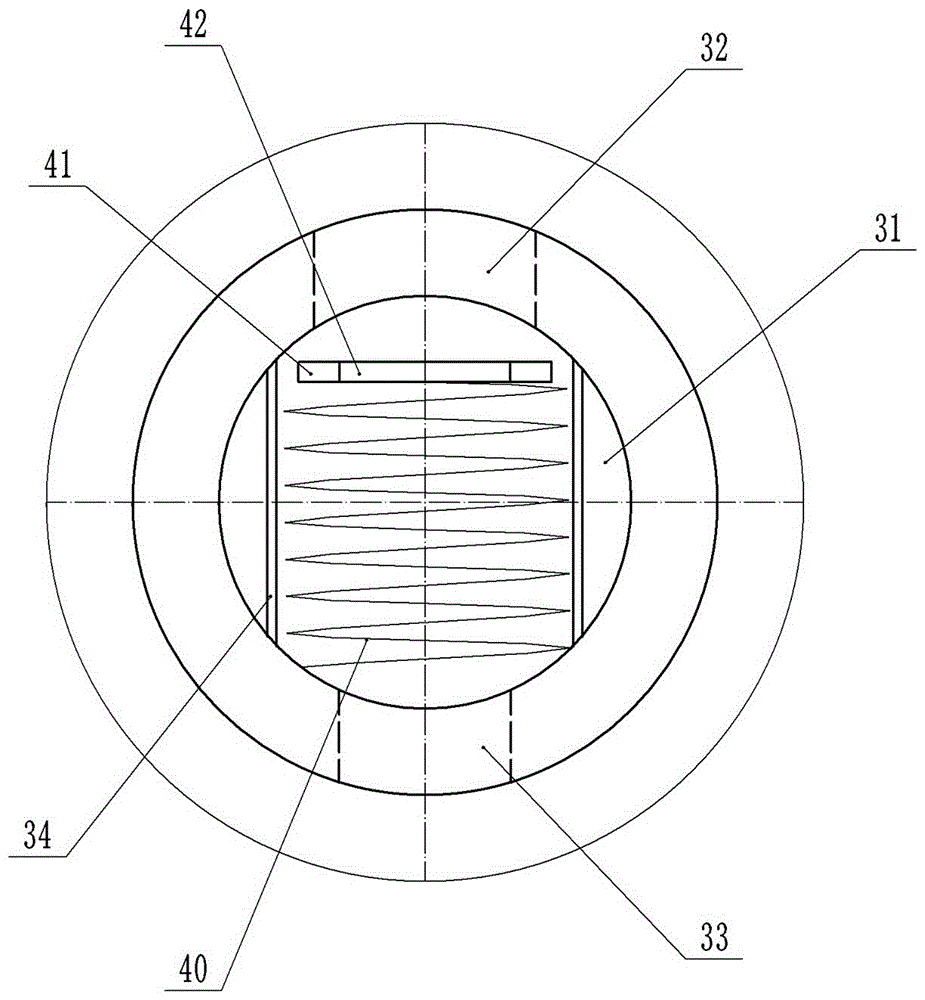

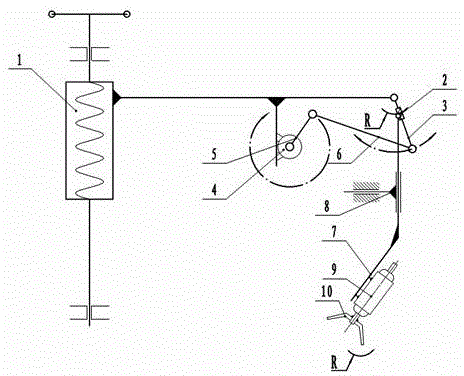

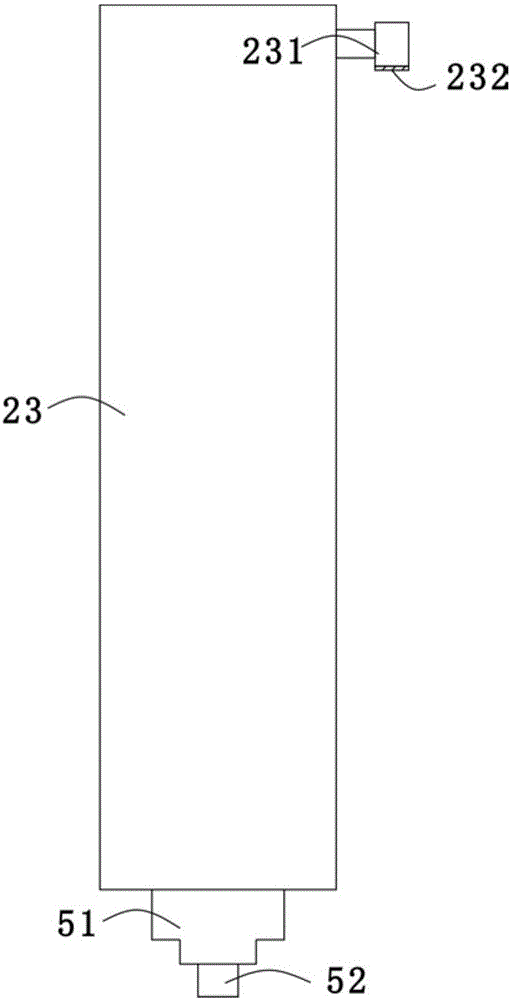

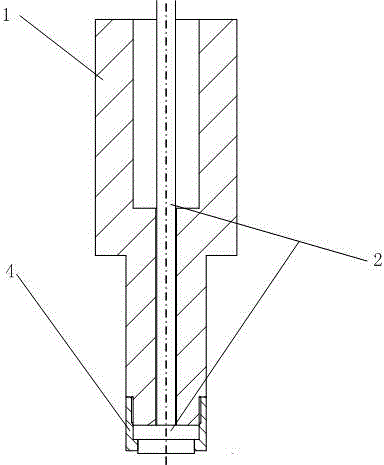

High-frequency vibration auxiliary micro-blanking forming device and method for foil plate

ActiveCN102962331AInhibition of germinationInhibition of scalabilityMechanical vibrations separationEjection devicesHigh frequency powerEngineering

The invention relates to a micro-blanking forming device and a forming method, in particular to a high-frequency auxiliary micro-blanking forming device and a method for a foil plate. The device and the method aim at solving the problems in the existing high-precision blanking forming of the foil plate that an interval between a female die and a male die is small, a blanking force is significantly increased by a size effect, and the dies are badly worn and have short service lives. The device comprises a female die fixing plate, a lower bolster and a lower die plate that are sequentially connected from the top down, wherein an upper die plate and a male die fixing plate are sequentially arranged above the female die fixing plate; a female die is embedded into the middle part of the upper surface of the female die fixing plate; a vibration component and a punch are sequentially mounted in the male die fixing plate from the top down in an inserting manner; a middle line of the punch is coincided with that of the female die; the vibration component is connected with a high-frequency power source; a guide sleeve is mounted on the upper surface of the female die fixing plate in an inserting manner; the upper end of a guide column is mounted in the male die fixing plate in an inserting manner; and the lower end of the guide column is mounted in the guide sleeve in an inserting manner. The device and the method are used for blanking forming of the foil plate.

Owner:HARBIN INST OF TECH

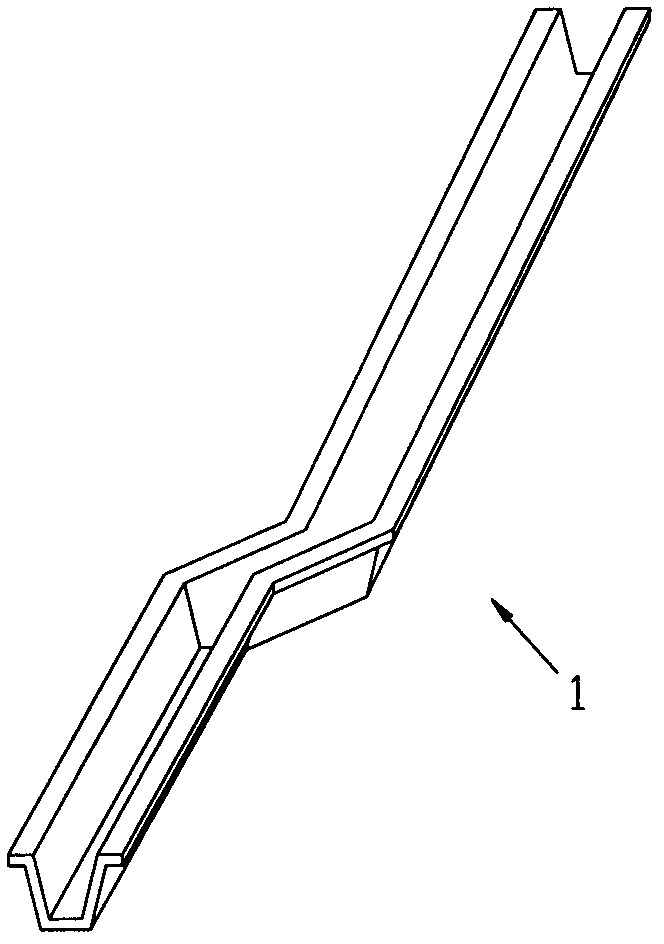

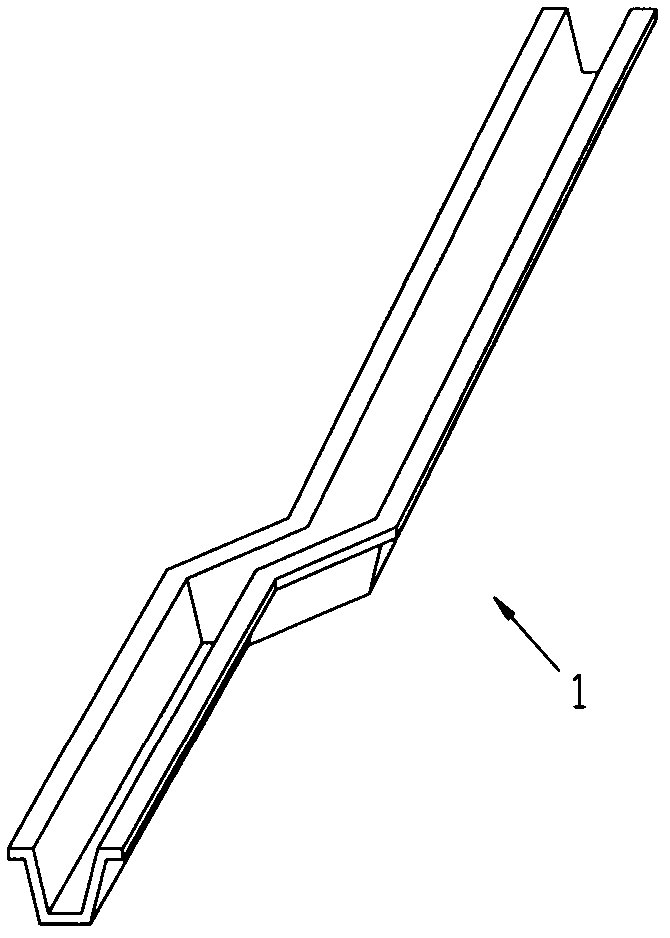

Manufacturing process of automobile longitudinal bearing beam

InactiveCN102357612AHigh surface hardnessLightweight bodyLoad-supporting pillarsHot stampingPunching

The invention discloses a manufacturing process of an automobile longitudinal bearing beam. The process comprises the following steps: (a) blanking; (b) removing oil and rust from the blanked material; (c) performing hot stamping forming on the clean material; (d) performing final punching and trimming on the formed piece; and (e) performing rust prevention treatment. The hot stamping is performed in a closed cavity filled with nitrogen; a plate is uniformly heated to 770-780 DEG C to form a uniform austenite structure and then is pressed by using a stamping die; then the temperature reduction process is quickly finished at a constant speed in the stamping die; and finally the automobile longitudinal bearing beam is in a uniform martensite structure. Through the invention, high strength can be realized as long as the wall thickness of the automobile longitudinal bearing beam is just 6 mm; the shortcomings of cold stamping, such as crack, excessive rebound and the like, are avoided; the automobile longitudinal bearing beam has high anti-collision level and is safe and reliable; the automobile becomes light, the automobile oil consumption is reduced, and CO2 discharge is reduced; and moreover, the generation of an oxidized layer on the automobile longitudinal bearing beam is avoided at a high temperature, and therefore regular cleaning of oxidized layers is not required.

Owner:上海德真工贸有限公司

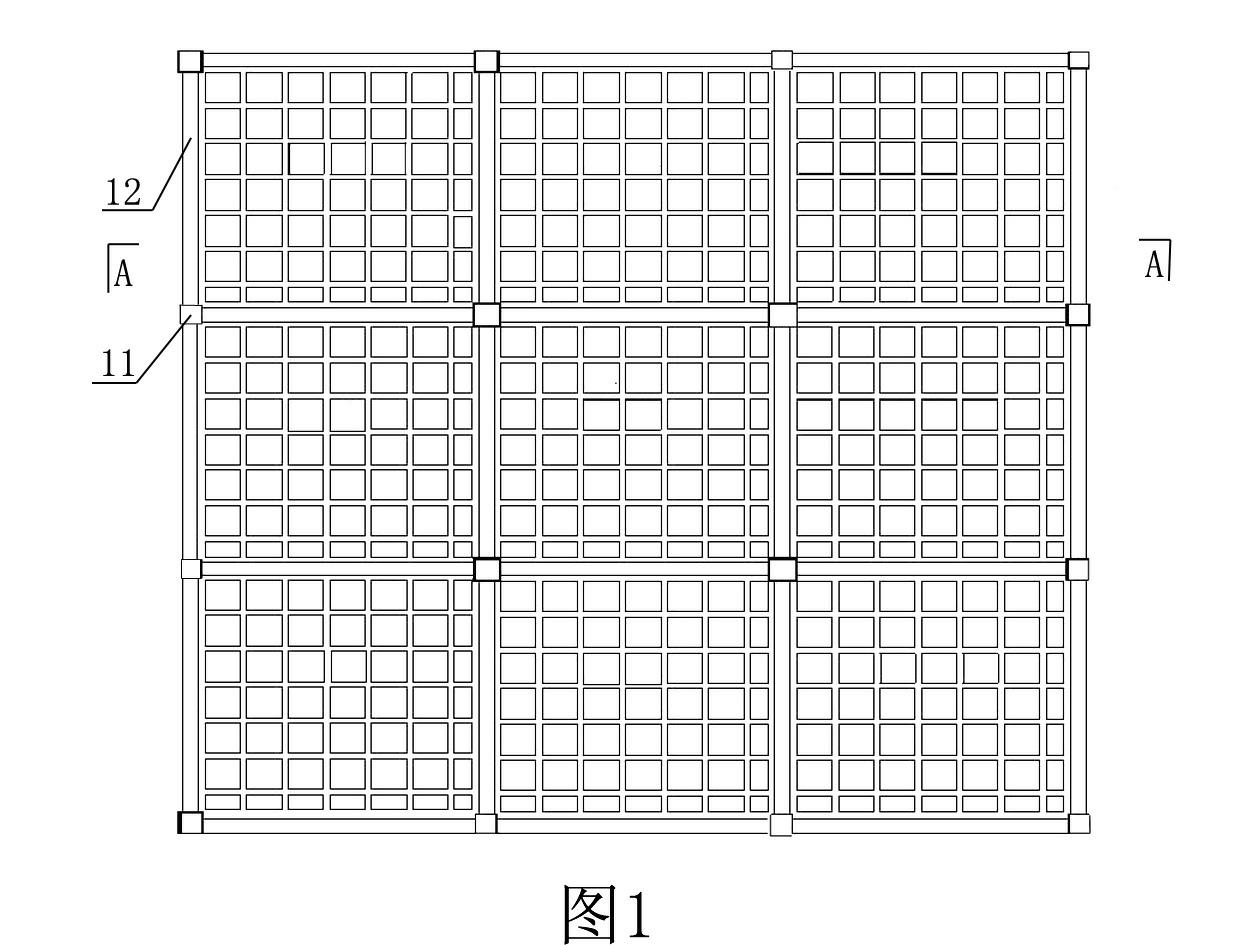

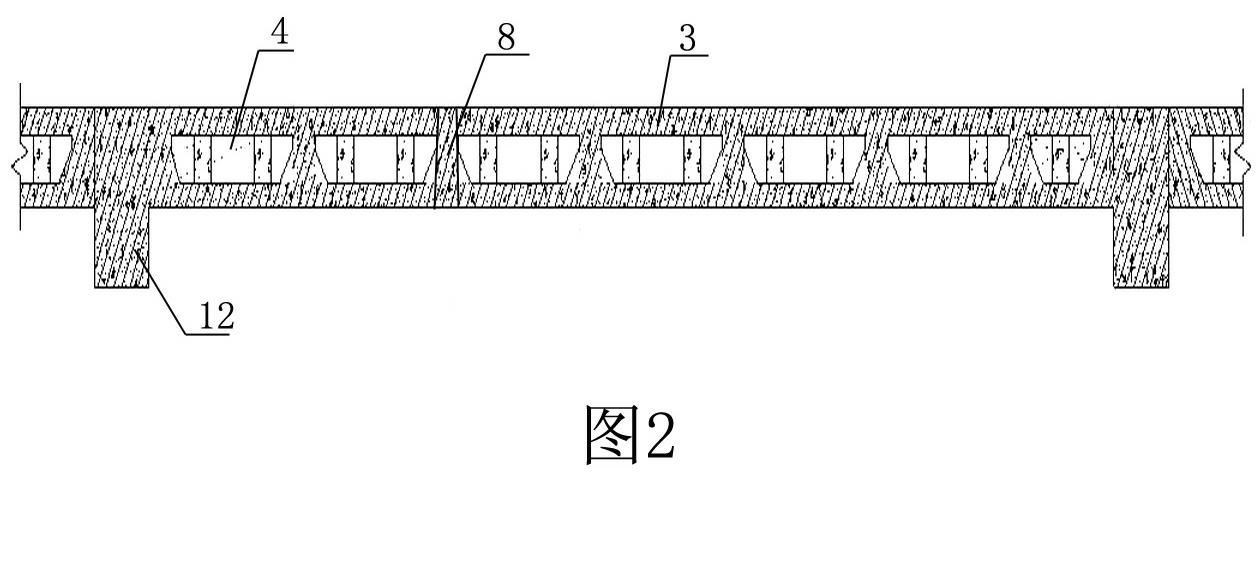

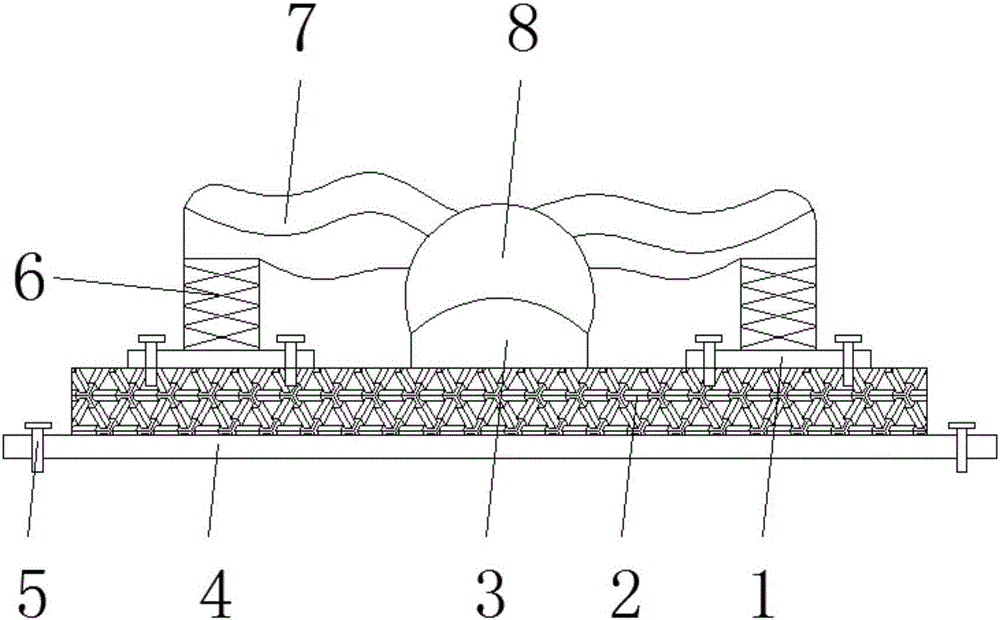

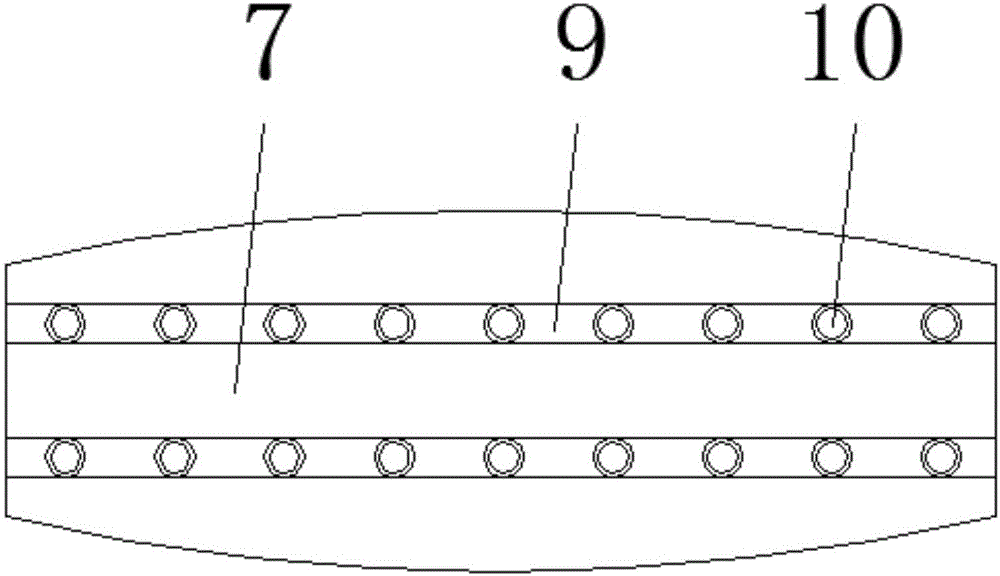

Phase change material (PCM) cast-in-place reinforced concrete large-size sandwiched floor and construction method thereof

