Edge exposure device

An edge exposure and edge technology, applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problem of no exposure size and dose monitoring, the problem of energy efficiency becomes particularly serious, and the method of adjusting the best focal plane is complicated And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

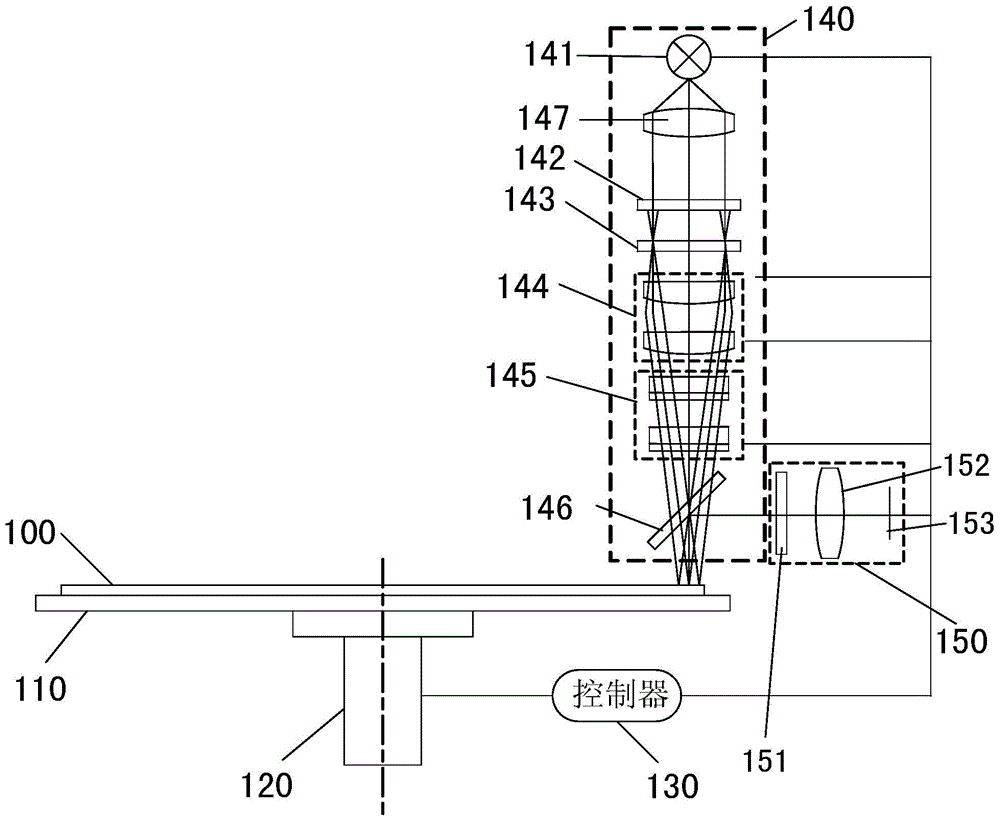

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

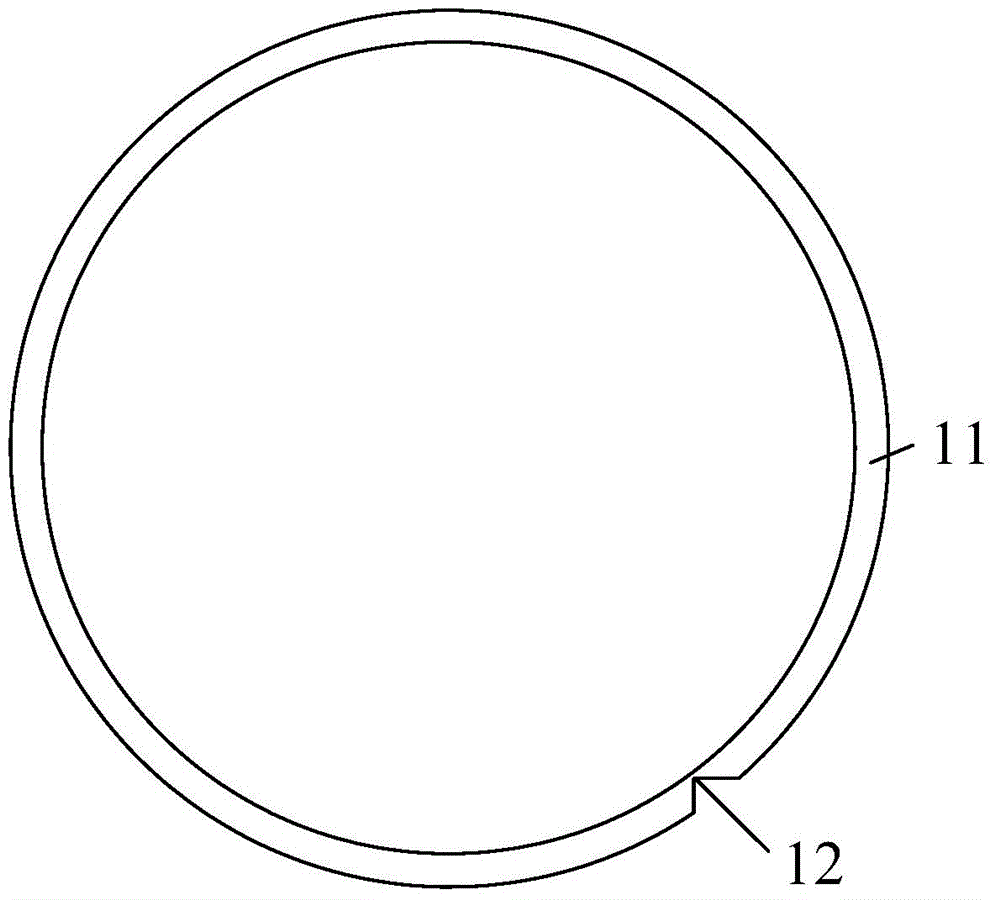

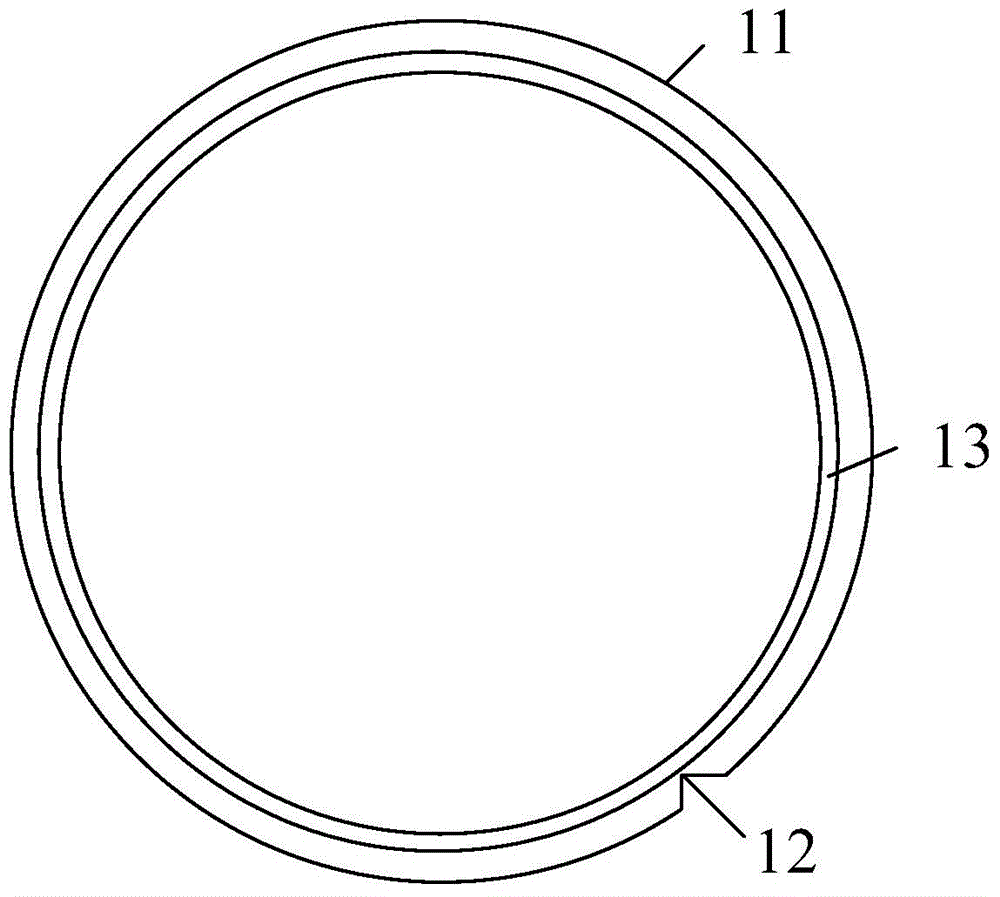

[0036] Please refer to Figure 3-6 , The edge exposure device of the present invention is mainly composed of four parts: the adsorption rotary table 110, the motor 120, the controller 130 and the edge exposure lens assembly. specifically,

[0037] The adsorption rotary table 110 is a device for absorbing and driving the silicon wafer 100 to rotate so as to perform edge exposure.

[0038] The motor 120 is a moving device that drives the rotation of the adsorption turntable 110 .

[0039] The controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com