Automatic grinding device for die punch arc

A die punch and arc technology, which is applied in the field of die punch circular arc automatic grinding device, can solve the problems of grinding amount, arc shape grinding size, surface roughness concentricity cannot be guaranteed, and save money. , The effect of reducing the punching force and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

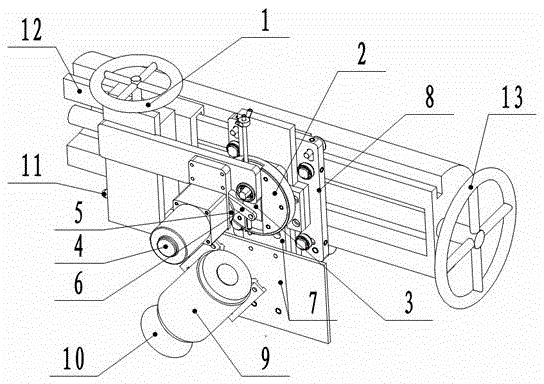

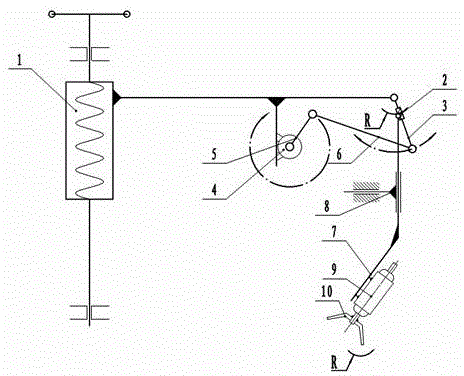

[0011] As shown in the figure, the present invention relates to an automatic grinding device for mold punch arcs, including a screw lifting pair, a radius adjustment disc, a swing rod, a drive motor, a drive rod a, a drive rod b, a grinding head motor mounting plate, Installation plate freedom limit mechanism, grinding head motor, bowl-shaped grinding wheel, horizontal slide rail seat locking handle, and horizontal slide rail are characterized in that: the whole device is installed on the horizontal slide rail 12, and the screw lifting pair 1 is installed on the column or the horizontal slide rail. On the rail 12, the horizontal slide rail 12 has a horizontal slide rail seat locking handle 11, the back of the mounting plate freedom restriction mechanism 8 is installed on the vertical lathe or the horizontal slide rail 12, and the grinding head motor mounting plate 7 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com