Embroidery machine head suitable for high-speed embroidery

An embroidery machine and embroidery technology, applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of complex control frame, unsatisfactory improvement effect, lack of structural versatility, etc., and achieve good operation stability, Reduce labor maintenance costs, flexible installation space selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

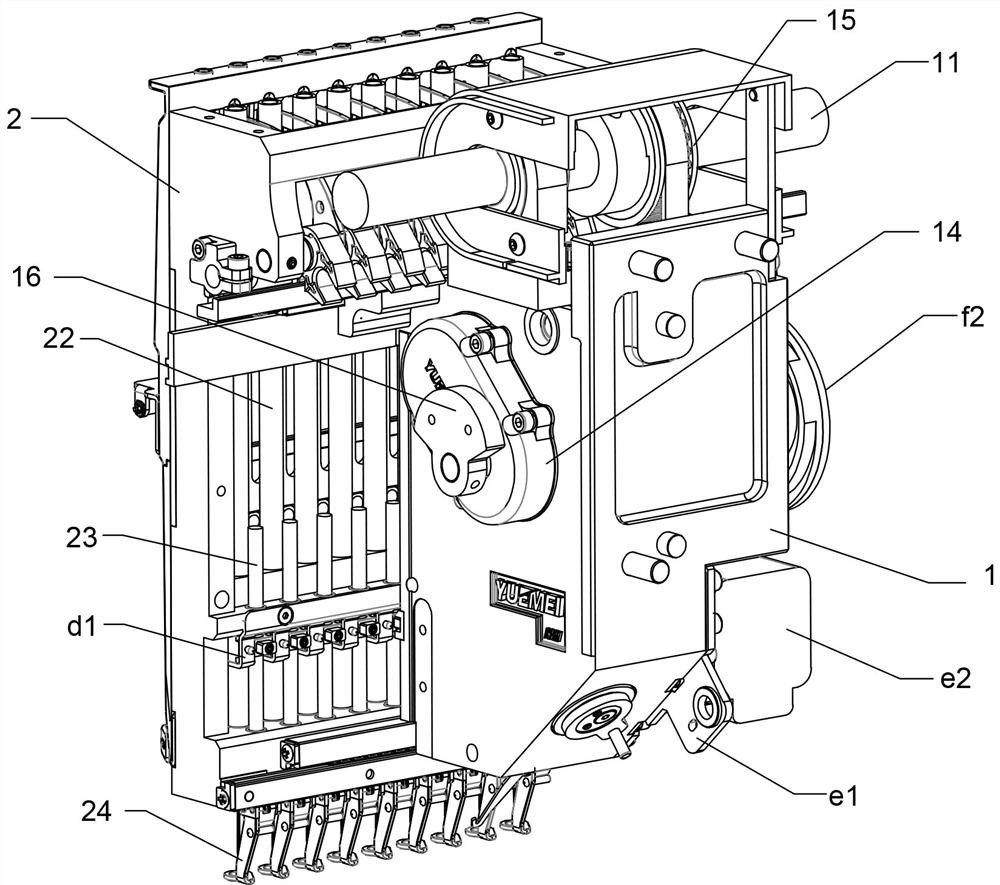

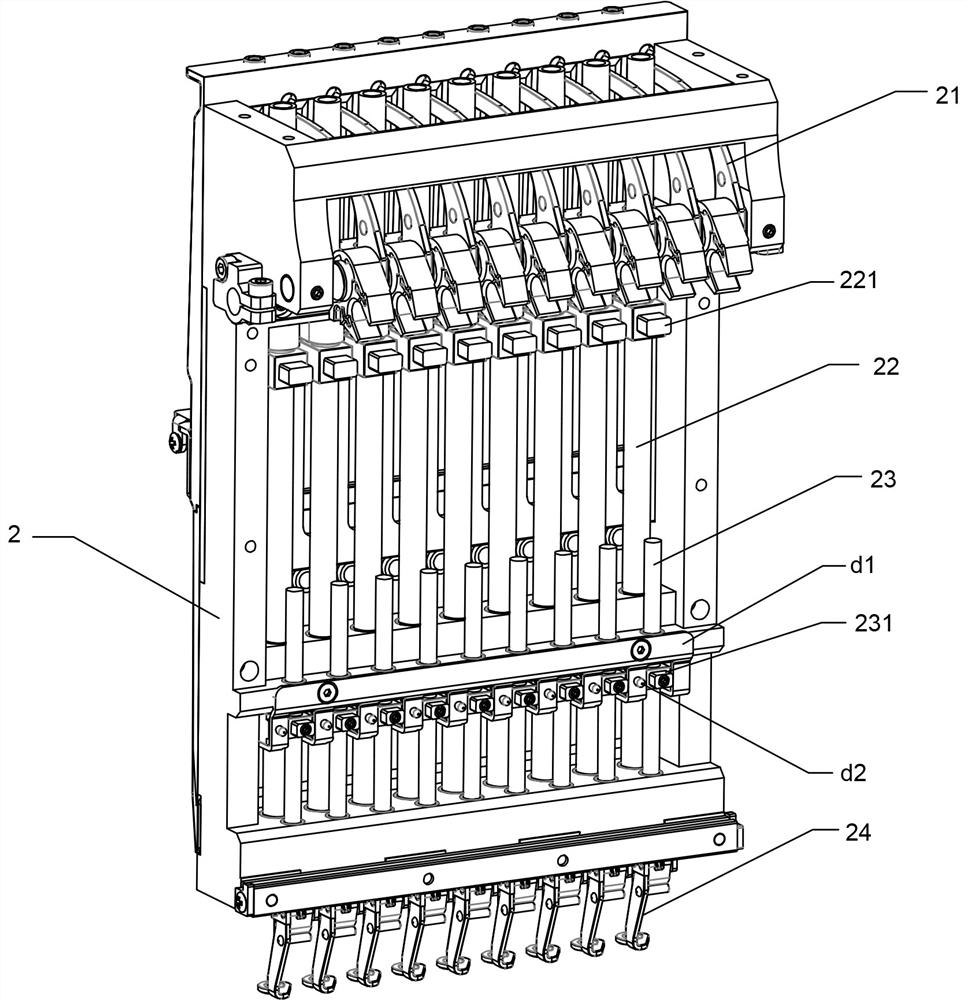

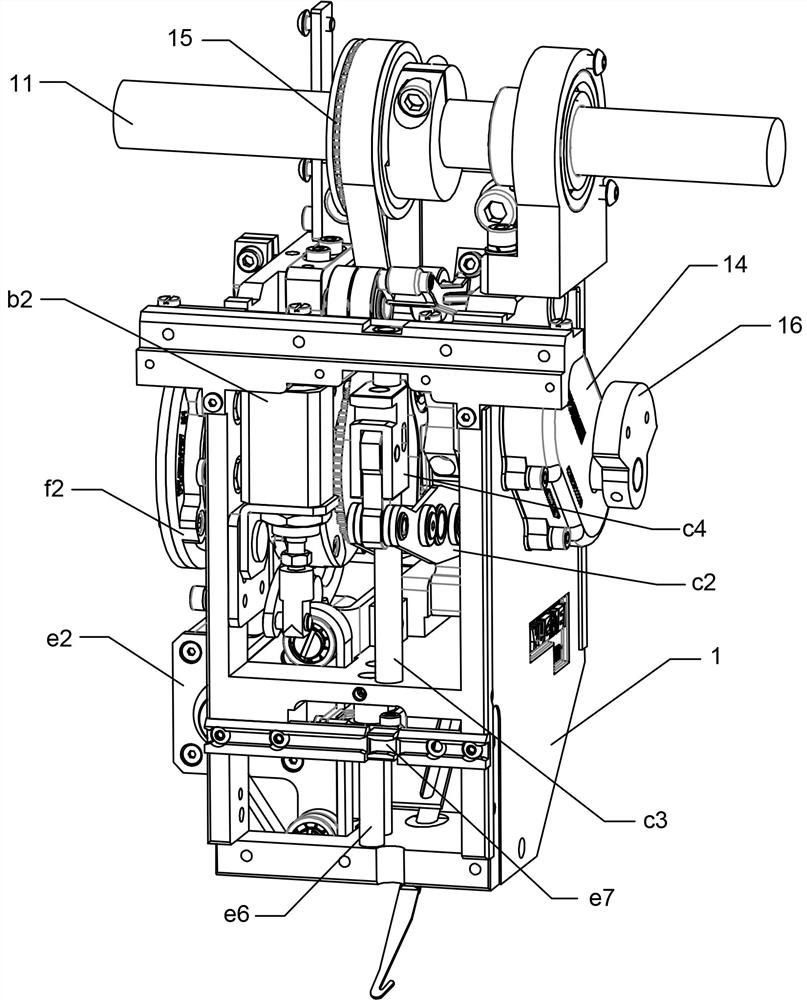

[0058] See Figure 1~Figure 5 , an embodiment of an embroidery machine head suitable for high-speed embroidery, including a casing 1 and a needle bar frame 2, the casing 1 is provided with an upper guide rail and a lower guide rail respectively with a guide rail bead group, and the needle bar frame 2 passes through The upper and lower guide rails are slidingly connected on the casing 1 and can slide horizontally. The needle bar frame 2 is provided with a thread take-up lever 21, a needle bar 22, a presser foot shaft 23 and a presser foot 24. The casing 1 is provided with a main shaft 11 for The needle bar drive mechanism for driving the needle bar 22, the presser foot drive mechanism for driving the presser foot shaft 23, the thread take-up drive mechanism for driving the thread take-up lever 21 and the thread catcher 17 for thread hooking. The casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com