InactiveCN102409788AGuarantee the pouring qualitySpeed up the flowFloorsBuilding material handlingReinforced concreteKeel

The invention relates to a phase change material (PCM) cast-in-place reinforced concrete large-size sandwiched floor and a construction method thereof. Concealed beams are arranged in the sandwiched floor at intervals; the sandwiched floor consists of a core die, upper steel bars, lower steel bars and outer-packed concrete; and the core die is a solid polystyrene block, the upper steel bars are bound on the top of the core die, the lower steel bars are bound on the bottom surface of the die core, and the steel bars and the core die are wrapped into a whole through the outer-packed concrete. An inner die floats upwards in the pouring process, and the lower steel bars and the upper steel bars are bound with the keel of a bottom template through anti-floating steel wires. The sandwiched floor has the advantages of light dead weight, good anti-seismic and sound insulation effects, no limit on embedded pipelines in the construction process and the like. The sandwiched floor can be widely applied to multi-layer and high-layer buildings with larger spans and loads and thicker floors.

Owner:北京建工博海建设有限公司 +1

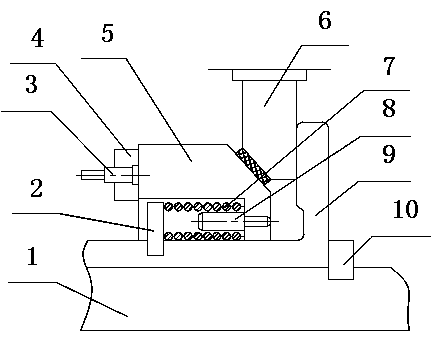

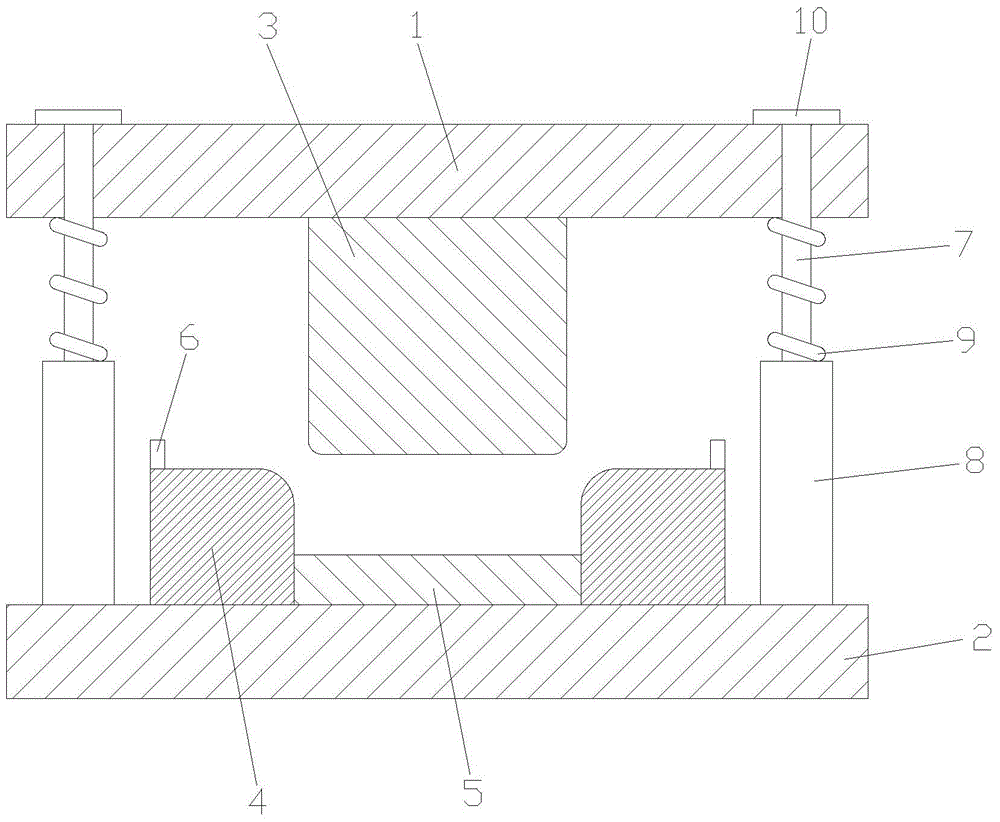

Plastic piece punching and cutting die

InactiveCN102229151AReduce punching forcePrevent overflowMetal working apparatusPunchingStructural engineering

The invention discloses a plastic piece punching and cutting die, which comprises a cylinder, an upper die base plate, an upper die, a cutting-off cavity die, a pressure plate, a stripping plate, stripping springs, a punching head, a lower die and a lower die base plate. One end of the cutting-off cavity die is fixed inside the upper die base plate and is sleeved inside the upper die; cutting edges are obliquely and inwards formed on the surfaces at another end of the cutting-off cavity die; the pressure plate is movably sleeved in the cutting-off cavity die; a piston rod of the cylinder penetrates through the upper die base plate and is supported and pressed on the stripping plate; the stripping plate is in clearance sleeve connection with the punching head; the stripping springs are arranged between the stripping plate and the lower die base plate; and the lower die is fixed on the lower die base plate. As the cutting edges are obliquely and inwards formed on the surfaces at another end of the cutting-off cavity die, the blanking force for punching and cutting a plastic piece by using the plastic piece punching and cutting die is greatly reduced, the occurrence of the phenomena of spillover, cement extrusion and crushing of optical cement used for bonding plastic during the process of punching is better avoided, and the size of punched and cut products is stable and accurate.

Owner:厦门加新精密金属有限公司

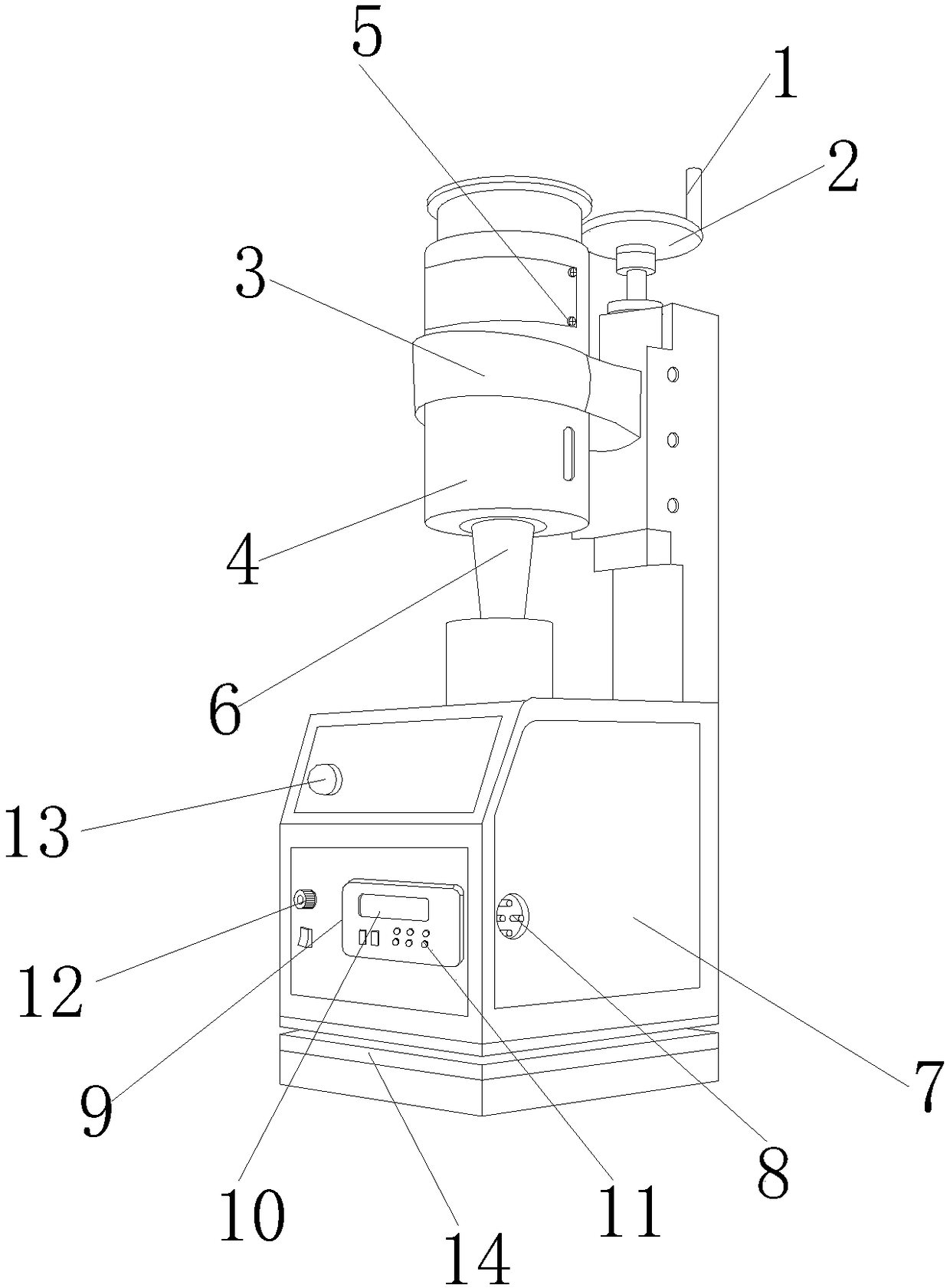

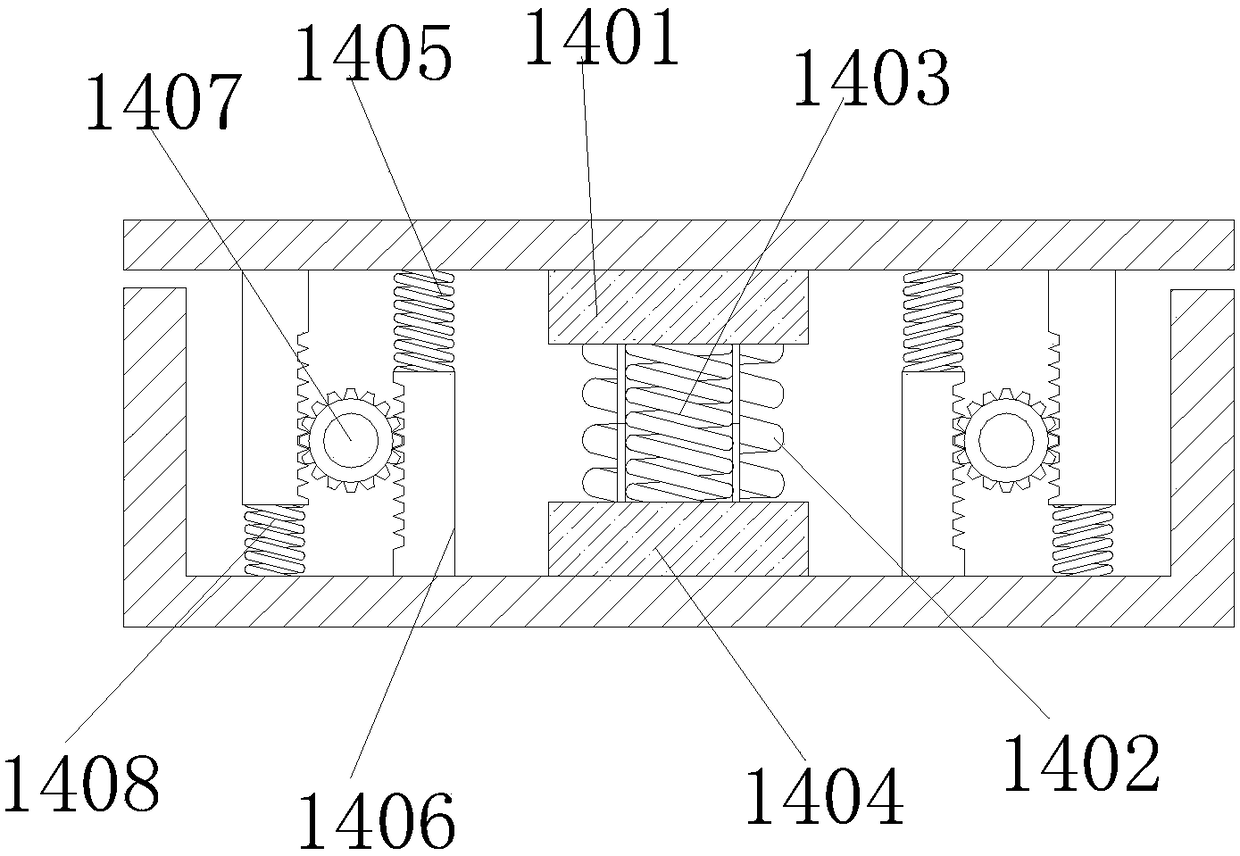

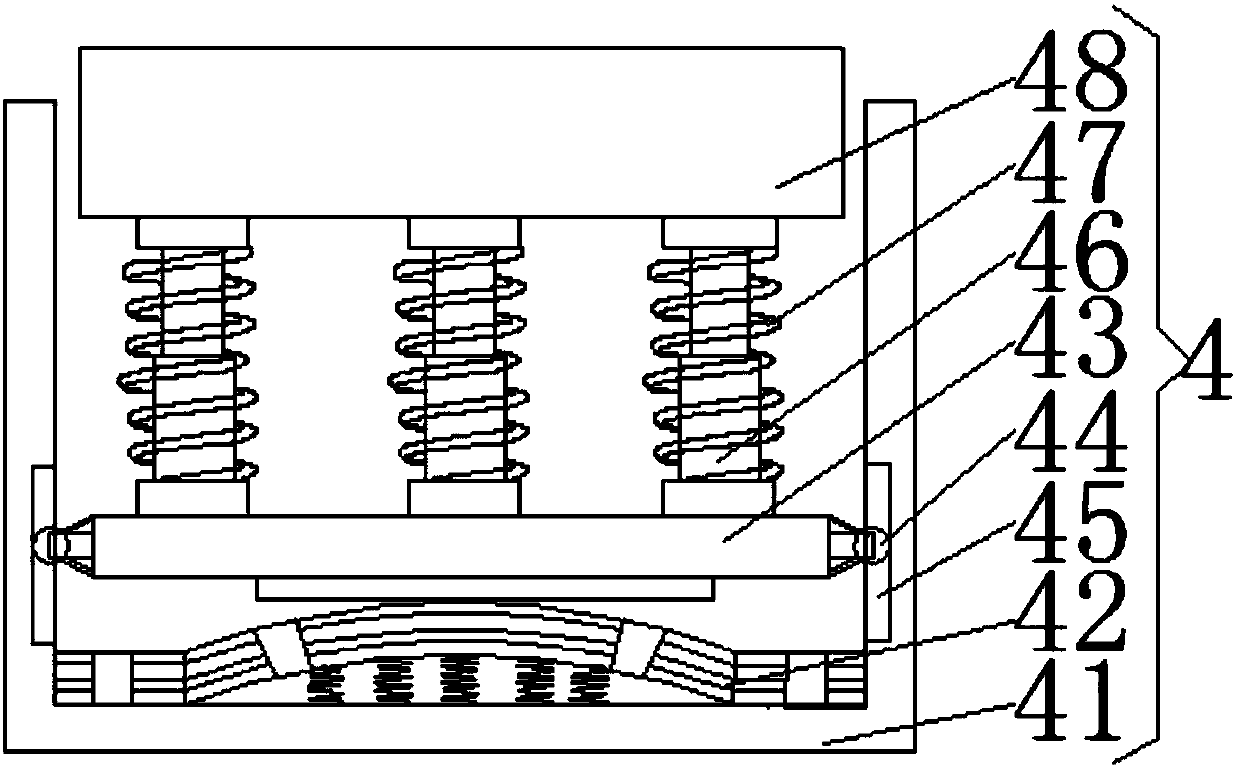

Punching equipment capable of preventing elements from being easily damaged

InactiveCN108556039AReduce punching forceNon-rotating vibration suppressionMetal working apparatusPunchingDisplay device

The invention discloses punching equipment capable of preventing elements from being easily damaged. The punching equipment structurally comprises a handle, a debugging wheel, a fixing block, a protection shell, a bolt, a machining head, a base, a power supply connection port, a panel, a displayer, a button, a debugging button, an indicating lamp and a damping device; the debugging button is arranged on the left side of the panel, the debugging button is arranged on the left side of the displayer, and the base is welded to the damping device; the damping device comprises a first connecting block, a central spring, an inner spring, a second connecting block, a first spring, a gear strip, a gear and a second spring. The punching equipment capable of preventing the elements from being easilydamaged is structurally provided with the damping device, and the central spring and the inner spring are arranged at the middle section of the first connecting block and the middle section of the second connecting block, so that the working pressure of the equipment is reduced; the first spring is installed on the gear strip, the second spring is extruded when the gear and the gear strip move downwards, remaining impact force is reduced, and the elements in the base are protected.

