Patents

Literature

255 results about "Double emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

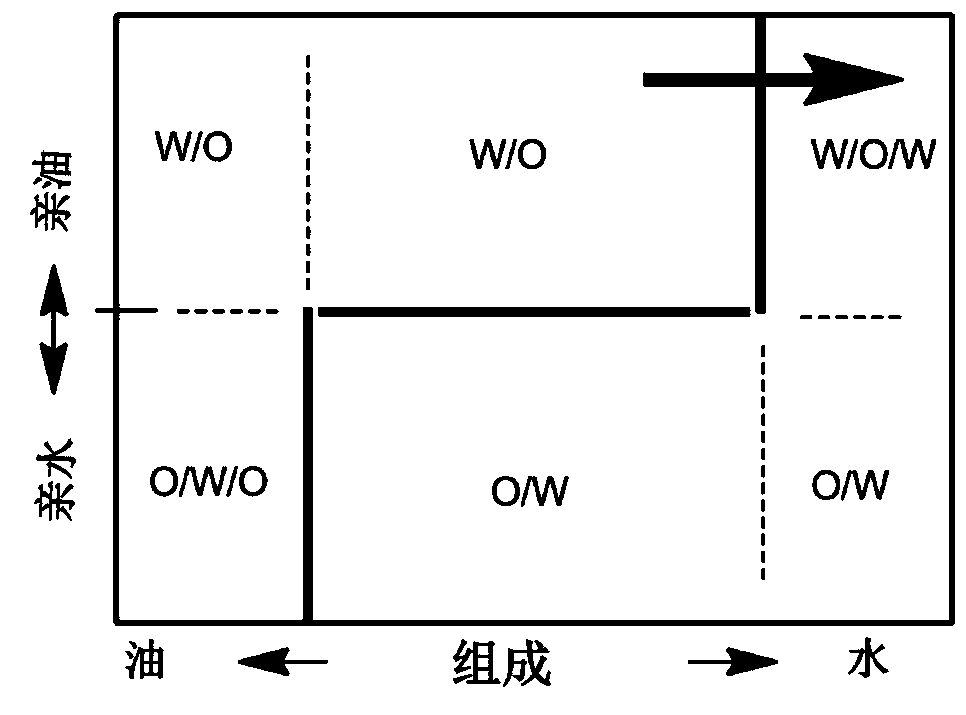

Double emulsion(Noun) A colloid in which an emulsion is suspended either in a third liquid, or in a second instance of the inner liquid e.g. water in oil in water.

Preparation of degradable pollutant polyalcohol stephanoporate microballoons and uses thereof

InactiveCN101249077ALarge specific surface areaImprove loading performancePeptide/protein ingredientsPharmaceutical non-active ingredientsPolyvinyl alcoholFreeze-drying

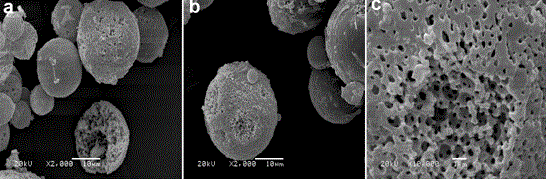

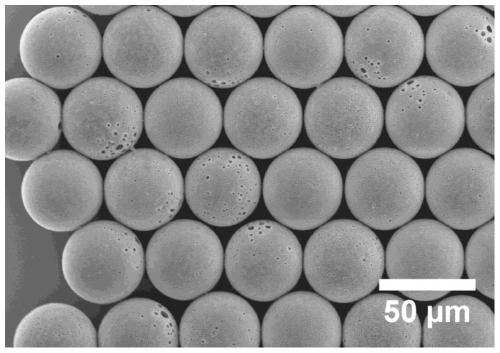

A preparation method for porous microspheres of a biodegradable polymer is provided. The method comprises the following steps: (a) dissolving a biodegradable polymer in an organic solvent to form an oil phase of 1-30% (g / ml) concentration; (b) selecting a pore-forming agent 1-50% of the biodegradable polymer in the step (a) and dissolving the pore-forming agent in water to form an internal water phase; (c) adding dropwise the internal water phase into the oil phase at a volume ratio of (1-30):100, and stirring to form a primary emulsion; (d) preparing a polyvinyl alcohol aqueous solution of 0.5-10% (g / ml) concentration, which serves as an external water phase; (e) pouring the primary emulsion into the external water phase at a volume ratio of (3-30):100, stirring or performing ultrasonic treatment to form a double-emulsion, and allowing the polymer in the double-emulsion to solidify, thereby forming microspheres; (f) freeze-drying the microspheres to obtain the final product. The obtained porous microspheres of the biodegradable polymer have high porosity, large specific surface area and good adsorption and encapsulation properties; and are used for the adsorption and encapsulation of unstable protein drugs, polypeptide drugs and growth factors and can retain pharmaceutical activity and effectiveness thereof.

Owner:SOUTHWEST JIAOTONG UNIV

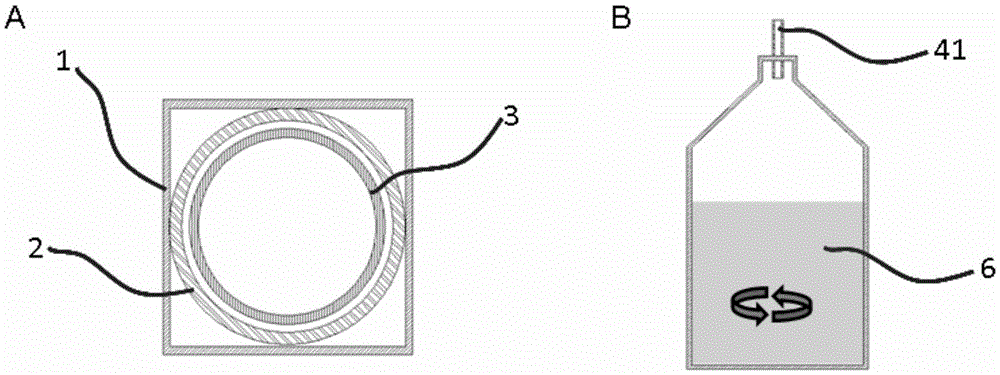

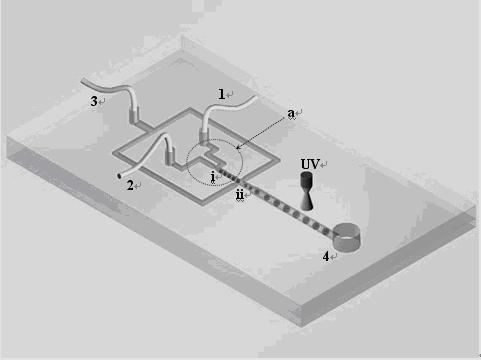

Microfluidic device and method for preparing microgel by using microfluidic device

ActiveCN105641743ASuitable for industrial mass productionStable capillary forceBioreactor/fermenter combinationsBiological substance pretreatmentsPolyvinyl alcoholChemistry

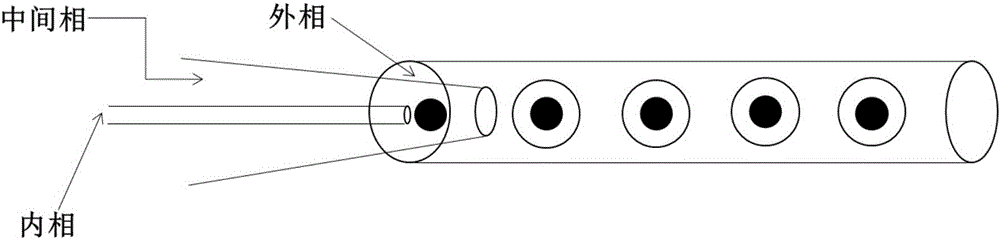

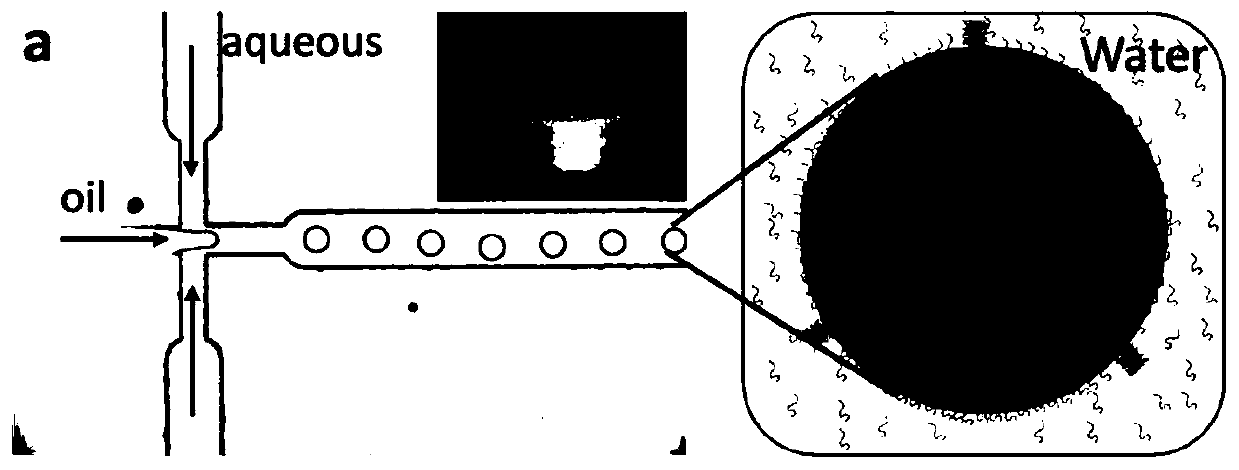

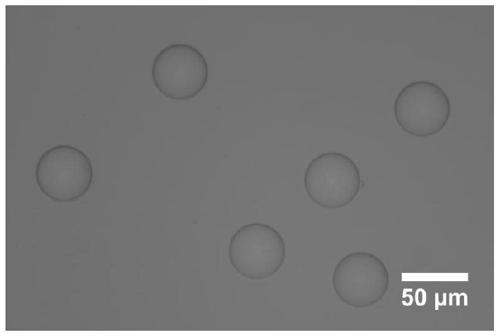

The invention provides a microfluidic device and a method for preparing microgel by using the microfluidic device. The method comprises the steps of (1) taking a solution containing live cells or bioactive molecules, a photocuring agent and a hydrogel prepolymer as an internal phase, taking a mixed solution containing oil and an surfactant as an intermediate phase, and taking a polyvinyl alcohol aqueous solution as an external phase; (2) respectively conveying the internal phase, the intermediate phase and the external phase into a corresponding microchannel of the microfluidic device through a micro pump or a micro injector to form a monodispersed water-in-oil-in-water double emulsion; (3) enabling the monodispersed water-in-oil-in-water double emulsion in the step (2) to pass through an output channel of the microfluidic device, and collecting the monodispersed water-in-oil-in-water double emulsion in the step (2) into a collection vessel filled with an aqueous solution, thus obtaining the microgel immobilizing with the live cells or the bioactive molecules. The preparation of the microgel immobilizing with cells by a one-step method is realized, the obtained microgel is controllable in size, and narrow in size distribution, and meanwhile the survival rate of cells is maintained.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

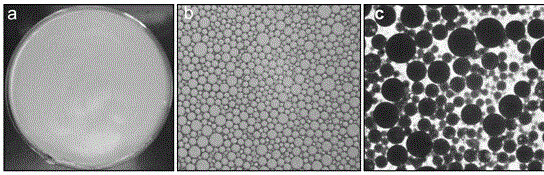

Stable double emulsions

InactiveUS20100233221A1Cosmetic preparationsEdible oils/fats ingredientsDouble emulsionPhotochemistry

The invention relates to double emulsions, in particular double emulsions of the water-in-oil-in-water type, which are organoleptically similar to full-fat oil in water emulsions and which are stabilised by mixture of emulsifiers. The invention also relates to a method for producing said double emulsions, and to the use of a mixture of emulsifier for stabilising said emulsions.

