Driller design scheme

A technology for drilling rigs and drilling rig platforms, which is applied to rotary drilling rigs, drilling equipment, earth-moving drilling, etc., can solve the problems of inability to achieve the overall movement of the drilling rig, different design structures of drilling rigs, and large relocation workload. Save the time and cost of disassembly and installation, and increase the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

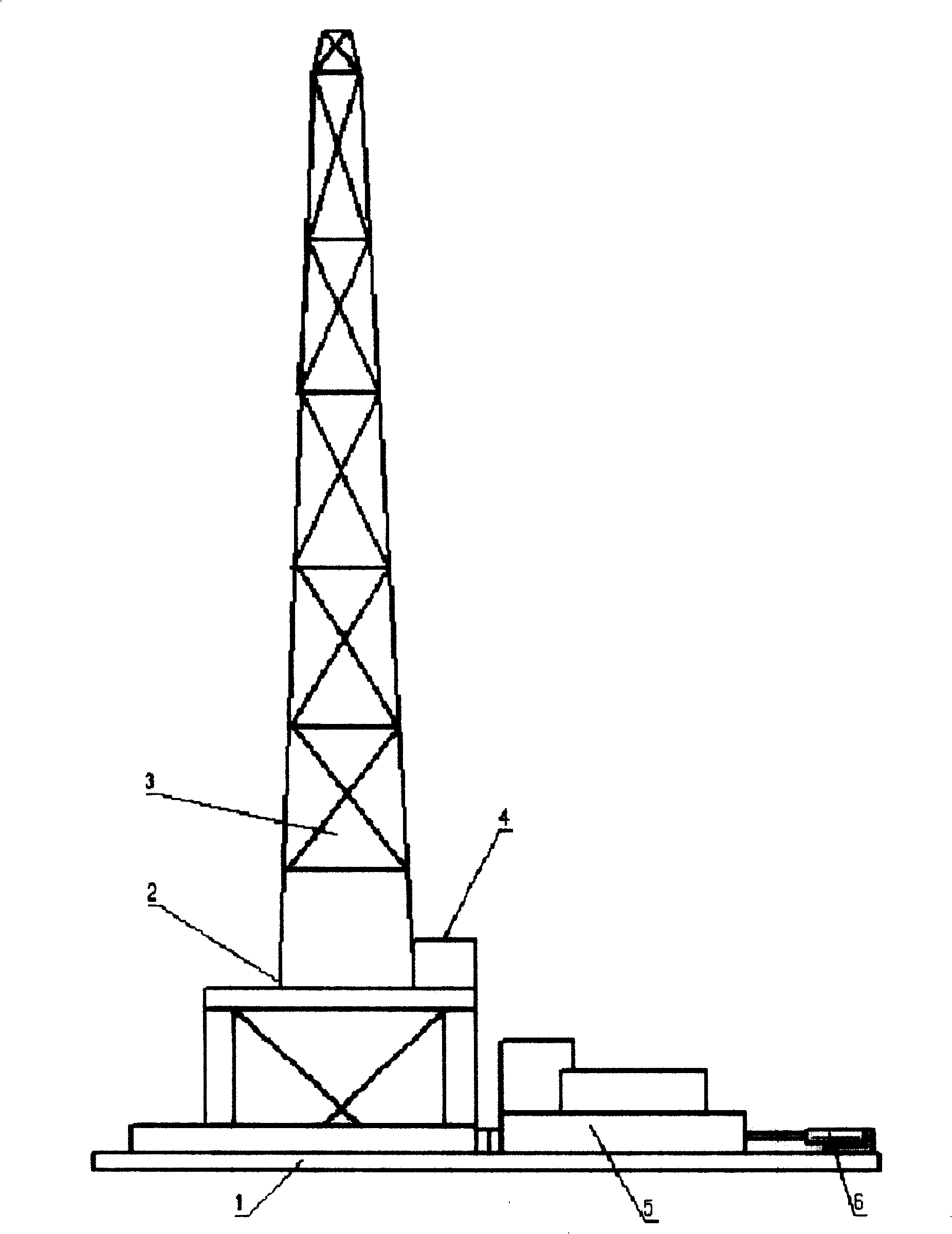

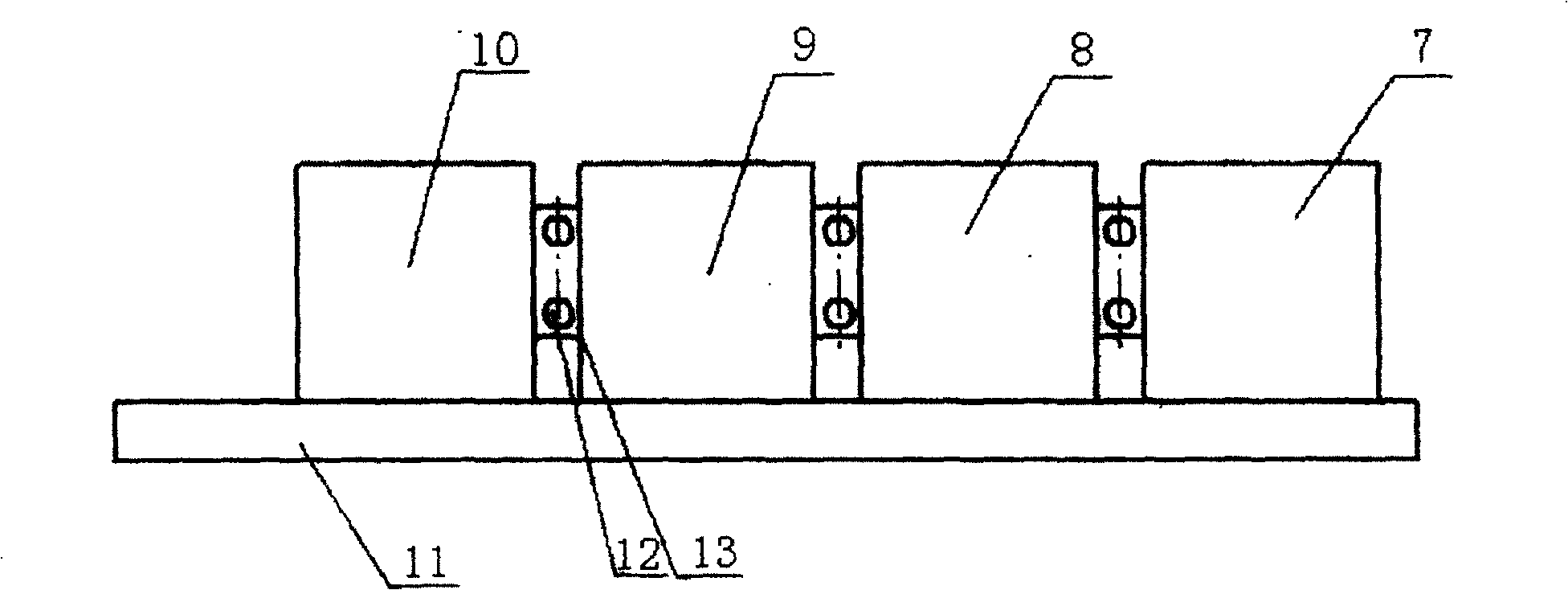