Owner:徐美琴

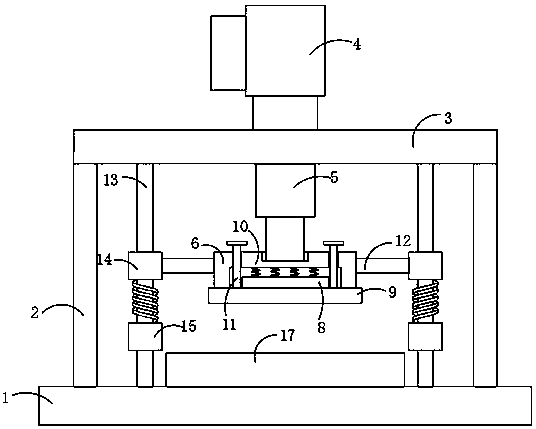

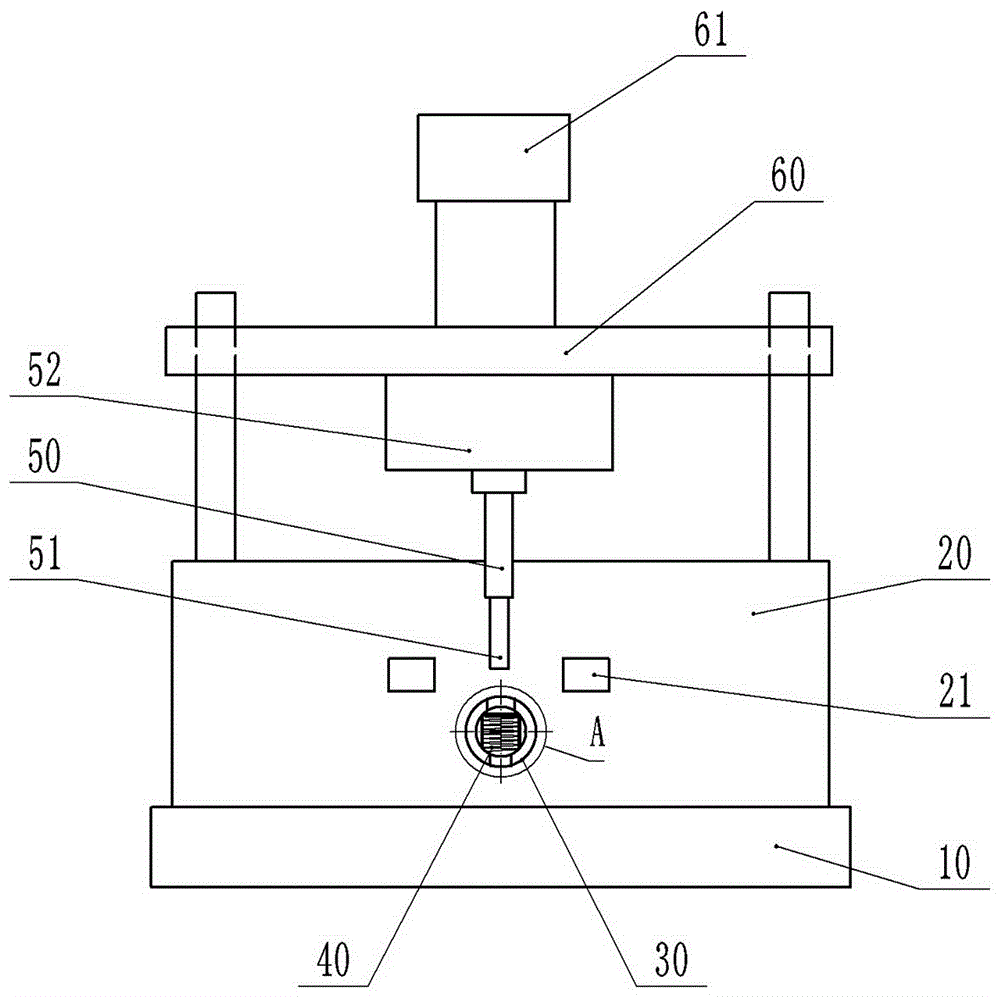

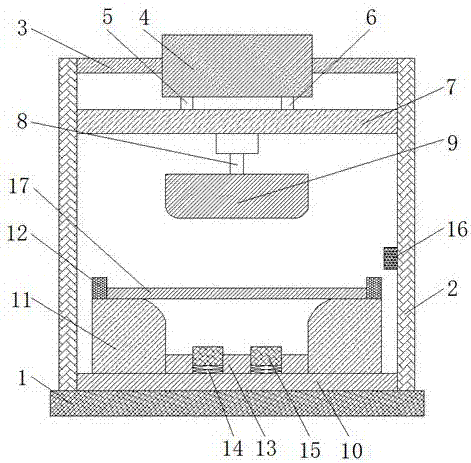

Press machine high in machining precision

InactiveCN109332495AHigh precisionImprove stamping precisionShaping toolsShaping safety devicesHydraulic cylinderPunching

The invention discloses a press machine high in machining precision. A base is included. The upper end of the base is fixedly connected with an upper cover plate through two supporting plates. A hydraulic cylinder is fixedly connected to the upper end of the upper cover plate. The two supporting plates are symmetrically arranged on the two sides of the lower end of the hydraulic cylinder. The telescopic end of the hydraulic cylinder penetrates through the upper cover plate and is fixedly connected with a punching head. The lower end of the punching head is fixedly connected with a punching buffering device. The two sides of the punching head are symmetrically provided with guiding columns corresponding to the punching buffering device in position. The upper ends and the lower ends of the two guiding columns are fixed to the opposite side walls of the upper cover plate and the base correspondingly. The press machine is compact in structure, the punching buffering device is arranged at the lower end of the punching head and matched with a damping mechanism, damping buffering and protection functions are achieved for to-be-punched accessories and other mechanical structures on the press machine in the punching process, and meanwhile the punching precision is improved under the guiding action of the guiding columns.

Owner:江苏纽克光谱科技有限公司

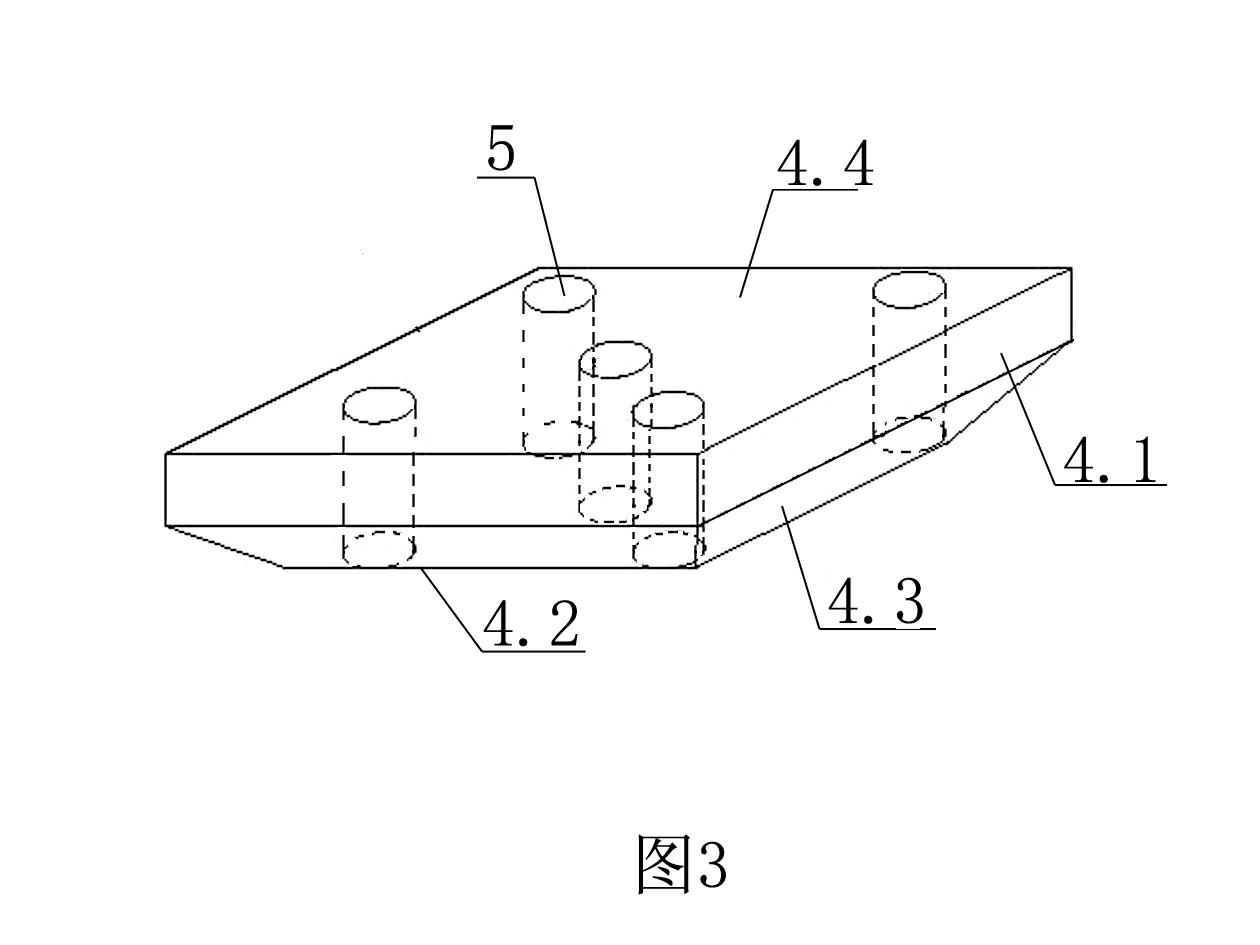

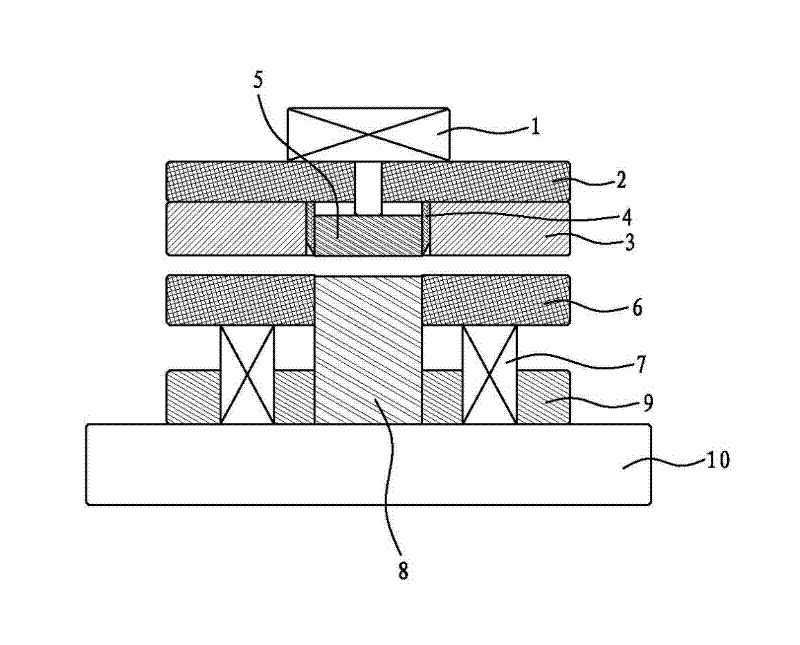

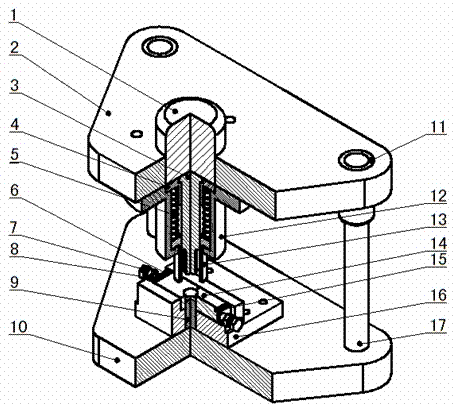

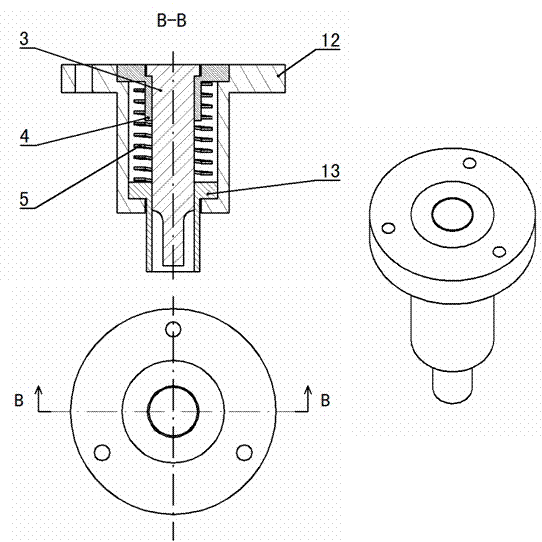

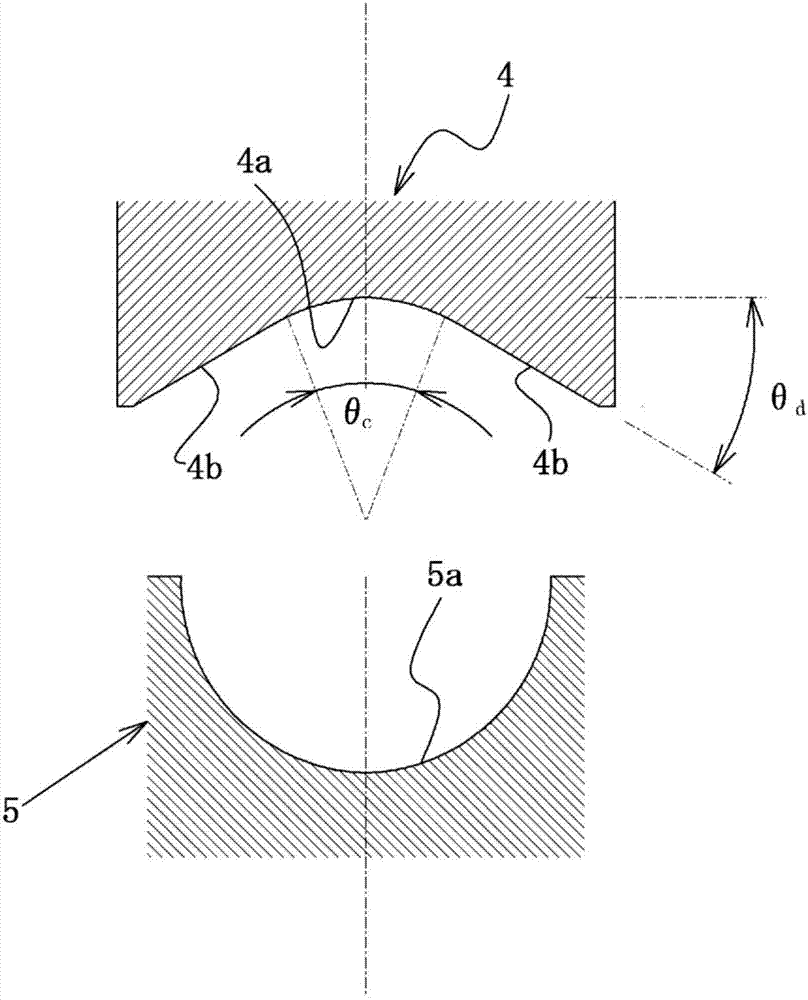

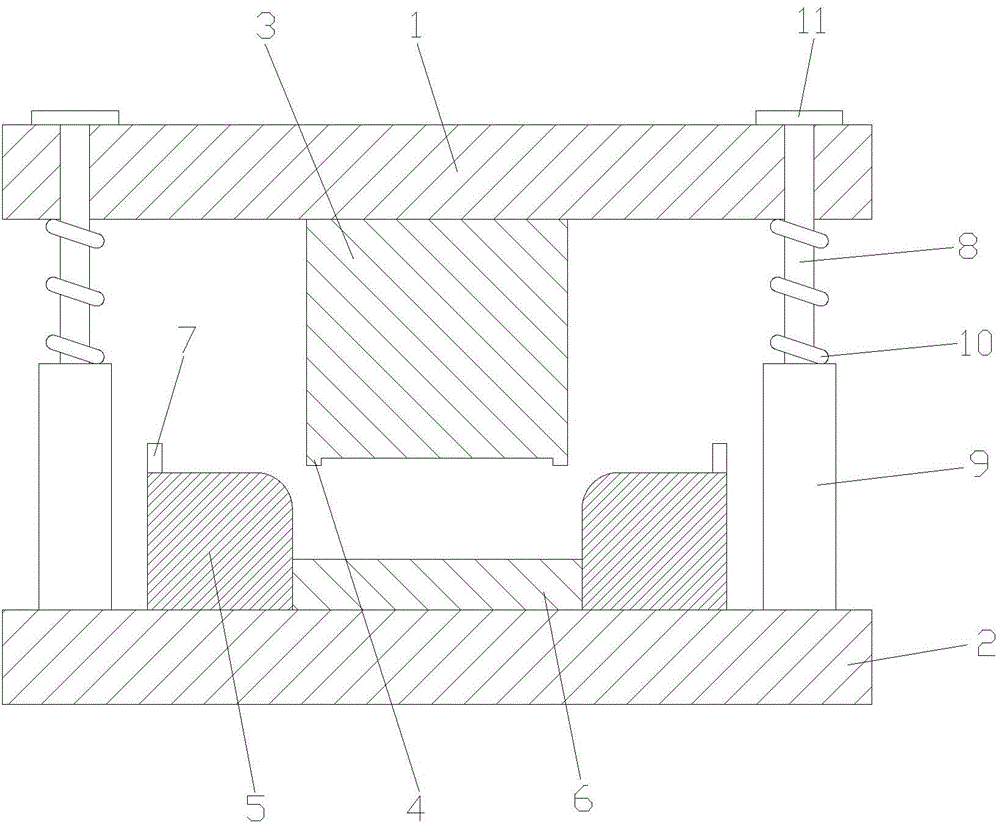

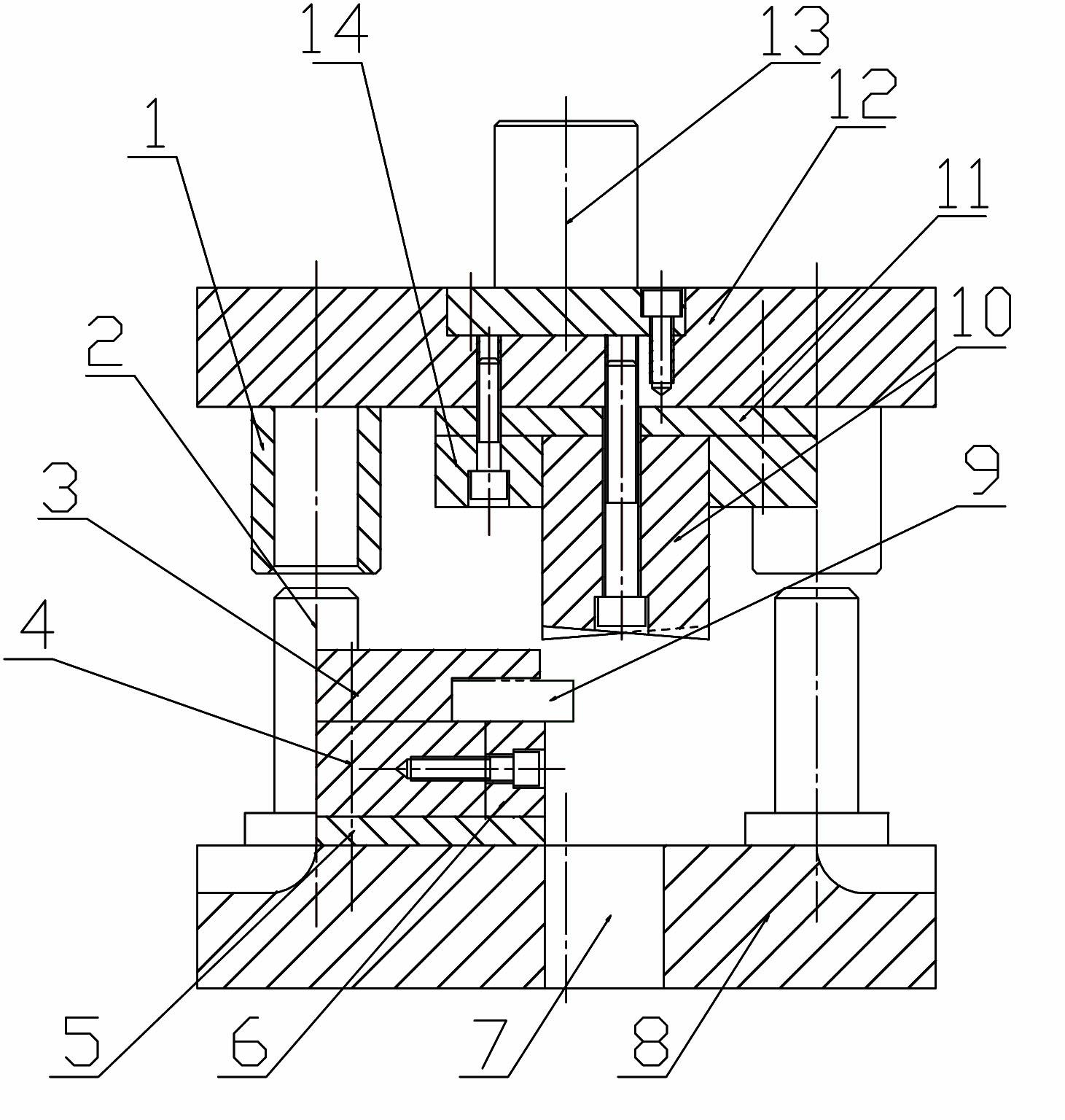

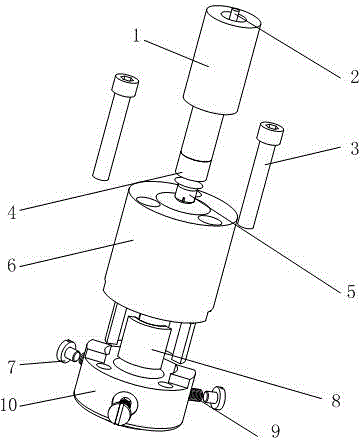

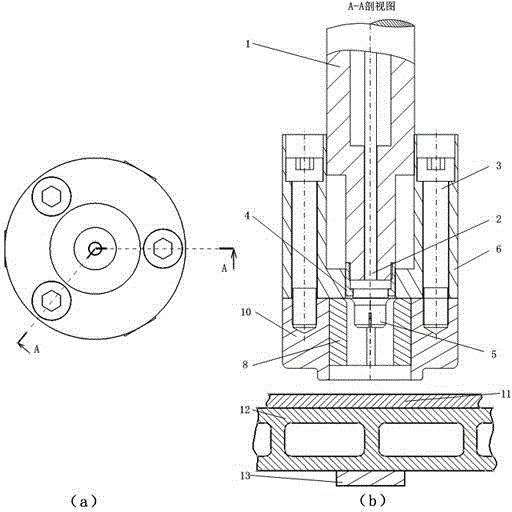

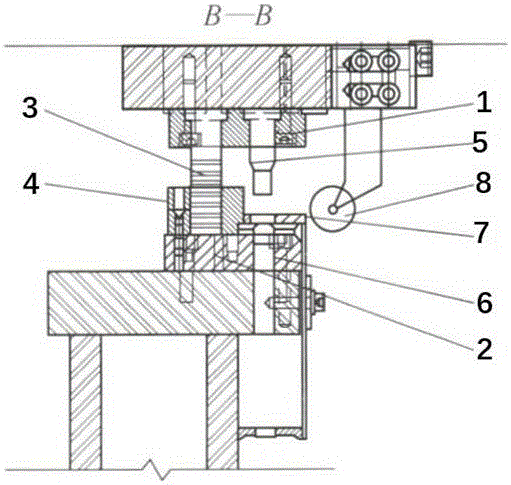

Combined type precision sheet metal stamping and riveting mould

InactiveCN102784841AImprove loading and unloading efficiencyReduce punching forceShaping toolsPunch pressMan-hour