Owner:NESTEC SA

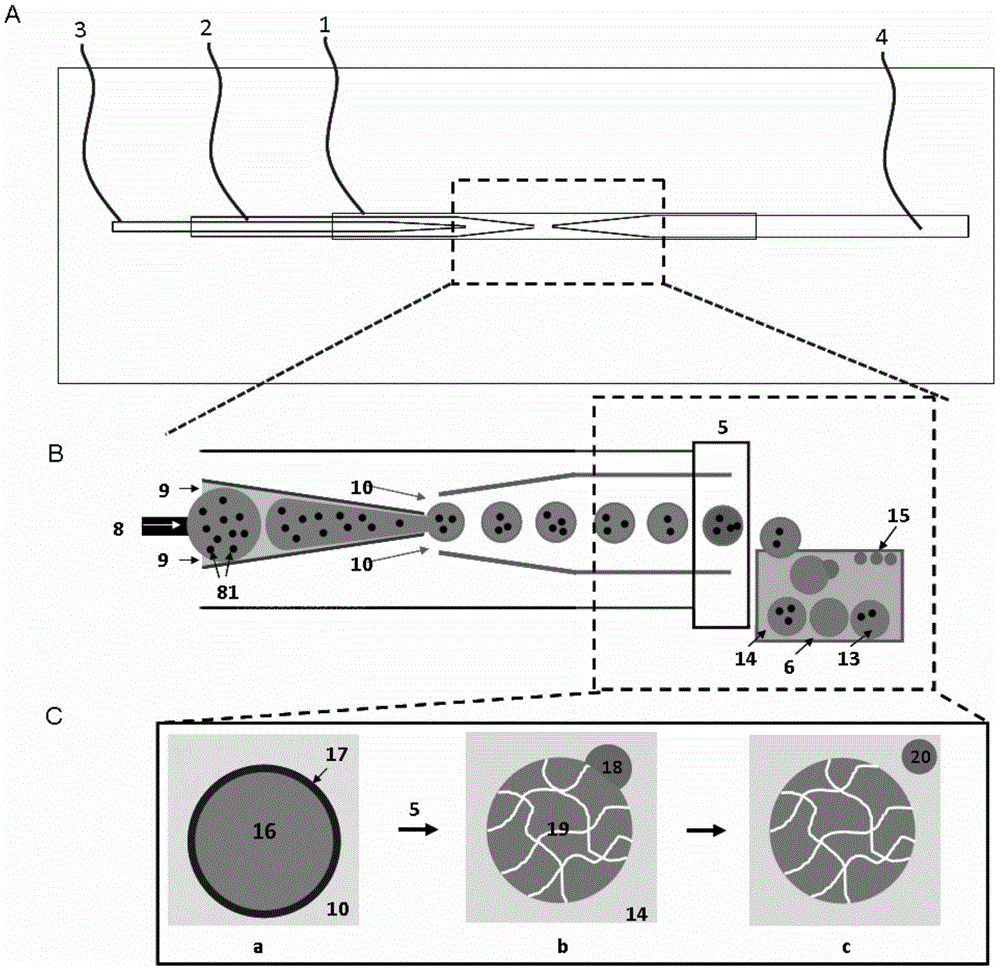

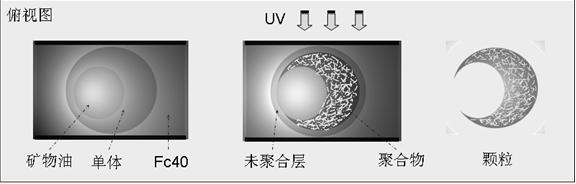

Method for synthesizing nonspherical polymer microparticles

The invention provides a method for synthesizing nonspherical hydrogel microparticles. In a first stage, oil-in-water droplets are formed by adopting a T-channel structure; and in a second stage, oil / water / oil double emulsion is formed by adopting a flow focusing structure. Under the irradiation of ultraviolet light, the intermediate phase of the double emulsion is polymerized to form the hydrogel microparticles, and polymerization reaction on an interface of an external phase and the intermediate phase is suppressed, so that hydrogel cannot wrap internal-phase oil cores, and the hydrogel microparticles taking the internal-phase oil cores as templates are formed. The method has the advantages that: the volume velocity ratio of the internal phase to the intermediate phase is controlled to form a series of hydrogel microparticles with similar shapes; the number of internal cores of single double emulsion is controlled to form hydrogel microparticles with different shapes such as meniscal shapes and polypod shapes; additives in a monomer solution are controlled to form hydrogel microparticles with special functions such as fluorescence and magnetism; and compared with microparticles formed by a photoetching method, the microparticles formed by the method have three-dimensional shape structures.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing zirconium dioxide ceramic microspheres with microfluid device

The invention relates to a method for preparing zirconium dioxide ceramic microspheres with a microfluid device, belonging to the technical field of material synthesis and formation. The method comprises the following steps: by using zirconium dioxide precursor sol as an inner phase fluid, an oily solution as an intermediate phase fluid and an aqueous solution as a continuous phase fluid, preparing monodisperse water-in-oil-in-water double-emulsion drops with a microfluid device by regulating the flow rates of the three phases of fluids, adding an alkaline solution into the continuous phase to initiate the gel reaction, cleaning and drying the gel microspheres obtained by the gel reaction, and sintering to obtain the ZrO2 ceramic microspheres. The zirconium dioxide ceramic microspheres prepared by the method have the advantages of high sphericity and uniform dimension; on the micrometer level, the action of surface tension of the zirconium dioxide ceramic microspheres is far larger than the deformation generated by gravity; and the reaction synthesis on the sol-gel system by using the double-emulsion drops as the template has universality, thereby having potential application prospects in the nuclear fuel preparation.

Owner:TSINGHUA UNIV

Compound medicine microcarrier with core-shell structure

ActiveCN106309407AThe size is easy to controlGood monodispersityOrganic active ingredientsMacromolecular non-active ingredientsBiocompatibility TestingCompounds drug

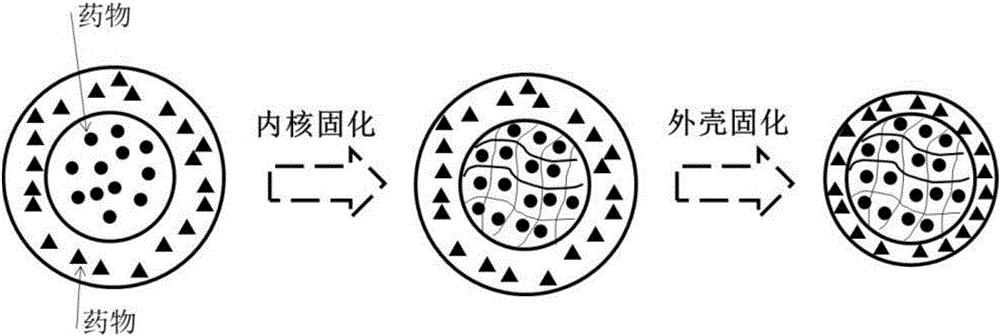

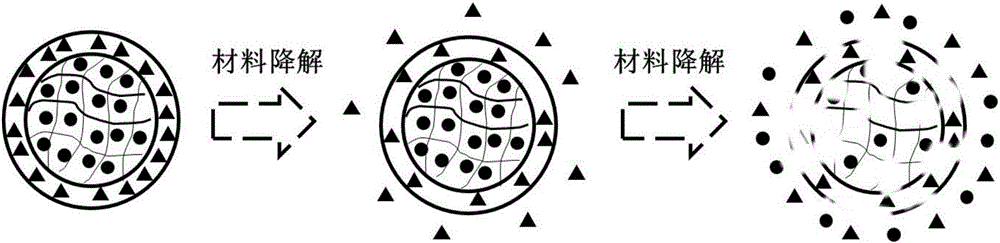

The invention discloses an emulsion multi-dimensional rapid preparation microfluidic device, and discloses a compound medicine microcarrier with a core-shell structure, and applications thereof. The compound medicine microcarrier with the core-shell structure is characterized by being prepared through taking W / O / W or O / W / O double emulsion as templates by adopting a microfluidic method, a core and a shell are respectively made of two degradable polymer materials with biocompatibility and are respectively hydrophilic and hydrophobic. The hydrophilic part can be loaded with various hydrophilic medicines, the hydrophobic part can be loaded with various hydrophobic medicines; along with the degradation of the core-shell material, the hydrophilic and hydrophobic drugs loaded internally can be sustainably released, and the purpose that the hydrophilic and hydrophobic medicines are simultaneously delivered and synergically slow-released can be achieved. In addition, the release rate of the medicine can be controlled by controlling the thickness of the shell layer. The microcapsule with the core-shell structure has the characteristics that the preparation method is low in cost, easy to operate and convenient to produce on large scale, and the like, the prepared medicine microcarrier has good biocompatibility, is high in medicine encapsulation rate, and good in controllability.

Owner:SOUTHEAST UNIV

Encapsulation and controlled delivery of strong mineral acids

ActiveUS20160017215A1Reduce corrosionImprove efficiencyFluid removalFlushingMineralogyDouble emulsion

A polymer-encapsulated mineral acid solution and a method for forming the polymer-encapsulated mineral acid solution. Introducing a strong mineral acid solution to a monomer solution occurs such that a primary emulsion that is a water-in-oil type emulsion forms. Introducing the primary emulsion to a second aqueous solution forms a secondary emulsion that is a water-in-oil-in-water type double emulsion. The monomer in the secondary emulsion is cured such a polymerized shell forms that encapsulates the strong mineral acid solution and forms the capsule. The strong mineral acid solution has up to 30 wt. % strong mineral acid. A method of stimulating a hydrocarbon-bearing formation using the polymer-encapsulated mineral acid solution includes introducing a capsule suspension into a fissure in the hydrocarbon-bearing formation to be stimulated through a face in a well bore. The capsule is maintained within the fissure until the polymer shell degrades.

Owner:RTI INT BV +1

Microencapsulation method of concrete water-based repair agent

InactiveCN103613318ALow costProcess stabilityMicroballoon preparationMicrocapsule preparationWater basedOil phase

Owner:SHENZHEN UNIV

Probiotic liquid preparation based on double-emulsion structure and preparation method thereof

ActiveCN108853021AImprove stabilityImprove physiological activityDigestive systemUnknown materialsOil phaseProtection sex

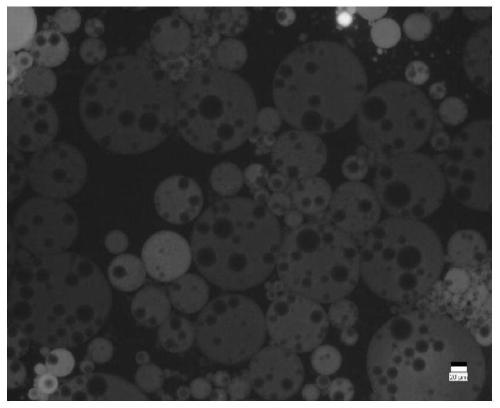

The invention discloses a probiotic liquid preparation based on a double-emulsion structure and a preparation method thereof. The method comprises the following steps that S1, a probiotic bacterium suspension, a thickener and an intestinal tract auxiliary release material (namely a material capable of assisting in the release of probiotics in an intestinal tract) are mixed, and induction is carried out with bivalent salt ions to form a gel-like inner water phase W1; S2, an oil-soluble emulsifier is dissolved in edible oil to form an oil phase O, and the oil phase O and the inner water phase W1are subjected to high-speed shearing and mixing so as to obtain a water-in-oil type primary emulsion W1 / O; and S3, a suspension of colloidal particles is served as an outer water phase W2, the outerwater phase W2 is added into the primary emulsion W1 / O, and intermediate-speed shearing and mixing are carried out so as to obtain the probiotic emulsion preparation based on the W1 / O / W2 type double-emulsion structure. According to the probiotic liquid preparation and the preparation method thereof, protective embedding is carried out on probiotics by adopting a Pickering double-emulsion system, so that the probiotic effect is fully guaranteed, meanwhile, the probiotics can be prevented from being damaged by oxygen and the environment of a gastrointestinal tract, and therefore the action of gastric acid and cholate can be resisted, in addition, colonization can be better carried out in the intestinal tract, and a wide application prospect is achieved.

Owner:SOUTH CHINA AGRI UNIV

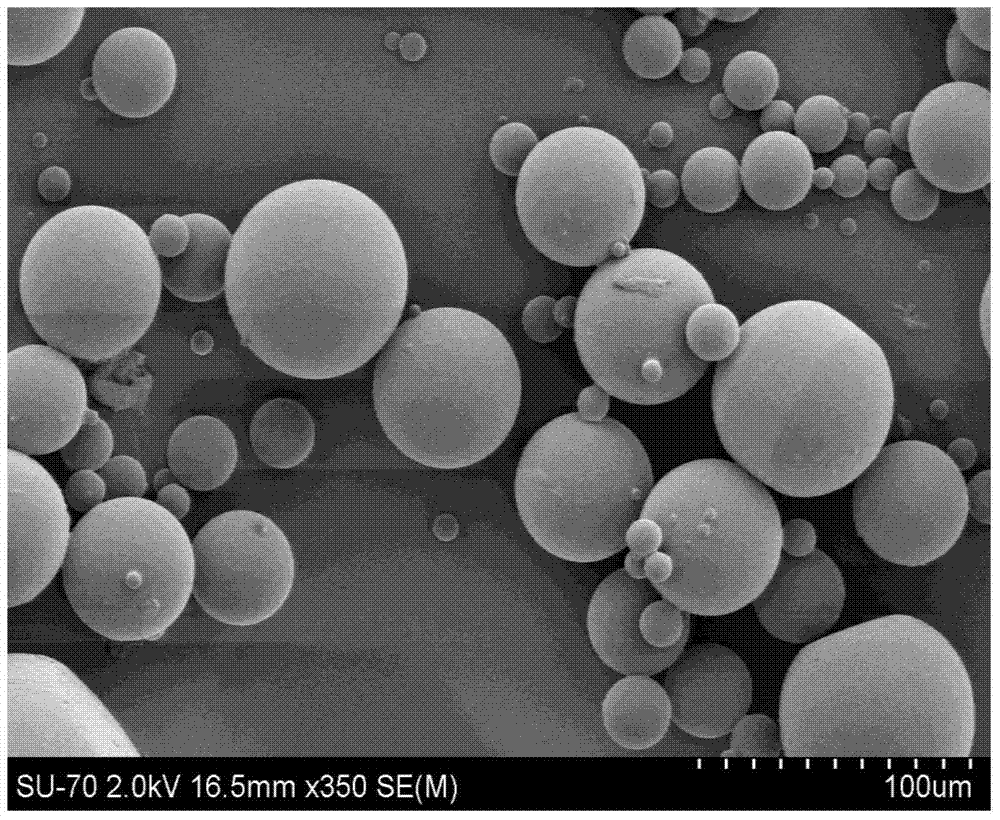

Preparation method of porous polymer microspheres

The invention provides a preparation method of porous polymer microspheres. The preparation method comprises the following steps: mixing an oil soluble monomer, a cross-linking agent and an emulsifying agent to obtain an oil phase; mixing the oil phase with water to obtain double emulsion; and performing polymerization reaction on the double emulsion to obtain the porous polymer microspheres. According to the preparation method of the porous polymer microspheres, the double emulsion is high in stability, so that an electrolyte and a stabilizer are not needed for improving the stability of the double emulsion; the polymerized porous polymer microspheres are high in yield and have regular shape and high pore connectivity; the microspheres are high in size monodispersity and wide in size adjustment range; and the finally obtained product is simple to process.

