Semi-automatic keycap press

A pressing machine, semi-automatic technology, applied in the field of semi-automatic keycap pressing machine, can solve problems affecting production capacity and quality, high work intensity, work fatigue, etc., to improve production capacity and quality, improve work efficiency, and reduce labor The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

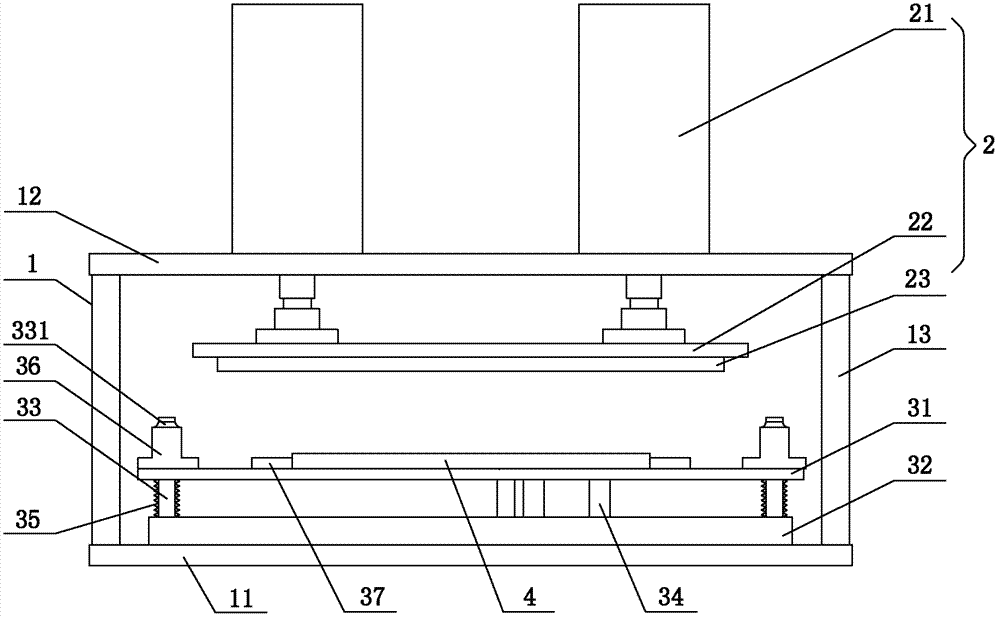

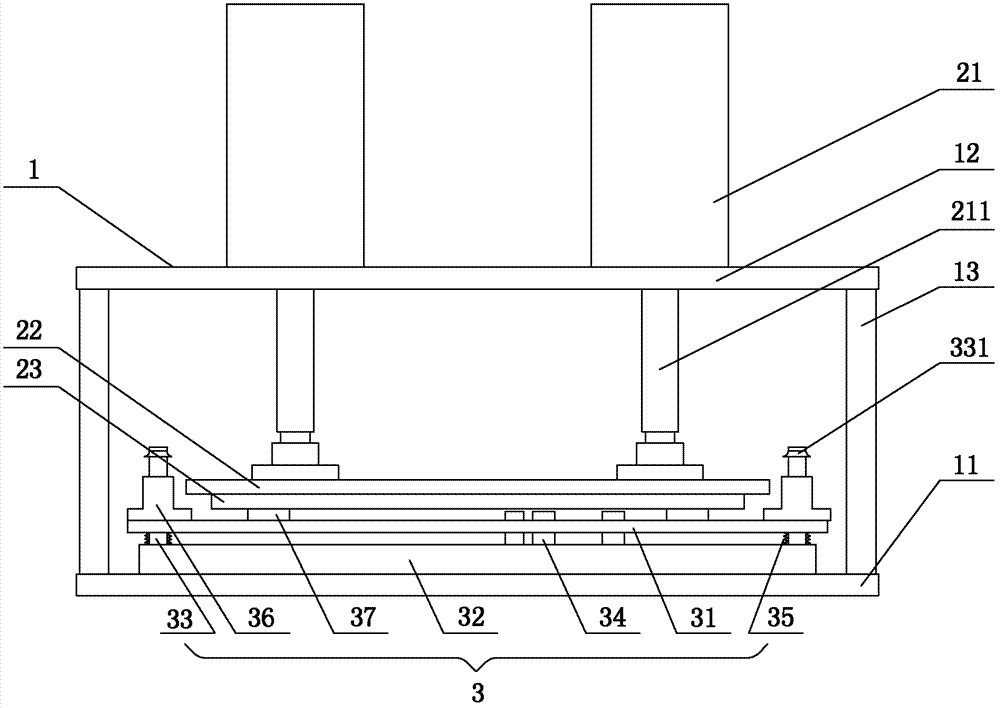

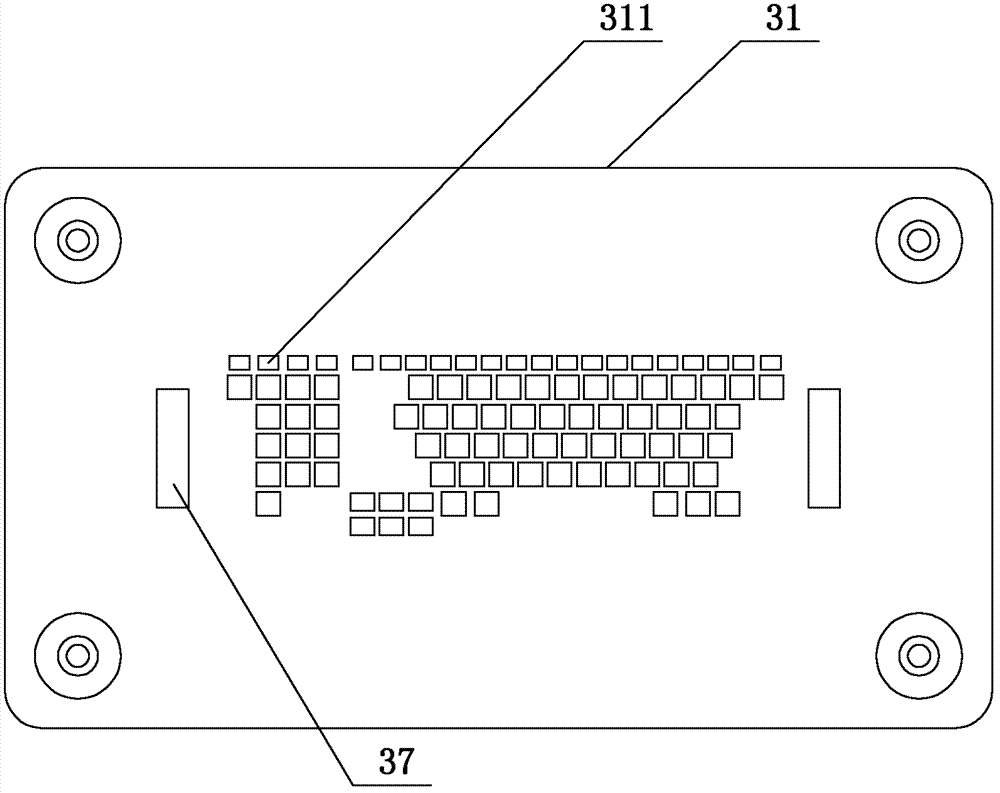

[0025] Such as Figure 1-5 The shown semi-automatic keycap pressing machine has a machine support frame 1, a push module 2, an ejection module 3 and a keycap placement die plate 4; the machine support frame 1 is composed of a base plate 11, a top plate 12 and Composed of four pillars 13; the pushing module 2 has a cylinder 21, a pushing plate 22 and a pressing plate 23; there are two cylinders 21, which are arranged symmetrically on the top plate 12, and the piston rod 211 of the cylinder 21 stretches out from the top plate 12 The push plate 22 is connected to the lower end of the piston rod 211; the pressing plate 23 is connected below the push plate 22; the ejection module 3 has upper and lower support plates 31, 32, guide posts 33 and ejector posts 34; The lower support plate 32 is fixedly arranged on the base plate 11; the guide column 33 has four, which are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com