Patents

Literature

41results about How to "Good running stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

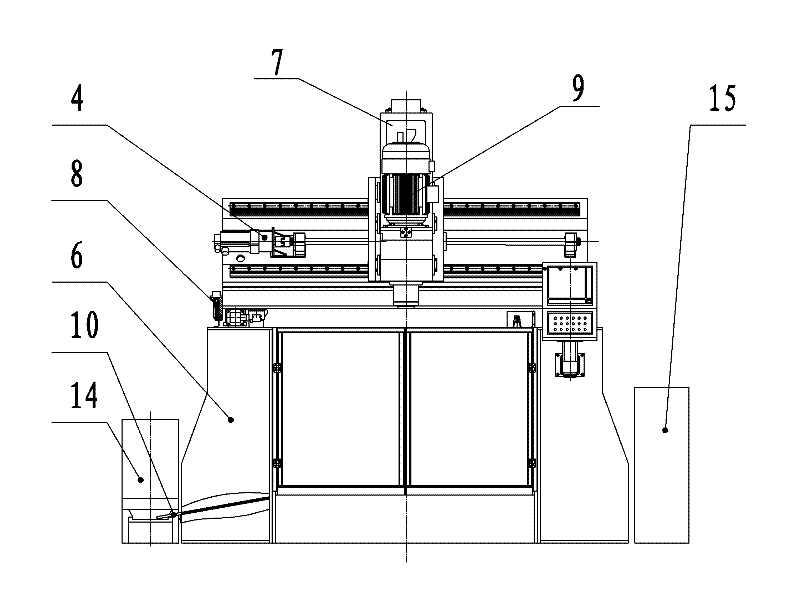

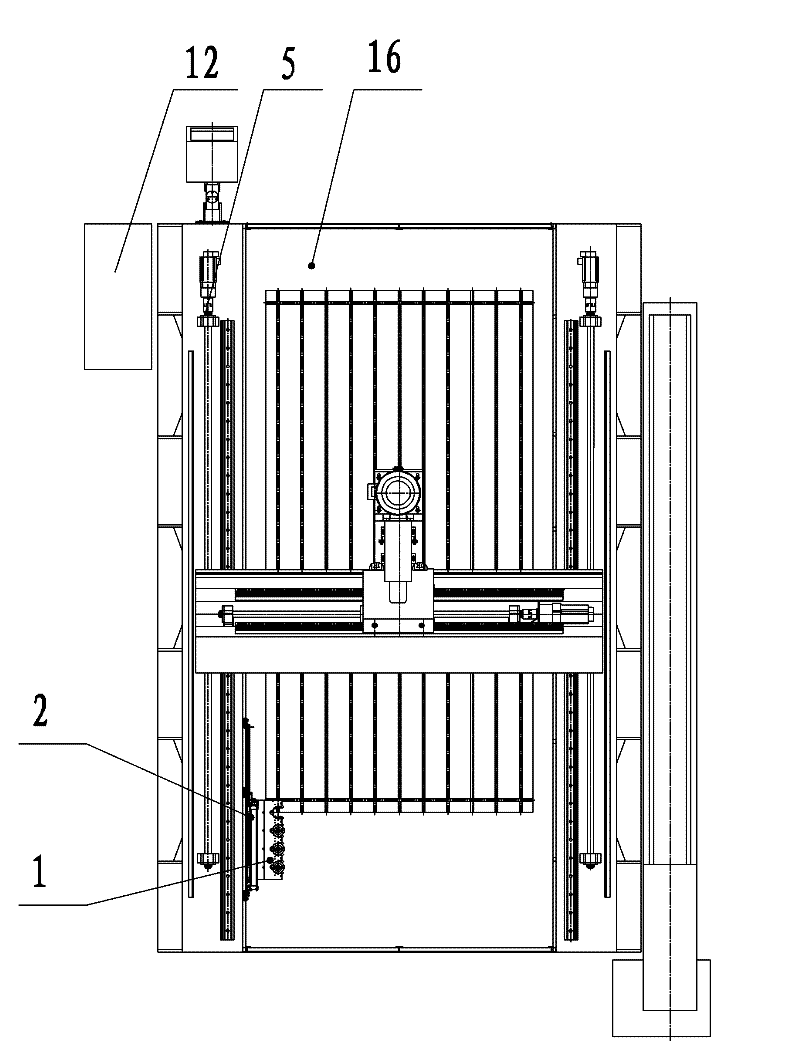

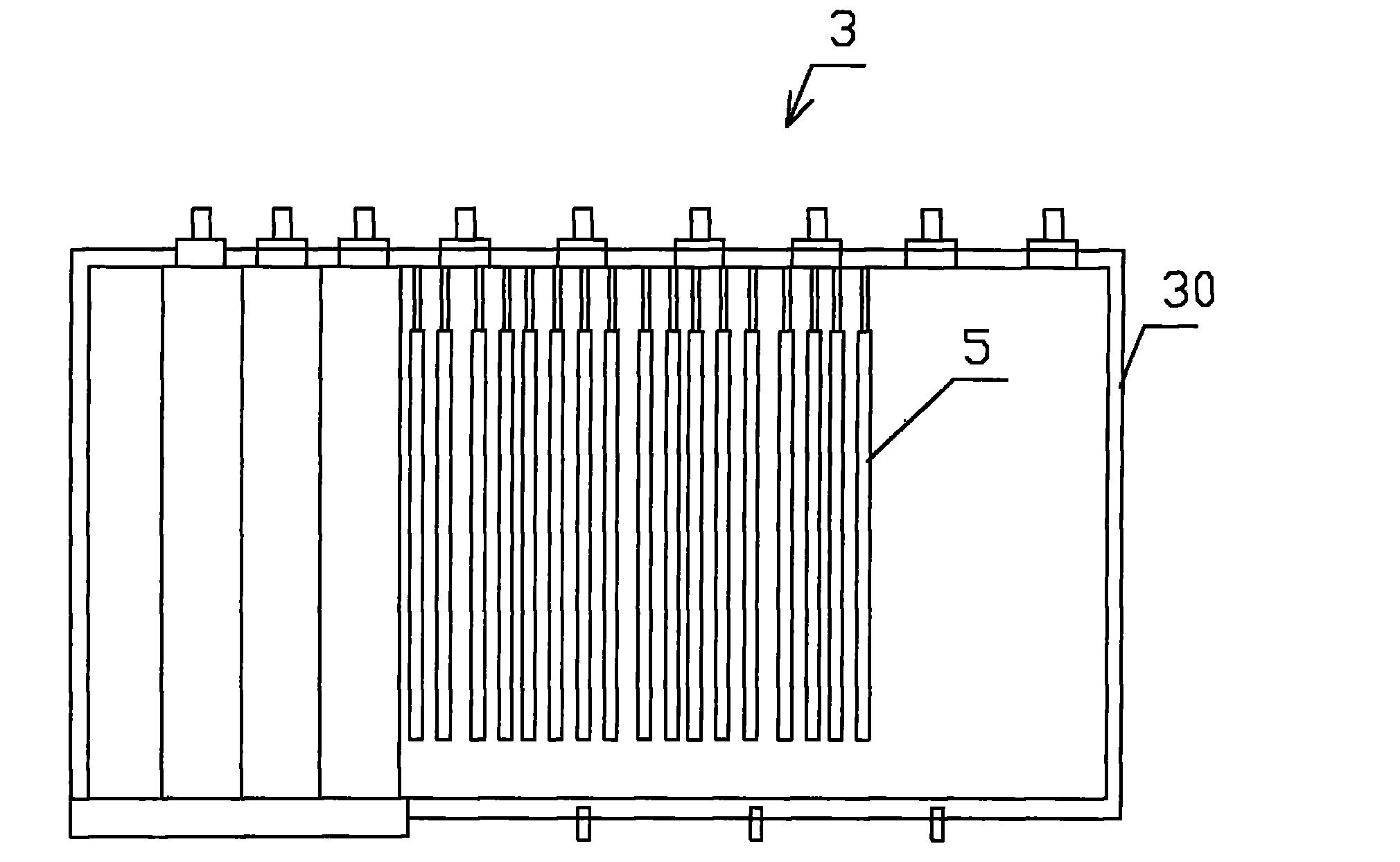

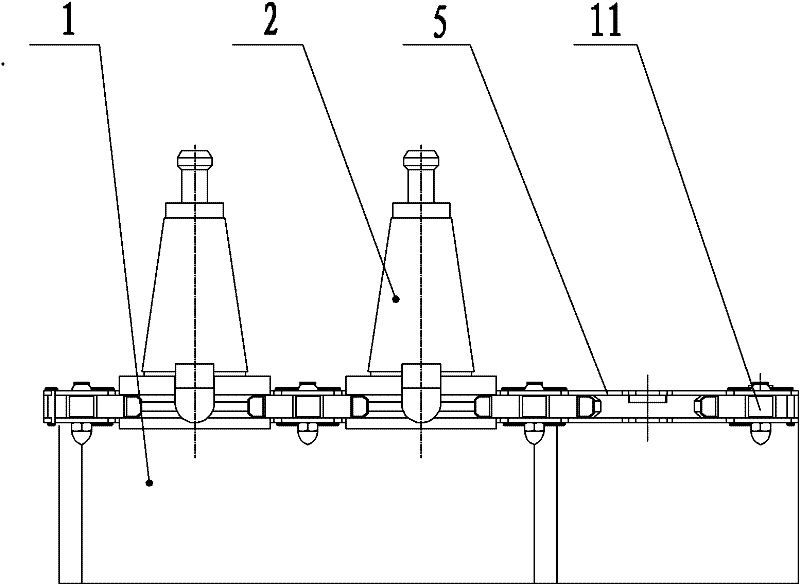

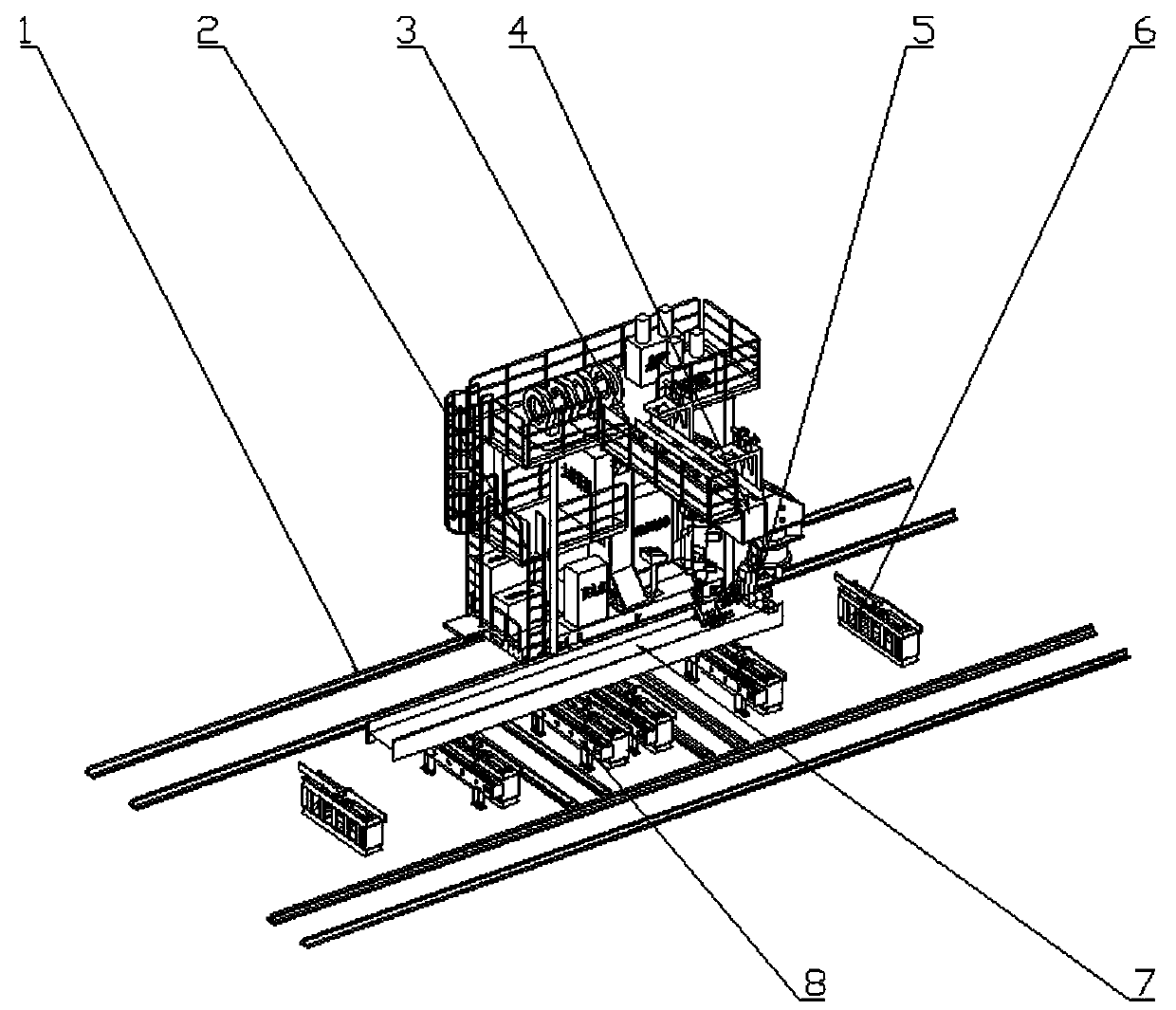

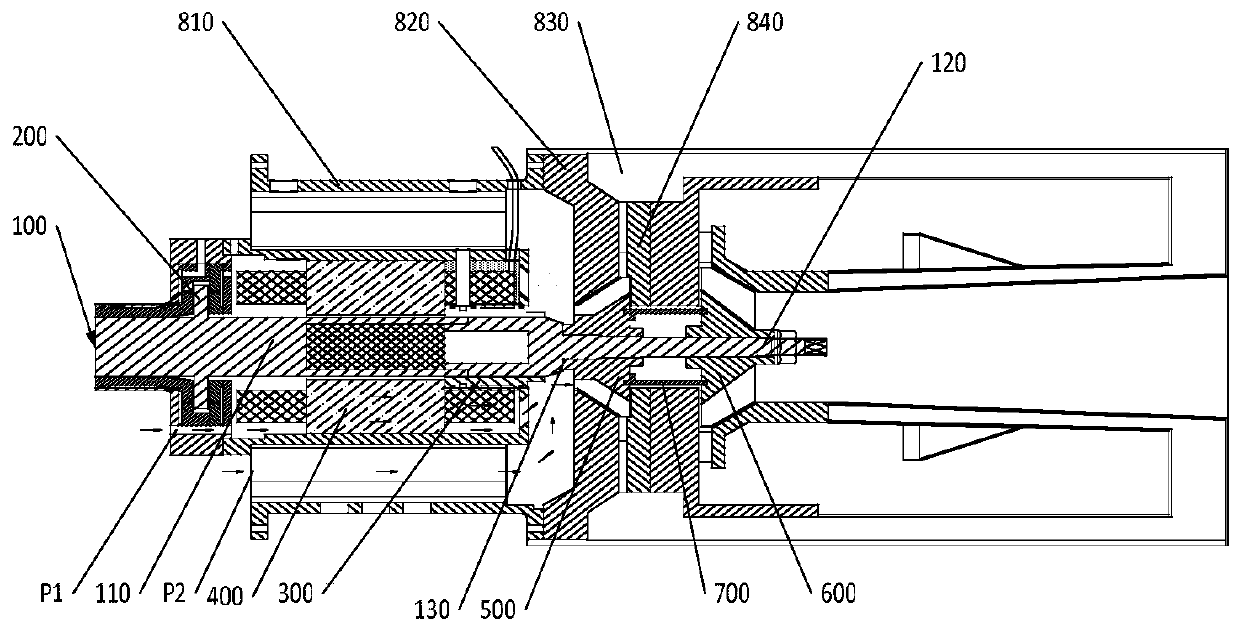

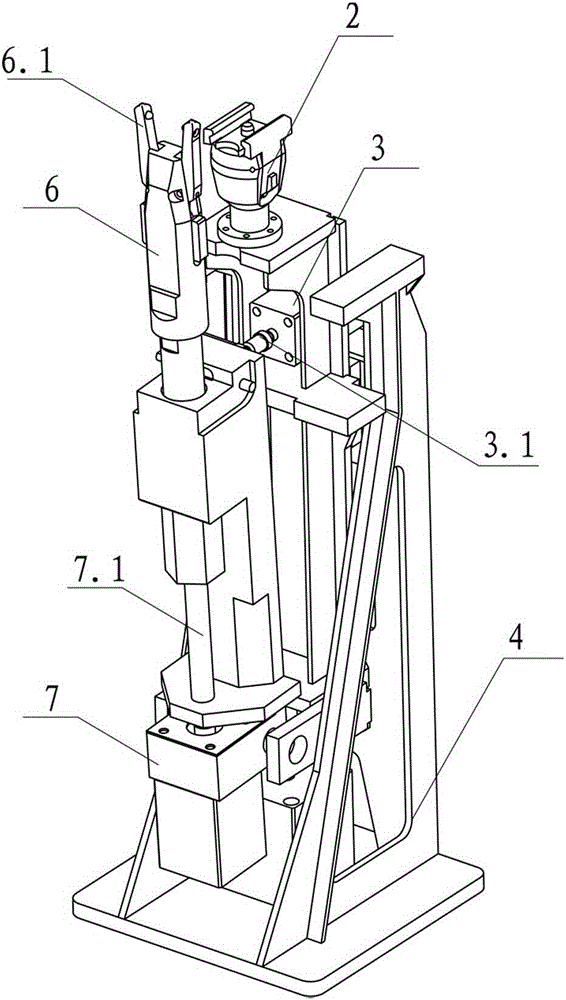

Numerical control milling and drilling machine

InactiveCN102189405AReasonable craftsmanshipGood running stabilityFeeding apparatusOther manufacturing equipments/toolsBeam transmissionEngineering

The invention relates to a numerical control milling and drilling machine. A worktable is fixedly arranged on a welding frame structure; a beam transmission structure is arranged on the welding frame structure on the left and right sides of the worktable and is provided with a beam oblique installation surface structure; the beam oblique installation surface structure is fixedly provided with a hydraulic system, is provided with a transverse transmission mechanism and is slidably provided with a movable frame; a lifting structure is arranged on the movable frame and is provided with a spindletransmission structure; the beam oblique installation surface structure is provided with a hydraulic locking structure; and the welding frame structure is fixedly provided with a locking strip, is provided with a tool magazine mechanism and a tool magazine feeding mechanism, and is fixedly provided with a dust falling plate, a numerical control operating system and an electric control cabinet. The machine can ensure the quickness and accuracy of milling and drilling and brings great convenience to an operator, and the automatic degree of the machine is improved.

Owner:WUXI HUALIAN PRECISION MACHINERY

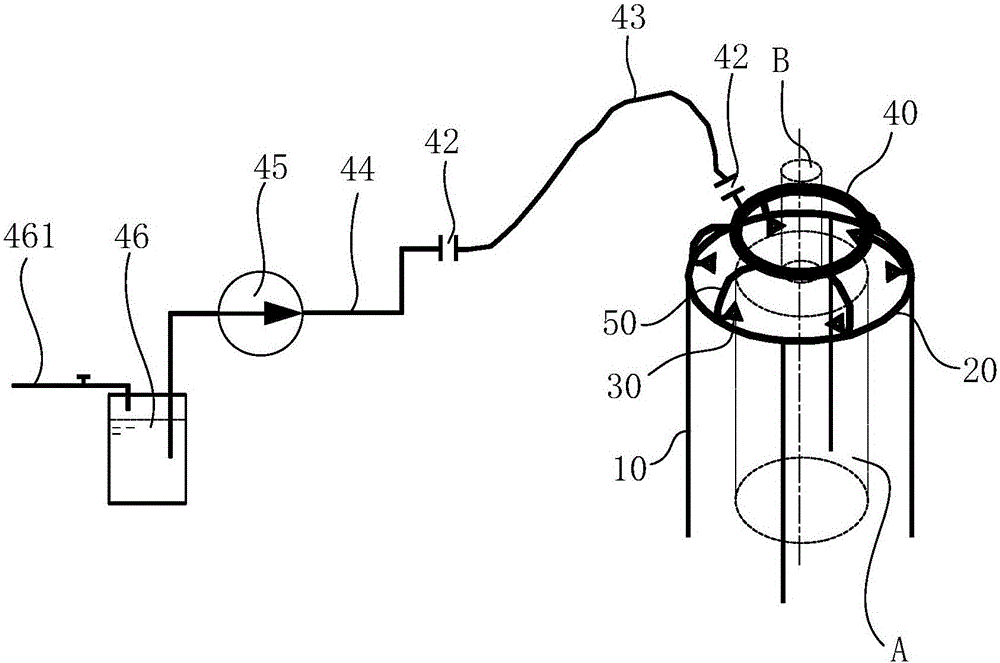

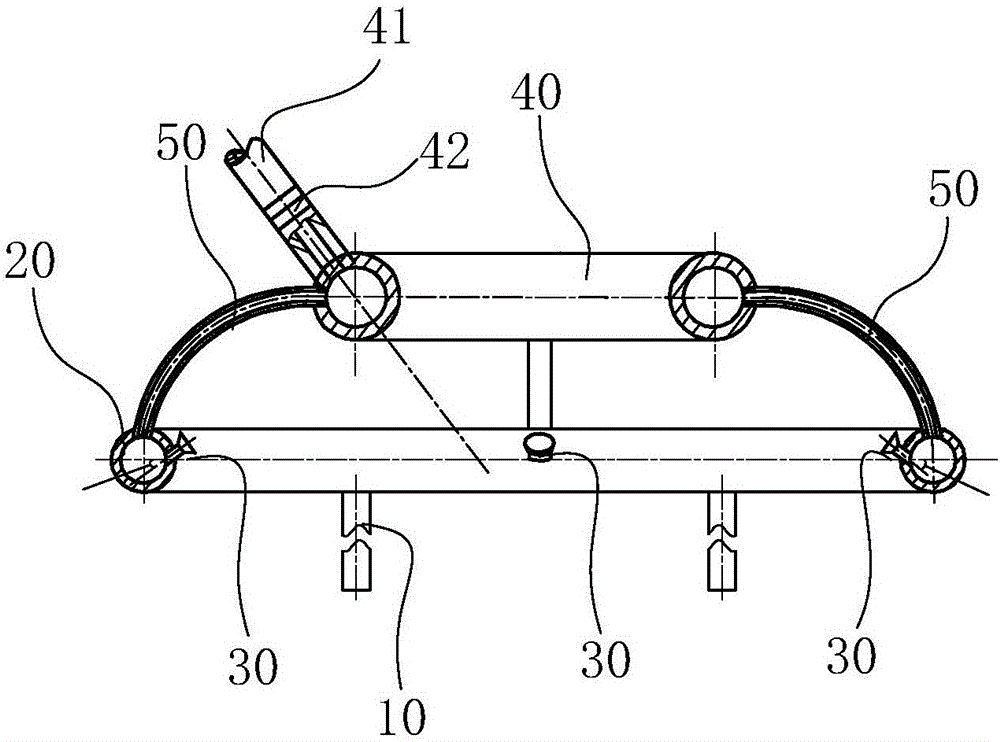

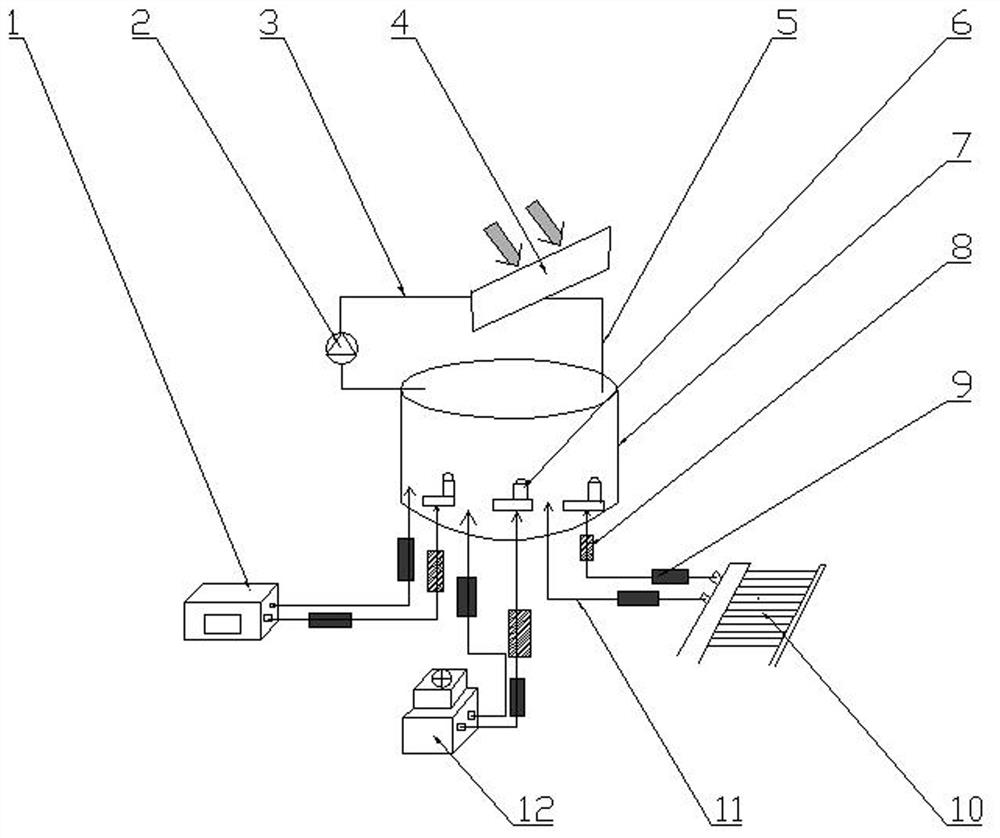

High-temperature cylindrical compression member test spray cooling system

InactiveCN106840844AGood running stabilityUniform water flowStrength propertiesSpray nozzleEngineering

The invention relates to a high-temperature cylindrical compression member test spray cooling system, which comprises a metal support arranged around a cylindrical compression member, an annular secondary water distribution pipe is arranged on the metal support, the whole annular secondary water distribution pipe is of a ring-shaped structure matching the profile of the cylindrical compression member, the annulus of the annular secondary water distribution pipe is horizontal and is arranged coaxially with the cylindrical compression member, a plurality of cooling water nozzles are distributed at intervals along the circumference of the annular secondary water distribution pipe, and the spraying directions of the cooling water nozzles point to the center of the annulus of the annular secondary water distribution pipe and are obliquely upward. The operational stability of the high-temperature cylindrical compression member test spray cooling system is good, no straying and spattering phenomena of water flow occur in the process of a test, almost no deviating flow is produced along the circumferential surface of the cylindrical compression member, and therefore, the cooling effect on the high-temperature cylindrical compression member is good. The high-temperature cylindrical compression member test spray cooling system has the characteristics of simple overall structure, small size, light weight and flexibility and convenience in assembly and disassembly.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

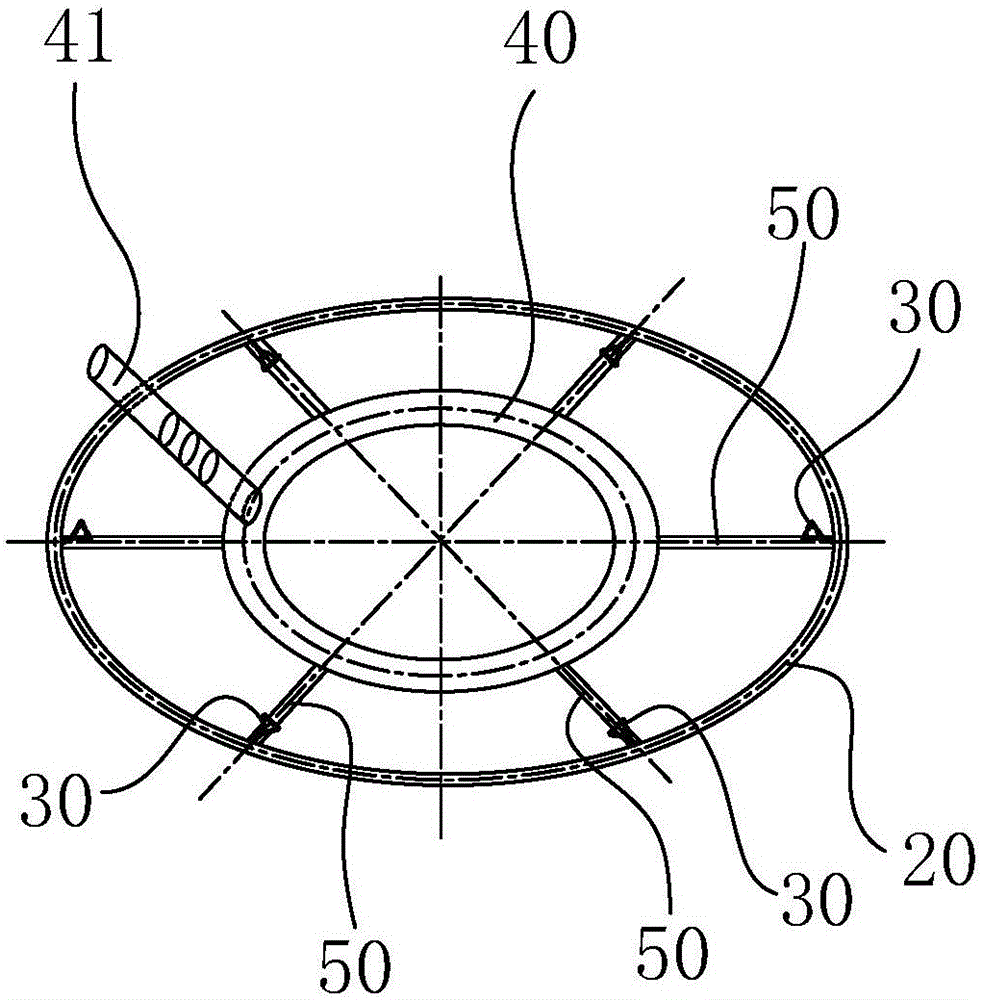

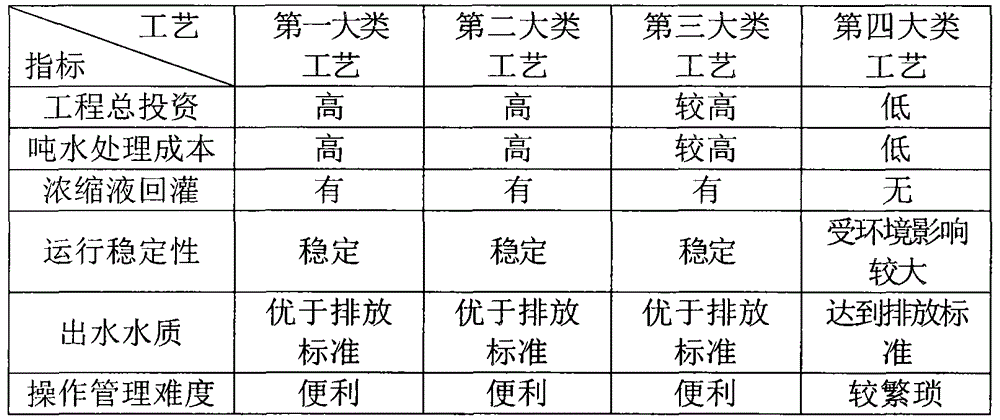

Landfill leachate treatment method

InactiveCN105060607AReduce processing costsGood running stabilityMultistage water/sewage treatmentChemistryAmmonia adsorption

The invention relates to a landfill leachate treatment method. The landfill leachate treatment method comprises following steps in sequence: pretreatment comprising steps of flocculating sedimentation, ammonia stripping, ammonia adsorption and processes of regulating pH and adjusting the temperature of the leachate to be not lower than 15 DEG C, primary anoxic-aerobic biological treatment, primary sedimentation treatment, chemical oxidation treatment, secondary sedimentation treatment, secondary anoxic-aerobic biological treatment, tertiary sedimentation treatment and disinfection treatment. According to the landfill leachate treatment method, a physicochemical and biochemical combined treatment system is adopted based on the characteristics of the municipal solid waste landfill site leachate, so that stable and efficient operation of the whole system is guaranteed, and the landfill leachate reaches the emission standard of Standard for Pollution Control on the Landfill Site Of Municipal Solid Waste (GB16889-2008) finally.