Owner:UNIV OF SCI & TECH OF CHINA

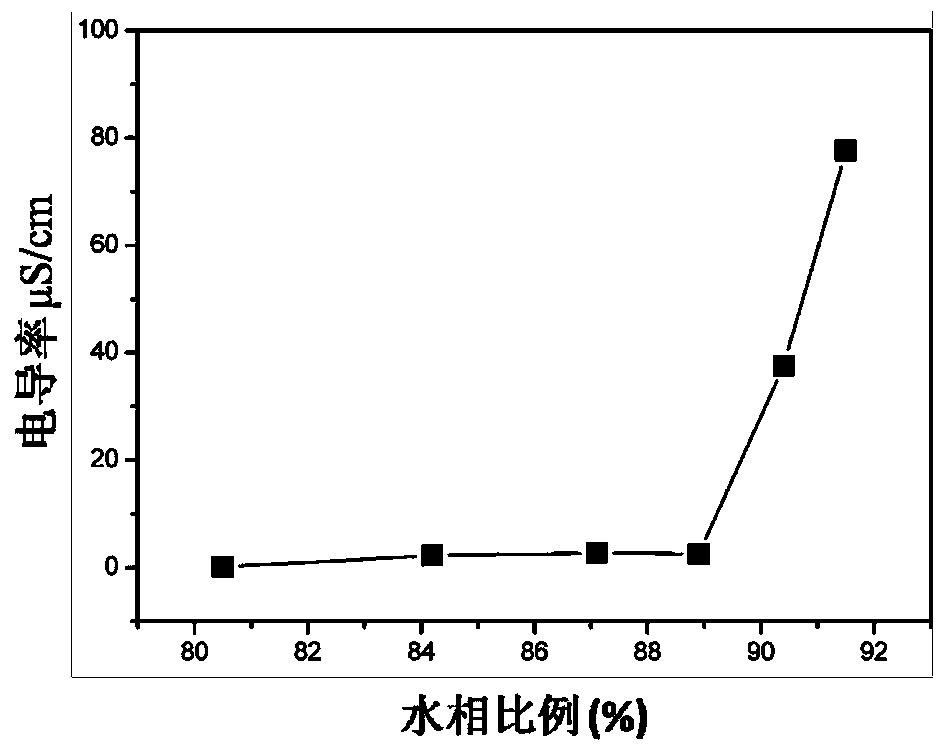

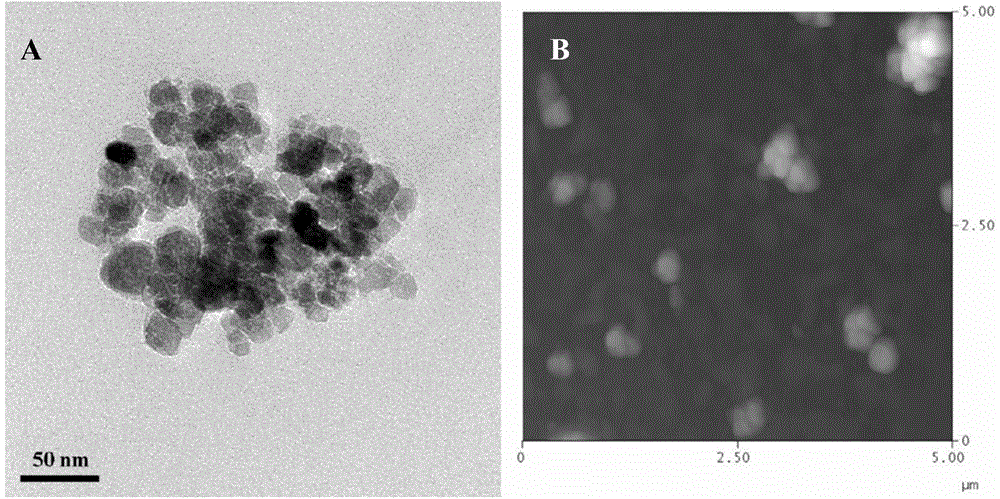

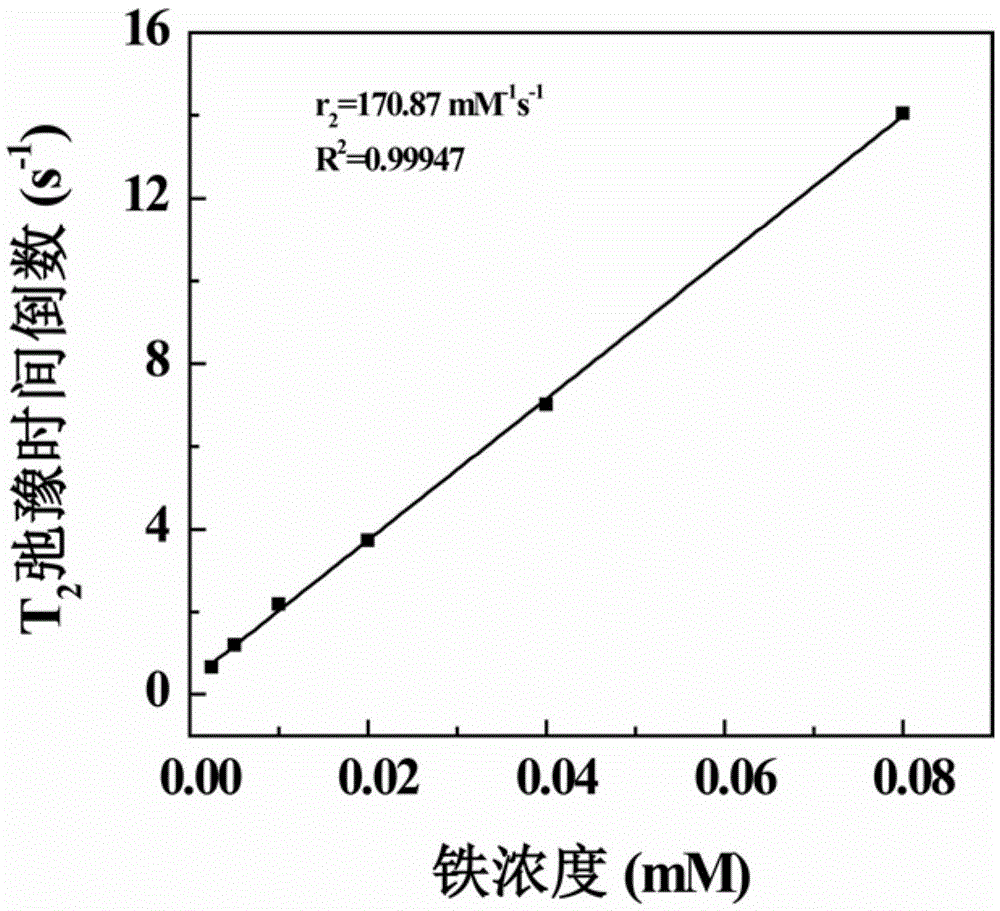

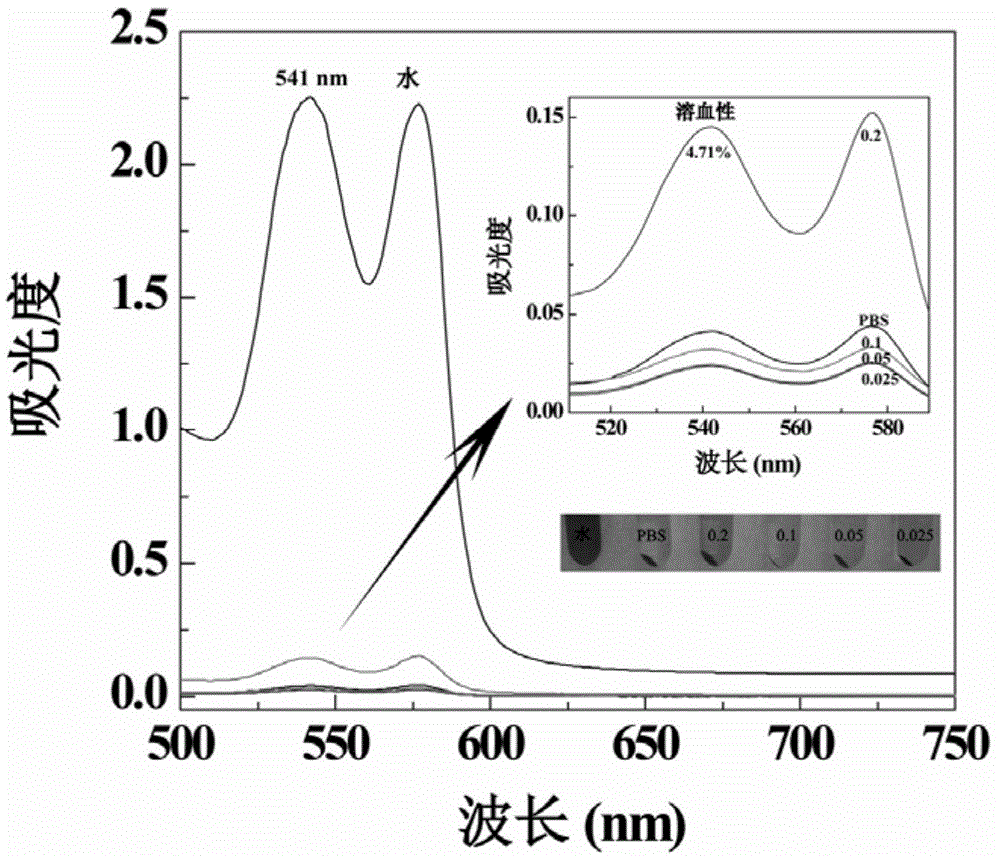

Preparation method of ferric oxide nanoparticle supported sodium alginate nanogel

InactiveCN104606687ASimple processEasy to operate and separateEmulsion deliveryIn-vivo testing preparationsSolubilityBiocompatibility Testing

The invention relates to a preparation method of ferric oxide nanoparticle supported sodium alginate nanogel. The preparation method comprises steps as follows: (1), PEI (polyethylenimine) coated Fe3O4 nano-particles (Fe3O4-PEI) are synthesized with a hydrothermal method; (2), an aqueous solution of sodium alginate is firstly activated by EDC (carbodiimide) and has a double emulsion reaction to form a W / O / W polymer emulsion; (3), Fe3O4-PEI in the step (1) is taken as a crosslinking agent and added into the polymer emulsion in the step (2) to have a crosslinking reaction, and the ferric oxide nanoparticle supported sodium alginate nanogel is obtained after an organic solvent and a surface active agent are removed. The method is very simple, and operation and separation are easy; meanwhile, sources of raw materials are extensive; the prepared sodium alginate nanogel has a smaller grain diameter, is uniformly distributed, high in relaxation rate and low in cost, has a remarkable radiography effect, simultaneously has excellent water solubility, gel stability, biocompatibility and blood compatibility, doesn't have a harmful effect on a living body, and has potential application value in the magnetic resonance imaging diagnosis field.

