Patents

Literature

129results about How to "Increase operating load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

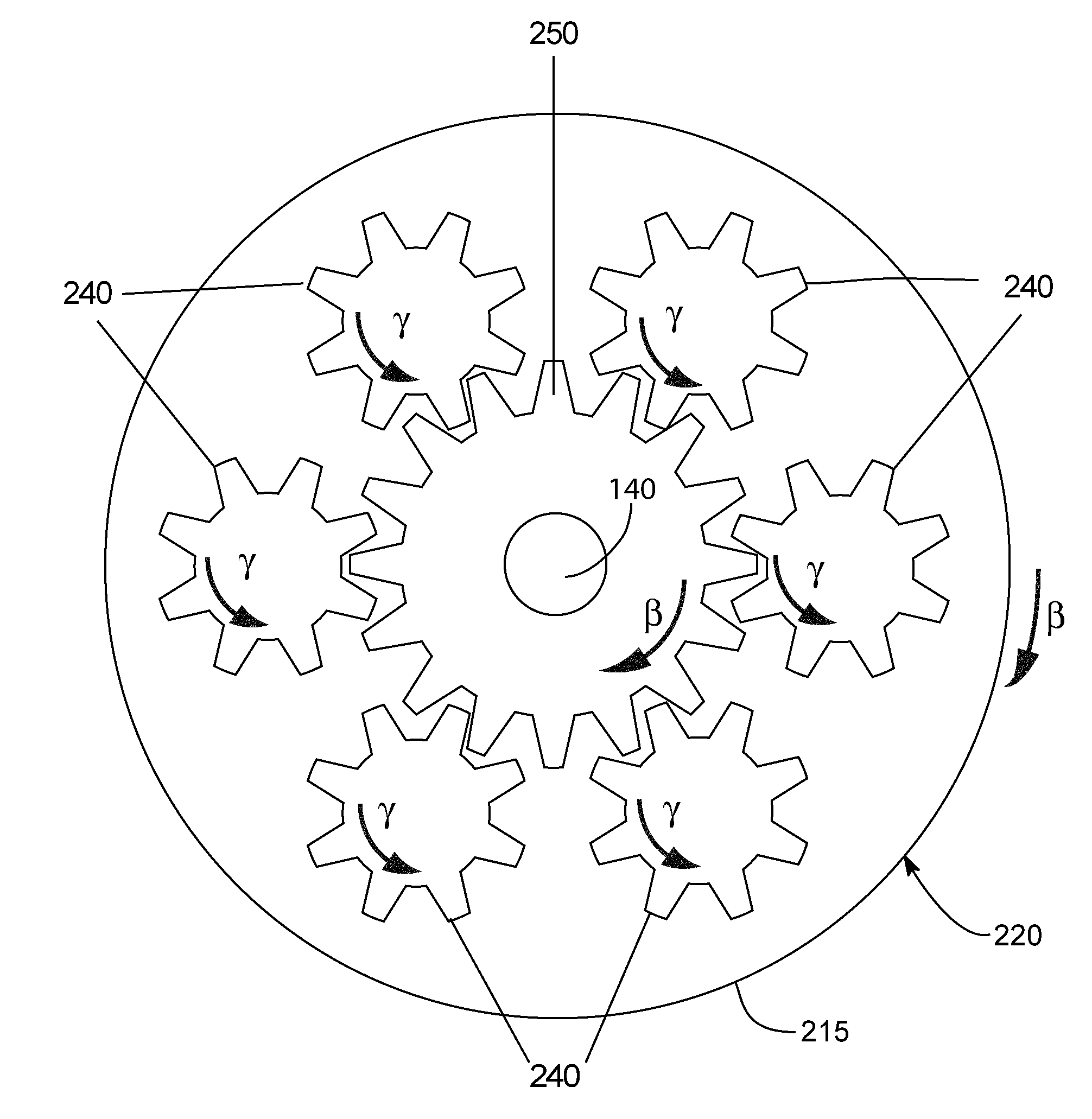

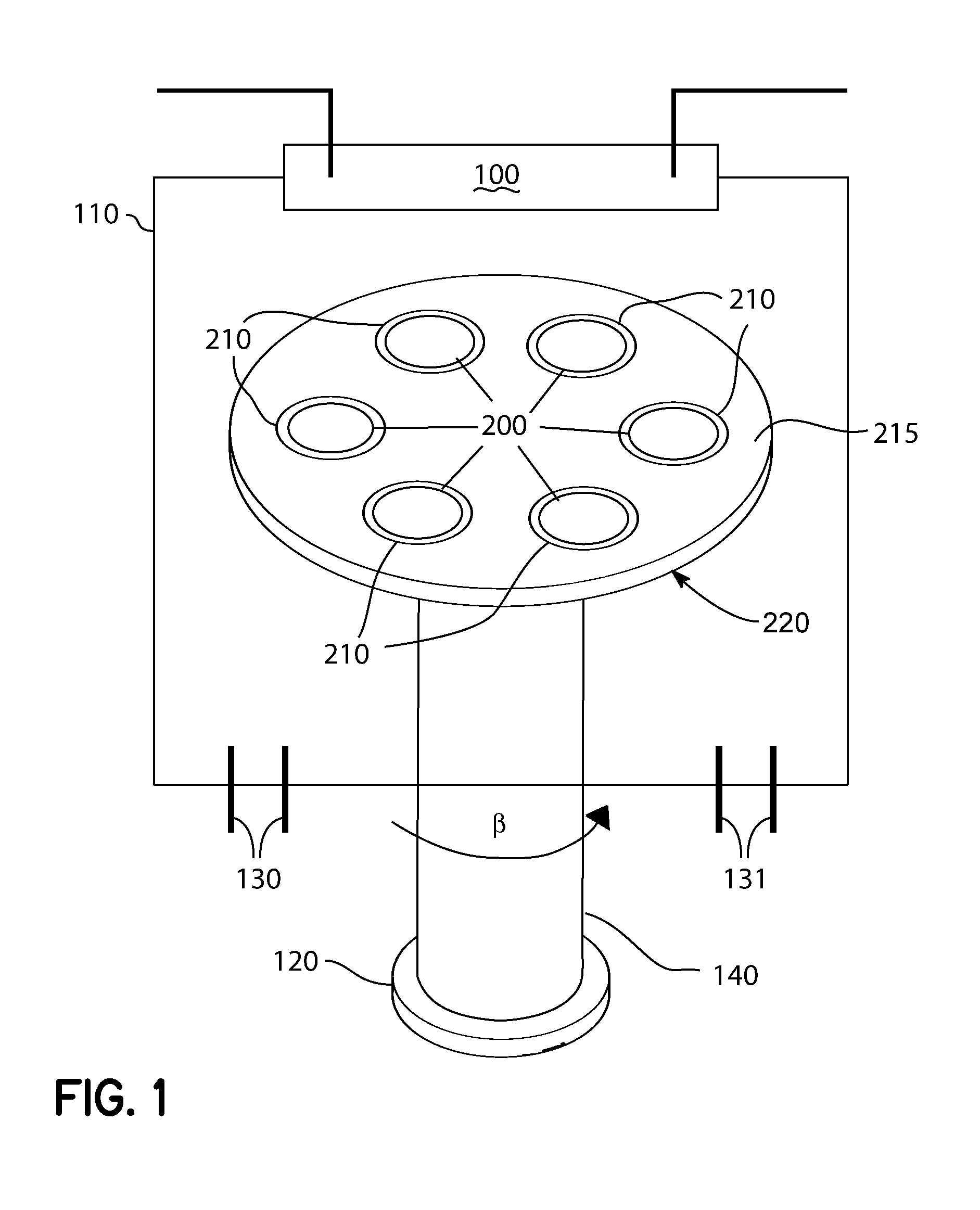

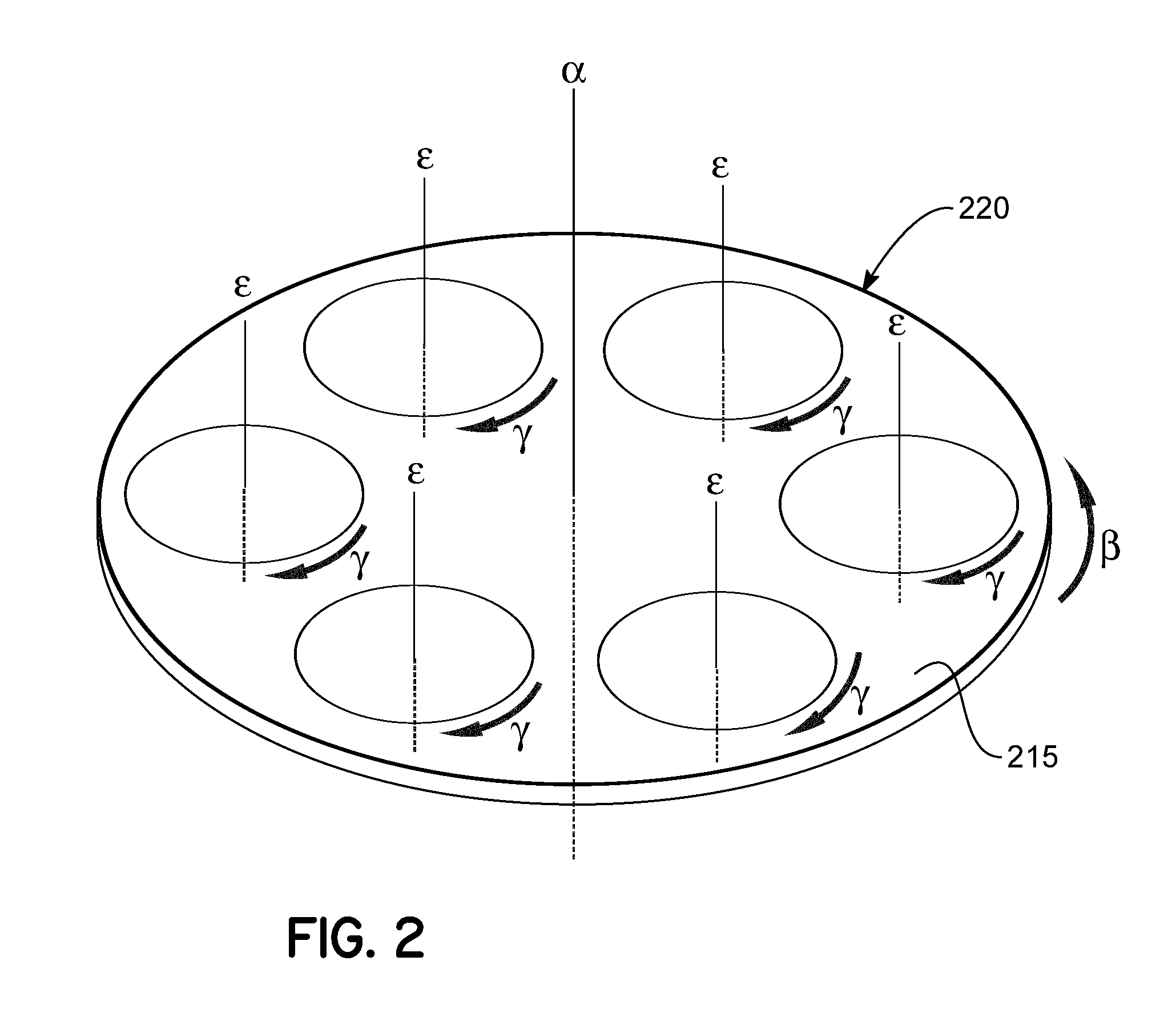

Multi-wafer rotating disc reactor with inertial planetary drive

InactiveUS20110300297A1Improve performanceEasy loadingLiquid surface applicatorsSemiconductor/solid-state device manufacturingAngular velocityEngineering

Wafer carriers and methods for moving wafers in a reactor. The wafer carrier may include a platen with a plurality of compartments and a plurality of wafer platforms. The platen is configured to rotate about a first axis. Each of the wafer platforms is associated with one of the compartments and is configured to rotate about a respective second axis relative to the respective compartment. The platen and the wafer platforms rotate with different angular velocities to create planetary motion therebetween. The method may include rotating a platen about a first axis of rotation. The method further includes rotating each of a plurality of wafer platforms carried on the platen and carrying the wafers about a respective second axis of rotation and with a different angular velocity than the platen to create planetary motion therebetween.

Owner:VEECO INSTR

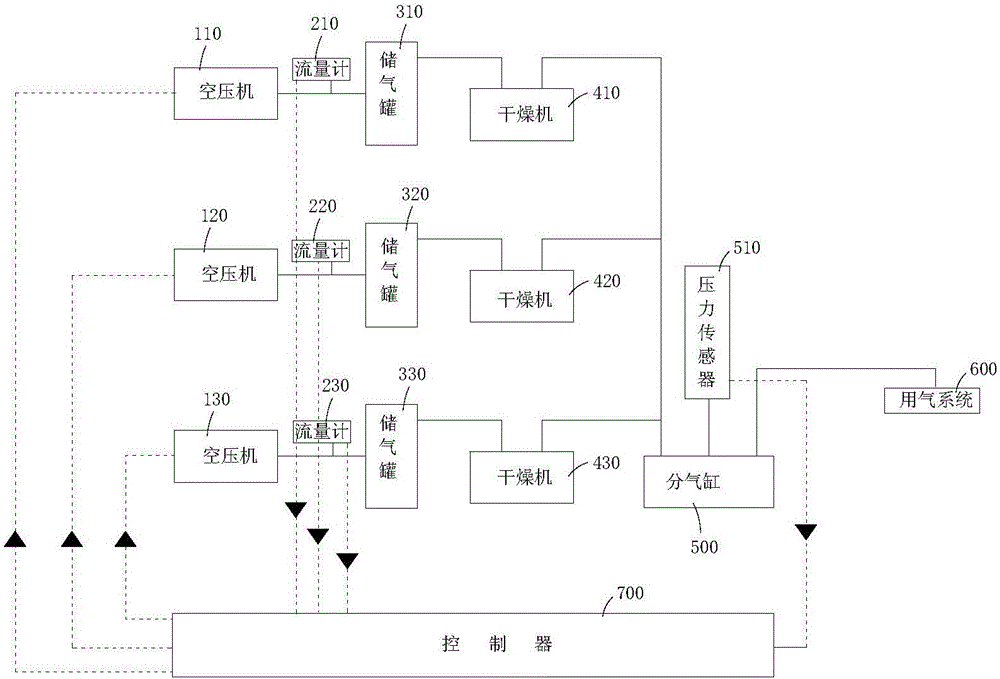

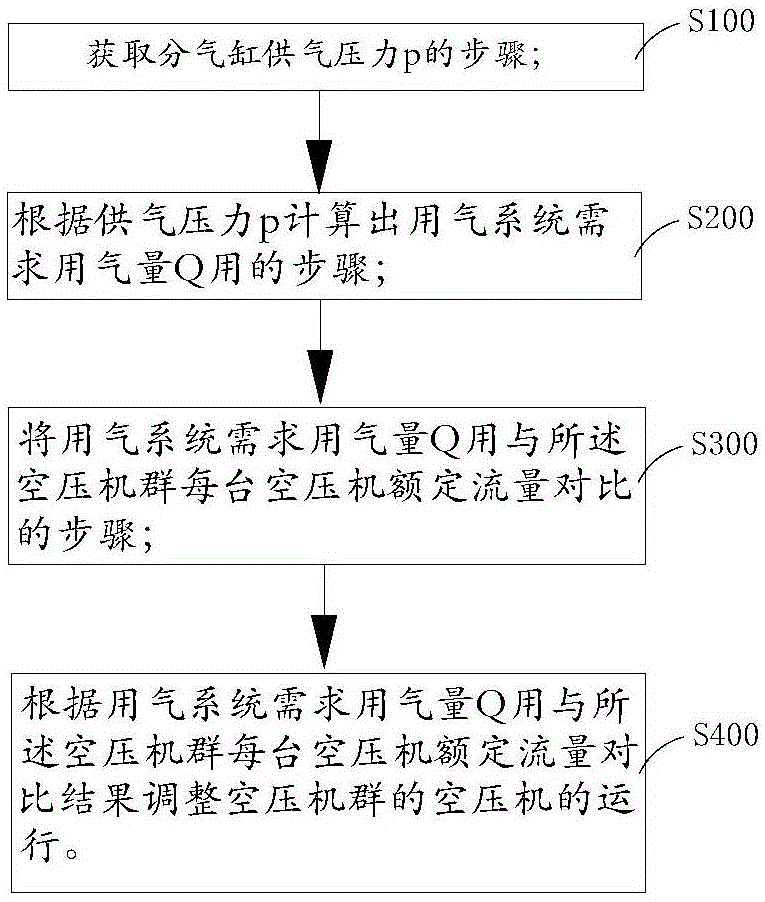

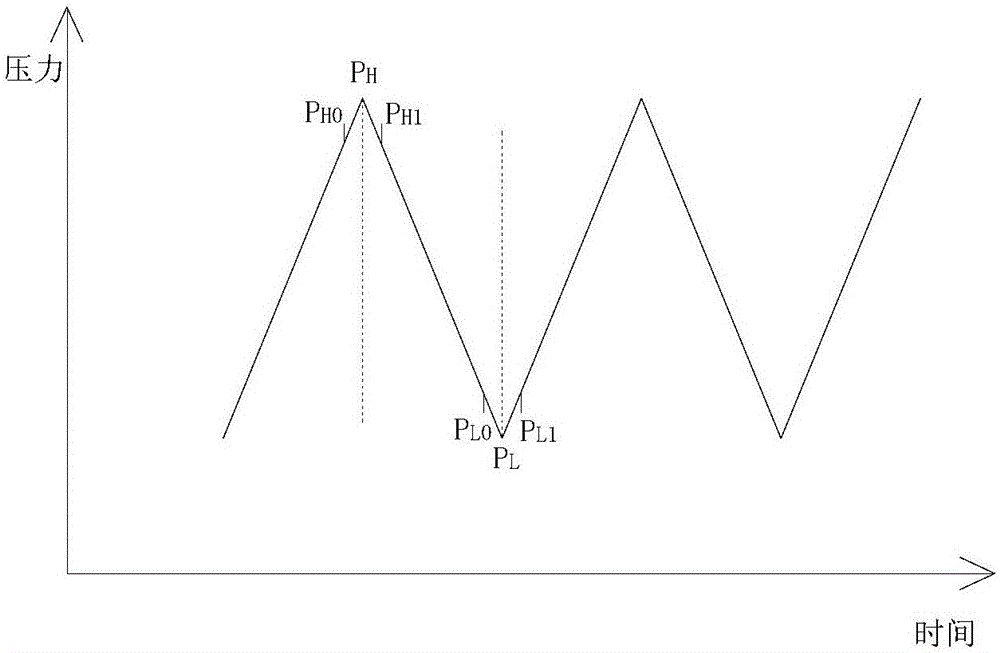

Air compressor group control system and method capable of achieving calculation based on required air consumption

ActiveCN106150996AGuaranteed uptimeIncrease operating loadPump testingPump controlControl systemEngineering

The invention discloses an air compressor group control system and method capable of achieving calculation based on the required air consumption, and relates to the technical field of air compressor group control. The system comprises air compressor units, an air distributing cylinder and a controller; an air compressor air outlet of each air compressor unit is connected with a flowmeter, and the flowmeters are used for collecting the air supply flow of an air compressor, the air distributing cylinder is provided with a pressure sensor, and the pressure sensor is used for collecting air supply pressure of the air distributing cylinder; the controller receives the air supply flow collected by the flowmeter of each air compressor unit and air supply pressure collected with the pressure sensor, the received air supply flow and the received air supply pressure are subject to data processing, and according to the processing result, running of air compressors of an air compressor group is adjusted; the method is a calculation method of the controller; the control system and method promote stable and efficient running of the air compressor, and the running and maintaining cost of an air compressor group are reduced.

Owner:SHENZHEN XINHUANNENG TECH

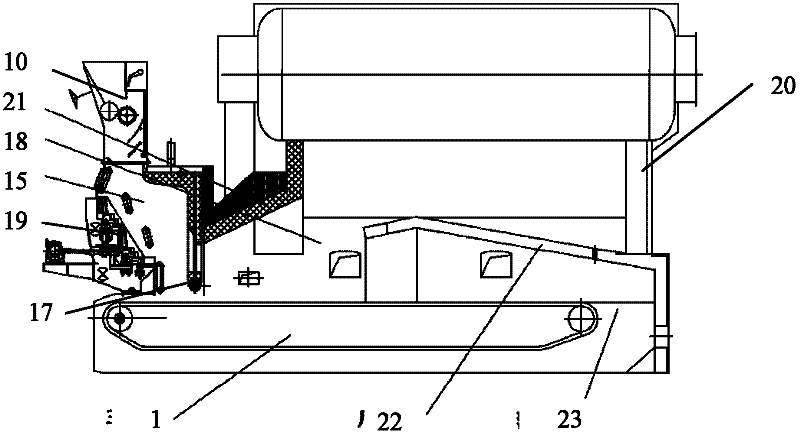

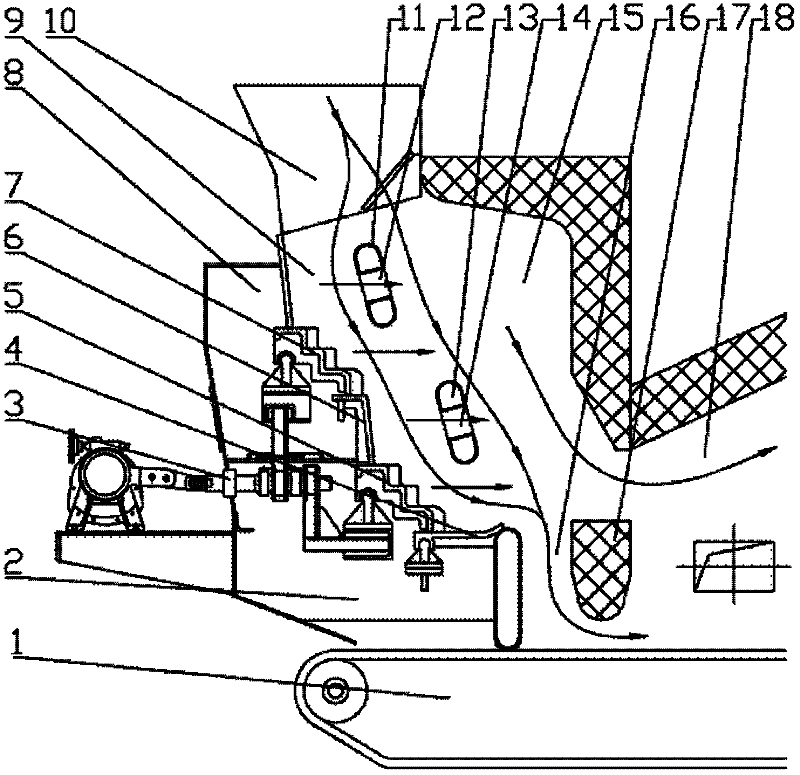

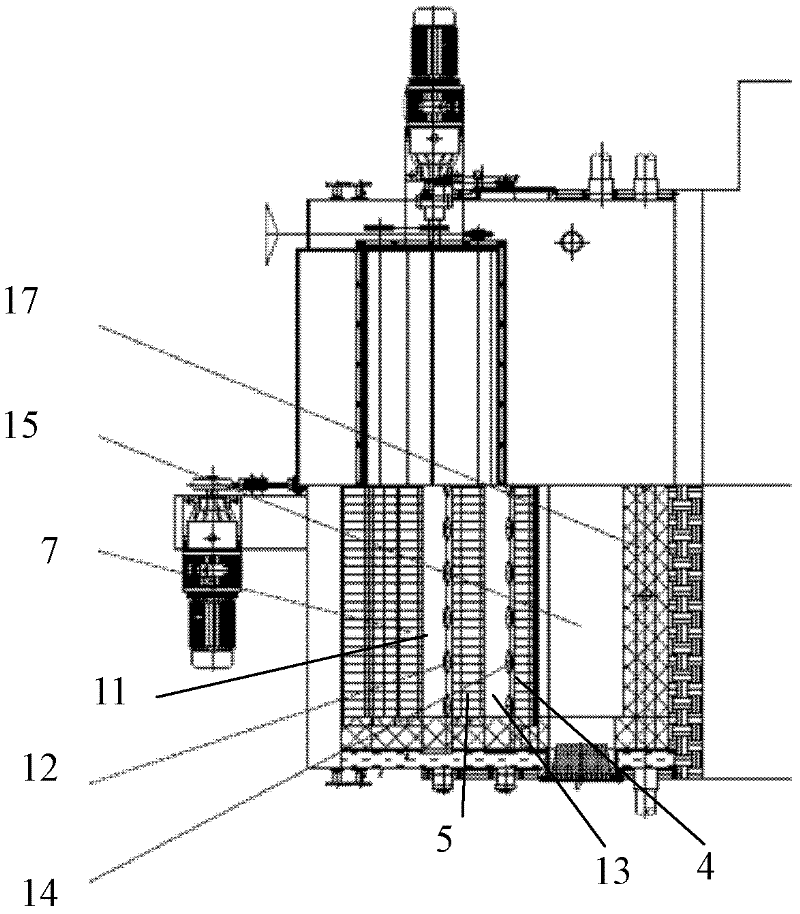

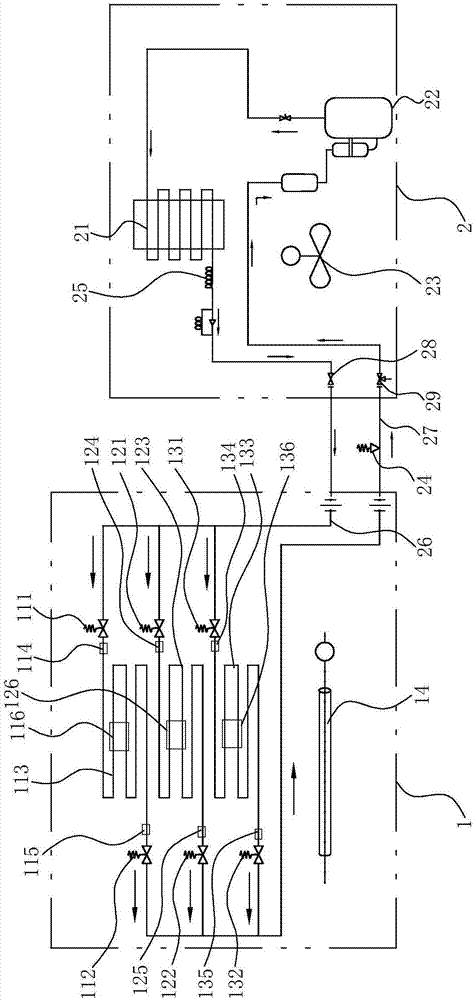

Pre-combustion mechanical grate decoupling combustion furnace and combustion method for same

ActiveCN102563614AGuaranteed uptimeSimmer speed controlSolid fuel combustionCombustion apparatusInterior spaceCombustion chamber

The invention provides a pre-combustion mechanical grate decoupling combustion furnace, which comprises a furnace body, a main grate (1) and a pre-combustion grate. A combustion chamber division wall (17) is arranged inside the furnace body, the internal space of the furnace body is generally divided into an upstream pre-combustion chamber (15) and a downstream main combustion chamber (18), the main grate (1) is arranged on the lower portion of the furnace body, the pre-combustion chamber (15) is positioned above the front of the main grate (1), the main combustion chamber (18) is positioned above the rear of the main grate (1), the pre-combustion chamber (15) is communicated with the main combustion chamber (18) through a flue gas channel above the division wall (17) and a coal bed channel below the division wall (17), and the pre-combustion grate is positioned in the pre-combustion chamber (15) and is arranged above the main grate (1) by a certain inclination angle, so that a coal bed runs to the main grate (1) along the pre-combustion grate. By the aid of the pre-combustion mechanical grate decoupling combustion furnace, pre-combustion load can be effectively matched with main combustion load, and the problem of flameout can be avoided while the running load of the decoupling combustion furnace is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