Owner:湖南省交通科学研究院有限公司

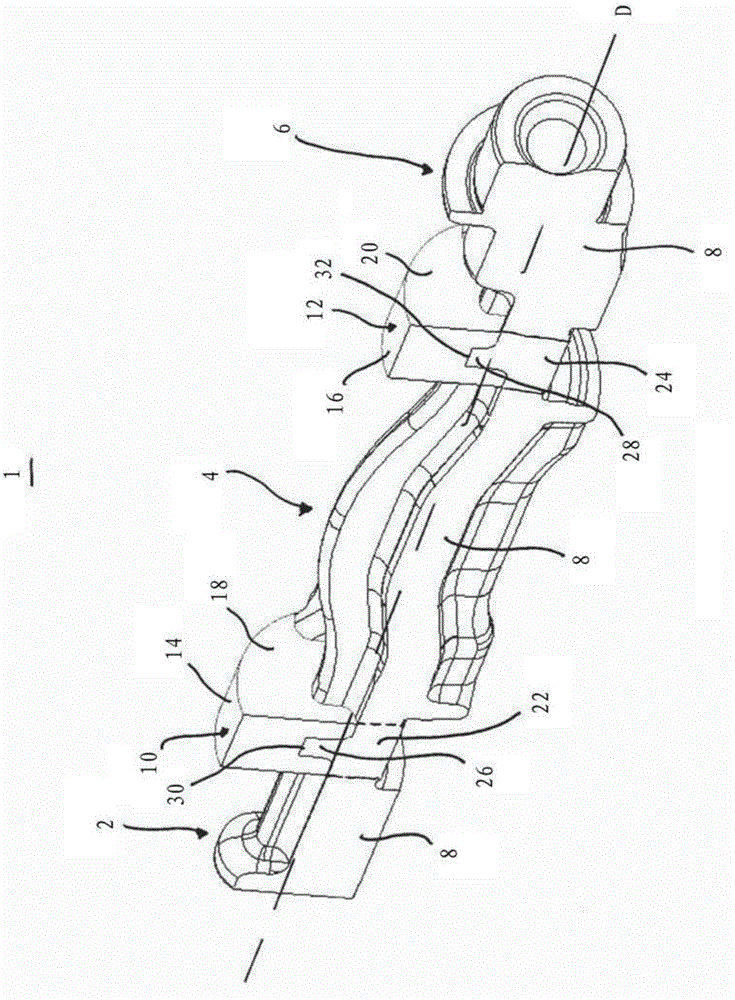

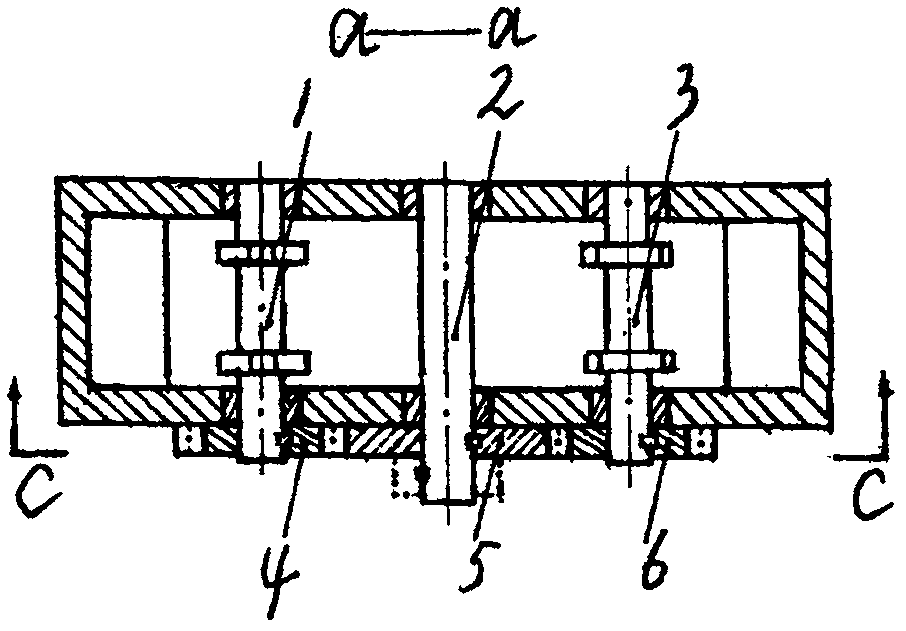

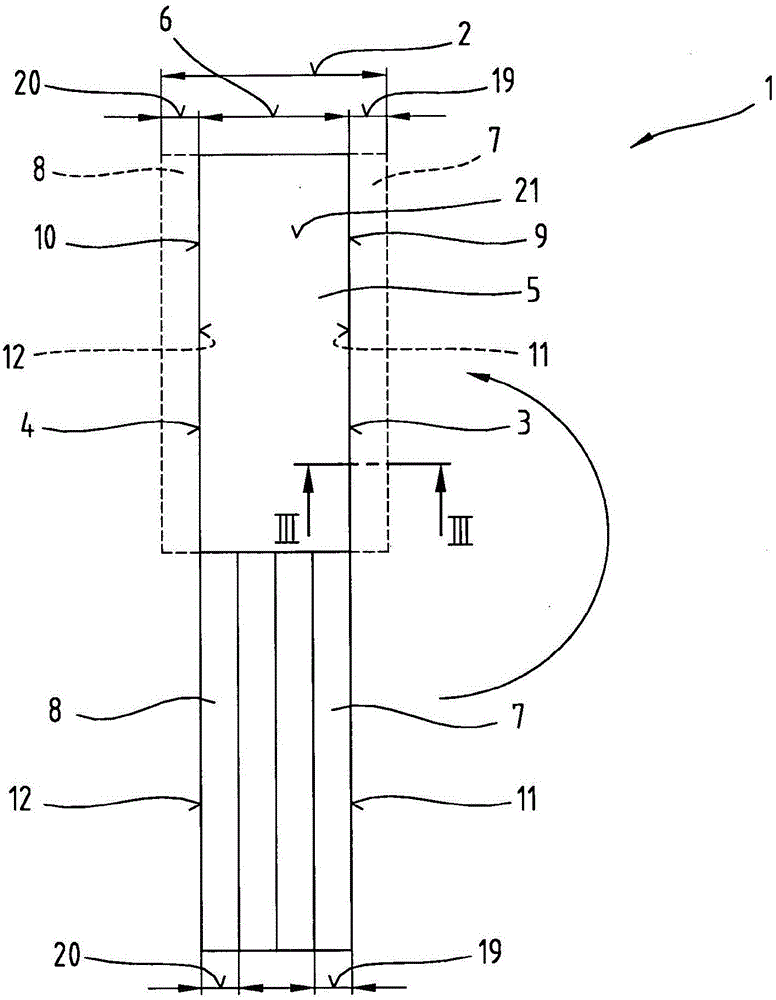

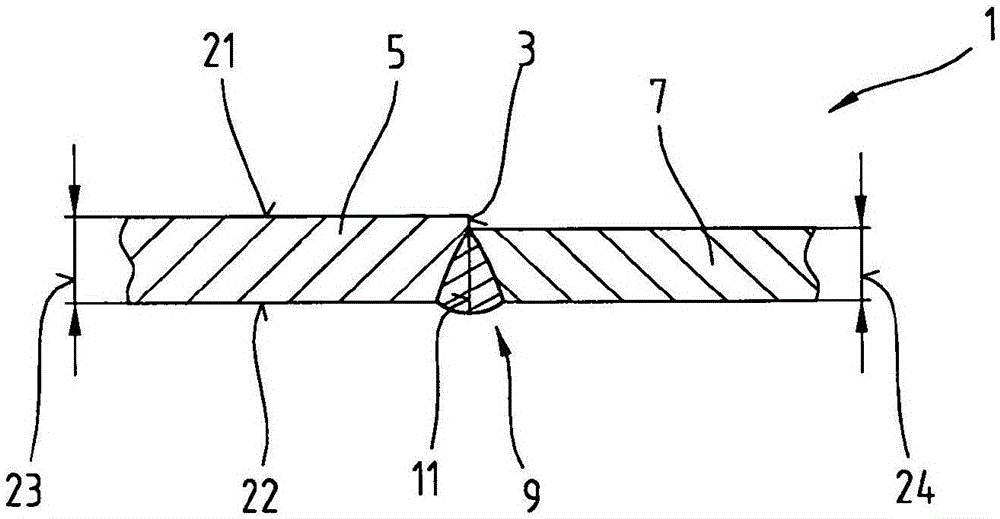

Unbalanced shaft

InactiveCN105276081AReduce susceptibility to distractionEasy to makeInertia force compensationMachines/enginesMoment of inertiaEngineering

An unbalanced shaft (1) for compensating inertial forces and / or moments of inertia for a reciprocating internal combustion engine includes at least one shaft section (2,4,6) and a bearing journal (10,12) adjacent to the at least one shaft section (2,4,6) and an unbalance mass (8) disposed on the shaft section (2,4,6). The bearing journal (10,12) is formed from at least two parts including a first solid bearing segment (18,20) and a second solid bearing segment (22,24), and a center of gravity of the shaft section (2,4,6) and the bearing journal (10,12) is eccentric to an axis of rotation (D) of the unbalanced shaft (1). The first solid bearing segment (18,20) includes a portion projecting into the second solid bearing segment and the second solid bearing segment (22,24) include a portion projecting into the first solid bearing segment such that the first and the second solid bearing segment are secured at least axially relative to each other.

Owner:AB SKF

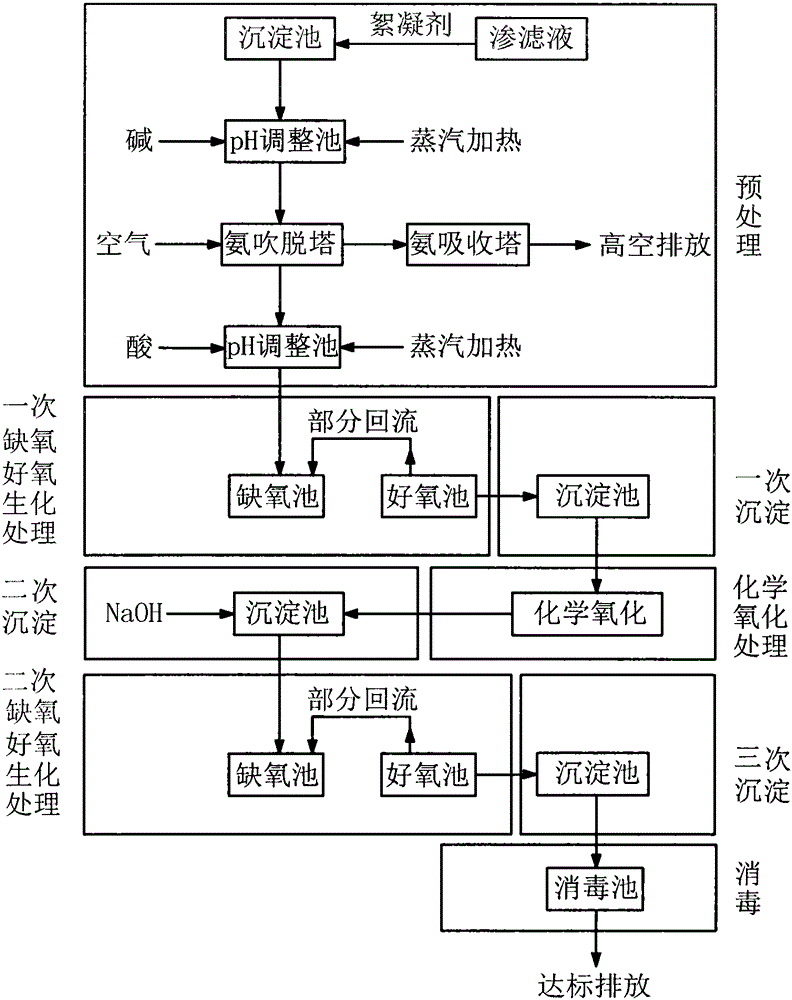

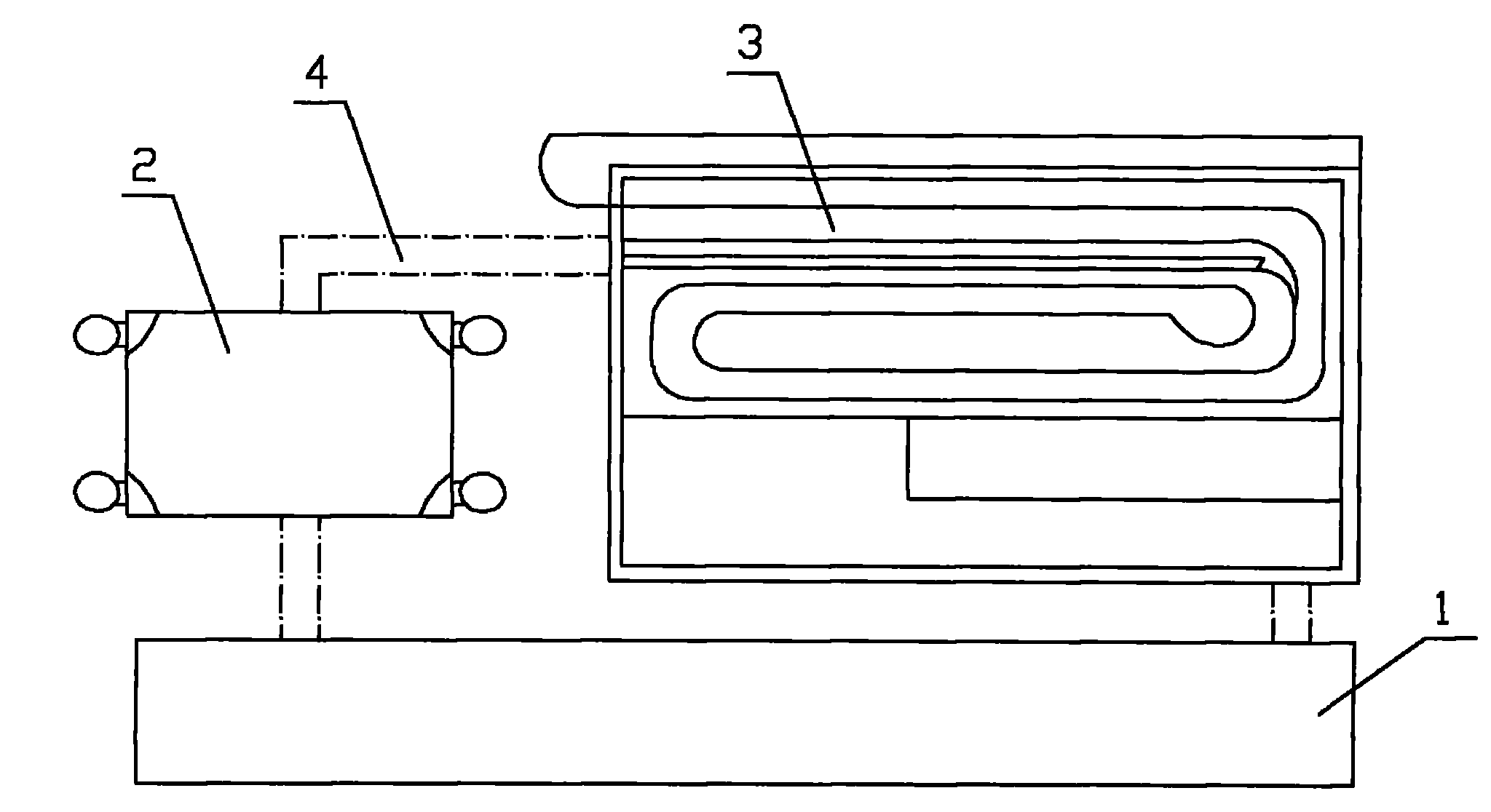

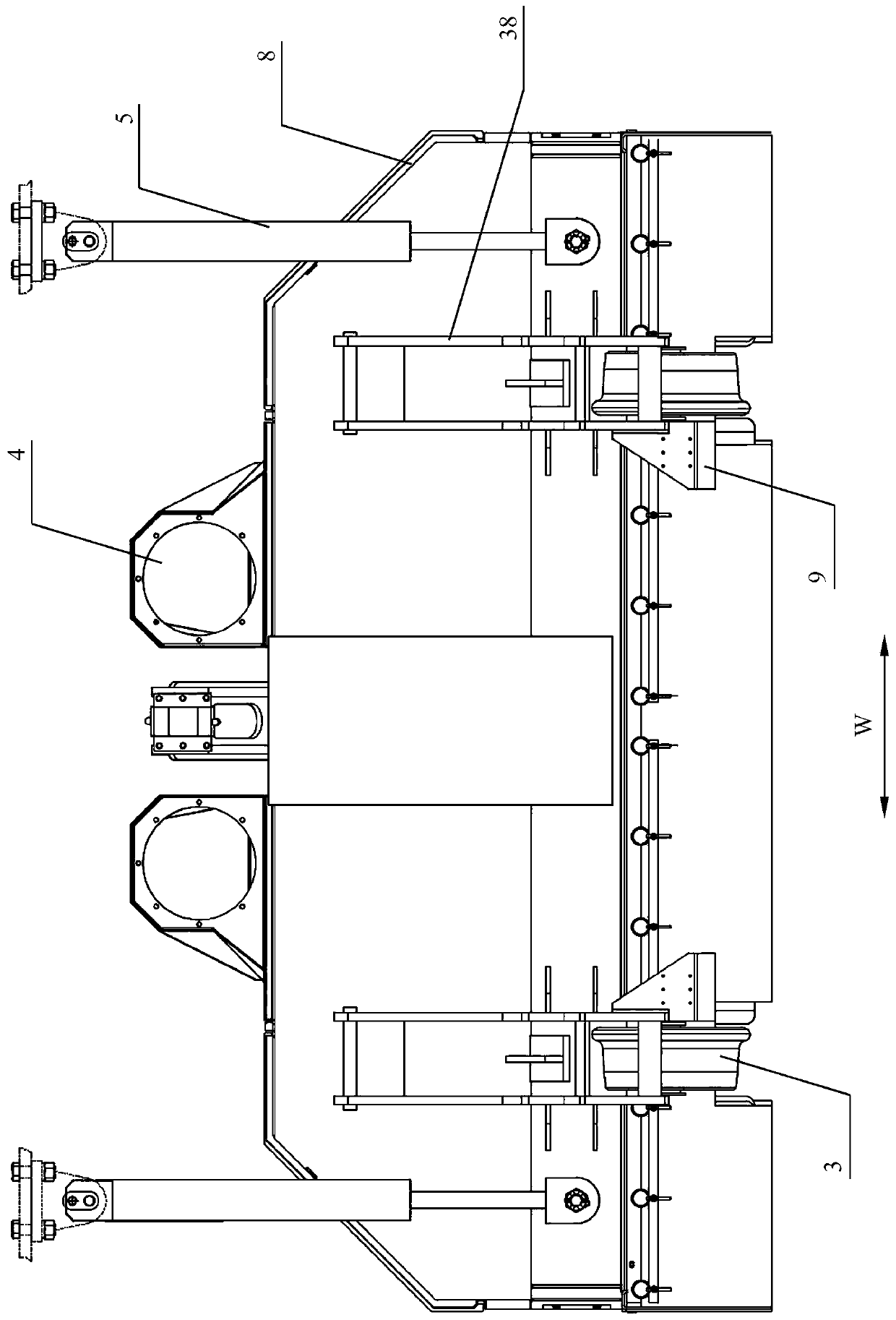

Vertical automatic coating production line of aluminum profile

InactiveCN102161022APowder evenlyGood running stabilityLiquid spraying plantsPretreated surfacesPre treatmentEngineering

The invention discloses a vertical automatic coating production line of an aluminum profile. The production line comprises pre-treatment equipment, coating equipment and drying equipment, wherein both of the pre-treatment equipment and the drying equipment are connected through a conveyer belt; a drying passage shell of the drying equipment consists of a gum sealed plate layer, an inner rock cotton layer, an air heat-isolating layer and an outer rock cotton heat-preserving layer from inside to outside; and a workpiece is vertically hung in the coating equipment and the drying equipment. Through the production line, the aluminum profile is automatically coated without human labor and is uniformly powdered; rotation is not required in work; the stability is high; and the surface layer temperature of the equipment is at most 5 DEG C more than the environment temperature.

Owner:ZHEJIANG MINGQUAN INDAL COATING

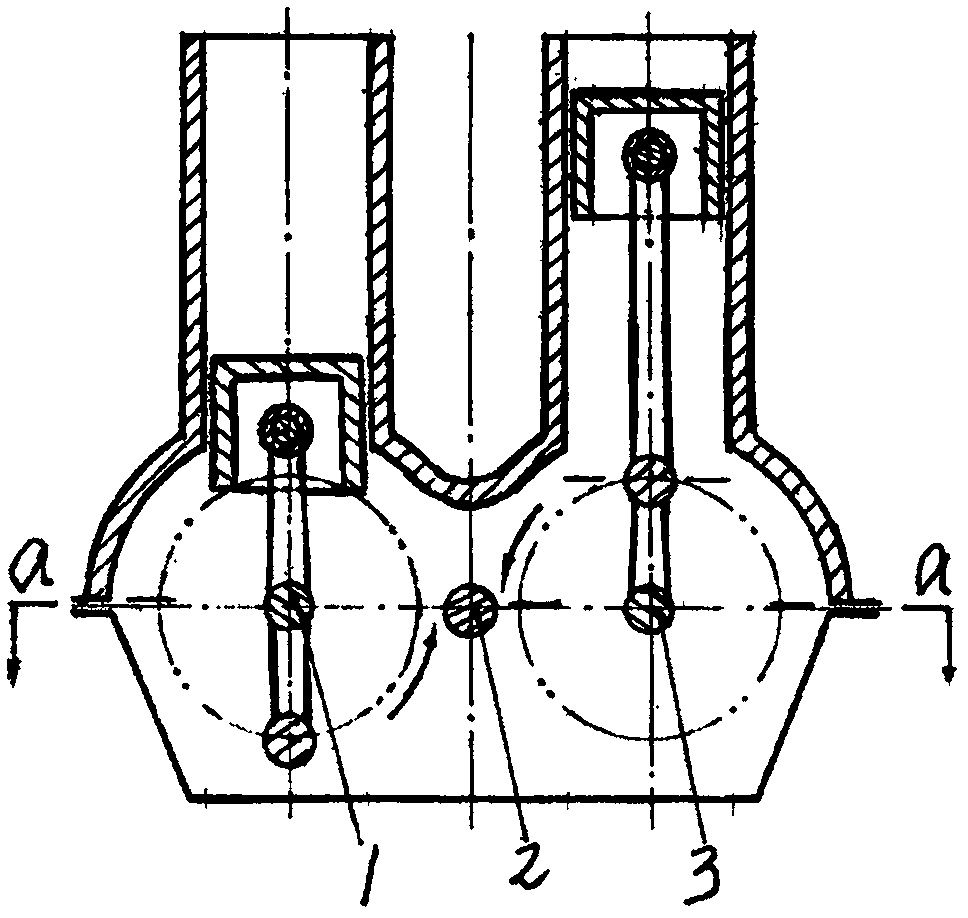

Piston reciprocating double-cylinder engine

InactiveCN107237689AIncrease the lengthMeet the requirements of the rated speedMachines/enginesLow speedEngineering

The invention discloses a piston reciprocating double-cylinder engine which is formed by paralleling L-shaped engine double cylinders, and the declared speeds of a left crankshaft (1) and a right crankshaft (2) are the same and equal to the declared speed of an existing engine; the declared speed of an output shaft (2) is the declared speed output by the engine to the outside and can be equal to, smaller than or larger than the declared speeds of the crankshafts according to the requirements of the outside; thus, the working property is optimized, the application range of the engine is enlarged, auxiliary devices additionally arranged among devices are omitted or simplified, and the cost of occupied by the auxiliary devices and the device bearing and assembly spaces are saved; meanwhile, the piston reciprocating double-cylinder engine has the advantages that the structures of the L-shaped engine double cylinders and the crankshafts are simple, the manufacturing cost is low, stability is high, the low-speed torque characteristic is good, and the total length of the V-shaped engine is small, so that the space is saved, and arrangement is facilitated; and the disadvantages that a V-shaped engine is complex in structure, high in manufacturing cost and difficult to maintain and repair, and an L-shaped engine is long, so that arrangement is difficult are overcome.