The invention relates to a combined type precision sheet metal stamping and riveting mould, belonging to the field of pressed deformation connection and mould in mechanical engineering. The combined type precision sheet metal stamping and riveting mould comprises a guide device which comprises a postposed guide pillar and a guide sleeve, a precise upper mould and a precision lower mould to realize the precise stamping and riveting process so as to improve the loading and unloading efficiency of the sheet metal in the mould. The combined type precision sheet metal stamping and riveting mould can overcome the quality defects that riveting joints are asymmetric, riveting gaps appear in the riveting process, and that the riveting joints are easy to pull off and realizes a single-gate shearing-free stamping and riveting process; riveting joints with high strength, high rigidity, rotational symmetry and even stress can be formed; and the self-locking ability of the riveting joints is improved. The height increase of the riveting joint at the concave mould is small and the riveting joint at the concave mould is more attractive. The stamping force required by the convex mould is relatively small, so the combined type precision sheet metal stamping and riveting mould is suitable for a general punch press. The combined type precision sheet metal stamping and riveting mould is simple in structure and convenient to operate, saves installing and debugging man-hour, improves the labor productivity and thereby increases the economic benefit.

Owner:JIANGSU UNIV

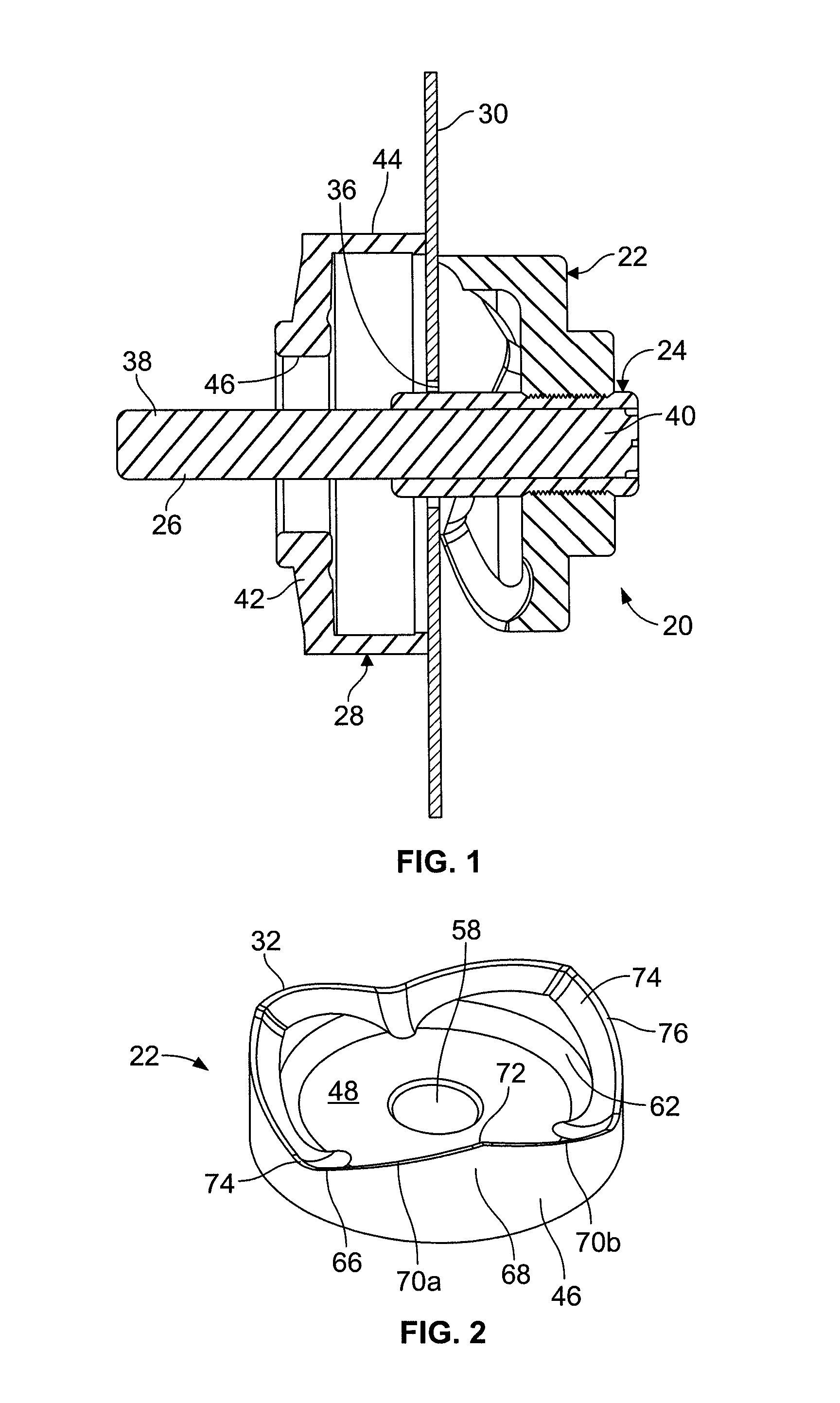

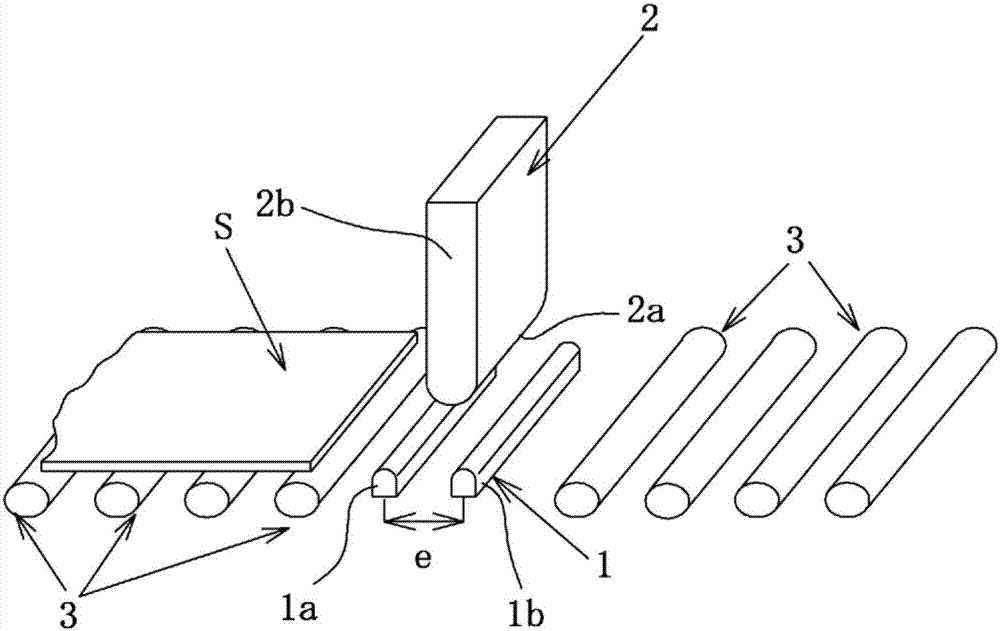

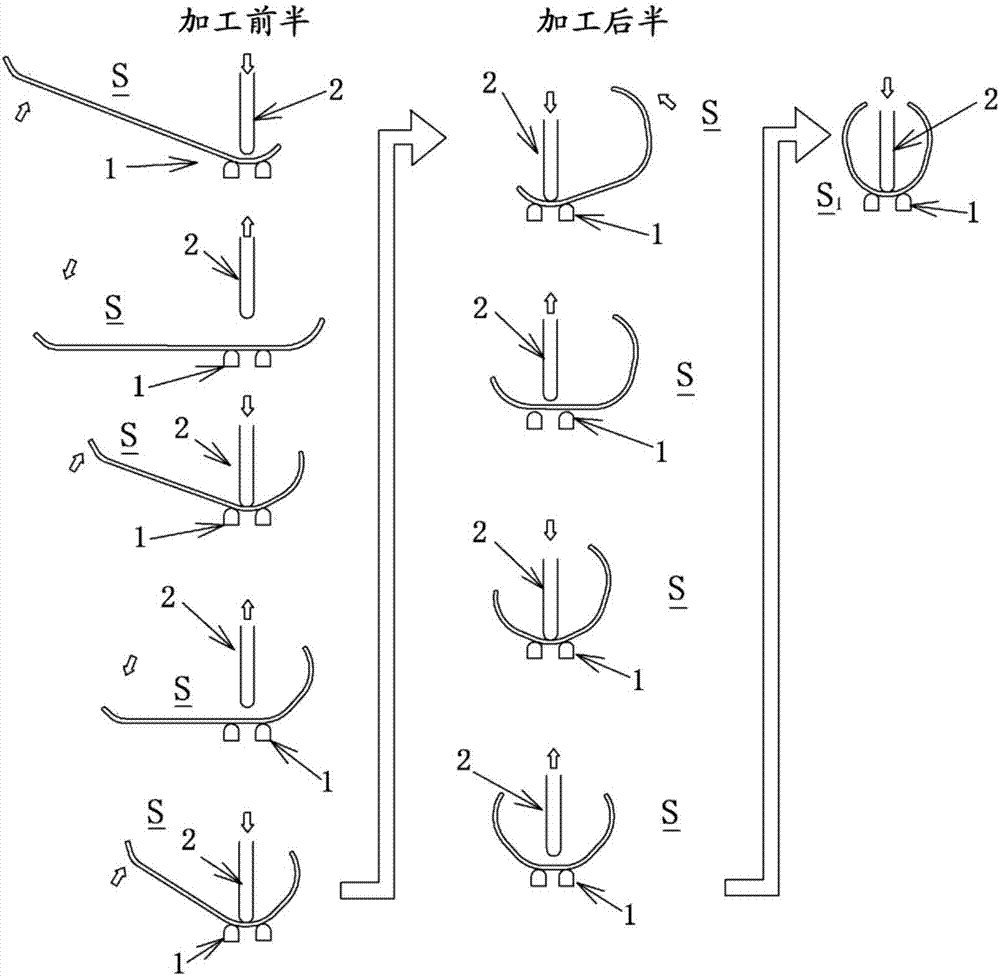

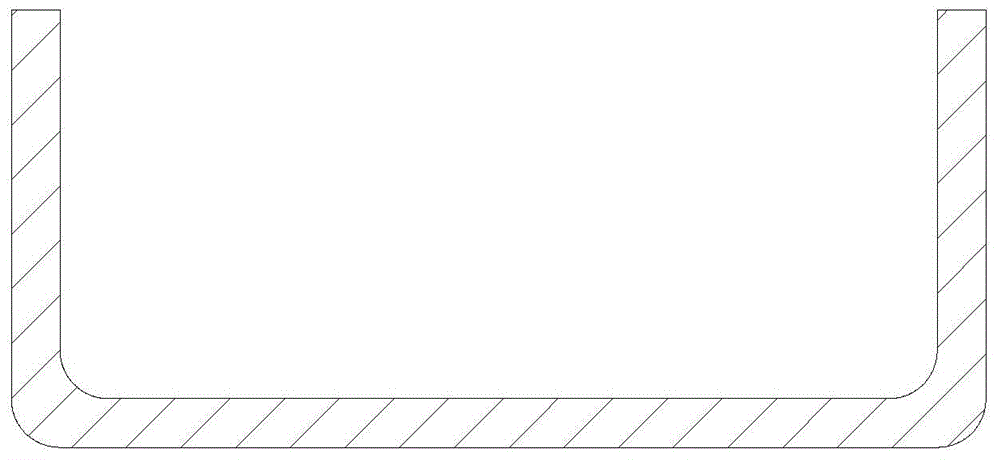

Method for manufacturing steel pipe and press mold used in said method

[Problem] To propose a method for manufacturing steel pipe by implementing a bending process on sheet material, and a press mold used in said method. [Solution] Provided is a method for manufacturing steel pipe that forms a molding (S1), which has a U-shaped cross-section, from a sheet material having an end bent part, forms an open pipe (S2) by applying bending force to the molding, and then butt joins the end surfaces of a gap part of the open pipe (S2) so as to form steel pipe, wherein: at the stage of carrying out the bending process, a lightly worked part to which a much smaller curvature than the other areas is imparted, or an unprocessed part (P), which is not bent, is provided on at least part of the sheet material; and at the stage of pressing down on the molding and forming the open pipe (S2), bending force is applied to sites separated at least W / 4 (where W is the width dimension of the sheet material) in the direction of width end parts from the middle of the lightly worked part or unprocessed part (P) without restricting the lightly worked part or the unprocessed part (B). Thus, it is possible to efficiently form steel pipe with a high degree of roundness with comparatively little bending force.

Owner:JFE STEEL CORP

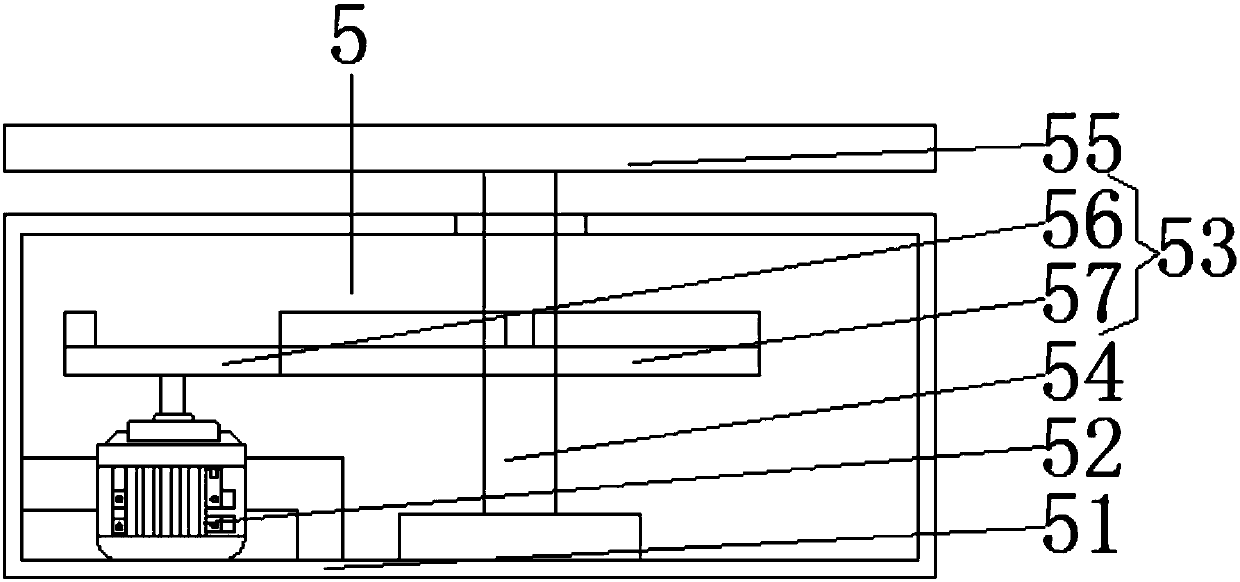

Tube piercing device

ActiveCN106734539AImprove work efficiencyImprove processing efficiencyPerforating toolsMetal-working feeding devicesEngineering

The invention discloses a tube piercing device. The tube piercing device comprises a base, a fixed plate, a mandrel, a punch and a pressure plate, wherein the fixed plate is perpendicularly fixed on the base; the mandrel is fixed on the fixed plate; limiting blocks are arranged on the fixed plate; guide pillars are also arranged on the fixed plate; the pressure plate penetrates through the guide pillars and is slidably connected with the guide pillars; a die shank is fixed at the upper end of the pressure plate; a punch seat is arranged at the lower end of the pressure plate; the punch comprises a small punch and a large punch; a hollow cavity is formed in the mandrel; a through hole is formed in a position, which corresponds to the punch, of the mandrel and comprises a large through hole and a small through hole; an elastic piece is arranged in the hollow cavity and positioned at the through hole; the elastic piece is fixed on the mandrel and positioned on one side close to the small through hole; and a straight hole capable of allowing the small punch to penetrate through is formed in the elastic piece. Compared with the prior art, the tube piercing device has the characteristics that holes with different sizes and diameters can be formed in a tube by punching at a time, meanwhile, wastes generated by piercing can further be discharged out of the tube and the mandrel, and therefore, the tube piercing efficiency is greatly improved.