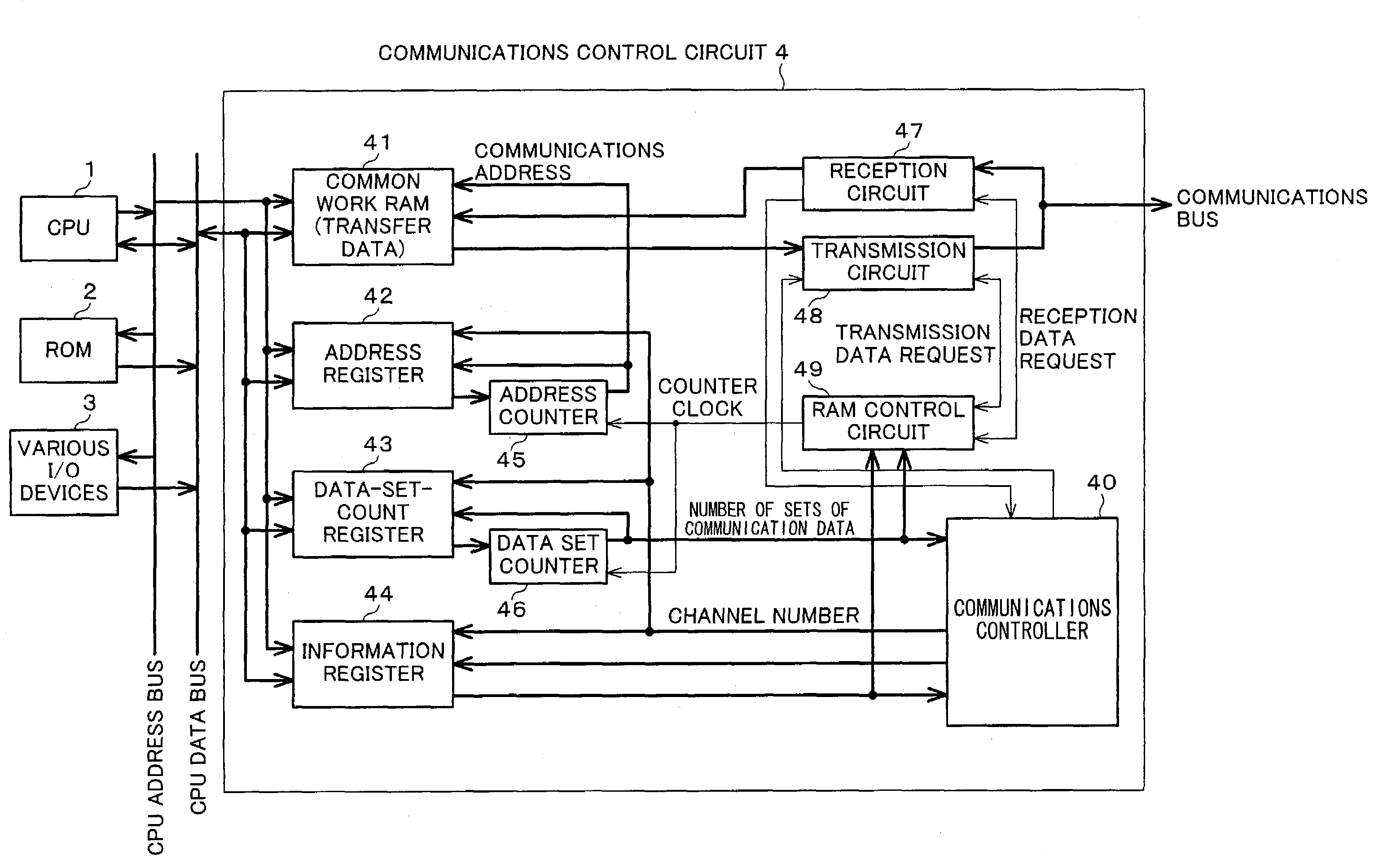

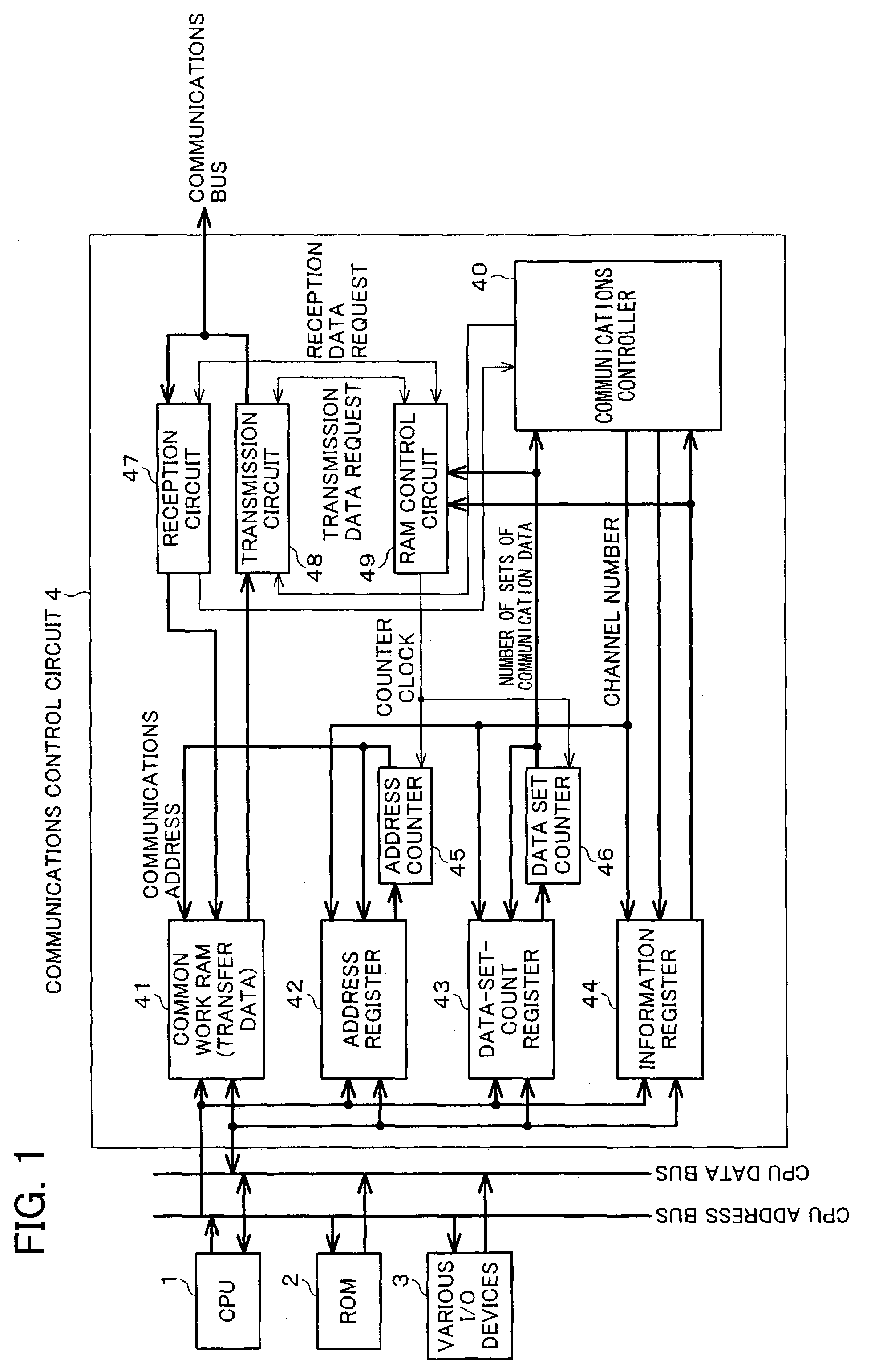

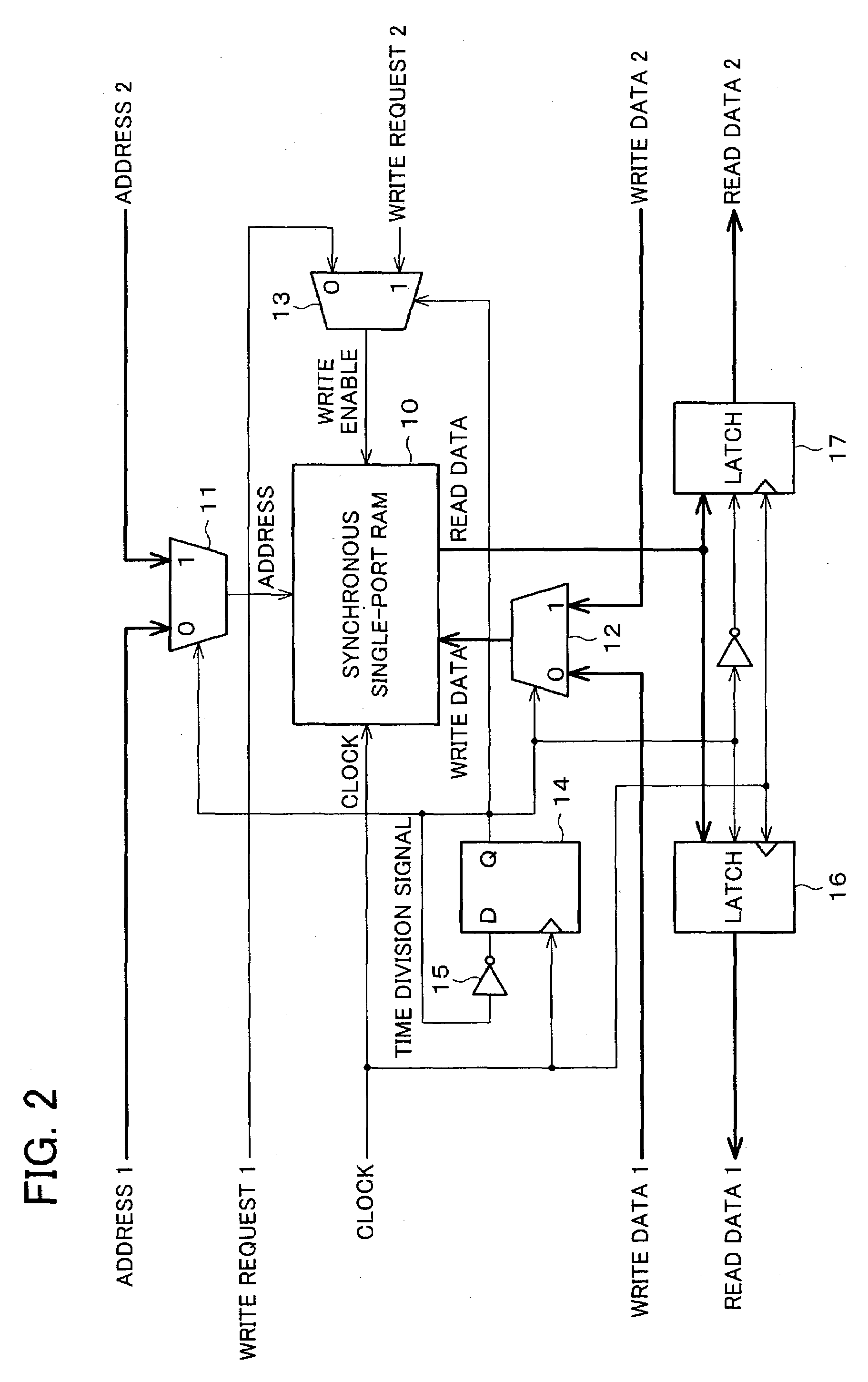

Transmission control circuit, reception control circuit, communications control circuit, and communications control unit

InactiveUS7035956B2Least possible circuit complexityIncrease operating loadTransmissionElectric digital data processingData setProcessor register

A communications control circuit includes: a common work RAM storing communications data; an address register; a data-set-count register; an information register; an address counter; a data set counter; a RAM control circuit reading transmission data from a common memory in response to a transmission data request, writing reception data to the common memory in response to a reception data request, and generating a counter clock; a transmission circuit; a reception circuit; and a communications controller setting the address counter to an address upon transmission / reception and a counter to a number of sets of data, and if transmission / reception has been successful, writing the address back to the address register and the number of sets of data back to the register.

Owner:SHARP KK

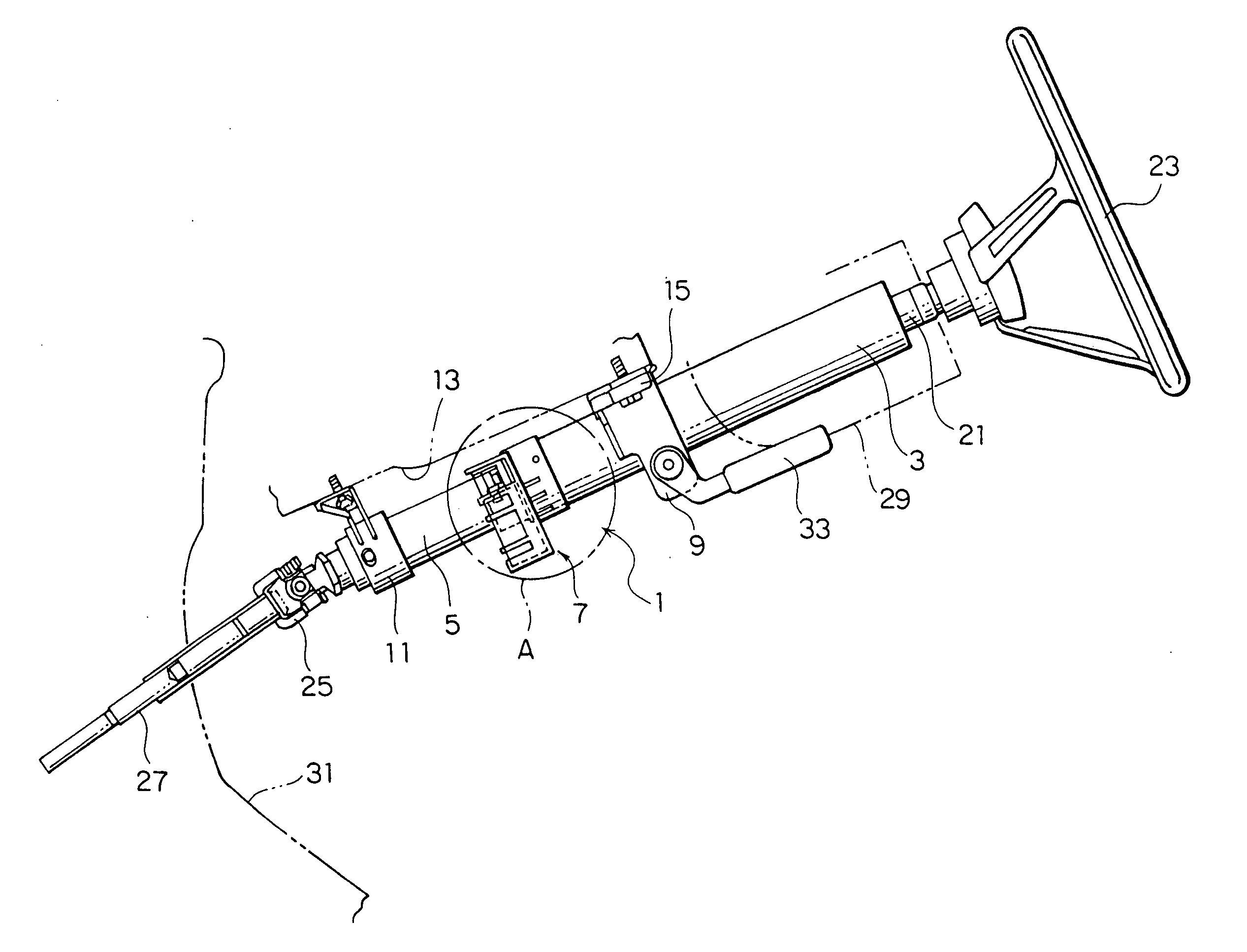

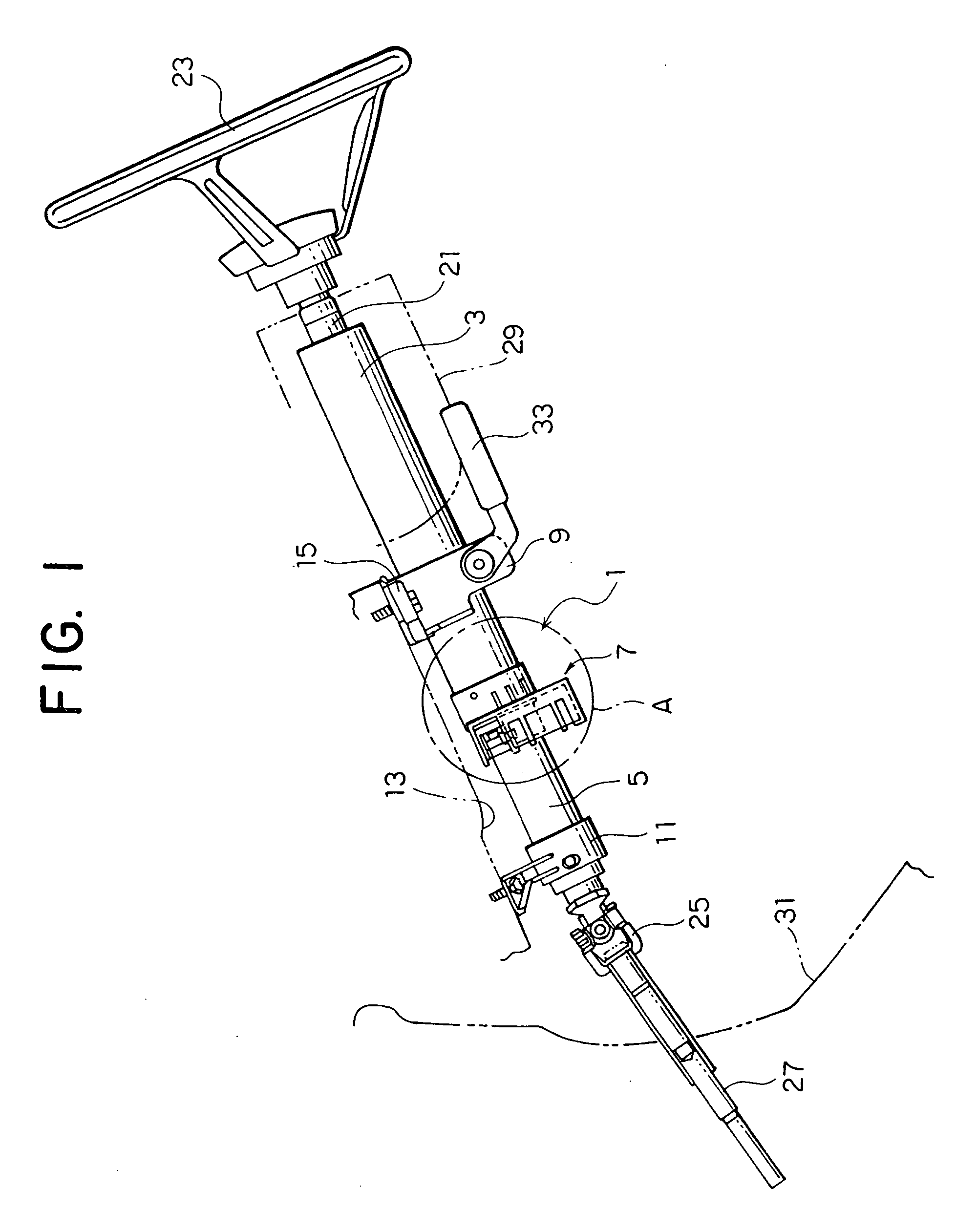

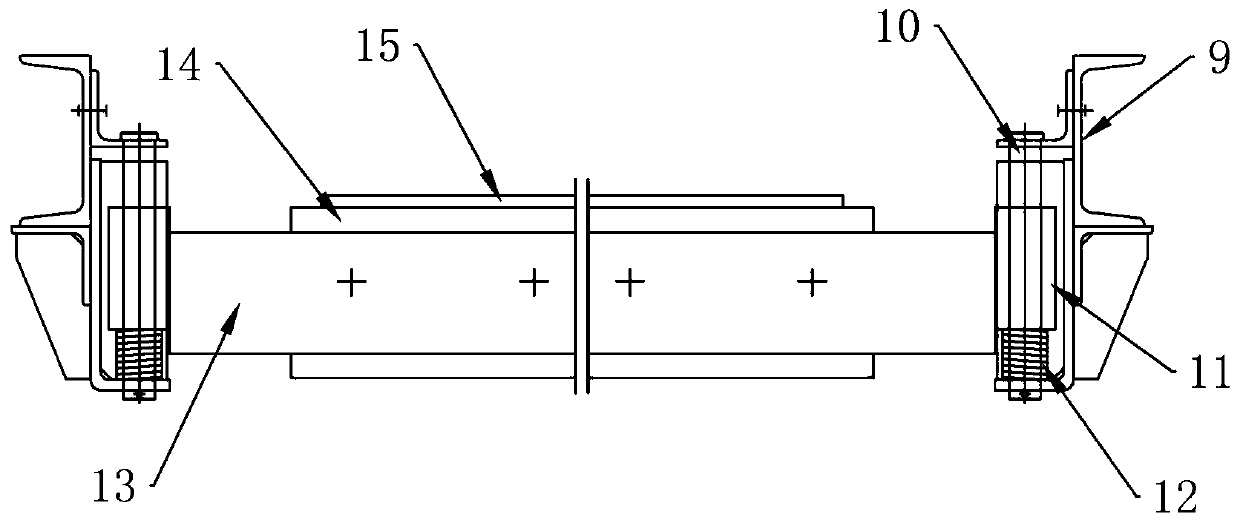

Impact absorbing type steering column apparatus

InactiveUS20060163862A1Easy loadingReduce loadSteering columnsElastic dampersSteering columnEnergy absorption

An impact absorbing type steering column apparatus provided with a collision energy absorbing device for absorbing an energy of a secondary collision of an occupant upon a collision of a vehicle comprises an energy absorption quantity adjusting device for changing a secondary collision energy absorption quantity of the collision energy absorbing device, at least one sensor for detecting a condition of the occupant or the vehicle, and electric control device for controlling a drive of the energy absorption quantity adjusting device on the basis of a result of detection by the sensor.