Owner:肖光宇

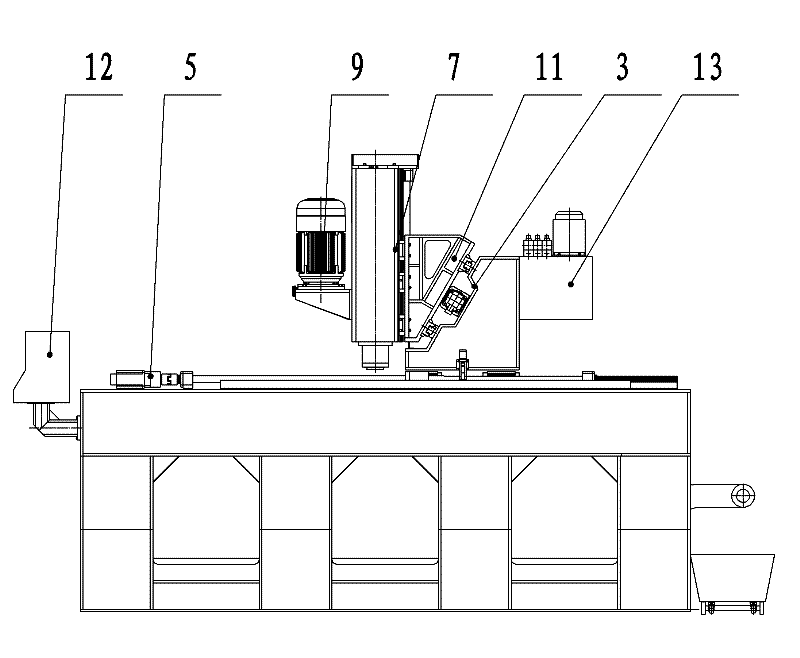

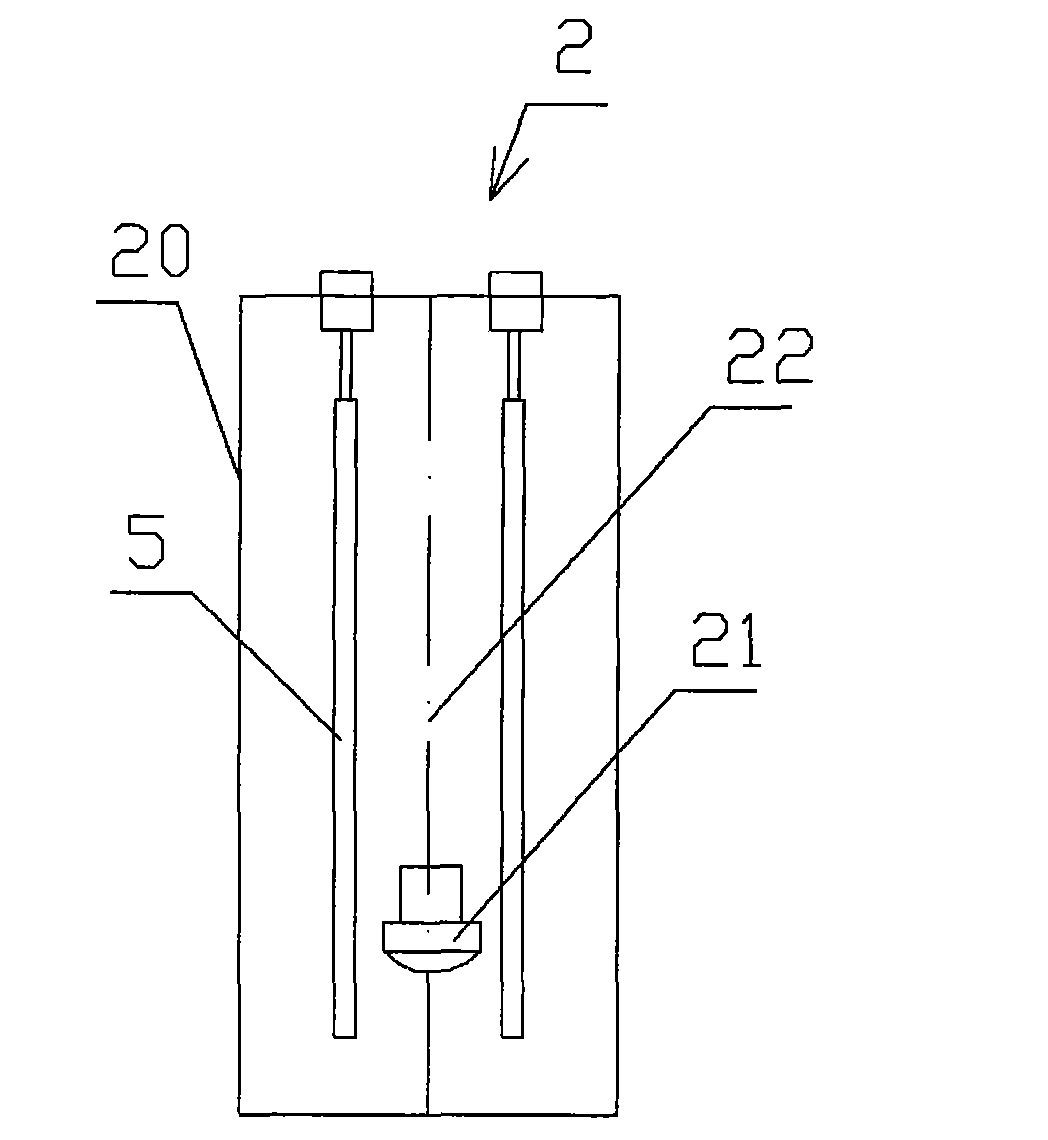

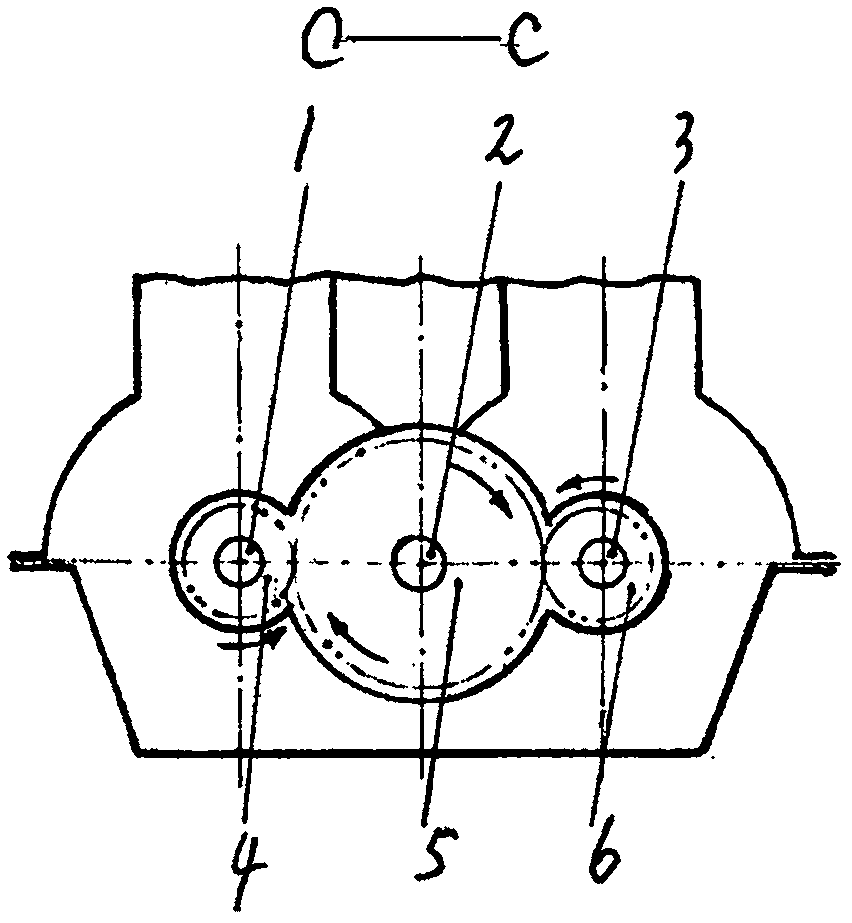

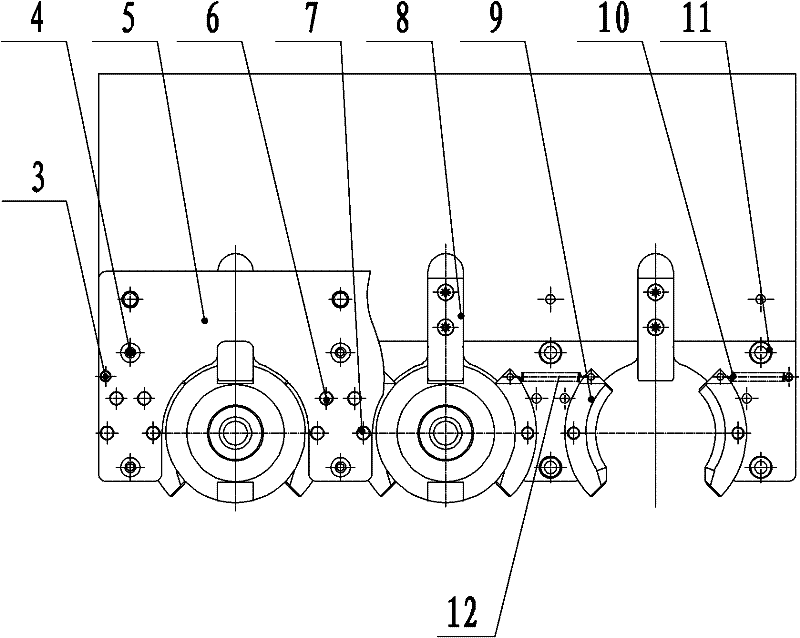

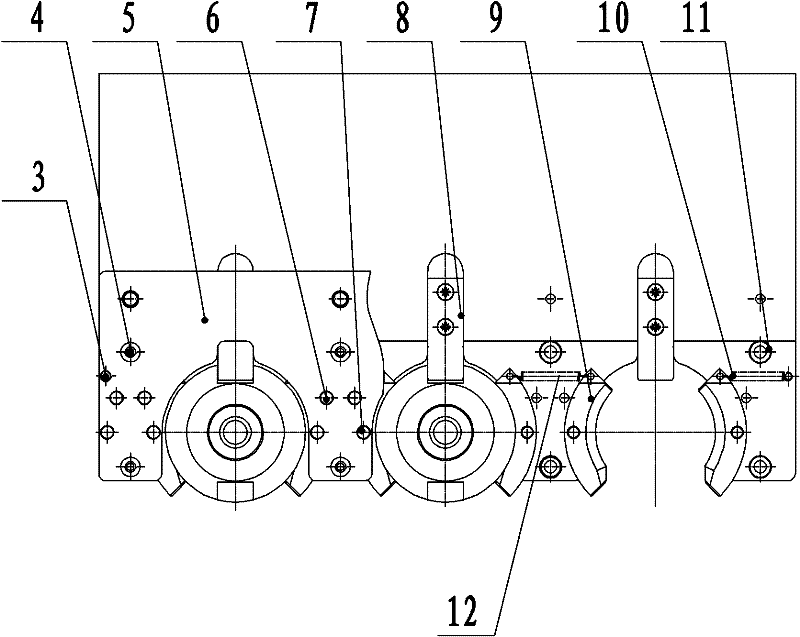

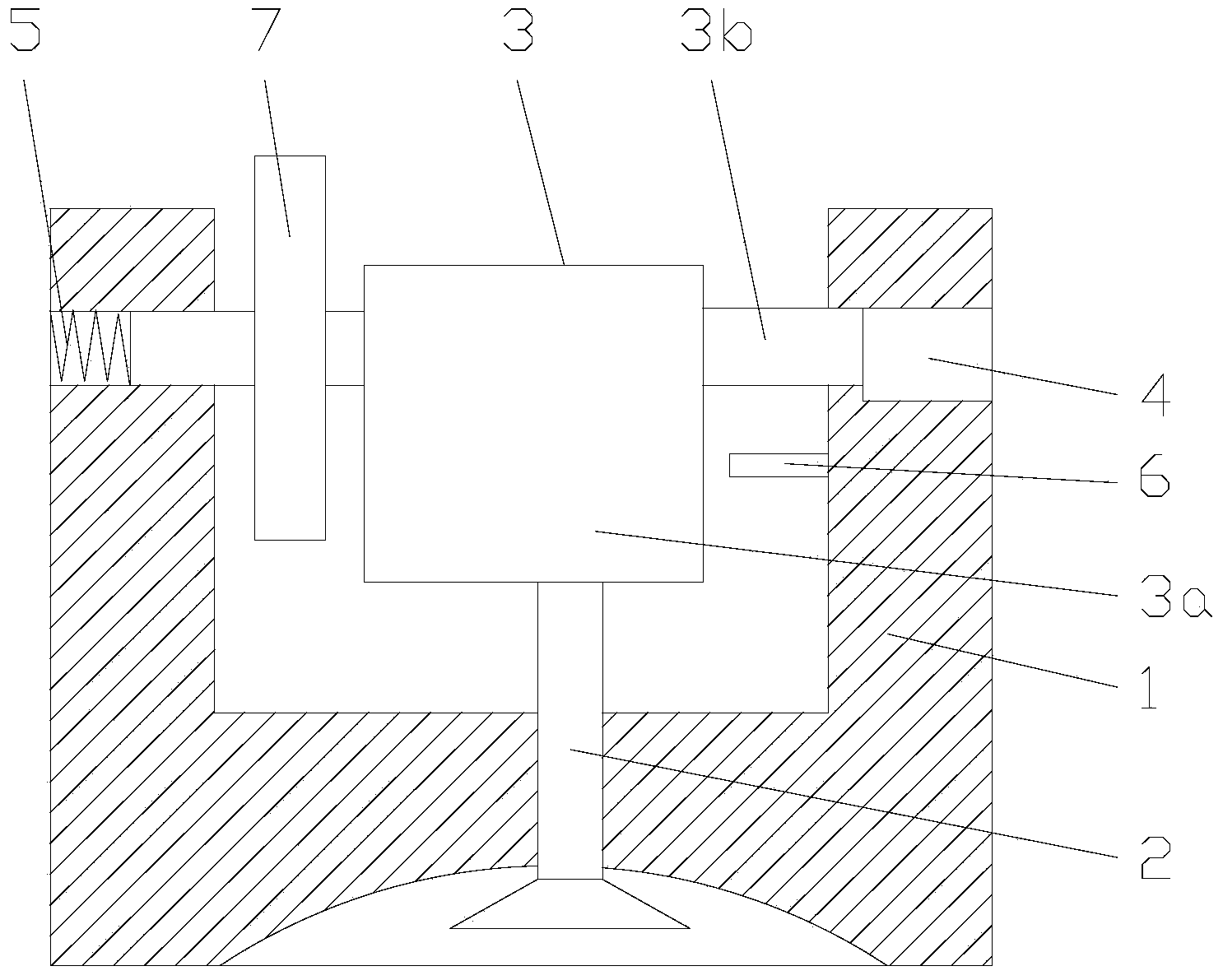

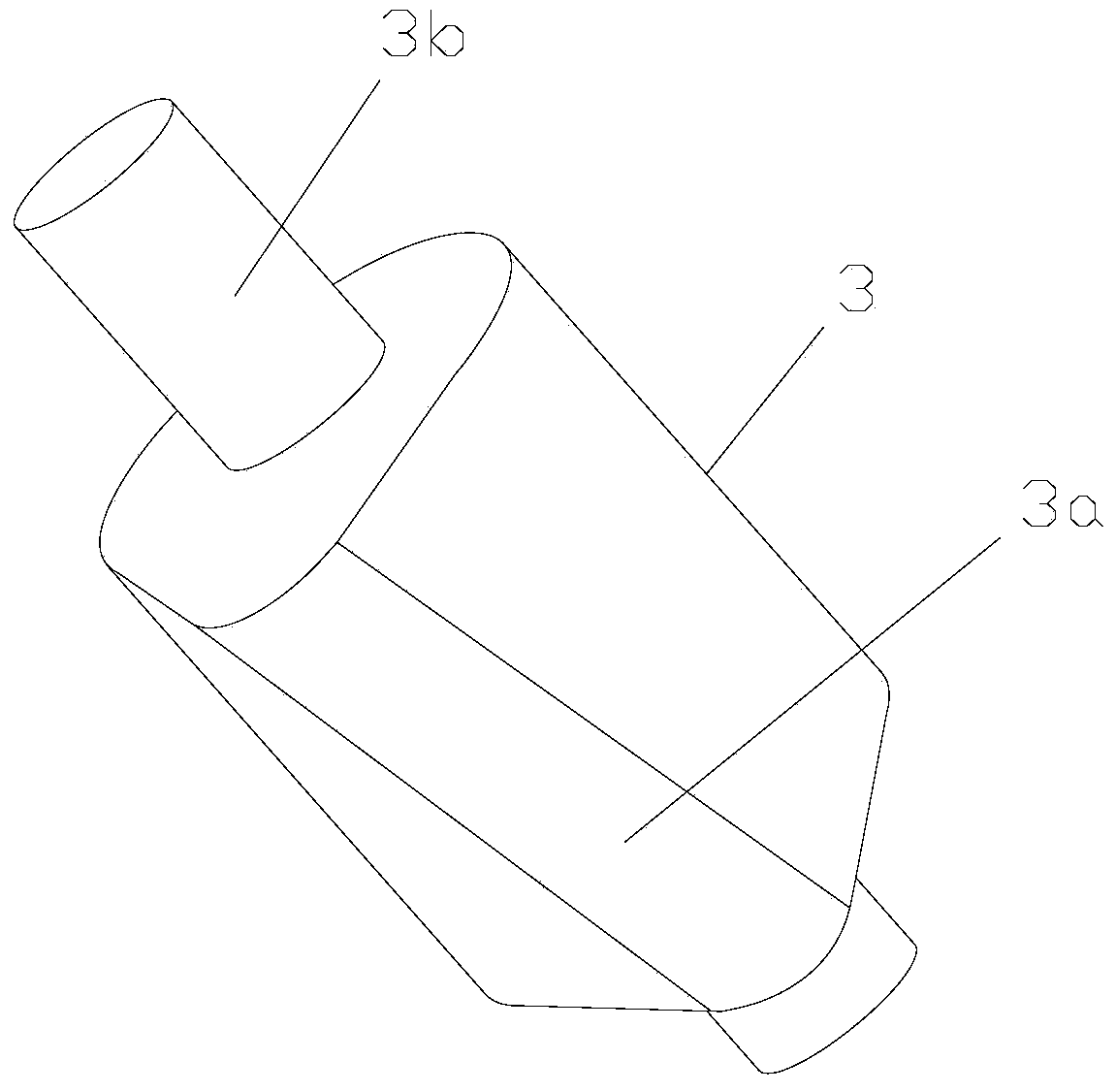

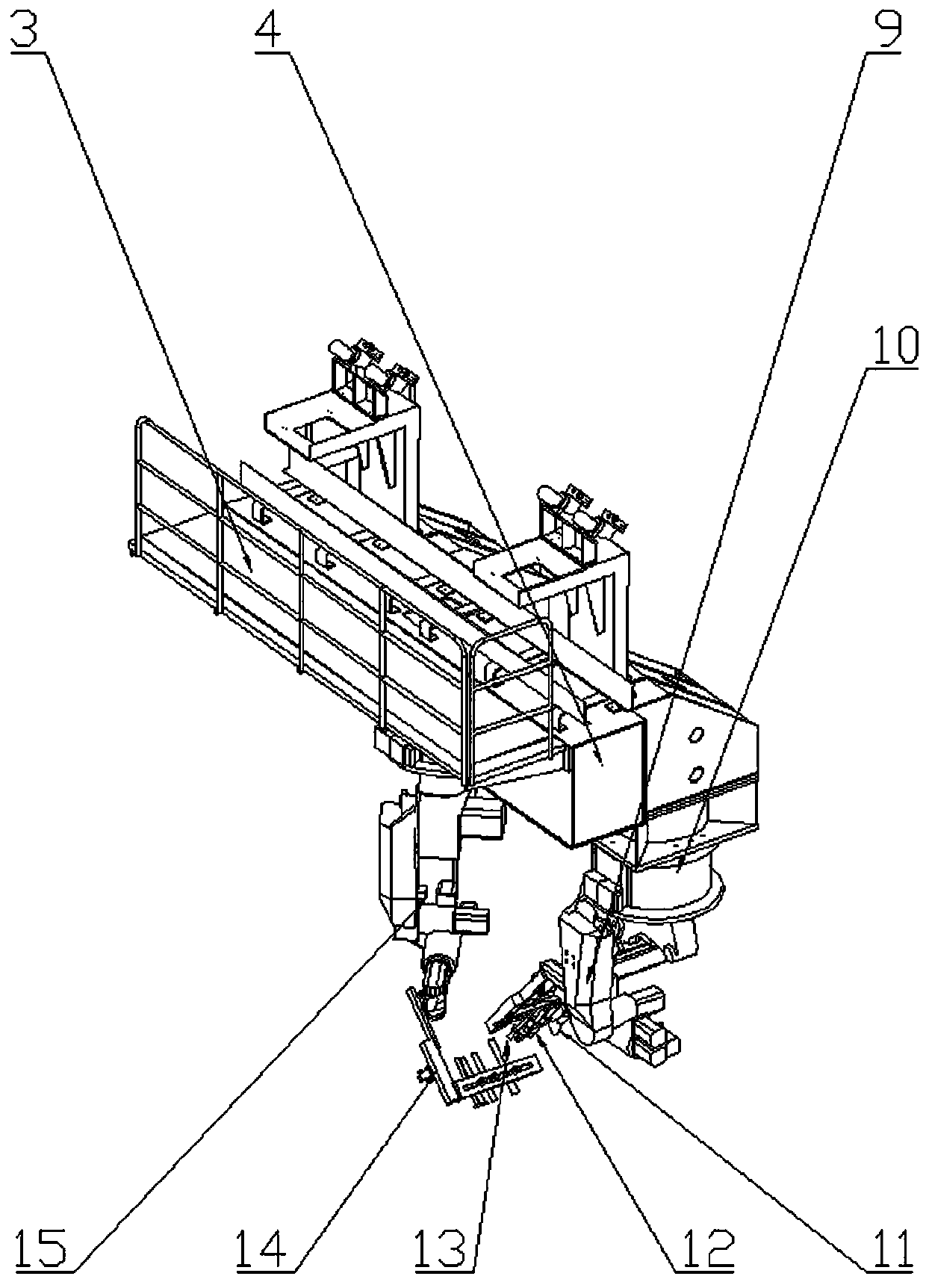

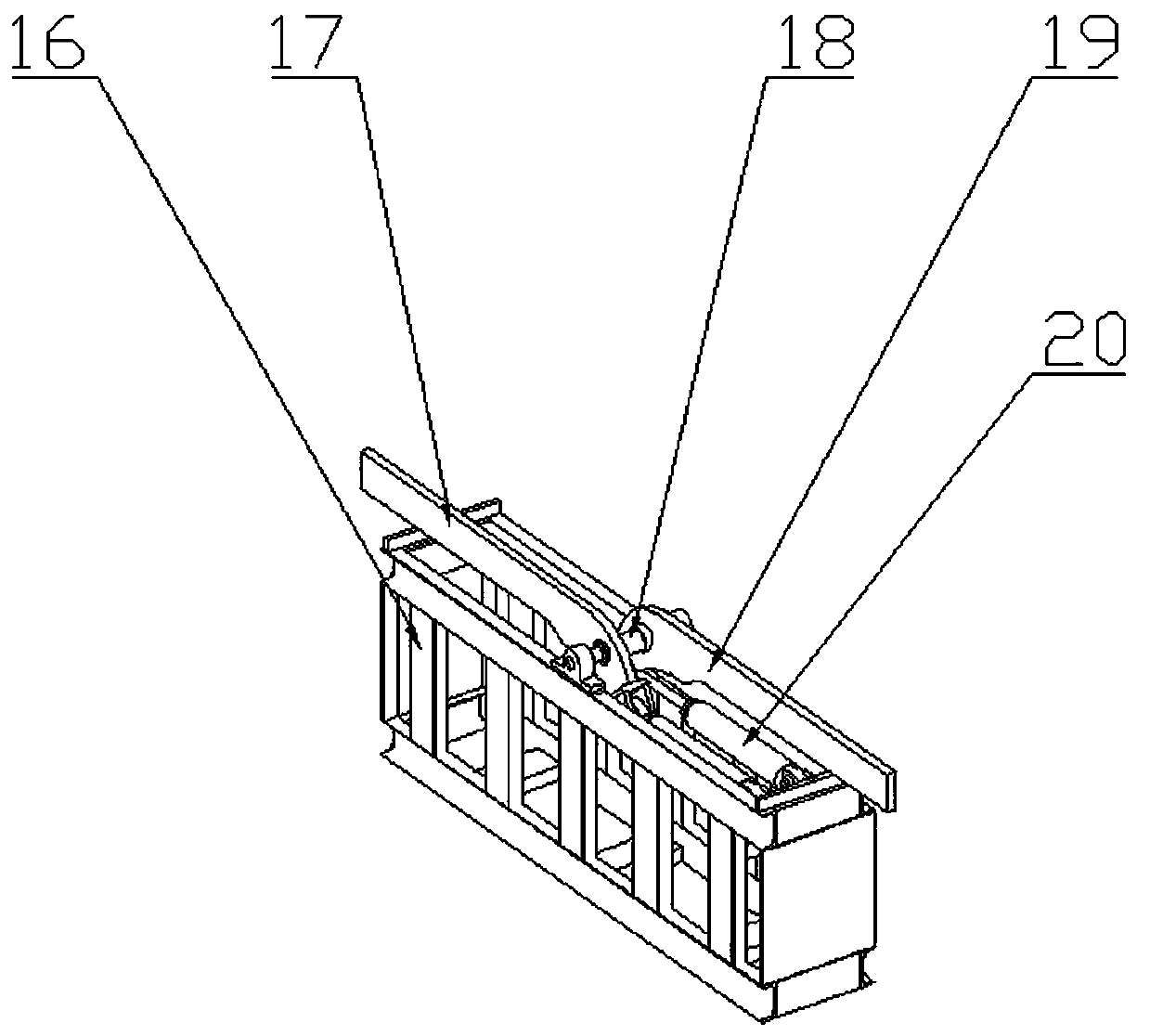

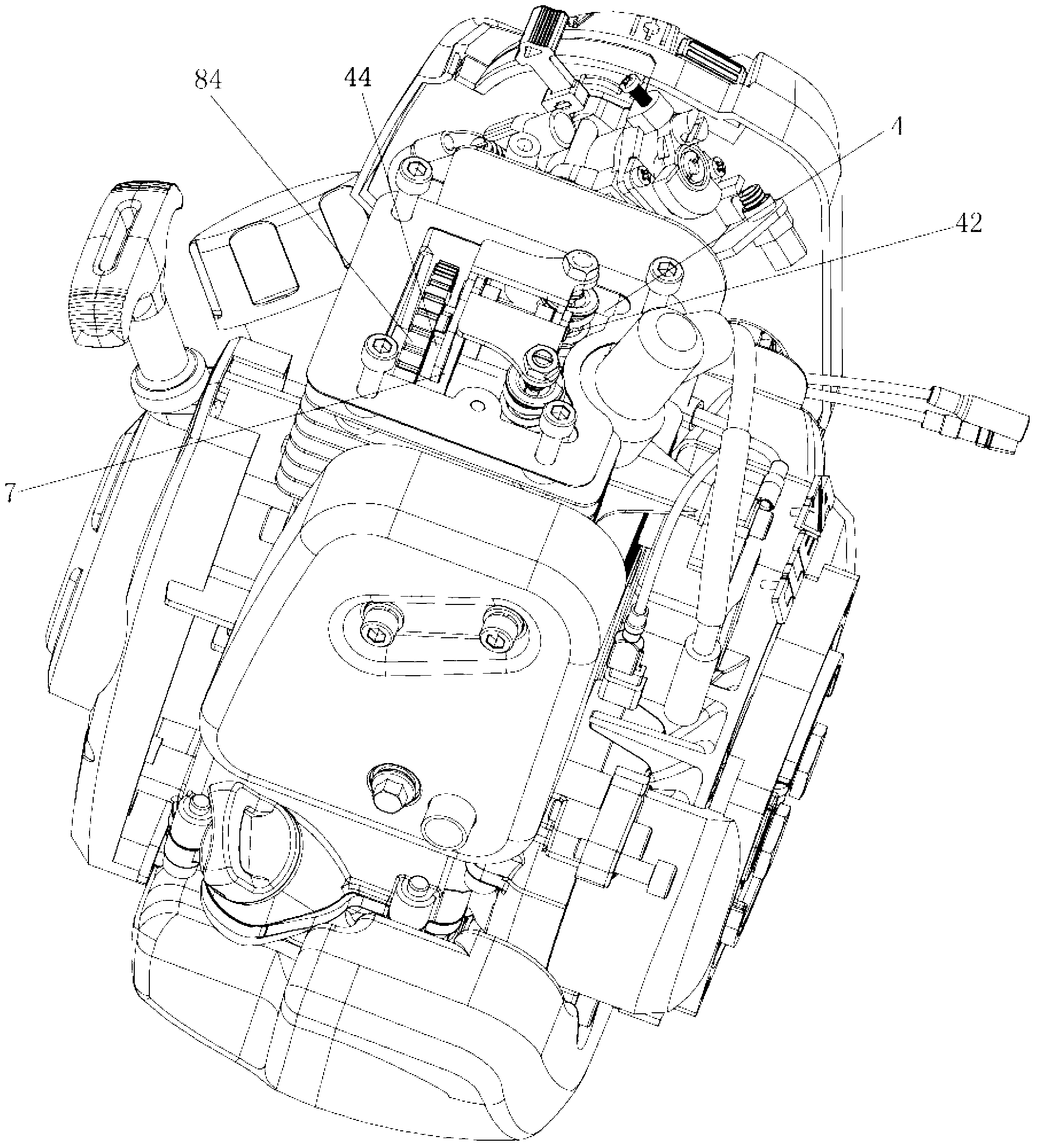

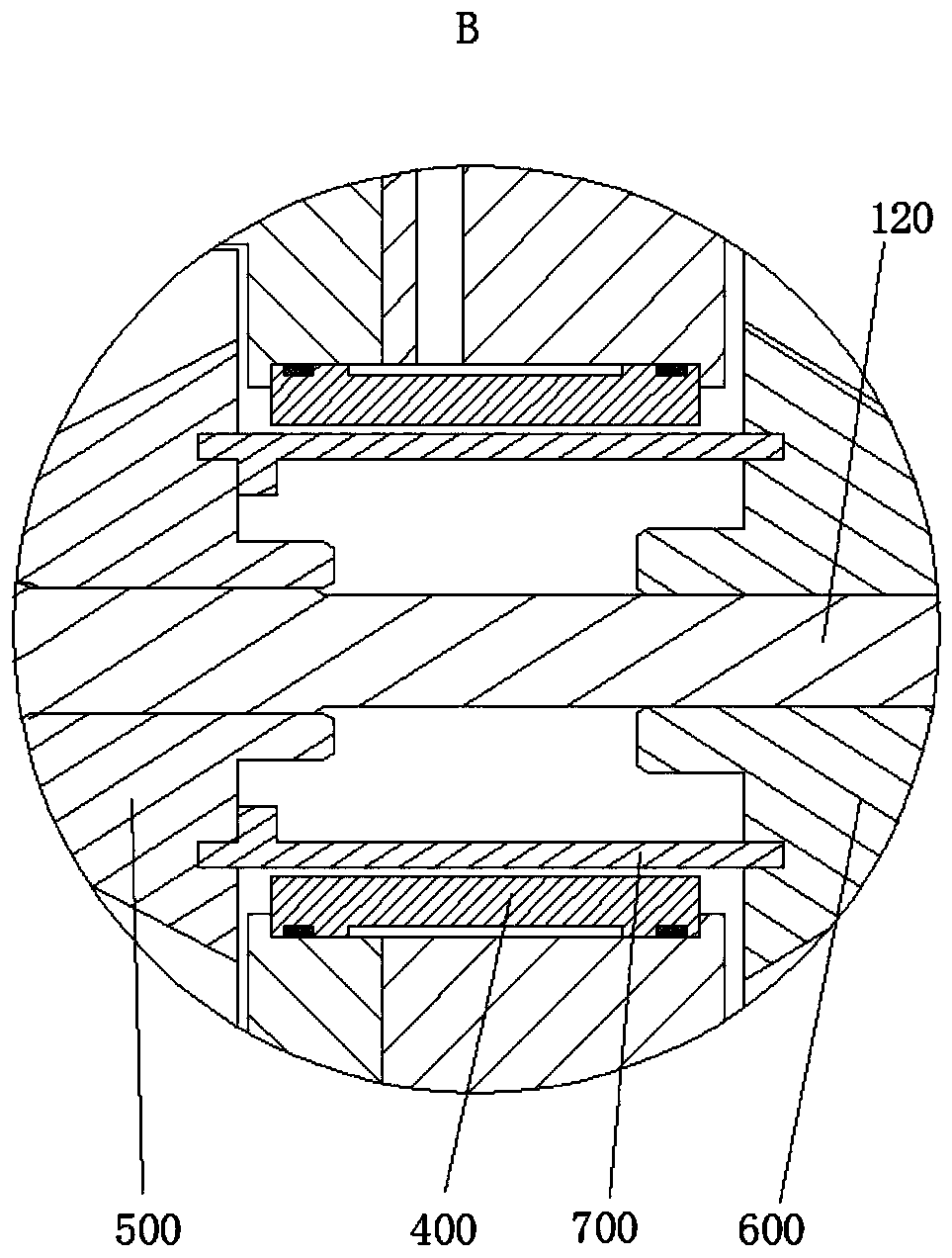

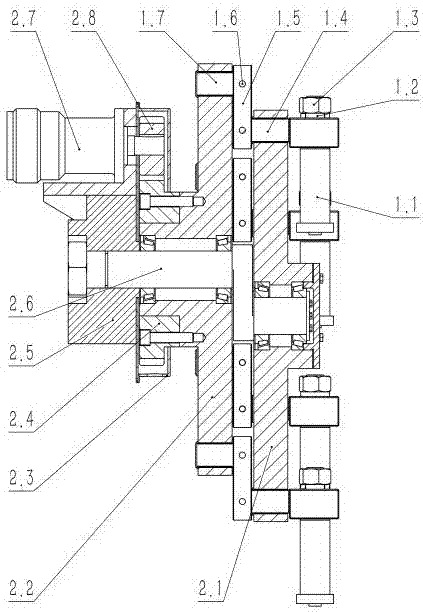

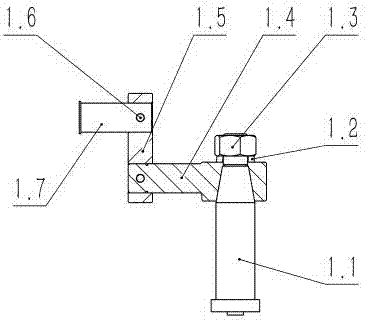

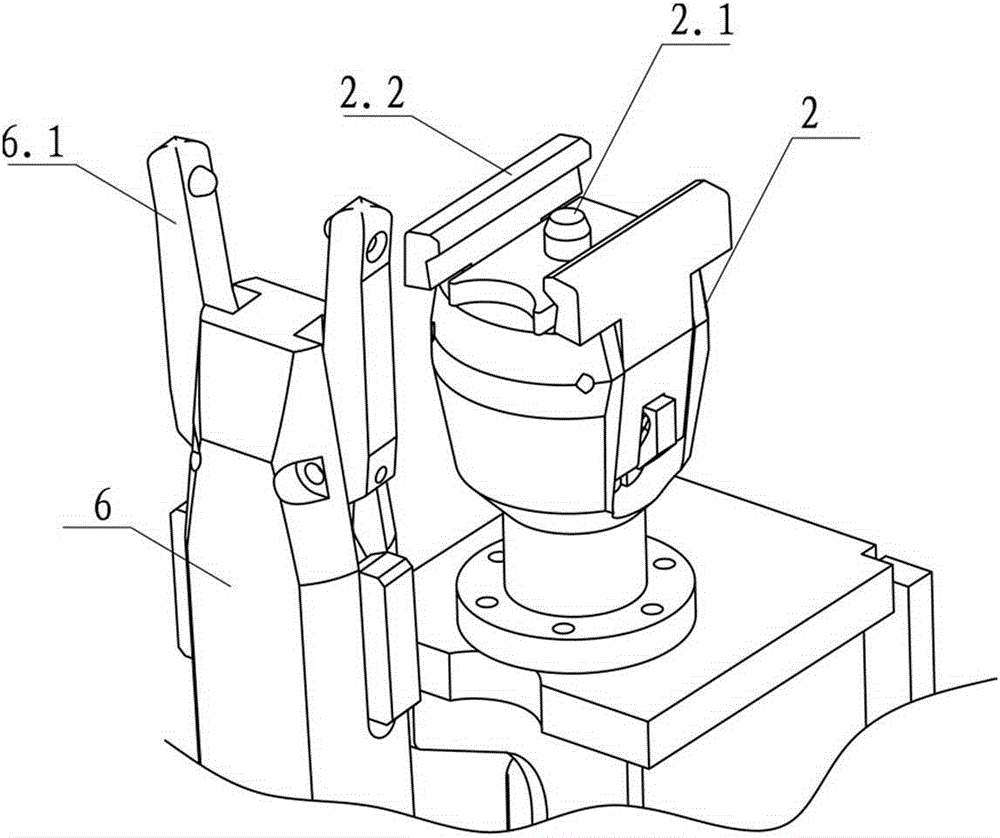

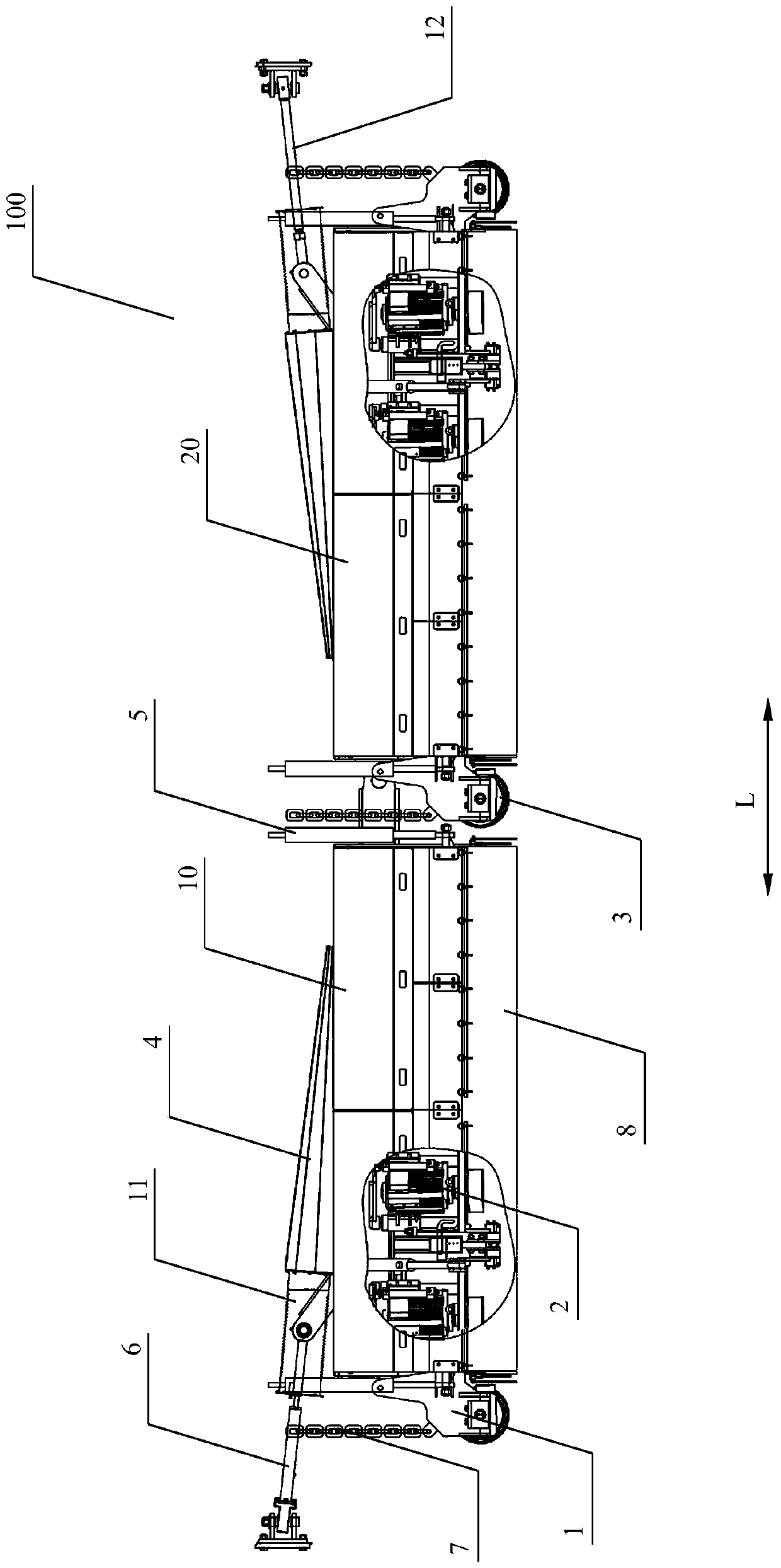

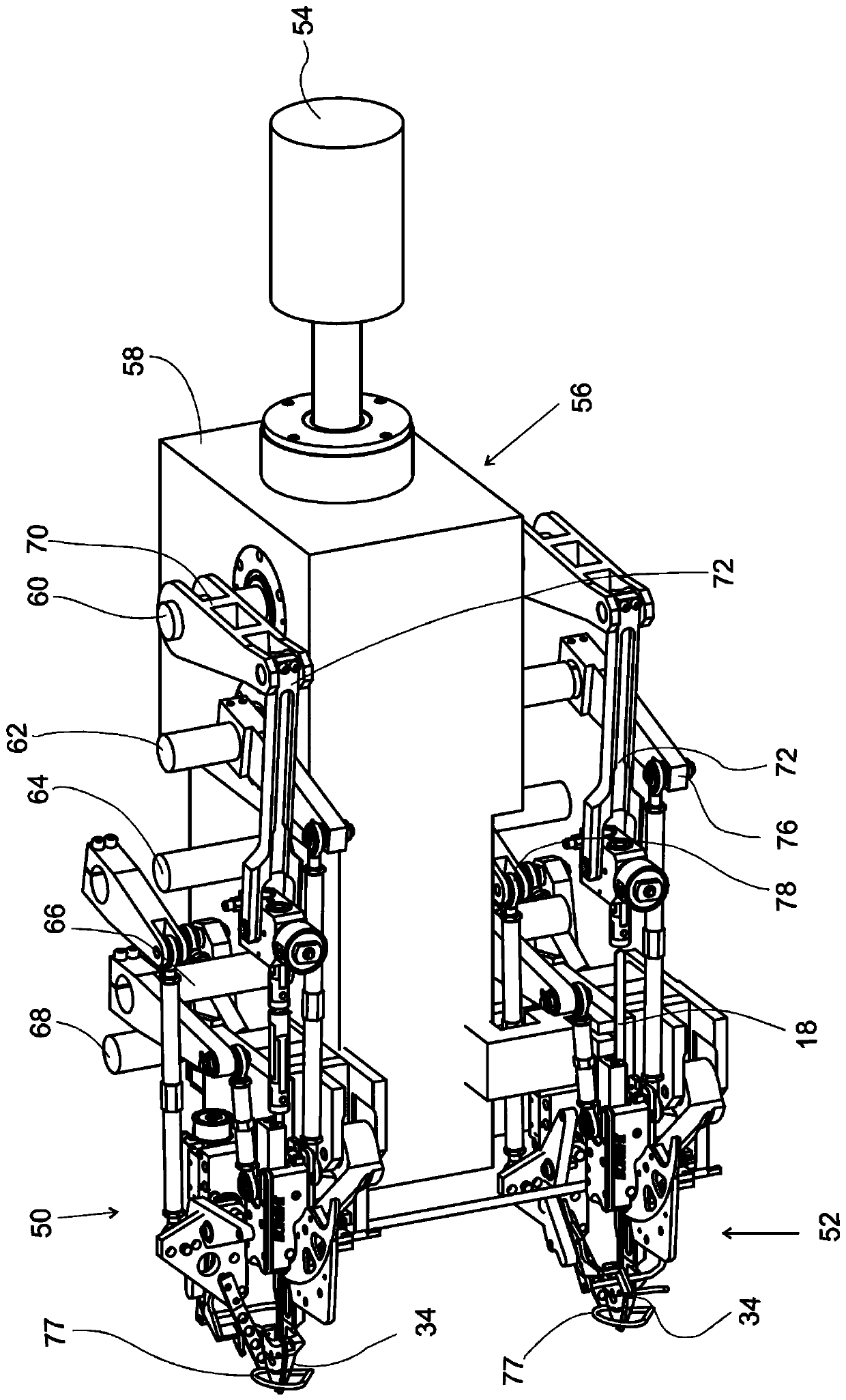

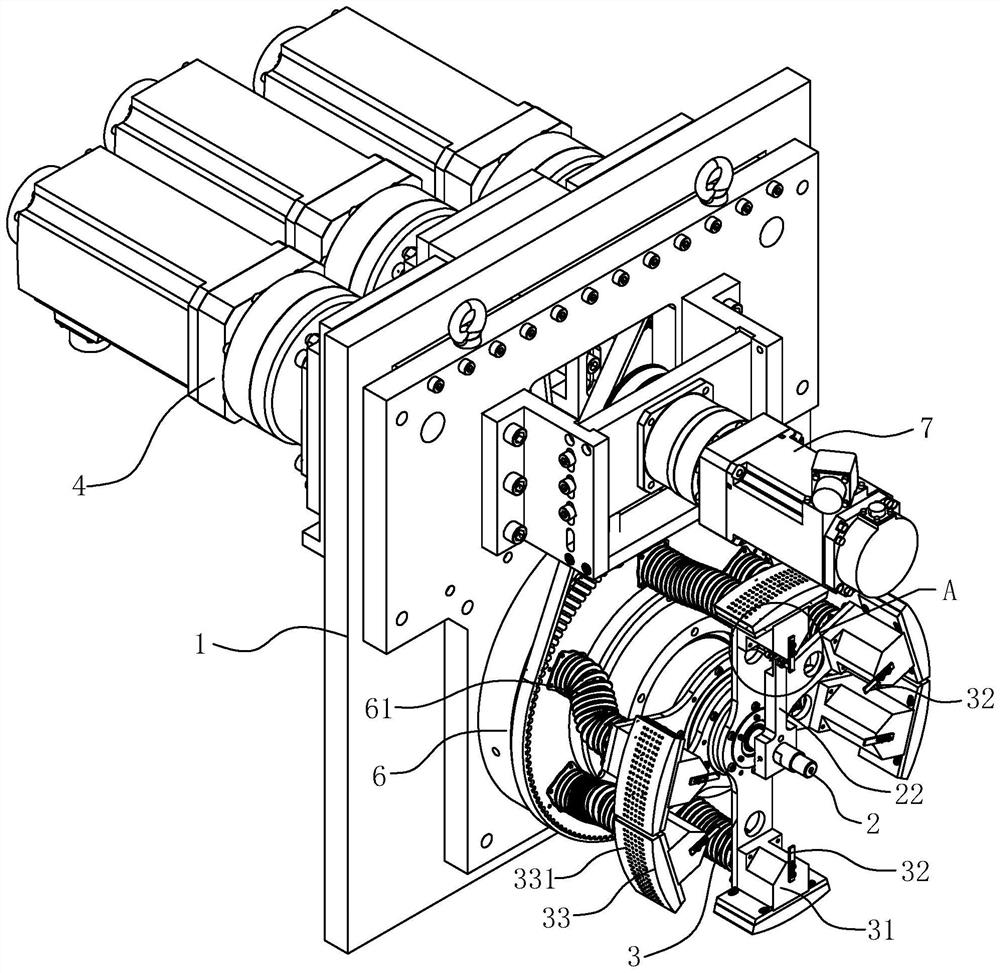

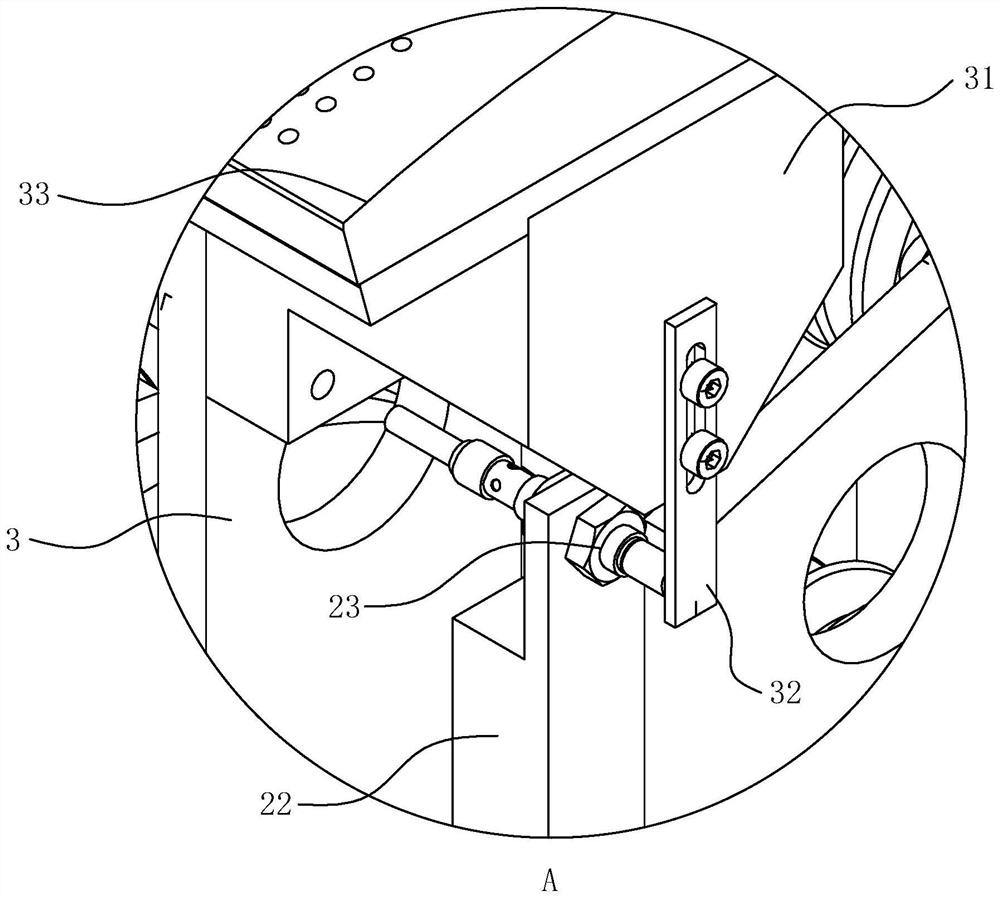

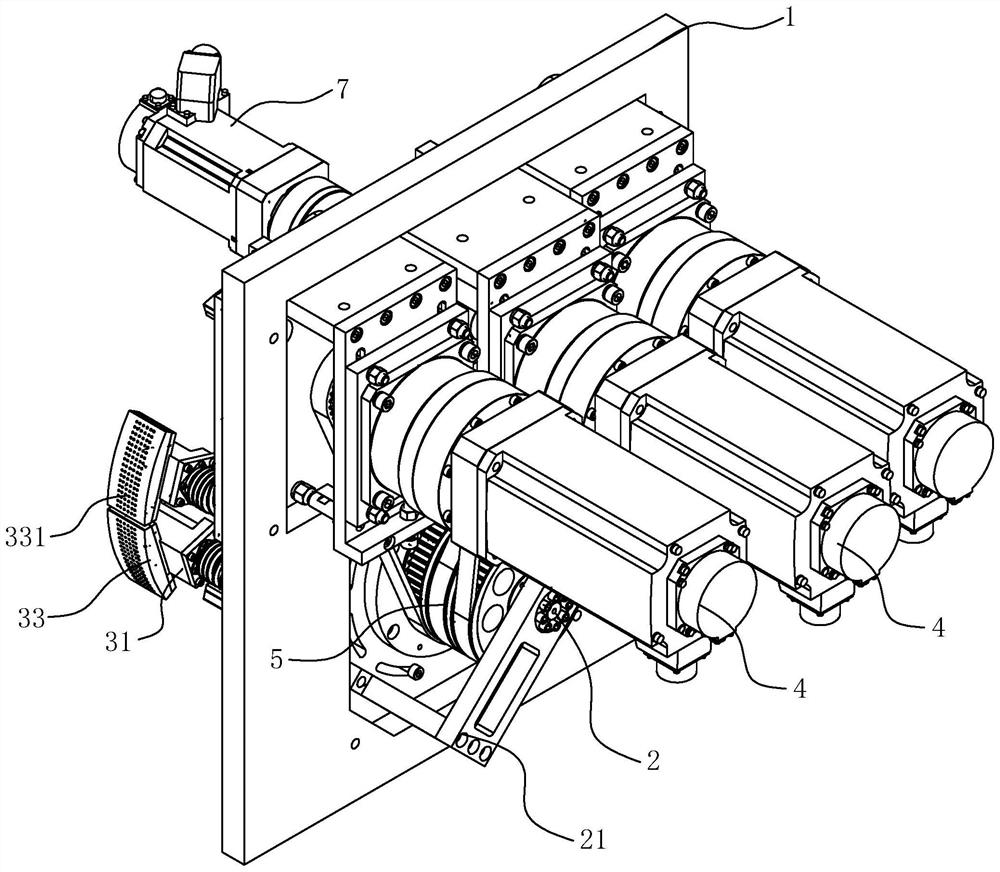

Tool storage mechanism of numerically controlled drilling and milling machine

InactiveCN102189427AReasonable craftsmanshipGood running stabilityPositioning apparatusMetal-working holdersStructural rigidityKnife handles

The invention relates to a mechanism for storing spindle tool shanks on a numerically controlled drilling and milling machine, in particular to a tool storage mechanism of a numerically controlled drilling and milling machine. The tool storage mechanism is characterized in that a tool holder is fixedly mounted on an upper mounting surface and a lower mounting surface of a bracket respectively; a bushing is arranged between the upper and lower tool holders; multiple sets of clamping devices are arranged in parallel between the upper and lower tool holders; each set of clamping devices is formed by combining two single clamping devices; the middle part of each single clamping device is hinged between the upper and lower tool holders through a hinge pin shaft; the tool storage mechanism is also provided with an edge extension spring and a middle extension spring; one end of the edge extension spring is connected to the bracket; and the other end of the edge extension spring is connected with the upper end parts of the single clamping devices on the edges at the left and right ends of the tool holders. The tool storage mechanism provided by the invention is more reasonable in structural rigidity, arrangement mode, adjustment mode and manufacturability, has high operation stability and reliability, can ensure space precision and stability of the tool shanks, and remarkably improves the usability and service life of the tool storage.

Owner:WUXI HUALIAN PRECISION MACHINERY

Variable timing system of engine valve