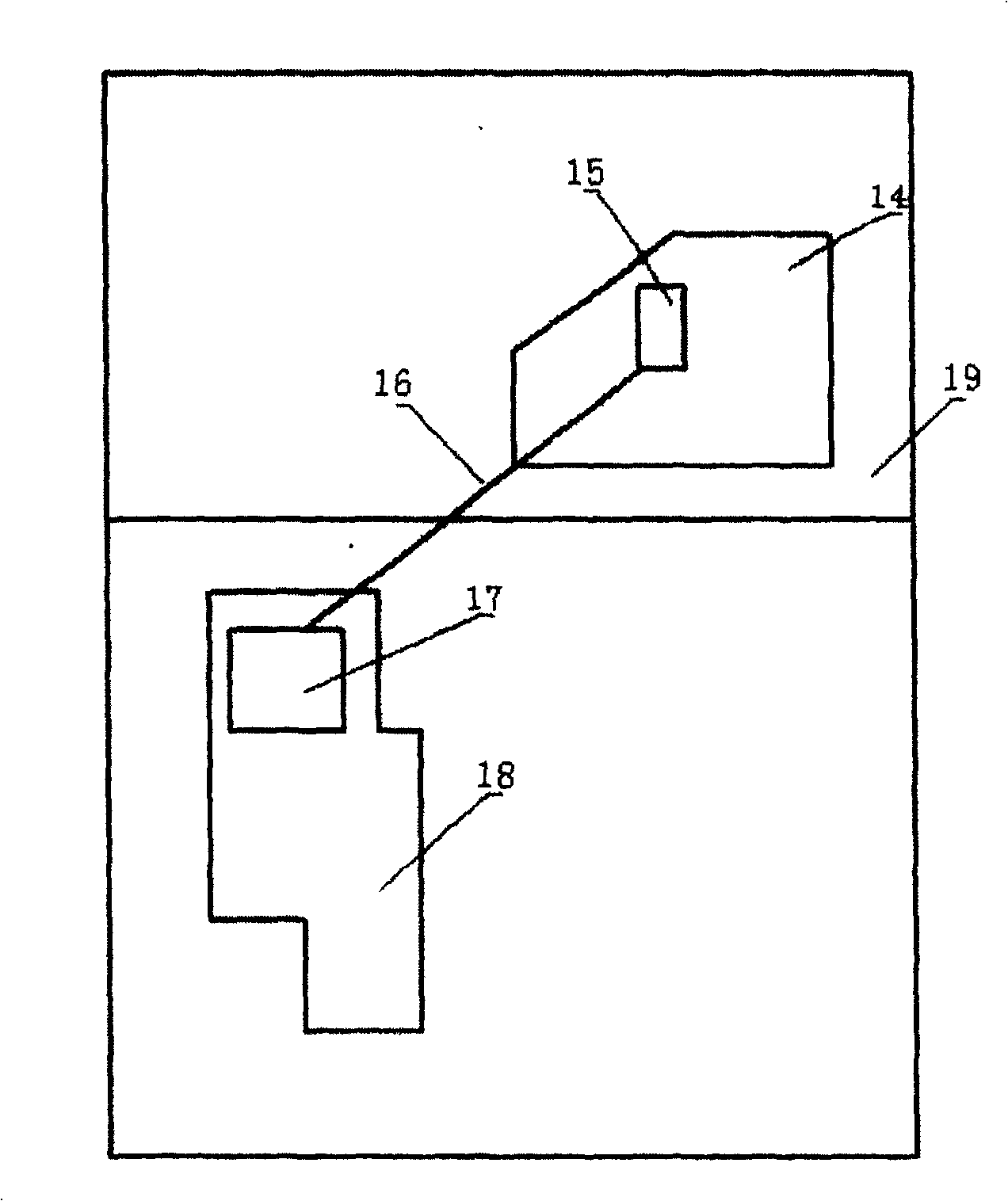

[0046] figure 1 It is a structural schematic diagram of the overall moving device of the drilling rig in the embodiment, as figure 1 As shown, it consists of rail sliding 1, hydraulic control mechanism 4, hydraulic cylinder 6, drilling rig background 5 and drilling rig front 2. The drilling rig front 2 and drilling rig background 5 are arranged on the rail sliding 1 side by side. 5 are connected, the hydraulic control mechanism 4 is fixed on the front desk 2 of the drilling rig, the hydraulic cylinder 6 is fixed on the rail slide 1 and connected with the backstage 5 of the drilling rig, and the front desk 2 of the drilling rig is connected with the derrick 3 . When in use, it realizes the expansion and contraction of the hydraulic cylinder 6 by operating the hydraulic cylinder control mechanism 4, pushes and pulls the backstage 5 of the drilling rig to slide 1 back and forth along the track, and pushes and pulls the front desk 2 of the drilling rig through the backstage 5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com