Owner:重庆鼎汉巅宏汽车零部件有限公司

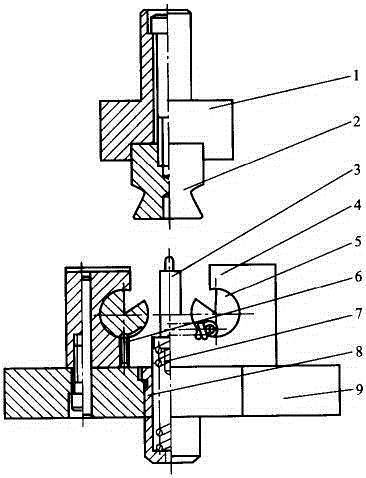

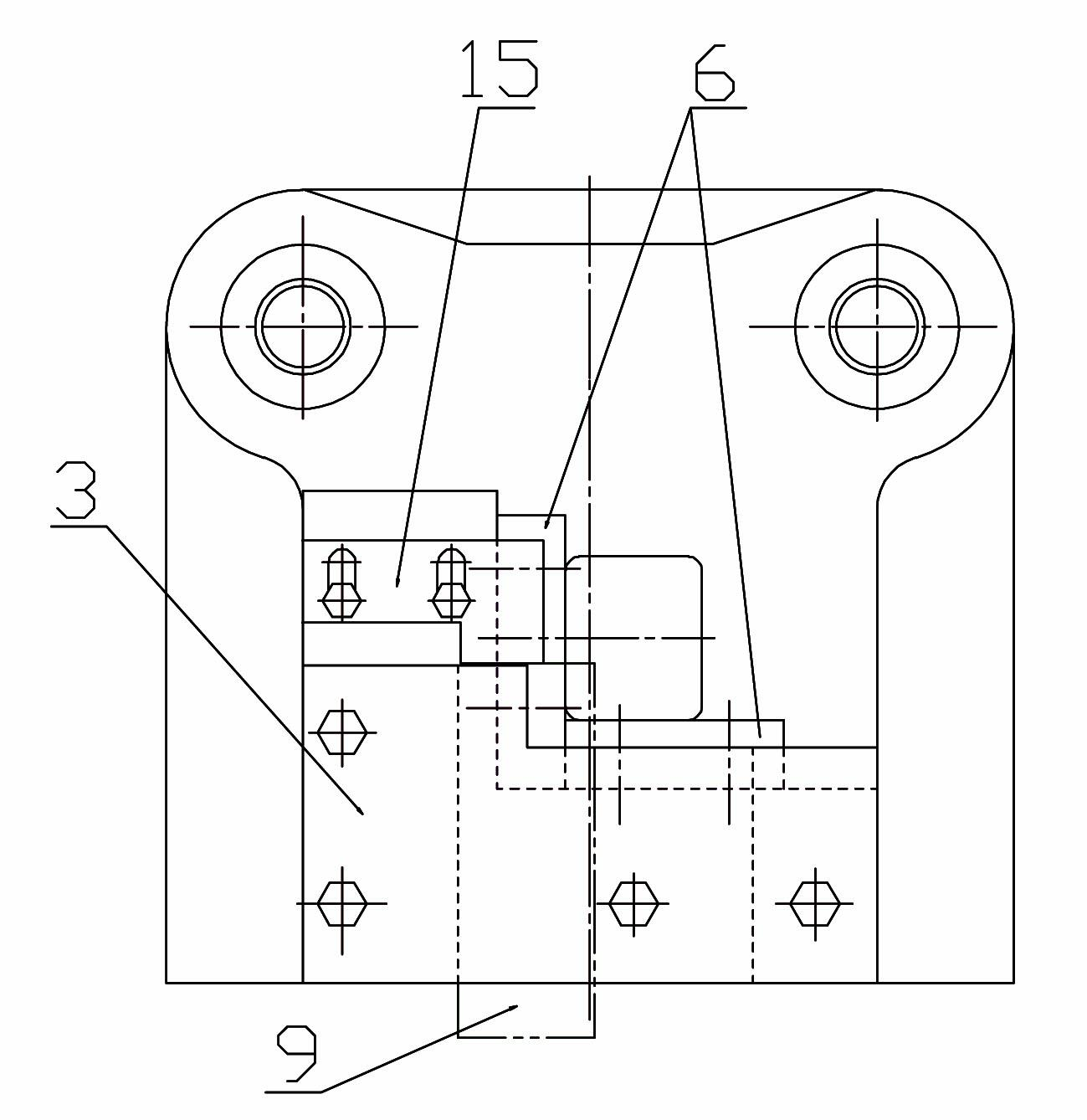

Inclined slider mechanism

The invention discloses an inclined slider mechanism and relates to die equipment. The inclined slider mechanism comprises an upper die holder, a lower die holder and a male die. A wedge holder which is L-shaped is fixedly connected to the lower die holder. An inclined slider is disposed on the wedge holder which is also provided with a slide way. The inclined slider can slide along the slide way. A return mechanism and a limit mechanism are disposed in the inclined slider. The part of the upper die holder, corresponding to the inclined slider, is provided with a wedge which is provided with a slant matching with the inclined slider. A wear pad is disposed on the slant of the wedge. The side of the wedge, far away from the inclined slider, is in sliding fit with the wedge holder. The male die is disposed on the side of the inclined slider, far away from the wedge. The inclined slider mechanism has the advantages that horizontal punching is achieved, die strength and rigidity are high, blanking force is small, the service life of the die is longer, stoppage and maintenance time is shorter, productivity is higher, and machining cost is lower.

Owner:CHENGDU SIMAO TECH

Automatic grinding device for die punch arc

The invention discloses an automatic grinding device for a die punch arc. The automatic grinding device comprises a screw lifting pair, a radius adjusting disc, a swing rod, a drive motor, a drive rod a, a drive rod b, a grinding head motor installing plate, an installing plate freedom degree limiting mechanism, a grinding head motor and a bowl-shaped grinding wheel. The drive motor drives the swing rod to drive the radius adjusting disc to swing, and therefore the installing plate and the grinding head motor on the installing plate are driven to do same-radius arc track swinging. The device is low in cost, reasonable in structure, convenient to use, practical and suitable for grinding the punch die blanking force reduction arc.

Owner:SHANDONG LIJIU SPECIAL PURPOSE ELECTROMOTOR CO LTD

Metal plate pressure tank bending die

The invention discloses a metal plate pressure tank bending die which comprises an upper die plate, a lower die plate, a guide post device, a male die, a female die component and projecting strips. The upper die plate is connected with the lower die plate through the guide post device, the male die is arranged below the upper die plate, the female die component is arranged on the lower die plate and comprises two female die blocks, a bottom plate and positioning blocks, the bottom plate is arranged between the two female die blocks, the height of each female die block is larger than that of the bottom plate, the positioning blocks are arranged on the female die blocks, the projecting strips are arranged on the lower surface of the male die close to two ends of the female die blocks, and connecting angles of the inner slide faces and the upper surfaces of the female die blocks are circular angles. The metal plate pressure tank bending die is fine in punching effect, high in punching efficiency and suitable for batch punching and does not easily rebound, and punching quality is improved.

Owner:吴中区光福华宇钣金厂

Shutter die

The invention discloses a shutter die which comprises a male die and a female die. The female die is provided with a forming die, the male die is provided with at least one cutter which is used for punching plates, the cutter is provided with a blade, and height difference exists between the first end and the second end of the blade. According to the shutter die, from the aspect of microscopic view, point-by-point cutting of the plates is achieved in short time, and the punching force, the noise and the vibration are lowered.

Owner:GREE ELECTRIC APPLIANCES INC

Stamping device for new energy automobile brake disc production and application method of stamping device

InactiveCN112296156ARealize partial stamping repair treatmentReduce punching forceShaping toolsMetal-working feeding devicesBrakeNew energy

The invention discloses a stamping device for new energy automobile brake disc production and an application method of the stamping device, and relates to the technical field of new energy automobiles. The stamping device aims to solve the problem that existing stamping equipment cannot repair an element needing to be stamped after stamping is solved. The stamping device specifically comprises a supporting bottom plate, a third supporting plate is in bolted connection to the outer wall of one end of the top of the supporting bottom plate, and first supporting plates are in bolted connection tothe outer walls of the two sides of one end of the third supporting plate. According to the stamping device for new energy automobile brake disc production and the application method of the stampingdevice, first electric guide rails and a protective plate are arranged at one ends of the first supporting plates, the protective plate can be driven by first electric sliding blocks to move up and down, then the stamping position of the bottom of the device is protected by the protective plate, a stamping part is prevented from bursting out accidentally, or outside workers or parts are preventedfrom stretching into the stamping position, and the use safety of the device is improved.

Owner:马鞍山贺辉信息科技有限公司

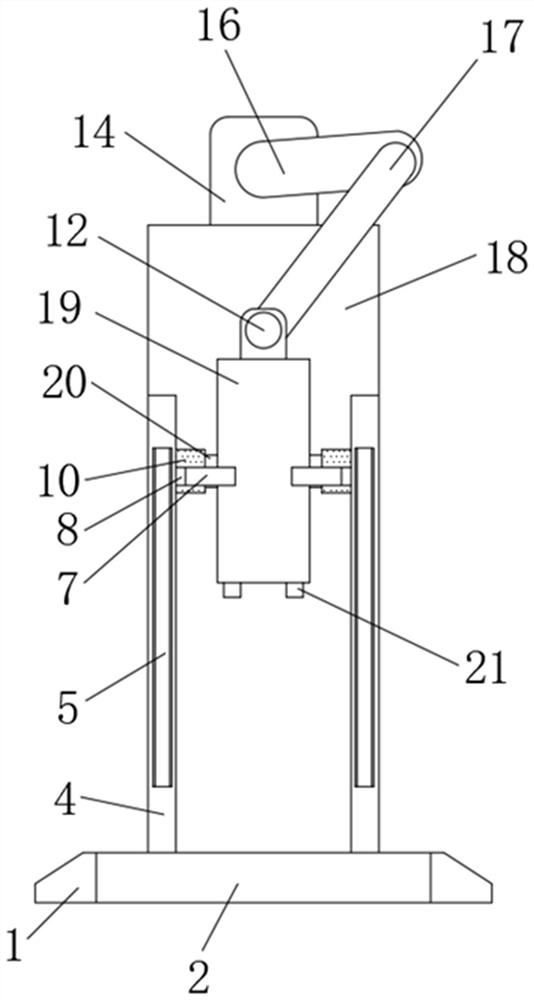

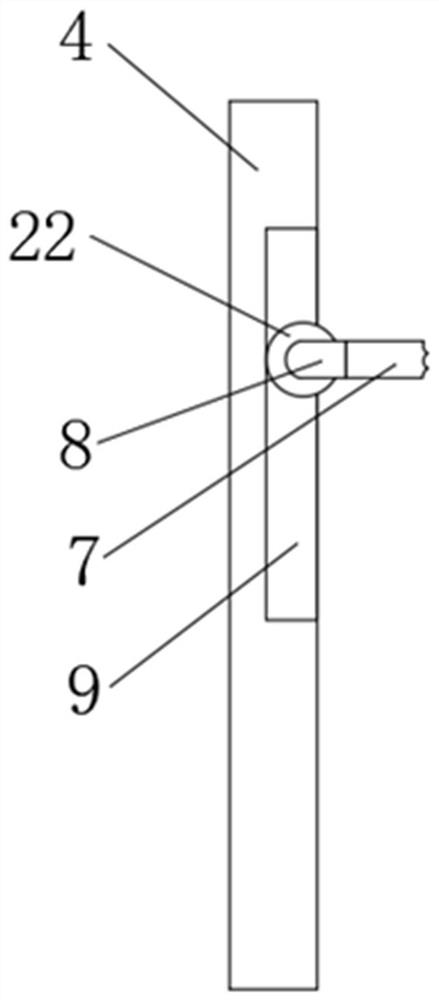

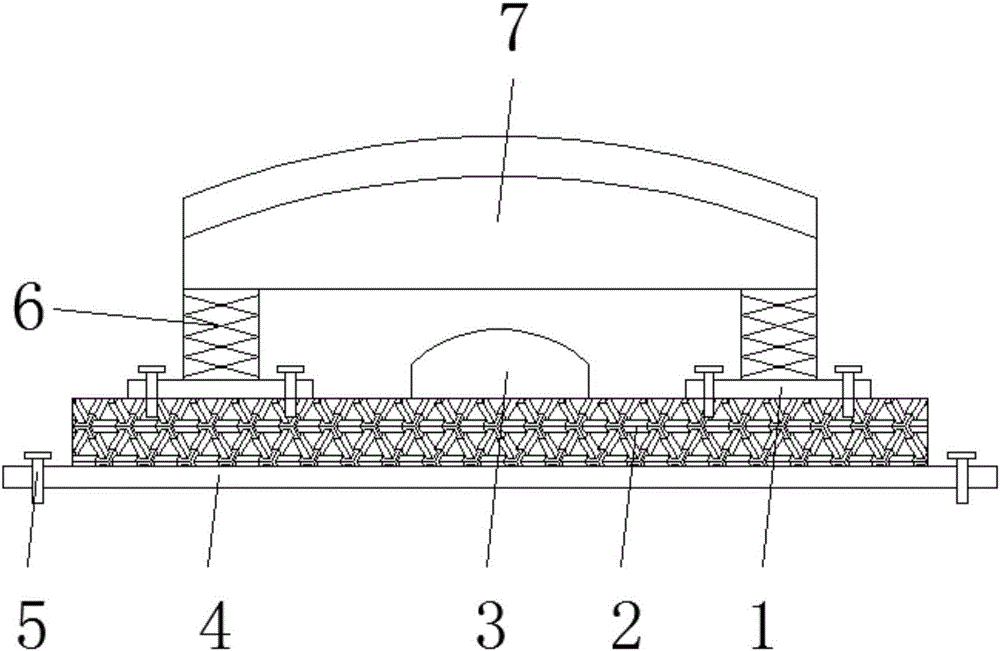

Fracture-preventing automotive sheet metal part stamping device

InactiveCN107030166AAvoid breakingReduce punching forceShaping toolsShaping safety devicesHydraulic cylinderHydraulic pump

The invention relates to the technical field of automotive part manufacturing and discloses a fracture-preventing automotive sheet metal part stamping device. The device comprises a base. Stand columns are fixedly mounted at the two ends of the upper surface of the base. A hydraulic pump is fixedly mounted between the two stand columns through a fixing rod. The bottom of the hydraulic pump communicates with an oil outlet pipe and an oil inlet pipe. A hydraulic cylinder is fixedly connected between the two stand columns. The top of the hydraulic cylinder communicates with the oil inlet pipe and the oil outlet pipe. A hydraulic telescopic rod is movably connected with the bottom of the hydraulic cylinder. According to the fracture-preventing automotive sheet metal part stamping device, by arranging a male die and a female die, the hydraulic telescopic rod drives the male die to stamp downwards so that a sheet metal part can be in a U shape, the corners, connected with the two side faces, of the lower surface of the male die are circular beads, and the corners where the upper surface of the upper surface is connected with the inner side are circular beads, so that stamping force to the sheet metal part is buffered during stamping, the sheet metal part is protected, fraction of the sheet metal part in the stamping process is avoided, the stamping effect is good, and the stamping quality is improved.

Owner:于法周

Metal plate stamping die

InactiveCN104384344AAvoid breakingGood stamping effectShaping toolsMetal-working feeding devicesEngineeringSheet metal stamping

The invention discloses a metal plate stamping die which comprises an upper die plate, a lower die plate, guide column devices, a male die and a female die assembly. The upper die plate is connected with the lower die plate by the guide column devices; the male die is arranged on the lower side of the upper die plate; the female die assembly is arranged on the lower die plate; the female die assembly comprises two female die blocks, a bottom plate and positioning blocks; the bottom plate is arranged between the two female die blocks; each female die block is higher than the bottom plate; each positioning block is arranged on the corresponding female die block; joint corners of two side surfaces and the lower surface of the male die are rounded corners; joint corners of the inner side surfaces and the upper surfaces of the female die blocks are rounded corners. The metal plate stamping die has the advantages that good stamping effects can be realized, the stamping quality can be improved, and the metal plate stamping die is high in stamping efficiency and suitable for stamping metal plates on a large scale.

Owner:吴中区光福华宇钣金厂

Rotating shaft bending die

The invention discloses a rotating shaft bending die adopting a floating lower die body. The problem that a part is excessively deformed or an upper die body is prone to being jammed due to the fact that the impact force of the upper die body is too large can be solved. The rotating shaft bending die comprises an upper die seat and the upper die body mounted on the lower portion of the upper die seat, wherein the upper die body can move up and down; a lower die seat is located under the upper die seat, a vertical mounting groove is formed in the upper portion of the lower die seat, and a pressure spring is arranged in the mounting groove. The lower end of the pressure spring is fixed to the bottom of the mounting groove, the upper end of the pressure spring extends out of the mounting groove, and the floating lower die body is arranged in the middle of the pressure spring; a circle of annular table is arranged on the periphery of the lower die body, the upper end of the pressure spring is fixed to the annular table, and the diameter of the annular table is larger than the aperture of the mounting groove; a convex column is arranged on the top of the lower die body, the upper portion of the convex column is a spherical surface, a stamping groove is formed in the bottom of the upper die body, and the stamping groove and the convex column are matched to bend parts.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

Rear anti-collision device for automobile

The invention discloses a rear anti-collision device for an automobile comprising a plastic cushioning backing plate, a connecting plate and a cushioning plate, wherein the connecting plate is fixedly connected to the rear of the automobile by fastening screws; the outer surface of the connecting plate is fixedly provided with the plastic cushioning backing plate; the cushioning plate is in an elastic connection with fixing plates by buffer spring seats; the fixing plates are fastened and connected with the plastic cushioning backing plate by the fastening screws; an anti-collision airbag body is fixed on the inner end of the plastic cushioning backing plate; and a protective airbag is fixedly arranged in the interior of the anti-collision airbag body. When the automobile is parked at night, fluorescent rings of the rear anti-collision device achieve the aim of giving warnings to passing vehicles and pedestrians. When a collision occurs, the plastic cushioning backing plate is in contact with the rear of the automobile in a large area. Under the action of the plastic cushioning backing plate, the impact pressure is effectively reduced to ensure that the automobile is not deformed. When the impact force is too large, the anti-collision airbag body will be triggered to eject the protective airbag and reduce the impact force between the two automobiles so as to ensure the safety of automobiles and drivers. In addition, the rear anti-collision device has a simple structure.