InactiveCN103953414ASimple structureGood running stabilityMachines/enginesNon-mechanical valveCamTiming system

The invention discloses a variable timing system of an engine valve. The variable timing system comprises a cylinder cover, a valve, a cam and a control mechanism, wherein the valve is arranged on the cylinder cover and driven by the cam to move; the cam is in rotary connection with the cylinder cover in an axially sliding manner; the projection of bulge parts of the cam in the cam axial direction is not overlapped completely; the control mechanism is connected between the cam and the cylinder cover, and used for driving the cam to slide axially and carrying out axial location to the cam. The variable timing system of the engine valve, with improvement of the cam shape and the installing structure thereof, enables the opening time of the valve to be changed, realizes variable timing, is simple in structure, good in running stability, and beneficial to save cost.

Owner:CHONGQING JIAOTONG UNIVERSITY

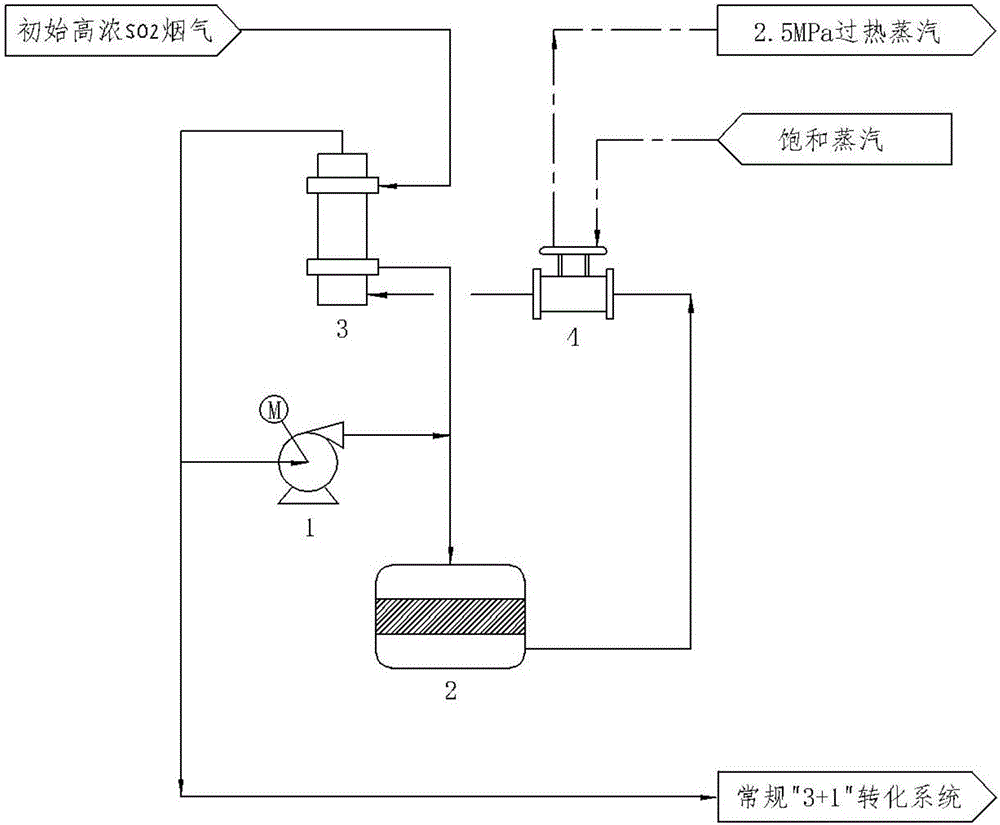

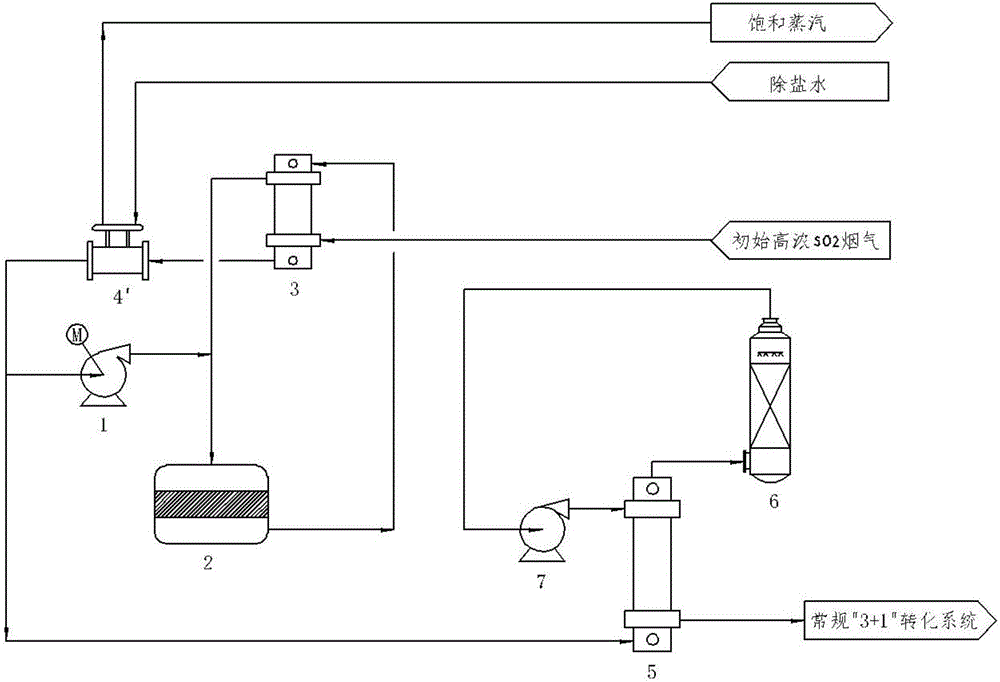

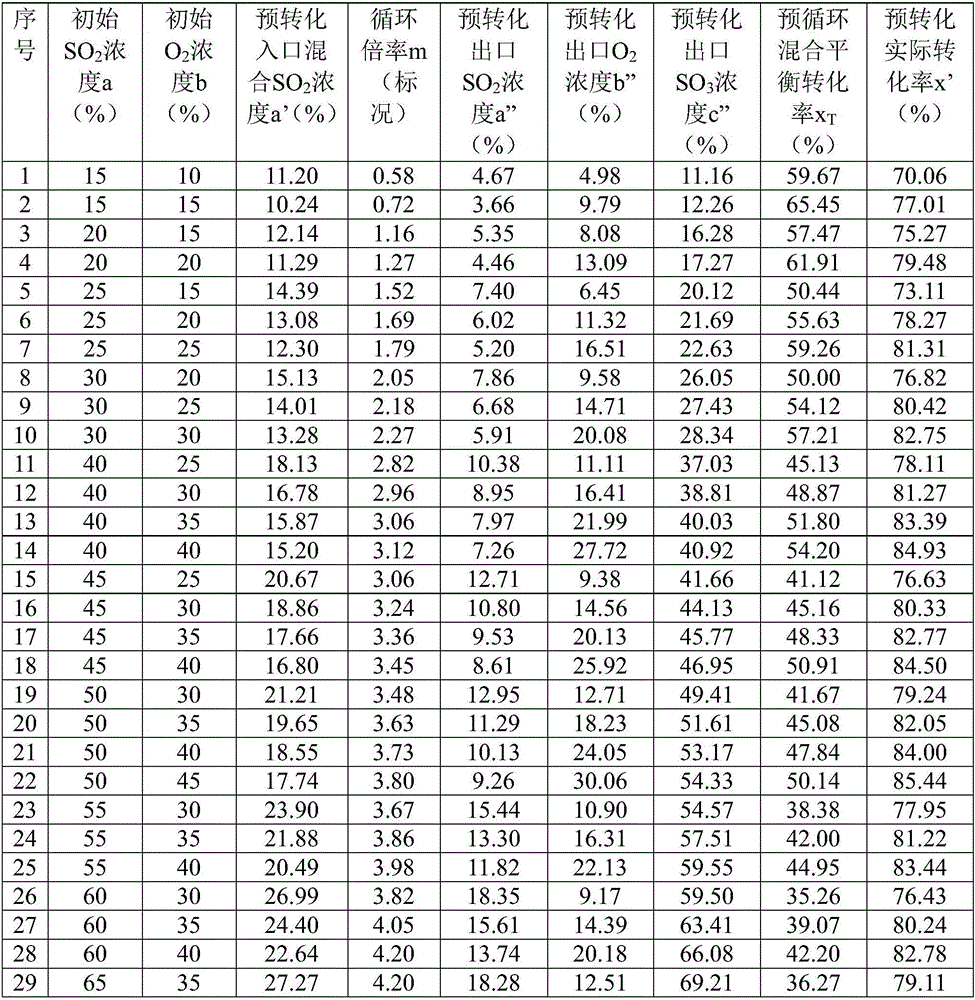

Acid making process and device adopting SO2 pre-reforming

ActiveCN106672919AGood running stabilityAdaptableSulfur-dioxide/sulfurous-acidChemistryPre treatment

The invention relates to an acid making process and device adopting SO2 pre-reforming. Initial SO2 flue gas mixed with O2 is heated by a pre-circulating heat exchanger and mixed with SO3 flue gas sent by a pre-circulating fan, and the mixed gas enters a catalyst layer of a pre-reformer for a reaction; SO3 flue gas at an outlet of the pre-reformer enters the pre-circulating heat exchanger directly or through a steam superheater, and the initial SO2 flue gas is heated; the SO3 flue gas cooled by the pre-circulating heat exchanger is divided into two parts; one part is extracted by the pre-circulating fan and mixed with the heated initial SO2 flue gas, and the mixed gas enters the pre-reformer; the other part enters a traditional SO2 reforming acid system directly or through a pre-absorbing device. The pre-circulating reforming process has very high adaptability to concentration fluctuation of SO2 in the flue gas and can be taken as a preprocessing module to be directly connected before a traditional '3+1' double-reforming double-absorbing acid making system without intervening in a follow-up '3+1' acid making process. High-concentration SO2 reforming requirements not exceeding the extreme resisting temperature of a catalyst are met.

