Kelp drying device and kelp drying method

A drying device and drying method technology, applied in the fields of application, food processing, food science, etc., can solve the problems of low drying efficiency, heavy labor, low utilization rate of heat energy in hot air drying, etc. The effect of small footprint and maximum energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

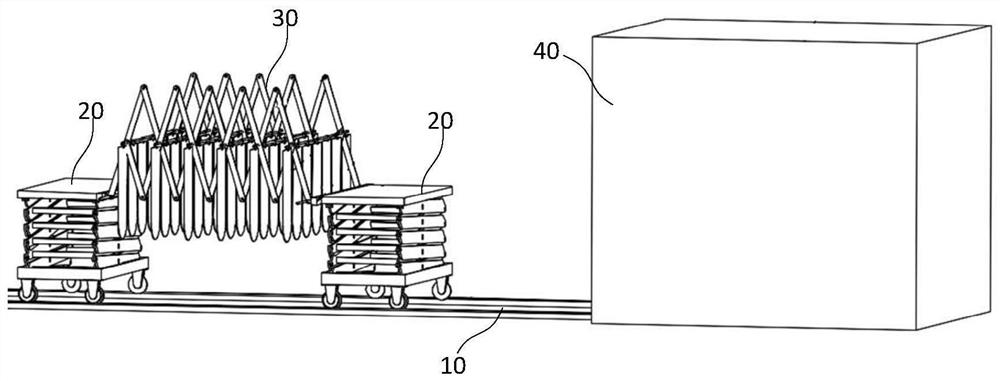

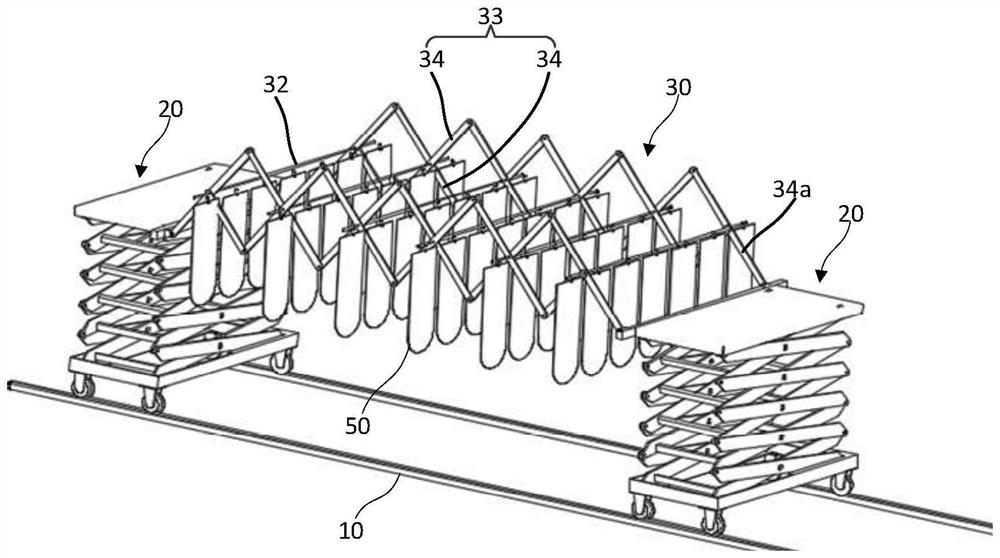

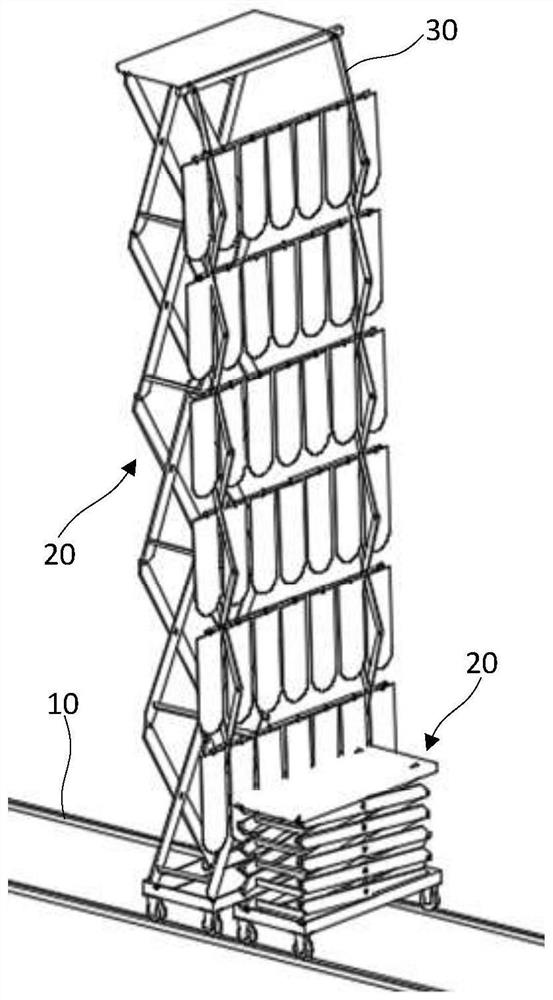

[0038] Example: such as figure 1 As shown, the embodiment of the present invention includes a kelp drying device, which includes: a guide rail 10 , two lifting mobile trolleys 20 , a telescopic drying rack 30 and a drying chamber 40 arranged on the guide rail 10 . The lifting mobile trolley 20 runs on the guide rail 10, and it has a liftable platform. Retractable airing rack 30 is used for mounting for sea-tangle, can be set up between the lifting platforms of two lifting mobile dollies 20, adopts sunlight to dry sea-tangle, also can be arranged in drying room 40, sea-tangle is dried by heat pump.

[0039] Such as figure 2 , 5 As shown, a connecting rod 31 is provided at both ends of the telescopic drying rack 30 , and the connecting rod 31 is arranged along the horizontal direction and perpendicular to the telescopic direction of the telescopic drying rack 30 . The lifting platform of the lifting mobile trolley 20 is provided with an overlapping structure for the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com