Owner:NSK LTD

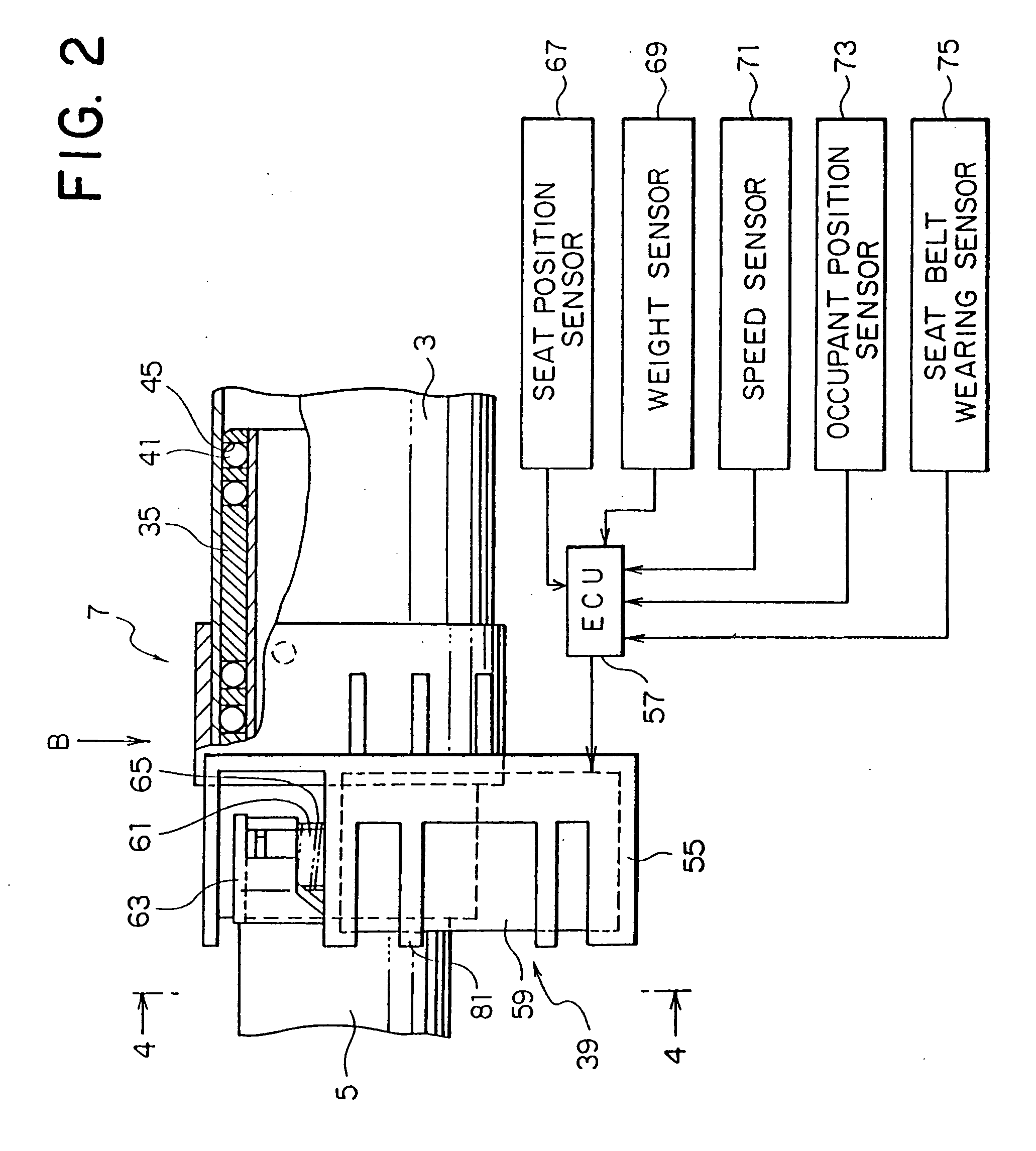

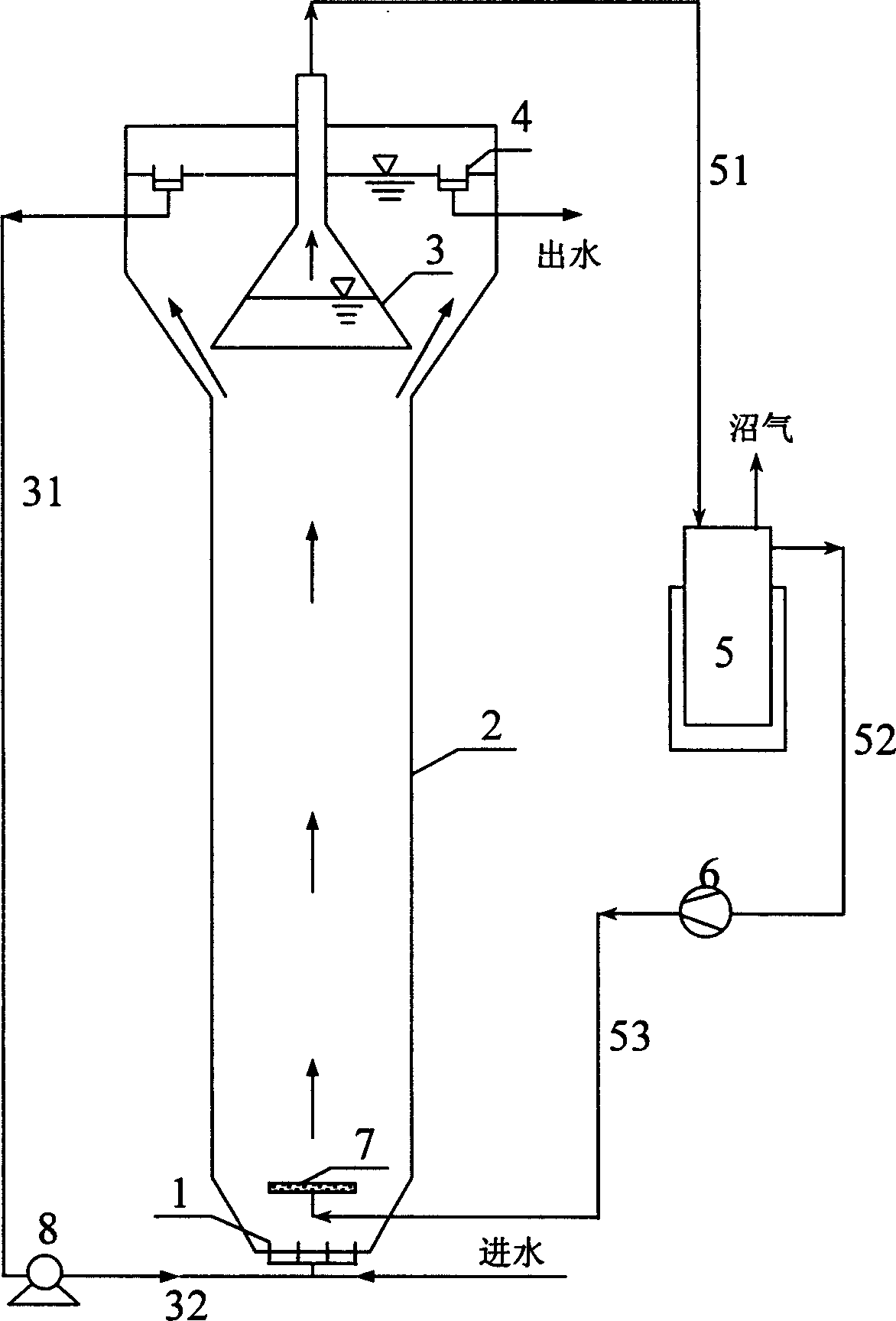

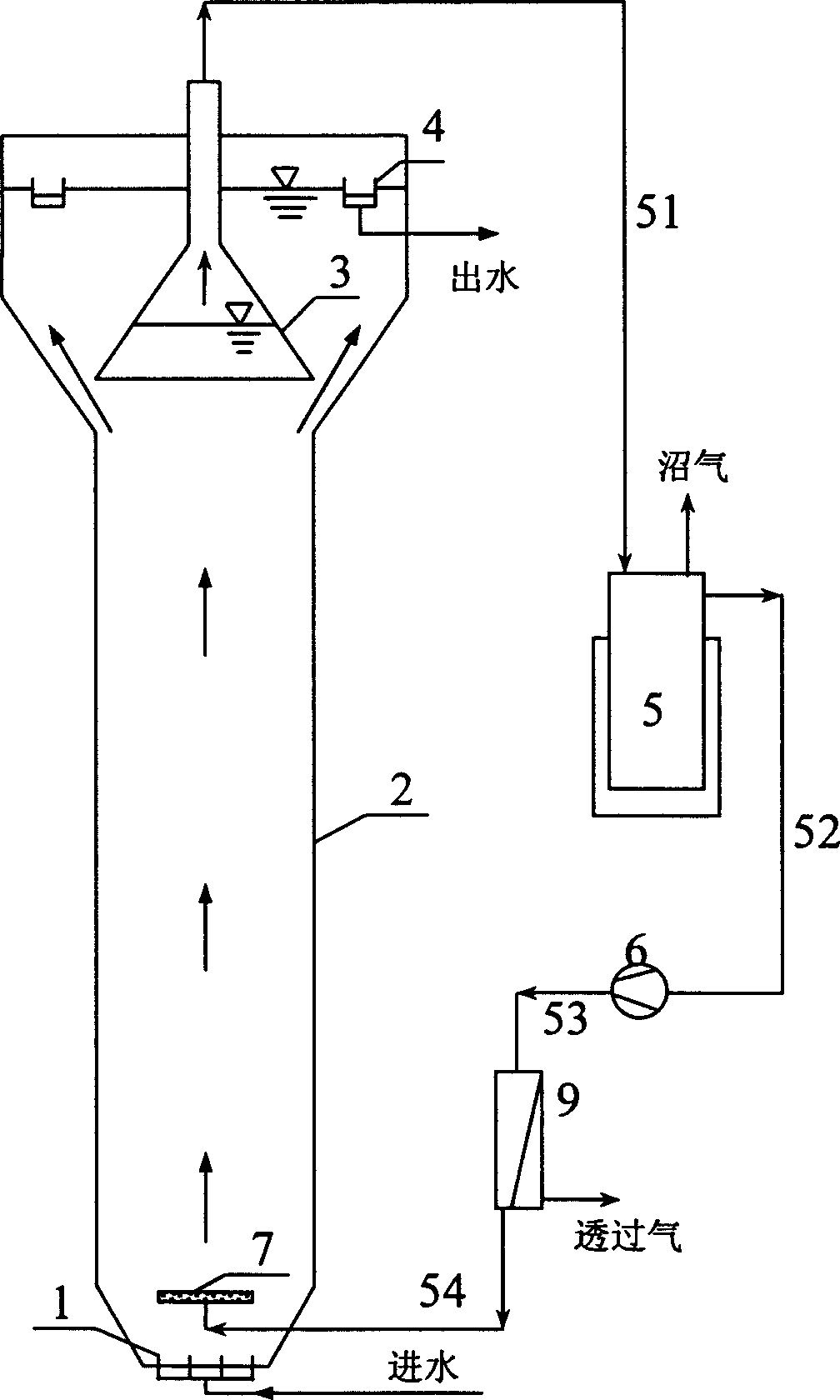

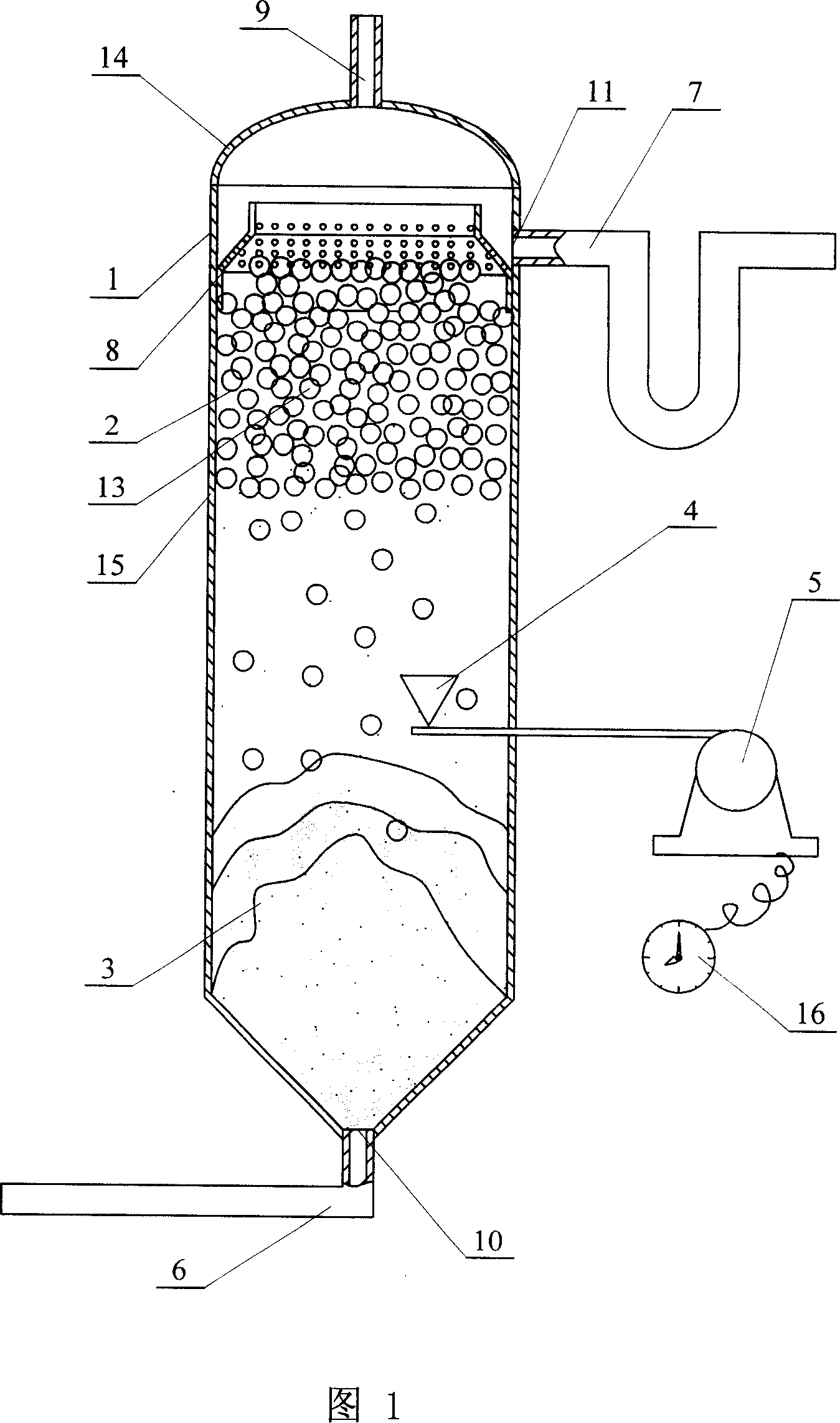

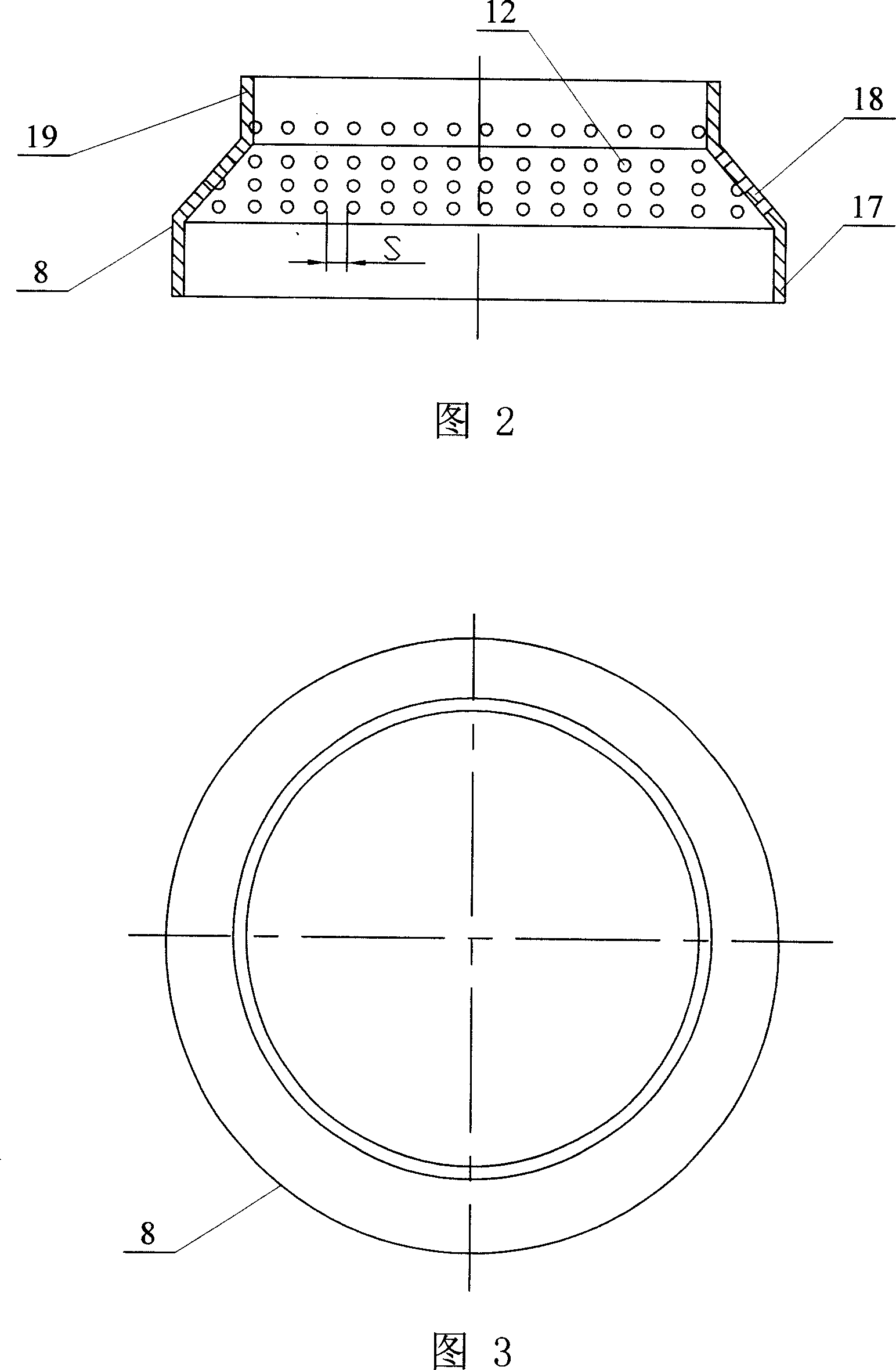

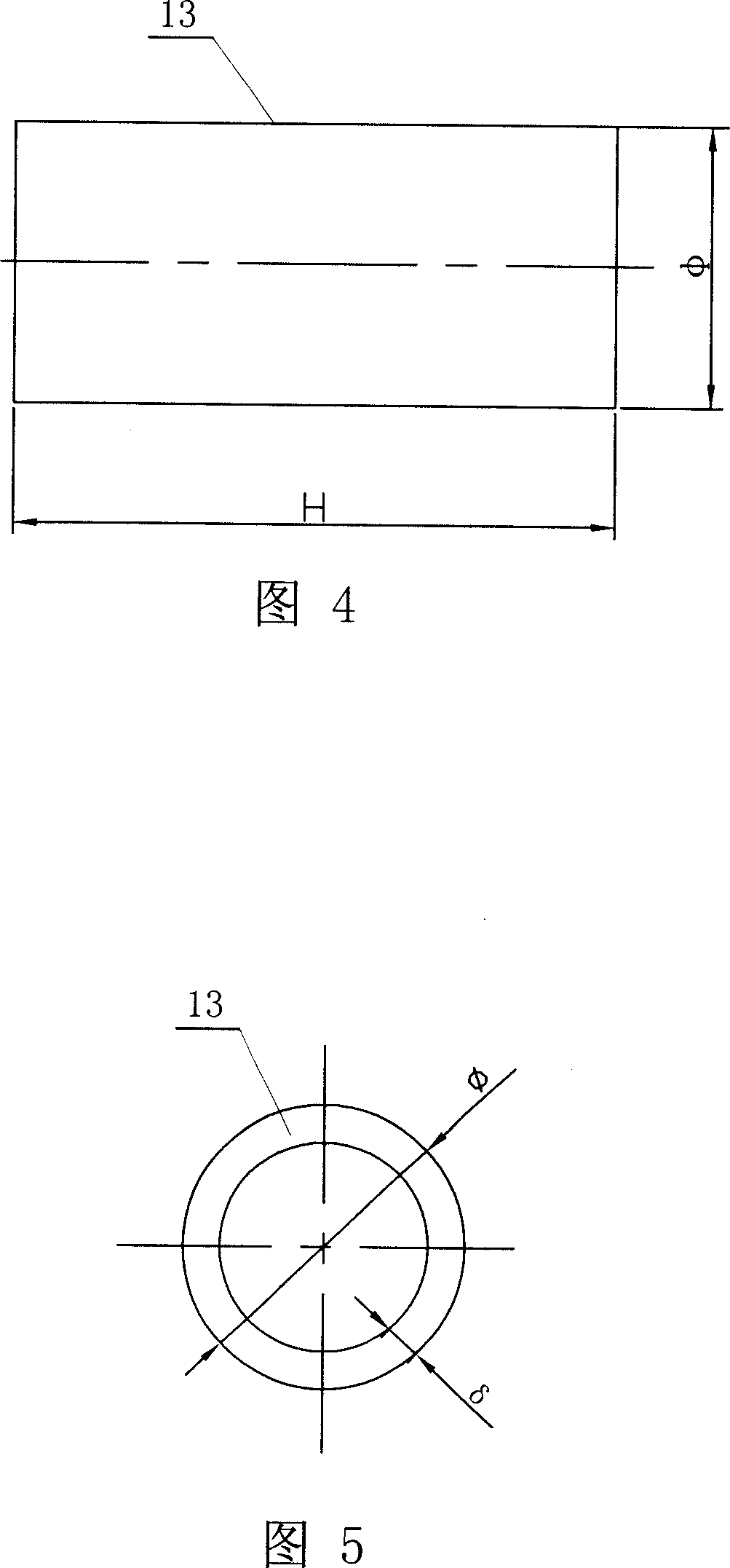

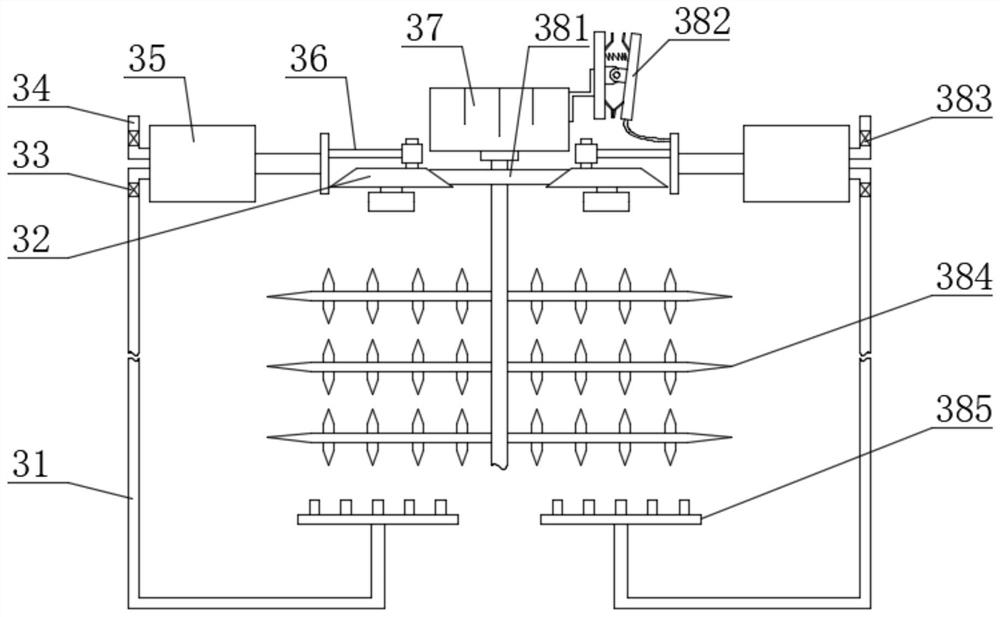

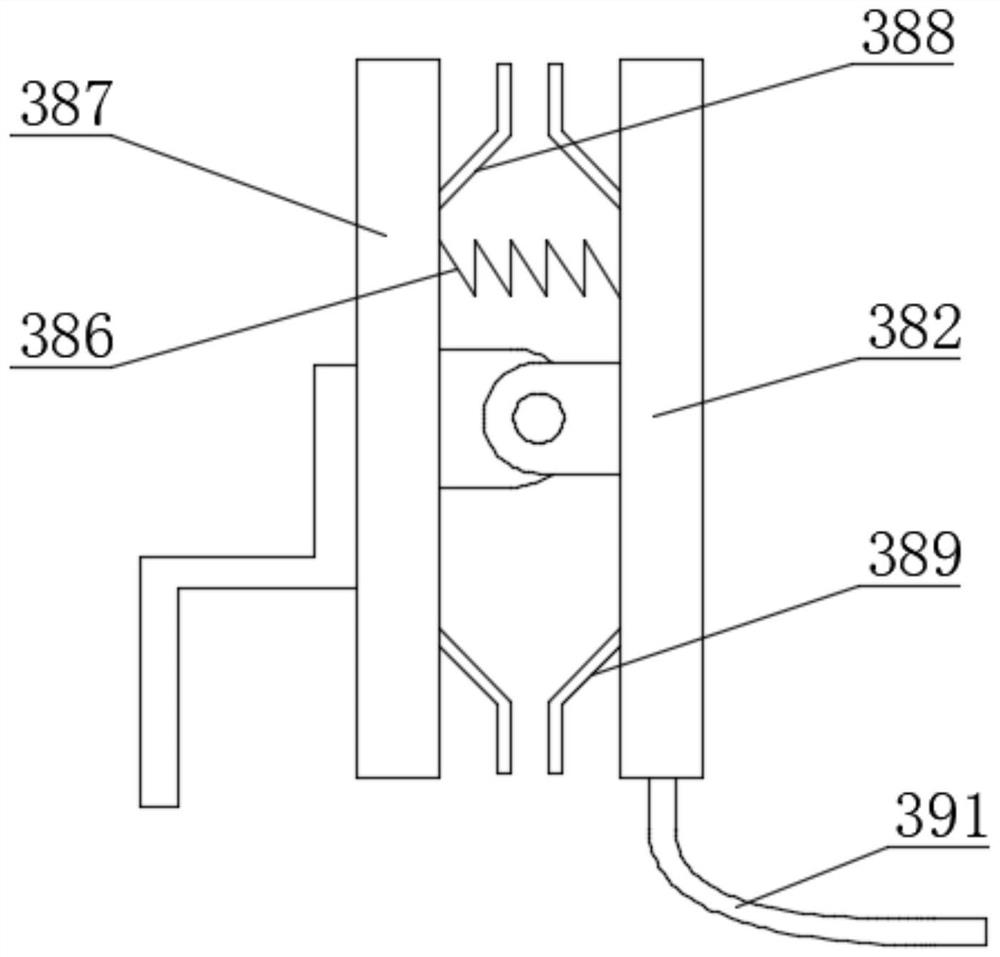

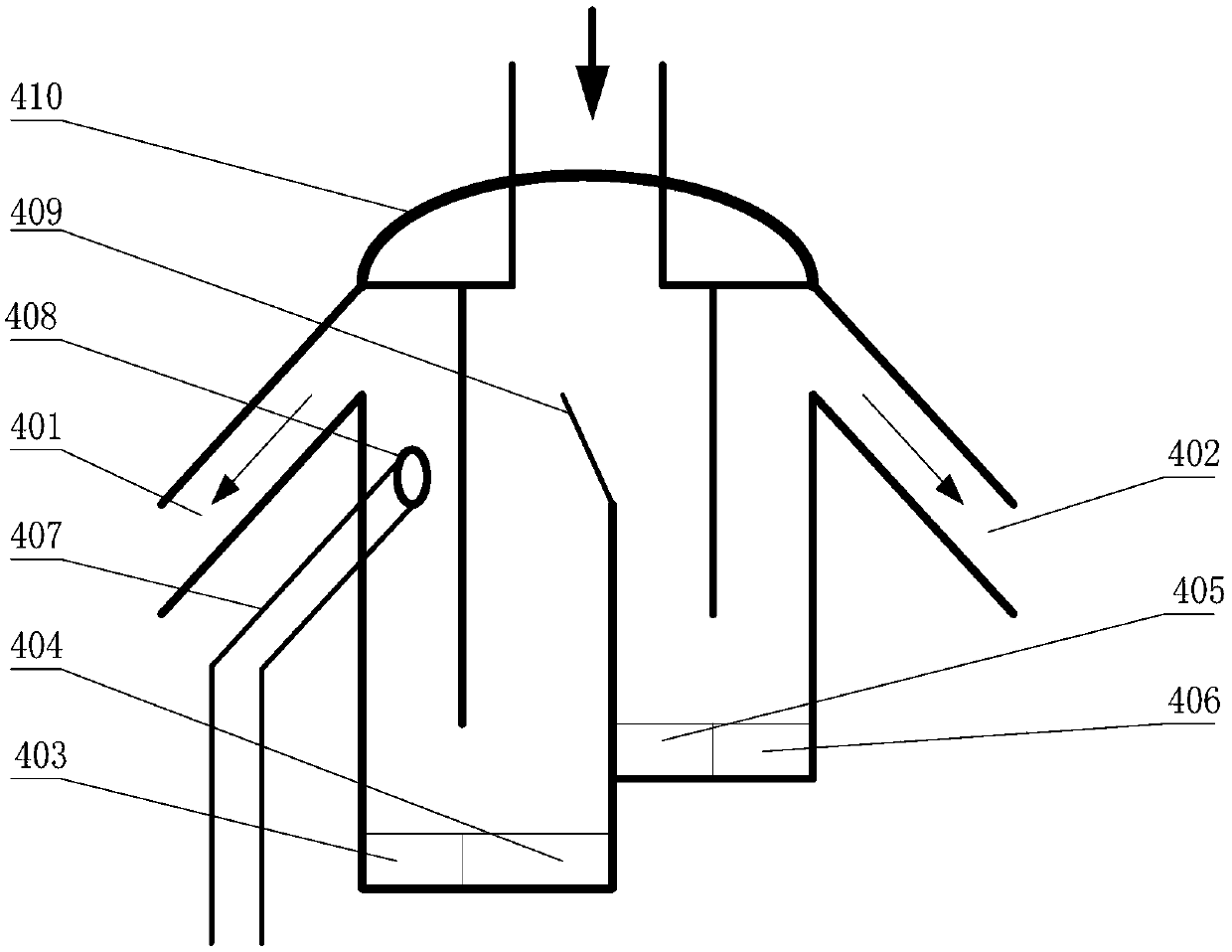

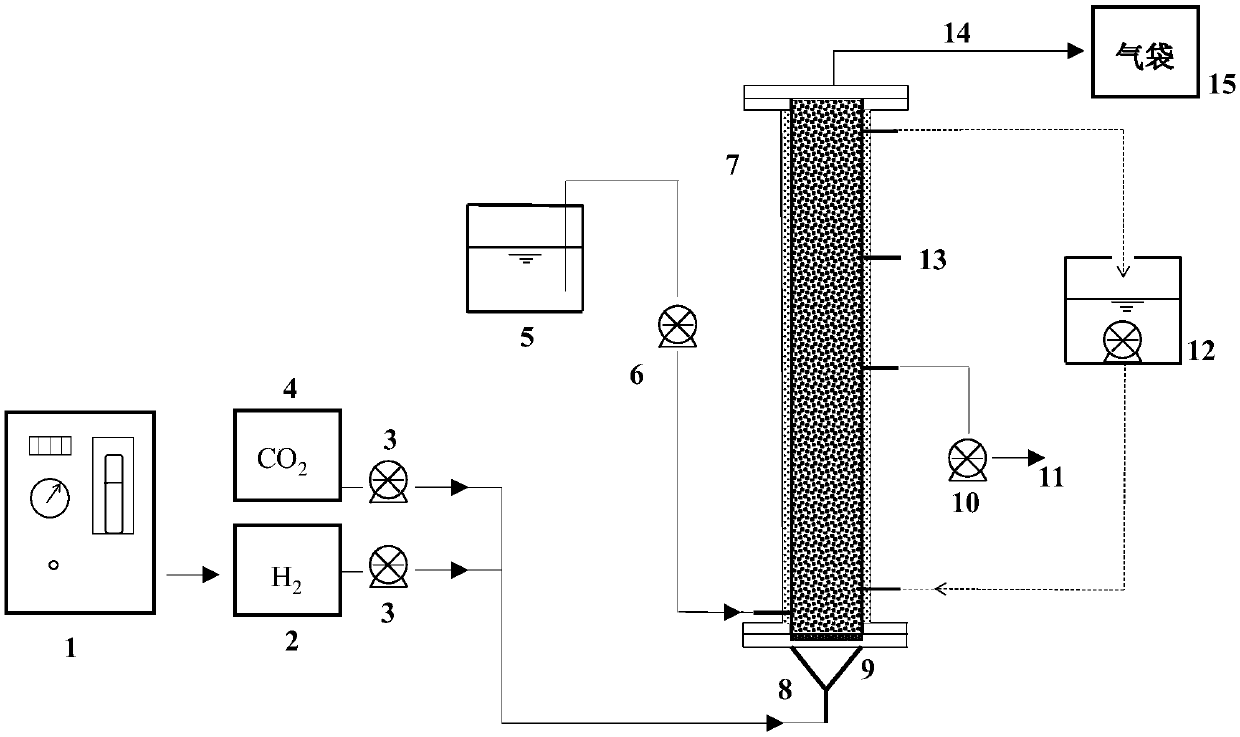

Reactor with anaerobic suspension bed

InactiveCN1583601ARegulate the running statusIncrease operating loadWaste based fuelSludge processingProcess engineeringSewage

An anaerobic suspension-bed reactor for biologically treating sewage is composed of a biologic reaction unit whose main component is a biologic reaction tower with water distributor and three-phase separator, and a marsh gas circulation unit consisting of march gas buffering cabin, pneumatic pump and gas distributor.

Owner:TSINGHUA UNIV

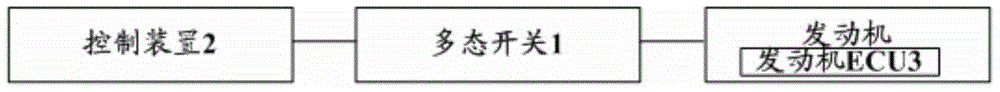

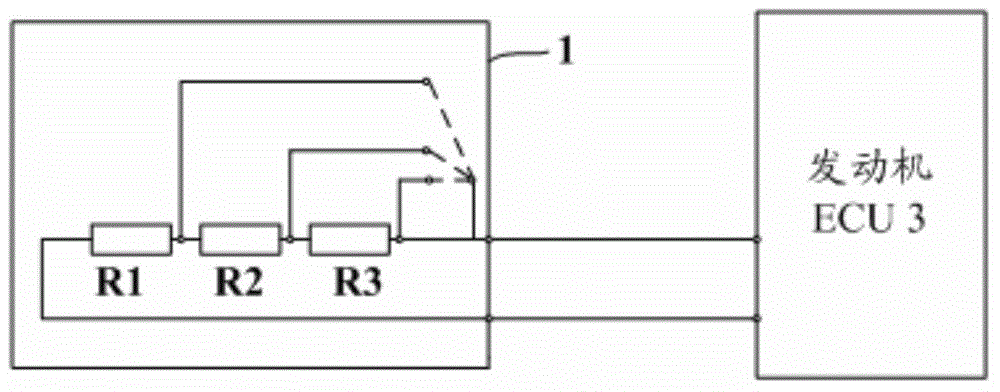

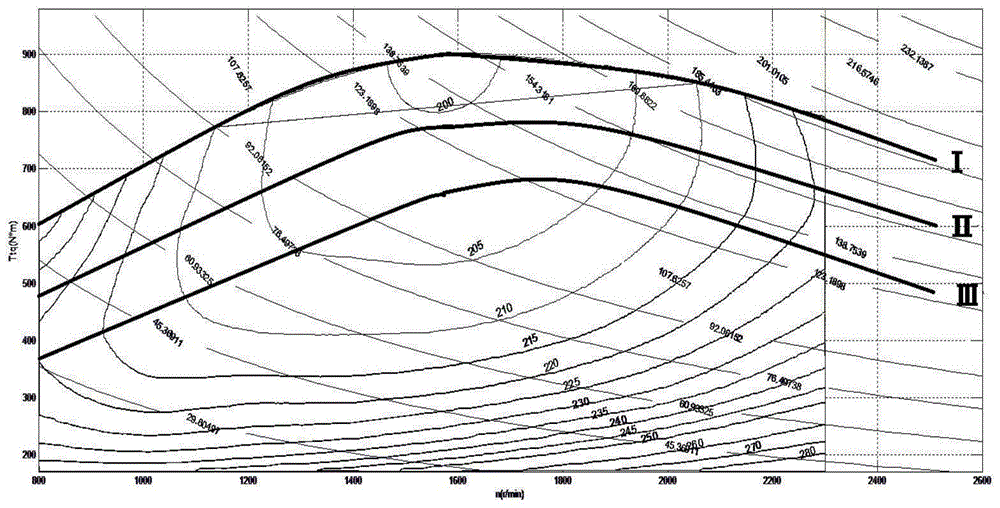

Energy-saving control system of vehicle engine, method, device and engineering vehicle

ActiveCN105332805AReduce fuel consumptionIncrease load factorEngine controllersMachines/enginesCurrent loadControl system

The invention relates to the technical field of engineering vehicles, and discloses an energy-saving control system of a vehicle engine, a method, a device and an engineering vehicle. The energy-saving control system of the vehicle engine, the method, the device and the engineering vehicle are used for increasing the running load rate of the engine and lowering the oil consumption of the engine in the transportation operation process of the engineering vehicle by adjusting load operation gears of a multi-state switch. The system comprises the multi-state switch, the control device and an engine electronic control unit. The multi-state switch is provided with at least two load operation gears. The control device is in signal connection with the multi-state switch and used for determining the current whole vehicle load and the current load operation gear of the vehicle and outputting adjusting signals to the multi-state switch according to the current load operation gear so that the multi-state switch can be configured to the current load operation gear. The engine electronic control unit is in signal connection with the multi-state switch and used for storing a set engine external characteristic curve corresponding to each load operation gear and controlling the engine to output the torque and rotating speed not larger than those limited by the corresponding engine external characteristic curve according to the current load operation gear of the multi-state switch.

Owner:ZOOMLION HEAVY IND CO LTD

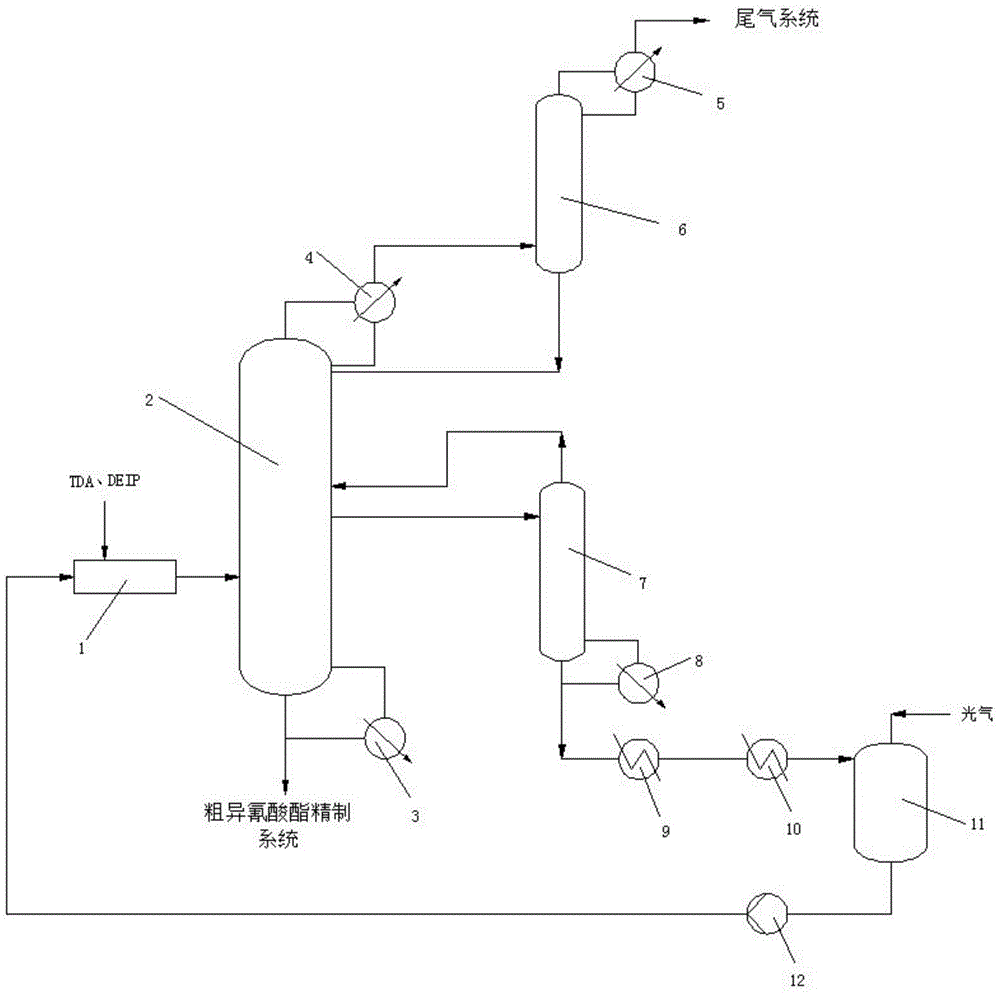

Method for preparing isocyanate via reaction distillation method

InactiveCN104892458ALower side discharge temperatureIncrease operating loadChlorine/hydrogen-chloride purificationOrganic compound preparationReactive distillationPhysical chemistry

The invention belongs to the technical field of isocyanate preparation and relates to a method for preparing isocyanate via a reaction distillation method. The method includes that amine reacts with liquid phosgene to prepare the isocyanate, the amine and the liquid phosgene are in cold reaction in a jet reactor firstly prior to entering a reactive distillation column to be subjected to thermal reaction for preparing crude isocyanate, meanwhile excessive phosgene and a by-product HCL (hydrogen chloride) gas are separated by distillation, and the phosgene and the HCL gas are refined prior to recycling. The method is simple in technique, convenient to operate, capable of separating the by-product in time, energy saving, low in cost, high in efficiency and environment friendly.