Owner:中铝国际南方工程有限公司

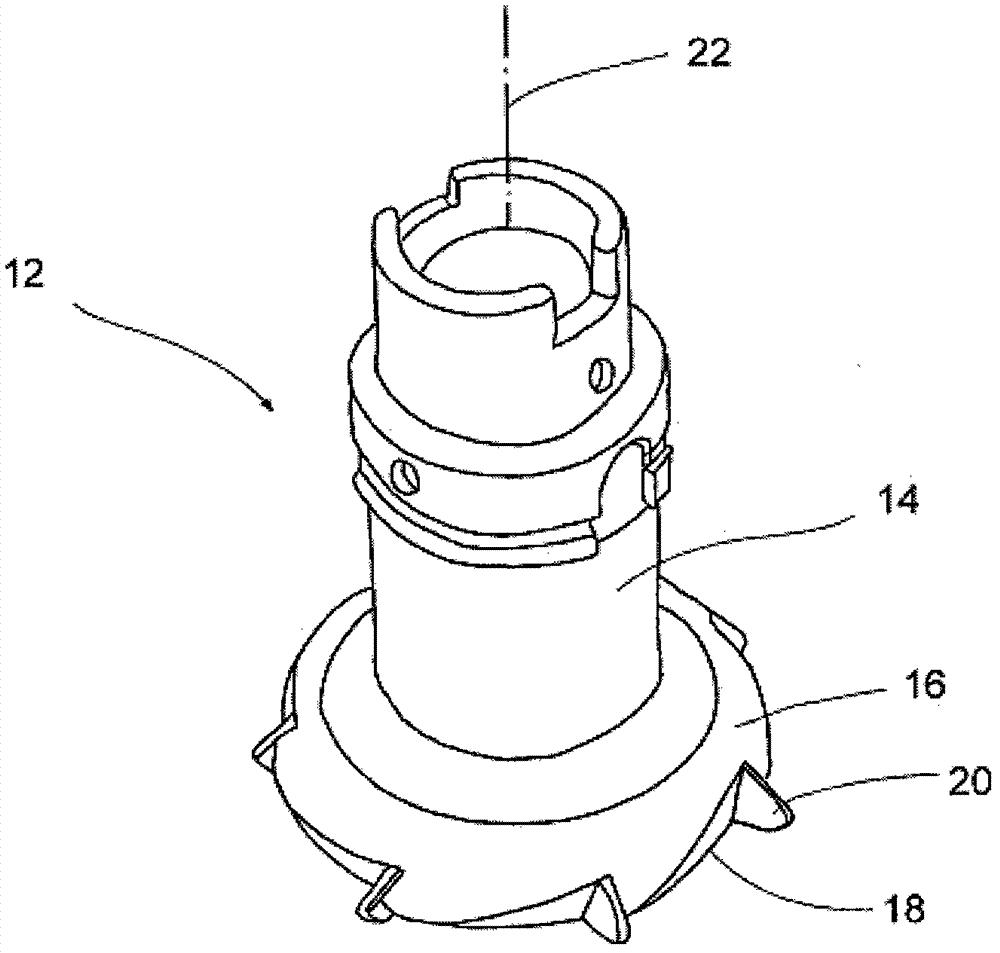

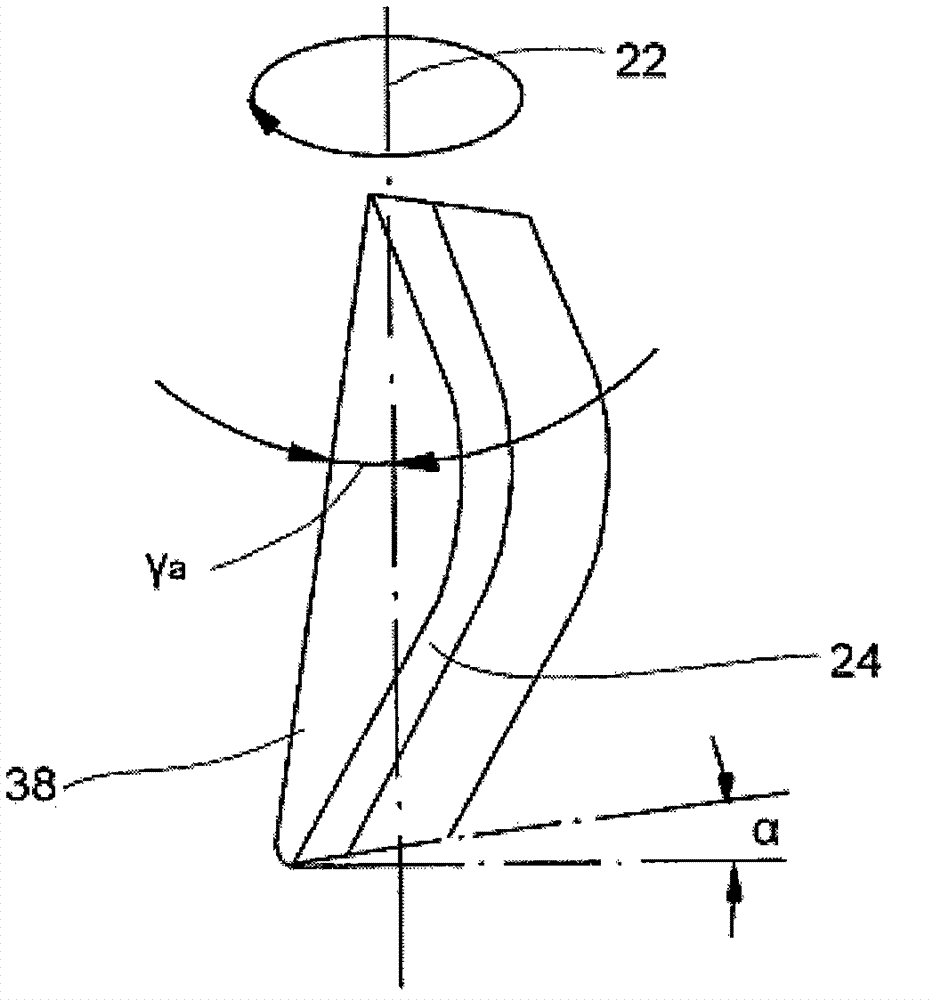

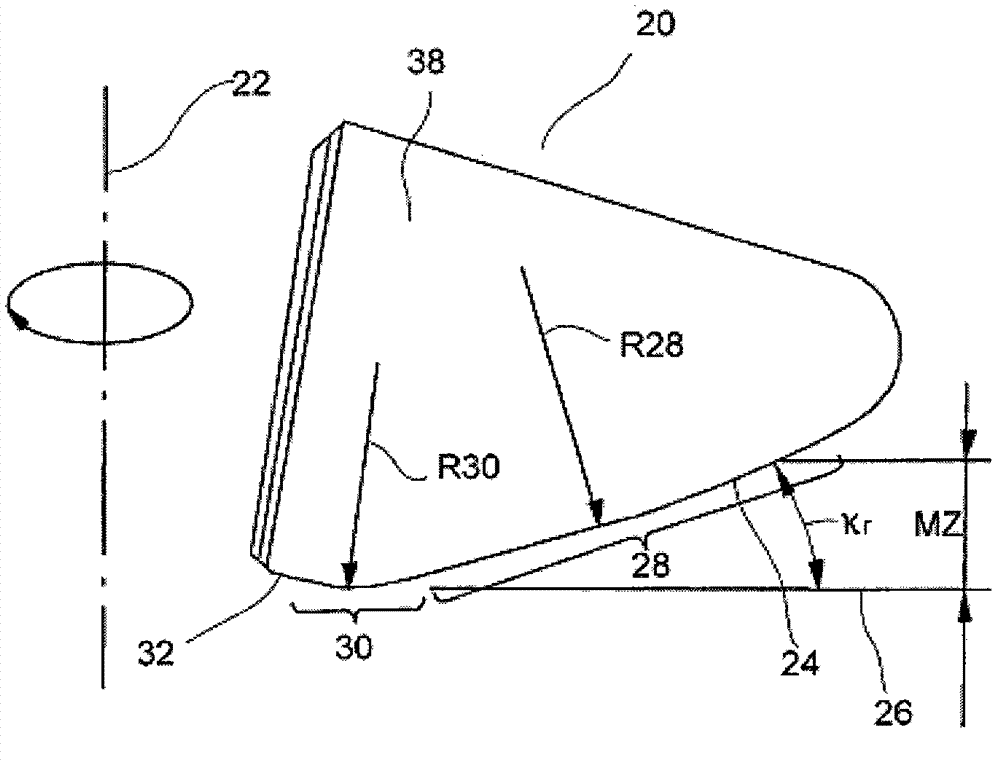

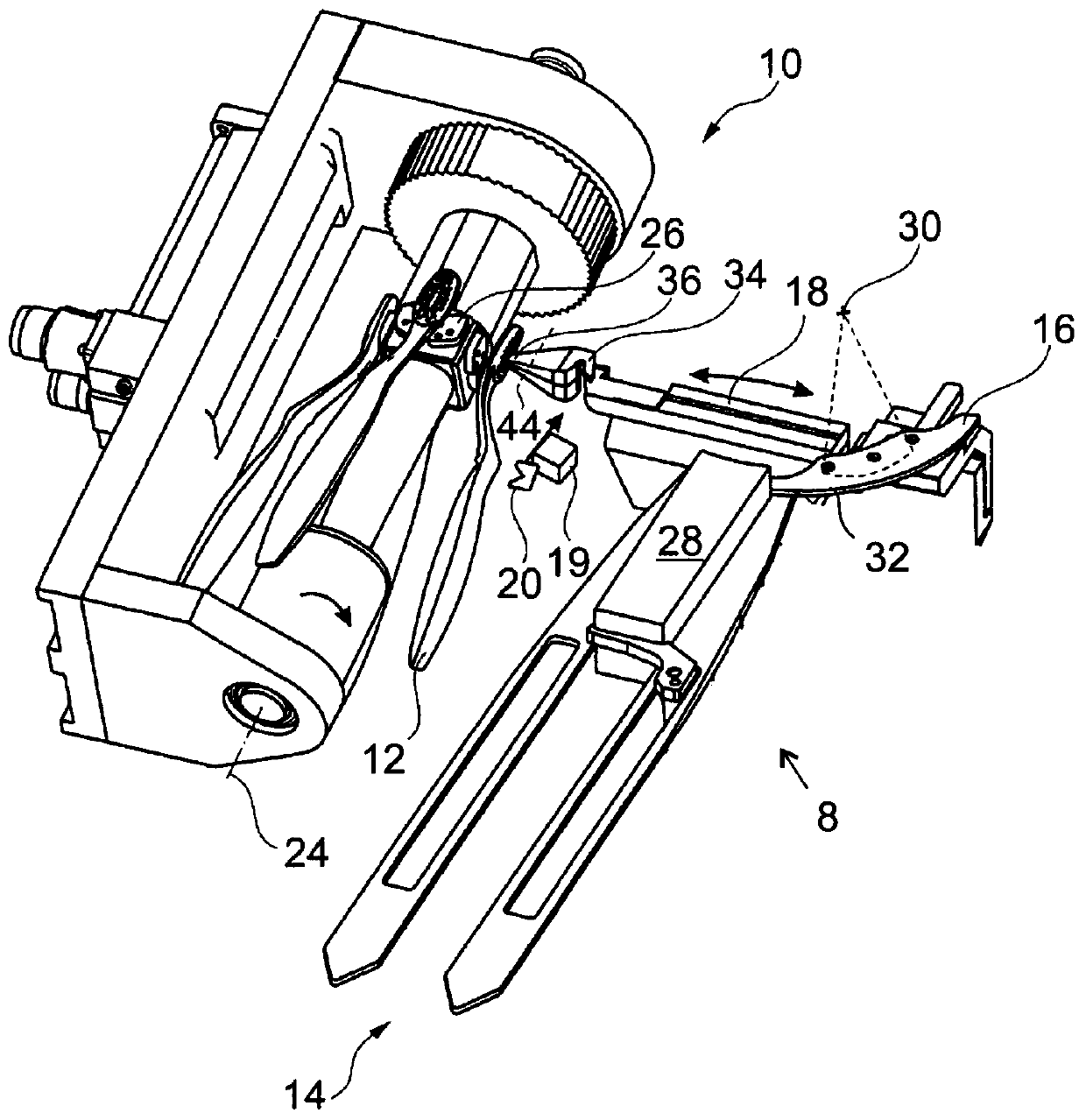

Face miller and use thereof

InactiveCN102791408AReduced torque absorptionFast cutting speedTool workpiece connectionRotary broachRake angle

The face miller (12) is equipped with a plurality of plate-shaped hard material cutting inserts (20) that are distributed over the circumference. The hard material cutting inserts are located on a graduated circle in pockets (18) of a blade carrier (16) and have a main cutting edge (24), which is adjusted at a cutting edge angle (Kr) smaller than 90 relative to the working plane (26) of the miller. In order to ensure maximum machining performance at a good service life, the cutting edge angle (Kr) is selected to range between 10 DEG and 30 DEG, preferably between 15 DEG and 25 DEG, wherein the main cutting edge (24) at the same time has a slightly convex design. The main cutting edge (24) transitions into the secondary cutting edge (32) via a transition radius (R30) having a value that ranges between 0.5 and 1.5 mm. The axial rake angle (ya) ranges between 20 DEG and 30 DEG , preferably between 23 DEG and 27 DEG. According to an advantageous further development, the radial rake angle (yr) ranges between -6 DEG and -10 DEG, preferably between -7 DEG and -9 DEG.

Owner:GUEHRING OHG

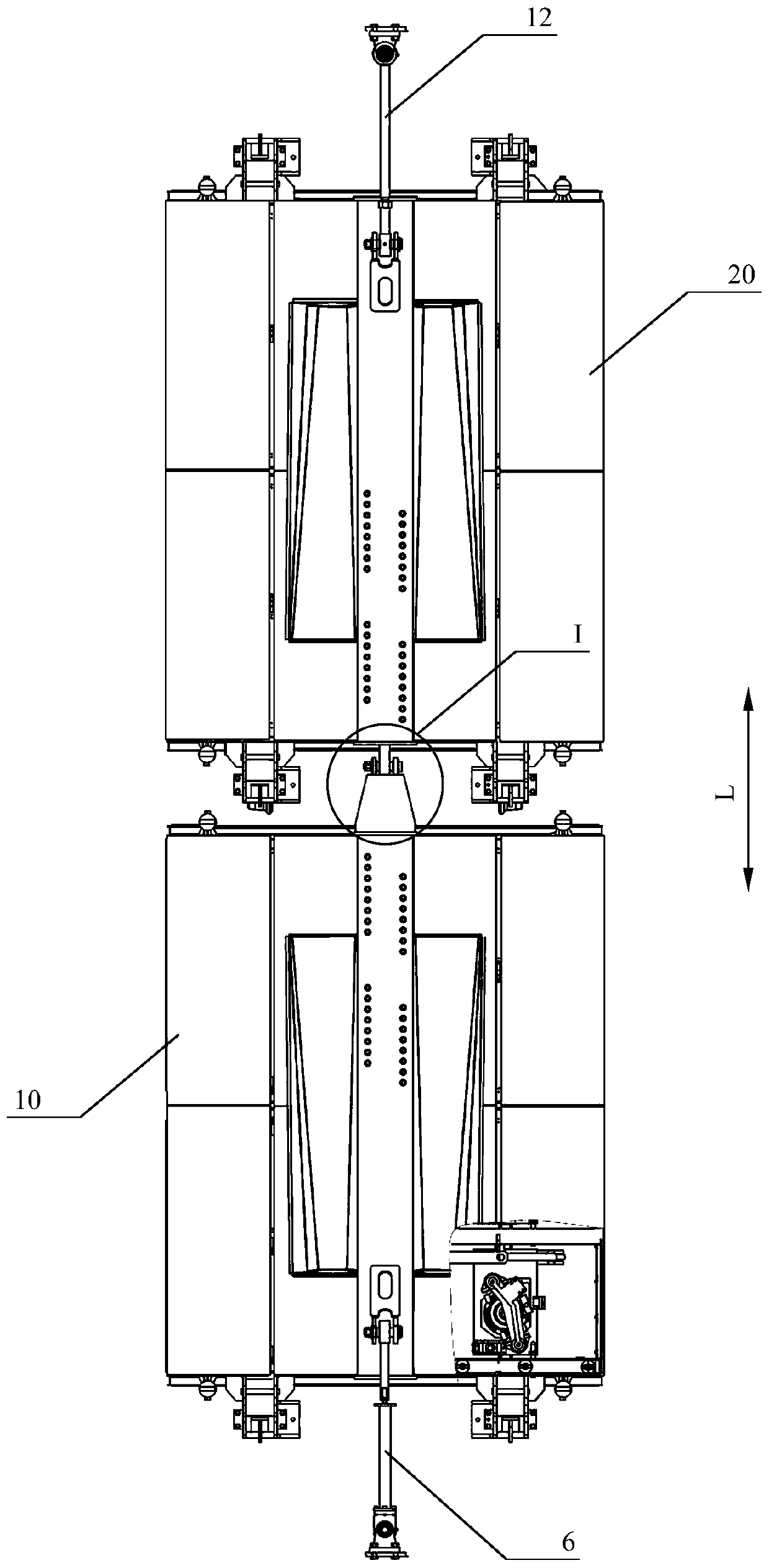

H-shaped steel robot submerged arc welding method

InactiveCN111482681AGood running stabilityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsSubmerged arc welding

The invention relates to an H-shaped steel robot submerged arc welding method, and belongs to the technical field of structural steel welding. The H-shaped steel robot submerged arc welding method comprises the following operation steps that firstly, assembled pre-welded H-shaped steel is placed on a both-way overturning assembly through an RGV conveying trolley; secondly, after the pre-welded H-shaped steel is placed, a submerged arc welding robot conducts the running preparing process; thirdly, the submerged arc welding robot conducts positioning welding work; fourthly, after upper-end-facewelding work is finished, the submerged arc welding robot resets to the original position, then, the both-way overturning assembly runs and conducts 180-degree overturning on the pre-welded H-shaped steel; and fifthly, the submerged arc welding robot continuously conducts the submerged arc welding process on two welding lines on the other end face of the pre-welded H-shaped steel, and after all welding is finished, the RGV conveying trolley is used for conducting material taking and replacing. The characteristics that running stability is good, time and labor are saved, the welding efficiencyis high, and the usage effect is good are achieved. The structural steel deformation phenomenon caused by hoisting and overturning is reduced, and the welding quality is improved.

Owner:浙江东南网架股份有限公司

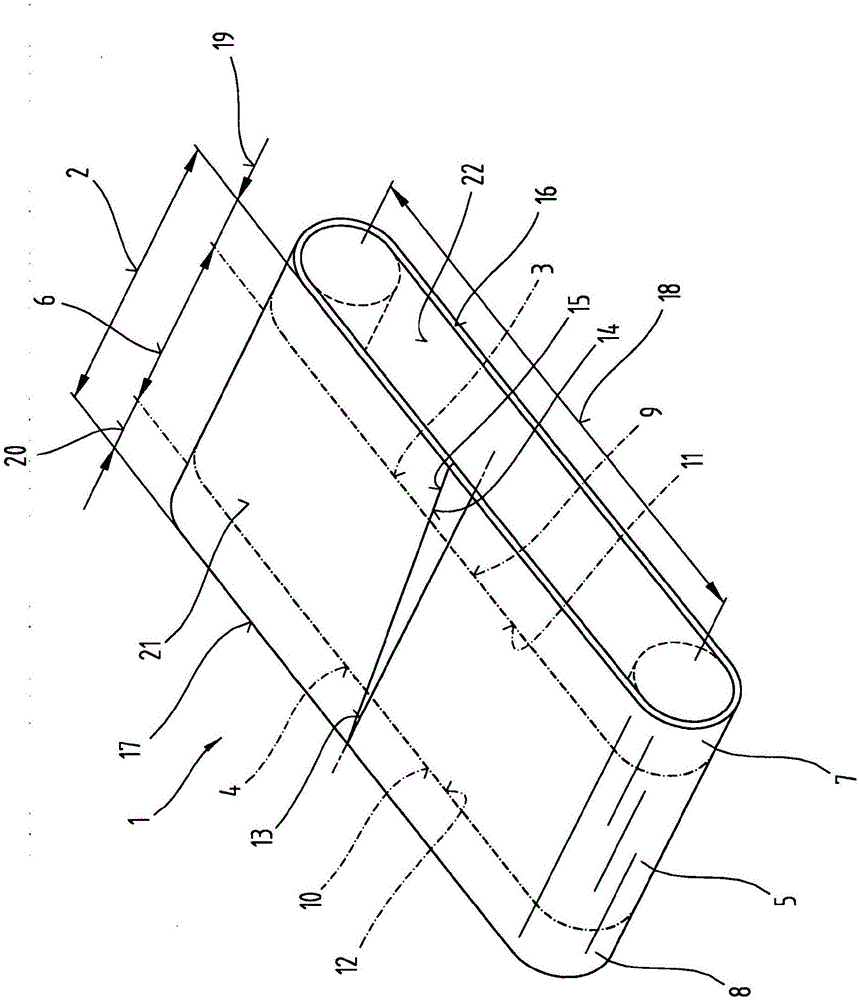

Endless belt having a belt body made of metal and method for checking the pore size in the belt surface of the outer belt side

The invention relates to an endless belt (1) having a belt body made of metal, wherein the endless belt has an outer belt side (21) and an inner belt side (22) that are connected to one another by side surfaces, each of the side surfaces having a smaller surface area than the inner belt side (21) or the outer belt side (22). The endless belt (1), viewed over the entire outer belt side (21), has no pores or has only pores with a maximum size of 70 µm.

Owner:BERNDORF BAND GMBH

Four-stroke engine

ActiveCN103277166AThe overall structure is simpleGood running stabilityValve drivesLubricant conduit arrangementsFour-stroke engineReturn channel

The invention discloses a four-stroke engine which comprises an oil tank, a crankshaft chamber, a distribution chamber, a rocker chamber, a combustion chamber and a lubricating system. The four-stroke engine is characterized in that the oil tank is communicated with the crankshaft chamber through an oil supply channel, the crankshaft chamber is communicated with distribution chamber through a first oil channel, a one-way valve is disposed in the first oil channel, the rocker chamber is communicated with the crankshaft chamber through at least one oil return channel, a one-way valve is disposed in each oil return channel, the distribution chamber is communicated with the oil tank and used for separating oil-gas mixture into oil mist and fluid oil. The four-stroke engine further comprises a cam and a transmission mechanism connected between the cam and a crankshaft of the crankshaft chamber in a matched manner. The cam is matched with a rocker of the rocker chamber and located above the combustion chamber. The four-stroke engine is simple in lubricating system arrangement, good in operation stability, low in noise, and simple in structure.

Owner:SUZHOU CLEVA PRECISION MACHINERY & TECH

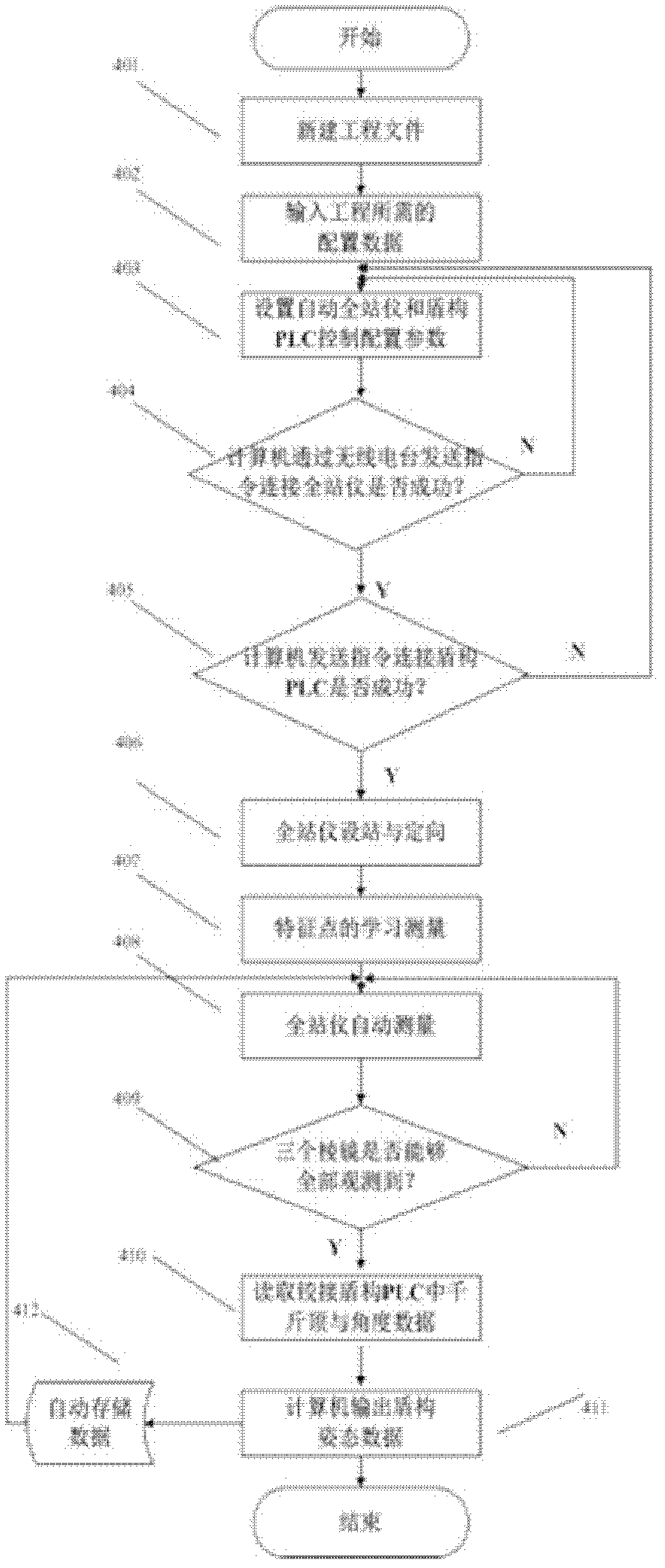

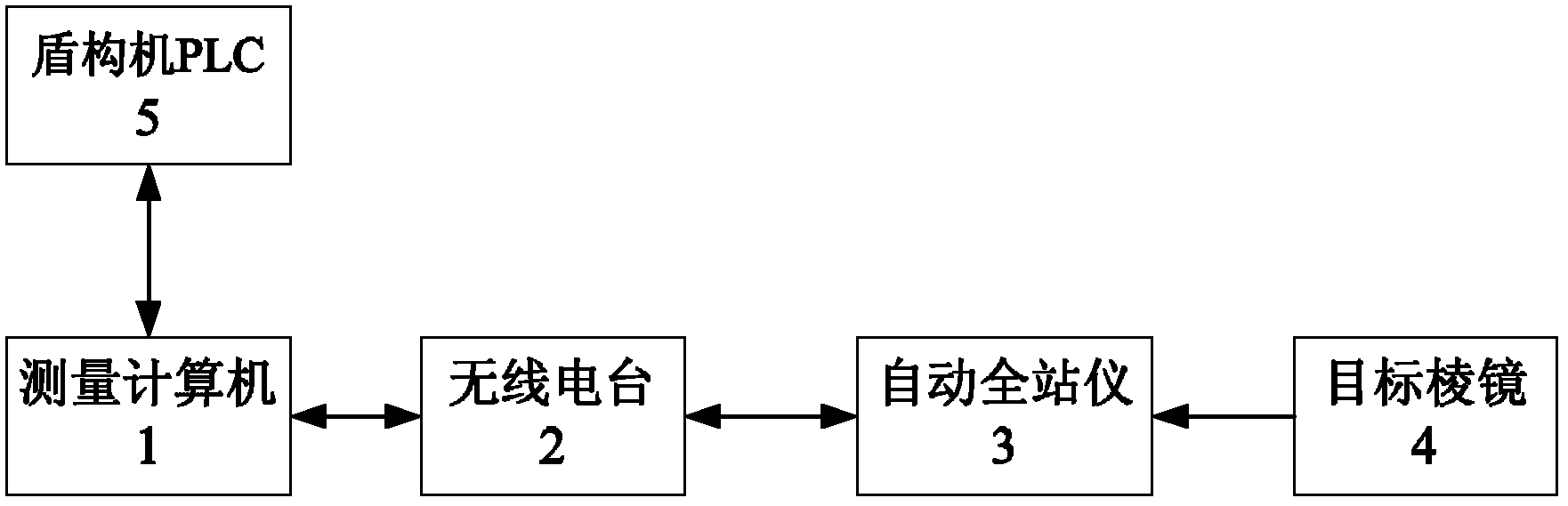

Automatic guiding measurement method for hinge connection shield machine, and apparatus thereof

InactiveCN102809374AGood running stabilityEasy to operateNavigation instrumentsData entryShield machine

The present invention relates to an automatic guiding measurement method for a hinge connection shield machine, and an apparatus thereof. The method comprises: 1) establishing a database file, and then performing a step 2); 2) inputting configuration data into the database file established in the step 1), and then performing a step 3); 3) setting control configuration parameters of an automatic total station and a shield machine PLC, and then performing a step 4 ); 4) determining whether a measurement computer and the automatic total station are successfully connected, if yes, performing a step 5), if no, returning to the step 3), and checking setting of the automatic total station; and other steps. The apparatus comprises an automatic total station, a wireless radio, a measurement computer, target prisms, and a shield machine PLC. Compared with the method and the apparatus in the prior art, the method and the apparatus in the present invention have advantages of good operating stability, high measurement precision, high automation degree, high visualization degree, and the like.