Owner:DONGHUA UNIV

Method for preparing high molecular micro nanometer capsule

InactiveCN101053810AAchieve compatibilityMeet size requirementsMicroballoon preparationMicrocapsulesFreeze-dryingWater soluble drug

The invention relates to a preparation method of macromolecule micro / nano-capsules in the field of macromolecule functional material, which has the following steps: firstly, to prepare a water soluble medical solution and an oil soluble medical solution; to dissolve the macromolecule material into the oil soluble medical solution to form a polymer solution; after that, to inject the water soluble medical solution into the polymer solution to make a water-oil latex; to inject the latex into stabilizer solution to get water-oil-water dual latex; then to inject the dual latex into the curing agent solution to get a suspension of curing microcapsules; to centrifuge the suspension to get the microcapsules, which is washed and cooling dried to get a dry powder put into the sealing container; and lastly to get the micro / nano-capsules after vacuumizing, charging to standard atmospheric pressure at moment and sealed conserving. The grain size of micro / nano-capsules is nm degree to micron degree, and can be used in the regular ultrasonic radiography and molecule imaging. The invention realizes the compatibility of water soluble and oil soluble medicines, and has the effect of controlled release.

Owner:SHANGHAI JIAO TONG UNIV

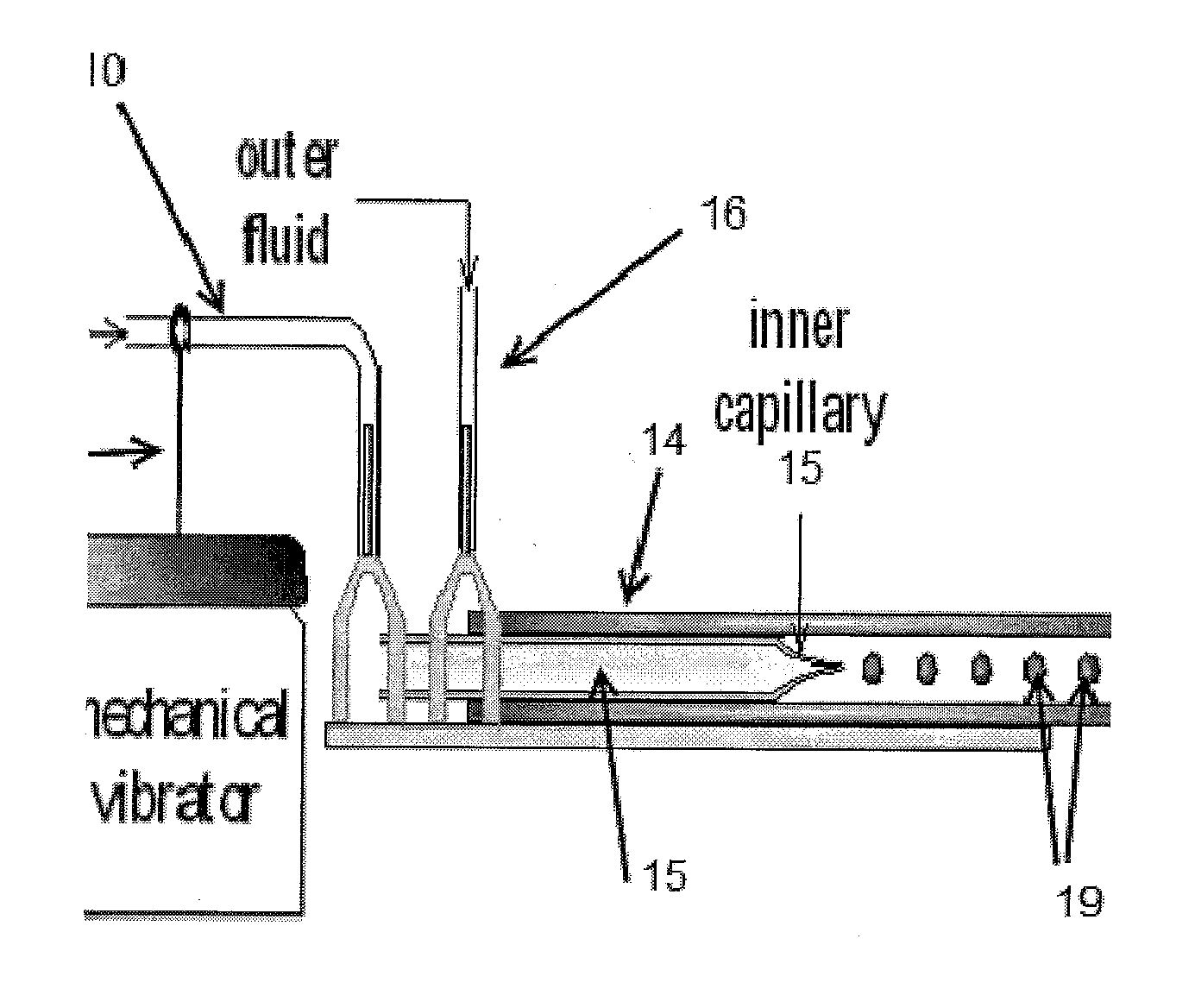

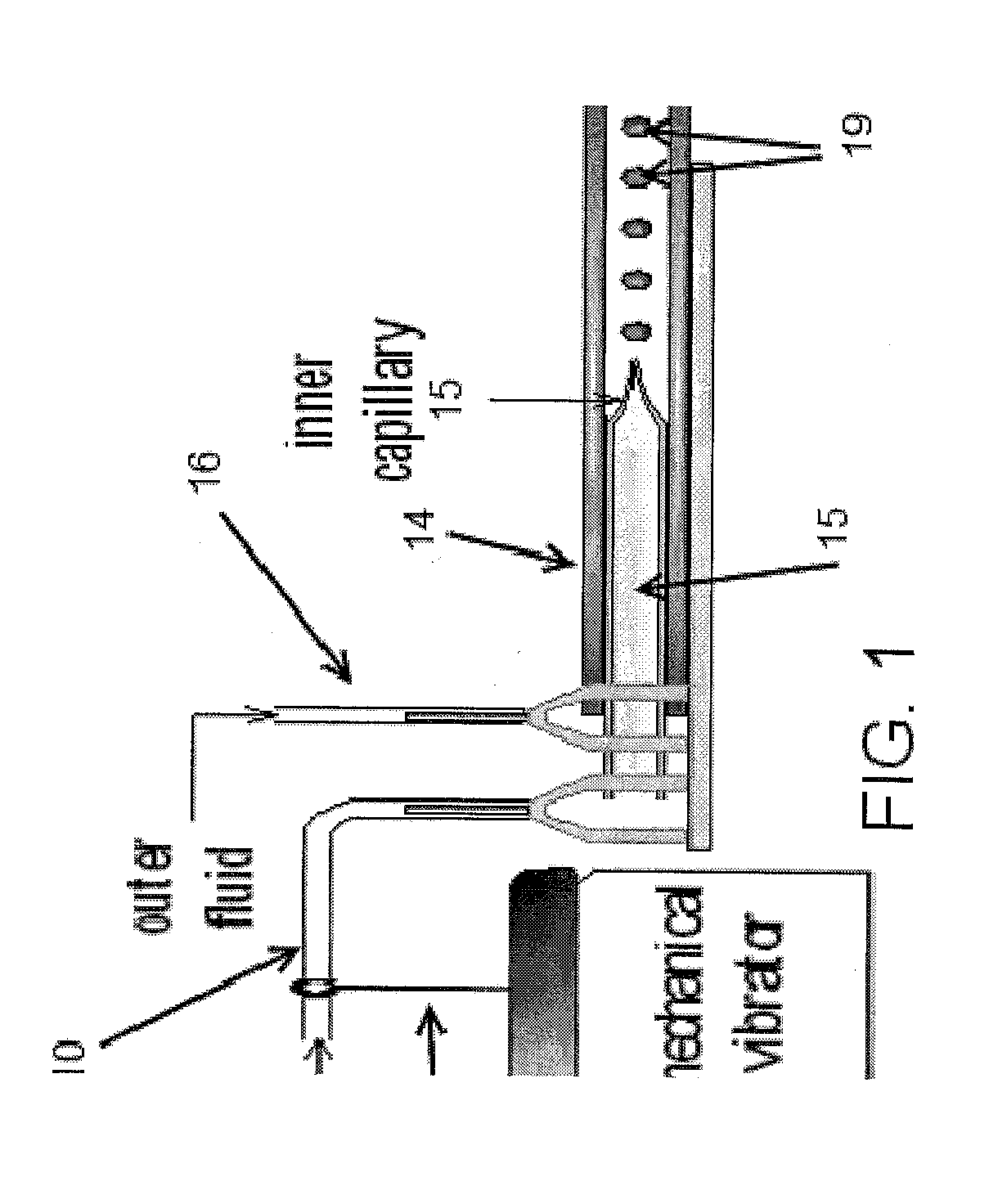

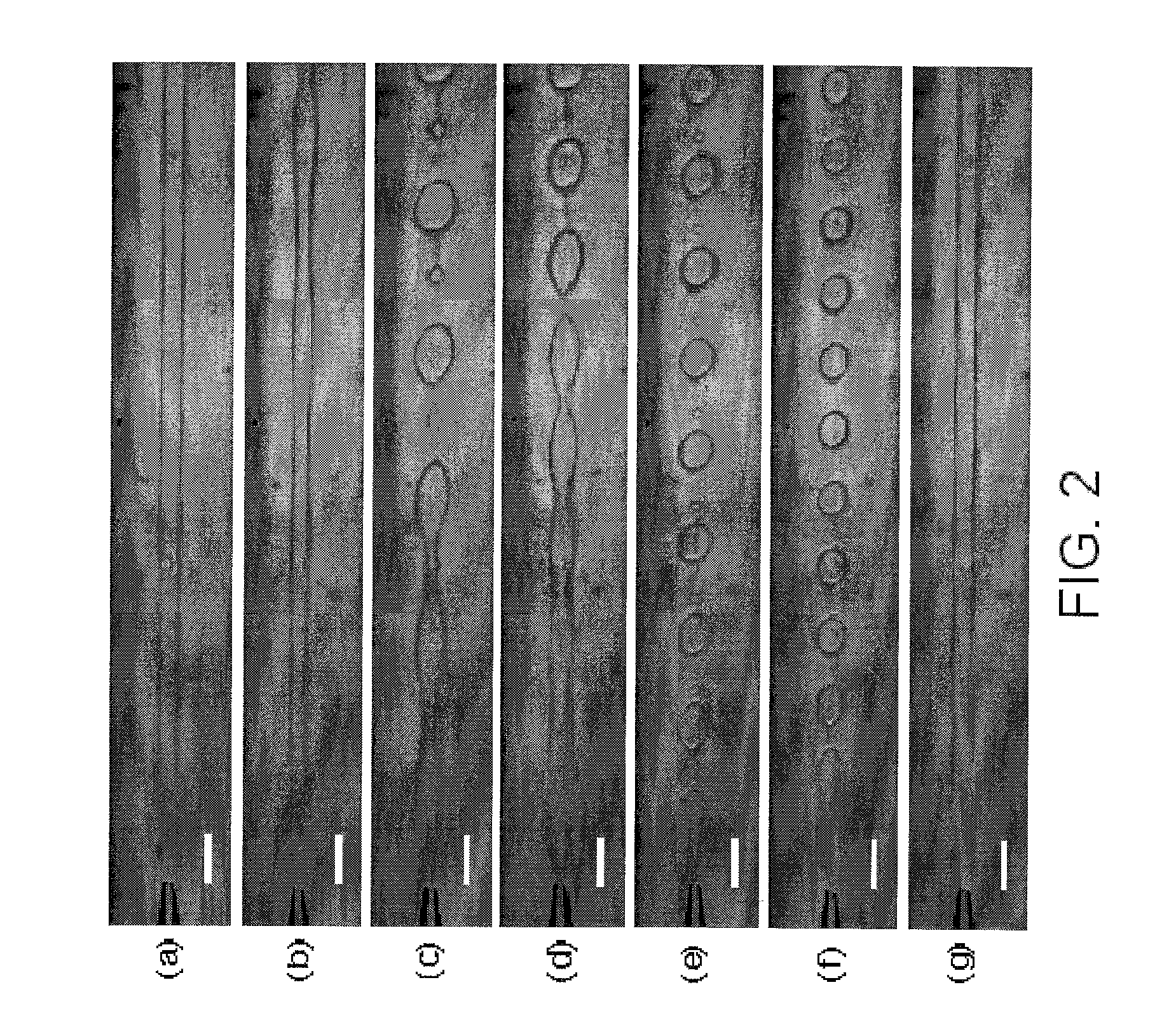

System and method for generation of emulsions with low interfacial tension and measuring frequency vibrations in the system

ActiveUS20130274353A1Reduce interfacial tensionVibration measurement in solidsShaking/oscillating/vibrating mixersSmall dropletBreakup

A method and apparatus for generating droplets with a high level of uniformity in liquid systems that present a low interfacial tension. This method and apparatus utilize the breakup of the dispersed phase in a controlled fashion by periodically varying the pressure that drives the fluids so as to successfully generate emulsions with a good control over the size. The method and apparatus can be used for the formation of simple emulsion or double emulsion where a larger droplet contains one or more smaller droplets.

