Die for multi-hole machining of aluminum template

A technology of hole processing and aluminum template, which is applied in the field of aluminum template porous processing molds, can solve the problems of multiple positioning times, the influence of product processing accuracy, and large punching force of punching punches, etc., to achieve improved performance, improved service life, and extended use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

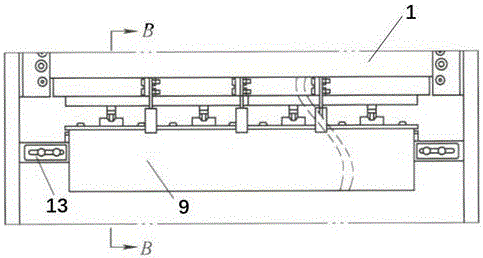

[0028] Such as figure 1 As shown, an aluminum template porous processing mold includes an upper mold fixing plate 1 and a lower mold fixing plate 2 arranged up and down, which are respectively used to fix the upper mold 5 and the lower mold 6, and the left and right ends of the lower mold fixing plate 2 are provided with positioning Block 13.

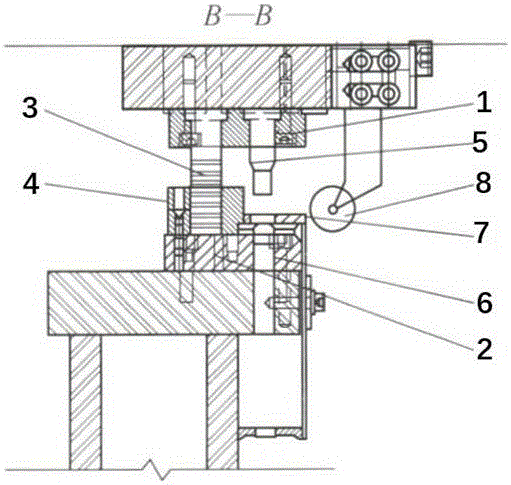

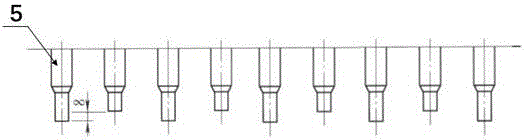

[0029] Such as figure 2 As shown, in order to ensure that the mold guides the mold stroke with precise positioning, the left part of the upper mold fixing plate 1 is vertically installed with a plurality of guide pillars 3, and the lower mold fixing plate 2 directly below the bottom of each guide pillar 3 A guide sleeve 4 matching the guide post 3 is arranged on the top; in order to realize the cutting edge at the bottom of the upper die 5 to punch the workpiece 9, a plurality of upper dies 5 are installed in the middle of the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com