Owner:TONGJI UNIV

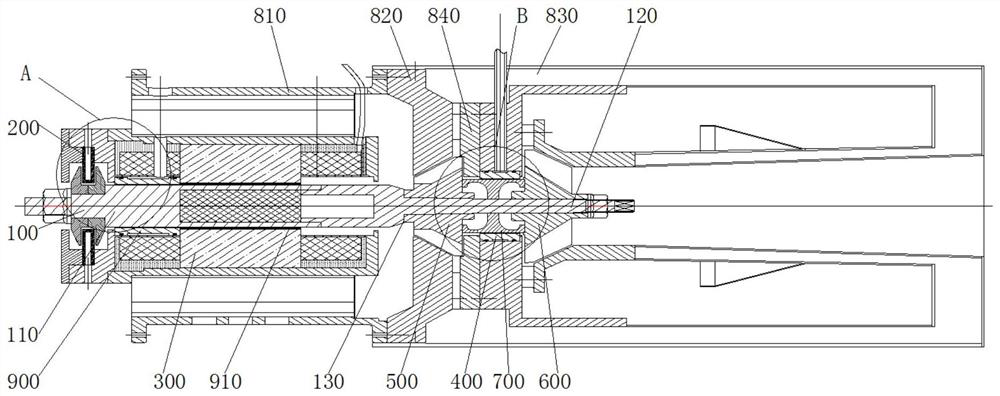

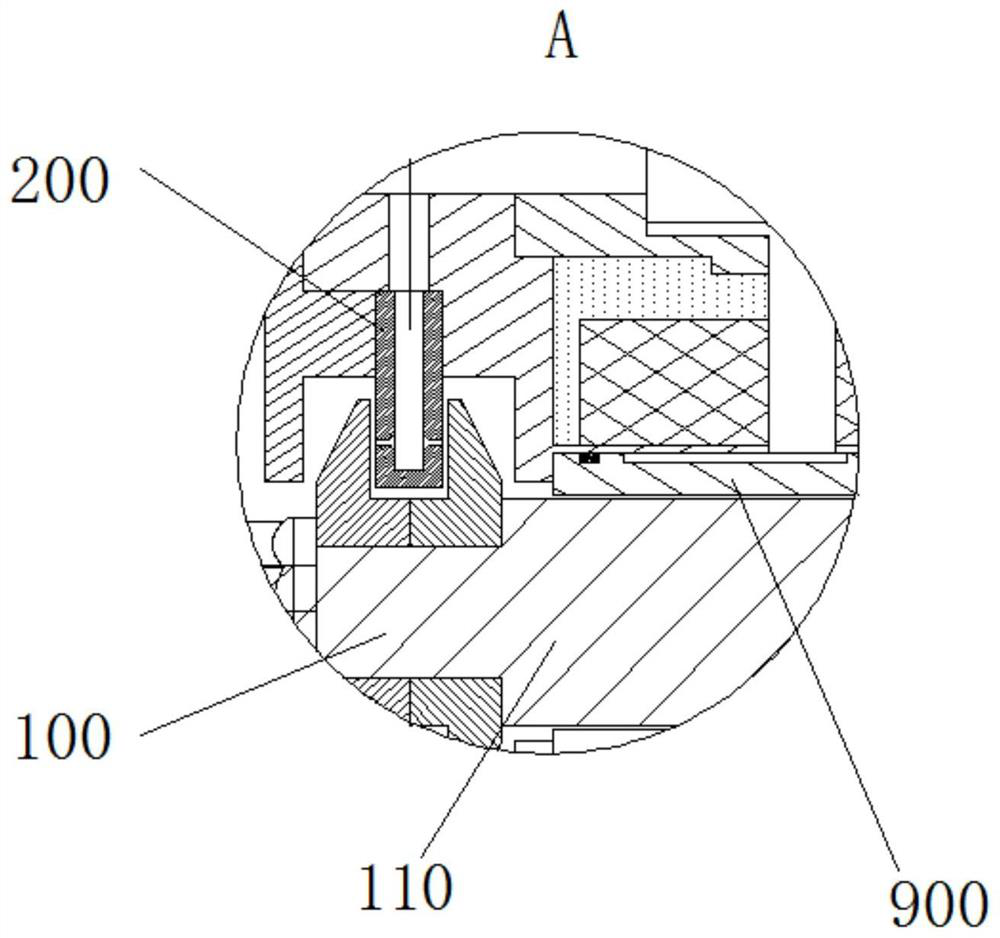

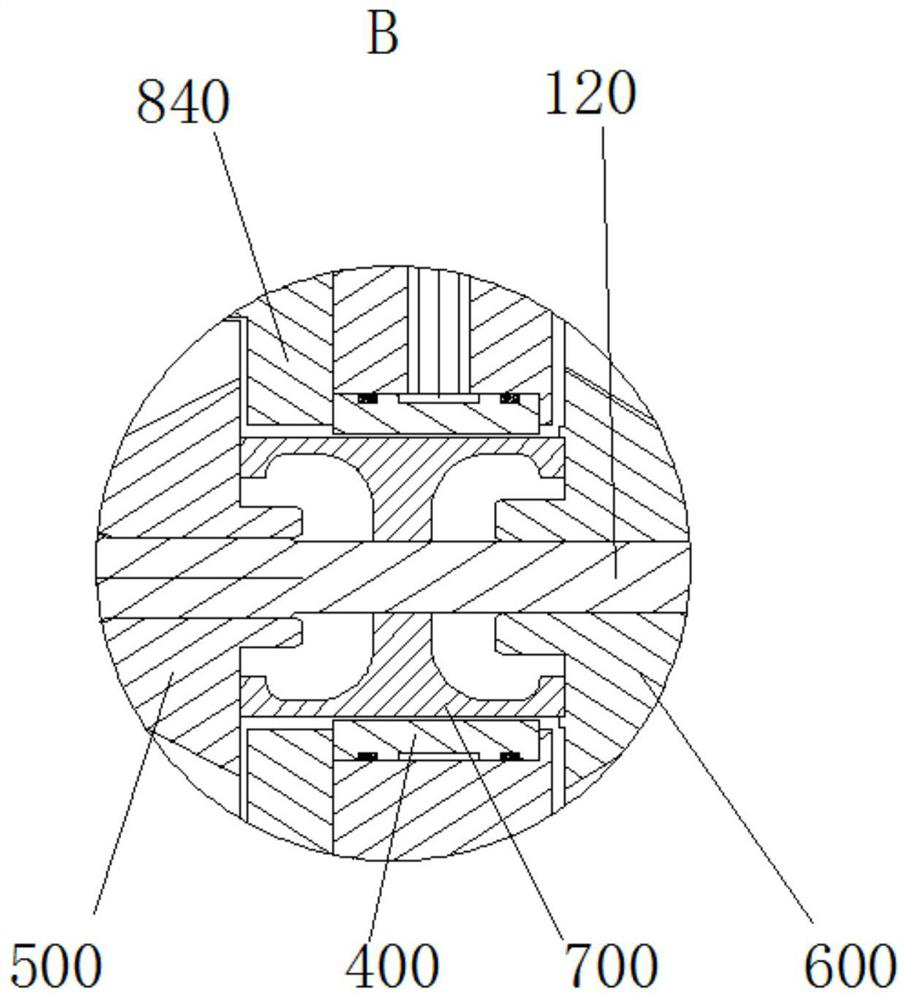

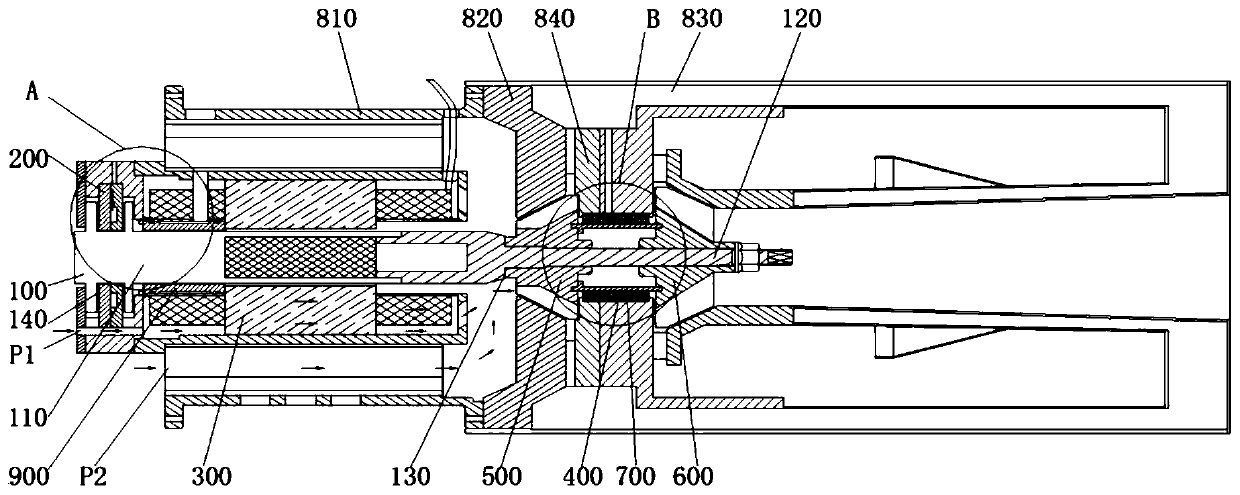

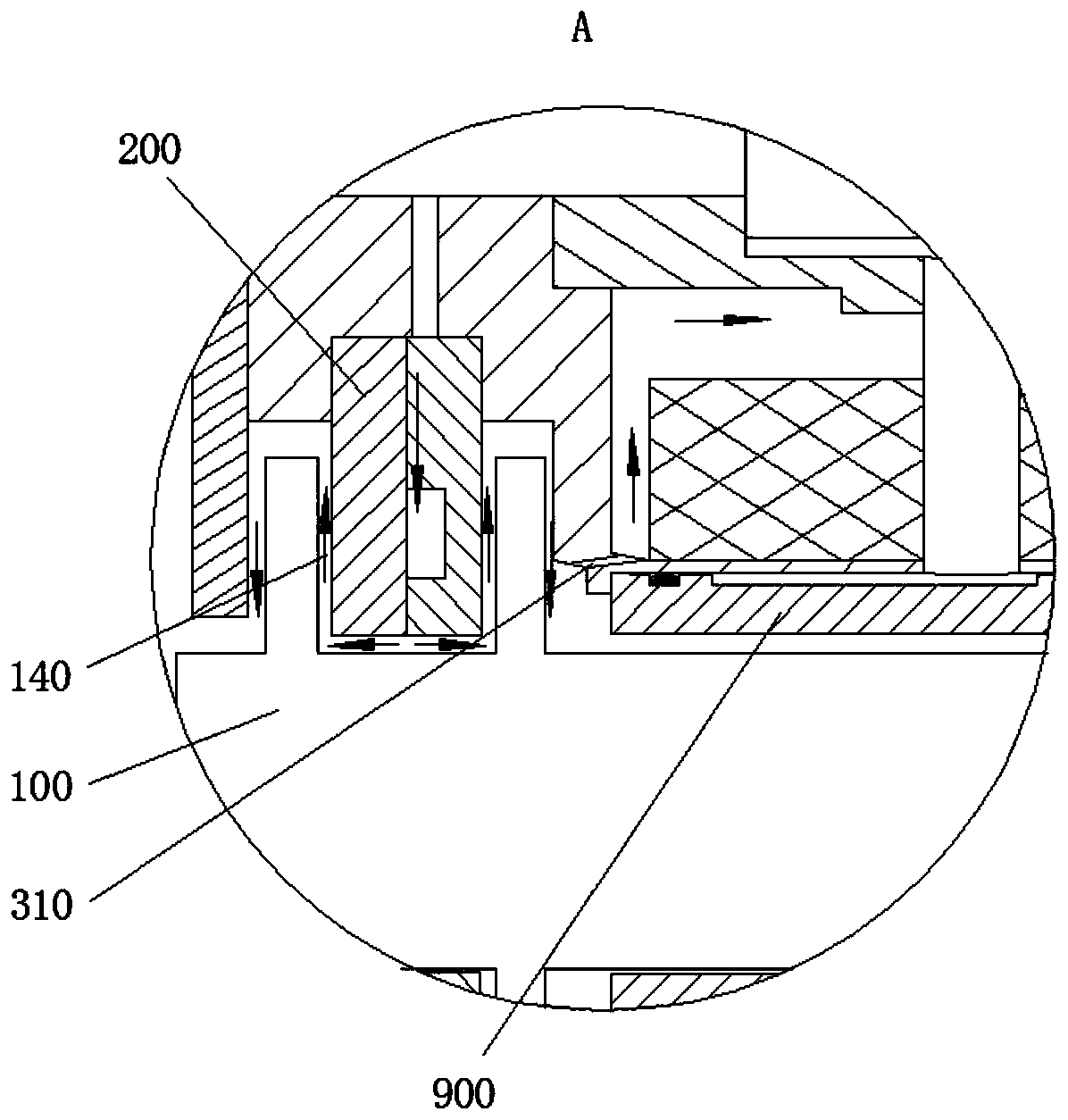

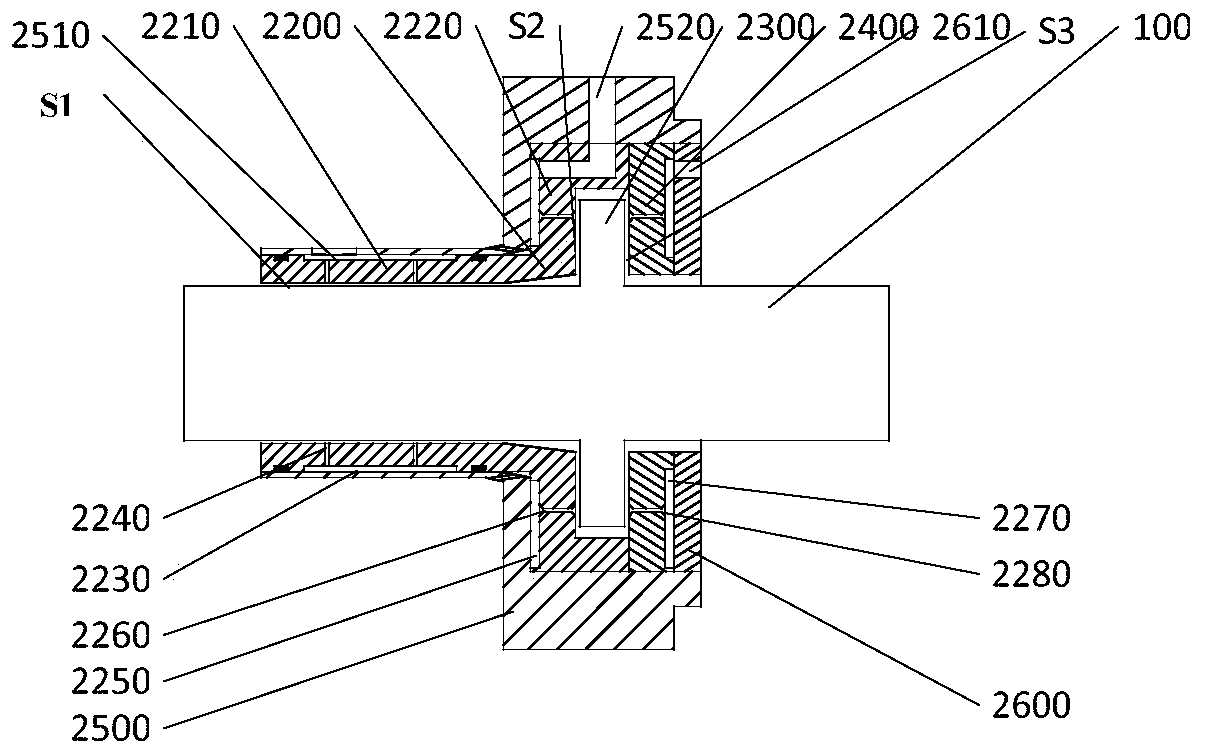

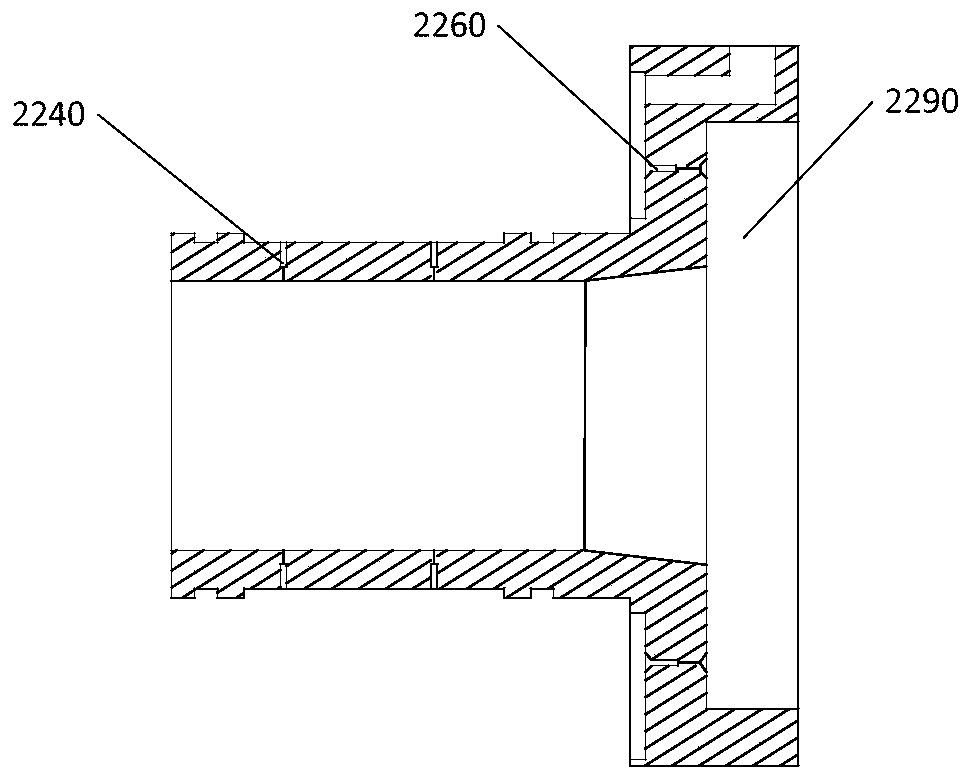

Miniature gas turbine with bearing embedded in motor

PendingCN112761791AImprove stabilityReduce mutual disturbancePump componentsEfficient propulsion technologiesCombustion chamberMicro gas turbine

The invention discloses a miniature gas turbine with a bearing embedded in a motor. The miniature gas turbine comprises a rotor system, a motor casing, a gas turbine casing and a combustion chamber, wherein the rotor system comprises a rotating shaft, a thrust bearing, a first radial bearing, the motor, a gas compressor, a second radial bearing and a turbine are sequentially arranged on the rotating shaft, and a third bearing is arranged between the rotating shaft and the motor; the motor casing covers the periphery of the motor; the gas turbine casing covers the peripheries of the gas compressor and the turbine and is connected with the motor casing; and the combustion chamber is connected with the gas turbine casing. According to the miniature gas turbine with the bearing embedded in the motor, the rotating shaft is supported by the bearings at the two ends, stress is uniform, the situation that the weight is unbalanced due to suspension of the shaft end of a rotor can be avoided, operation stability is good, and the adjustable range of the size of the rotating shaft in the axial direction is large. The radial bearing is arranged in the motor, so that mutual disturbance between the motor and the rotating shaft during high-speed rotation is reduced, and the stability of the rotor during operation of the gas turbine is effectively enhanced.

Owner:刘慕华

Long-span rotor system and gas turbine generator set

PendingCN110863910AImprove running stabilitySolve runnabilityGas turbine plantsJet propulsion plantsElectric machineGas compressor

The invention provides a long-span rotor system and a gas turbine generator set. The rotor system comprises a rotating shaft which is of an integrally formed structure. A thrust bearing, a first radial bearing, a motor, a gas compressor, a second radial bearing and a turbine are successively arranged on the rotating shaft. In the rotor system, two supporting points (the first radial bearing and the second radial bearing) are placed at two ends of the rotating shaft, separately, so that the rotating shaft is better in equilibrium and the rotor system is good in operating stability. The long-span rotor system can solve the problems of dimensional limit of the tail of the rotating shaft and unstable operation and severe vibration of the rotor system.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD +1

Rotor system and micro gas turbine generator set

PendingCN111042924AAxial dimension shortImprove dynamic propertiesTurbine/propulsion engine coolingGas turbine plantsElectric machineMicro gas turbine

The invention provides a rotor system and a micro gas turbine generator set. The rotor system comprises a rotating shaft, an integrated bearing, a motor, a radial bearing, an air compressor and a turbine, wherein the rotating shaft is of an integrated forming structure; the integrated bearing, the motor, the radial bearing, the air compressor and the turbine are arranged on the rotating shaft in sequence; the integrated bearing and the motor are provided with a first air inlet channel penetrating through the integrated bearing and the motor in the axial direction; and the first air inlet channel communicates with an air inlet of the air compressor. In the system, an air inlet is formed in a bearing shell and a stator part of a generator, the inlet air for the air compressor can enter the air compressor through the bearing shell and the air inlet in the stator of the generator, on one hand, the inlet air of the air compressor can cool the coil winding of the generator stator, on the other hand, the inlet air of the air compressor does not detour and does not increase the axial length of the rotor system, and sufficient air intake of the air compressor can be guaranteed.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD +1

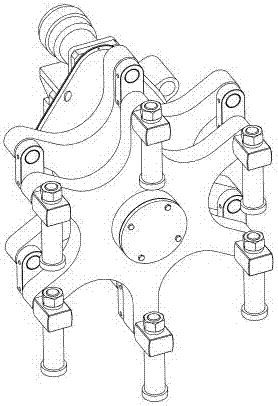

Novel single-foot rod multi-foot wheel

The invention provides a novel single-foot rod multi-foot wheel. Through redesign and innovation of the multi-foot wheel structure, the defects that an existing multi-foot wheel is complex in structure and poor in operation stable performance, the platform weight which can be borne is limited, and the structural performance is poor are overcome. The novel single-foot rod multi-foot wheel comprises an installation frame, a hydraulic motor, a driving gear, a driven gear, an eccentric shaft, a driving wheel, a driven wheel, foot rods, foot rod installation bases, connecting pieces and hinge shafts, wherein the driving wheel and the driven wheel are eccentrically arranged. A conical hole is formed in the middle of the foot rod installation frame and used for being matched with the conical surfaces at the upper ends of the foot rods, and thus the foot rods and the foot rod installation bases can bear larger acting force. The driving wheel and the driven wheel are connected through the eccentric shaft to form an eccentric wheel set, and the foot rods are made to be in a downwards perpendicular state all the time through rotation of the driving wheel and the driven wheel which are eccentrically arranged, so that the function that the foot rods are down to the ground and walk is achieved.

Owner:UNIV OF JINAN

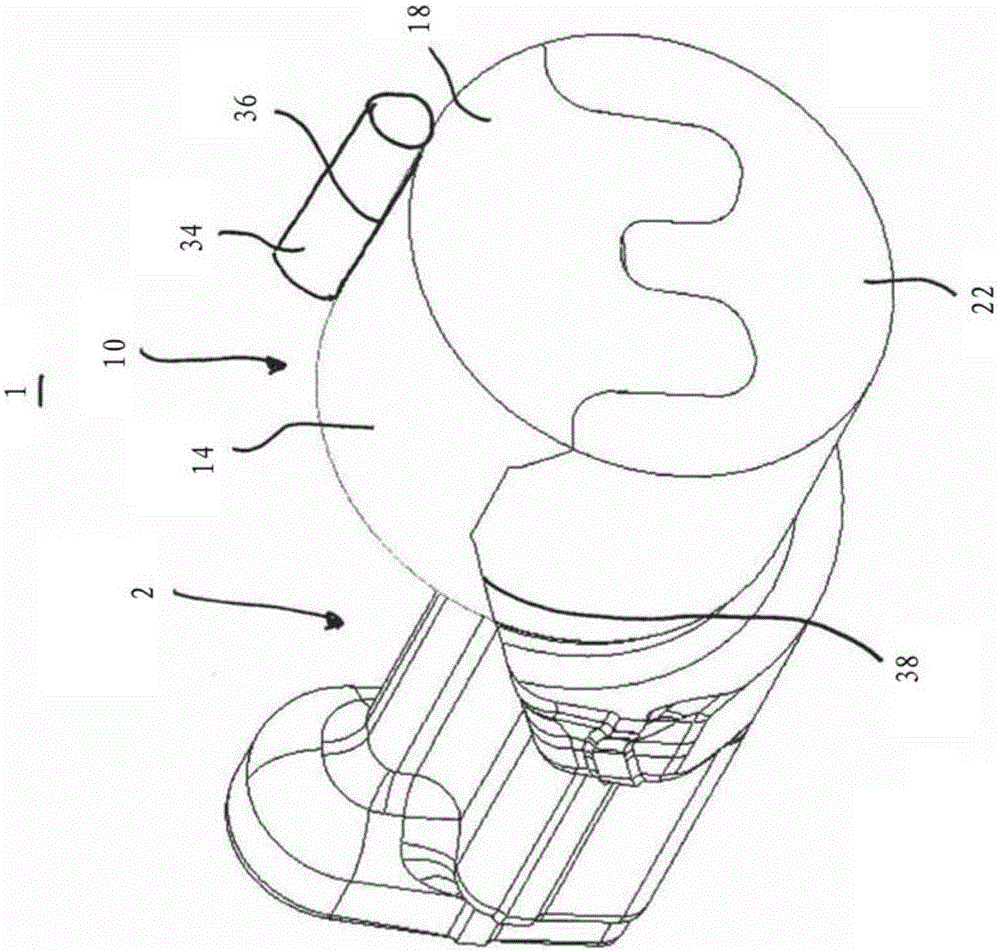

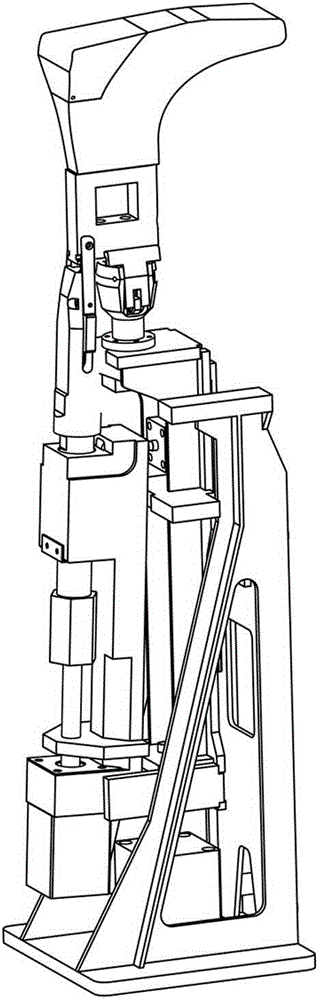

Shoe last clamping and releasing device

ActiveCN105212438AGood running stabilityHigh positioning accuracyLastingProgrammable logic controllerMarine engineering

A shoe last clamping and releasing device comprises a last clamping cylinder, a last releasing cylinder, a lifting cylinder and a push rod cylinder. The last clamping cylinder comprises a shoe last positioning pin and shoe last pneumatic clamps. The last releasing cylinder comprises a last releasing rod pneumatic clamp. The lifting cylinder is used for making the last releasing cylinder rise and fall. The push rod cylinder comprises a push rod. The last clamping cylinder and the last releasing cylinder are oppositely arranged. The push rod cylinder is located below the last clamping cylinder. The push rod of the push rod cylinder is right opposite to the last releasing cylinder. A lifting arm of the lifting cylinder is connected with the last releasing cylinder. Actions of the cylinders are sequentially controlled and implemented through a programmable logic controller (PLC). The shoe last clamping and releasing device has the advantages that the running stability is high, the positioning accuracy is high, the work efficiency is high, and shoe lasts are high in stability after being clamped. The shoe last clamping and releasing device is particularly suitable for shoe making automatic production lines.