Owner:QINGDAO UNIV OF SCI & TECH +1

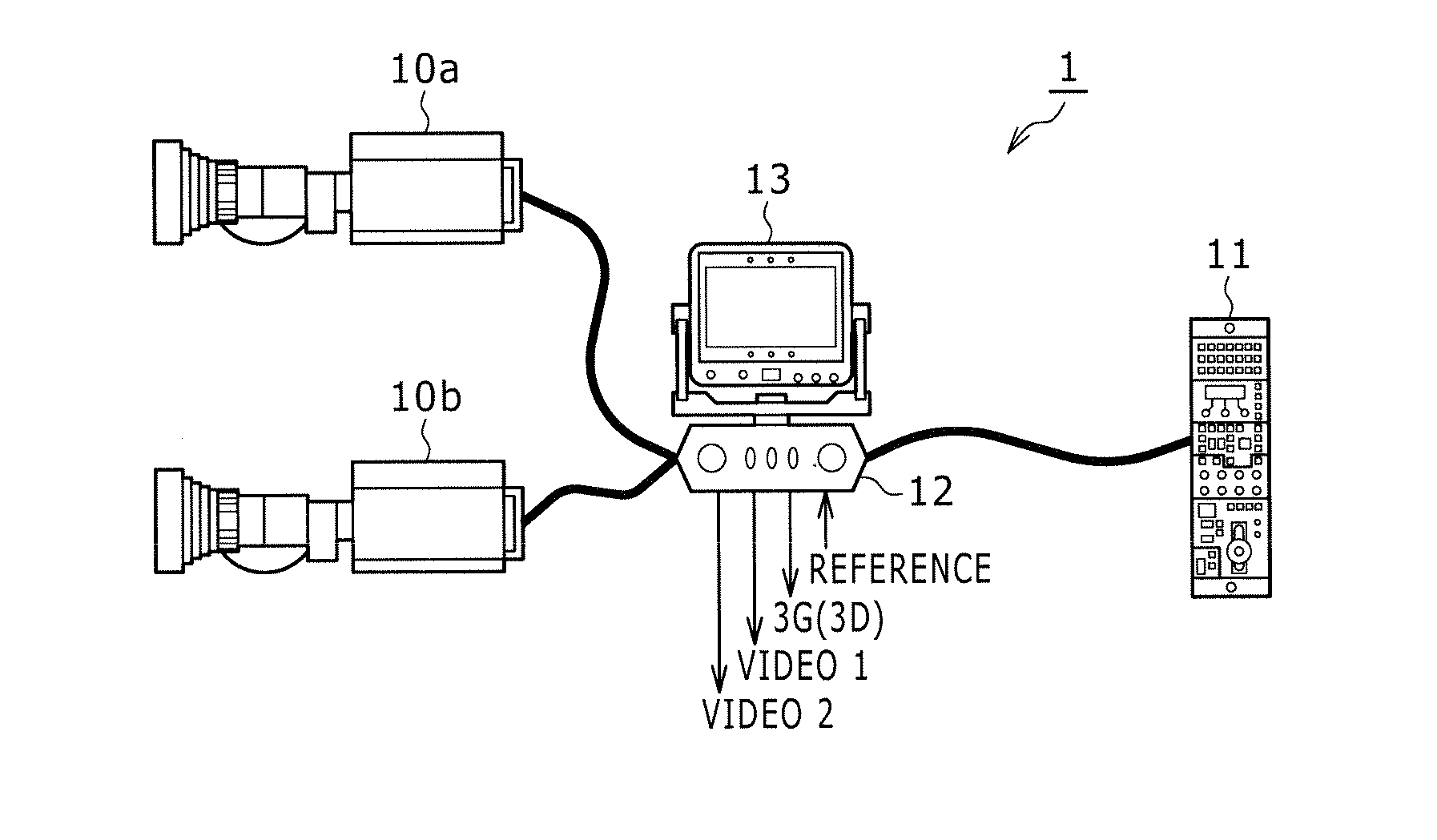

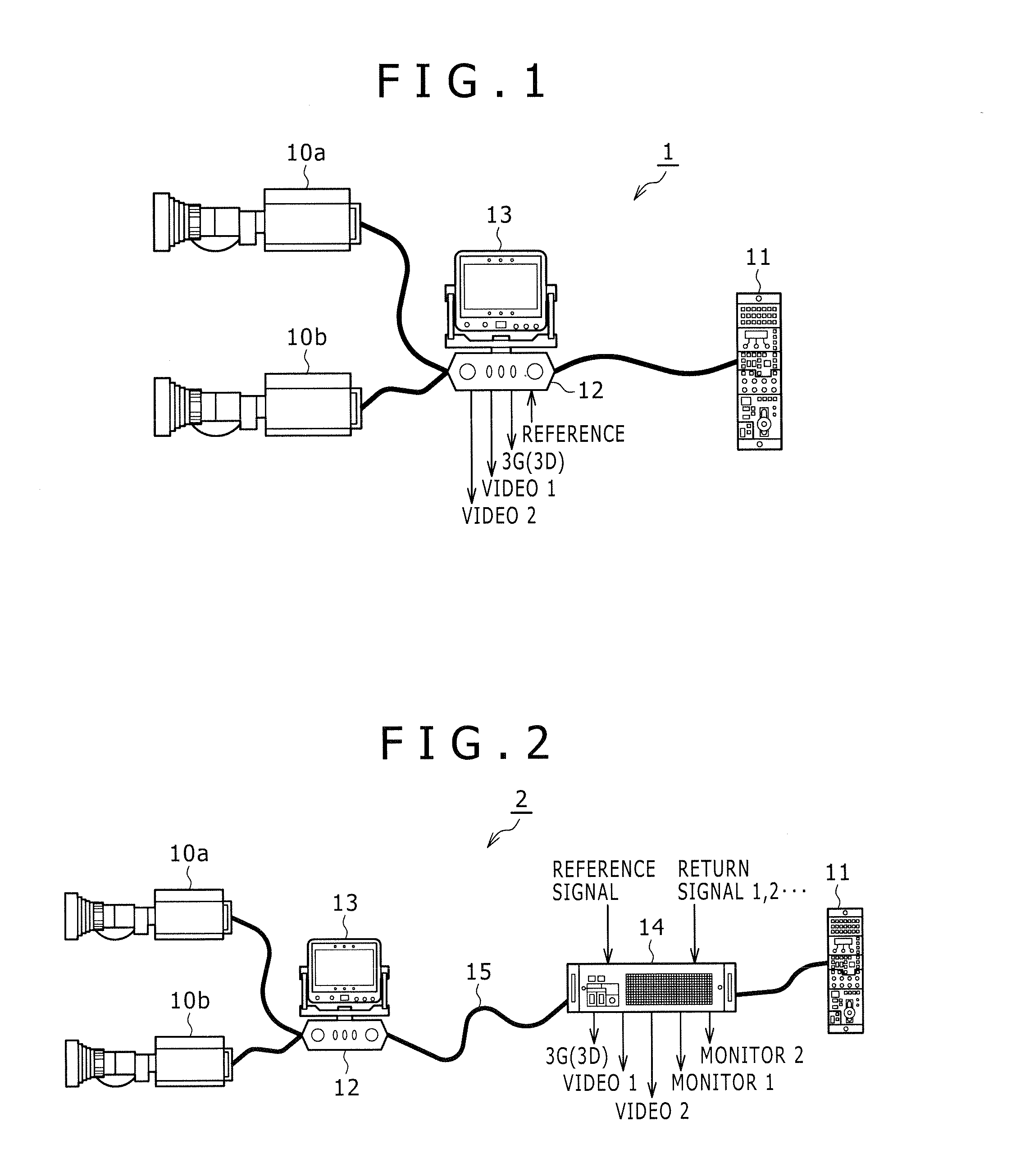

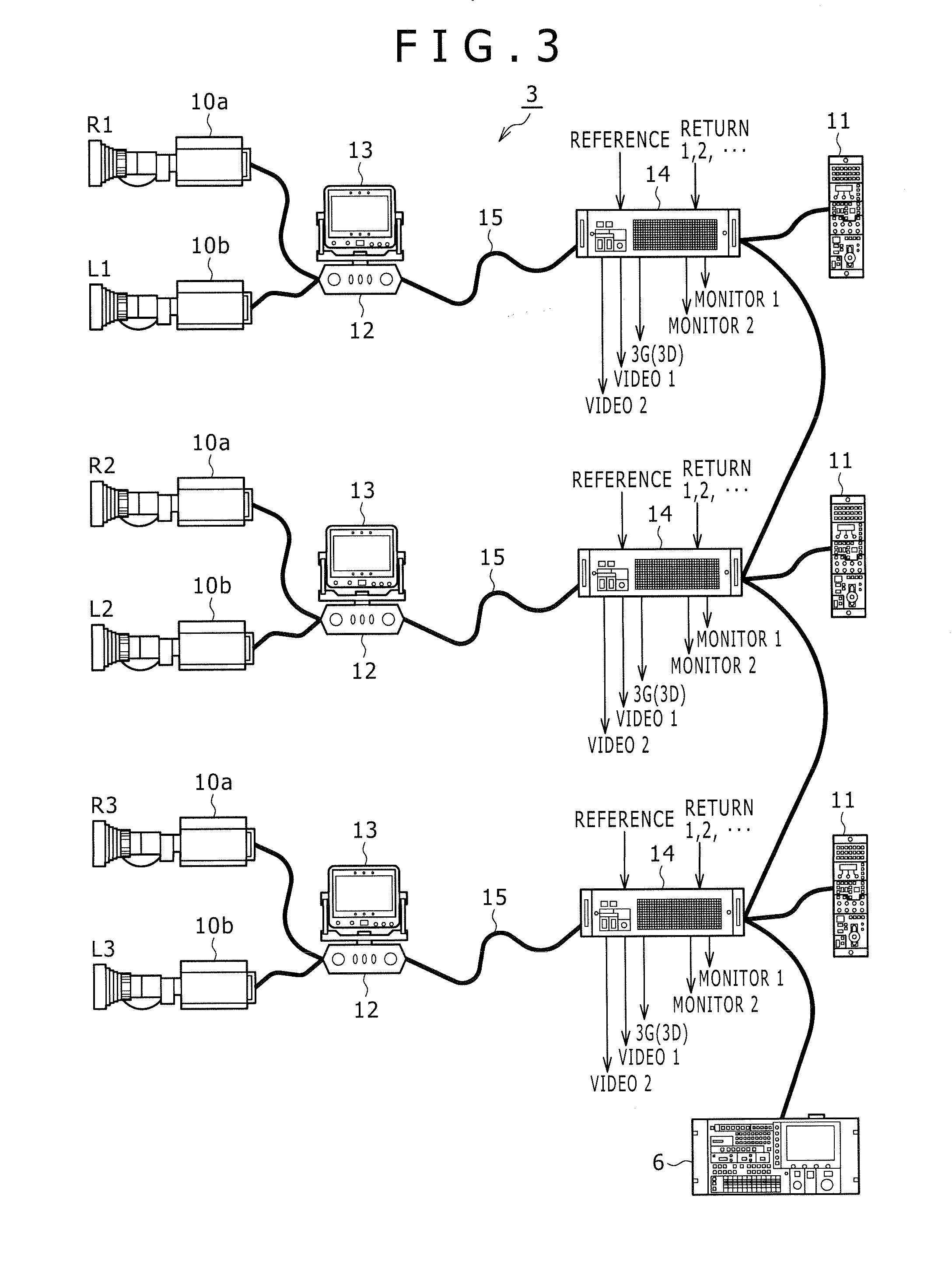

Camera system and camera control method

ActiveUS20110157317A1Saving loadFacilitates configuration of cameraTelevision system detailsSteroscopic systemsCamera controlCamera control unit

A camera system includes: a first camera and a second camera; a camera adaptor box; and a camera control unit.

Owner:SONY CORP

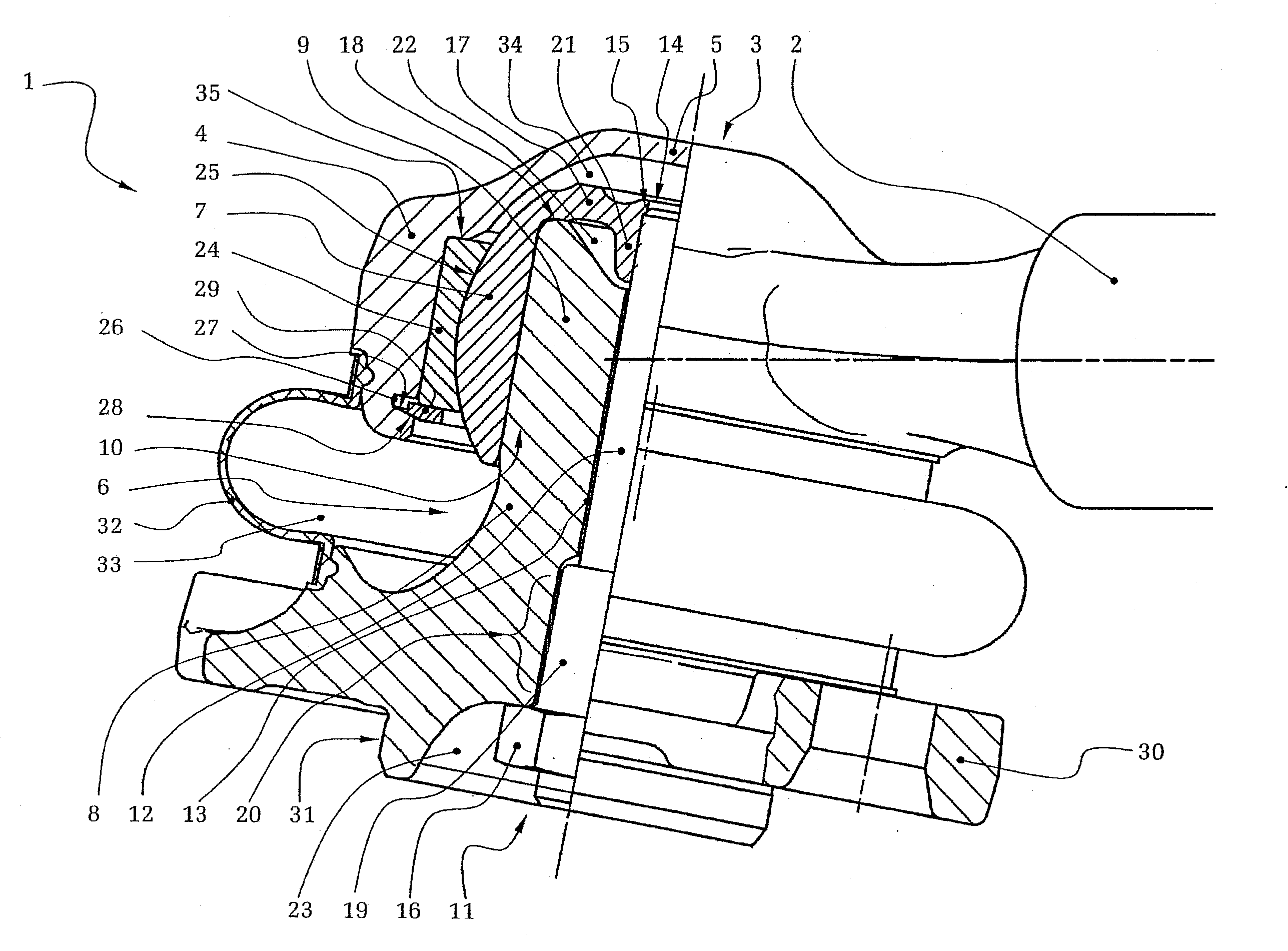

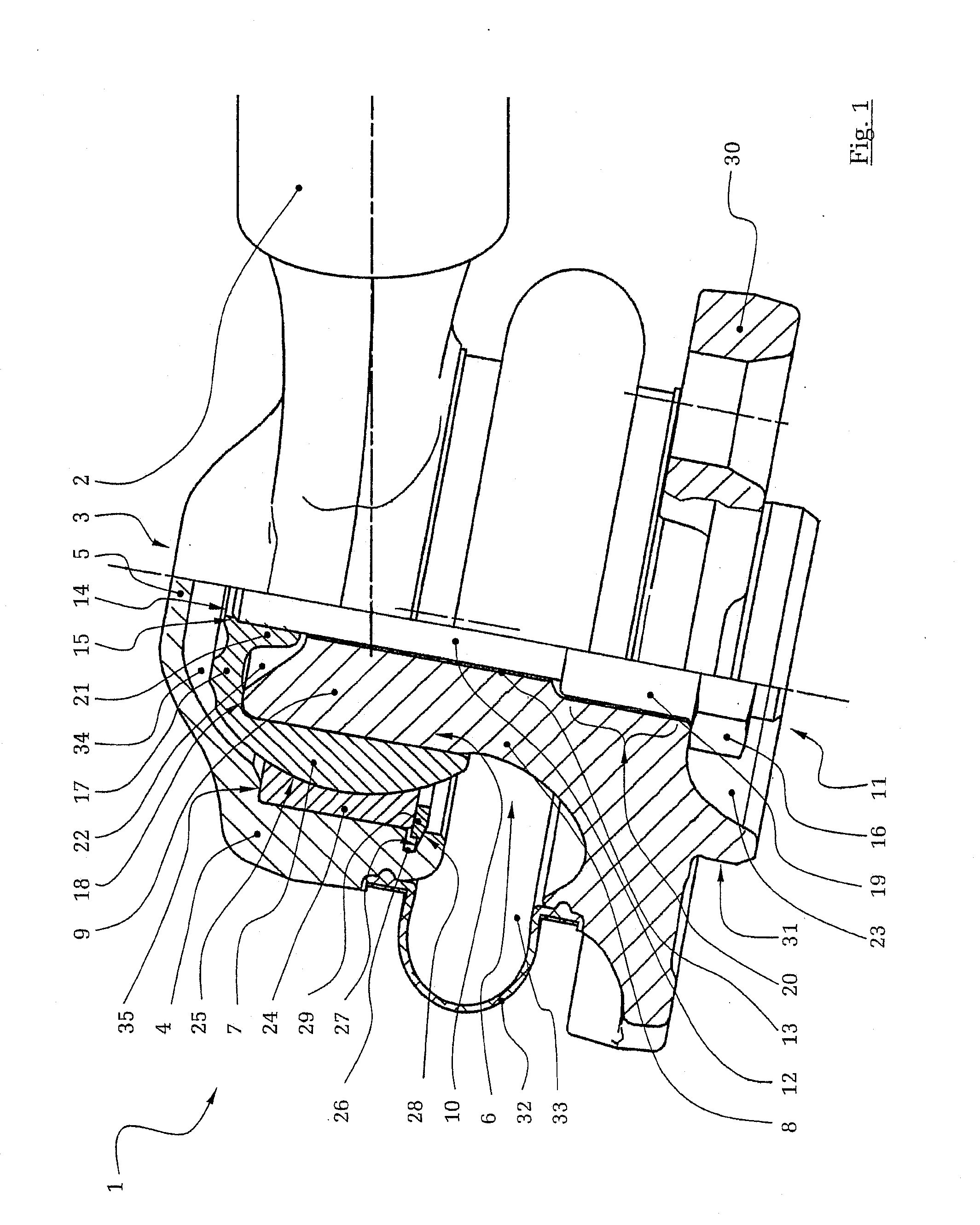

Central joint for a steering triangle of moto vehicles

InactiveUS20070183841A1Improve sealingSimple designCouplings for rigid shaftsPivotal connectionsEngineeringTower

A central joint (1) for a steering triangle of motor vehicles, especially utility vehicles, has a ball pivot (6) accommodated in a joint housing (3), wherein the joint housing (3) is formed from a joint housing body (4) and a joint housing bottom (5) and the ball pivot (6) is formed from a tower-shaped ball pivot body (8) and a joint ball (7) attached to the ball pivot body (8). The ball pivot (6) is mounted in a bearing shell (24) fixed in the joint housing (3) in a pivotingly and rotatingly movable manner. The joint housing (3) is formed from the joint housing body (4) and the joint housing bottom (5) in one piece.

Owner:ZF FRIEDRICHSHAFEN AG

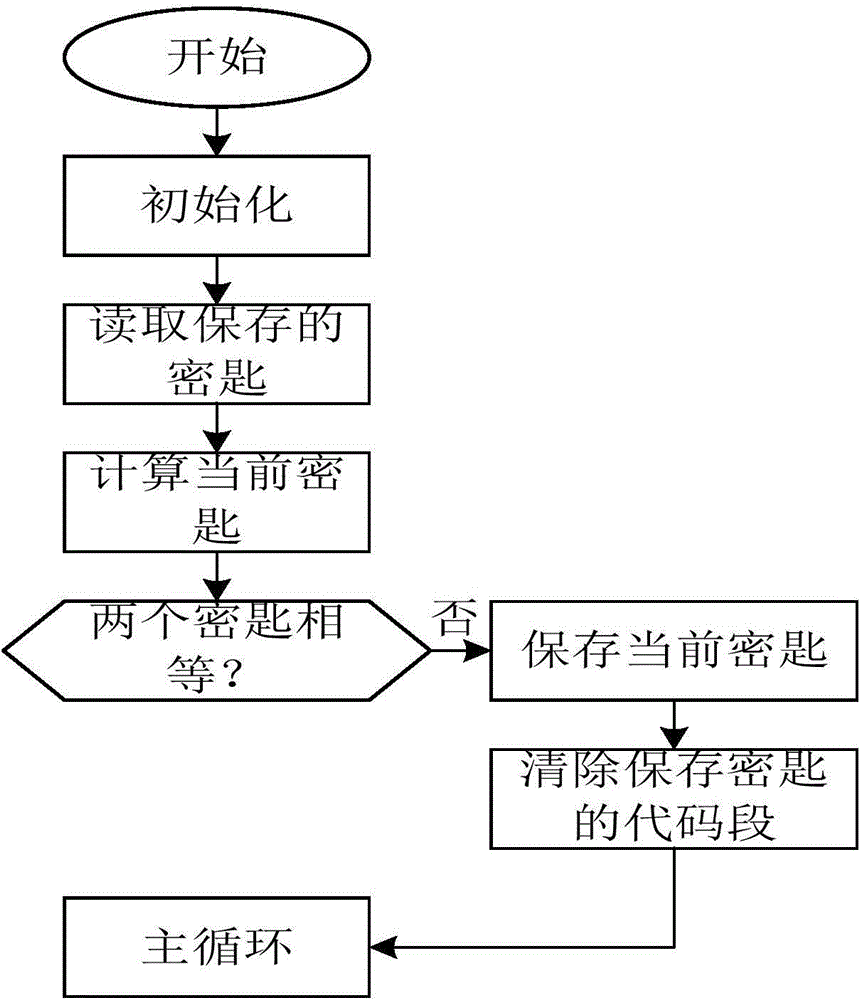

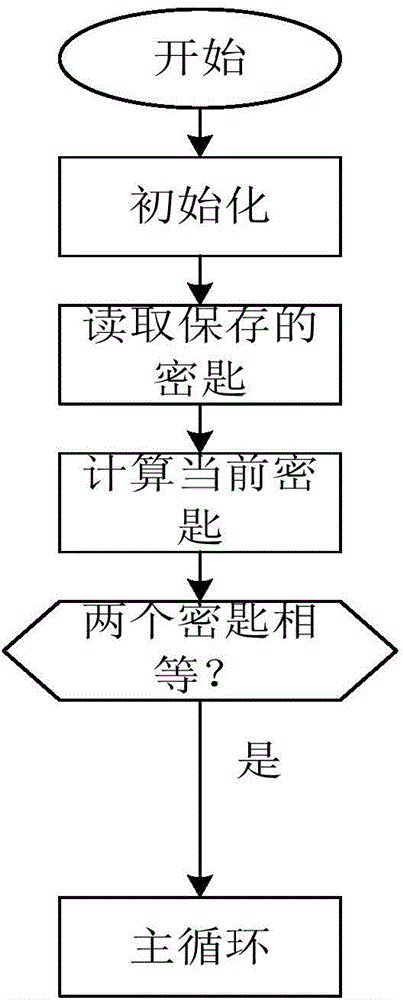

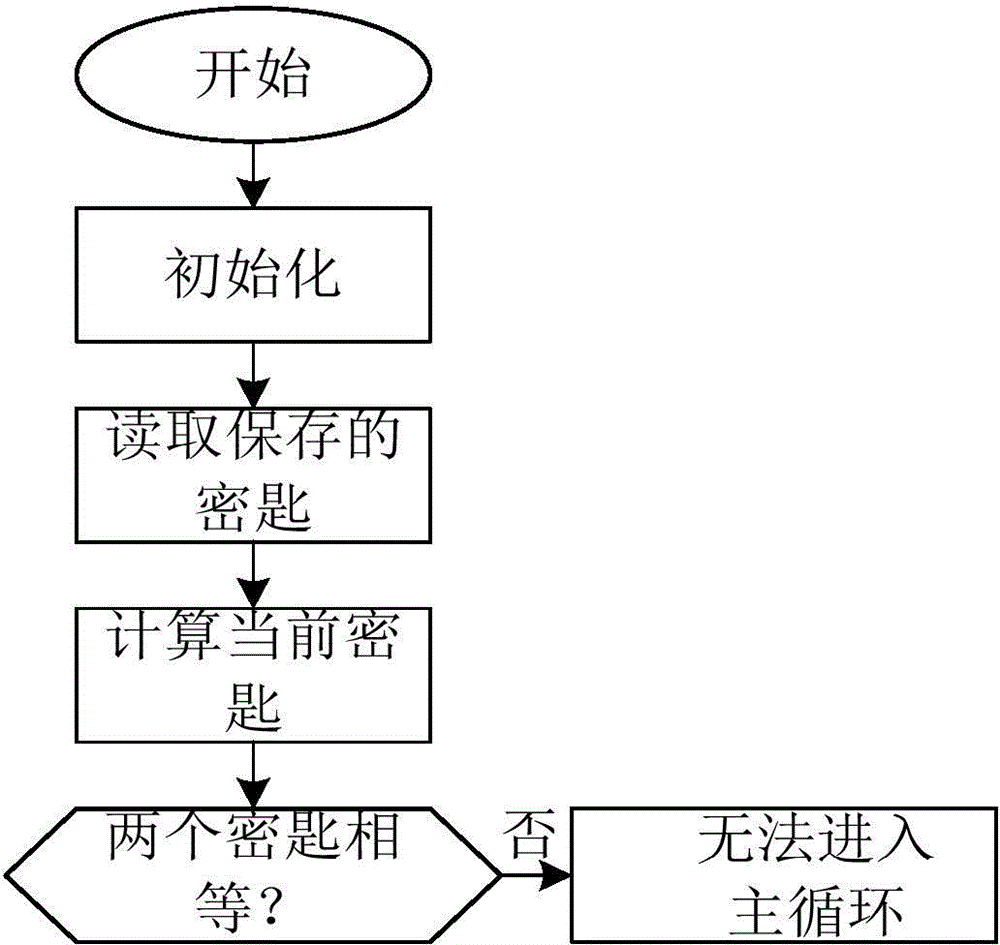

Automatic encrypting method and system for chip

InactiveCN104537320AIncrease operating loadDoes not increase operating burdenDigital data protectionInternal/peripheral component protectionKey storageEmbedded system

The invention discloses automatic encrypting method and system for a chip. The automatic encrypting method and system for the chip are applied to the chip which can be written online and erased and of which the storage area can be divided into blocks. The method comprises the steps of reading information for generating a key from a special register of the chip when the chip is electrified to operate the program for the first time; operating the program code for actuating the key calculation function through the information to obtain the key for the chip; storing the operated key into the storage area of the chip to be used as a verification key for subsequent electrifying operation; automatically erasing the program code for actuating the key storage function in step b, wherein the program code for actuating the key storage function is pre-divided into independent storage areas can be erased online. With the adoption of the method and system, the chip can be encrypted with low cost and good effect.

