Phase change material (PCM) cast-in-place reinforced concrete large-size sandwiched floor and construction method thereof

A reinforced concrete, large-scale technology, used in floors, building components, buildings, etc., can solve the problems that the embedded pipeline cannot pass through the core form, and the quality of concrete pouring at the bottom of the slab cannot be guaranteed, and achieve the effect of ensuring the pouring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

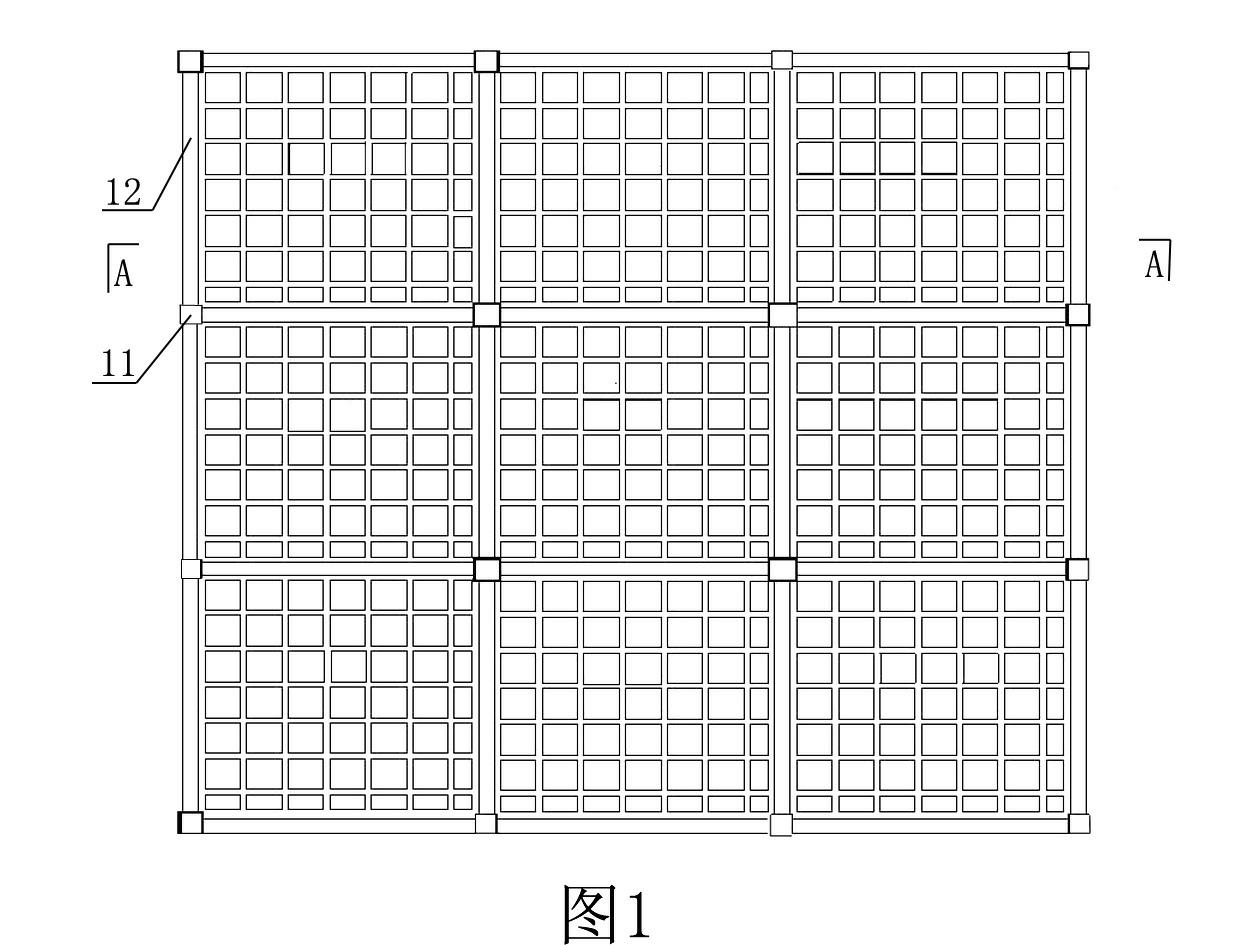

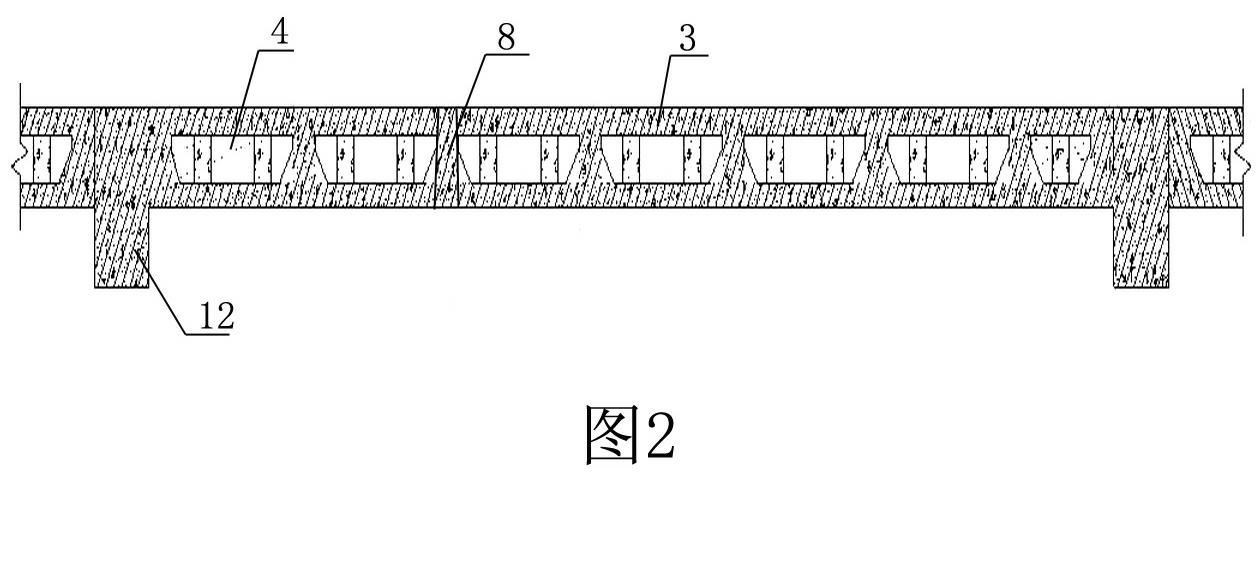

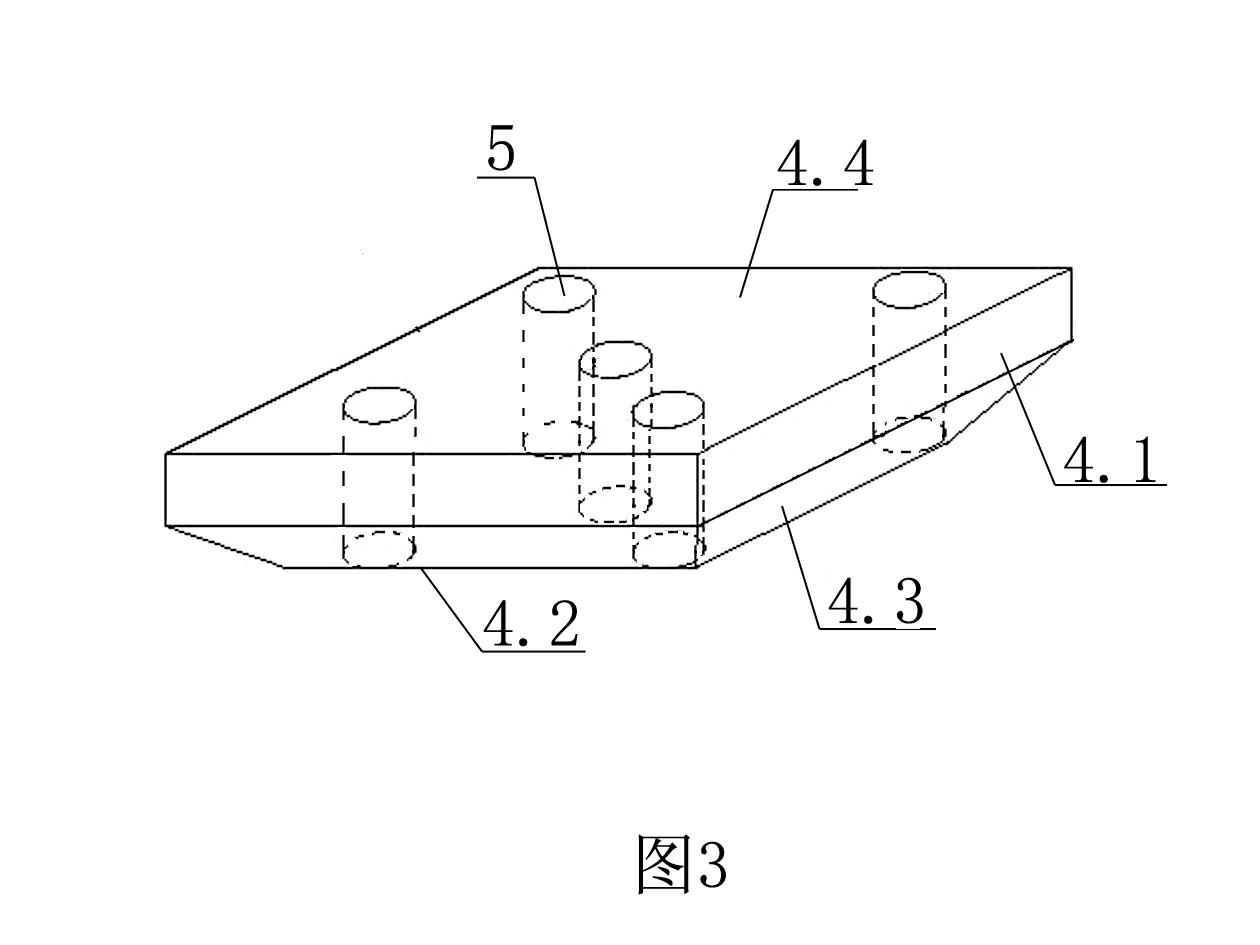

[0041] Examples see Figure 1 to Figure 5 As shown, a PCM cast-in-place reinforced concrete large-scale sandwich floor slab has concealed beams 8 at intervals, and is composed of a mandrel 4, upper steel bars 1, lower steel bars 2 and outsourcing concrete 3, and the mandrel 4 is a solid The polyphenylene block has an upper steel bar 1 bound on its top surface and a lower steel bar 2 bound on its bottom surface, and is wrapped by outsourcing concrete 3 to form a whole. The core mold 4 is a solid bucket-shaped body surrounded by four sides 4.1, four folded surfaces 4.3 folded into the body, a bottom surface 4.2 and a top surface 4.4, wherein each side 4.1 is connected with the folded surface 4.3. The bottom surface 4.2 is connected, and there is at least one inspection hole 5 . The diameter of the inspection hole 5 is 100mm-150mm. The angle α between the folding surface 4.3 and the bottom surface 4.2 is 30°-60°. The plane size of the mandrel is 1000mm×1000mm.

[0042] The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com