Owner:ZHEJIANG SHENMING SHOEMAKING MACHINERY

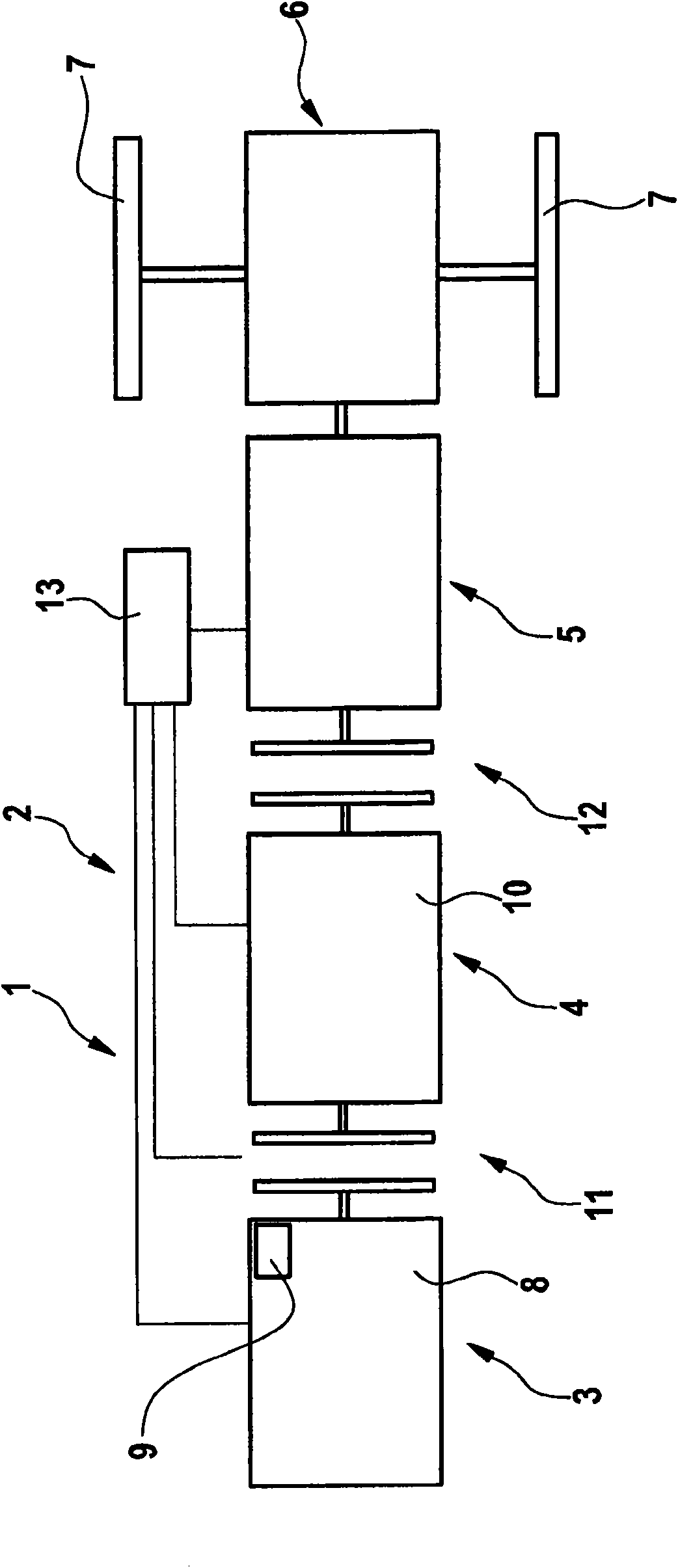

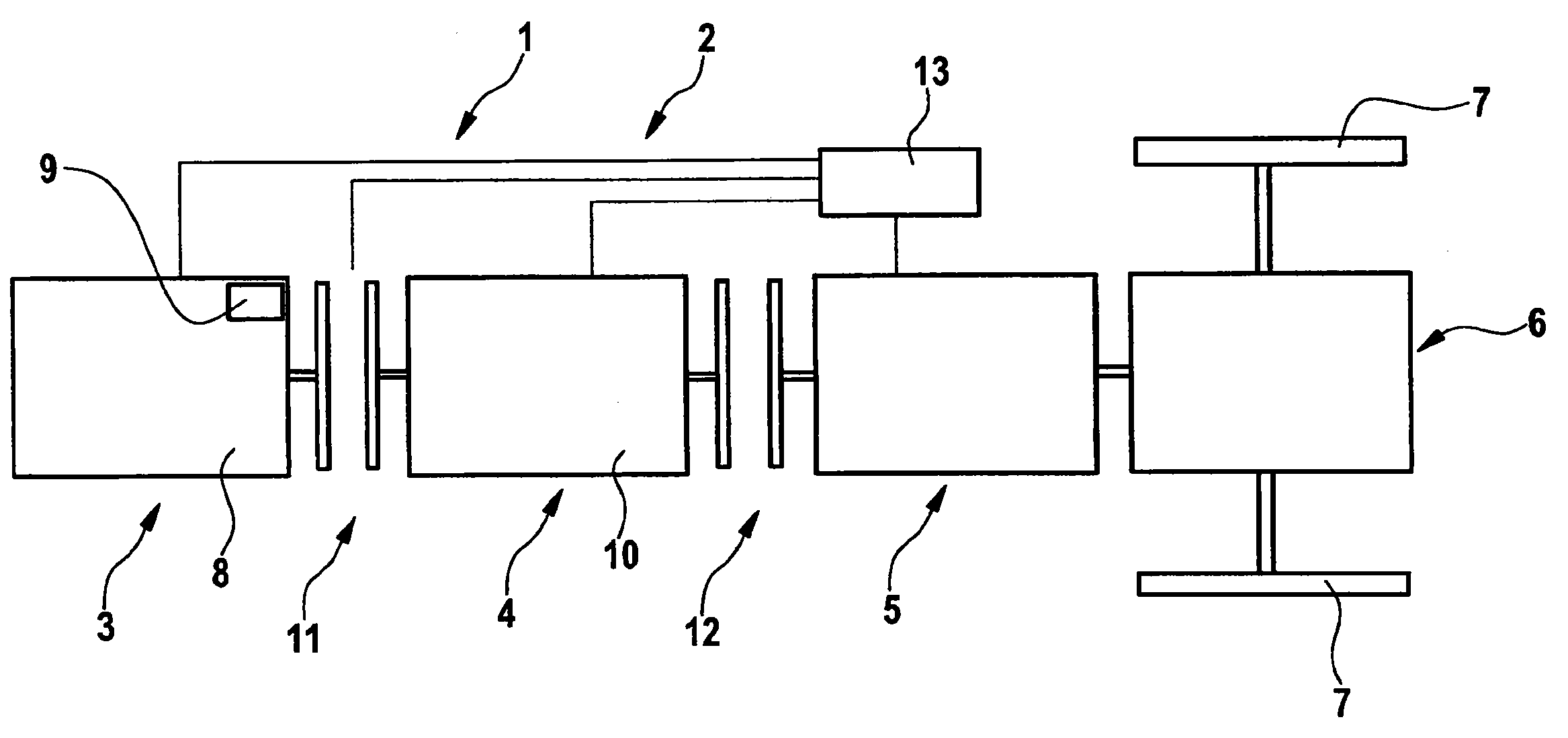

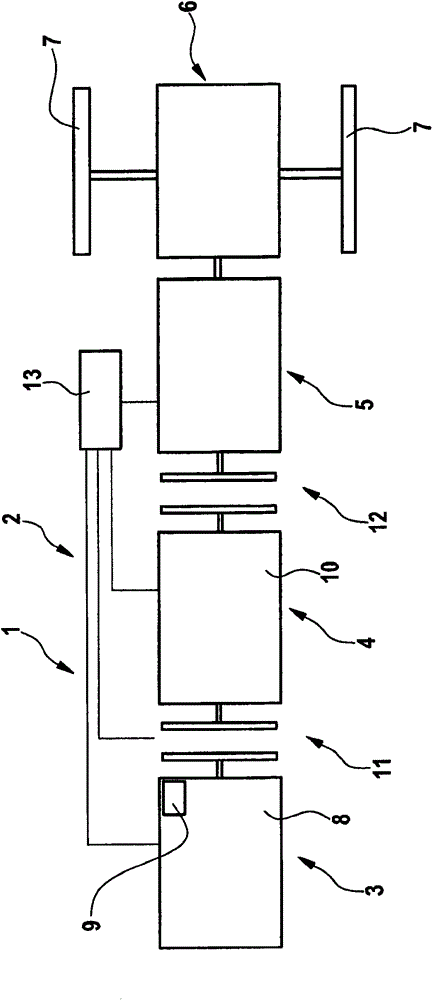

Method for operating hybrid vehicle and corresponding driving device

ActiveCN101954907AReach the transition temperatureHeating fastInternal combustion piston enginesGas pressure propulsion mountingElectricityCombustion

The invention relates to a method for operating a hybrid vehicle. The vehicle is provided with a driving device (1) with at least two different power devices (3, 4), wherein at least one motor (10) and at least one internal combustion engine (8) with a catalyst (9) can be used as the power devices (3, 4) and operated. According to the design, when the cold internal combustion engine (8) is initially started, the hybrid vehicle is at least electrically started; before starting, the internal combustion engine (8) is started simultaneously or thereafter and operated in internal combustion operation separated from the electric operation of the motor (10) to heat the catalyst (9). Moreover, the invention also relates to the corresponding driving device (1).

Owner:ROBERT BOSCH GMBH

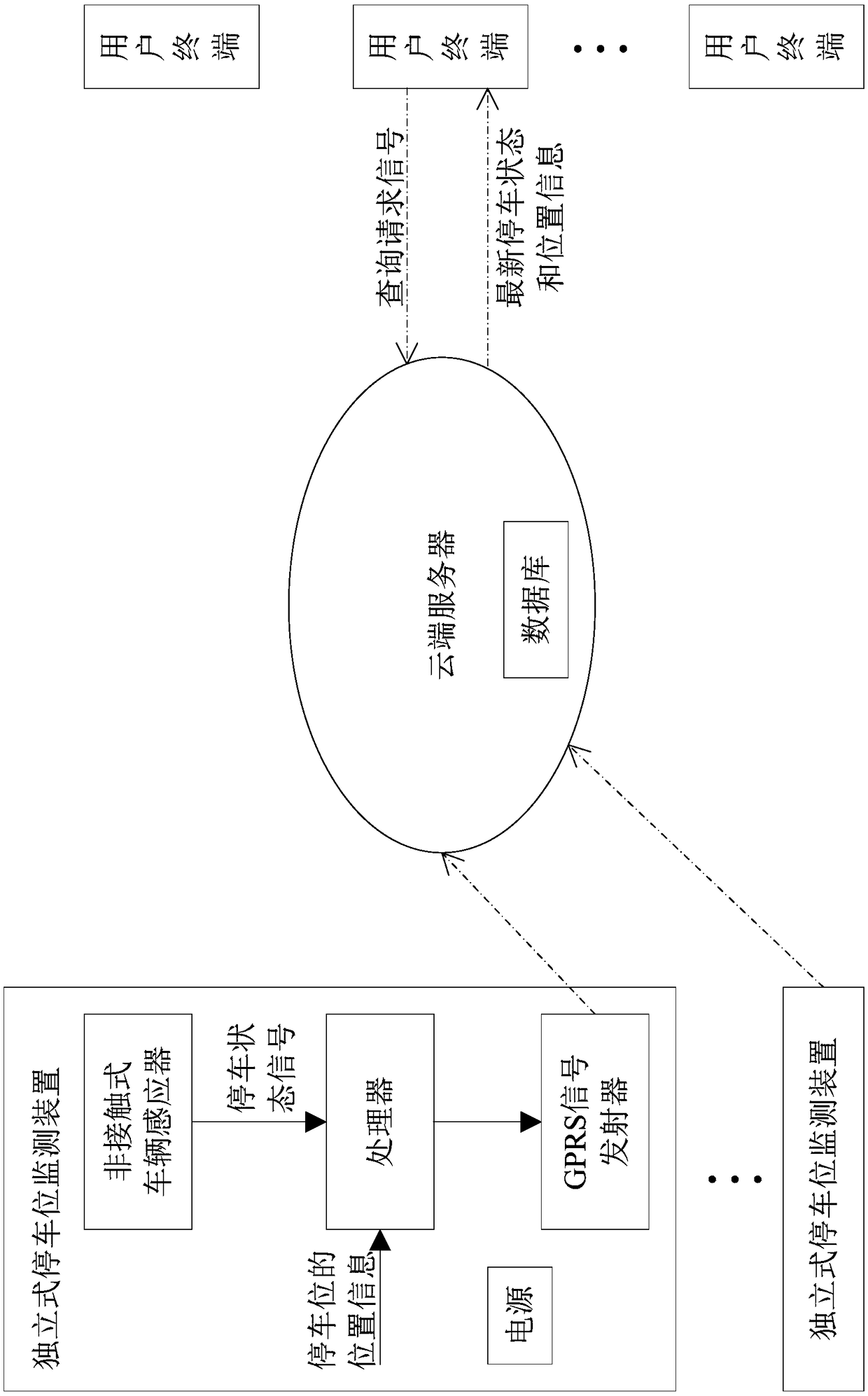

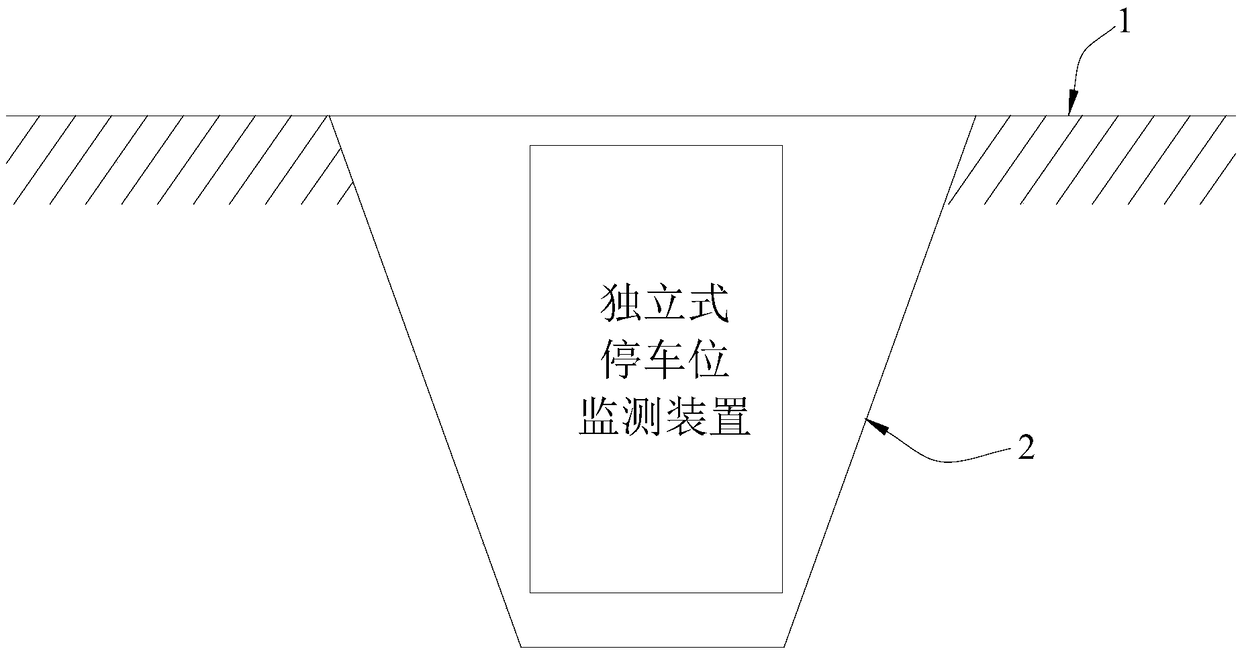

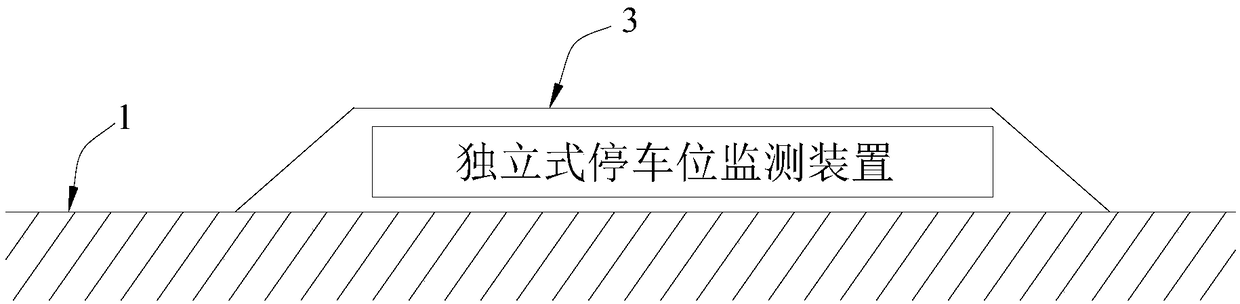

Independent parking space monitoring device and intelligent parking space information system

InactiveCN108922240AImprove reliabilityGood running stabilityIndication of parksing free spacesDriver/operatorInformation system

Owner:伍斯龙 +1

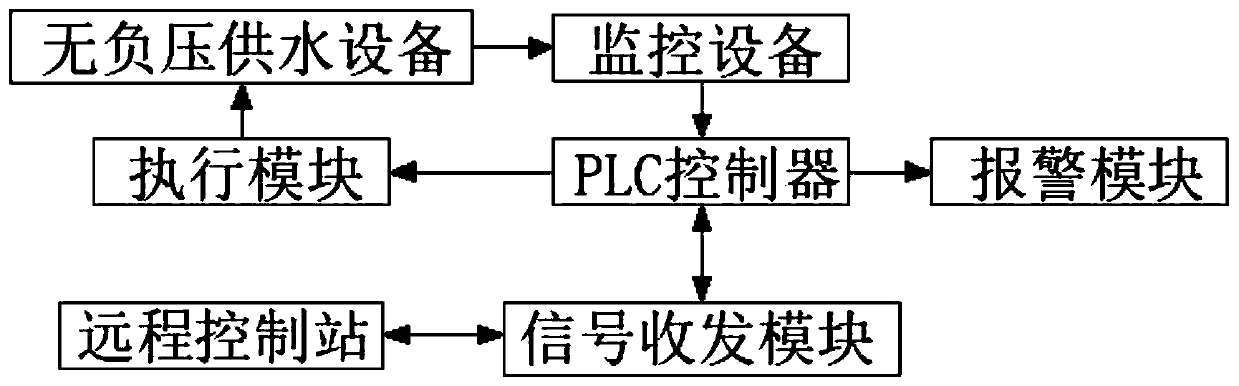

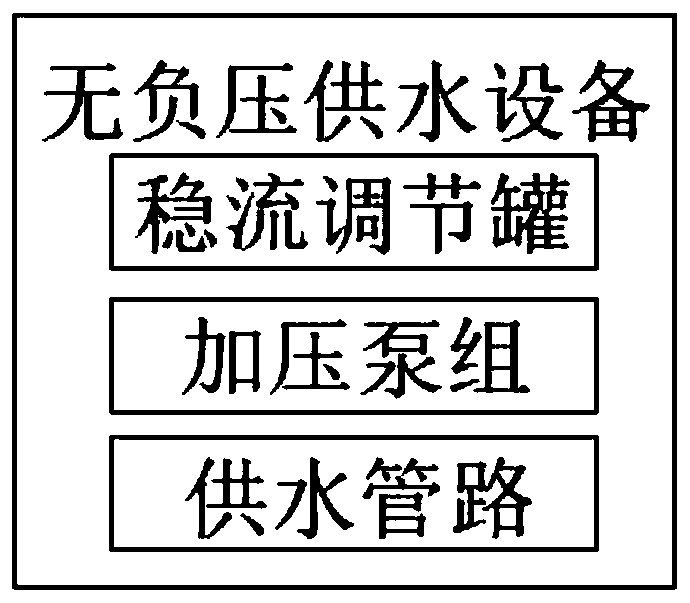

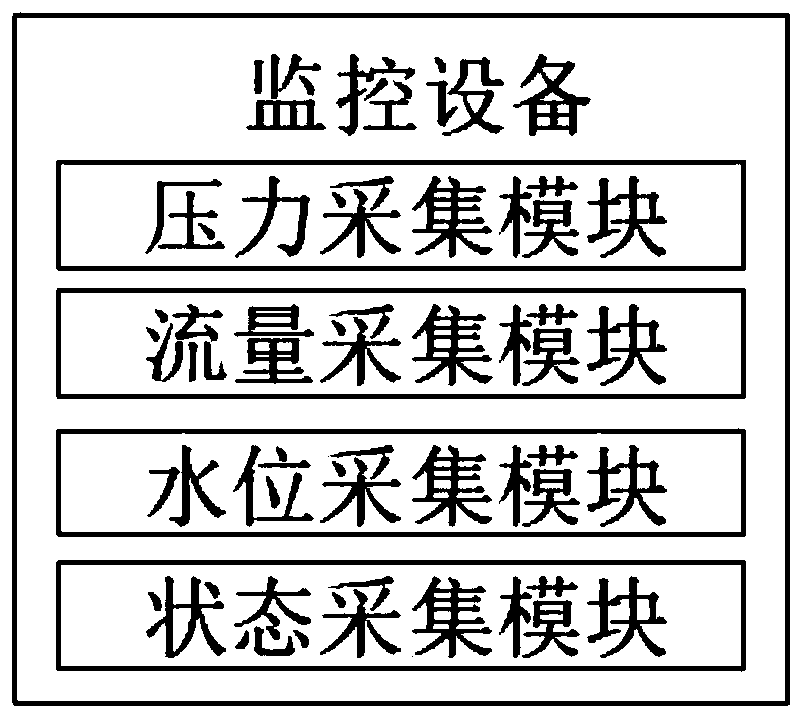

Modular intelligent non-negative pressure water supply system

InactiveCN111561018AGood running stabilityEasy TroubleshootingMeasurement devicesTransmission systemsWater supply networkProcess engineering

The invention discloses a modular intelligent non-negative pressure water supply system, and relates to the technical field of water supply systems. The modular intelligent non-negative pressure watersupply system comprises non-negative pressure water supply hardware equipment, monitoring equipment connected to the non-negative pressure water supply hardware equipment and a control terminal for intelligent operation. The non-negative pressure water supply hardware equipment comprises a water supply pipeline, a steady flow adjusting tank and a pressure pump set, the pressure pump set comprisesa plurality of water supply pumps connected in parallel and used for increasing the water pressure of the water supply pipeline, the water supply pumps are variable frequency water pumps, and the pressure pump set communicates with the steady flow adjusting tank and the water supply pipeline. The modular intelligent non-negative pressure water supply system is good in operation stability, the purpose of monitoring and controlling the whole water supply system can be achieved, various monitoring equipment can be classified and modularly processed, faults can be processed and reminded in time,fault points can be accurately positioned, and maintenance personnel can conveniently and rapidly process the faults in time.

Owner:潍坊赛沃环保科技有限公司

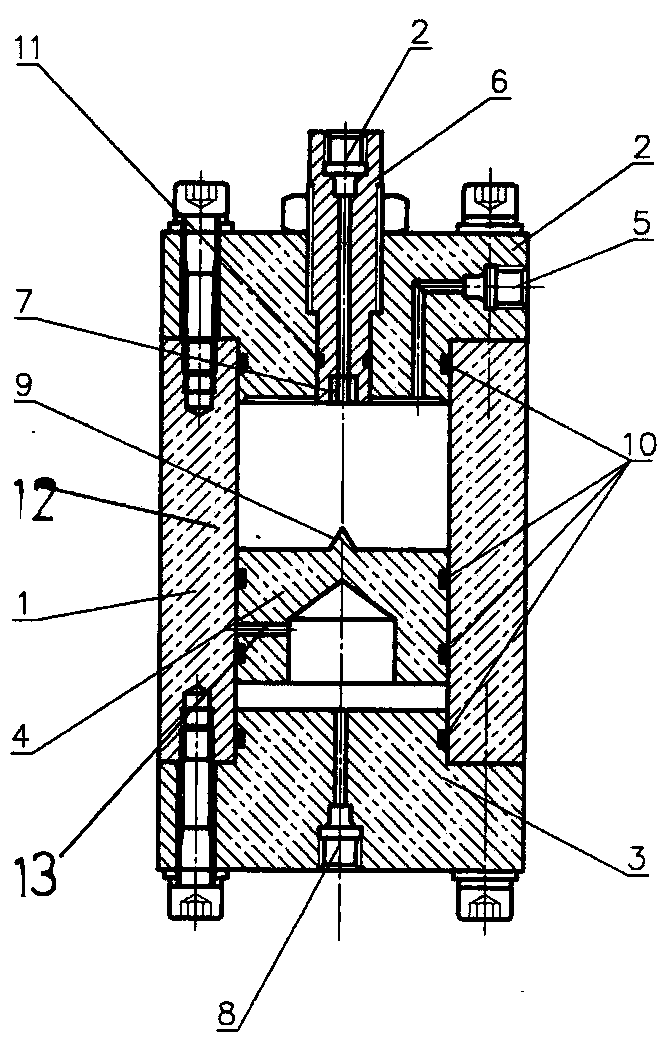

Back pressure valve

InactiveCN110260006AReasonable structureGood running stabilityEqualizing valvesSafety valvesPistonEngineering

The present invention discloses a back pressure valve, comprising a back pressure valve cylinder, wherein the upper and lower ends of the back pressure valve cylinder are respectively provided with an upper plug and a lower plug, and a back pressure valve piston body is arranged in the back pressure valve cylinder. The side surface of the upper plug is provided with a fluid inlet which communicates with the inner cavity of the cylinder, the central part of the upper plug is provided with a valve core with an overflow hole, and the lower plug is provided with a variable pressure adjusting hole which exerts pressure to the lower end of the back pressure valve piston body by adding fluid. The back pressure valve piston body is in the form of an inner hollow cavity, and the bottom of the hollow cavity communicates with an inner cavity of the back pressure valve cylinder, and the back pressure valve piston body and the contact surface between the back pressure valve piston body and the back pressure valve cylinder are each provided with upper and lower sealing gaskets. A through hole communicating with the inner hollow cavity of the piston body is arranged between the upper sealing gasket and the lower sealing gasket on the back pressure valve piston body. The back pressure valve has a reasonable structure, good operation stability and excellent working performance.

Owner:南通市中京机械有限公司

Steel rail grinding trolley

PendingCN111235982ABroaden the applicationGood running stabilityRailway track constructionVehicle frameManufacturing engineering

The invention discloses a steel rail grinding trolley. The steel rail grinding trolley comprises two grinding trolleys which are connected in a hinged mode. The grinding trolley comprises a frame, a polishing unit, a walking guide wheel, a dust collecting channel and a fireproof and dustproof device. The grinding unit is arranged in the frame, the walking guide wheels are arranged on the lower portion of the frame, and the dust collecting channel is arranged on the upper portion of the frame. The fireproof and dustproof device wraps the frame except the bottom, and a semi-closed structure of the polishing trolley is formed through the fireproof and dustproof device and the dust collecting channel. The steel rail grinding trolley further comprises an elastic traction rod and a rigid traction rod, one grinding trolley is connected with the trolley body through the elastic traction rod, and the other grinding trolley is connected with the trolley body through the rigid traction rod. The steel rail grinding trolley can solve the technical problems that an existing steel rail grinding trolley is limited in application occasion, poor in operation stability and poor in grinding quality and effect.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

Method for operating hybrid vehicle and corresponding driving device

ActiveCN101954907BReach the transition temperatureHeating fastHybrid vehiclesInternal combustion piston enginesElectricityInternal combustion engine

The method involves operating an internal combustion engine (8) with predefined load to heat a catalyst (9) for cold-starting of the engine of a hybrid vehicle, where the vehicle comprises a driving installation (1) with driving units (3, 4) having an electric motor (10). The electric motor is assisted for driving the hybrid vehicle. The internal combustion engine is operated in an idle state to continue heating process of the catalyst. An independent claim is also included for a driving installation comprising a control device for managing driving units.