Owner:VERSITECH LTD

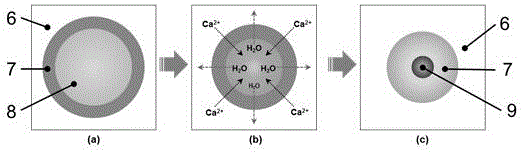

Method for preparing mono-dispersity calcium alginate microspheres based on emulsion liquid membrane mass transfer

ActiveCN106040117ASmall sizeGood size controllabilitySurgeryPharmaceutical non-active ingredientsDispersityCross-link

The invention relates to a method for preparing mono-dispersity calcium alginate microspheres based on emulsion liquid membrane mass transfer. The method includes the steps of firstly, preparing inner water phase, middle oil phase, outer water phase and collecting water phase fluid; secondly, respectively injecting inner water phase, middle oil phase and outer water phase fluid into the injection tube, the transition tube and the collecting tube of a microfluid device to form mono-dispersity water / oil / water emulsion, guiding the water / oil / water emulsion into the collecting water phase fluid, standing for at least 2 hours, allowing Ca<2+> in collecting water phase to enter inner water phase through the oil membrane mass transfer of water / oil / water double emulsion so as to have cross-linking reaction with sodium alginate to generate the calcium alginate gel microspheres, and allowing water in inner water phase to enter collecting water phase through oil membrane mass transfer; thirdly, using filter paper to filter collecting water phase solution containing the calcium alginate microspheres, and washing with deionized water to obtain the mono-dispersity calcium alginate microspheres.

Owner:SOUTHWEST PETROLEUM UNIV

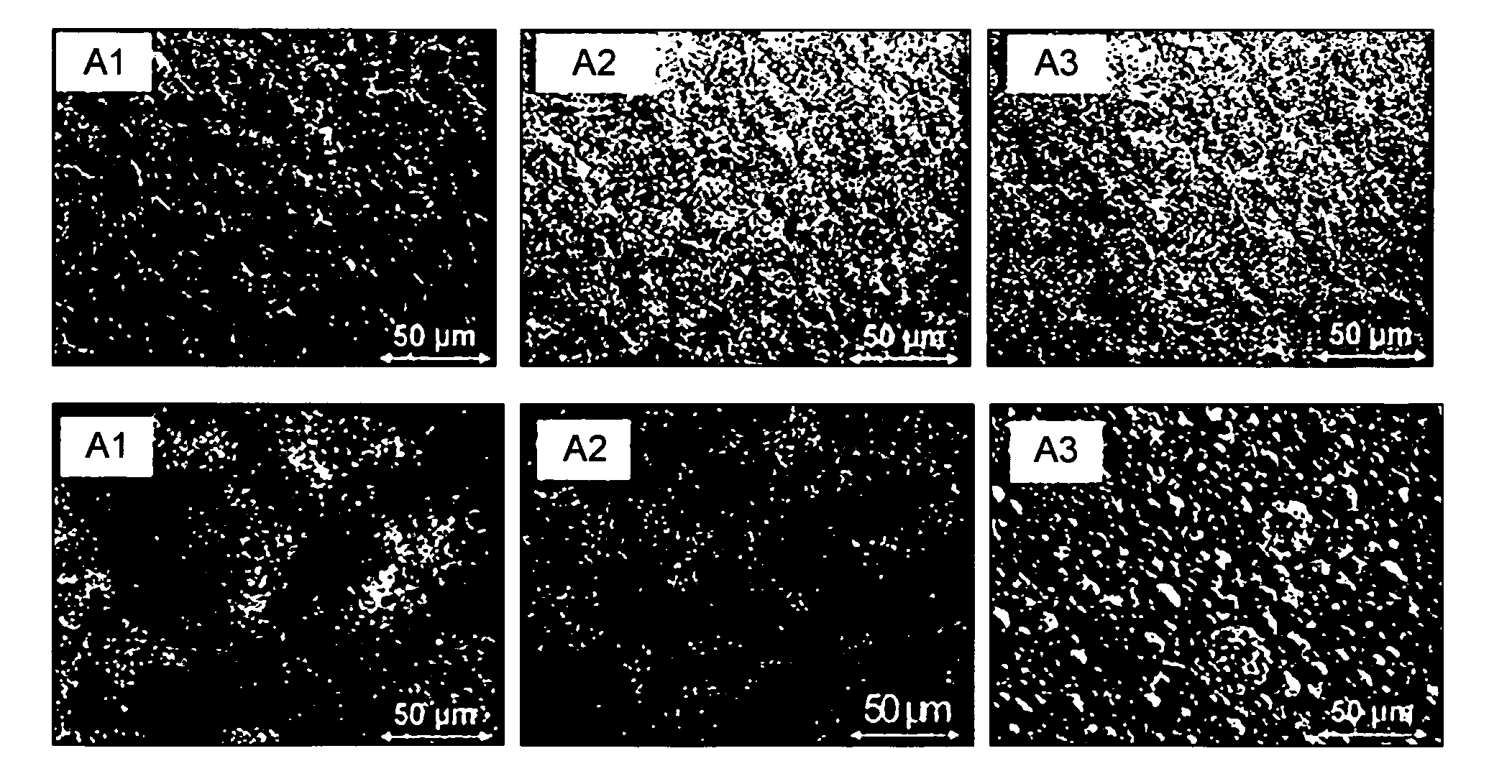

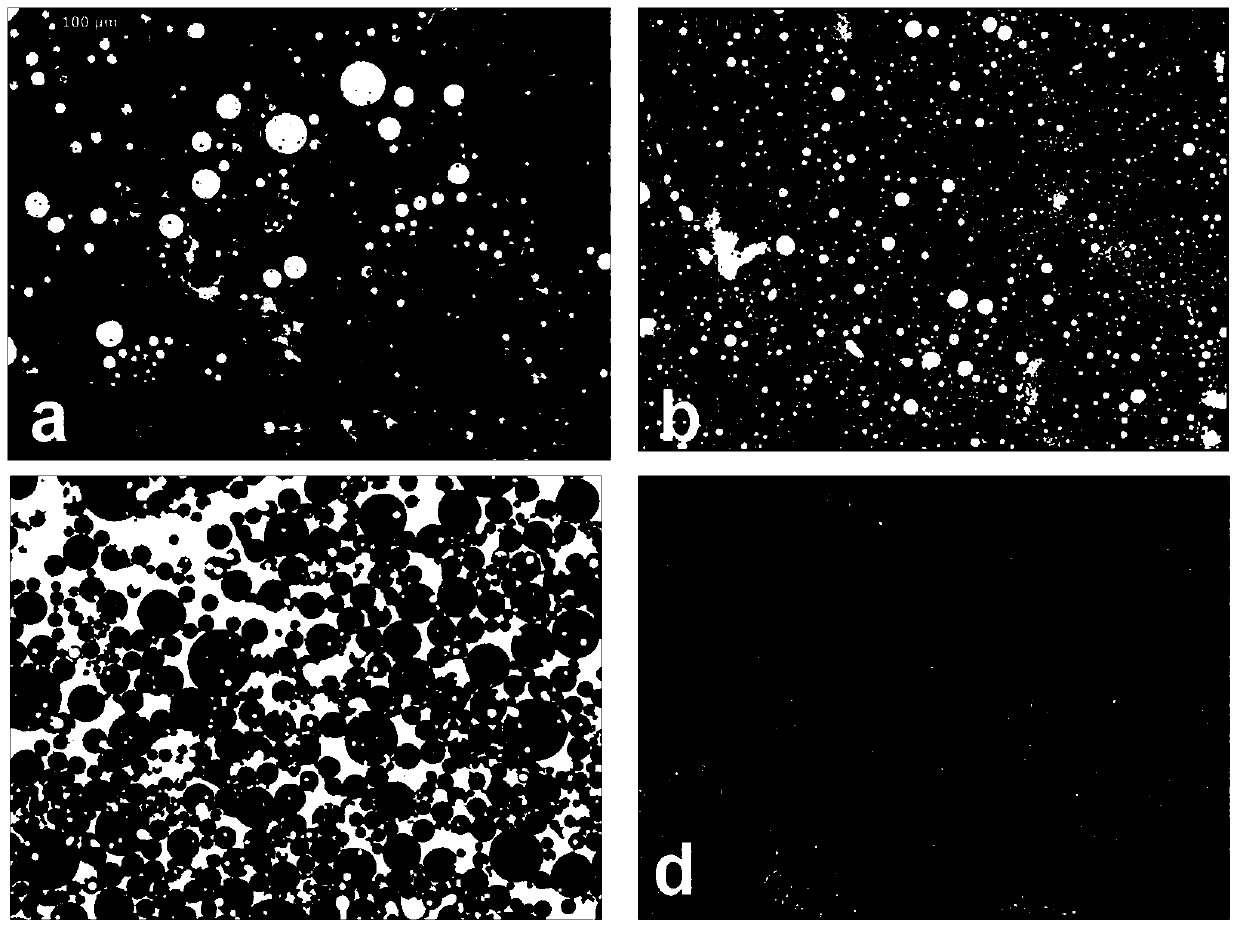

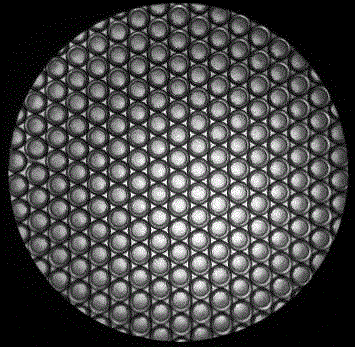

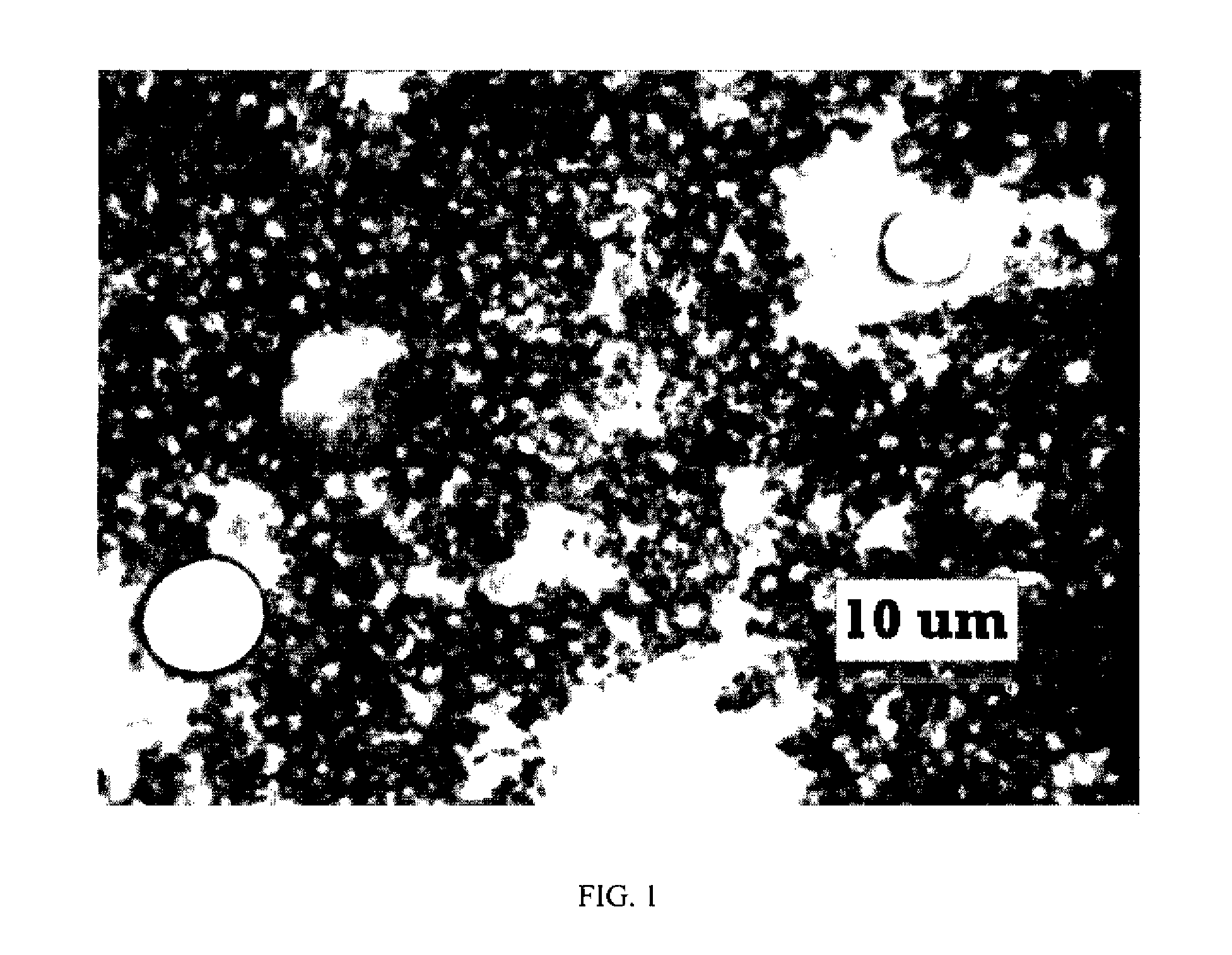

Method for preparing magnetic porous microsphere adsorbing material by utilizing O/W/O double emulsion template

