Gas uniformizing device for PECVD (Plasma Enhanced Chemical Vapor Deposition) system

A gas device and air-distribution plate technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of uneven air distribution in the chamber, and achieve uniform air distribution, good control, and guarantee. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

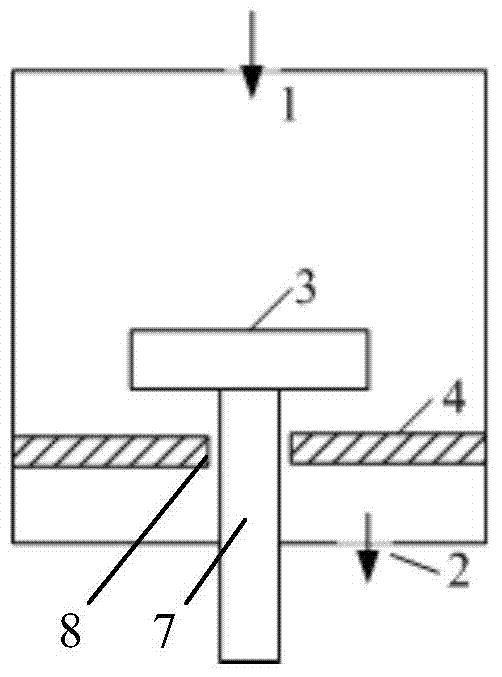

[0014] like figure 1 As shown, the present embodiment provides a uniform gas device for a PECVD system. The chamber of the PECVD system is provided with a substrate table 3 and a support rod 7 for supporting the substrate table. The first air distribution plate 4 below 3, the first air distribution plate 4 is a disc-shaped structure, and the outer edge of the first air distribution plate is closely attached to the inner wall of the chamber; the middle of the first air distribution plate 4 is provided with The ventilation hole 8, the support rod 7 is located in the ventilation hole 8, the ventilation hole 8 and the support rod 7 are arranged concentrically, the diameter of the ventilation hole 8 is larger than the diameter of the support rod 7, and the gap between the ventilation hole 8 and the support rod 7 is 1mm~20mm . The material of the first air distribution plate is stainless steel, aluminum or PTFE. The first air-distribution plate 4 can be a whole disc, can also be f...

Embodiment 2

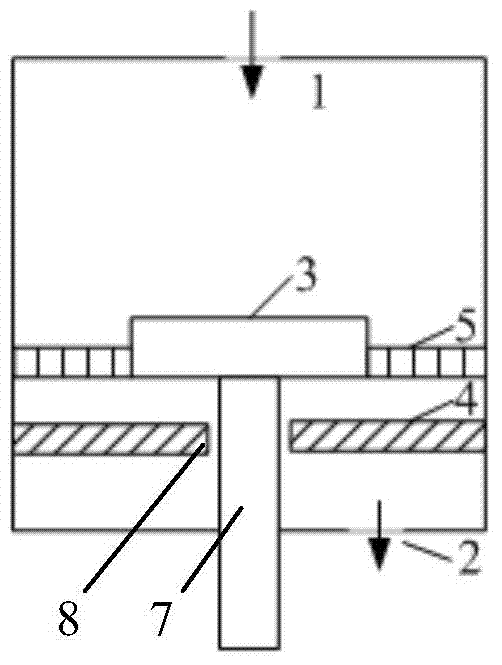

[0017] like figure 2 shown in figure 1 On the basis of , the air-distribution device also includes a second air-distribution plate 5, the second air-distribution plate 5 is arranged between the substrate table 3 and the inner wall of the chamber, and the second air-distribution plate 5 is connected to the substrate table 3 and the cavity respectively. The inner walls of the chamber fit snugly. According to actual needs, the second air distribution plate 5 can be selected from a single-layer air distribution plate or a multi-layer air distribution plate with evenly distributed ventilation holes.

[0018] The gas enters the chamber from the air inlet 1 of the chamber, passes through the second air distribution plate 5 and the first air distribution plate 4 in turn, and flows in the direction of the air outlet 2; the second air distribution plate 5 and the first air distribution plate The combination of 4 makes the effect of evenly distributing the airflow in the chamber bette...

Embodiment 3

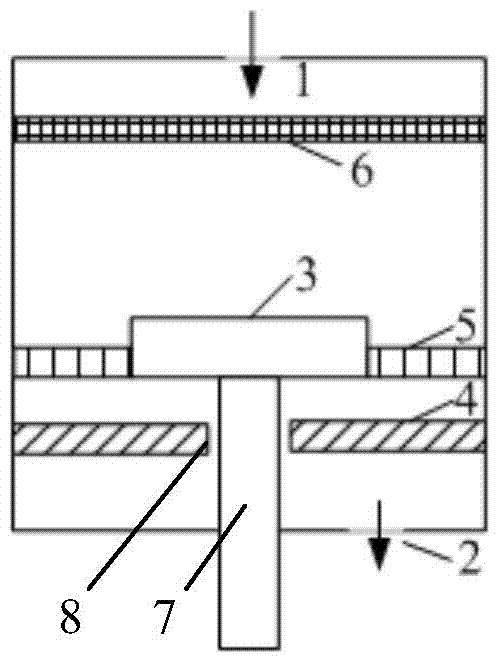

[0020] like image 3 shown in figure 2 On the basis of , the air distribution device also includes a third air distribution plate 6 , the third air distribution plate 6 is arranged above the substrate stage 3 , and the third air distribution plate 6 is closely attached to the inner wall of the chamber. According to actual needs, the third air distribution plate 6 can be selected from a single-layer air distribution plate or a multi-layer air distribution plate with evenly distributed ventilation holes. The third air distribution plate except image 3 The shown structure may also be a cylindrical structure with ventilation holes or a hollow annular structure with ventilation holes, which is directly communicated with the air inlet 1 .

[0021] The gas enters the chamber from the air inlet 1 of the chamber, passes through the third air distribution plate 6, the second air distribution plate 5 and the first air distribution plate 4 in sequence, and flows in the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com