Construction method for supporting template at construction joint of frame structure

A frame structure and construction method technology, applied in the field of construction, can solve problems such as difficult cleaning, quality problems, slag inclusions, etc., and achieve the effects of easy operation, good appearance quality, and good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is a construction method for formwork support at construction joints of a frame structure, which is carried out according to the following steps:

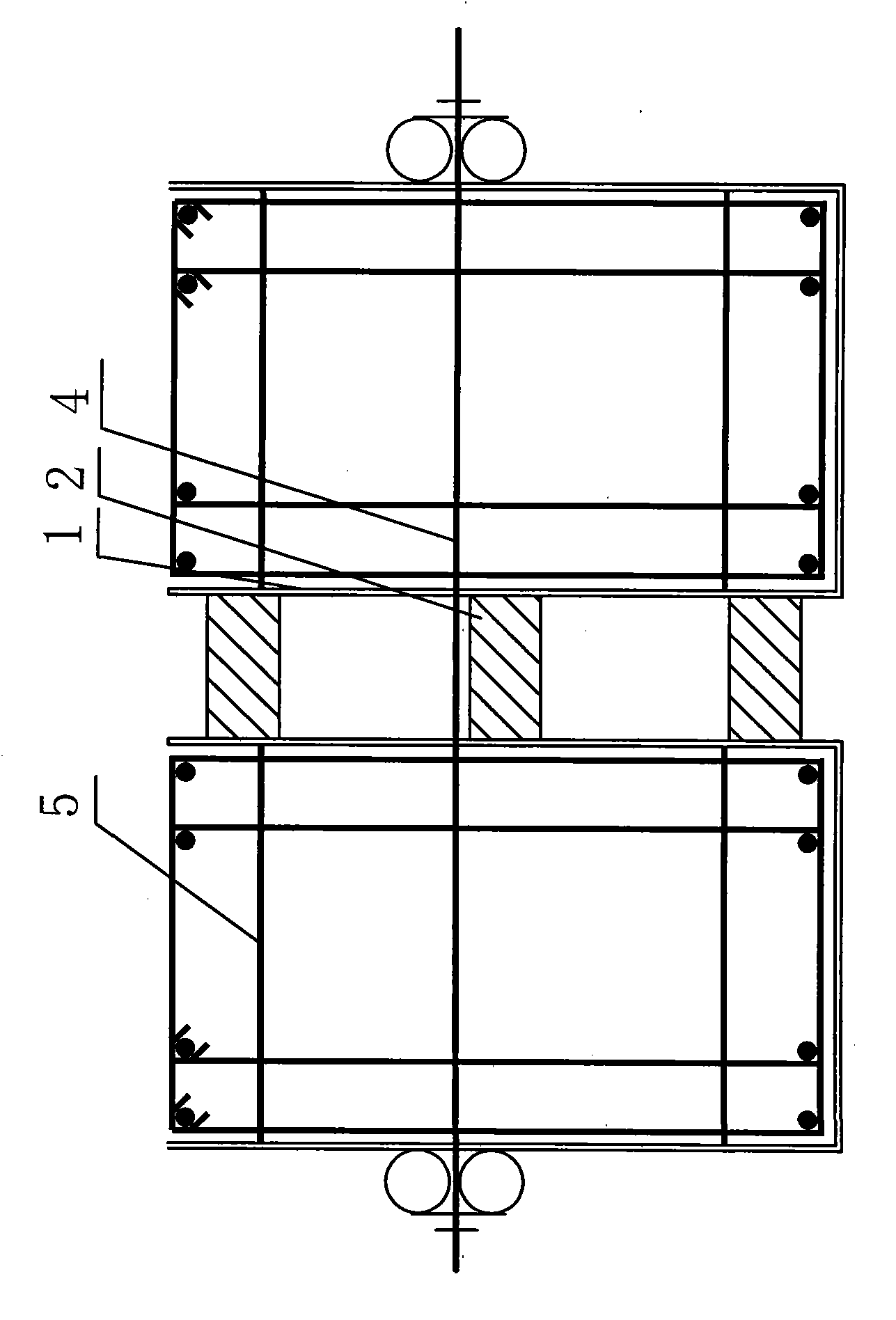

[0027] 1. Set the top support: see image 3 , set the top mold stick 5 at the components (double beams) on both sides of the construction joint according to the cross-sectional size, and the type and spacing of the top mold sticks 5 are effectively set according to the specific size of the components (double beams).

