Steel rail grinding trolley

A technology of rail grinding car and grinding trolley, which is applied in the direction of track, laying track, track maintenance, etc., can solve the problems of limited application occasions, poor operation stability, poor grinding quality and effect, etc., to achieve good grinding quality and effect, compression The effect of occupying space, beneficial to the design of the whole vehicle and the layout of the multi-power driving mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

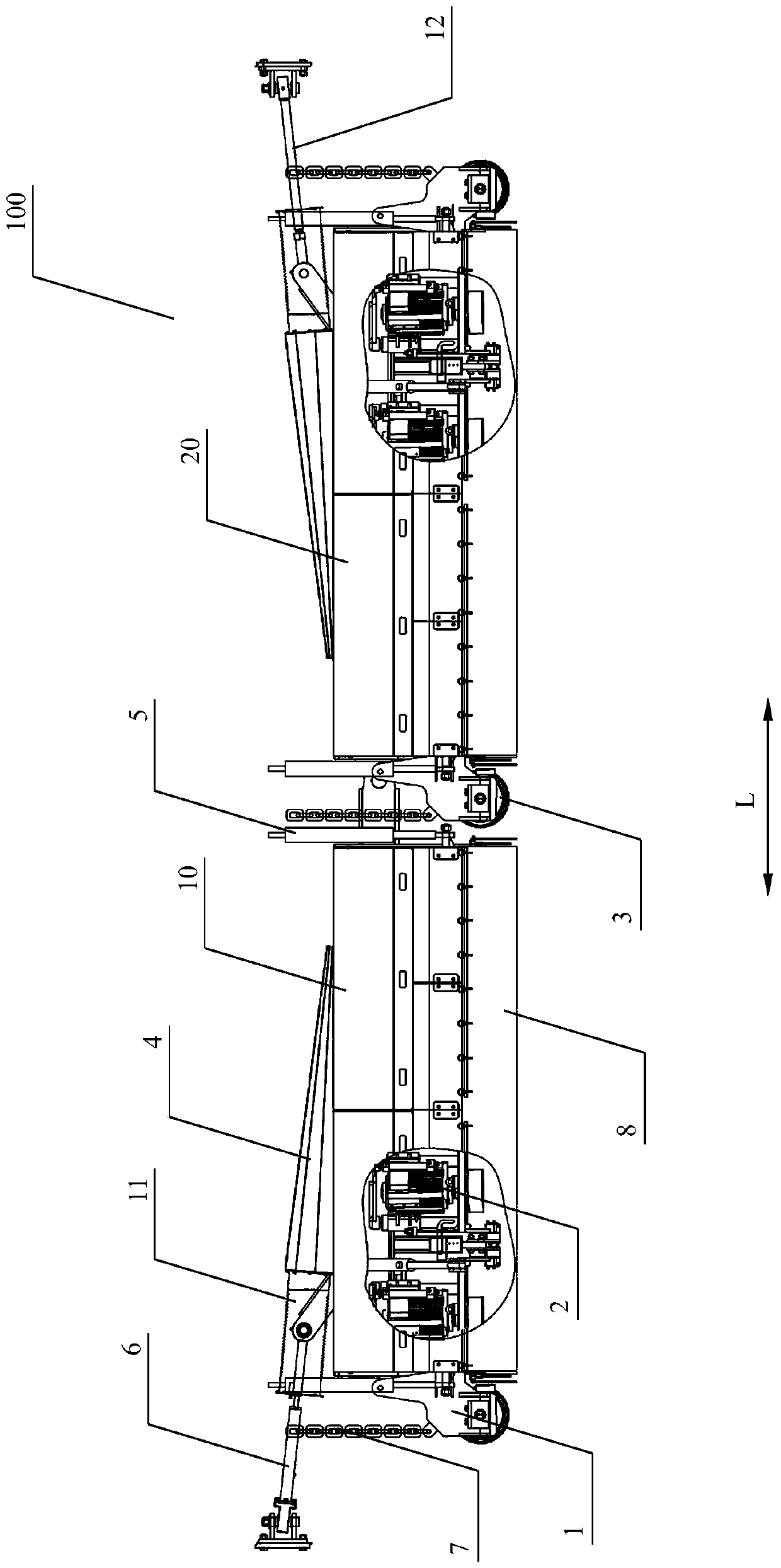

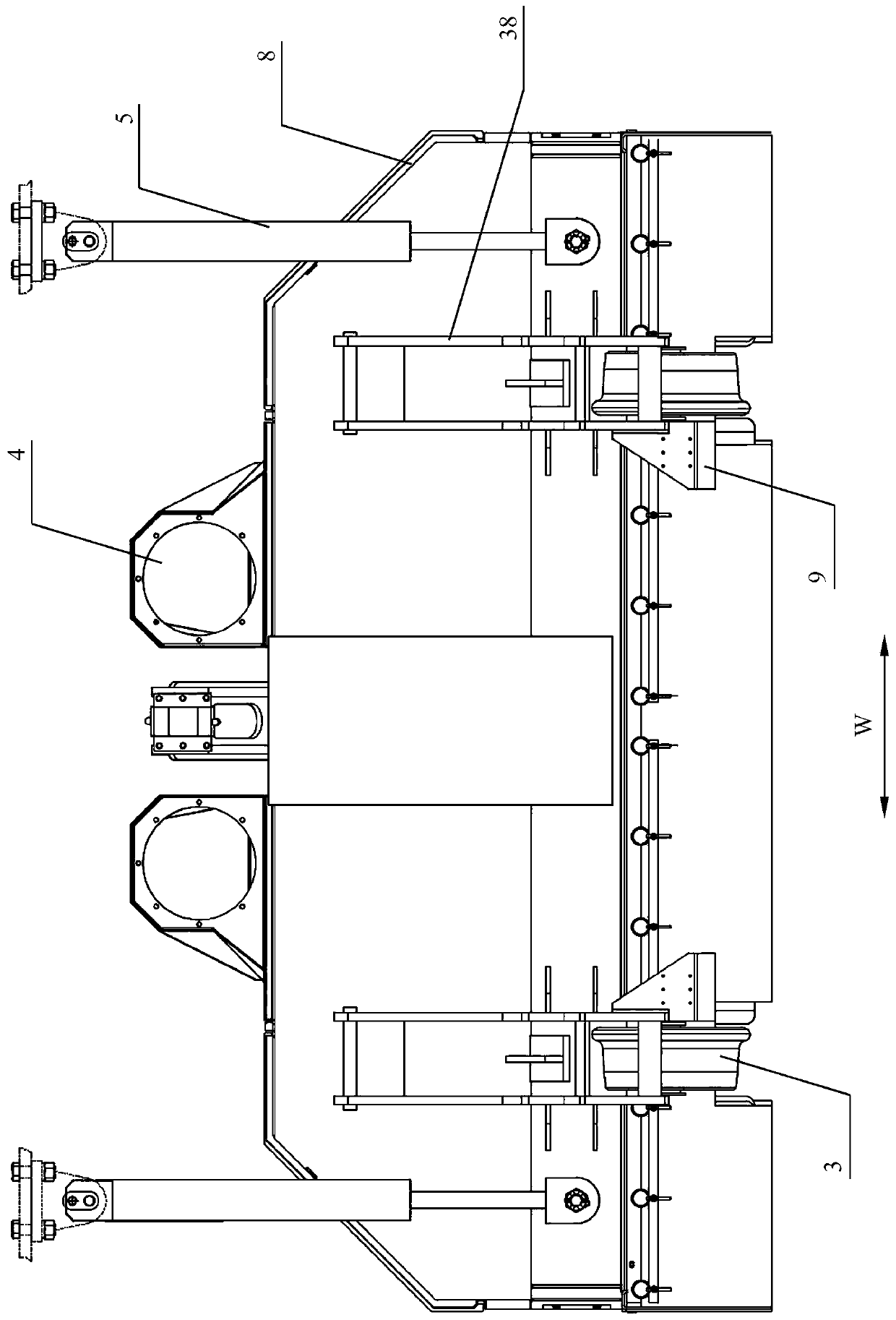

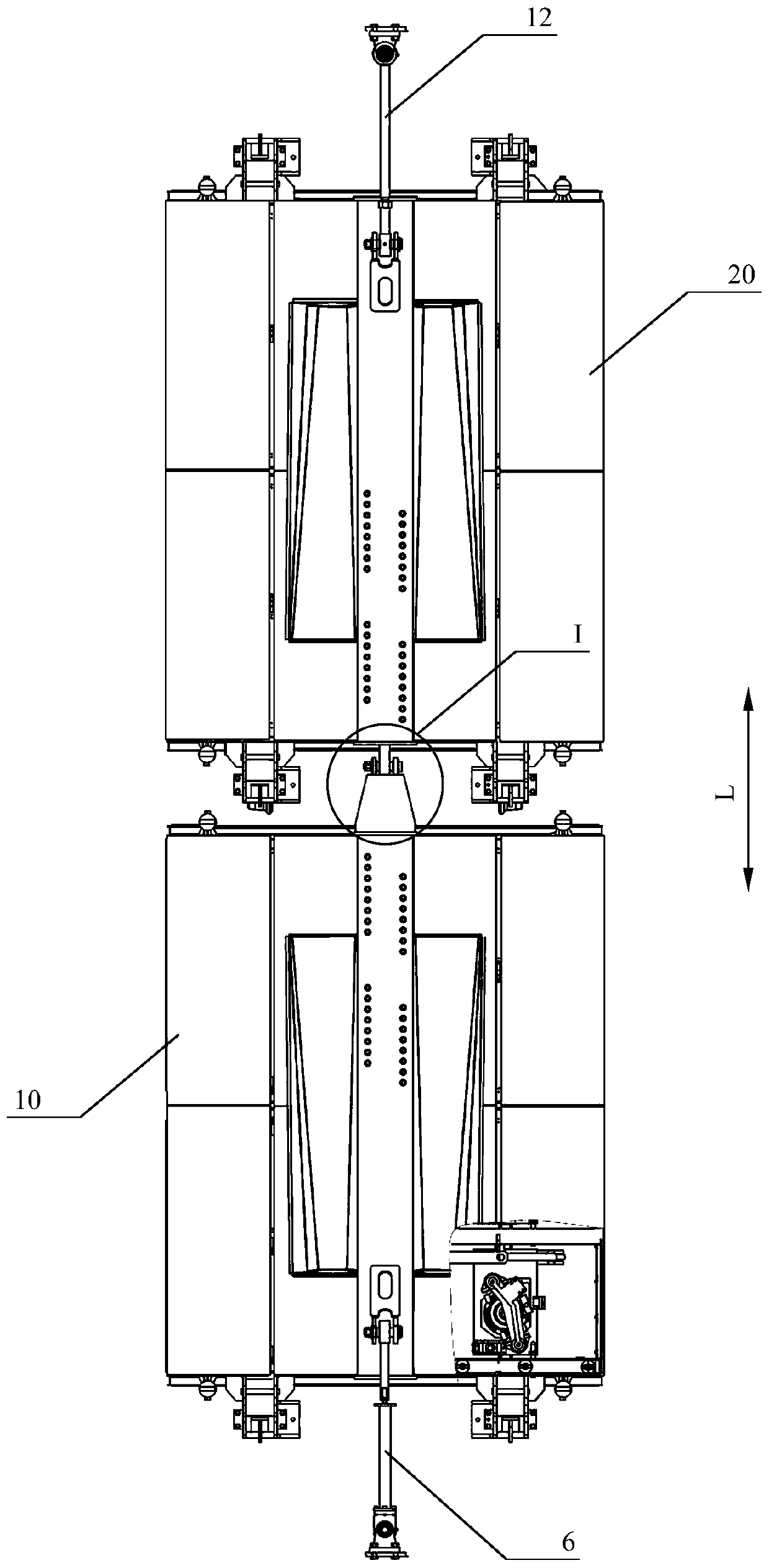

[0047] as attached Figure 7 As shown, an embodiment of a rail grinding trolley 100 is arranged on the lower part of the car body 200 of a subway rail grinding trolley 300. The rail grinding trolley 100 specifically includes: a first grinding