Owner:CHONGQING ZECHUANG ELECTROMECHANICAL

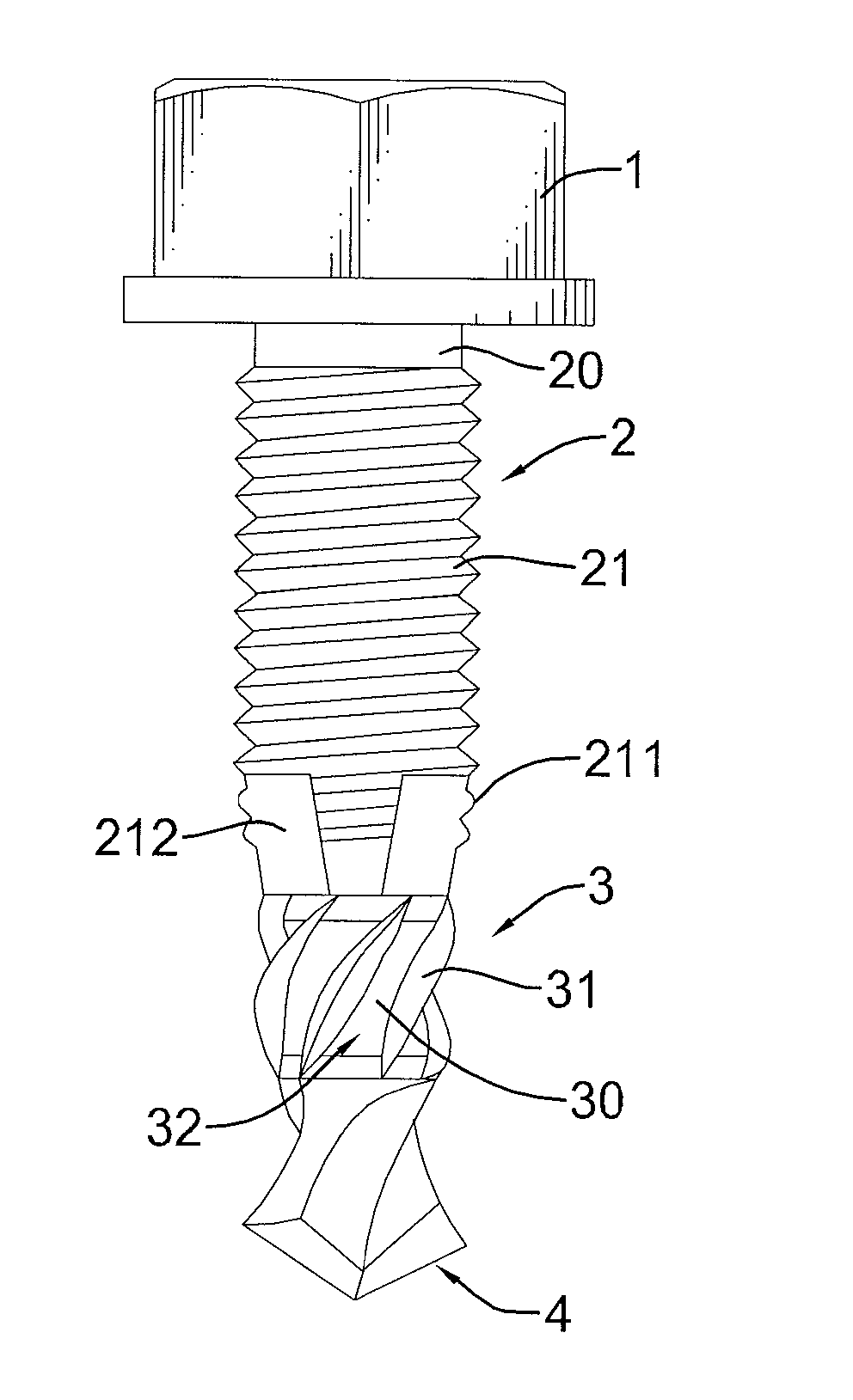

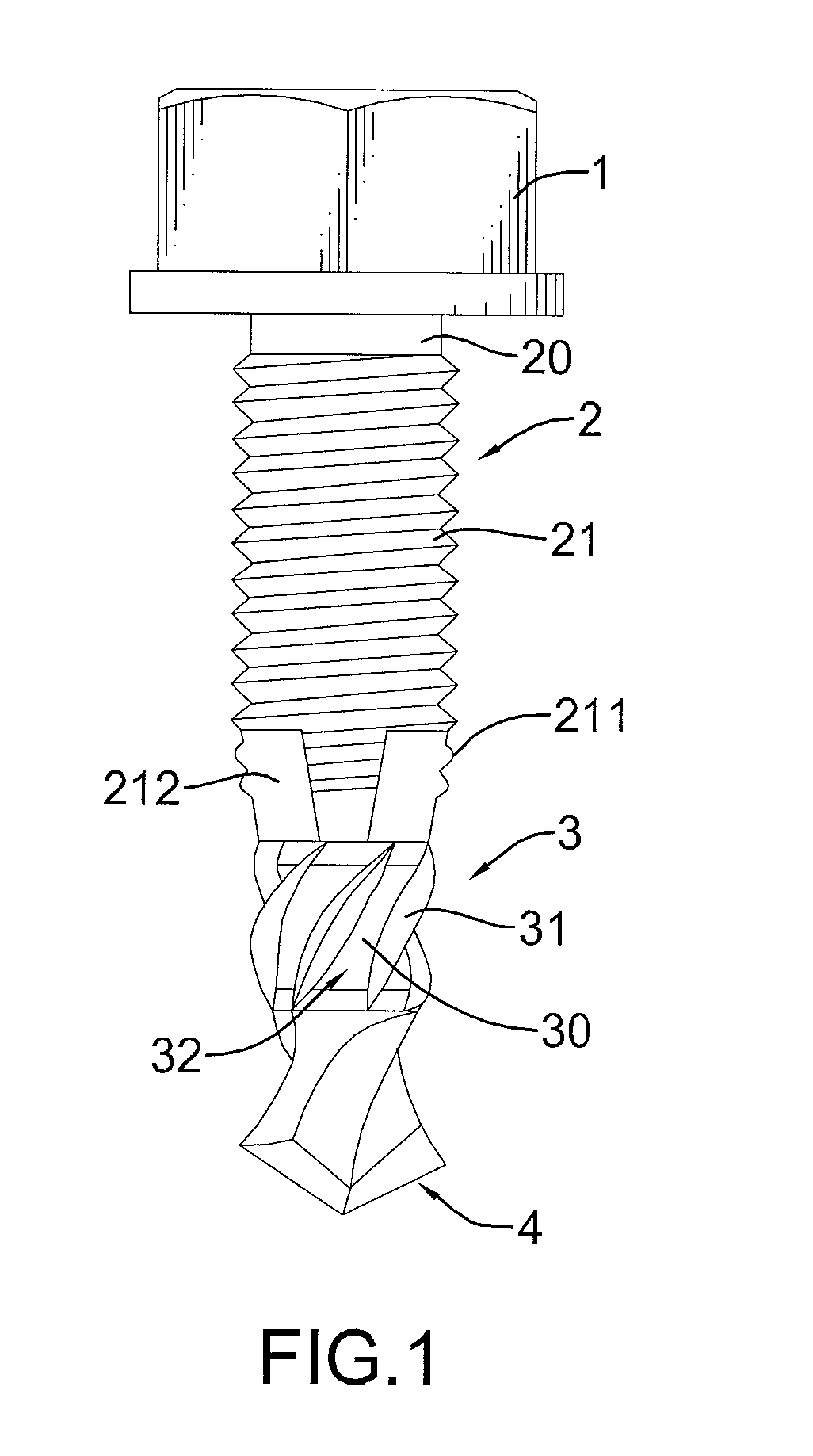

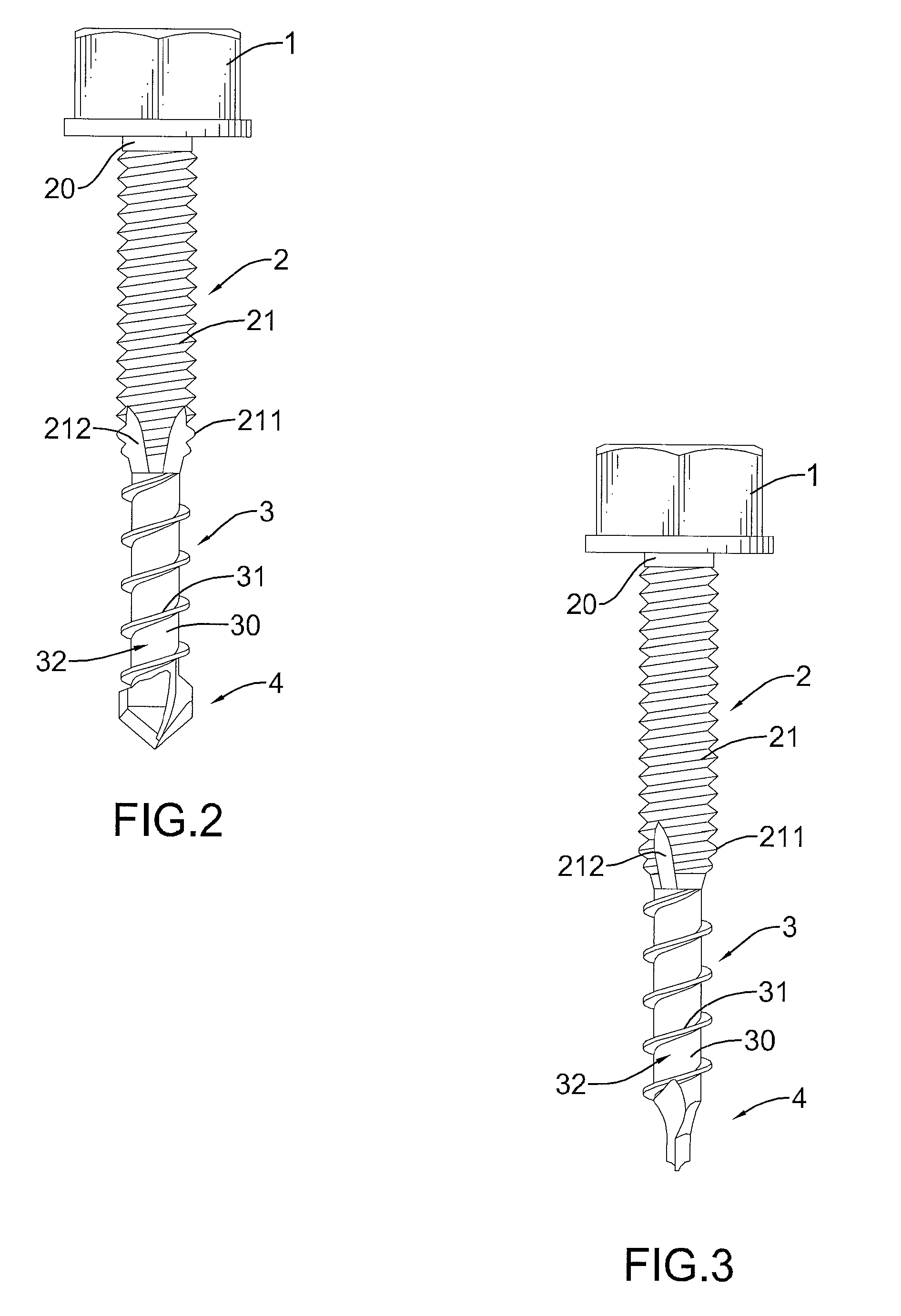

Self-drilling screw and fabricating method for the same

A fabricating method for the self-drilling screw has acts of forming a main section and a secondary section by punching, forming a flat drilling blade with a tapered end at a bottom end of the small diameter portion by punching, and forming a thread portion on an outer surface of the main section and a chip removal thread portion with a spiral chip removal groove on an outer surface of the secondary section by rolling. The self-drilling screw utilizes the flat drilling blade with the tapered end and the chip removal section having chip removal function to reduce the size of the drilling blade. Therefore, the self-drilling screw reduces the size of the punching die, lowers the punching force, lowers both the load of the punching die and the load of the punching machine, and lowers both the die cost and the manufacturing cost.