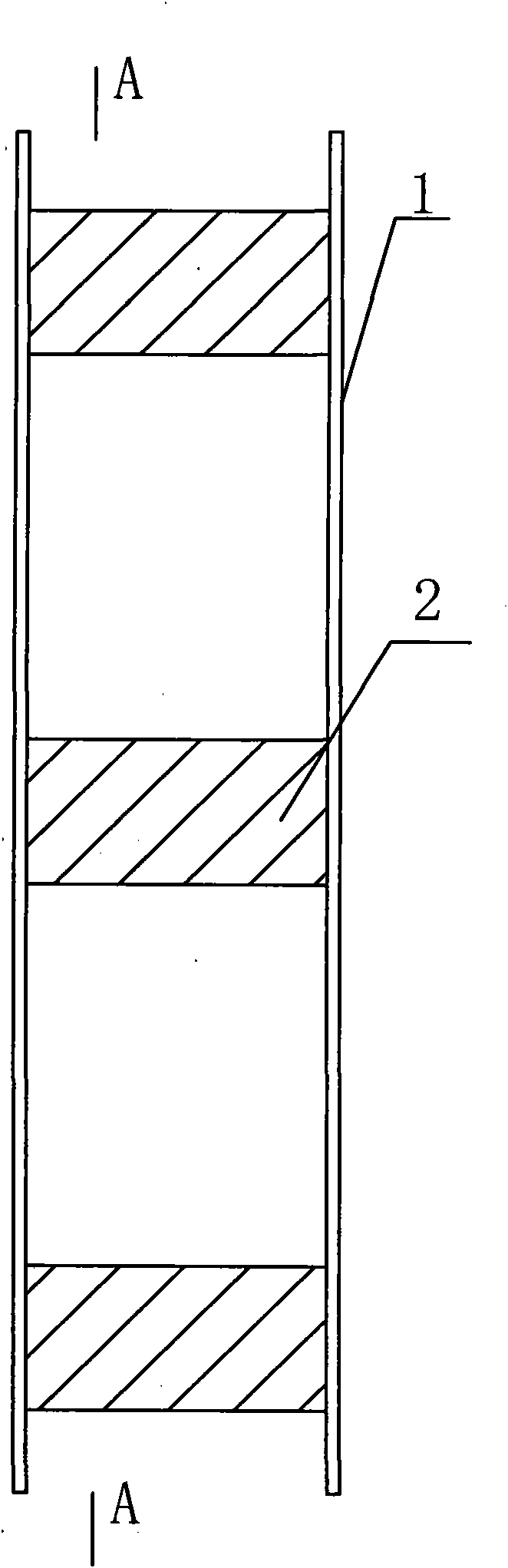

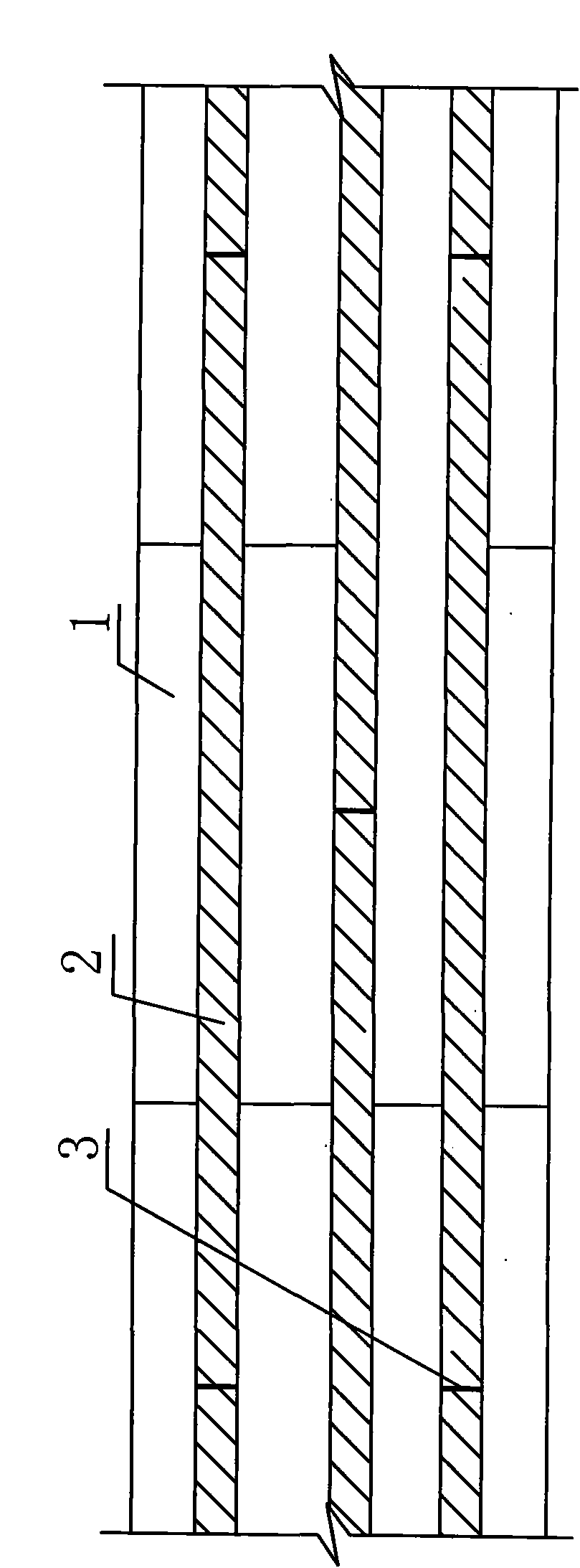

[0028] 2. Supporting (prefabricated) formwork: see figure 1 , figure 2 and image 3 , At the construction joints of the frame structure (taking 100mm as an example), use 50×100mm wooden squares to make the back flute 2, and the two sides of the wooden squares are supported by the formwork 1 at the construction joints, and the formwork 1 is supported in the construction joints. The template 1 at the construction joint is made of multi-layer board or bamboo plywood. Since the actual size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com