Preparing device of shell-core functional material

A technology of functional materials and preparation devices, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical/physical/physicochemical processes, etc., can solve the problems of process dispersion of core-shell functional materials, low yield of double emulsion, and low production efficiency. Achieve rapid preparation, compact and reasonable chip structure layout, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Carry out further detailed description below in conjunction with accompanying drawing:

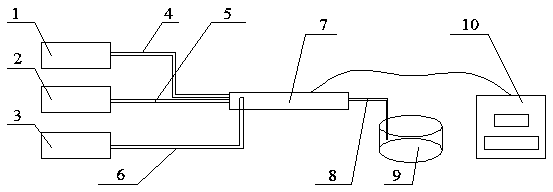

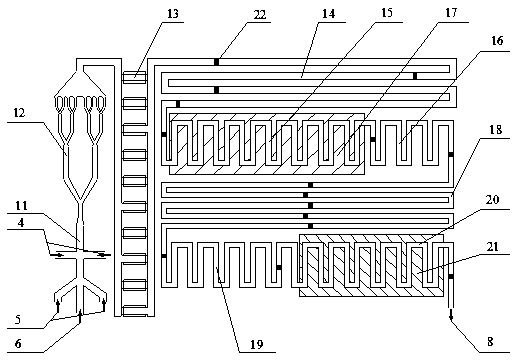

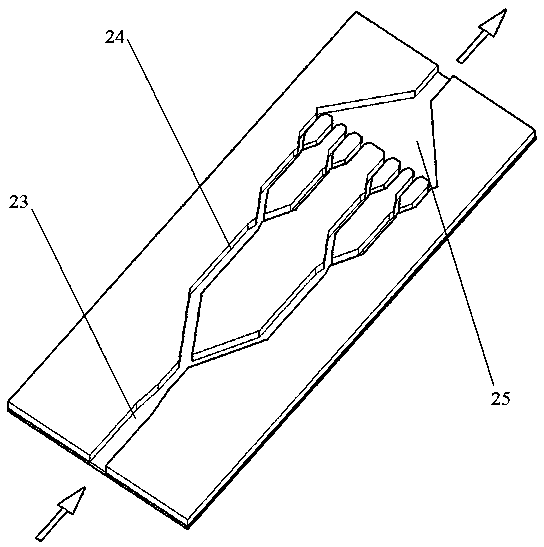

[0026] figure 1A system diagram of the present invention is given, a high-quality preparation device for core-shell functional materials, and the specific structure includes an outer phase fluid injection pump and a syringe 1, an intermediate phase fluid injection pump and a syringe 2, an inner phase fluid injection pump and a syringe 3 , external phase input channel 4, intermediate phase input channel 5, internal phase input channel 6, digital microfluidic integrated chip 7, functional material output channel 8, putamen functional material collector 9, controller 10 and other main components. The external fluid, the intermediate fluid, and the inward fluid are respectively driven by the external fluid injection pump and syringe 1, the intermediate fluid injection pump and syringe 2, and the internal phase fluid injection pump and syringe 3 and flow into the digital microfluidic int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com