Owner:深圳市雷赛软件技术有限公司 +1

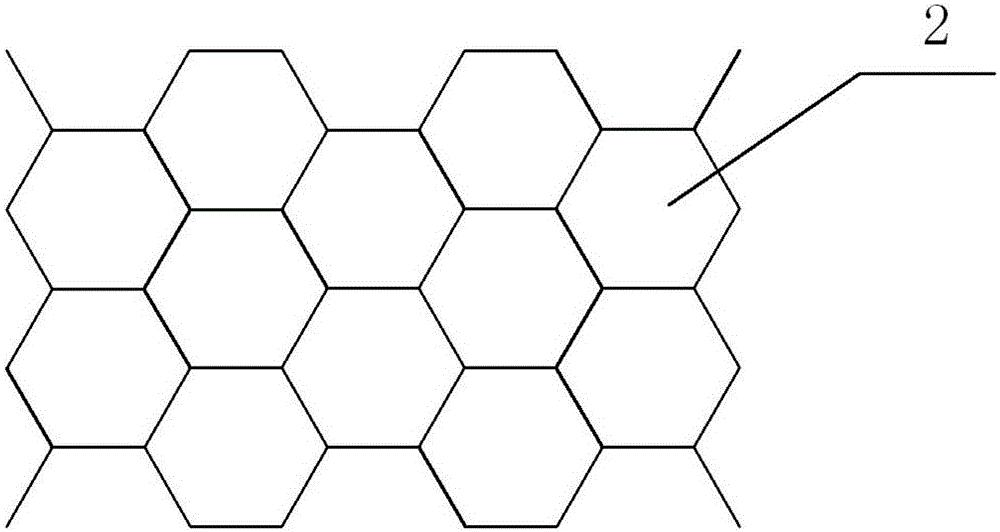

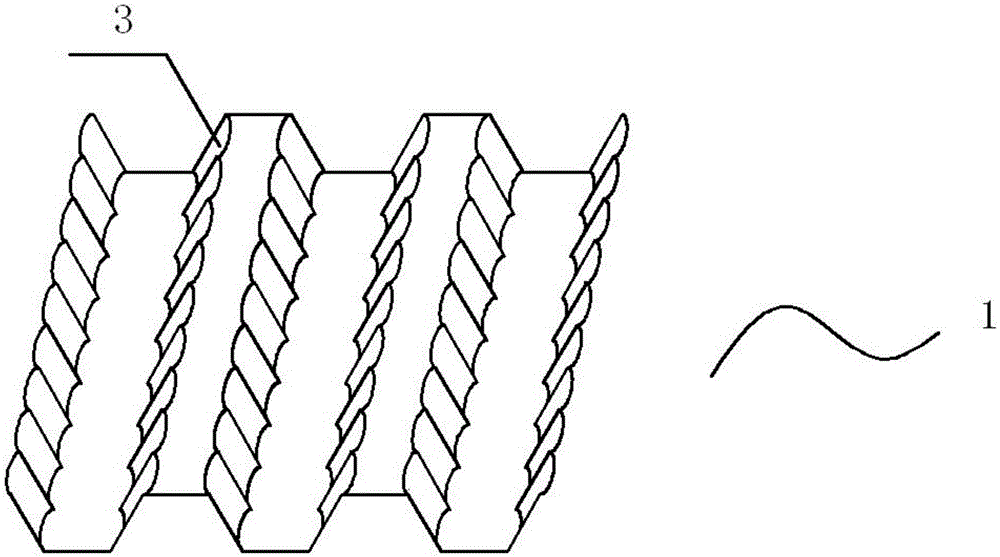

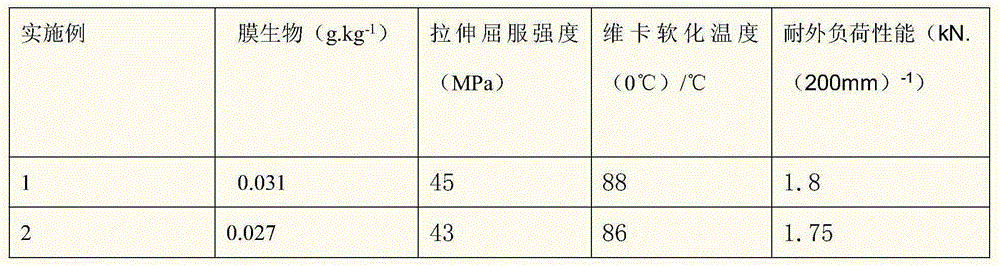

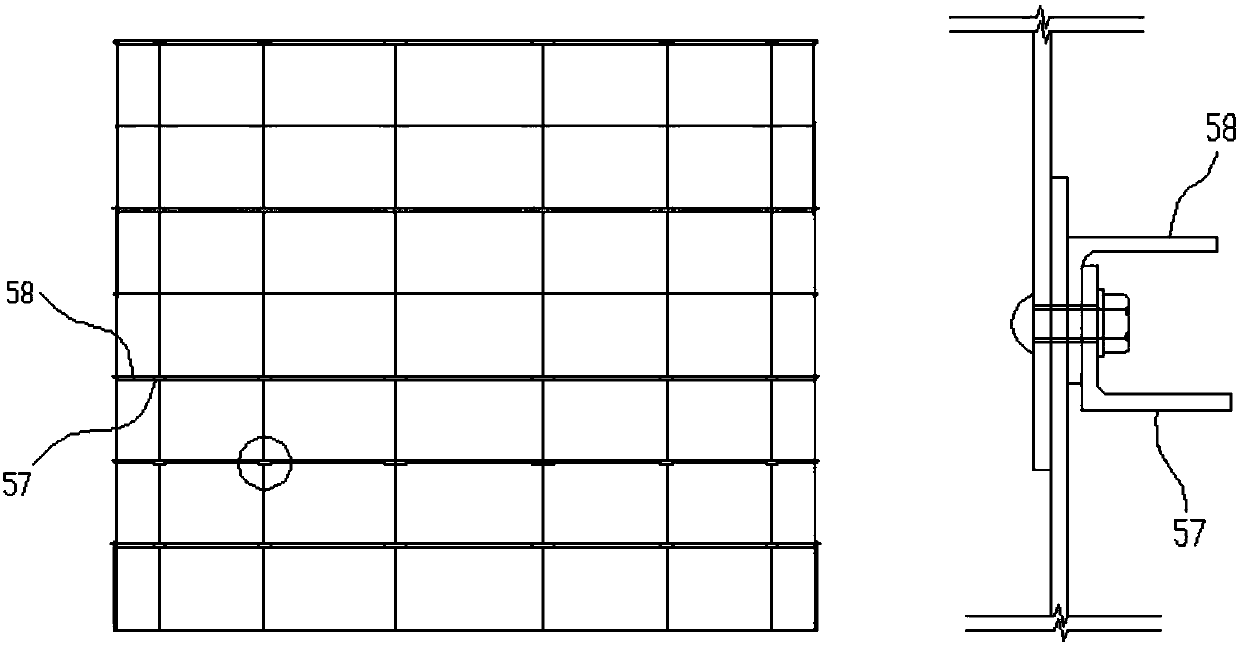

Marine tubular-type biofilm colonization filling material

ActiveCN105236562AReduce PVC instability factorsGood processing performanceSustainable biological treatmentBiological water/sewage treatmentActive carbonPollutant

The invention discloses a marine tubular-type biofilm colonization filling material. The marine tubular-type biofilm colonization filling material comprises honeycomb straight channels composed by mutual superposition of a plurality of trapezoidal PVC sheets bended like waves; the cross sections of the straight channels shape like regular hexagons; the surfaces of the trapezoidal PVC sheets bended like waves are provided with a plurality of dull polish bulges; the trapezoidal PVC sheets bended like waves are provided with grooves, wherein the grooves are designed to be concave towards a direction vertical to the straight channels; the thickness of the trapezoidal PVC sheets is controlled to be 0.05 to 0.3mm; and the trapezoidal PVC sheets are composed of 85 to 98 parts of PVC, 0.5 to 5 parts of salty mud, 1 to 5 parts of polyvinyl alcohol, 0.5 to 4 parts of polyacrylamide, and 0.1 to 4 parts of active carbon. The marine tubular-type biofilm colonization filling material can be used for removing pollutants effectively; contact area with pollutants is large; pollutants can be absorbed as far as possible; complete pollution removing and water body purification are realized; and wall flow time is short.

Owner:江西鑫淘科技股份有限公司

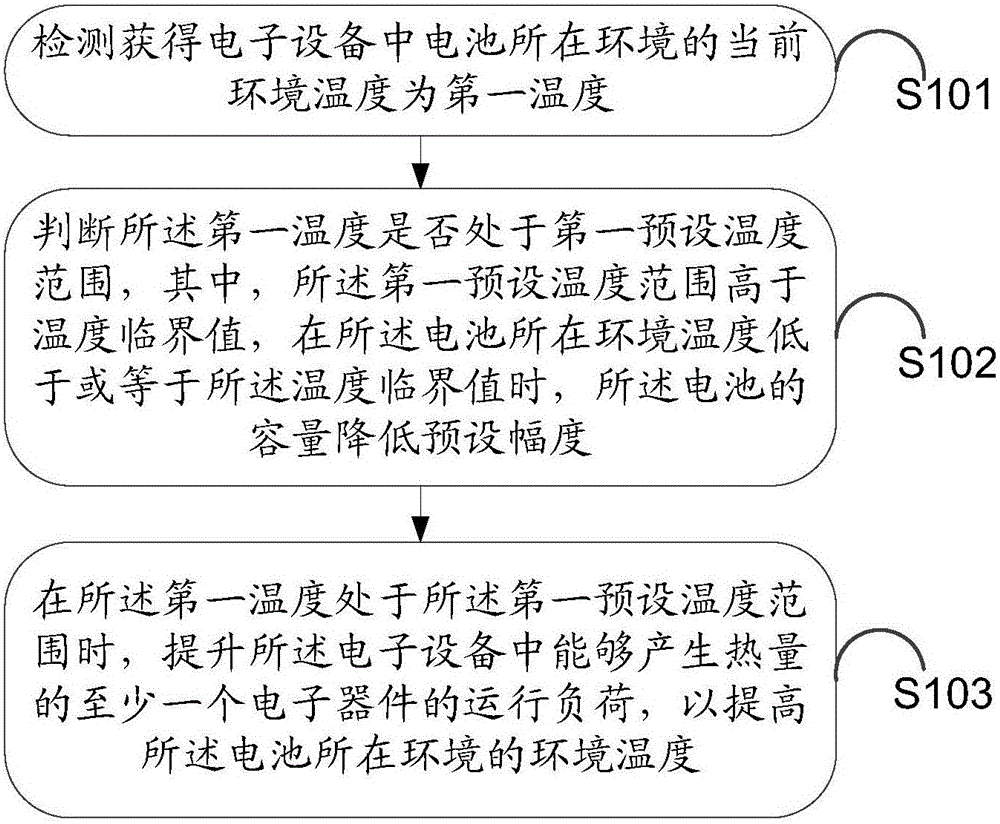

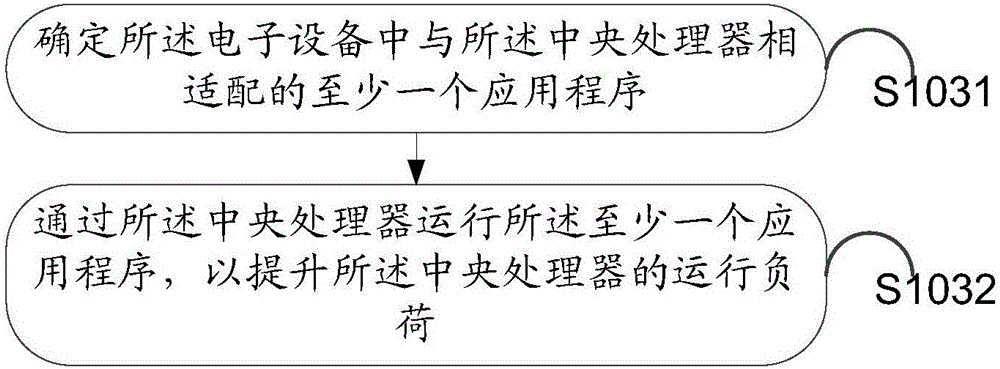

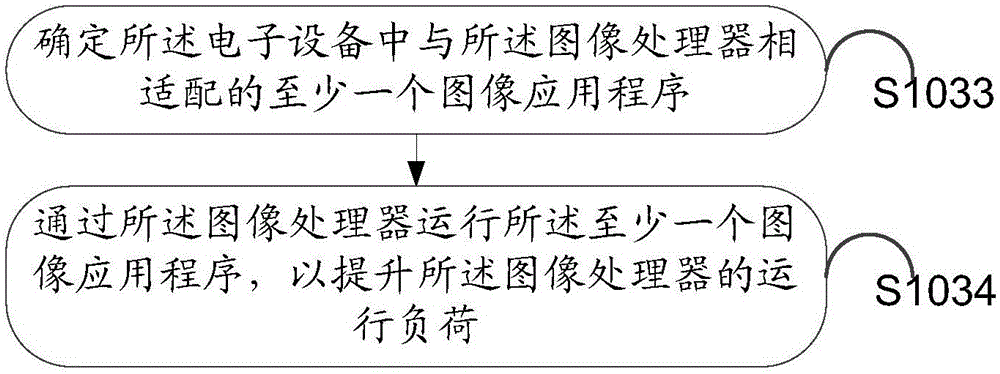

Information processing method and electronic equipment

ActiveCN105808409AReduce capacityIncrease the ambient temperatureSecondary cellsHardware monitoringInformation processingEngineering

The invention discloses an information processing method and electronic equipment. The information processing method includes the steps that the current environmental temperature of the environment where a battery in the electronic equipment is located is detected and obtained to serve as the first temperature; whether the first temperature is within the first preset temperature range or not is judged, the first preset temperature range is higher than the temperature critical value, and when the temperature of the environment where the battery is located is lower than or equal to the temperature critical value, the capacity of the battery is lowered by a preset range; when the first temperature is within the first preset temperature range, operation loads of one or more electronic devices capable of generating heat in the electronic equipment are raised, so that the environmental temperature of the environment where the battery is located is raised.

Owner:LENOVO (BEIJING) LTD

Intelligent detection method of air conditioner

ActiveCN107062538AIncrease operating loadIncrease the automatic judgment mode of lack of liquidSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringCooling capacity

The invention discloses an intelligent detection method of an air conditioner. The intelligent detection method comprises the steps: 1) roughly selecting the number of shunt circuits ON in a standard indoor unit according to the cooling capacity of an outdoor unit detected; 2) starting temperature sensors in the shunt circuits ON to detect the real-time temperature; when the outlet temperature of indoor heat exchangers in the shunt circuits is lower than the preset difference value of a coil temperature, turning on more than one shunt circuit; and so on, till the outlet temperature of the indoor heat exchangers in the shunt circuits is higher than the coil temperature; 3) upon completion of calibration of the standard indoor unit, state locking, locking the opening state of electronic expansion valves of the shunt circuits and the corresponding outdoor unit detected.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

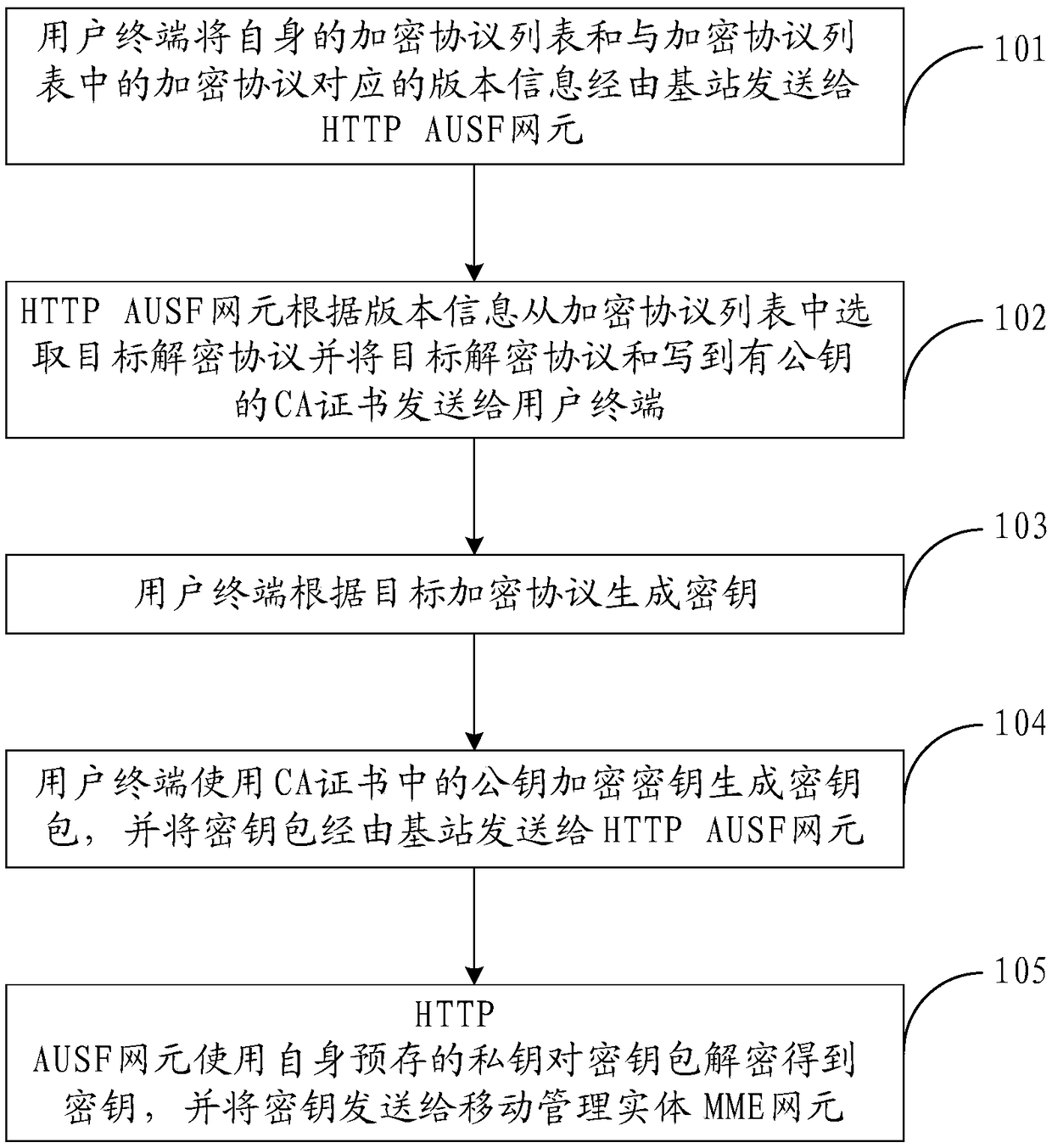

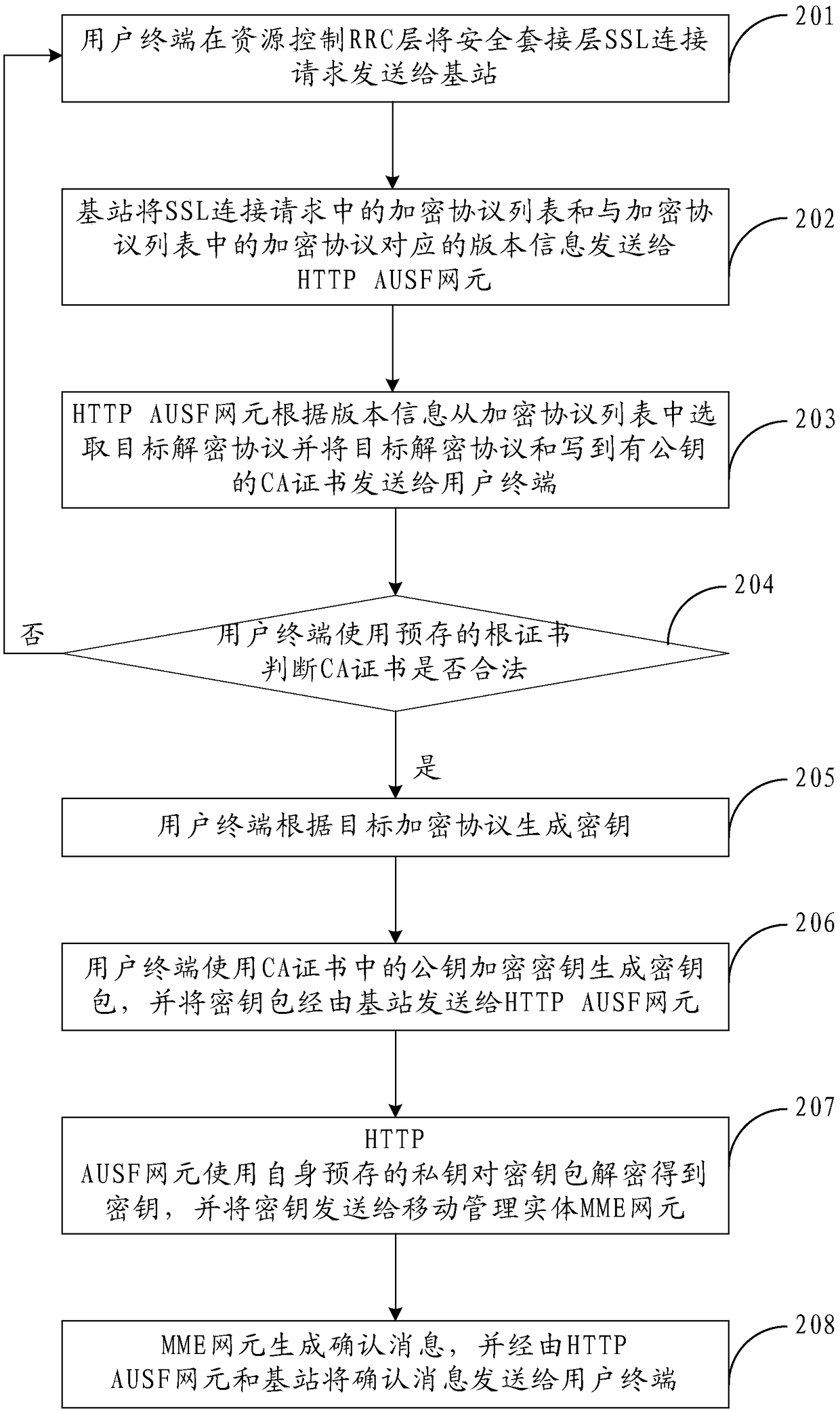

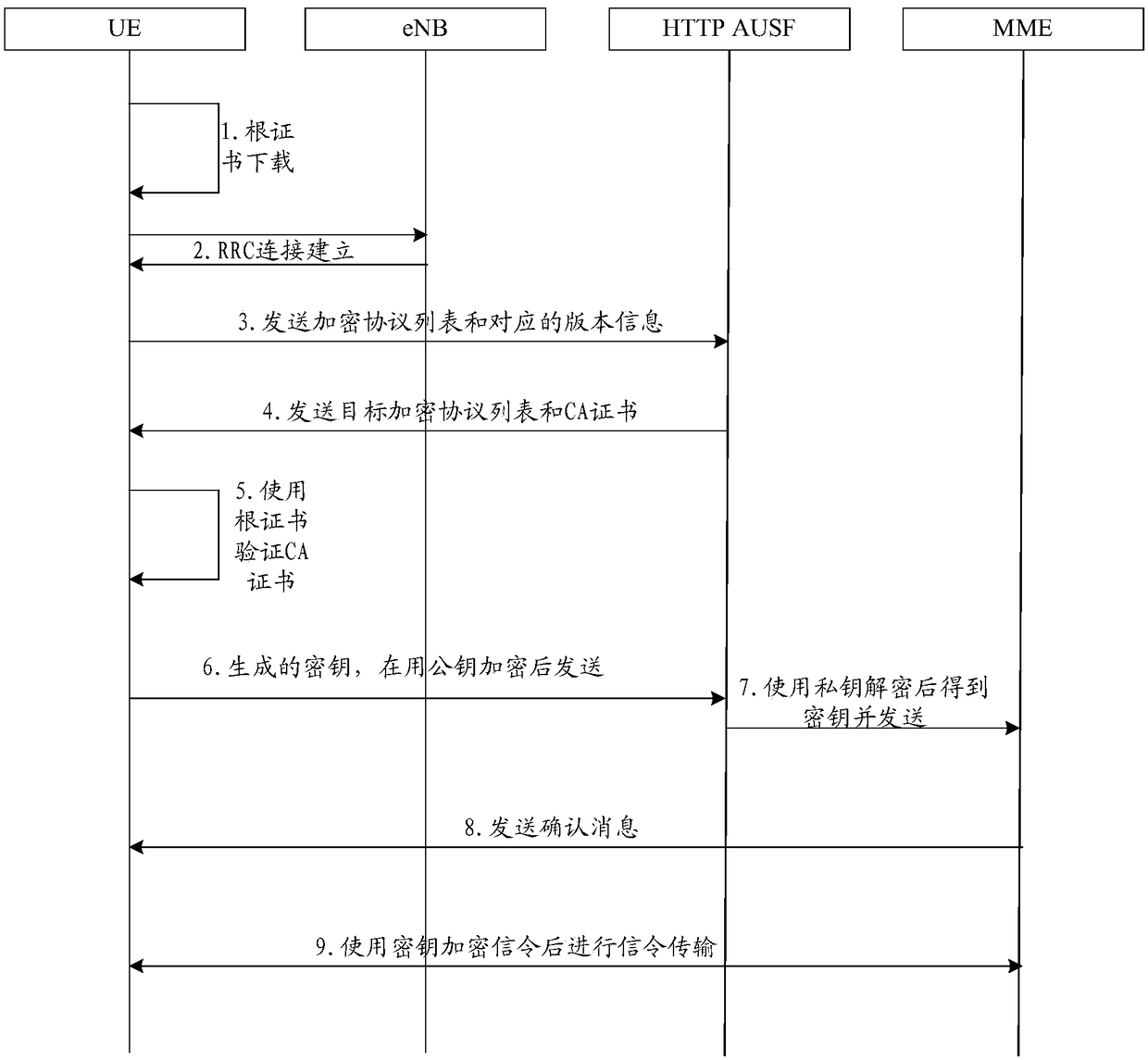

IMSI encryption method, core network, and user terminal

ActiveCN108882233APublic key secrecyAvoid LeakageTransmissionSecurity arrangementGPRS core networkProtocol for Carrying Authentication for Network Access

The embodiment of the invention provides an IMSI encryption method, a core network, and a user terminal, and relates to the field of communication. The IMSI of a user can be prevented from being leaked in a network access process without increasing the load of a base station. The method comprises the following steps: the user terminal sends an own encryption protocol list and version information corresponding to an encryption protocol in the encryption protocol list to an HTTP AUSF network element via the base station; the HTTP AUSF network element selects a target encryption protocol from theencryption protocol list according to the version information, and sends the target encryption protocol and a CA certificate carrying a public key to the user terminal via the base station; the userterminal generates a key according to the target encryption protocol, simultaneously generates a key package by using an encryption key of a public key in the CA certificate, and sends the key packageto the HTTP AUSF network element via the base station; and the HTTP AUSF network element decrypts the key package by using an own pre-stored private key to obtain the key, and sends the key to an MMEnetwork element, wherein the public key corresponds to the private key.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

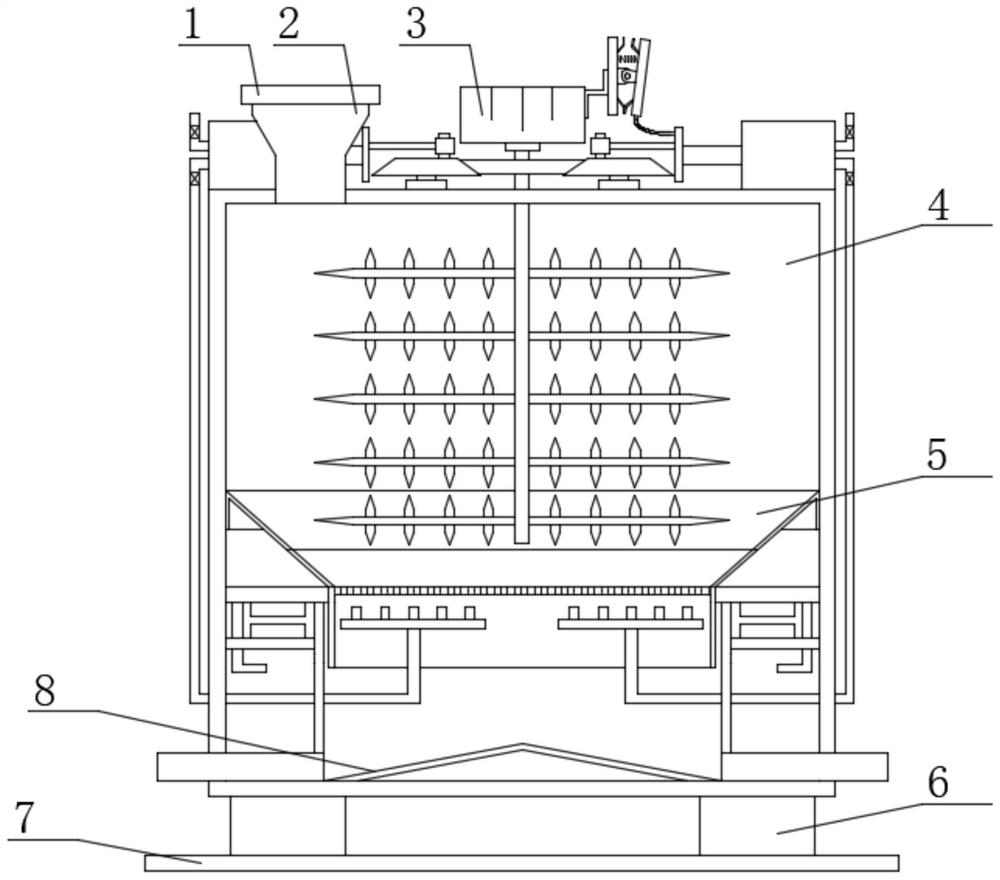

Efficient composite anaerobic reactor for treating high-concentration organic waste water

InactiveCN1935698AIncrease biomassSimple designWaste based fuelTreatment with anaerobic digestion processesHigh concentrationActivated sludge

The invention is a high efficiency combined anaerobic reactor for treating high concentration organic waste water, relating to a high concentration organic waste water treating device, where an activated sludge bed, an aeration head and a lightweight filling bed are arranged in a reaction vessel, the aeration head is connected with an air pump, the reaction vessel is equipped with biological air outlet, water outlet and water inlet, a water outlet weir is arranged at the water outlet in the reaction vessel, and the outer wall of the water outlet weir is equipped with meshes. And it has advantages of large biological quantity, high load, high treating efficiency, less investment, and easy to operate and maintain, able to be widely applied to treating various high concentration organic waste water.