Owner:ROBERT BOSCH GMBH

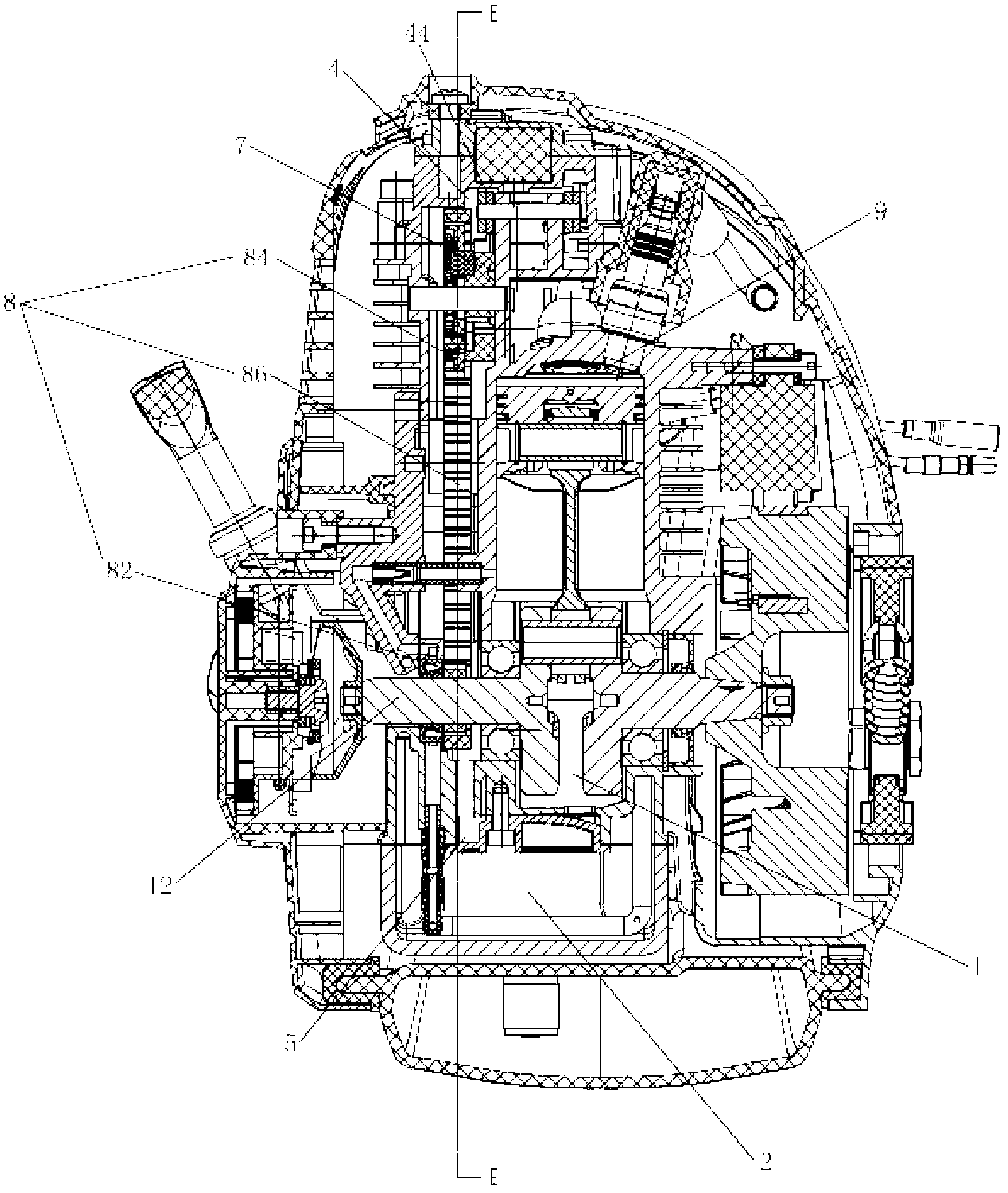

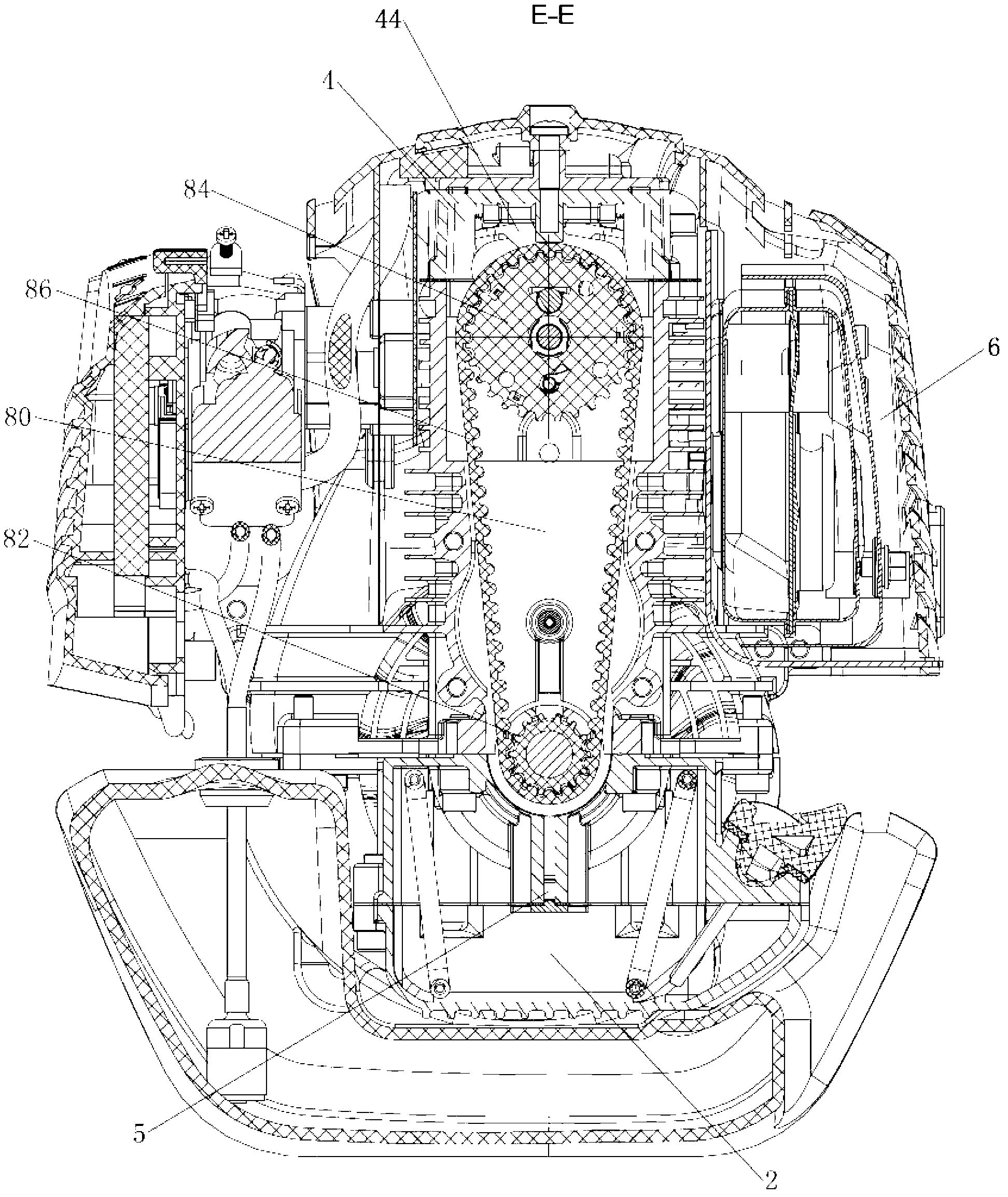

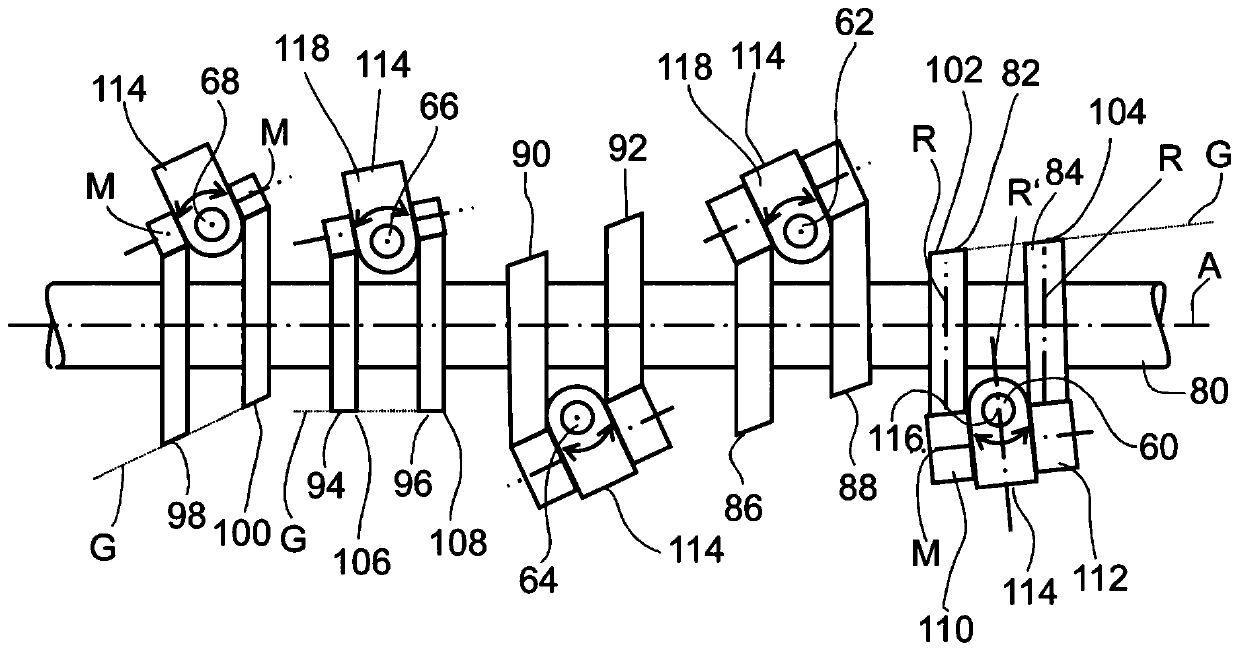

Brush tufting device

The invention relates to a brush tufting device, and the device comprises at least one tufting tool which has a plurality of sub-tools that can be moved back and forth on trajectories and that are driven by a camshaft (80) on which cams (82 to 100) having inclined cam surfaces (102 to 104) are mounted. Cam followers are mounted in pairs on a common rocker (114) that is tilted by the inclined cam followers (102, 104).

Owner:BORGHI SPA

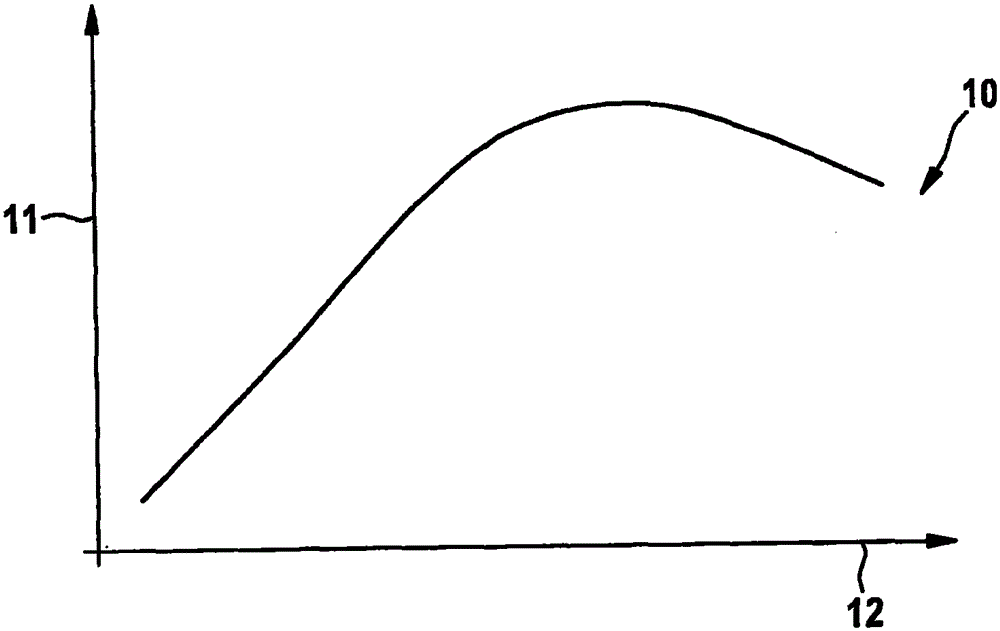

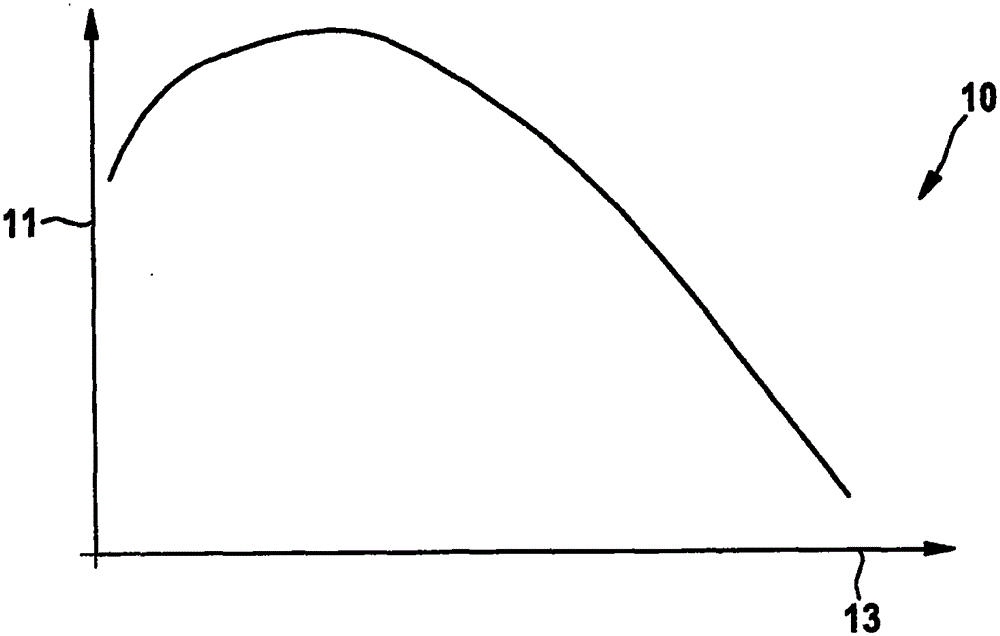

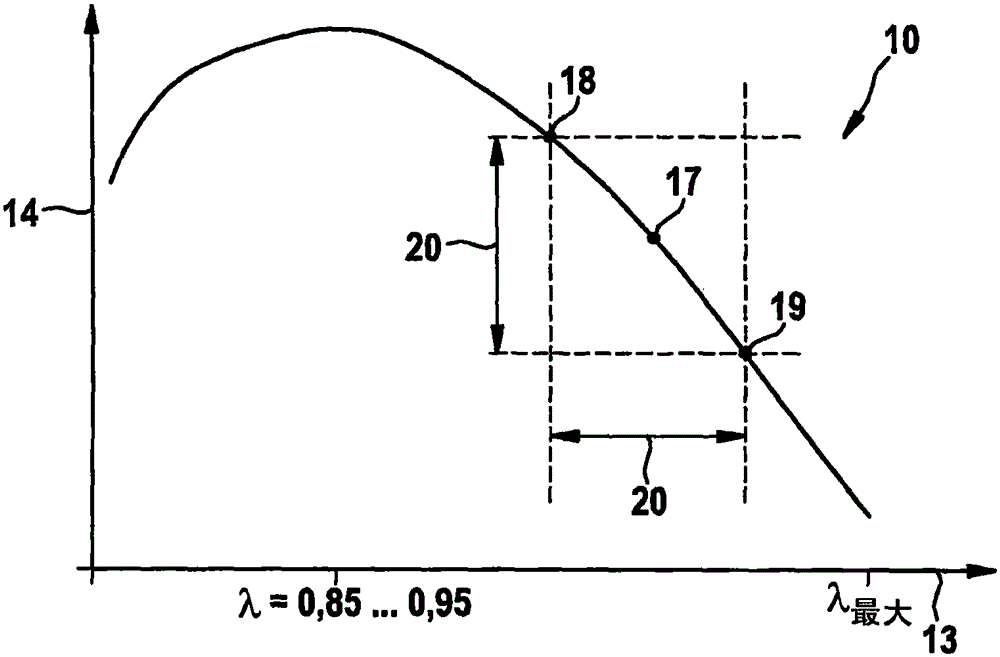

Method and apparatus for reducing running non-smoothness in an internal combustion engine

ActiveCN105317612AGood running stabilityOptimization is fast and error-freeElectrical controlInternal combustion piston enginesPollutant emissionsControl cell

The invention relates to a method for adjusting an air-fuel ratio for operating an internal combustion engine, a fuel injection quantity is varied from one combustion cycle to a directly or indirectly following the next combustion cycle. The invention further provides a corresponding apparatus, in particular to an engine control unit having at least one controller unit and a memory unit for implementing the method. According to the invention, in order to counteract running non-smoothness, periodic matching of the ignition angle is performed. If the method is used in single-cylinder internal combustion engines of motorcycles, power can be increased, pollutant emissions can be reduced, and a possible optimal compromise between all criteria can be achieved. Furthermore, the running non-smoothness caused by the injection quantity variation can be reduced, thereby resulting in a higher customer acceptability.

Owner:ROBERT BOSCH GMBH

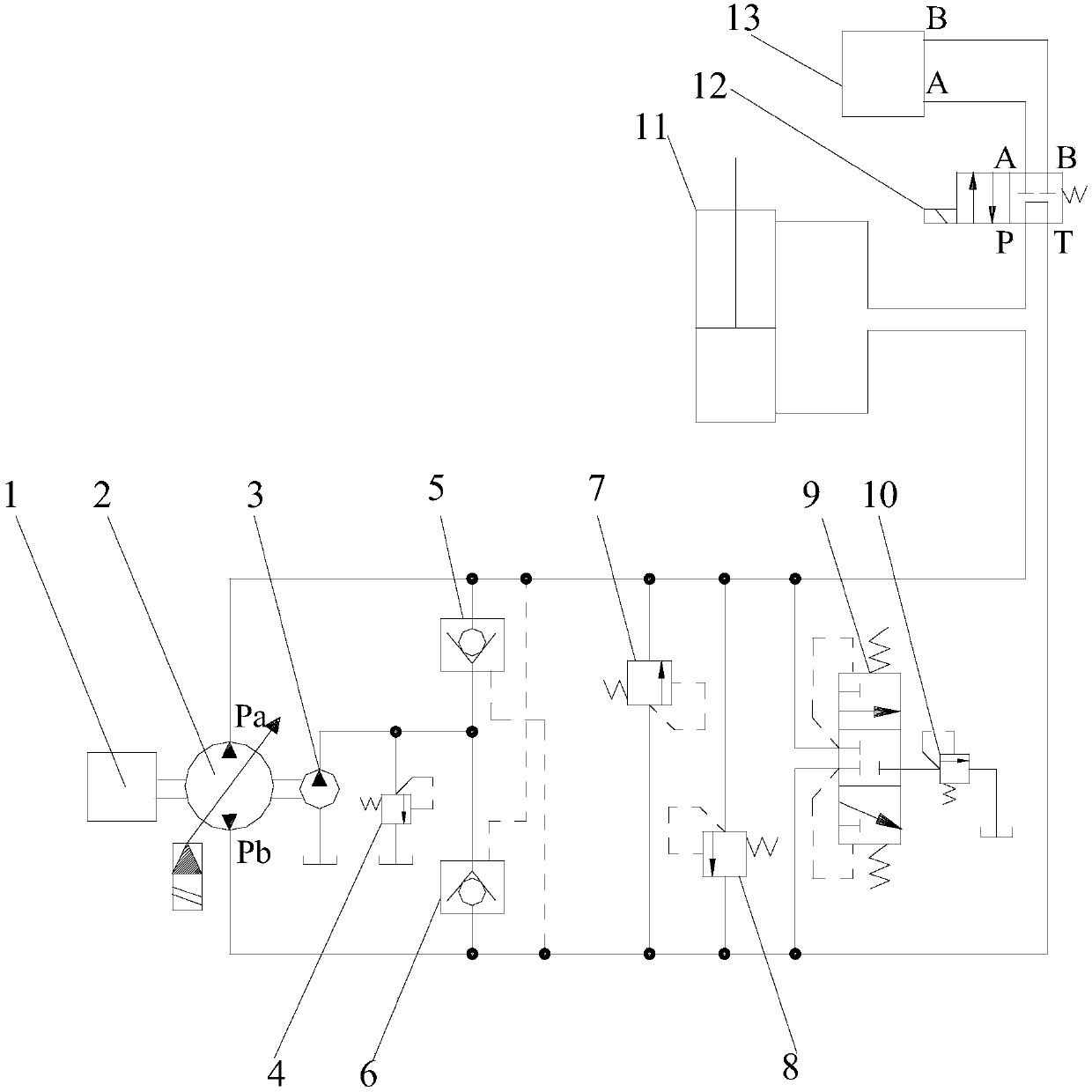

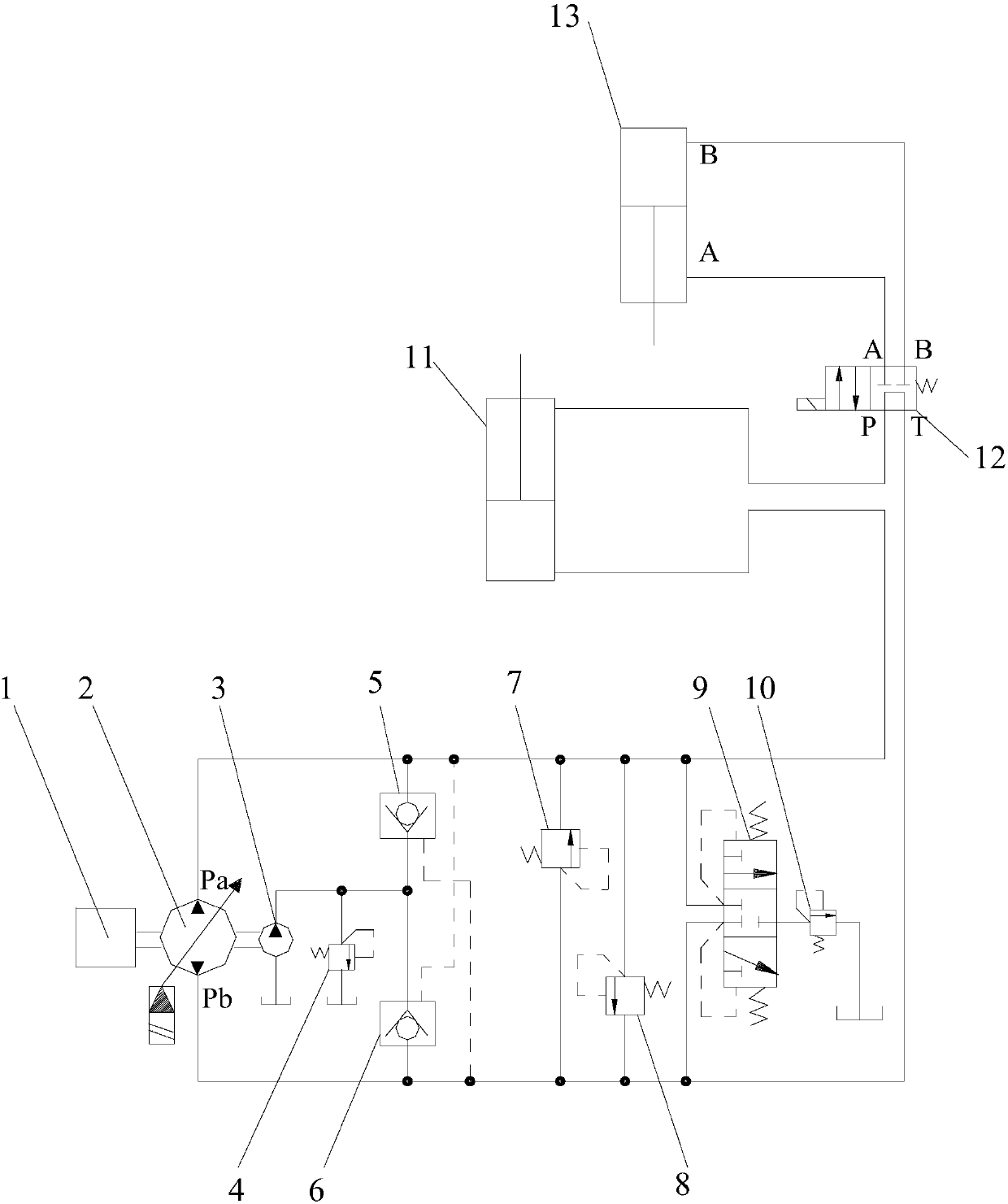

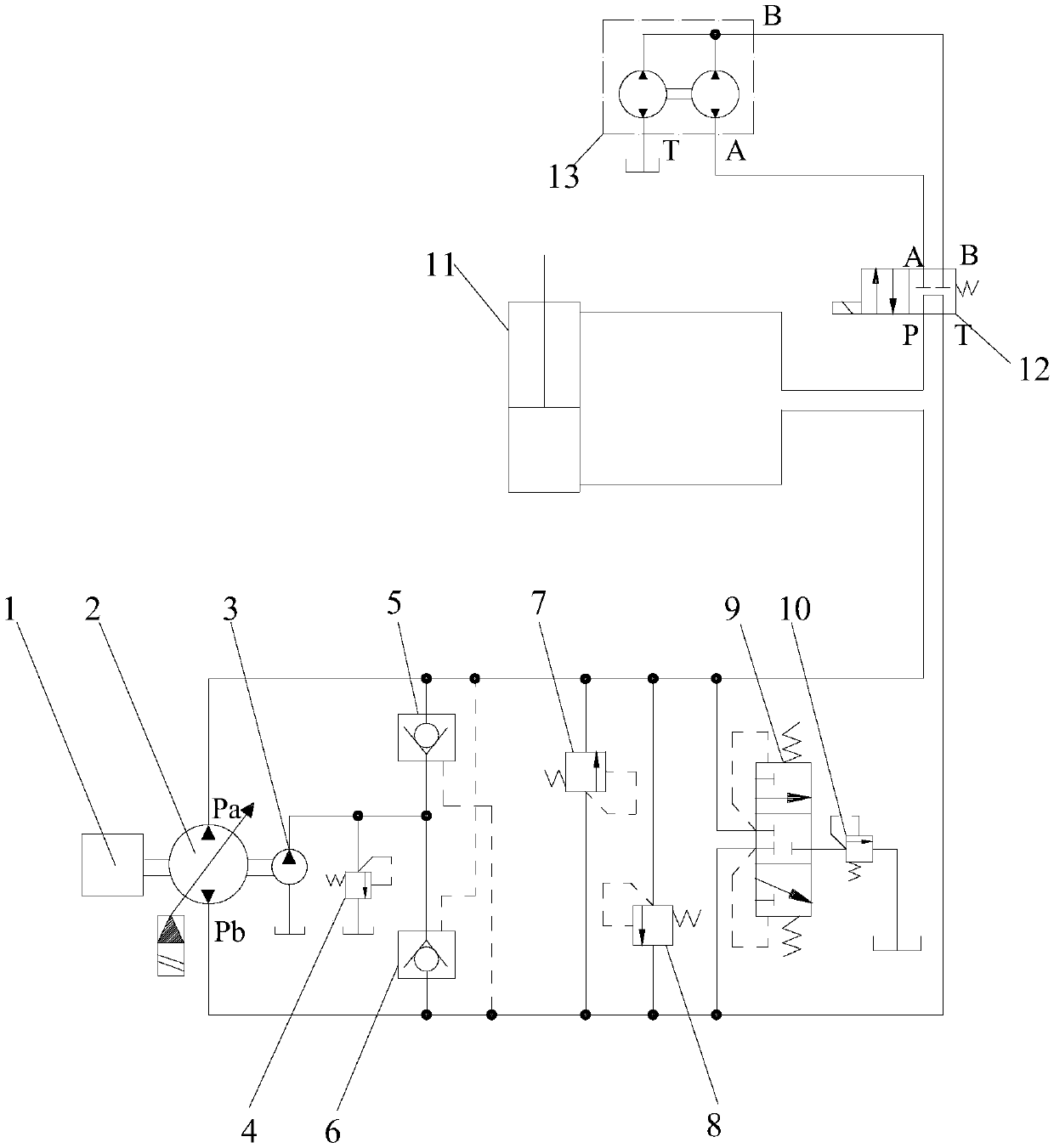

Hydraulic loop of pump-controlled single rod piston cylinder

InactiveCN108035921AImprove energy efficiencyGood running stabilityServomotor componentsServomotorsPiston cylinderShuttle valve

The invention discloses a hydraulic loop of a pump-controlled single rod piston cylinder and belongs to the technical field of hydraulic transmission. The hydraulic loop comprises a prime motor, a main pump, an oil supplementing pump, a first hydraulic control one-way valve, a second hydraulic control one-way valve, a shuttle valve, a working cylinder, a hydraulic transformer, a high-pressure reversing valve, an oil tank and a controller. The hydraulic loop is characterized in that the high-pressure reversing valve is a two-position four-way electromagnetic reversing valve, and a right workingposition of the reserving valve has the function of an M-shaped sliding valve; a first working cavity and a second working cavity of the working cylinder communicate with a port Pa of the main pump and a port P of the reserving valve correspondingly; a port T of the reserving valve communicates with a port Pb of the main pump; and a port A and a port B of the reserving valve communicate with a port A and a port B of the hydraulic transformer correspondingly. The hydraulic loop has the advantages that when the working cylinder is in the stable heavy-load and load working conditions, the two hydraulic control one-way valves are adopted to compensate the asymmetrical flow, so that the energy efficiency is high; and when the working cylinder is in the alternating load working condition, the hydraulic transformer is adopted to compensate the asymmetrical flow, so that sudden change of the speed of the working cylinder is avoided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel greenhouse production energy-saving environment control device based on heat storage heat pump

PendingCN113475272ASimple structureGood running stabilityClimate change adaptationSaving energy measuresGreenhouse productionCirculating pump

The invention relates to a novel greenhouse production energy-saving environment control device based on a heat storage heat pump, and belongs to the technical field of greenhouse production energy-saving heat pumps. The novel greenhouse production energy-saving environment control device comprises a heat storage tank, wherein a fan coil, an underground water-soil heat exchanger and an air-water heat pump are arranged on the outer side of the heat storage tank, a circulating pump which communicates with the fan coil, the underground water-soil heat exchanger and the air-water heat pump through pipelines is arranged in the heat storage tank, and circulating pipes are arranged between the heat storage tank and the fan coil, between the heat storage tank and the underground water-soil heat exchanger, between the heat storage tank and the air-water heat pump, between the circulating pump and the fan coil, between the circulating pump and the underground water-soil heat exchanger and between the circulating pump and the air-water heat pump. The novel greenhouse production energy-saving environment control device based on the heat storage heat pump has the characteristics of simple structure, good operation stability and high efficiency; and the temperature in the greenhouse is guaranteed, the temperature can be reduced and heat energy can be stored in the daytime, the temperature can be increased at night, and a proper temperature environment is provided for growth of crops in the greenhouse.

Owner:恩施不亦乐乎科技农业有限公司

Variable-speed conveying equipment for flexible materials

PendingCN114590627AGood running stabilityAdjustment EliminationMetal working apparatusWebs handlingRotational axisEngineering

The invention relates to the technical field of conveying devices, in particular to variable-speed conveying equipment for flexible materials. The equipment comprises a main supporting plate, a fixed middle shaft and rotating plates, the fixed middle shaft is rotatably sleeved with the center positions of the rotating plates, the two ends of each rotating plate are each provided with a negative pressure box, the negative pressure boxes on the rotating plates extend out towards the same side, and the inner side of each negative pressure box is provided with a receding space; the negative pressure box is provided with an induction plate extending towards the interior of the receding hole, one end of the fixing middle shaft extends to the receding space and is provided with a fixing rod located in the receding space, and a proximity sensor is arranged at the end of the fixing rod. The rotating plate adopts a structure that the negative pressure boxes are symmetrically arranged, the gravity center is positioned on the rotating shaft, the operation stability is good, and higher-speed rotating action and variable action with higher acceleration can be realized; the controller monitors the running state of the equipment in real time through the proximity sensor, real-time adjustment and error elimination can be achieved, and it is guaranteed that the equipment works accurately and stably for a long time.

Owner:JINJIANG HAINA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com