InactiveCN105664897AImprove adsorption capacityFast preparationOther chemical processesWater contaminantsCross-linkFunctional monomer

The invention discloses a method for preparing a magnetic porous microsphere adsorbing material by utilizing an oil-water-oil double emulsion template. The method comprises the steps of taking a natural polymer hydroxy propyl cellulose as a matrix, a polymerizable functional monomer as a modifier, water as a continuous phase, an organic solvent as an organic dispersed phase, modified Fe3O4 magnetic particles as an emulsion stabilizer and a nonionic surfactant as an emulsion co-stabilizer, stirring in the presence of an initiator and a cross-linking agent, and obtaining a Pickering emulsion; adding the Pickering-emulsion into the organic solvent containing a surfactant for further emulsification, and then obtaining the magnetic porous microsphere adsorbing material through a polymerization reaction, wherein the diameter of microspheres is within the range of 5 to 20mum. The spherical structure is regular, the surface and the interior of each microsphere contain abundant pore structures and functional groups, the adsorption rate and the adsorption capacity to heavy metal can be remarkably improved, and the magnetic porous microsphere adsorbing material has very good properties of magnetic separation and reuse.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

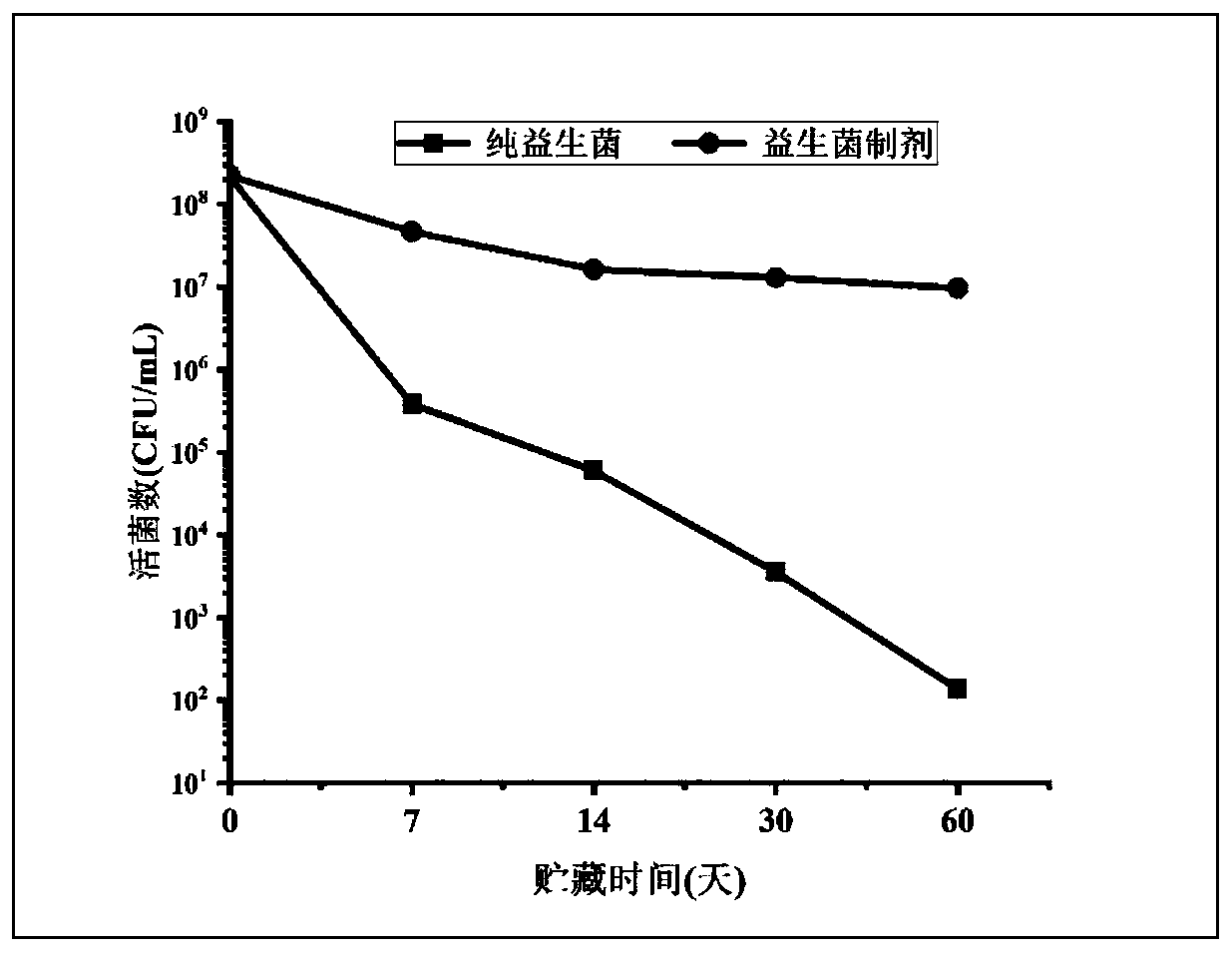

Probiotic preparation based on W1/O/W2 type dual emulsion structure, preparation method and application

InactiveCN111567669AGuaranteed survival rateExtended storage timeCosmetic preparationsMilk preparationBiotechnologyEngineering

The invention belongs to the technical field of biology, and particularly relates to a probiotic preparation based on a W1 / O / W2 type dual emulsion structure, a preparation method and an application. The preparation method comprises the preparation processes of mixing probiotic thalli with a probiotic protective agent to form an inner water phase W1; enabling an oil-soluble emulsifying agent to dissolve in edible oil to form an oil phase O, performing primary mixing on the oil phase O and the inner water phase W1, performing stirring, and performing emulsifying by a low-energy emulsification method or a high energy emulsification method to obtain water-in-oil raw milk W1 / O; and using a hydrophilic emulsifier as an outer water phase W2, adding the W2 to the raw milk W1 / O, performing stirring, and performing emulsifying by the low-energy emulsification method or the high energy emulsification method to obtain W1 / O / W2 type dual emulsion, and performing low-temperature preservation to obtain the probiotic preparation. A dual emulsion system is adopted for performing anti-freezing protection entrapping on probiotics, so that the probiotics can maintain activity in the cryogenic storage process and the frost thawing process, influence of external environment on the probiotics can be reduced, and the frost thawing and storage stability of the probiotics within shelf life of products can be improved.

Owner:HUAZHONG AGRI UNIV

Method of manufacturing wax-containing polymer particles

The present invention is directed towards methods of manufacturing wax-containing polymer particles by limited coalescence processes employing aqueous wax dispersions. In one embodiment, an aqueous wax dispersion or emulsion is dispersed in an oil phase comprising a water-immiscible solvent and a polymer to form a transient water-in-oil (W / O) emulsion, and a further aqueous phase containing a particulate stabilizer is then added to the W / O emulsion to induce phase inversion, and the mixture homogenized to form an oil-in-water (O / W) emulsion. The solvent is then removed from the emulsion to form particles containing wax domains inside. In another embodiment, the aqueous wax dispersion is first mixed with the aqueous phase containing the particulate stabilizer, and homogenization is made with the oil phase to form an O / W emulsion, from which wax-containing particles are obtained after solvent removal. In still further embodiments, the aqueous wax dispersion is used in the second water phase of a double emulsion (W1 / O / W2) process to form porous polymer particles containing the wax.

Owner:EASTMAN KODAK CO

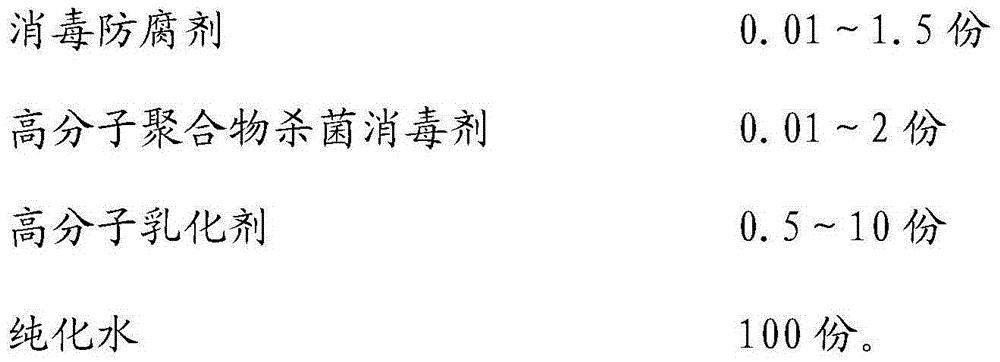

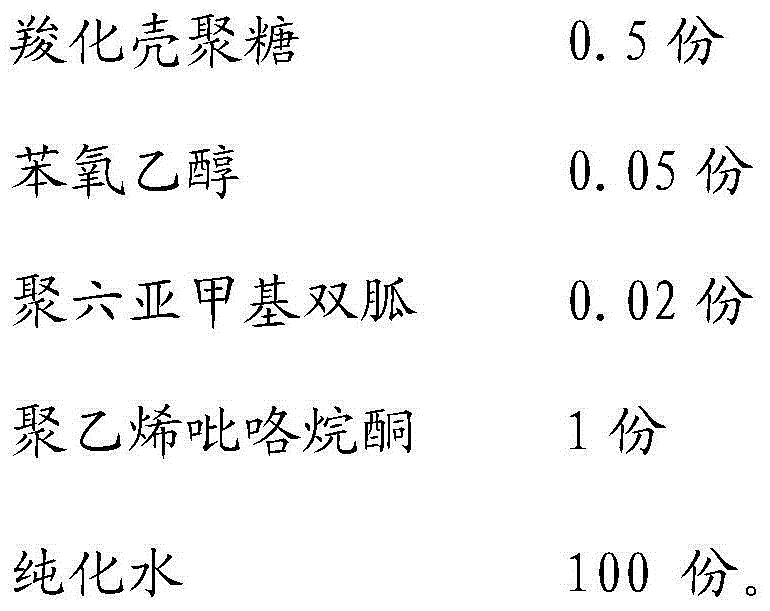

Liquid dressing capable of sterilizing and repairing wounds and production method of liquid dressing

The invention discloses liquid dressing capable of sterilizing and repairing wounds and a production method of the liquid dressing. The liquid dressing is double-emulsion-system solution using water-soluble amino polysaccharide, sterilizing preservatives and high-molecular polymer as main active constituents and high-molecular emulsifier as the emulsifier. The liquid dressing has the advantages that the liquid dressing can promote wound healing, resist exudation, inhibit bacteria and prevent infection and is applicable to washing or wet dressing treatment of related wounds such as scald wounds, knife wounds and chronic infection wounds. The production method of the liquid dressing includes: preparing water-soluble amino polysaccharide emulsion solution, preparing antibacterial compound emulsion solution, compounding a double-emulsion system and sterilizing.