Owner:HARBIN INST OF TECH

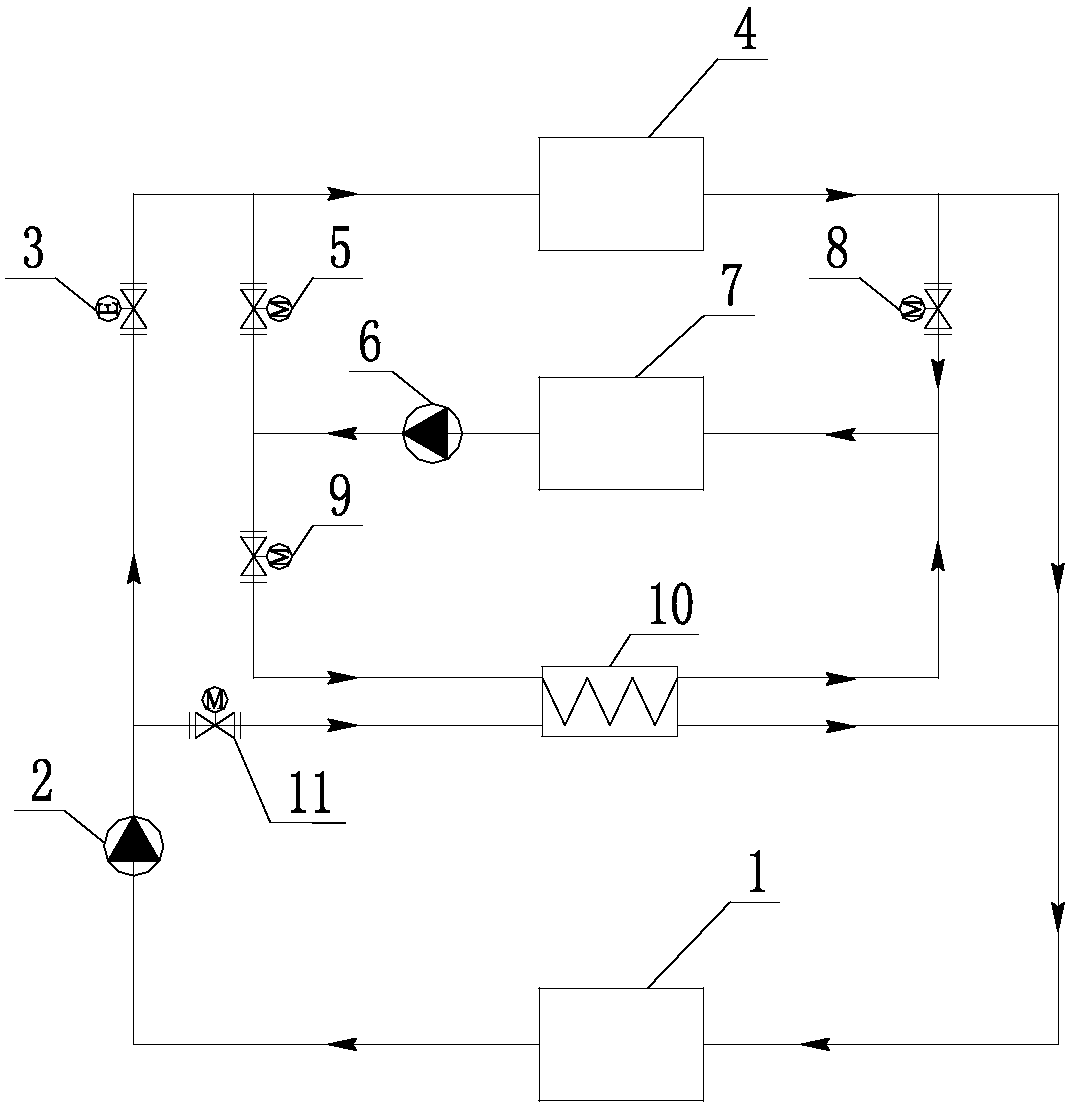

Gas use peak adjusting method for heating system

InactiveCN108266780ALower natural gas demandReduce gas demandHeating fuelCentral heating with accumulated heatProcess engineeringCirculating pump

The invention discloses a gas use peak adjusting method for a heating system. The heating system comprises a heating loop, a heat storage loop and a heat release loop; a gas boiler, a second electrictwo-way valve, a heat storage tank, a heat storage circulating pump and a first electric two-way valve are arranged on the heat storage loop in sequence according to a fluid circulating direction; a heat storage tank, a heat storage circulating pump, a third electric two-way valve and a heat exchanger are arranged on the heat release loop in sequence according to a fluid circulating direction; a primary side of the heat exchanger is connected to the heat release loop; and a secondary side of the heat exchanger is connected with the gas boiler in parallel. The method comprises the following steps: in the gas use valley period, the heat storage tank stores redundant heat generated by the gas boiler; and in the gas use peak period, the heat storage tank releases the heat to the heat exchanger, and the heat exchanger and the gas boiler provide the heat to a heat exchange unit together to reduce the gas use demands of the gas boiler. The gas use demands in the gas use peak period of naturalgas in cities can be greatly reduced.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

