Crawler type self-balancing transfer bridge

A self-balancing, crawler-type technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of short relocation distance, a lot of time for relocation, and large space required for relocation, so as to avoid belt deviation, Reduce the workload of relocation and expand the effect of application occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

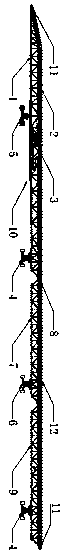

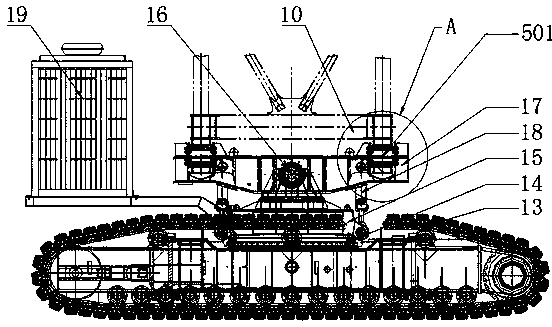

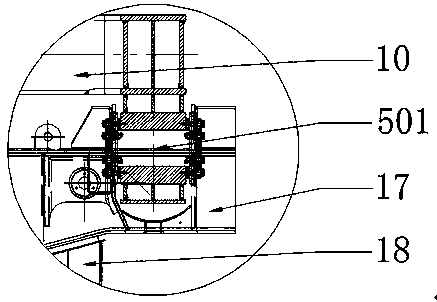

[0033] Such as Figure 1-8As shown, the crawler-type self-balancing reloading bridge includes the tail drive truss 1, the endless conveyor belt 2 and the belt drive mechanism 3. According to the conveying direction of the material from left to right, the front receiving end is the tail, and the rear discharging end is the head. The belt driving mechanism 3 is installed in the tail drive truss 1, a type II crawler chassis 5 is arranged at the front part below the tail drive truss 1, and a type I crawler chassis 4 is arranged at the rear part of the tail drive truss 1. The rear end of the tail drive truss 1 is rotatably connected to an intermediate conveying truss 7 through a hinge mechanism 8, and a type III crawler chassis 6 is arranged at the rear of the intermediate conveying truss 7, and the rear end of the intermediate conveying truss 7 is rotatable through a hinge mechanism 8 A head discharge truss 9 is connected, and a type I crawler chassis 4 is arranged at the rear und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com