Owner:GUIZHOU YANGSHENG MEDICAL INSTR

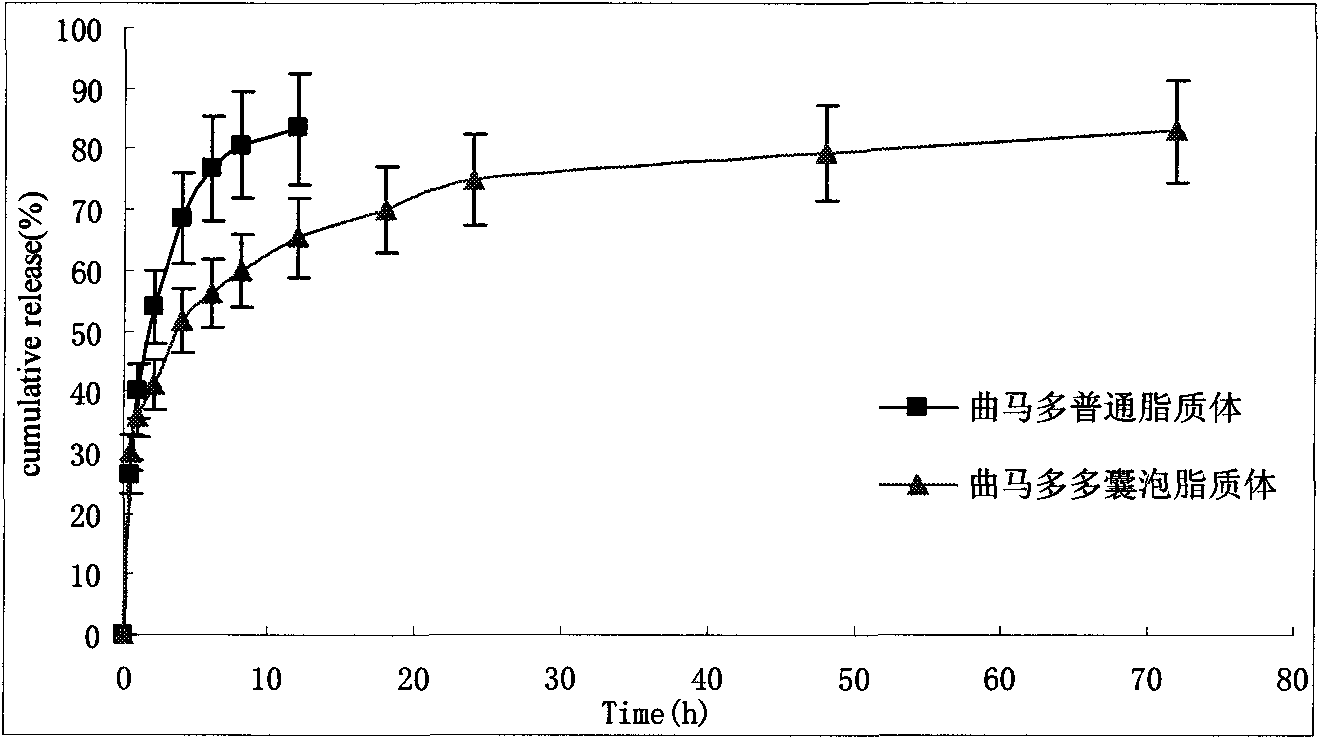

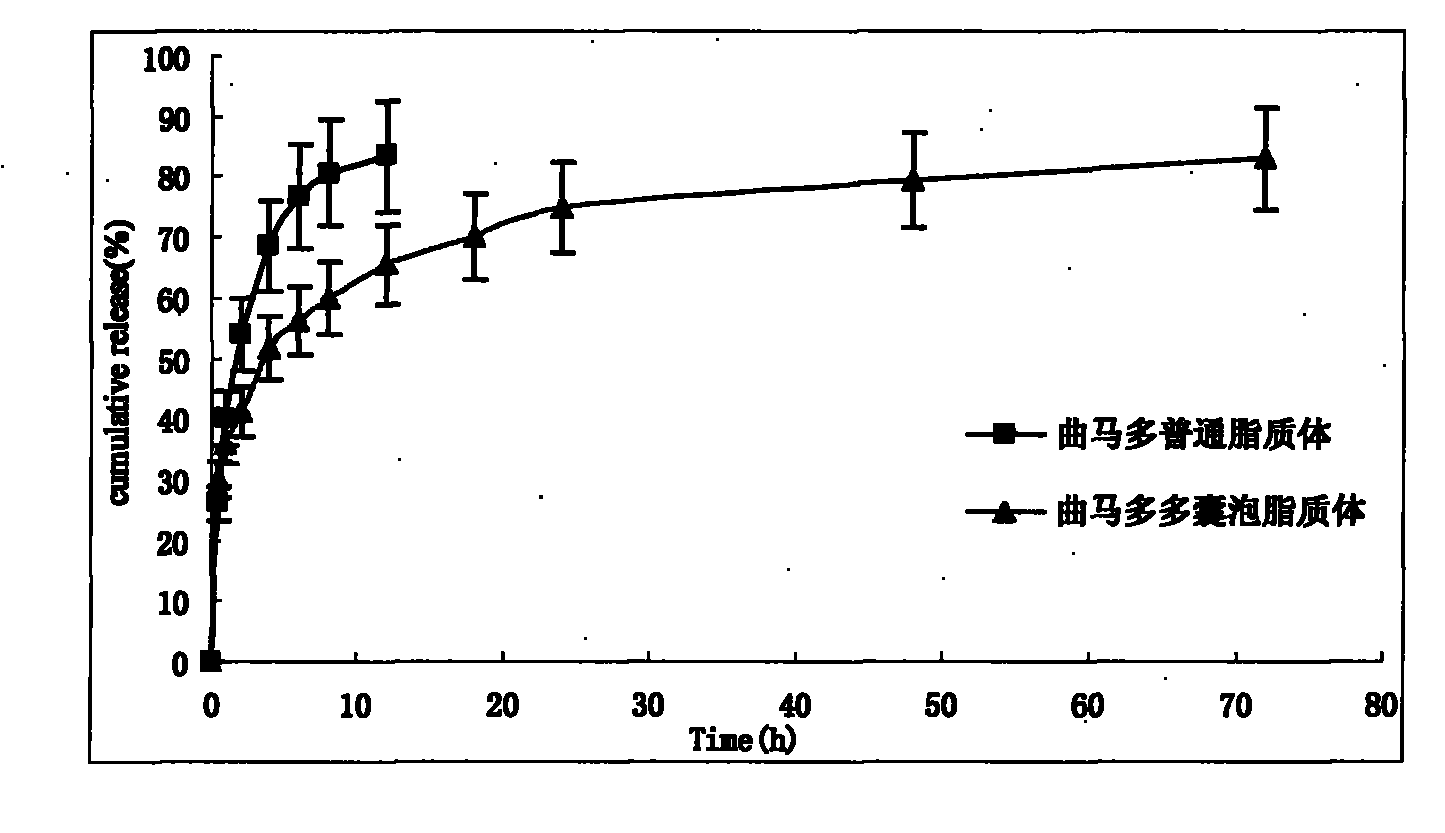

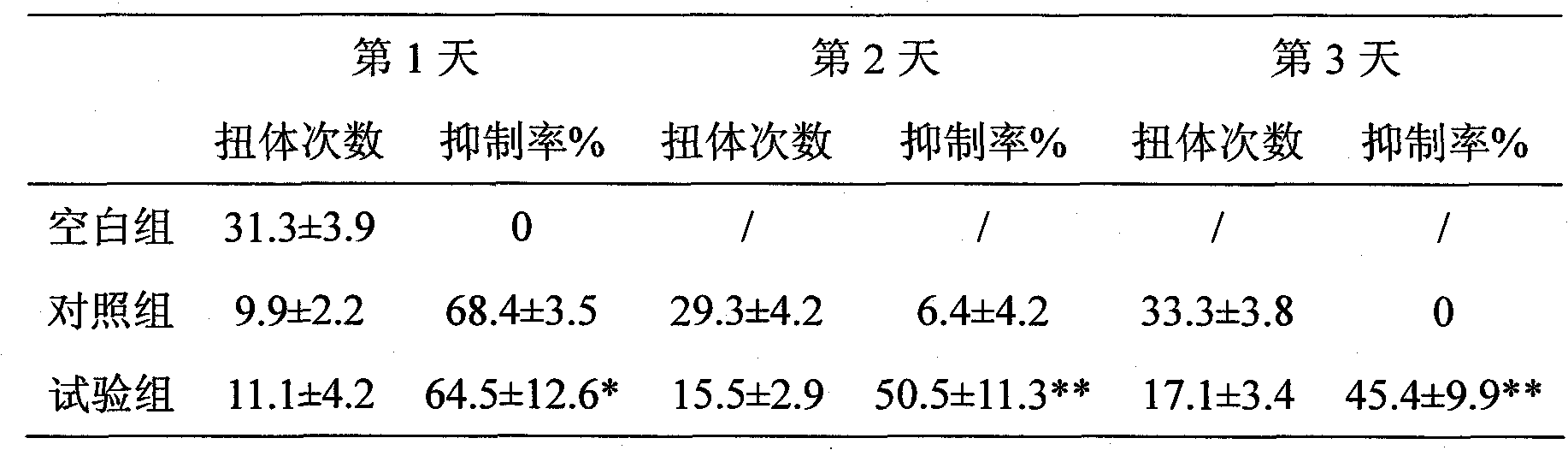

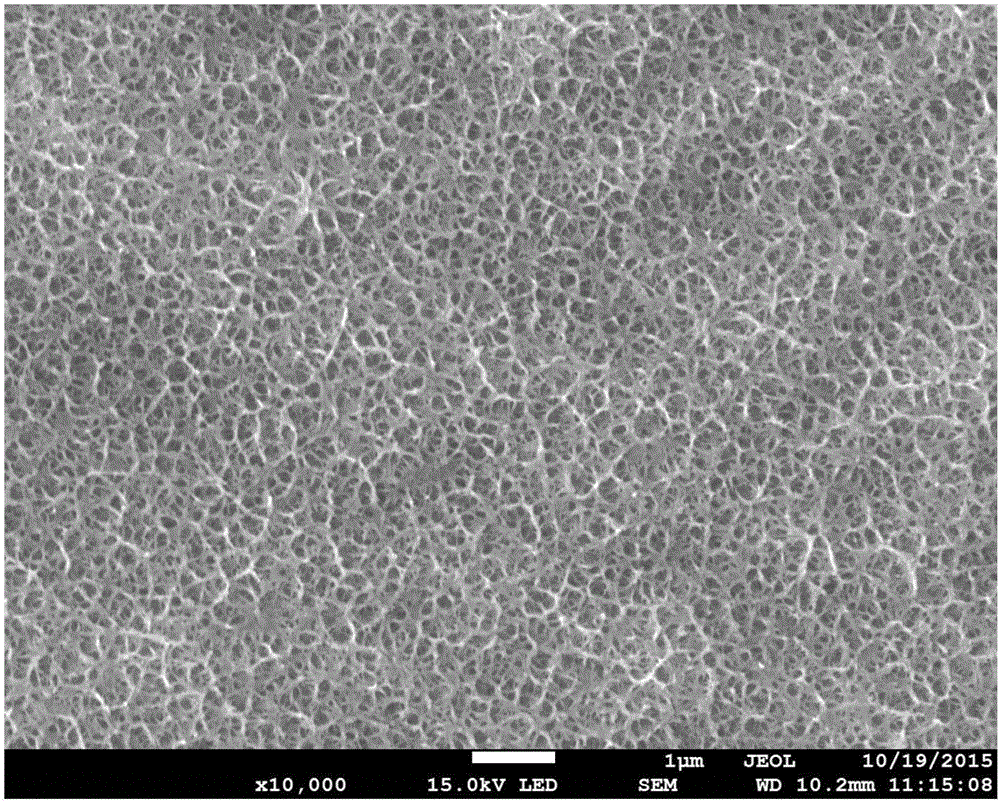

Tramadol multivesicular liposome and preparation method thereof

InactiveCN101780039AFirmly connectedHigh encapsulation efficiencyOrganic active ingredientsNervous disorderCholesterolNitrogen gas

The invention discloses a tramadol multivesicular liposome and a preparation method thereof. The preparation method comprises the following steps of: 1, dissolving phospholipids, cholesterol and neutral lipids into organic solvents to obtain a mixture which serves as an organic phase; 2, preparing 10 to 500mmol / L tramadol solution which serves as an internal water phase; 3, adding the internal water phase with the same volume as that of an organic phase into the organic phase, and mixing and emulsifying the mixture to obtain water-in-oil primary emulsion; 4, preparing an external water phase containing amino acid and osmotic modulators and / or surfactants, and adding the external water phase of which the volume is 2 to 10 times that of the water-in-oil primary emulsion into the water-in-oil primary emulsion, stirring the mixture to form oil-in-water type double emulsion; 5, adding the emulsion into the solution of the amino acid, introducing nitrogen or carbon dioxide into the mixed solution to remove the organic solvent from the emulsion to obtain suspension; 6, dissolving the suspension into the solution of amino acid, centrifuging and taking lower liposome suspension to obtain the tramadol multivesicular liposome. The prepared tramadol multivesicular liposome has the advantages of higher encapsulation efficiency, good slow release effect, and longer analgesic effect.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD +2

Medical titanium alloy preparation method

ActiveCN106512083AHas antibacterial propertiesImprove biological activityProsthesisOsteoblastTitanium alloy

The invention discloses a medical titanium alloy preparation method, the method comprises the steps of preparing nanometer particles of PLGA (Poly Lactic-co-Glycolic Acid) drug load with evenly distributed particle diameters and relatively light agglomeration degree using the double emulsion method, enabling the nanometer particles to have excellent bioactivity and bacteria resistance, then linking up the nanometer particles with APTES (3-aminopropyltriethoxysilane) layer using the reflux condensation method and using the hydrothermal process treated titanium alloy as the raw material, prompting the nanometer particles of the PLGA (Poly Lactic-co-Glycolic Acid) drug load to connect with titanium based surfaces better, and enabling the nanometer particles to have excellent osseous contributions as well as certain bacterial killing function. When the organism incurs medical infection in applications of the prepared medical titanium alloy, the ester linkages on the surface of the nanometer particles of the PLGA (Poly Lactic-co-Glycolic Acid) drug load open and the drug substances are gradually released with the degradation of the PLGA (Poly Lactic-co-Glycolic Acid), to inhibit bacterium growth and promote the proliferation and differentiation of osteoblast.