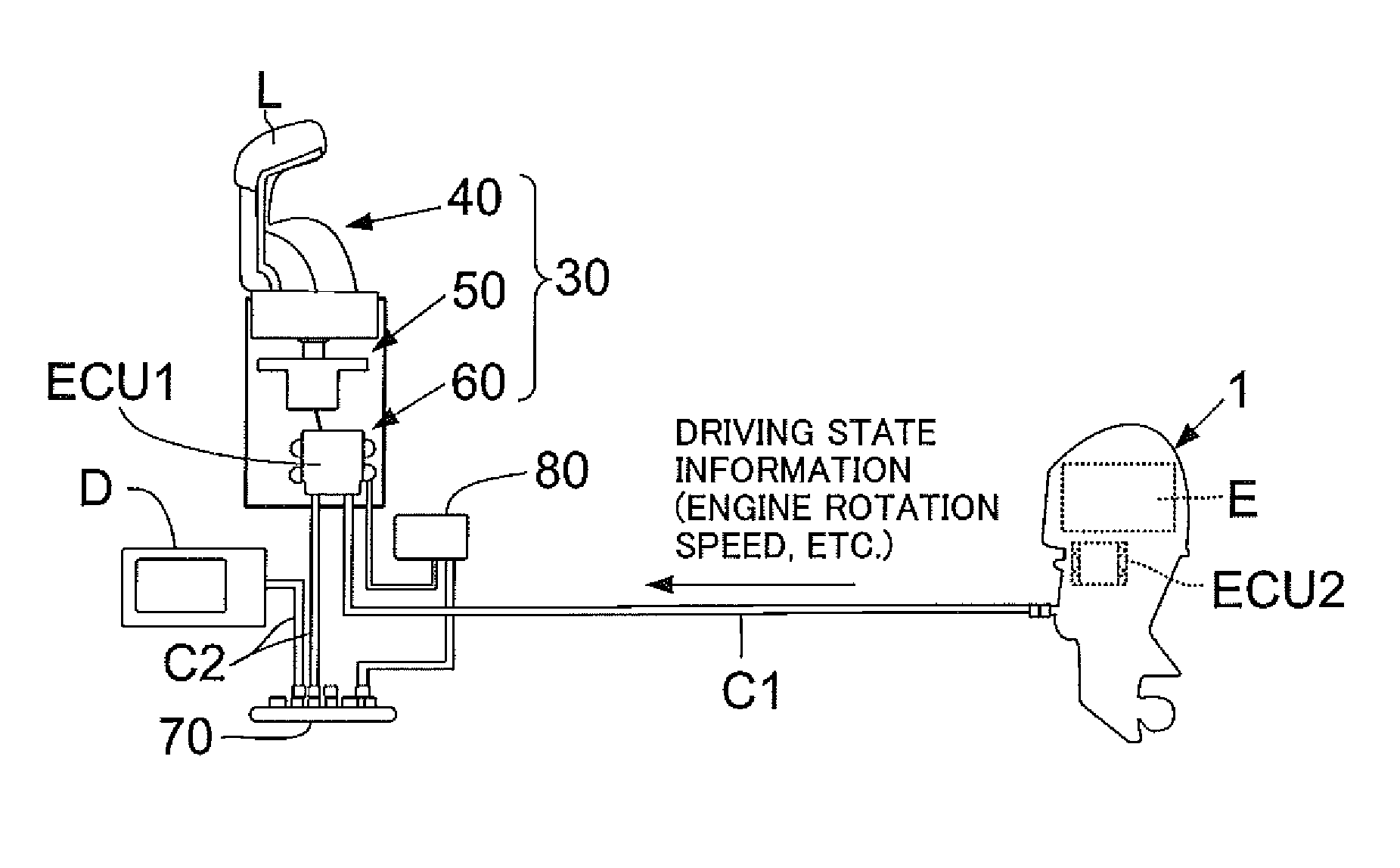

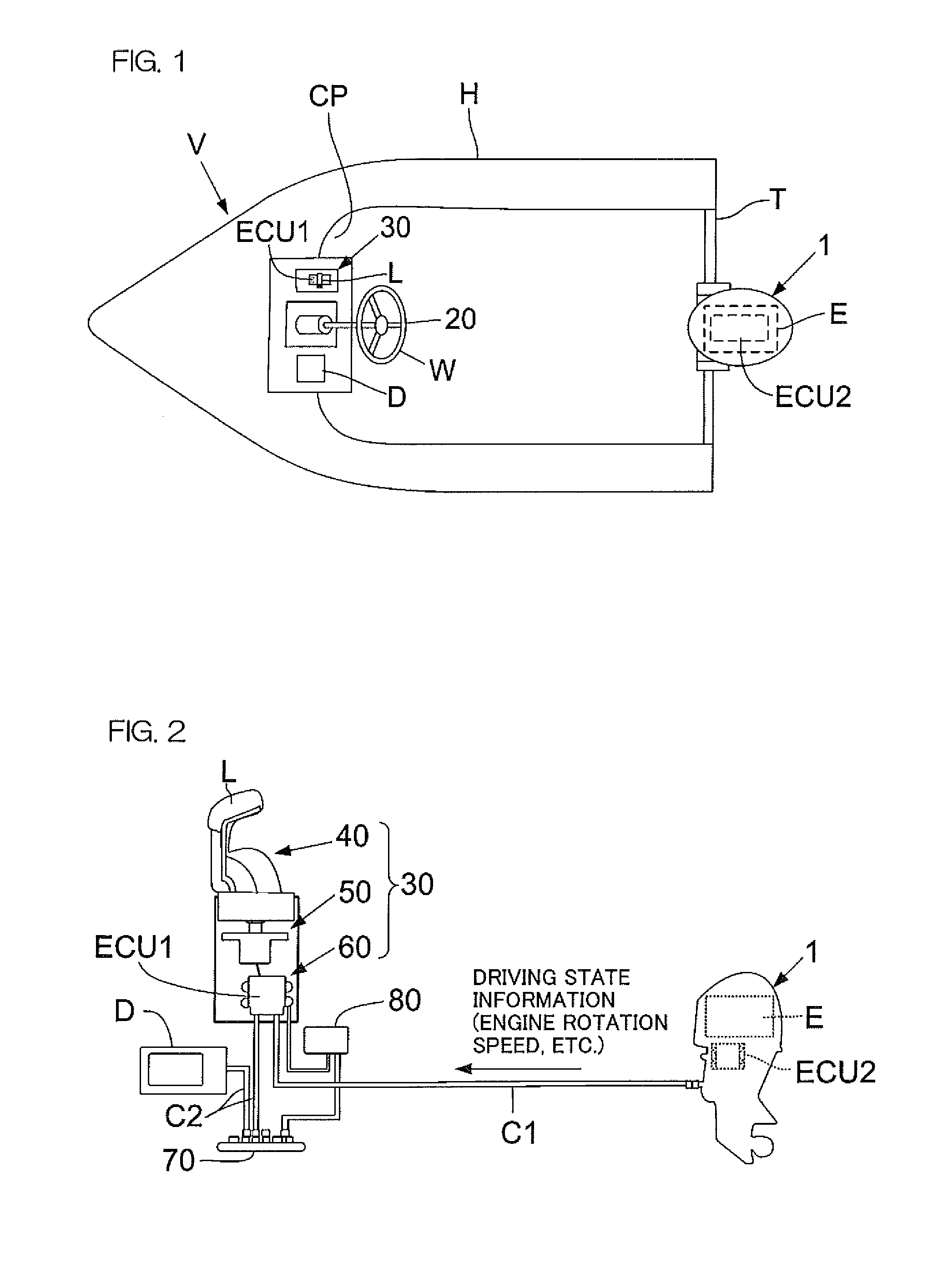

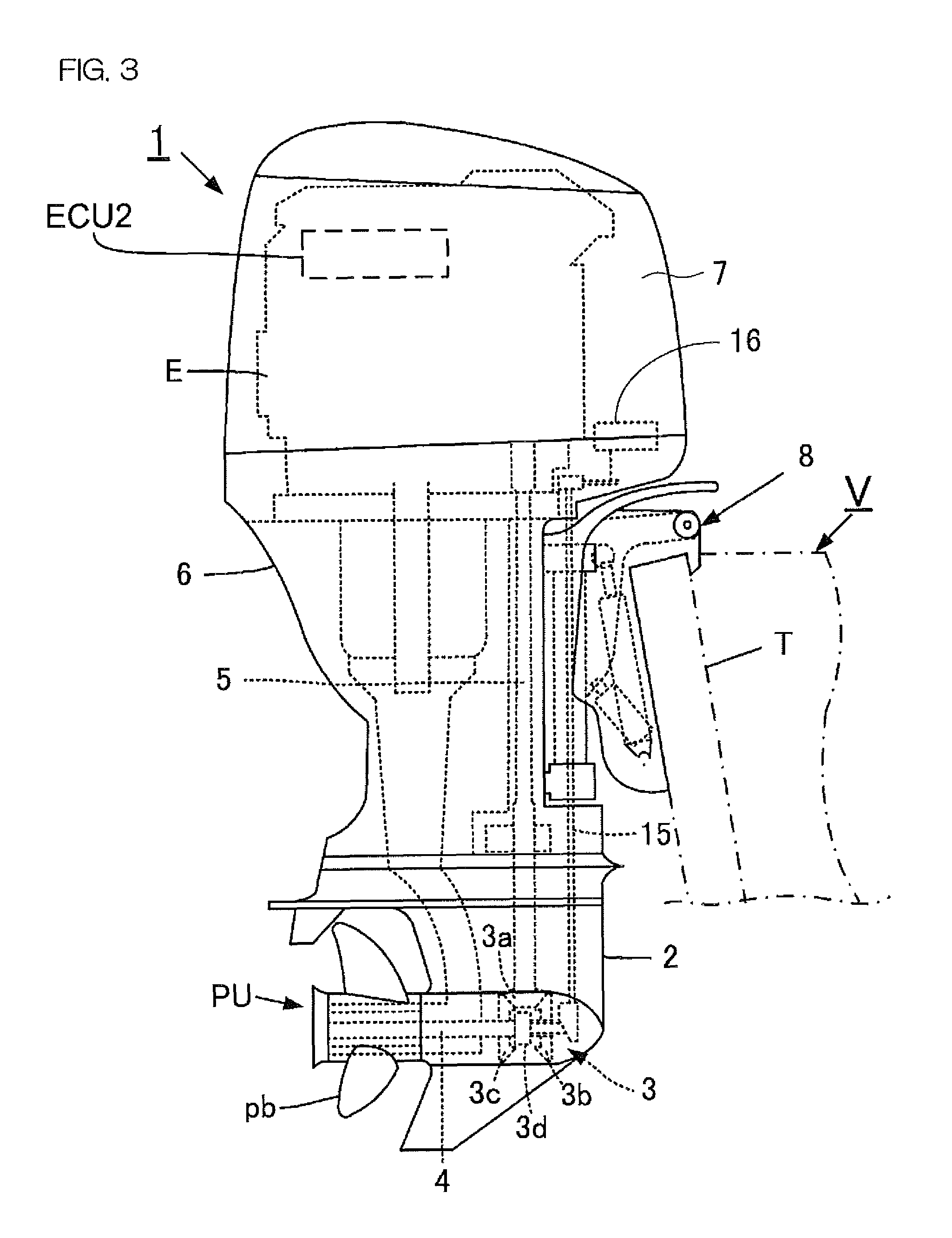

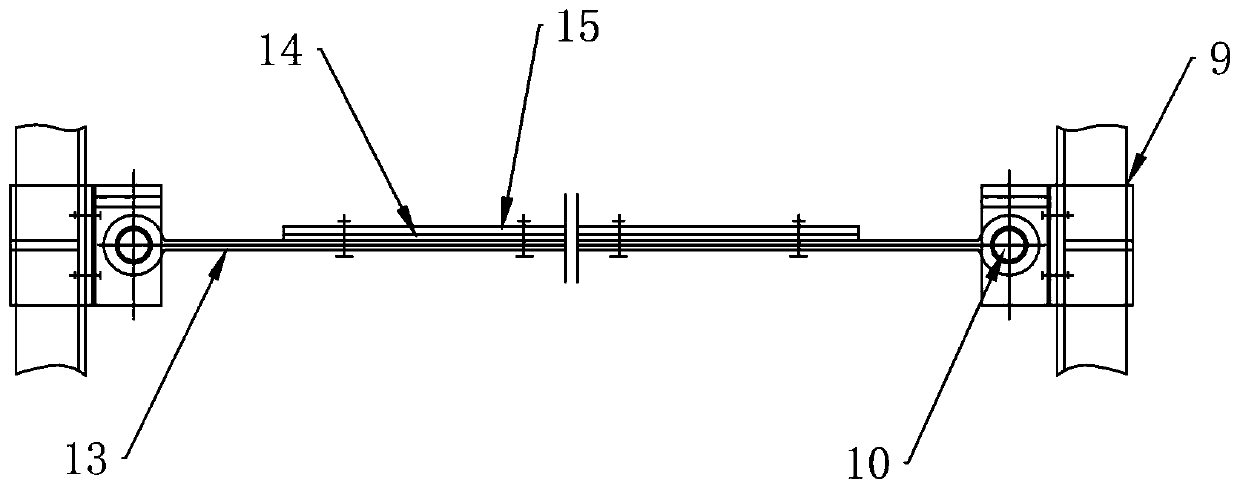

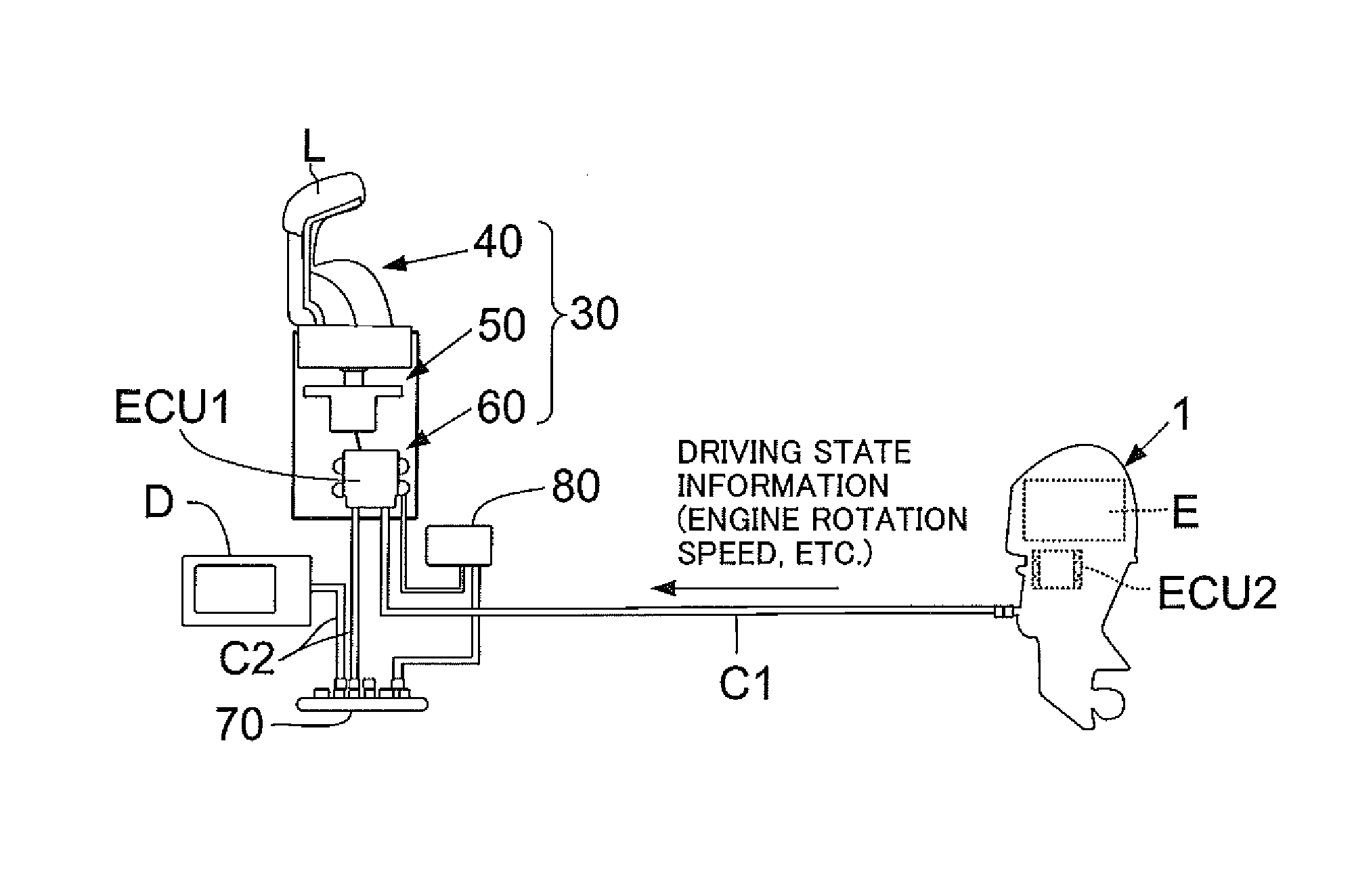

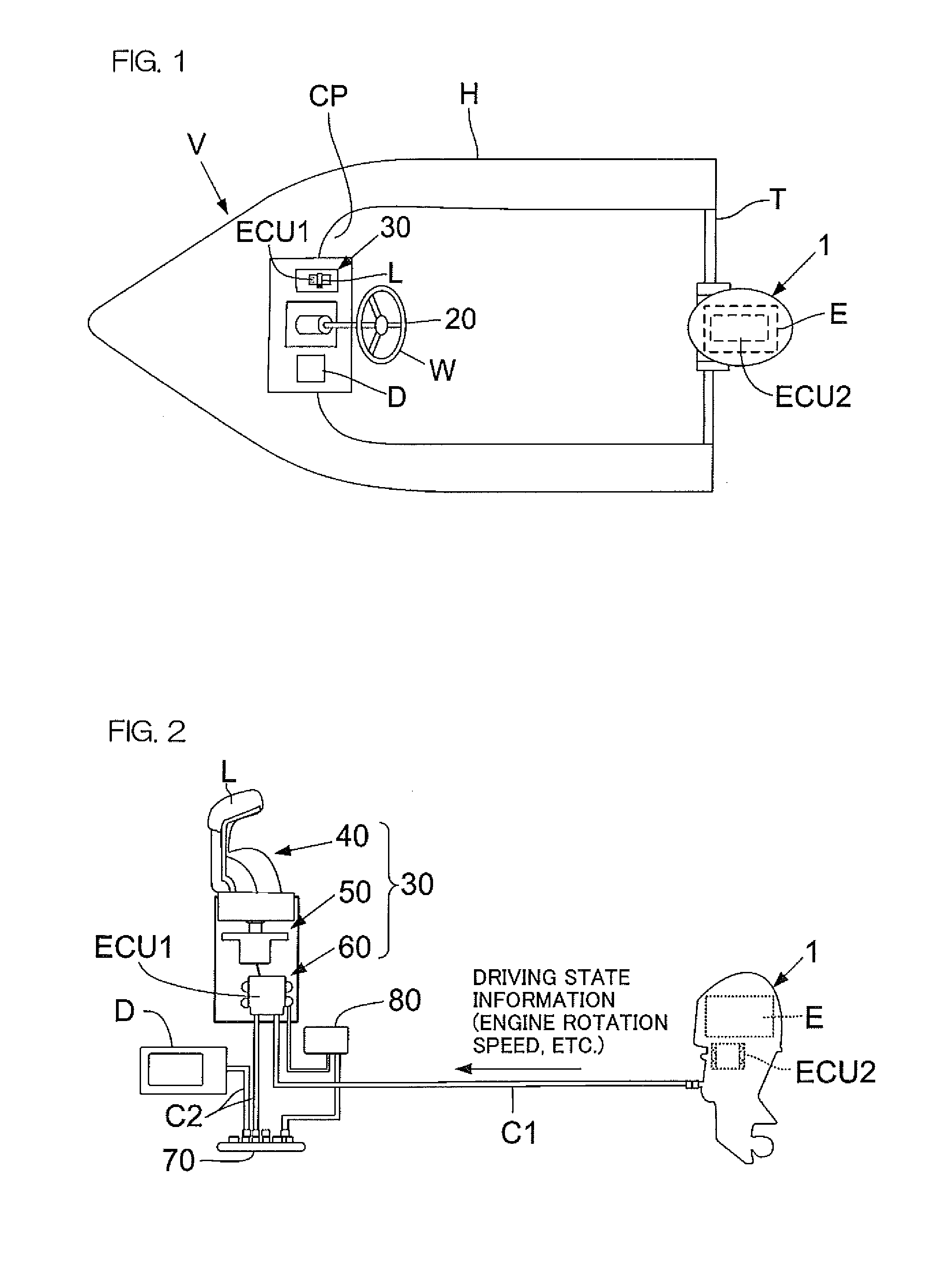

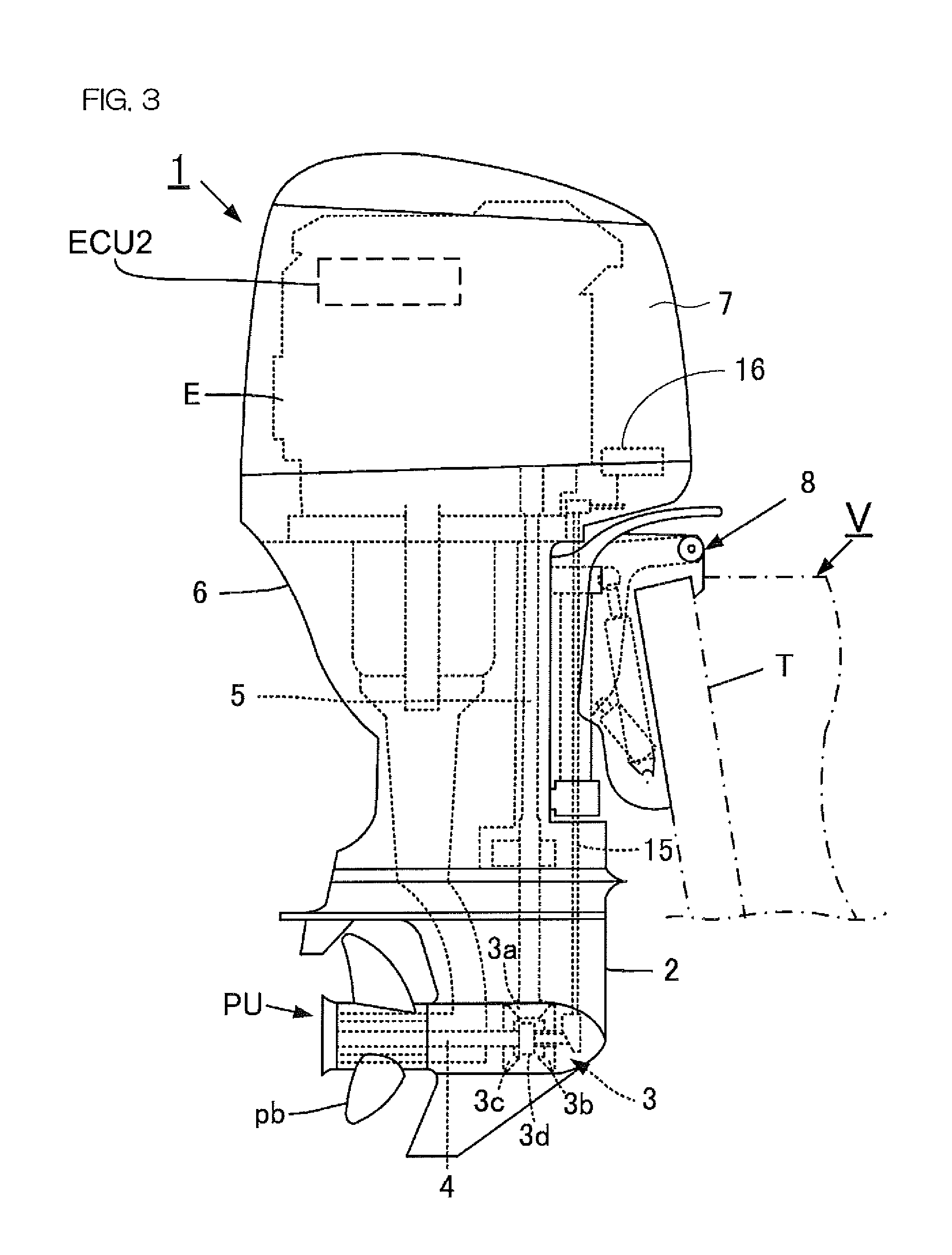

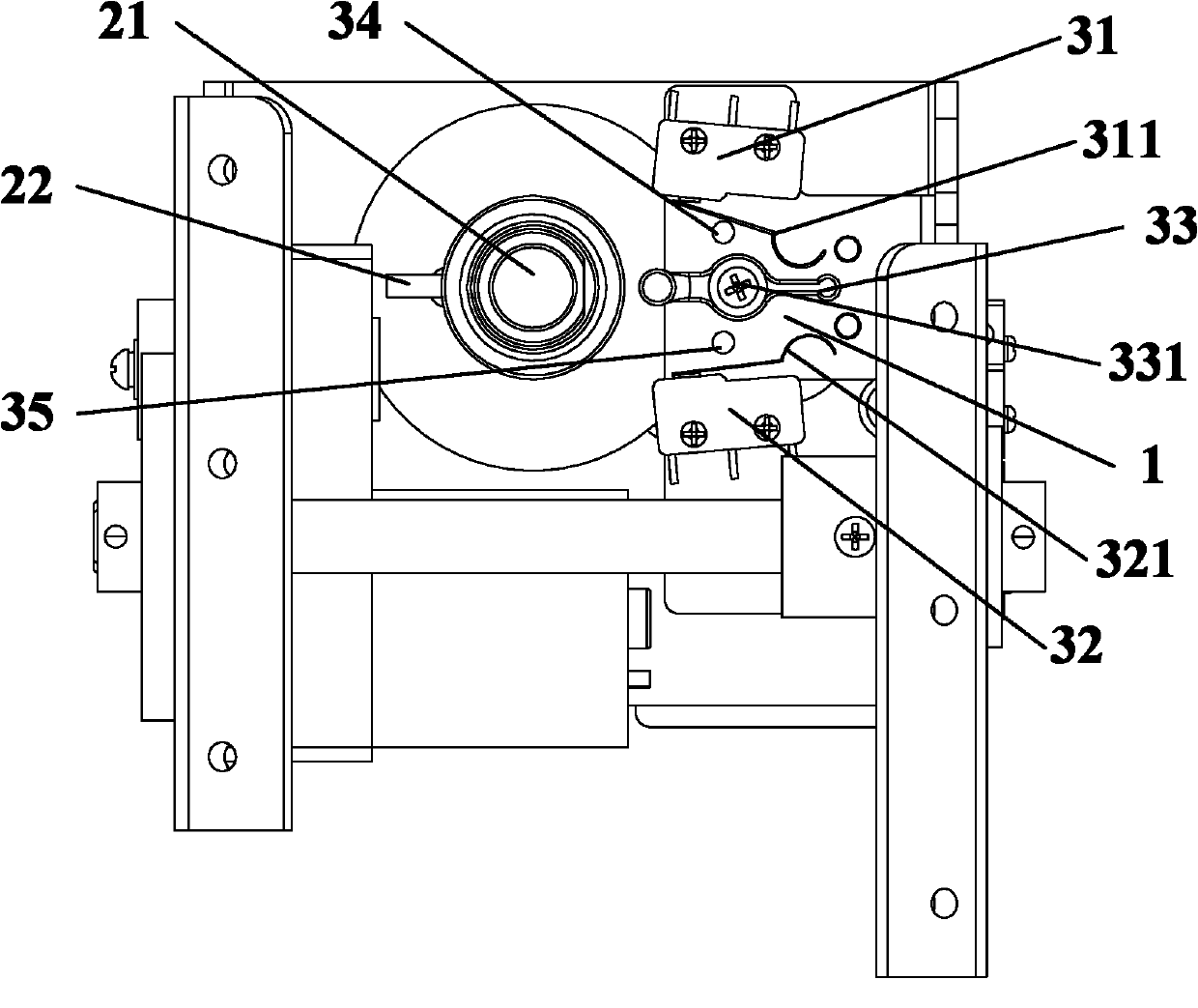

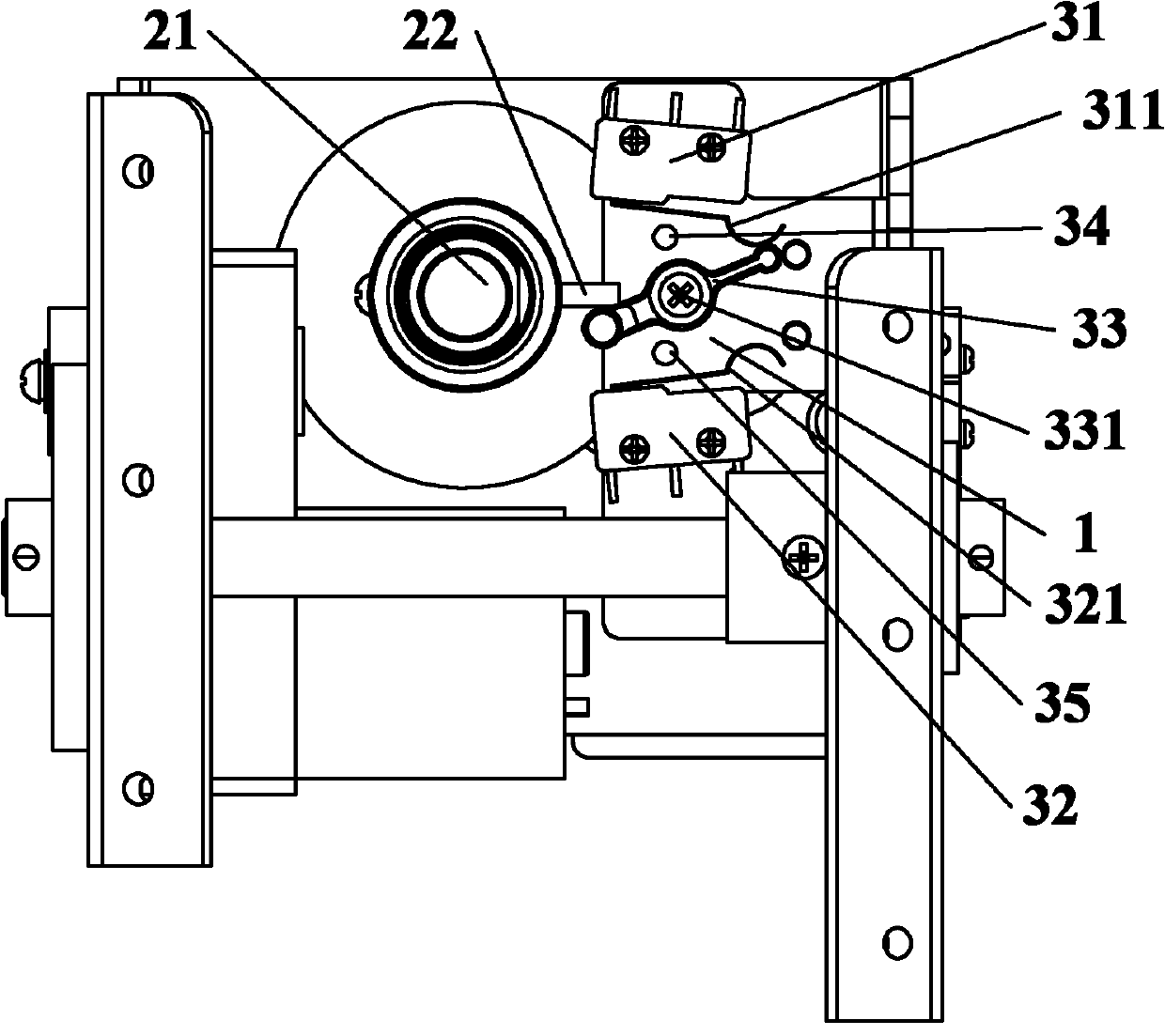

Remote control device for vessel and remote control method for vessel propulsion device

ActiveUS9272764B2Increase operating loadOperation load of the operation leverPropulsion power plantsOutboard propulsion unitsMarine engineeringRemote control

A remote control device for a vessel is installed in a vessel and remotely controls a vessel propulsion device of the vessel. The remote control device includes an operation member, an operation load applying mechanism, a control section, and an actuator. The operation member is supported rotatably around a rotation axis, and is operated by an operator to switch the shift position of a forward-reverse switching mechanism in the vessel propulsion device according to the operation angle of the operation member. The operation load applying mechanism applies an operation load to the operation member. The control section controls the operation load. The operation load applying mechanism includes an actuator that adjusts the operation load. The control section is arranged to control the actuator based on a vessel speed of the vessel.

Owner:YAMAHA MOTOR CO LTD

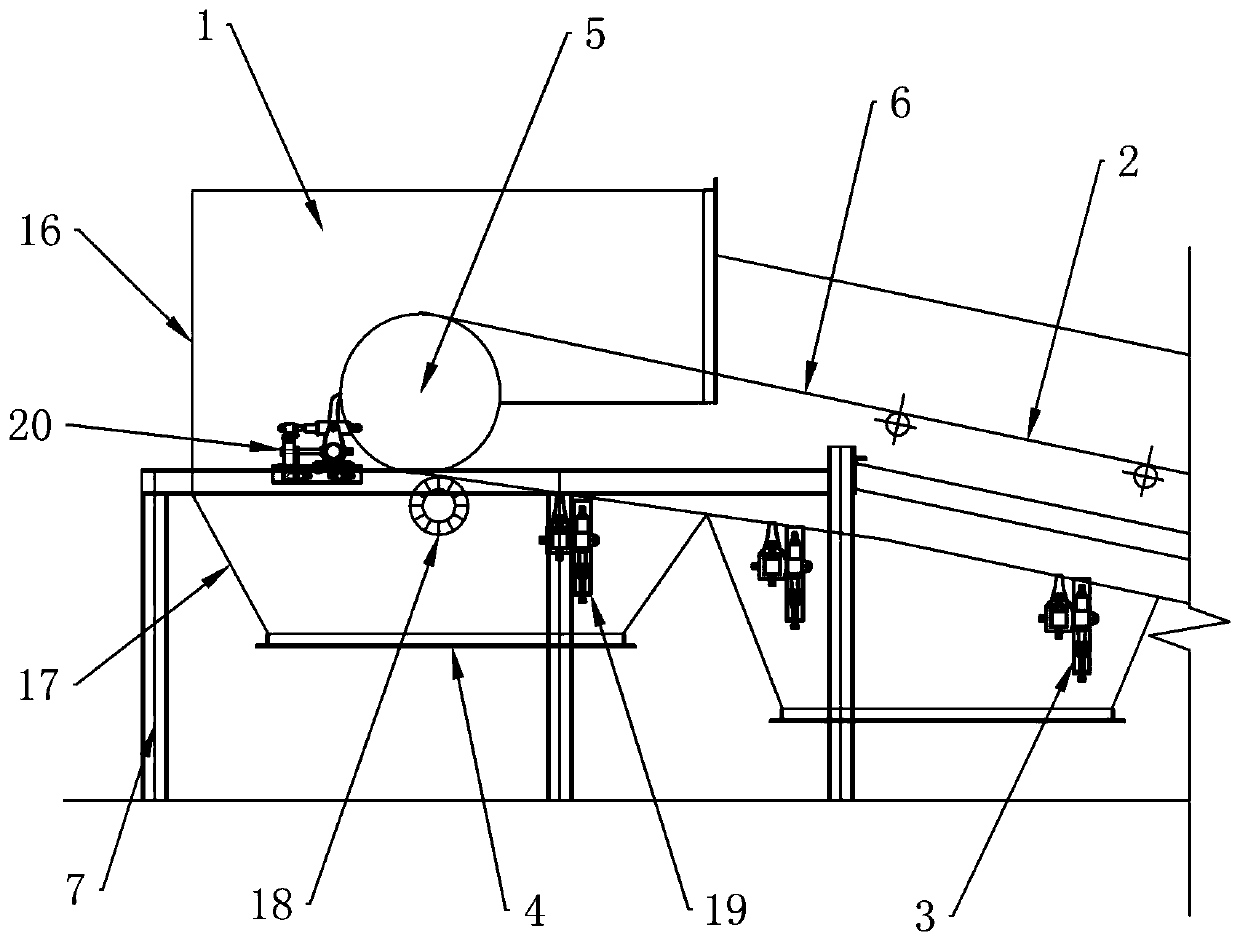

Belt conveyor hopper with multiple built-in sweepers

The invention discloses a belt conveyor hopper with multiple built-in sweepers. The belt conveyor hopper with the multiple built-in sweepers comprises at least one hopper, a belt conveyor, and the plurality of sweepers, wherein a feeding hole is formed in the side wall of the hopper; a discharging hole is formed in the lower end of the hopper; the belt conveyor is arranged in the hopper and comprises a main wheel and a conveying adhesive tape; the main wheel is connected to the conveying adhesive tape in a transmission manner; the feeding hole is located above one end of the conveying adhesive tape; and the plurality of sweepers are arranged in the hopper, are located below the conveying adhesive tape, are abutted against the lower side of the conveying adhesive tape and are used for clearing materials adhered to the conveying adhesive tape. The belt conveyor hopper with the multiple built-in sweepers enables the loss of materials to be less in the conveying process of the materials, and meets the increasingly severe environmental protection requirements and the requirements on providing a high-quality batch material for the production line.

Owner:CHINA TRIUMPH INT ENG

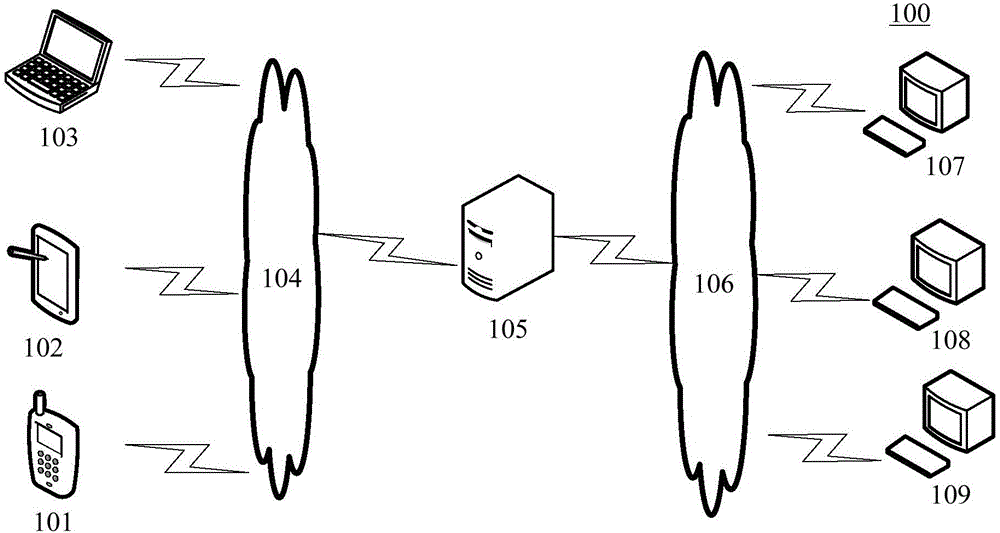

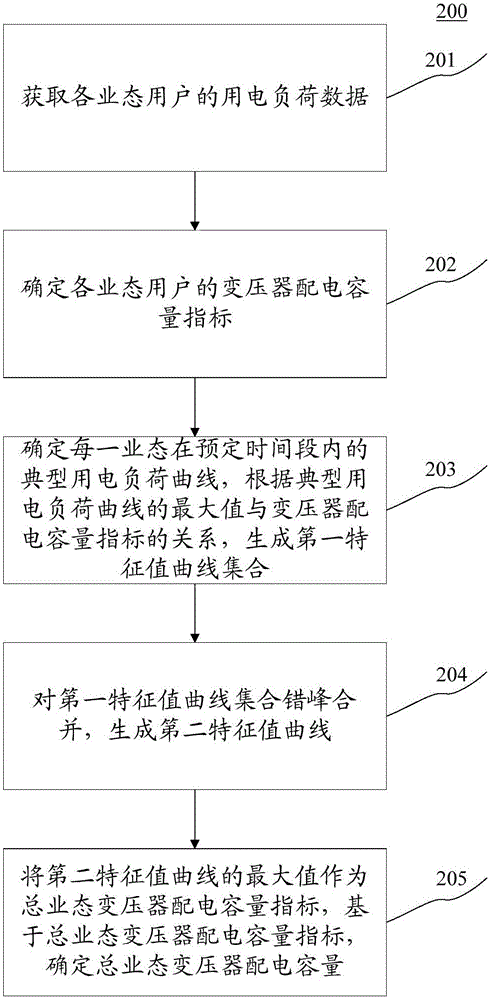

Transformer capacity determination method and device

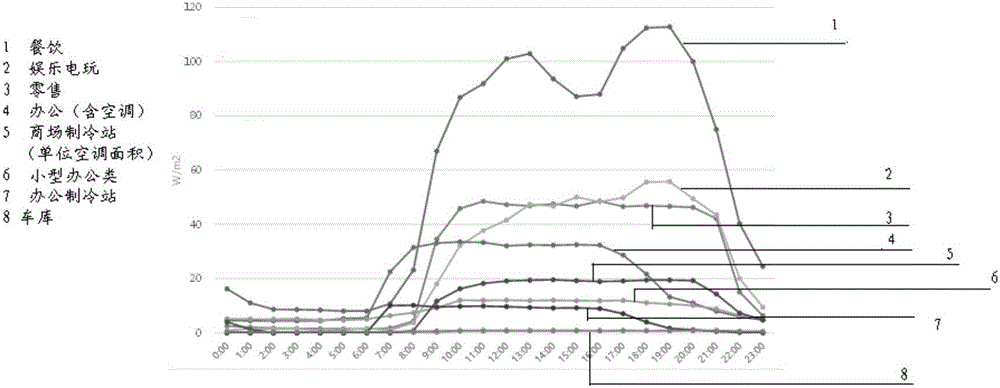

ActiveCN106056234AReduce distribution capacityIncrease operating load rateForecastingSystems intergating technologiesElectricityEngineering

The invention discloses a transformer capacity determination method and device. One specific embodiment of the method comprises the steps of: obtaining electricity load data of each commercial user; determining the transformer power distribution capacity index of each commercial user; determining a typical electricity load curve in a preset time interval of each commercial user, according to the proportion of the maximum value of the typical electricity load curve to the transformer power distribution capacity index, carrying out hour-by-hour load conversion on the typical electricity load curve, and generating a first characteristic value curve set; carrying out peak load shifting merging on the first characteristic value curve set, and generating a second characteristic value curve; and according to the maximum value of the second characteristic value curve, determining a total commercial transformer power distribution capacity. According to the embodiment, the capacity optimization of the power distribution transformer is realized, the capacity of the transformer is reduced, and resources are saved.

Owner:BEIJING PERSAGY ENERGY SAVING TECH

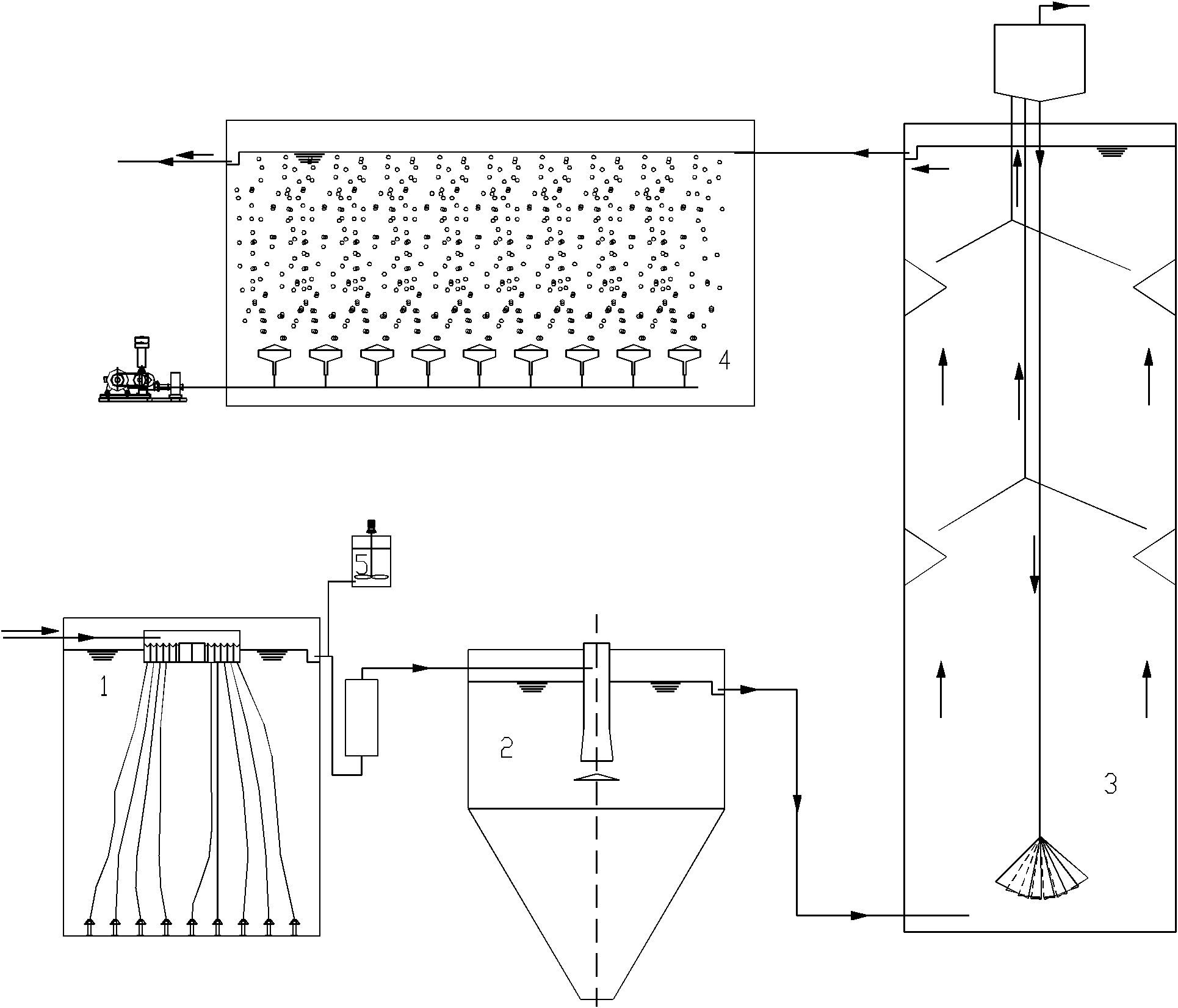

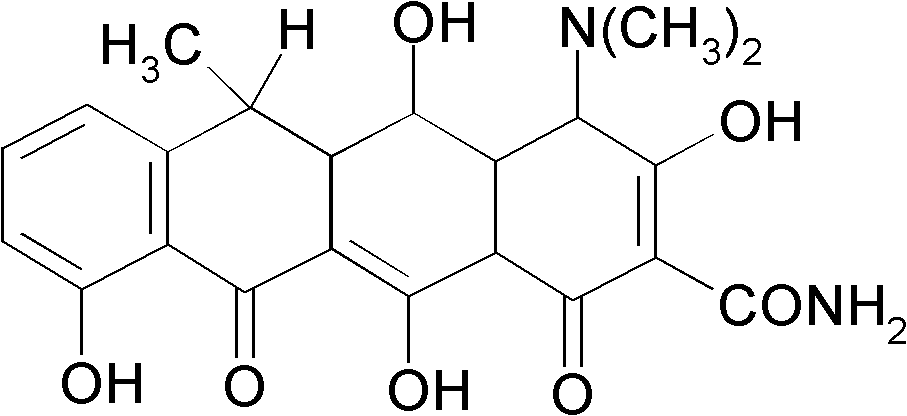

System and process for treating oxytetracycline waste water by anaerobic bio-treatment method

InactiveCN102126813AImprove biochemical behaviorSimple processWater contaminantsWaste based fuelChemical oxygen demandCalcium ion binding

The invention relates to a system and process for treating oxytetracycline waste water by an anaerobic bio-treatment method, which has the advantages of stable process, low investment, small occupied area and low energy consumption. The system comprises a hydrolysis and acidification tank, wherein waste water is hydrolyzed and acidified in the hydrolysis and acidification tank and the waste wateris then moved into a lime precipitation tank; in the lime precipitation tank, oxytetracycline in the waste water is combined with calcium ions to generate precipitates; then, the waste water is movedinto an anaerobic reactor; the anaerobic reactor removes most of COD (Chemical Oxygen Demand) in the outlet water and simultaneously emits generated marsh gas; and after going out of the anaerobic reactor, the waste water is moved into an aerobic tank, so that organic substances and ammonia nitrogen in the waste water can be further treated, thereby ensuring that the discharge of the waste water is reached the standards.

Owner:山东美泉环保科技有限公司

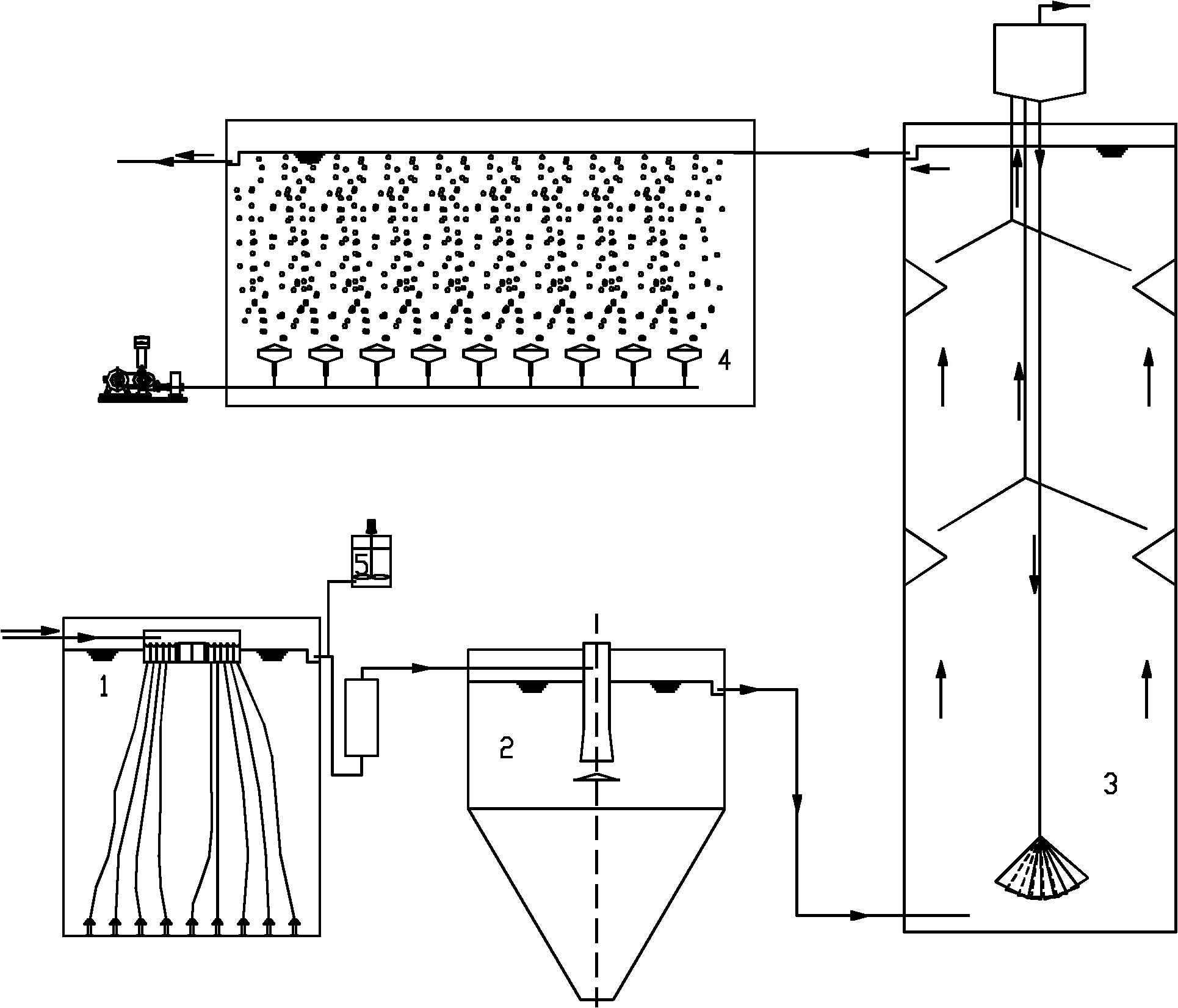

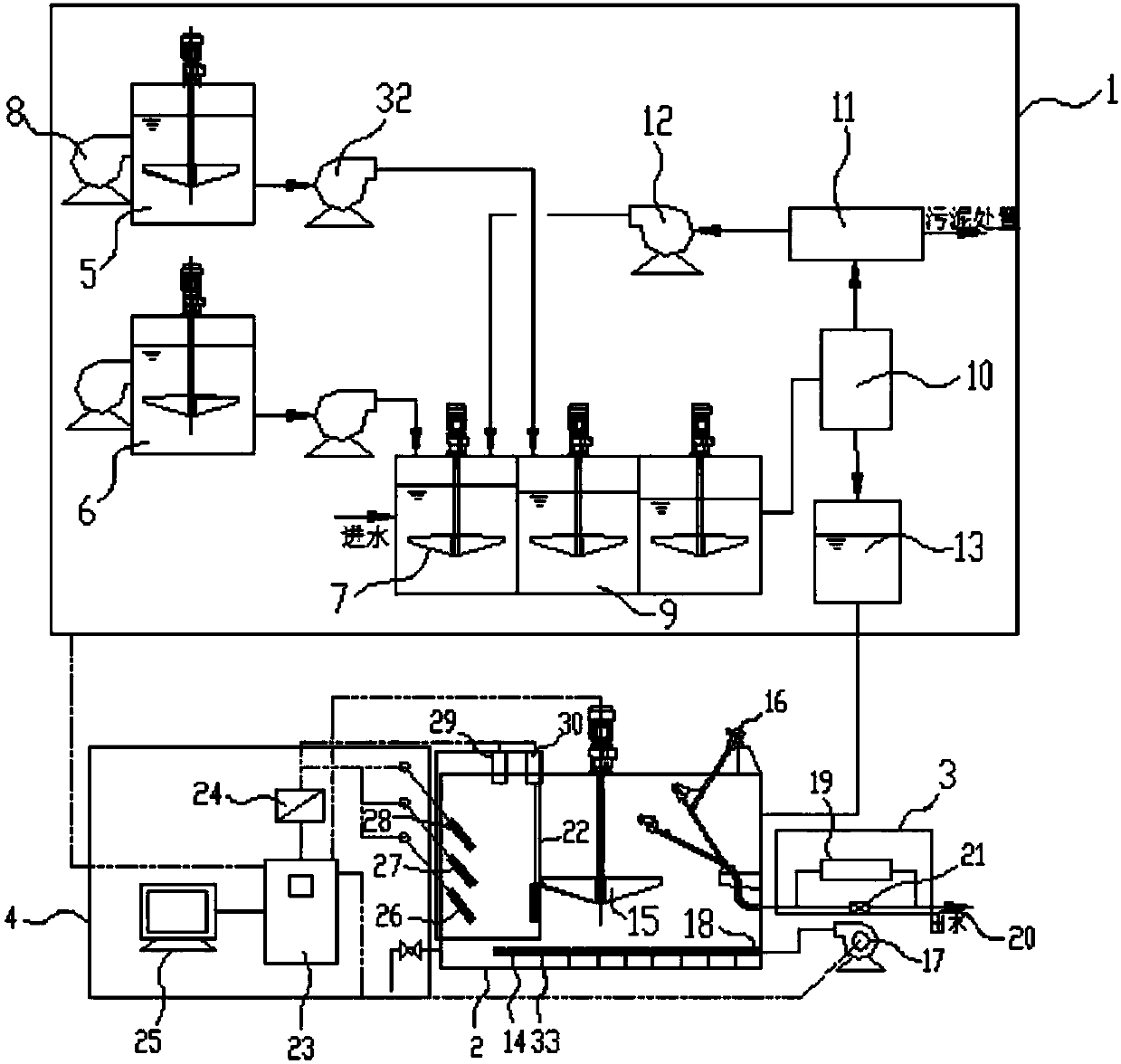

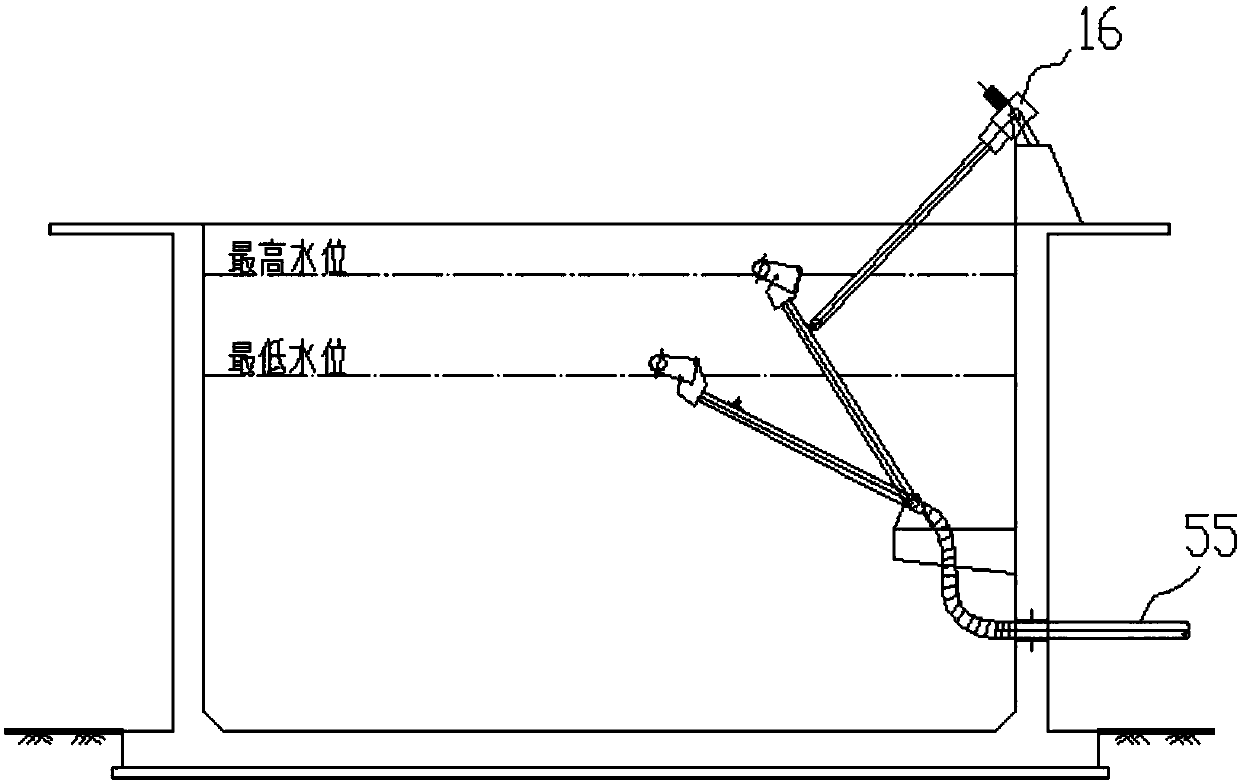

Wastewater treatment process based on combination of super magnetic separation and SBR (Styrene Butadiene Rubber) technique

PendingCN106698851ASmall footprintIncrease operating loadWater treatment parameter controlWater/sewage treatment by irradiationWater dischargeSludge

The invention discloses a wastewater treatment process based on combination of super magnetic separation and an SBR (Styrene Butadiene Rubber) technique. In the wastewater treatment process, a super magnetic separation system, an SBR system, an ultraviolet sterilization system and a self-control system are included, wherein the self-control system is connected with the super magnetic separation system, the SBR system and the ultraviolet sterilization system; the super magnetic separation system comprises a super magnetic separator, a magnetic seed recycling system, a magnetic seed pump and a water outlet pool; water feed, aeration, sedimentation, water discharge and sludge discharge are implemented in sequence in an SBR pool, organic matter degradation and nitrogen and phosphorus removal are effectively implemented in the SBR pool; the ultraviolet sterilization system comprises tubular type ultraviolet sterilization equipment and a valve; and the self-control system comprises a sensor. The wastewater treatment process has the advantages of being small in floor space, moveable, free of complex civil engineering, low in operation cost, high in automation degree, easy to operate and manage and the like; due to PLC (Programmable Logic Controller) real-time control, phenomena that the water quality is affected because of insufficient aeration or sludge swelling is caused and electric energy is wasted because of too long aeration can be effectively avoided, the labor cost is low, the service life of the equipment is long, and secondary investment is small.