trolley 10 and a second grinding trolley 20, the first grinding trolley 10 It is hingedly connected with the second grinding trolley 20. As a typical specific embodiment of the present invention, as attached Figure 4 As shown, the first grinding trolley 10 and the second grinding trolley 20 are hinged through the hinge seat 13 and the hinge joint 14 . The connection between the hinge base 13 and the hinge head 14 is realized by a bolt 15 , and a joint bearing 16 is arranged between the bolt 15 and the hinge head 14 . as attached figure 1 to attach image 3 As shown, the first grinding trolley 10 and the second grinding trolley 20 both include: a vehicle frame 1 , a grinding unit 2 , a running guide wheel 3 , a dust collection channel...

Embodiment 2

[0060] as attached figure 1 And attached Figure 7 As shown, an embodiment of a subway rail grinding car 300 including the rail grinding car 100 described in Embodiment 1 specifically includes: a car body 200 , and a rail grinding car 100 arranged at the lower part of the car body 200 . The rail grinding trolley 100 includes a first grinding trolley 10 and a second grinding trolley 20 hinged to each other. The rail grinding trolley 100 also includes an elastic drawbar 6 and a rigid drawbar 12. The first grinding trolley 10 is connected to the car body 200 through the elastic drawbar 6, and the second grinding trolley 20 is connected to the car body 200 through the rigid drawbar 12. As another typical embodiment of the present invention, the first grinding trolley 10 is connected to the vehicle body 200 through the rigid drawbar 12 , and the second grinding trolley 20 is connected to the vehicle body 200 through the elastic drawbar 6 .

[0061] as attached Figure 8 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com