Landfill leachate treatment method

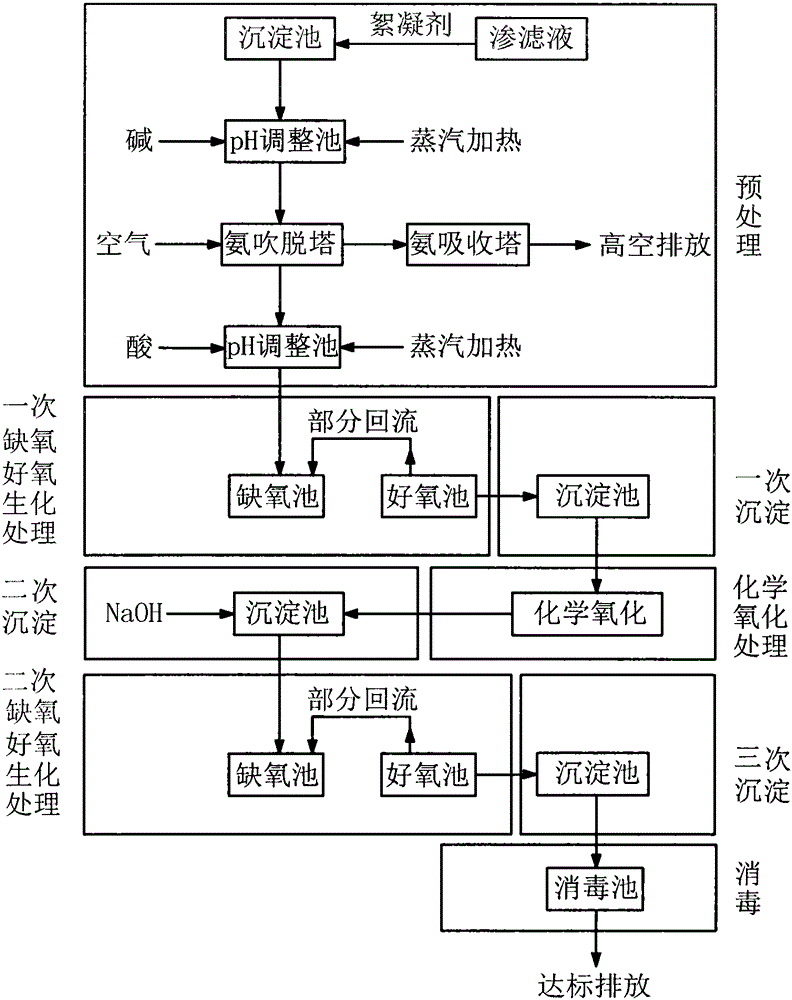

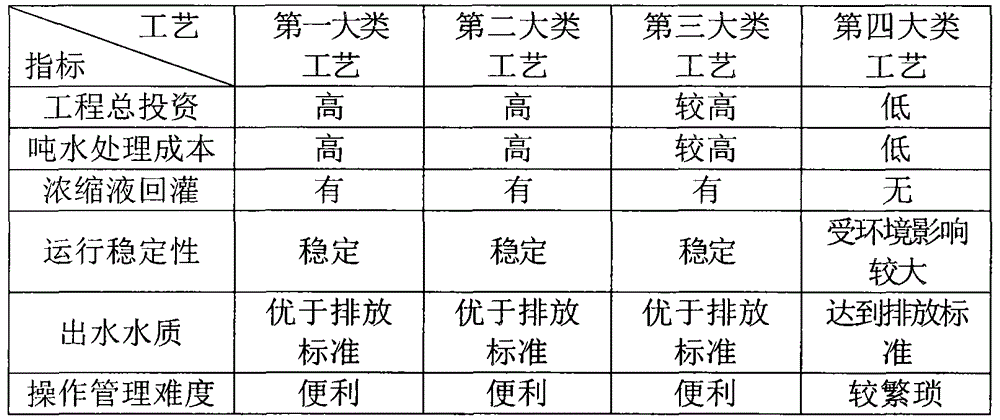

A technology of landfill leachate and treatment method, which is applied in the treatment field of leachate of urban domestic waste sanitary landfill, can solve the high investment and operation cost of landfill economic burden, the total project investment and the high cost of ton water treatment, and the high cost of treatment. The operation of the facility is greatly affected by the environment, etc., to achieve the effect of low cost per ton of water treatment, simple management and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

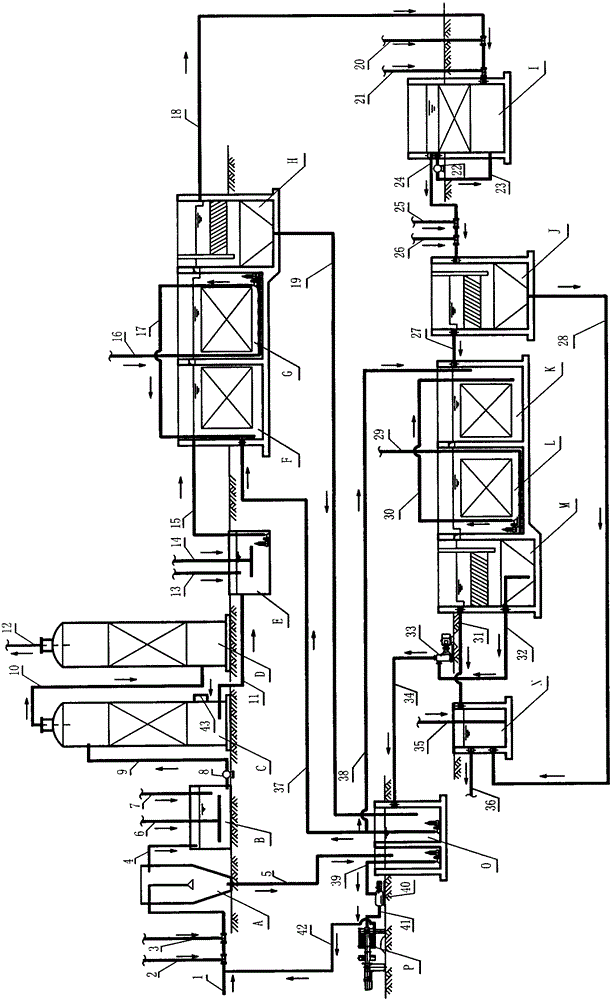

[0088] The leachate enters the sedimentation tank A through the leachate raw water inlet pipe 1, and iron salt flocculant is added to the leachate in the leachate raw water inlet pipe 1 through the iron salt dosing pipe 2 through the pipeline mixer, and at the same time, it is added by alkali as needed. Pipeline 3 adds an appropriate amount of NaOH to leachate raw water inlet pipe 1 to adjust the pH of the leachate to 7-9. The sedimentation time of the leachate in the sedimentation tank A is 1 to 3 hours. The sludge in the sedimentation tank A is discharged into the mud storage tank O through the sedimentation tank sludge discharge pipe 5, and the effluent of the sedimentation tank A enters the pH adjustment tank B through the sedimentation tank outlet pipe 4, and NaOH is added to adjust the osmosis in the tank through the alkali dosing pipe 7. The pH of the filtrate is 10.5-11.5. While adjusting the pH, according to the measured temperature of the leachate, an appropriate amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com