Owner:LAI TSUNG CHENG

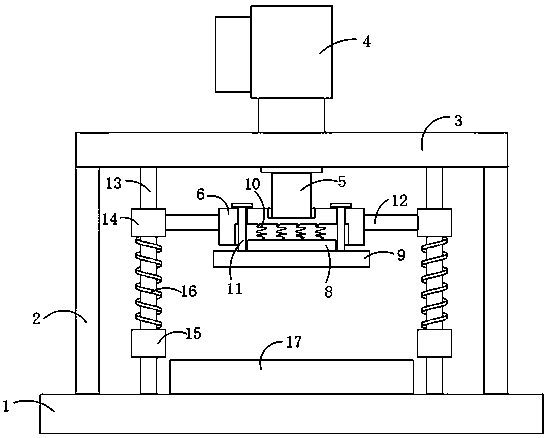

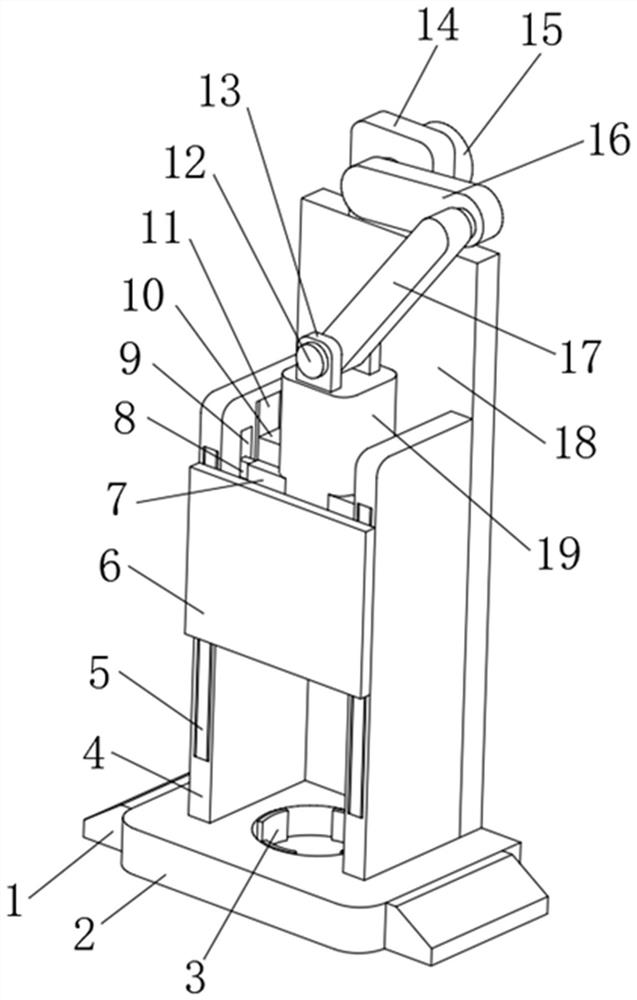

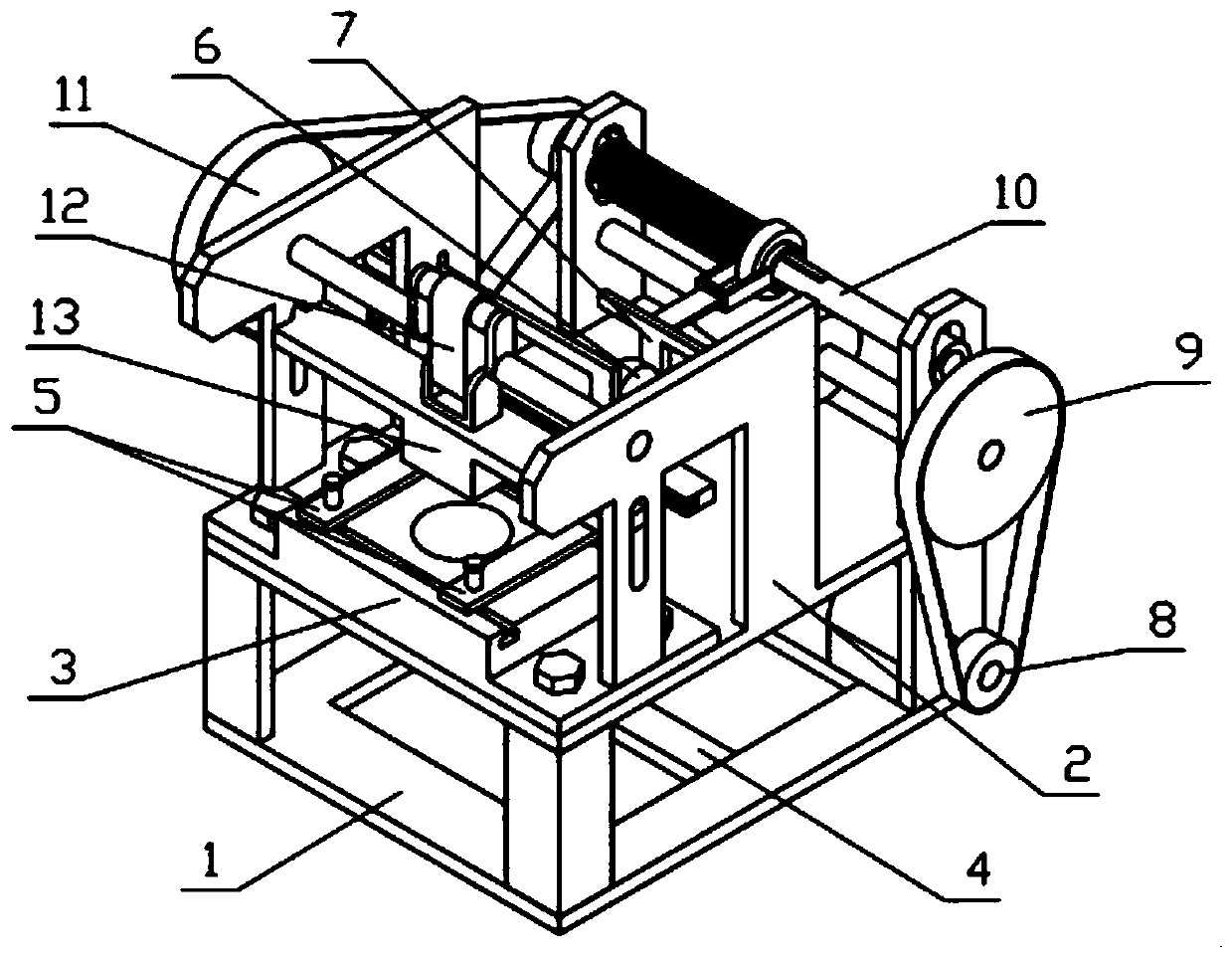

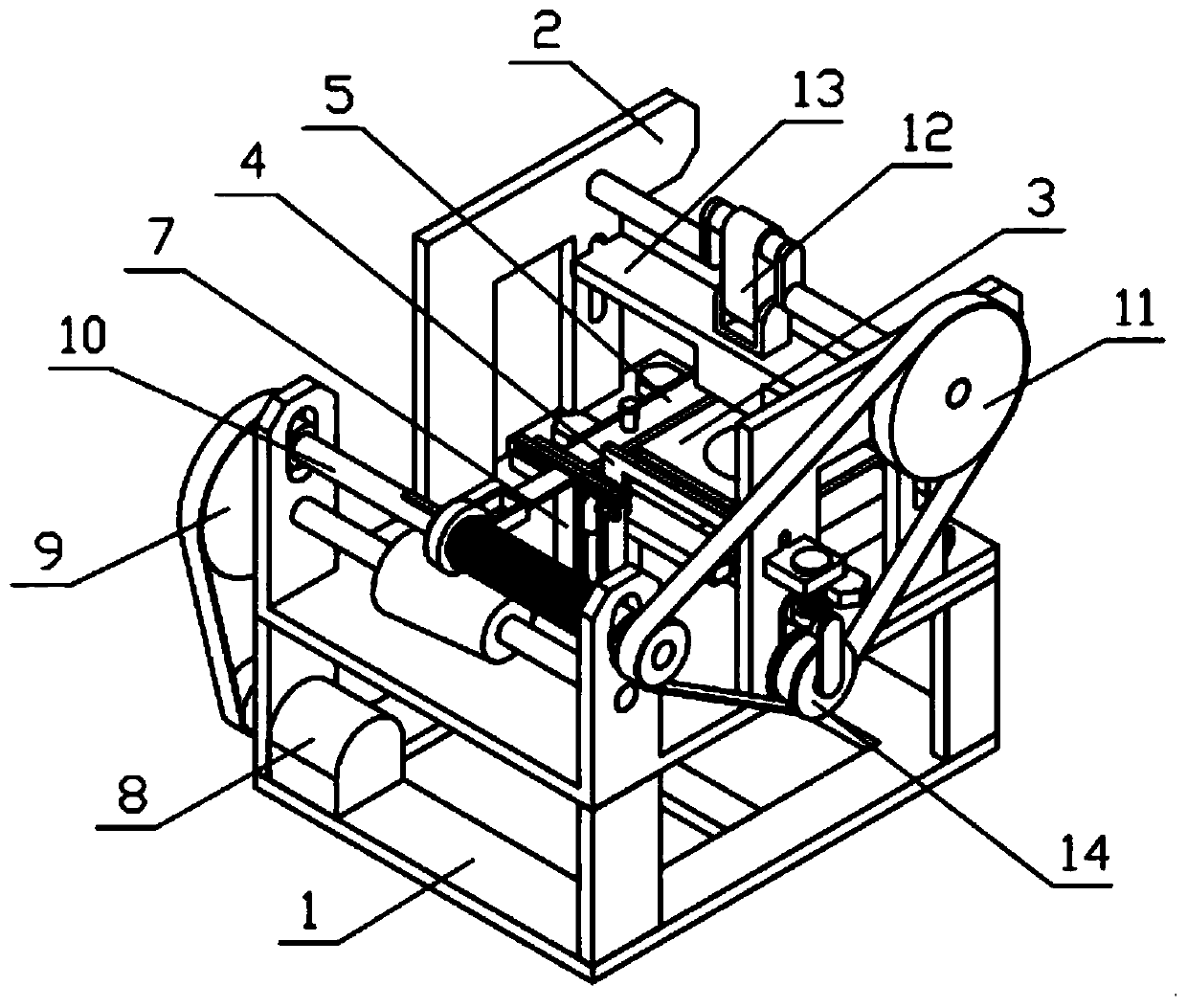

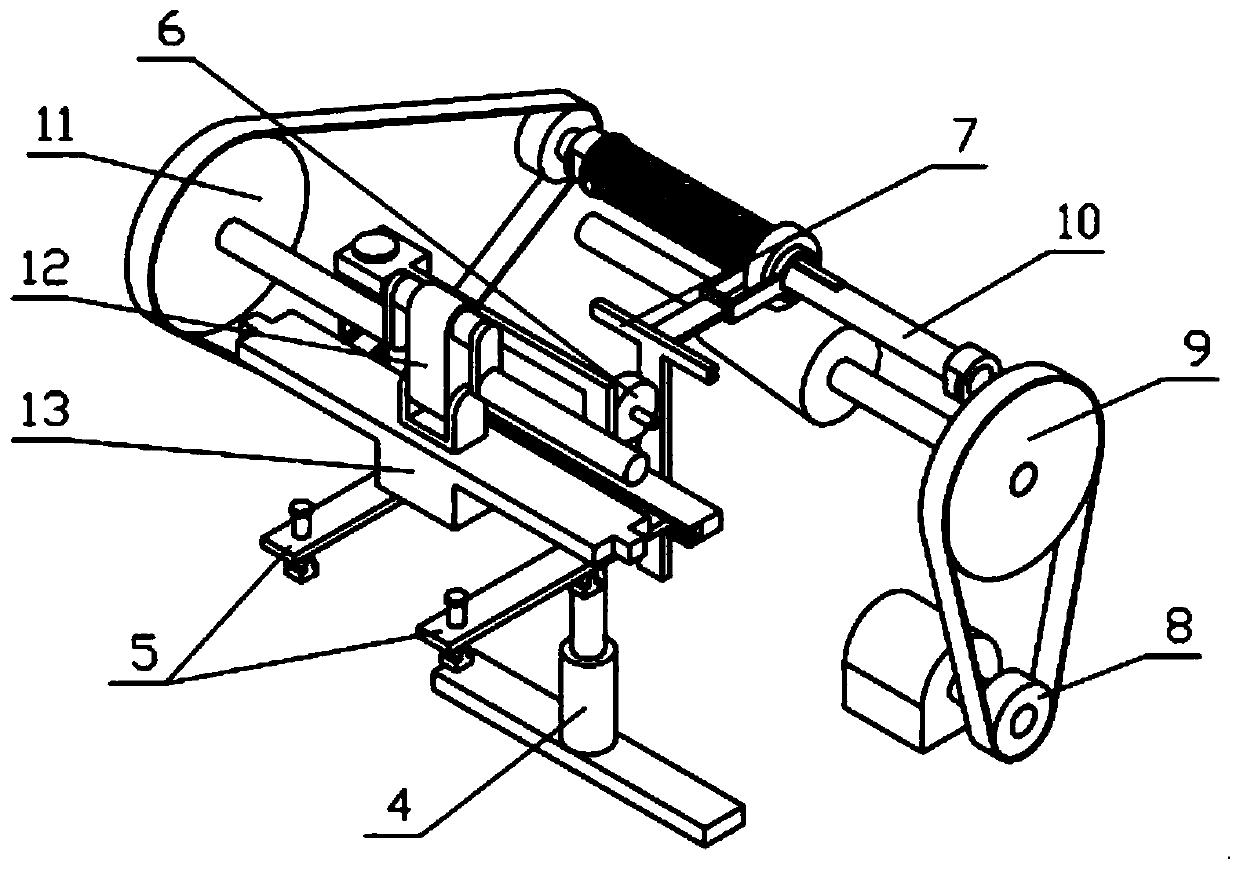

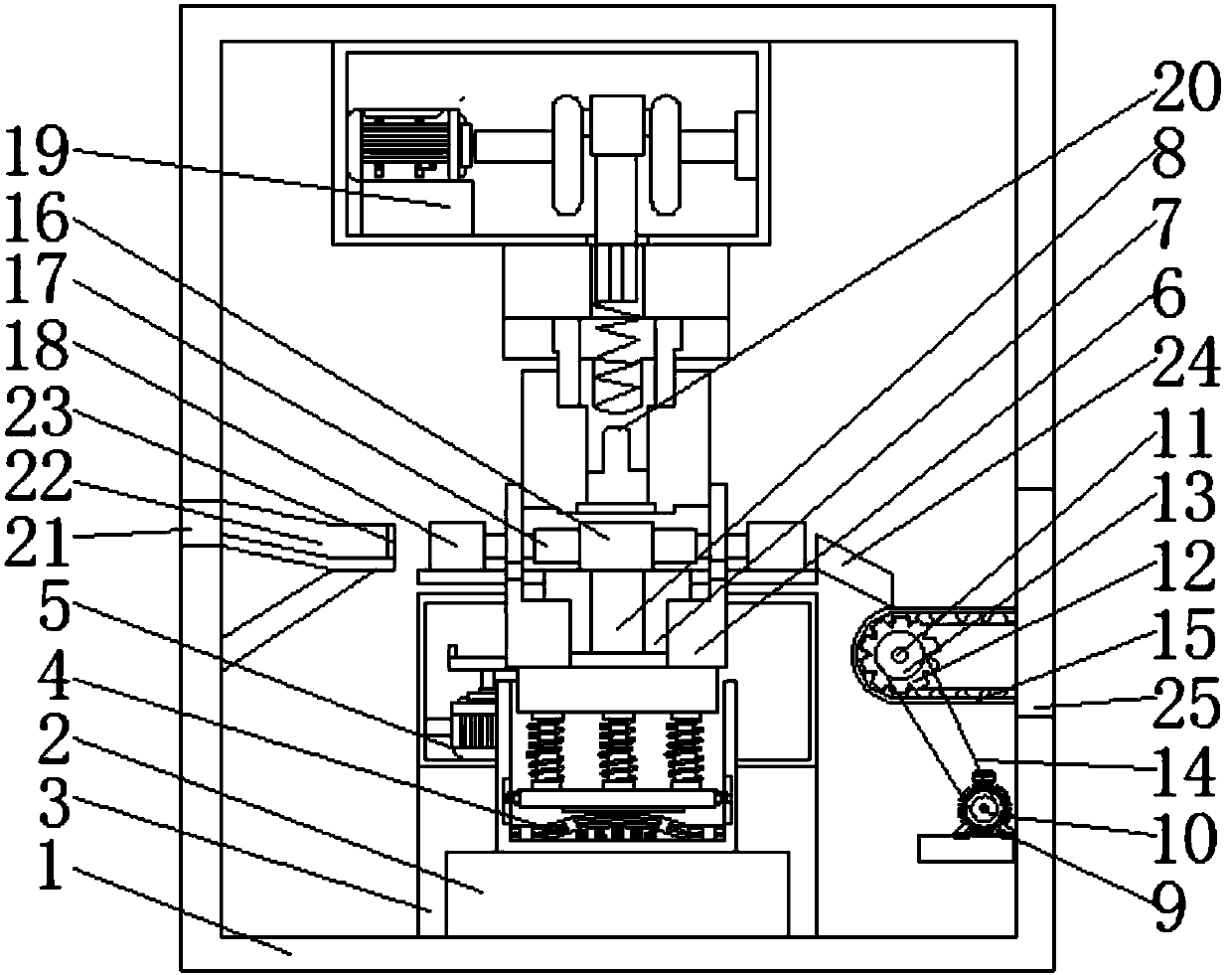

Working method of intelligent stamping device

ActiveCN111531053AReduce punching forceGuaranteed stamping effectMetal-working feeding devicesPositioning devicesStampingCrank

The invention relates to stamping devices, in particular to a working method of an intelligent stamping device. The intelligent stamping device comprises an underframe, a supporting frame, a stampingplatform, a hold-down mechanism, two clamping mechanisms, a lifting gear, a lifting rack, a power mechanism, a transmission mechanism I, a transmission mechanism II, a stamping crank, a stamping connecting rod, a stamping die and a tensioning mechanism. According to the intelligent stamping device, the two clamping mechanisms can be simultaneously driven by the hold-down mechanism to clamp plateswith different thicknesses and lengths; the transmission ratio of the transmission mechanism I to the transmission mechanism II is adjusted while the hold-down mechanism drives the two clamping mechanisms to move to clamp a plate, so that the transmission ratio of the transmission mechanism I to the transmission mechanism II adapts to the change of the plate thickness; the device generates a highstamping force when the plate is thick so as to guarantee the stamping effect; and the device generates a low stamping force when the plate is thin so as to guarantee the stamping efficiency.

Owner:湛江市顺泽实业有限公司

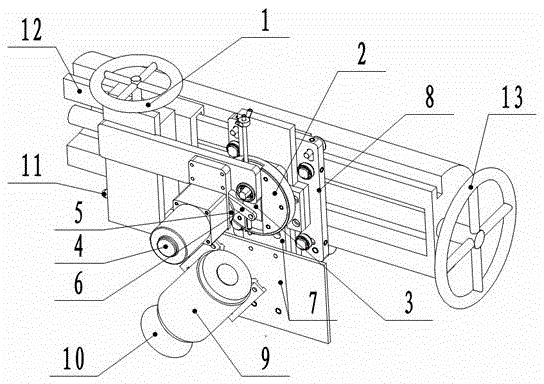

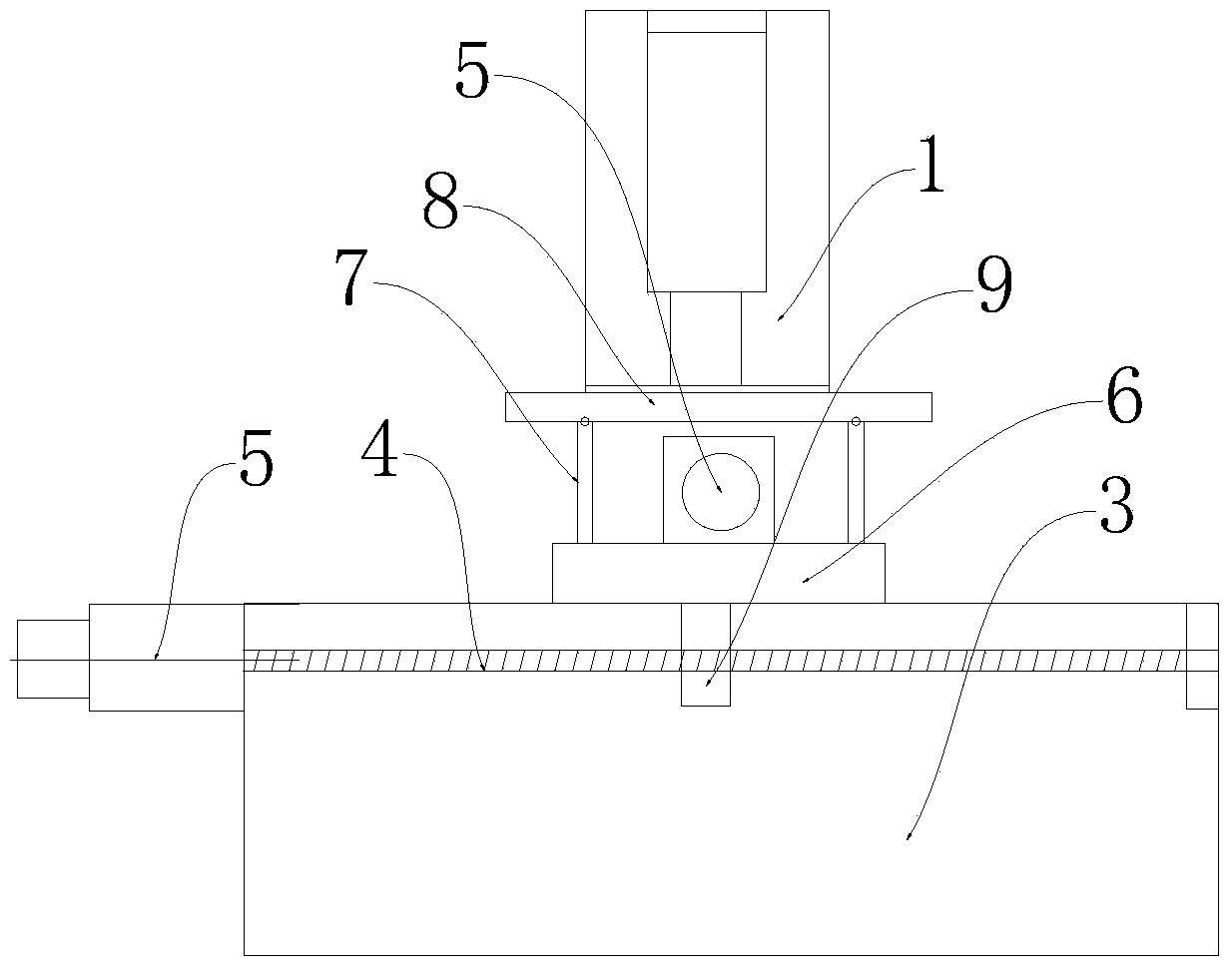

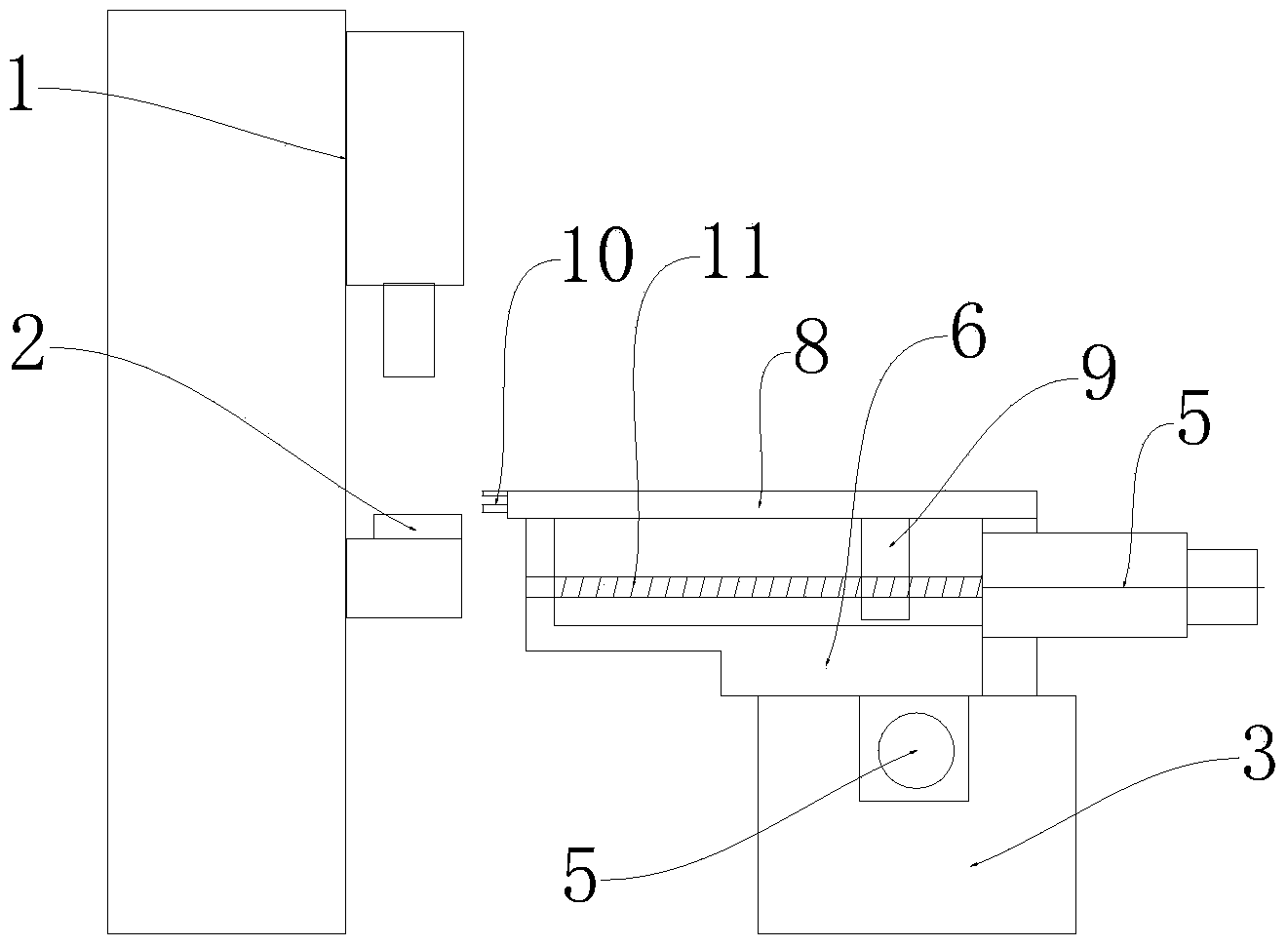

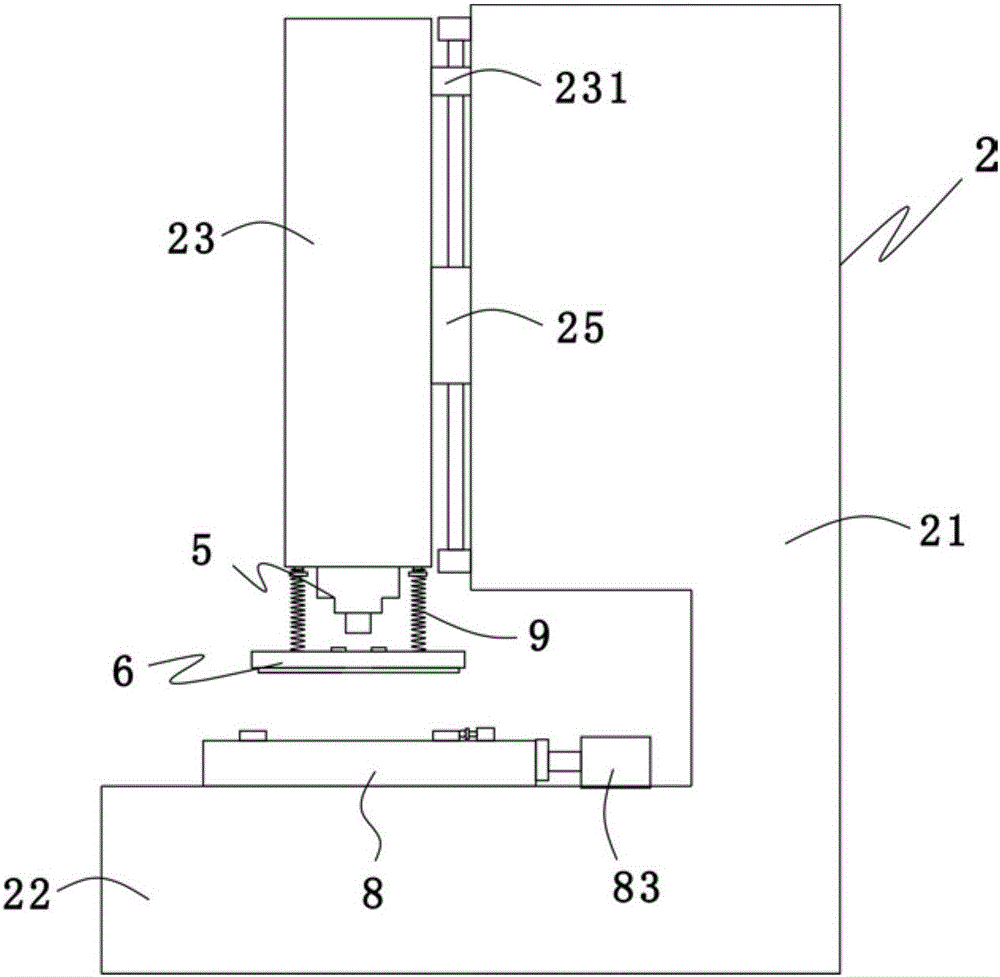

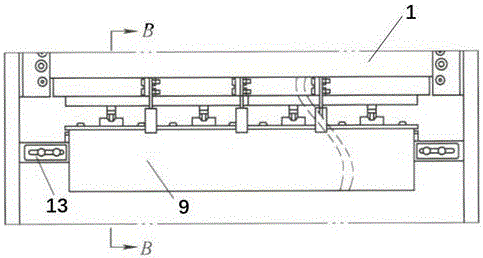

Stamping device of ventilation plate

InactiveCN103658299AImprove stamping precisionReduce volumeMetal-working feeding devicesPositioning devicesPunch pressMechanical equipment

The invention relates to the field of mechanical equipment and particularly discloses a stamping device of a ventilation plate, wherein the stamping device of the ventilation plate is low in production cost and little in energy consumption. The stamping device of the ventilation plate comprises a punch press and a moving clamp, the moving clamp is arranged on the face right opposite to the punch press, the moving clamp structurally comprises a base, a pedestal is arranged on the base, a longitudinal slide rail is arranged on the pedestal, a connecting arm is arranged on the longitudinal slide rail, a nut is arranged at the bottom of the connecting arm, and the nut is arranged on a longitudinal screw rod in a sleeved mode. A pneumatic gripper is arranged on the portion, close to one end of the punch press, of the connecting arm. According to the stamping device of the ventilation plate, a row of concave dies are arranged on a stamping die, the ventilation plate is stamped many times, and thus the size of the die can be effectively reduced, the stamping pressure and energy consumption can be reduced. Through transverse motion of the pedestal and longitudinal motion of the connecting arm, the pneumatic gripper can move in the horizontal plane so that the ventilation plate can be moved and positioned. Moreover, motion of the pneumatic gripper is achieved through the screw rod and the nut, so that the pneumatic gripper performs positioning more accurately, and thus the stamping accuracy of the ventilation plate is improved.