Owner:HANGZHOU WENYUAN ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Medical efficient traditional Chinese medicinal material crushing device

The invention discloses a medical efficient traditional Chinese medicinal material crushing device, and belongs to the technical field of medical treatment. The medical efficient traditional Chinese medicinal material crushing device comprises a crushing box, wherein a feeding hopper is fixedly connected to one end of the upper surface of the crushing box; a sealing top cover is in threaded connection with the top end of the feeding hopper; a crushing mechanism is arranged at the top end of the crushing box and comprises a driving motor; a crushing cutter is arranged at the output end of the driving motor; driven gears rotationally connected with the crushing box are arranged on the two sides of the driving motor; the output end of the driving motor is fixedly connected with driving gearsconnected with the driven gears in an engaged mode; piston cylinders are arranged on one sides of the driven gears; and the movable ends of the piston cylinders are fixedly connected with transmissionparts corresponding to the driven gears; The medical efficient traditional Chinese medicinal material crushing device provided by the invention is simple in structure, convenient to use and low in failure rate; and a filter screen is cleaned through the operation of the driving motor during use, so that the filter screen is prevented from being blocked due to continuous accumulation of materials,and the normal use of the crushing device by a user is guaranteed.

Owner:吴杭菲

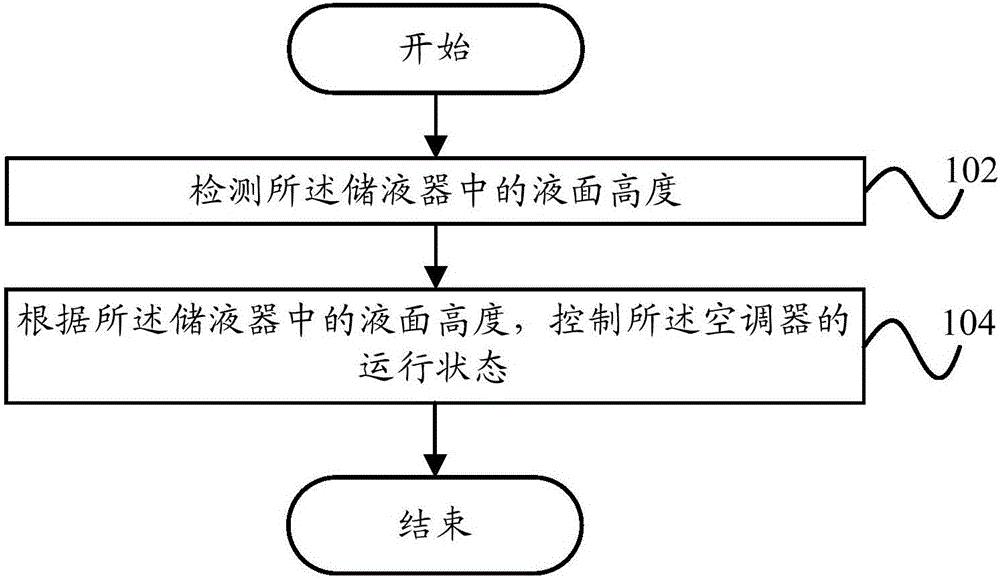

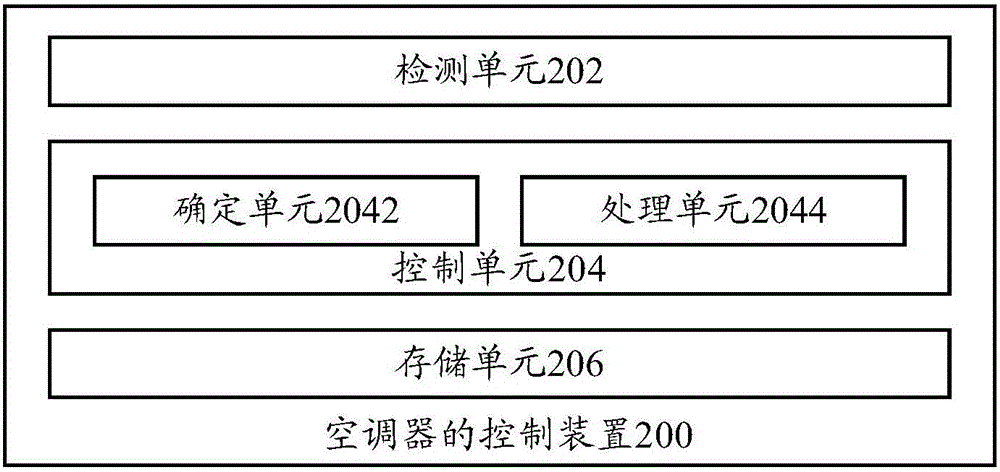

Air conditioner control method, air conditioner control device and air conditioner

ActiveCN106091510AAvoid damageReduce liquid shockRefrigeration safety arrangementControl theoryLiquid storage

The invention provides an air conditioner control method, an air conditioner control device and an air conditioner. The air conditioner comprises a liquid storage device used for storing a liquid refrigerant in the air conditioner. The air conditioner control method comprises the steps that the height of the liquid level in the liquid storage device is detected; and the running state of the air conditioner is controlled according to the height of the liquid level in the liquid storage device. By means of the technical scheme, the running state of the air conditioner can be controlled according to the height of the liquid level in the liquid storage device, and the situation that liquid impacts happen and an air conditioner system is damaged is effectively avoided.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

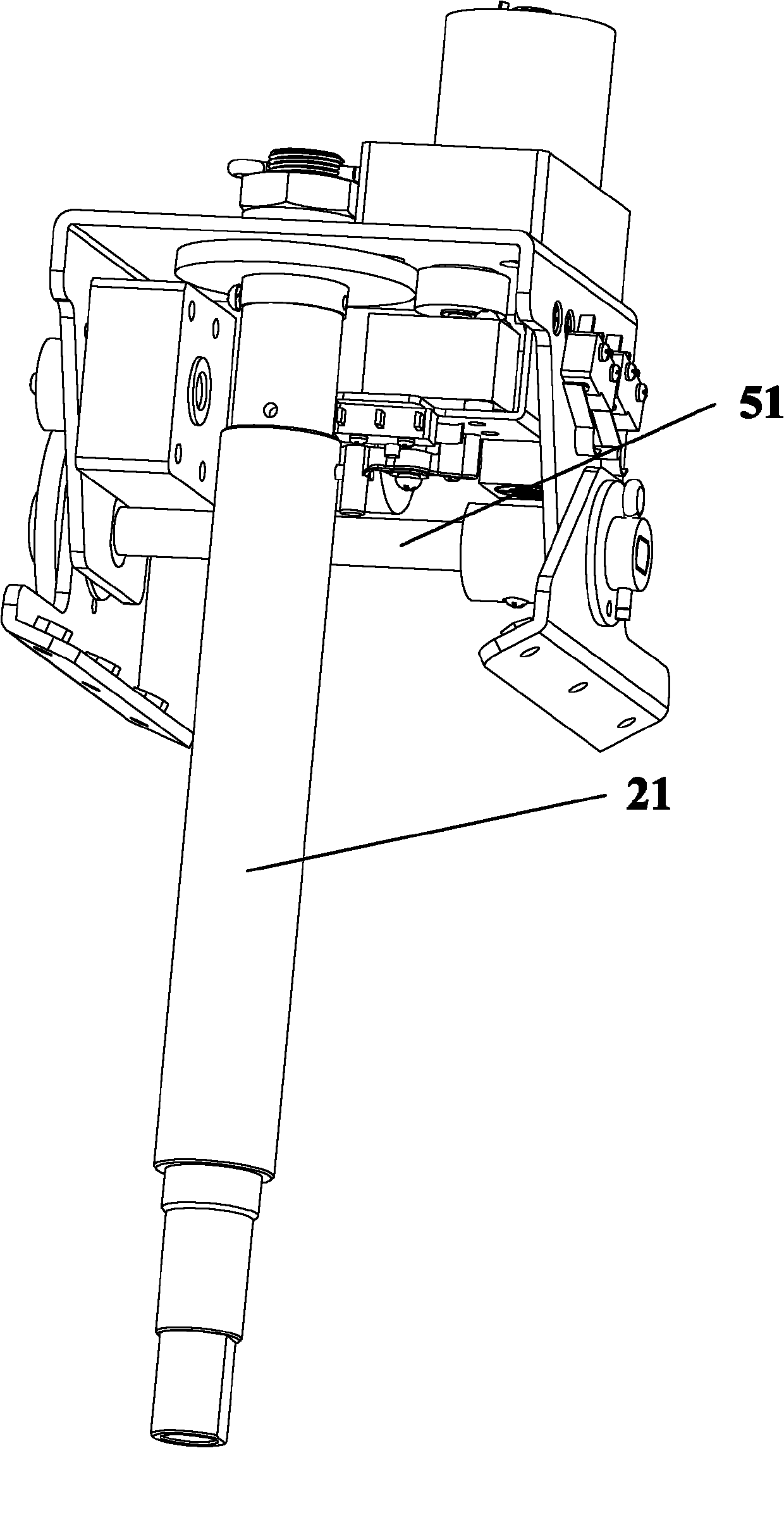

Embroidery machine head suitable for high-speed embroidery

An embroidery machine head suitable for high-speed embroidery comprises a machine shell and a needle bar frame, wherein the needle bar frame is connected to the machine shell in a sliding mode and canslide horizontally, a take-up lever, a needle bar, a presser foot shaft and a presser foot are arranged on the needle bar frame, a main shaft, a needle rod driving mechanism used for driving a needlerod, a presser foot driving mechanism used for driving the presser foot shaft and a take-up driving mechanism used for driving the take-up lever are arranged on the machine shell, and a clutch mechanism, a clutch driving mechanism, an input transmission shaft and an output transmission shaft are further arranged on the machine shell. On the basis of a traditional framework that the main shaft drives a machine head, comprehensive and perfect improvement and adaptation are conducted, so that all the components are organically combined into a whole, the universality and stability are excellent,various embroidery function requirements are met, the embroidery quality is good, and the embroidery machine head is worthy of application and popularization in the field.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Remote control device for vessel and remote control method for vessel propulsion device

ActiveUS20140303809A1Pressing load is increasedReduce increased pressing loadDigital data processing detailsPropulsion power plantsMarine engineeringRemote control

A remote control device for a vessel is installed in a vessel and remotely controls a vessel propulsion device of the vessel. The remote control device includes an operation member, an operation load applying mechanism, a control section, and an actuator. The operation member is supported rotatably around a rotation axis, and is operated by an operator to switch the shift position of a forward-reverse switching mechanism in the vessel propulsion device according to the operation angle of the operation member. The operation load applying mechanism applies an operation load to the operation member. The control section controls the operation load. The operation load applying mechanism includes an actuator that adjusts the operation load. The control section is arranged to control the actuator based on a vessel speed of the vessel.

Owner:YAMAHA MOTOR CO LTD

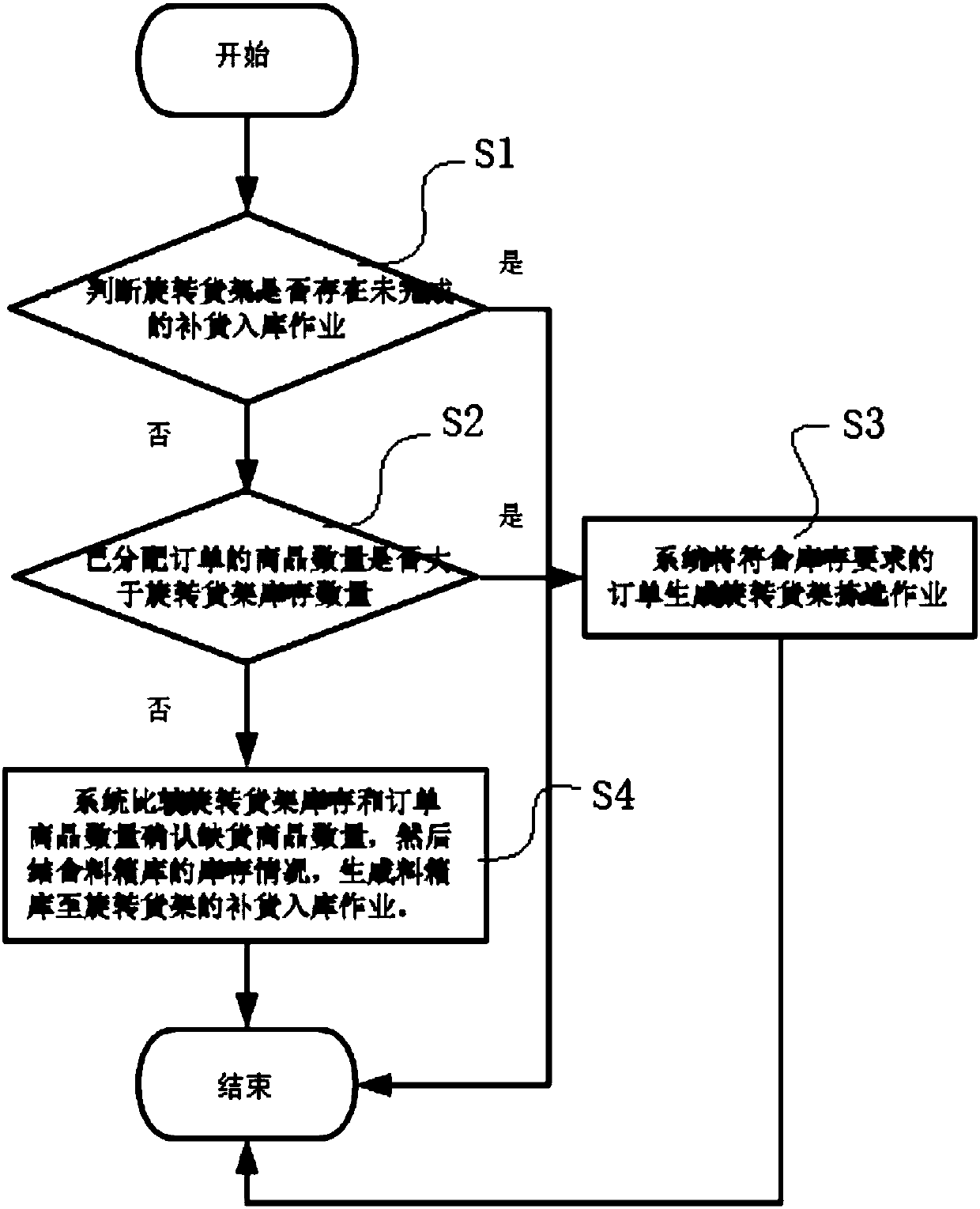

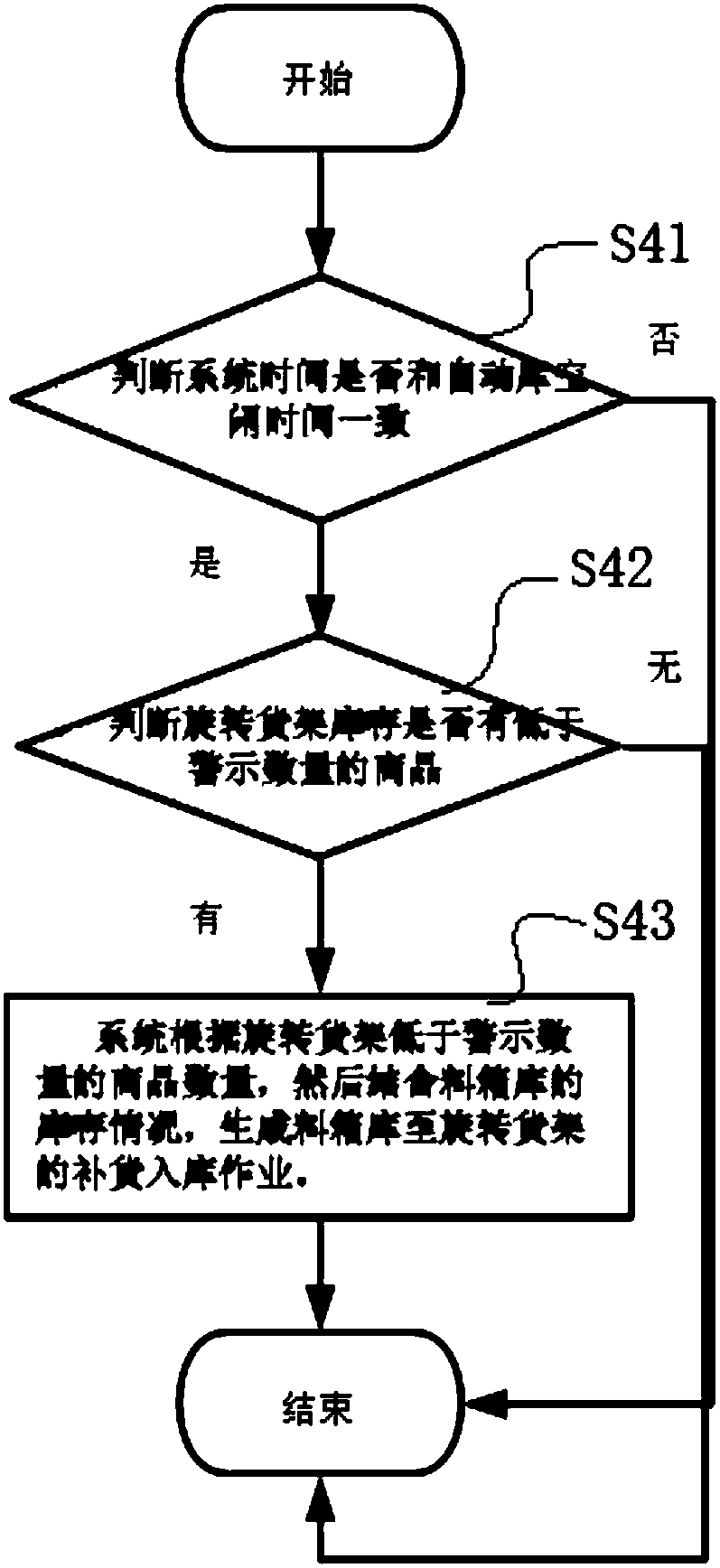

Optimization method for supplementing materials from material box warehouse to SCS rotary shelf

InactiveCN107563570AImprove work efficiencyIncrease operating loadForecastingLogisticsAutomationIndustrial engineering

The invention discloses an optimization method for supplementing materials from a material box warehouse to an SCS rotary shelf. The method comprises the steps of 1, checking whether an uncompleted material-supplementing and warehouse-entering task of a rotary shelf exists or not by a system; if not, conducting the step 2; 2, checking whether the number of unprocessed orders allocated to the rotary shelf exceeds the inventory number of the rotary shelf or not by the system; if yes, conducting the step 3; otherwise, conducting the step 4; 3, subjecting orders conforming to the rotary shelf to sorting operation by the system, sending a sorting operation indication to the automation system of the rotary shelf, judging whether the rotary shelf is in stockout condition or not by the system, automatically generating a material supplementing operation from the material box warehouse to the rotary shelf according to the stockout condition and the inventory condition of the rotary shelf when noprocessed sorting operation is available at present, and sending a material-supplementing and warehouse-entering operation instruction to the automation system of the material box warehouse. According to the invention, the condition that the material-supplementing operation and the sorting operation in the prior art cannot be conducted at the same time can be avoided. Therefore, the service of the system can be operated more flexibly according to the actual operation situation of the warehouse. The operation friendliness and the operation efficiency of the system are enhanced.

Owner:上海杜隆信息科技有限公司

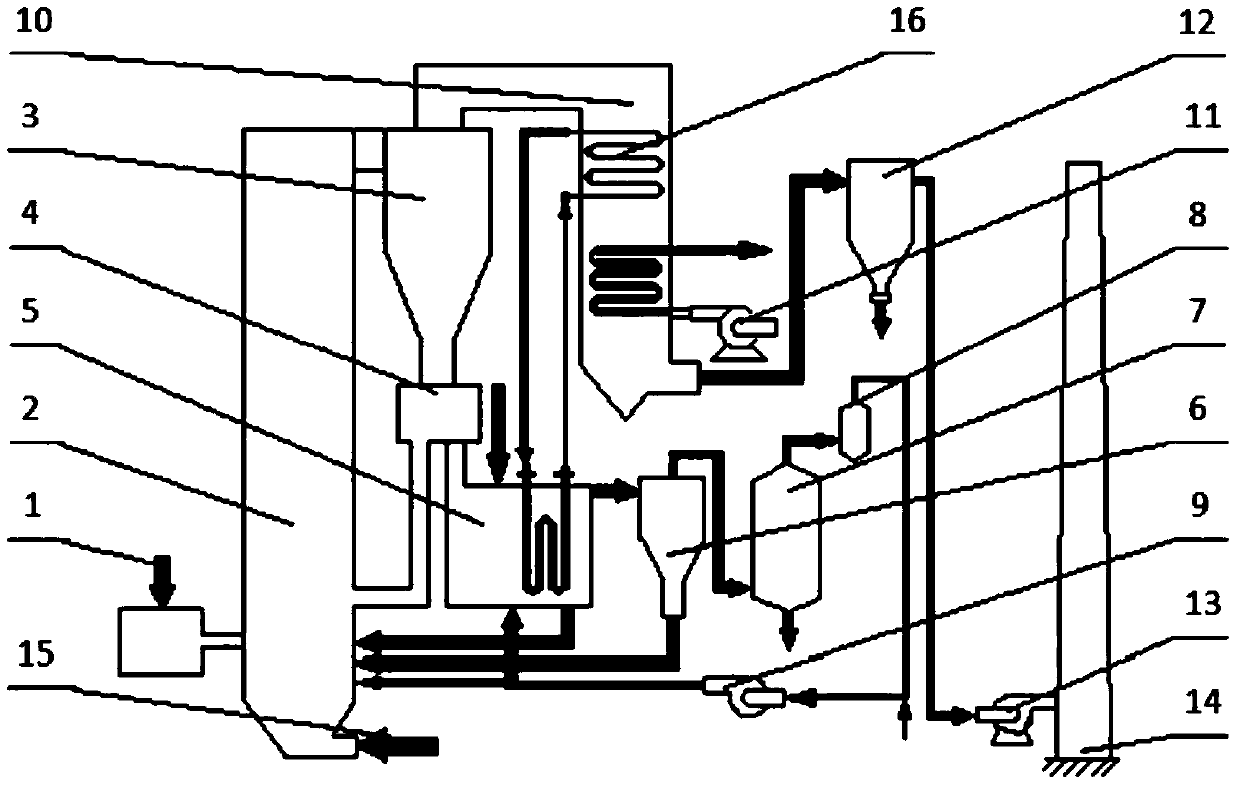

Integral sludge incineration system for circulating fluidized bed

PendingCN110748894AAffect the return effectGuaranteed pressureFluidized bed combustionIncinerator apparatusFlue gasFluidized bed

The invention discloses an integral sludge incineration system for a circulating fluidized bed, which includes an incinerator, a separator, a pneumatic distribution valve, a drying machine, a fine ashseparator, a condenser, a steam and water separator, a first blower, a tail heating surface, a dust remover, an induced draft fan and a chimney, wherein the upper part of the incinerator is connectedwith the separator and the tail heating surface respectively; the lower part of the separator is connected with the incinerator and the drying machine respectively through the pneumatic distributionvalve; dried sludge in the incinerator sequentially passes by the fine ash separator, the condenser and the steam and water separator, and then is conveyed into the incinerator under the action of thefirst blower; the tail heating surface is connected with the drying machine through circulating conduction oil, and high temperature flue gas inside the tail heating surface passes by the dust remover, and then is discharged from the chimney under the action of the induced draft fan. According to the invention, sludge drying and incineration are organically integrated, so that consumption of auxiliary fuel during sludge incineration is greatly reduced, and the drying and incineration technology is greatly simplified; and the system has the characteristics of simple operation, wide adjusting range, good control performance, low production cost, and the like.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

Movement limiting device for lamp and moving lamp

InactiveCN102707728ANot easy to damageIncrease operating loadGas-tight/water-tight arrangementsControl using feedbackEngineeringTouch switch

The invention discloses a movement limiting device for a lamp. The movement limiting device comprises a first limiting unit and a second limiting unit. The invention further provides a lamp containing the movement limiting device. The movement limiting device has the beneficial effects: when a lamp moving structure rotates to a limit position, a limiting protection device for switching off a power supply of a motor to stop the motor from running through a touch switch elastic sheet is adopted; and a gear supporting leg is arranged and is used for stopping a shifting rod or a bracket from rotating when a switch is damaged, so that the operating load of the motor is increased, the motor is stopped from rotating by using the overload protection of the motor, and the moving lamp is protected. The movement limiting device can be used for preventing the lamp from being damaged easily.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

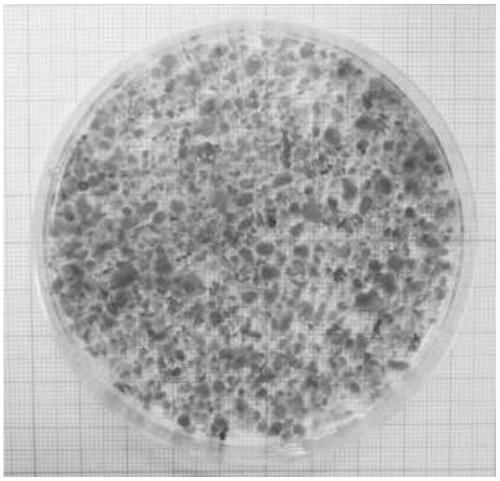

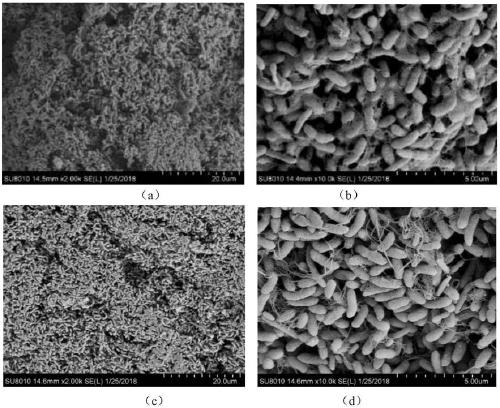

Method for culturing hydrogen autotrophic denitrification granular sludge

ActiveCN111410301AImprove denitrification activityEfficient removalWater treatment compoundsWater contaminantsSoil scienceSludge

The invention discloses a method for culturing hydrogen autotrophic denitrification granular sludge. The method comprises the following steps: 1) domesticating and culturing hydrogen autotrophic denitrification flocculent sludge; 2) inoculating the flocculent sludge cultured in the step 1) into a reactor; (3) continuously operating for 8-15 days by adopting an SBR operation mode, wherein an operation period is 90-120 minutes; and taking simulated nitrate wastewater as inflow water; 4) continuously operating for 7-15 days by adopting an SBRoperation mode, wherein the operation period is 30-40minutes; and using the simulated nitrate wastewater as inflow water. The hydrogen autotrophic denitrification granular sludge prepared by the method is ochre, mature granules are basically ellipsoids,and the interior of each mature granule is relatively compact. The granular sludge has good settling performance, the microbial biomass in the reactor can be increased, the sludge age can be increased, and the operation load of a hydrogen autotrophic denitrification process can be increased.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com