A cement deep mixing ship pile frame system and pile forming method

A technology of deep mixing and pile frame, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of small pile area, high energy consumption, and shallow treatment depth of pile frame, and achieve obvious economic and social benefits. Benefits, wide range of engineering adaptation, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

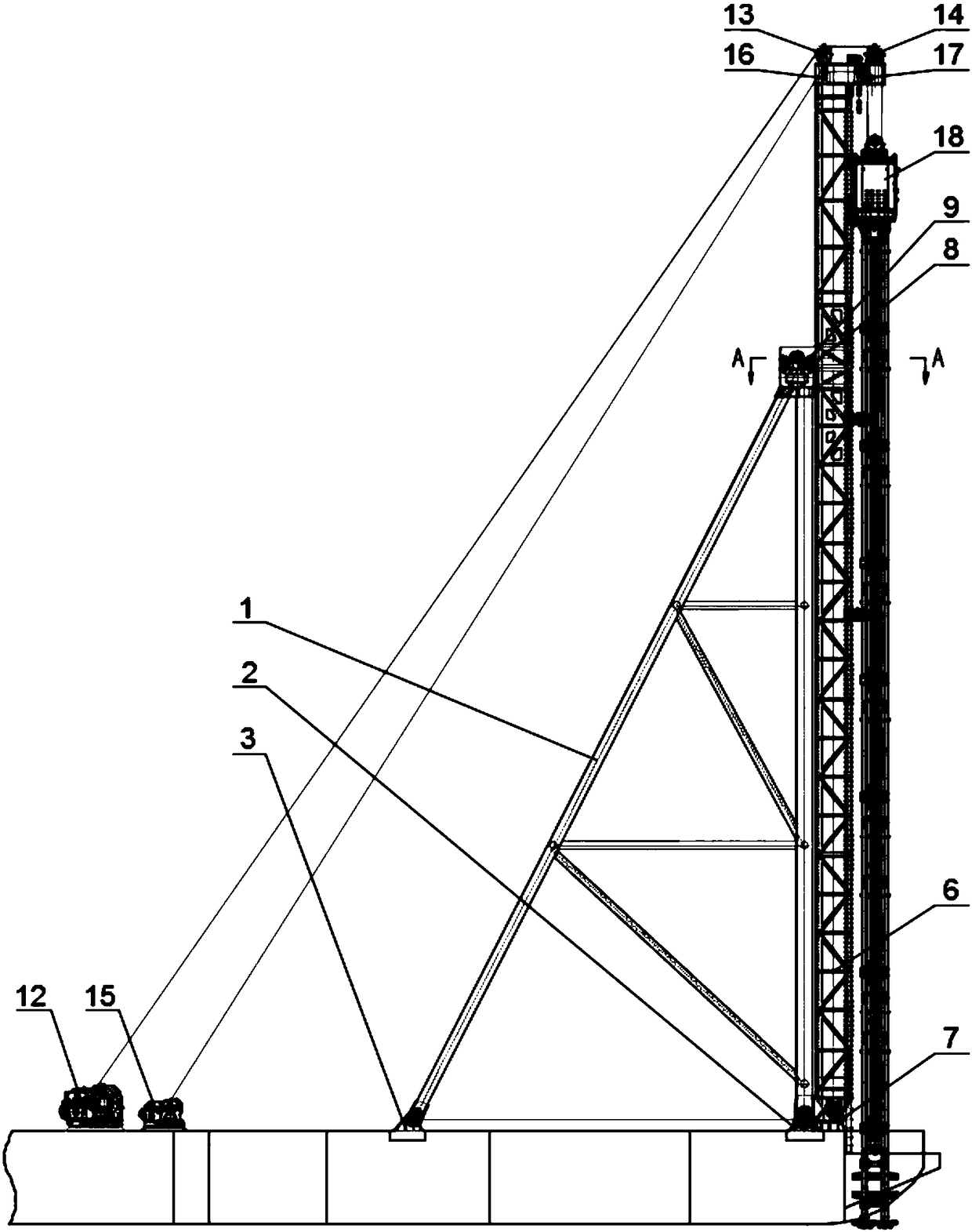

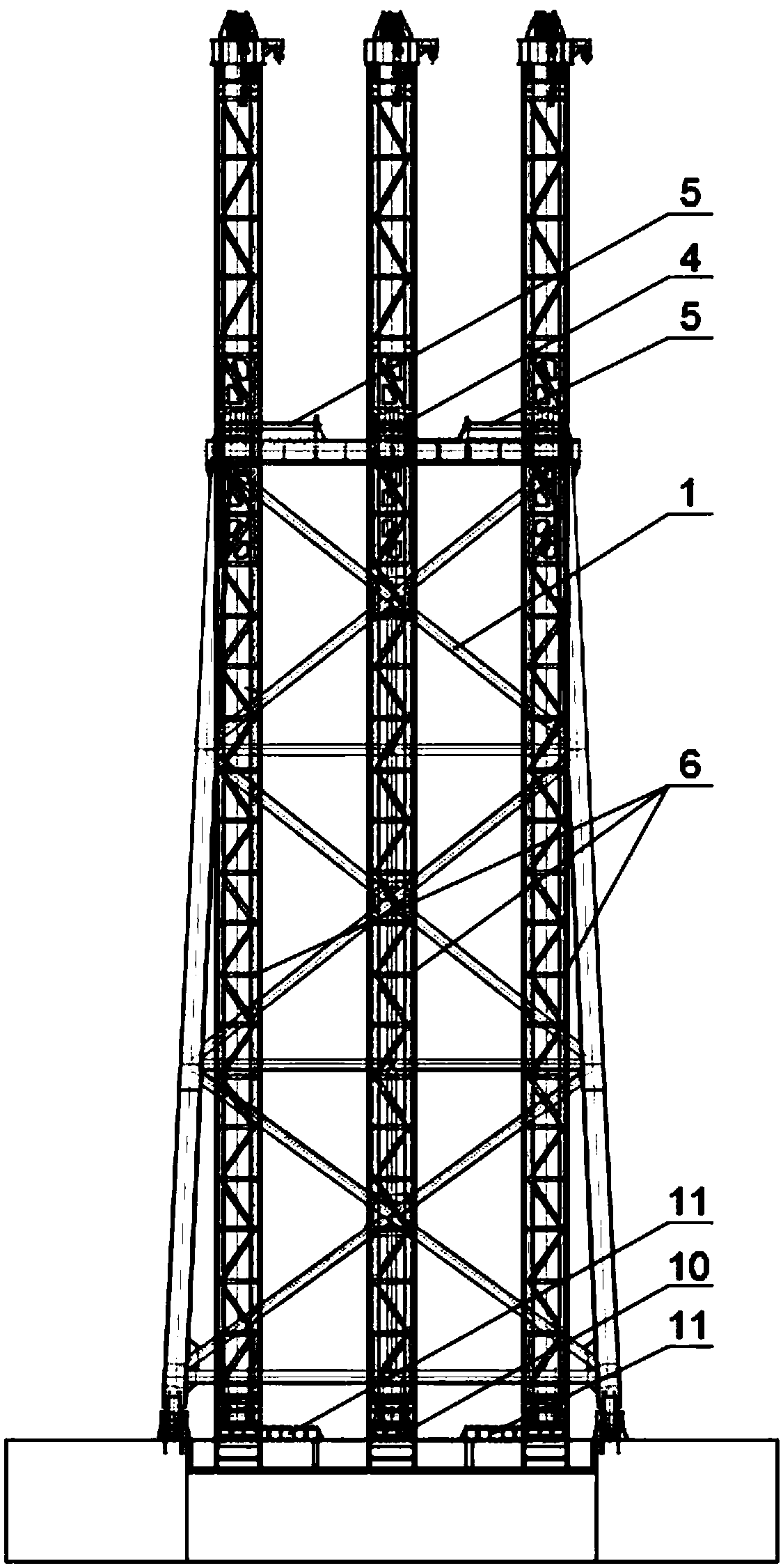

[0035] The pile frame system of the present invention comprises an A frame, a pile frame, a pile frame base, a pile frame sliding seat, a main lifting mechanism for hanging piles, an auxiliary lifting mechanism, and a cement deep mixing processor.