Owner:JIAXING YONGFA ELECTRONICS

Scraper blade blanking die

The invention discloses a scraper blade blanking die which comprises an upper die part and a lower die part that are connected through a guide sleeve and a guide pillar, wherein in the upper die part, an upper module is arranged on an upper template through an upper fixing plate and an upper backing plate, a die handle is arranged on the upper template, and mutually-vertical beveling cutters are arranged on the upper module; and in the lower die part, a lower module is arranged on a lower die base through a lower backing plate and a lower die fixing plate, and a pressing plate is arranged on the lower die fixing plate. According to the scraper blade blanking die provided by the invention, under the condition of ensuring that the processing size of a scraper blade accords with the design requirement, the labor production efficiency is greatly increased, the production cost consumption is saved, and the production period is shortened. A beveling blade is adopted in the upper module, the punching gap of the upper die part and the lower die part can be reduced, and the blanking surfaces of parts are smoother. The blanking force can be reduced, the vibration during the blanking of a thick plate is reduced so that the blanking process is more stable, and the quality of the scraper blade and the safety of the production are ensured.

Owner:湖北宜都机电工程股份有限公司

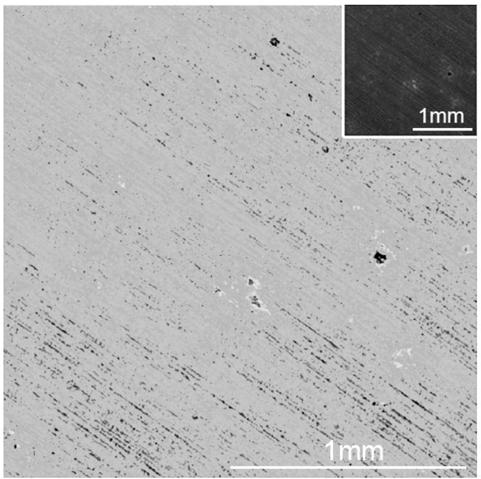

Solid lubricating film for aluminum alloy sheet stamping forming and preparation method thereof

ActiveCN109054951ASufficient lubricityAvoid breakingPolyurea/polyurethane coatingsLubricant compositionDiluentSpecific time

The invention discloses a solid lubricating film for aluminum alloy sheet stamping forming and a preparation method thereof. The solid lubricating film is prepared from a lubricating property imparting agent A, an elastic organic coating material B as a lubricating imparting agent binder, and a wetting dispersant C used for improving the lubricating property imparting agent A, wherein the weight parts of the lubricating property imparting agent A, the elastic organic coating material B, and the wetting dispersant C are respectively 5 to 20 parts, 80 to 95 parts, and 0.2 to 2 parts. In addition, according to the preparation method of the solid lubricating film disclosed by the invention, a solid lubricating film component and a diluent are mechanically mixed according to a specific ratio toobtain a precursor fluid; the precursor fluid is sprayed or brushed on the surface of a material to be lubricated, and the solid lubricating film is formed at a specific temperature in a specific time. The lubricating film has excellent lubricity and easy removal; when stamping forming is performed, the lubricating film provides lubrication and protects the surfaces of a sheet and a mold, and theformed part has excellent surface quality.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Riveting and pressing device used for alarm machining

ActiveCN107900230AAvoid damageFast deliveryMetal-working feeding devicesShaping safety devicesEngineering

The invention discloses a riveting and pressing device used for alarm machining, and relates to the technical field of alarm machining. The riveting and pressing device includes a box. The side, awayfrom the bottom of an inner cavity of the box, of a first supporting table is fixedly connected with a shock-absorbing and pressure-resisting device. The side, away from the bottom of the inner cavityof the box, of a second supporting table is fixedly connected with a loading table. The side, away from the first supporting table, of the shock-absorbing and pressure-resisting device is fixedly connected with a riveting and pressing main body. The bottom of an inner cavity of the riveting and pressing main body is fixedly connected with a lower pressing die. The end, away from a fixer, of a telescopic rod is fixedly connected with a picking and sending device. The top of the inner cavity of the box is fixedly connected with a power device. The side, away from the top of the inner cavity ofthe box, of the power device is fixedly connected with a riveting and pressing device body. According to the riveting and pressing device, materials can be quickly picked, sent, positioned and fastened, the fact that a workpiece is damaged due to position offset of the machined workpiece is prevented, the machining efficiency and yield are improved, impact force is reduced, the device safety is protected, the service life of equipment is ensured, the machining accuracy is further ensured, and the product quality is improved.

Owner:南通天福机械有限公司

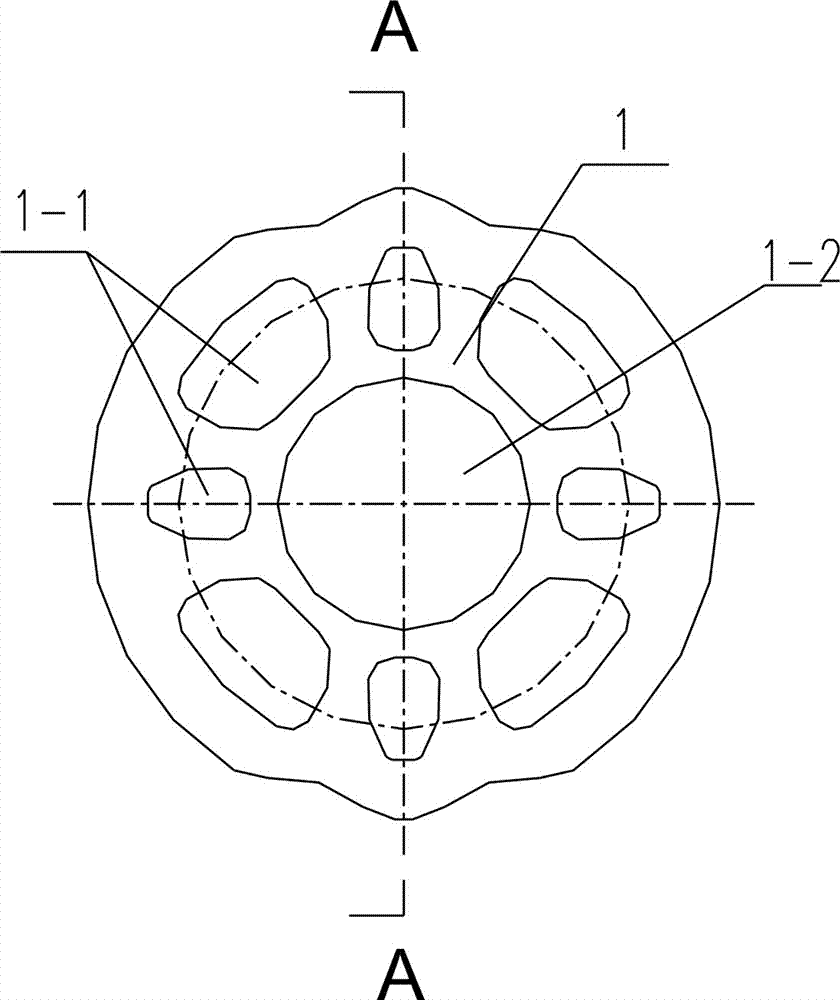

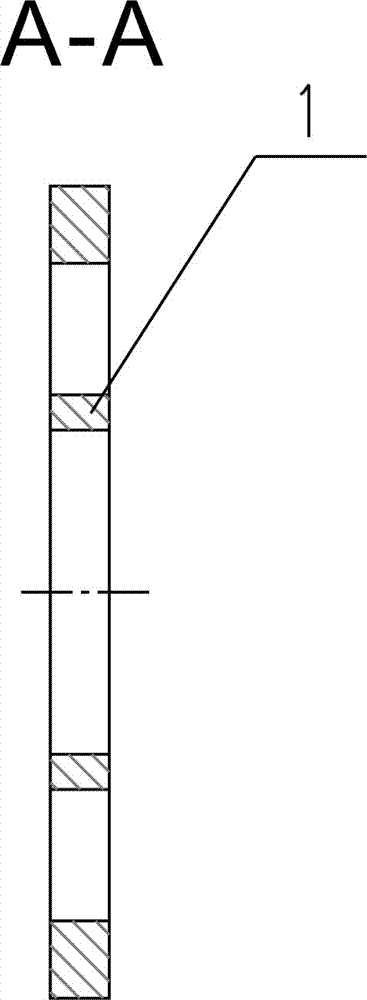

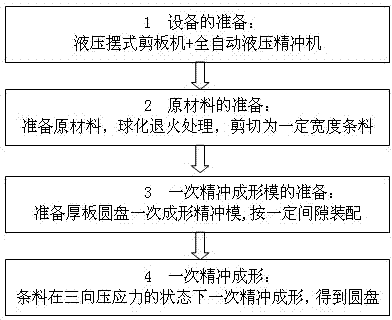

Once fine blanking forming method for thick plate disc

ActiveCN102756247AReduce punching forceGuaranteed dimensional accuracyThick plateHigh volume manufacturing

The invention provides a once fine blanking forming method for a thick plate disc. The method comprises the following steps of: 1) preparation of equipment, raw materials and upper and lower once fine blanking forming dies; and 2) once fine blanking forming. The step 2) comprises the following steps that: 1, the upper and lower once fine blanking forming dies are arranged on an upper tabletop and a lower tabletop of a fine blanking machine respectively, and when a fine blanking mold is at an opening position, a bar stock is fed to a fine blanking station; (2) the fine blanking machine is started, and a lower workbench of the fine blanking machine moves upwards to apply blanking force FS to a female die, a round hole male die and an irregularly-shaped hole male die, apply blank holding force FR to a dowel bar, a round knock-out pin and an irregularly-shaped knock-out pin and apply back pressure FG to the knock-out pins; and 3, a lower workbench of the fine blanking machine moves downwards, a pressure plate withdraws the cut bar stock from a punch die under the action of the blank holding force FR, and a pushing plate ejects a thick plate disc part from the female die under the action of the back pressure FG to obtain the formed thick plate disc part. The method is applied to batch production, and has the characteristics of operational simplicity, high efficiency, cost saving and stable quality.

Owner:武汉华夏精冲技术有限公司

Novel pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Dissimilar metal rivet welding connecting device, notch rivet and control method

ActiveCN104475950APrevent deviationGuaranteed mechanical propertiesResistance electrode holdersRivetsEngineeringMechanical property

The invention discloses a dissimilar metal rivet welding connecting device, and belongs to the field of mechanical manufacturing. The dissimilar metal rivet welding connecting device comprises an impact electrode arranged from top to bottom, a guide mechanism, a spring pressure block mechanism, and a guide plate; the guide mechanism has a hollow structure; the impact electrode is connected with a power supply positive pole; the impact electrode is arranged in the guide mechanism and can slide along the guide mechanism from top to bottom; the spring pressure block mechanism is mounted below an inner hole of the guide mechanism and used for supporting a rivet; the guide plate is connected with a power supply negative pole; and the surfaces of an impact guide rod, the guide mechanism and the spring pressure block mechanism are coated with insulating layer. By the dissimilar metal rivet welding connecting device, stamping force of a notch rivet penetrating through a material and the deformation of a joint can be effectively reduce, the rivet welding contact area between the rivet and dissimilar metal can be increased, the rivet welding stability of the dissimilar metal can be improved, cracks of the rivet can be avoided, mechanical properties of the material can be ensured, and the stability of the connection is enhanced. The invention also discloses a notch rivet and a rivet welding control method which are used for the dissimilar metal rivet welding connecting device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

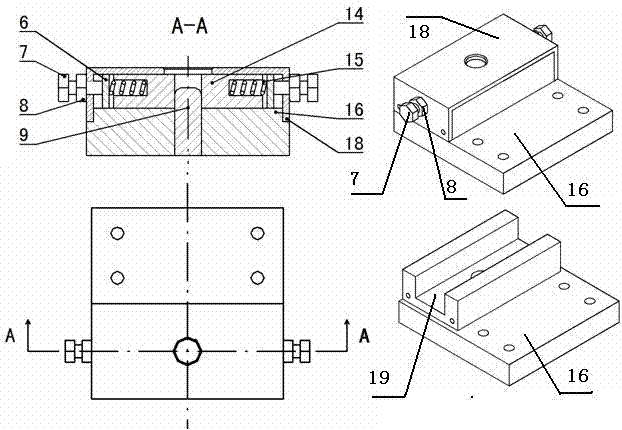

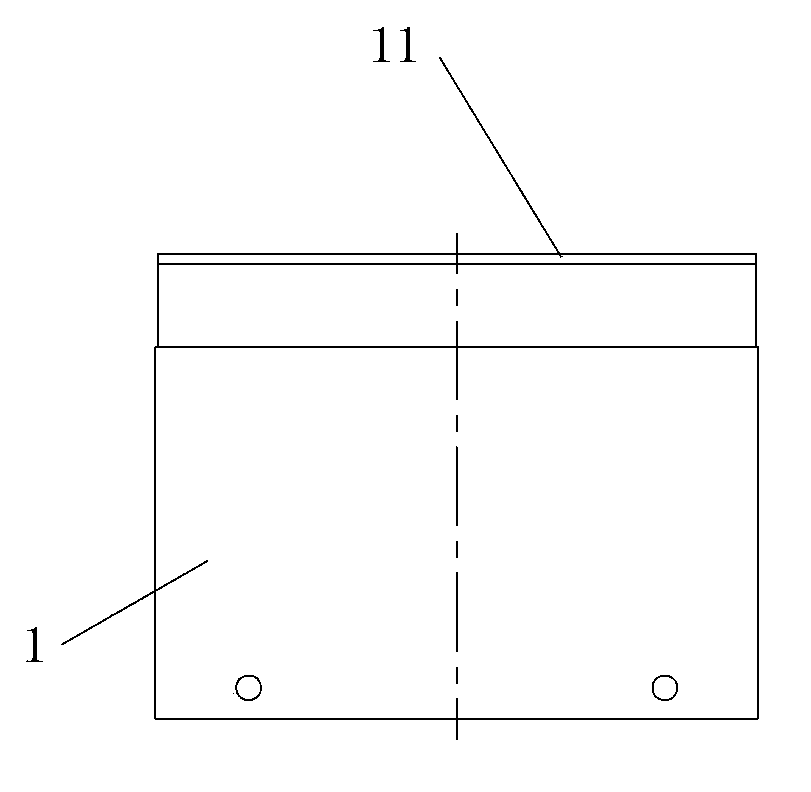

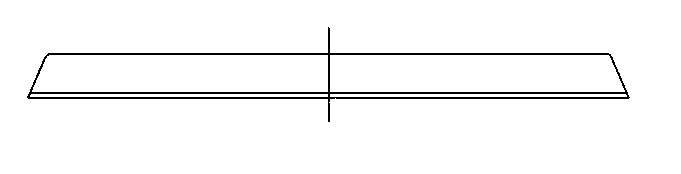

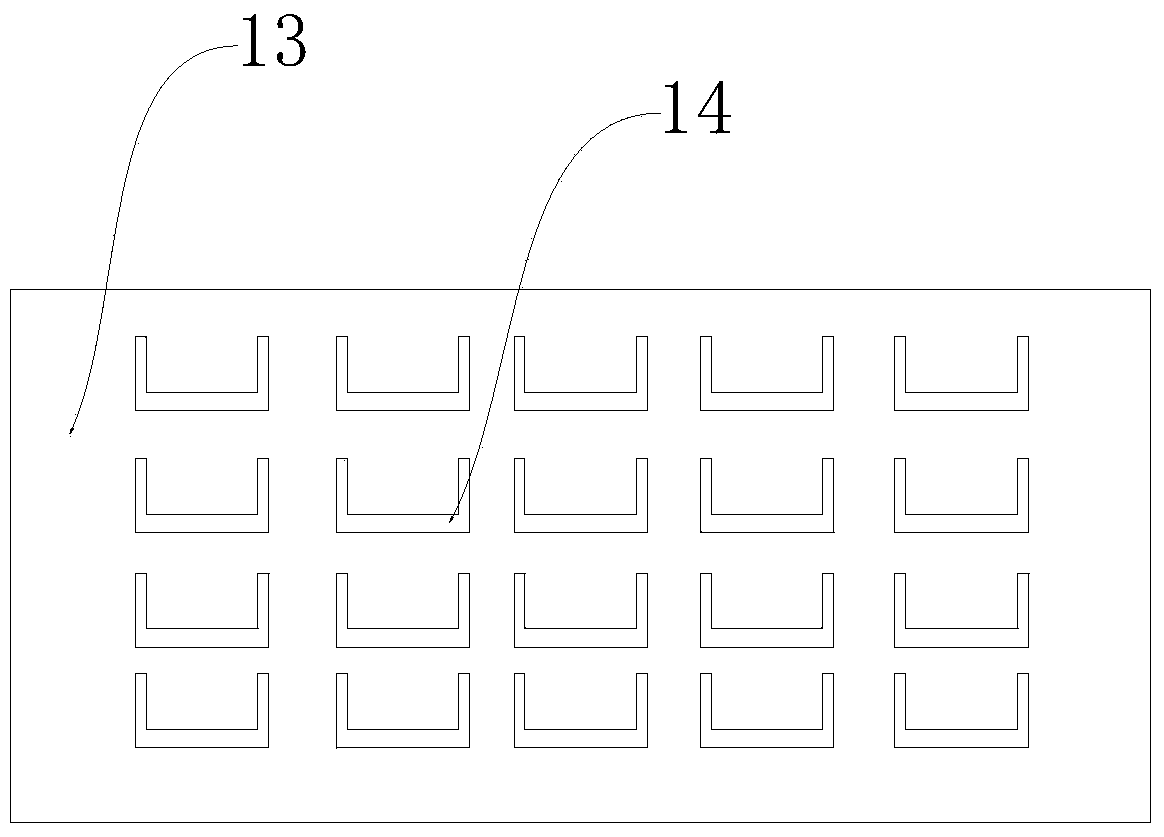

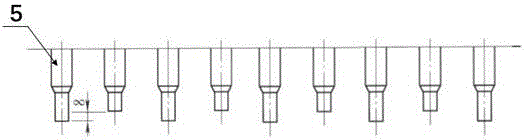

Die for multi-hole machining of aluminum template

InactiveCN106391841AMeet the precision requirementsEasy to useShaping toolsPerforating toolsEngineeringLubrication

The invention discloses a die for multi-hole machining of an aluminum template. The die comprises an upper die fixing plate and a lower die fixing plate which are arranged up and down. Guide columns, a plurality of upper die bodies and a rubber pressing roller are installed on the upper die fixing plate. Guide sleeves, lower die bodies and a discharge plate are installed on the lower die fixing plate. According to a product machined through the die, the hole tolerance between a hole formed in the head of the product and a hole formed in the tail of the product can be controlled within + / -0.4mm, the precision requirement for parts is met, and the usability is greatly improved; meanwhile, the upper die bodies are divided into two groups for operation in two batches, the total stamping force is decreased by half, the service life of the upper die bodies is prolonged, and high economical efficiency and energy conservation are achieved; furthermore, double oblique surfaces are designed on the edge of each upper die body, the stamping force is greatly decreased, a smooth hole can be obtained, and the discharging force is reduced almost to zero; and the guide columns have a self-lubrication function, abrasion caused by dry friction between the guide columns and the corresponding guide sleeves is avoided, the service life of the whole die is prolonged, and the use requirement of long-service-life and high-precision dies are met.

Owner:湖北森峰铝模科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com