Scraper blade blanking die

A mold and scraper technology, which is applied in the field of scraper blanking dies, can solve the problems of production efficiency not meeting the market demand, large quantity of each specification, and high production cost, so as to improve labor production efficiency, good stability, and save energy. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

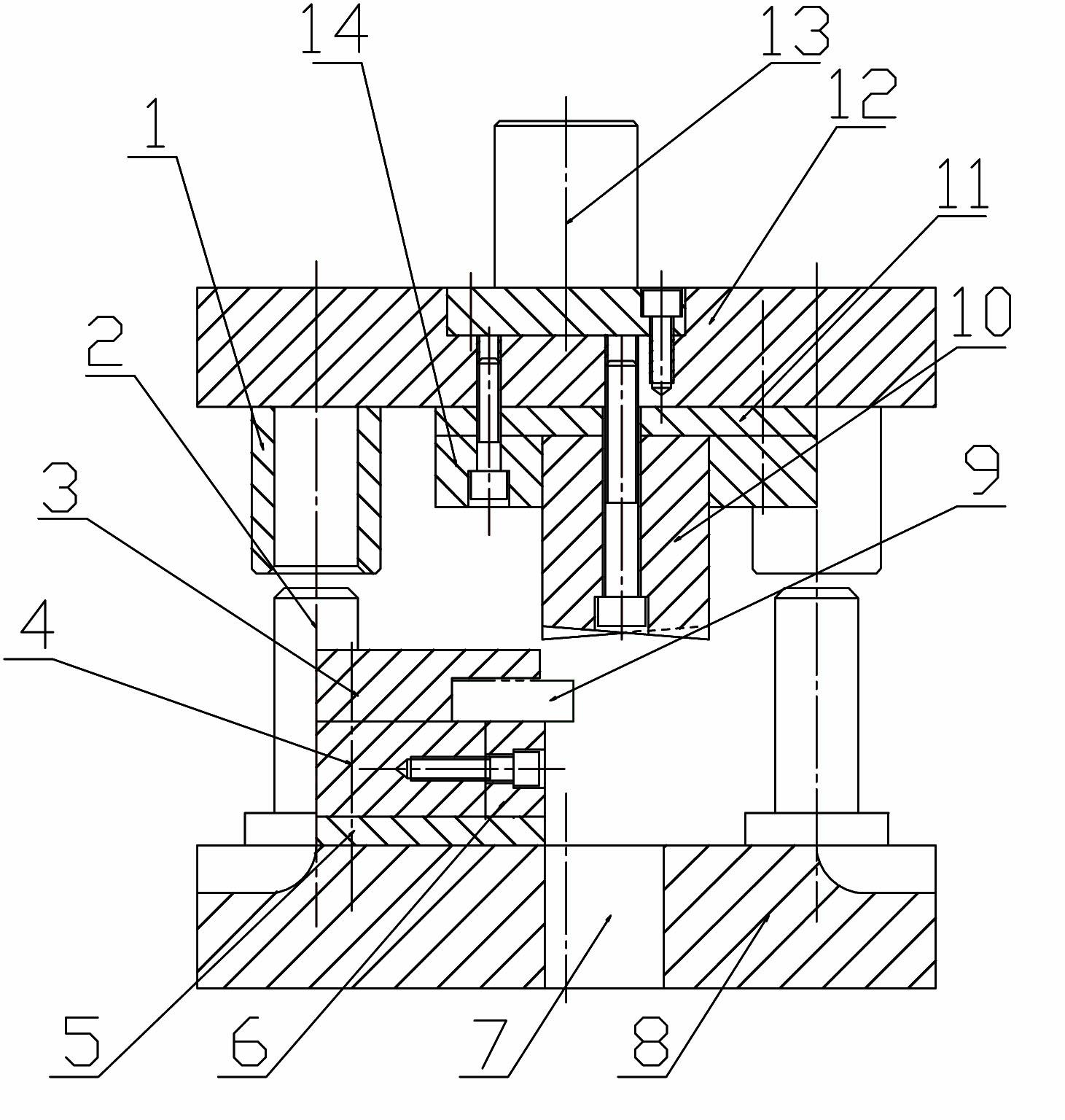

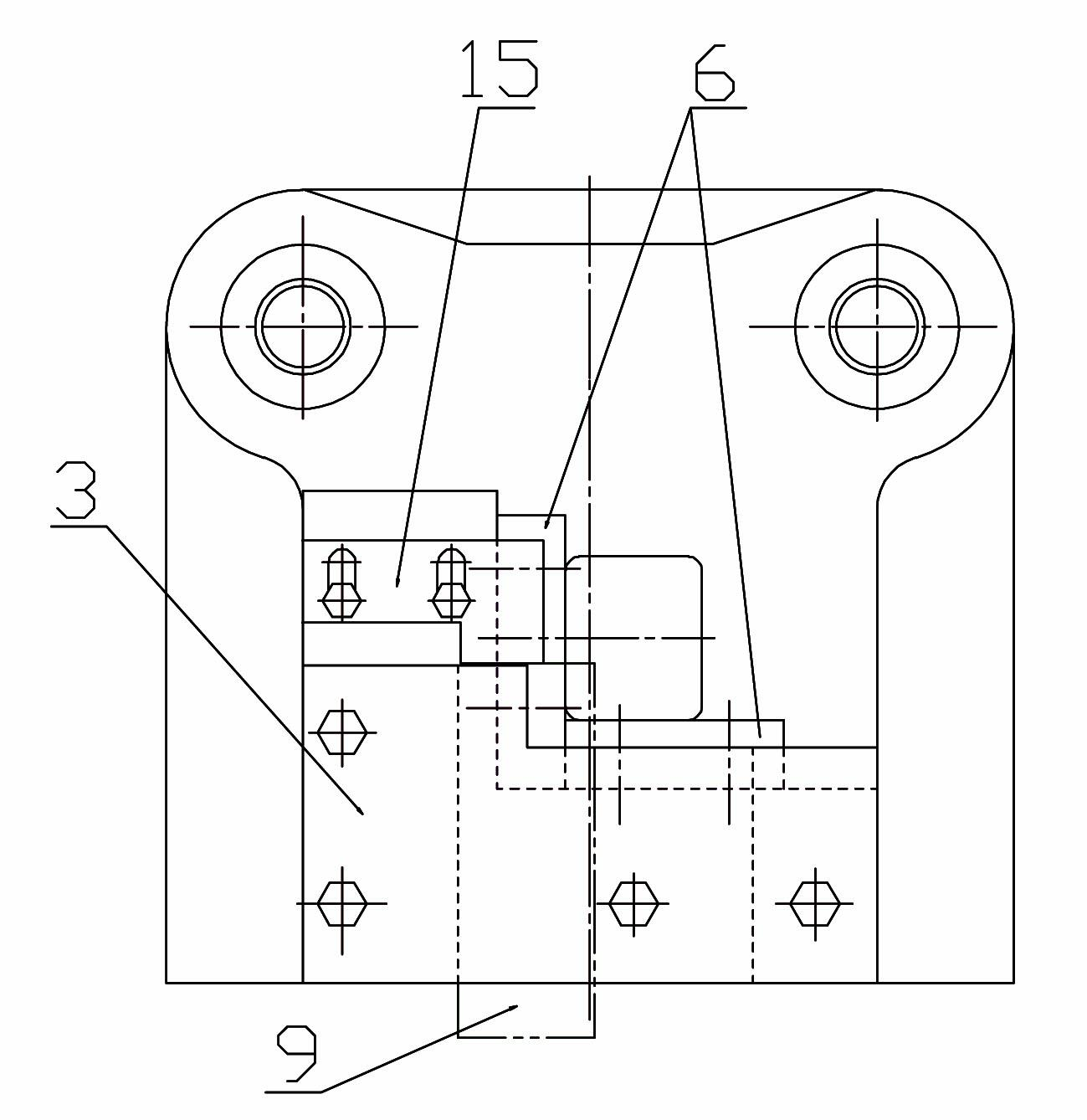

[0017] like figure 1 Among them, a scraper blanking die, the upper die part and the lower die part are connected through the guide sleeve 1 and the guide post 2; the relative position of the upper module 10 and the lower module 6 during work, that is, the blanking gap, is determined by the lower die base. The guide column 2 on the upper template 12 and the guide sleeve 1 on the upper template 12 ensure the relative position of the upper template 12 and the lower mold base 8, which also ensures the relative position of the upper and lower modules, that is, the blanking gap.

[0018] In the upper mold part, the upper module 10 is installed on the upper template 12 through the upper fixing plate 14 and the upper backing plate 11, and the installation method is to connect with M16 inner hexagonal bolts. A mold handle 13 is installed on the upper template 12, and the upper module 10 is provided with mutually vertical oblique cutting edges. The use of inclined cutting edges can red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com