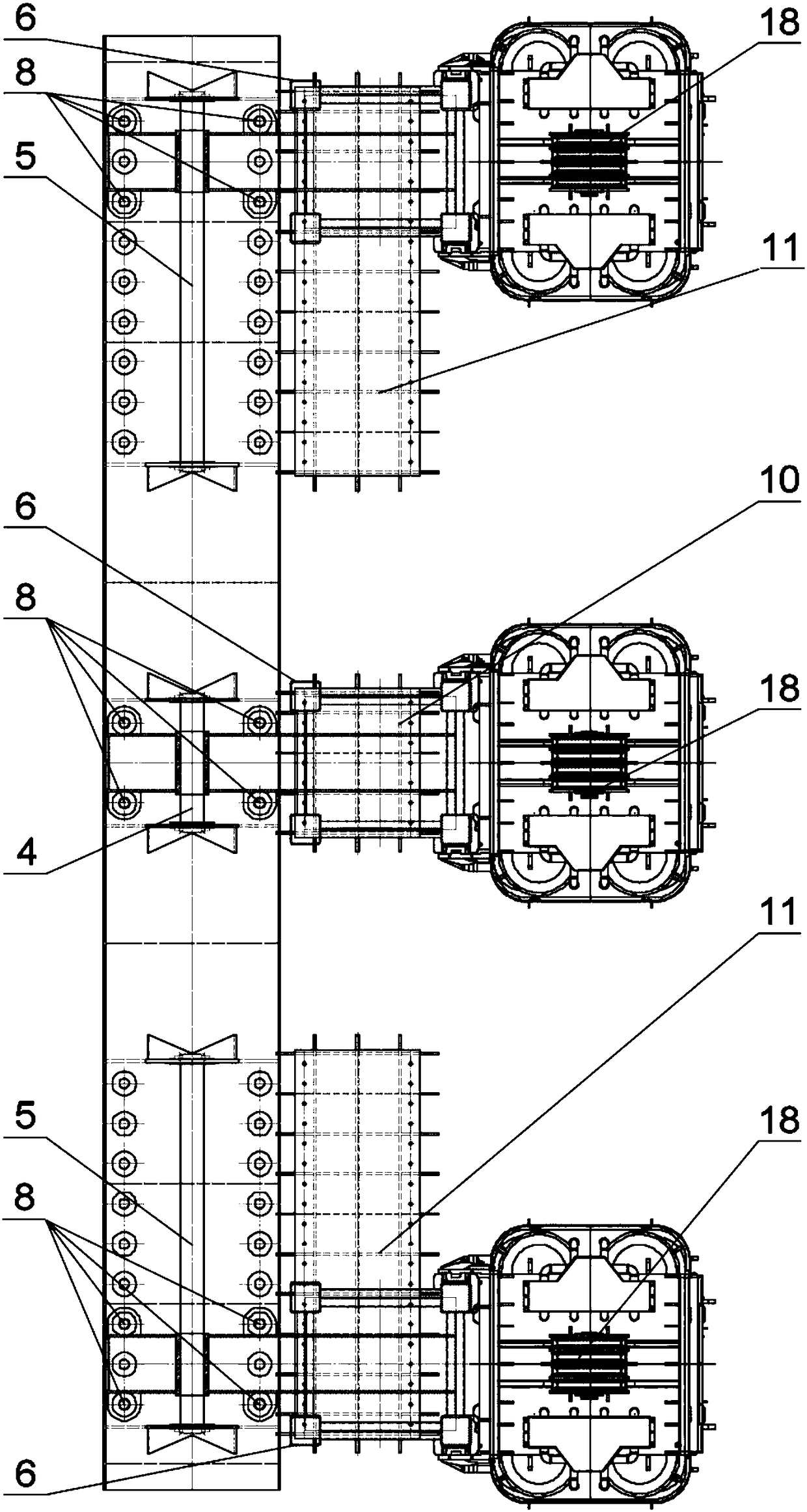

[0036] In this embodiment, there are three groups of pile frames, and the horizontal spacing of the three groups of pile frames is adjustable, wherein the middle pile frame is fixed and cannot be adjusted horizontally, and the lateral distance between the pile frames on both sides relative to the middle pile frame is adjustable.

[0037] A group of cement deep mixing processors are installed on each group of pile frames. Vertical rails are arranged on the pile frames.

[0038] A-frame is composed of A-frame main structure 1, front hinge seat 2, rear hinge seat 3, top short hinge shaft 4, top long hinge shaft 5, A-frame main structure 1, front hinge seat 2, rear hinge seat 3 Both are hinged by pin shafts, and the front hinge seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com