Owner:HUBEI UNIV

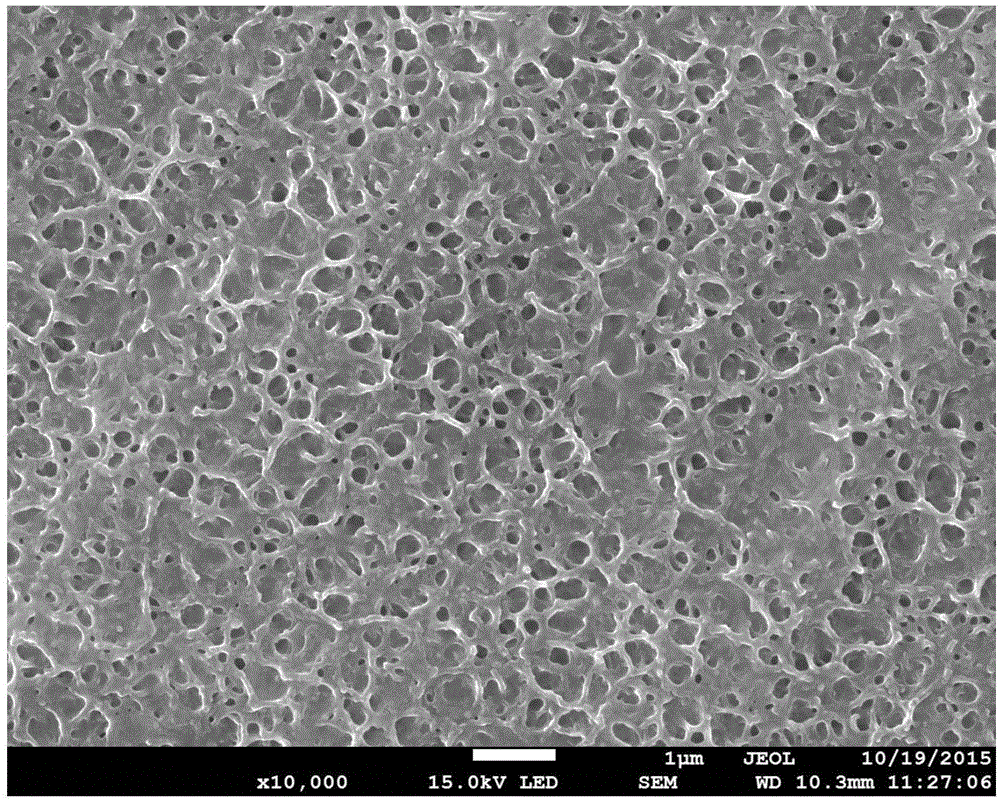

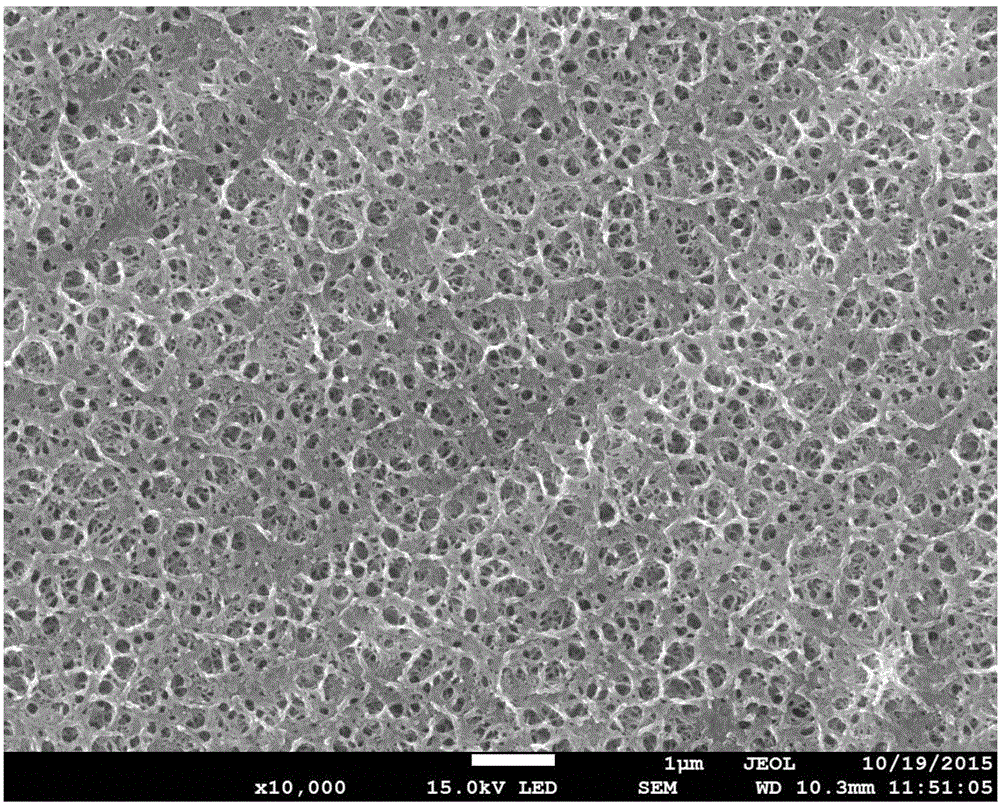

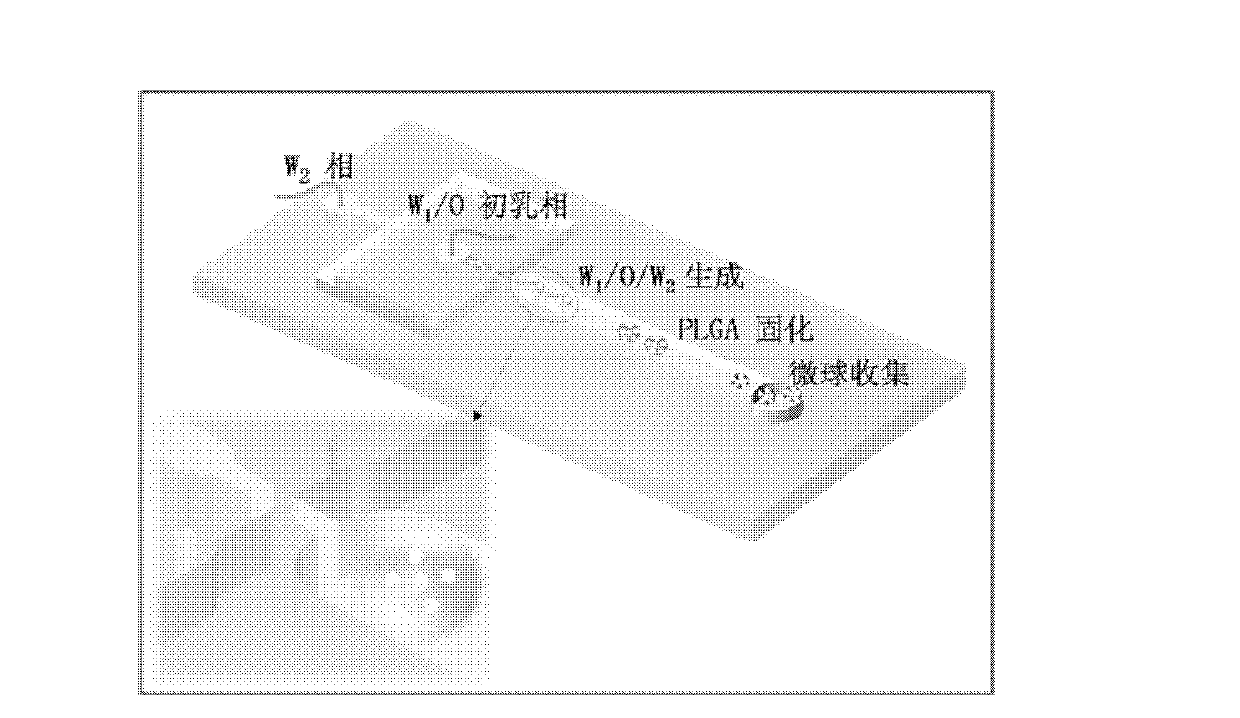

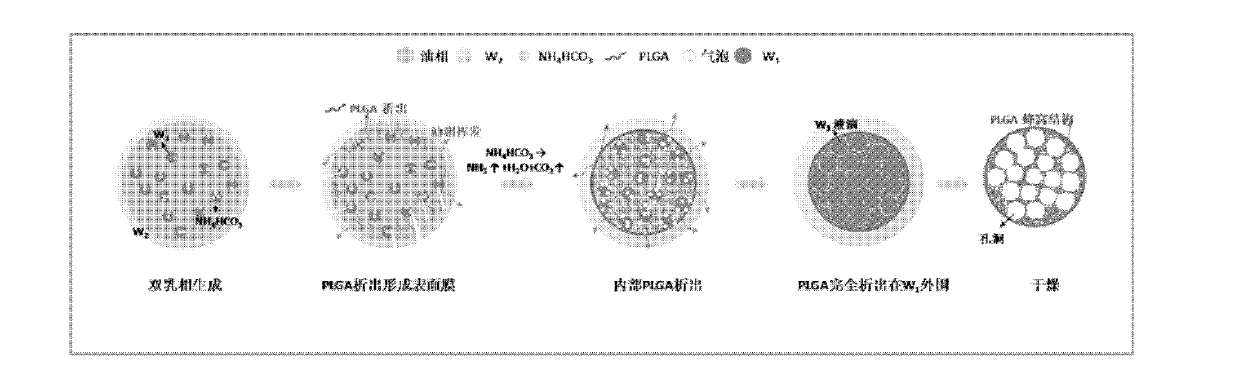

Method for preparing faveolate polymer microsphere on basis of micro-fluidic chip

The invention relates to a method for preparing a faveolate polymer microsphere on the basis of a micro-fluidic chip. The method comprises the following steps that: an initial emulsion phase (W1 / O) obtained through ultrasonic dispersion is used as a dispersed phase, and double-emulsion phase (W1 / O / W2) liquid drops inside the micro-fluidic chip are formed under the action of a continuous phase (W2); and an effervescing agent dissolved in an inner water phase (W1) is decomposed to play an expanding role, and a polymer dissolved in an oil phase is separated out and solidified with the volatilization of a solvent and deposited on the periphery of an inner water phase (W1) liquid drop mould plate to form the polymer microsphere with a unique structure. The micro-fluidic chip based on a liquid drop operation and control technology is designed and manufactured, and the micro-fluidic chip is applied to preparation of a monodisperse polylactic acid-hydroxyacetic acid copolymer microsphere with a specific bionic faveolate structure. The method is characterized by preparing microspheres with different sizes and patterns by regulating the concentration of the effervescing agent inside the inner water phase (W1). The method disclosed by the invention has the advantages of easiness and fastness for preparation and has an extremely high potential application capacity in the fields of pharmacy and tissue engineering.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

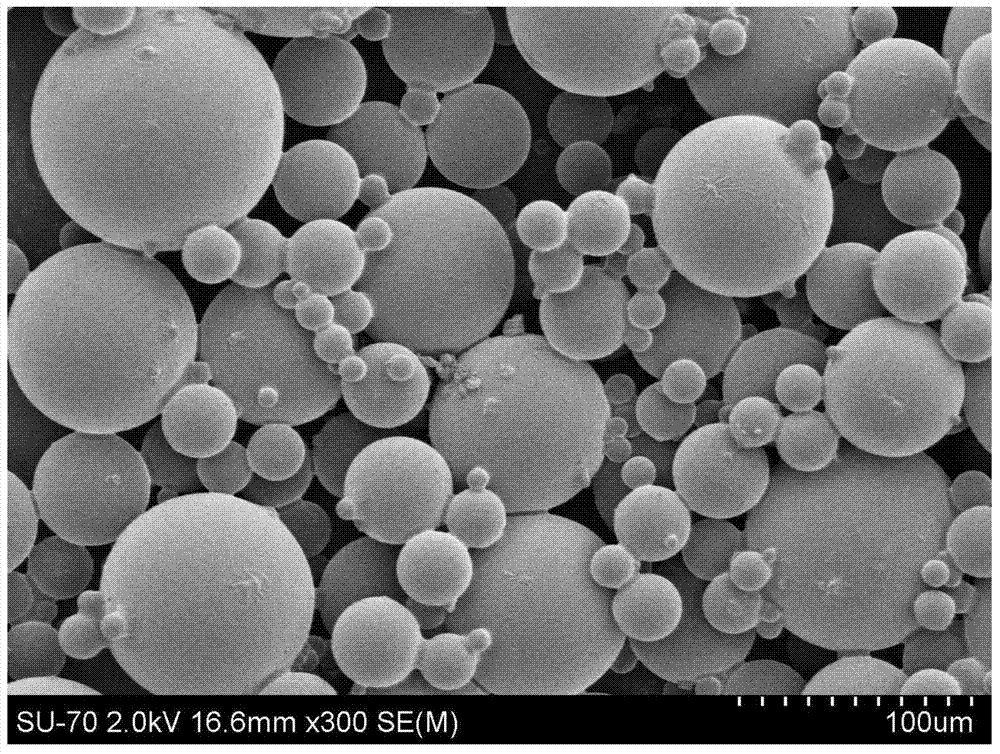

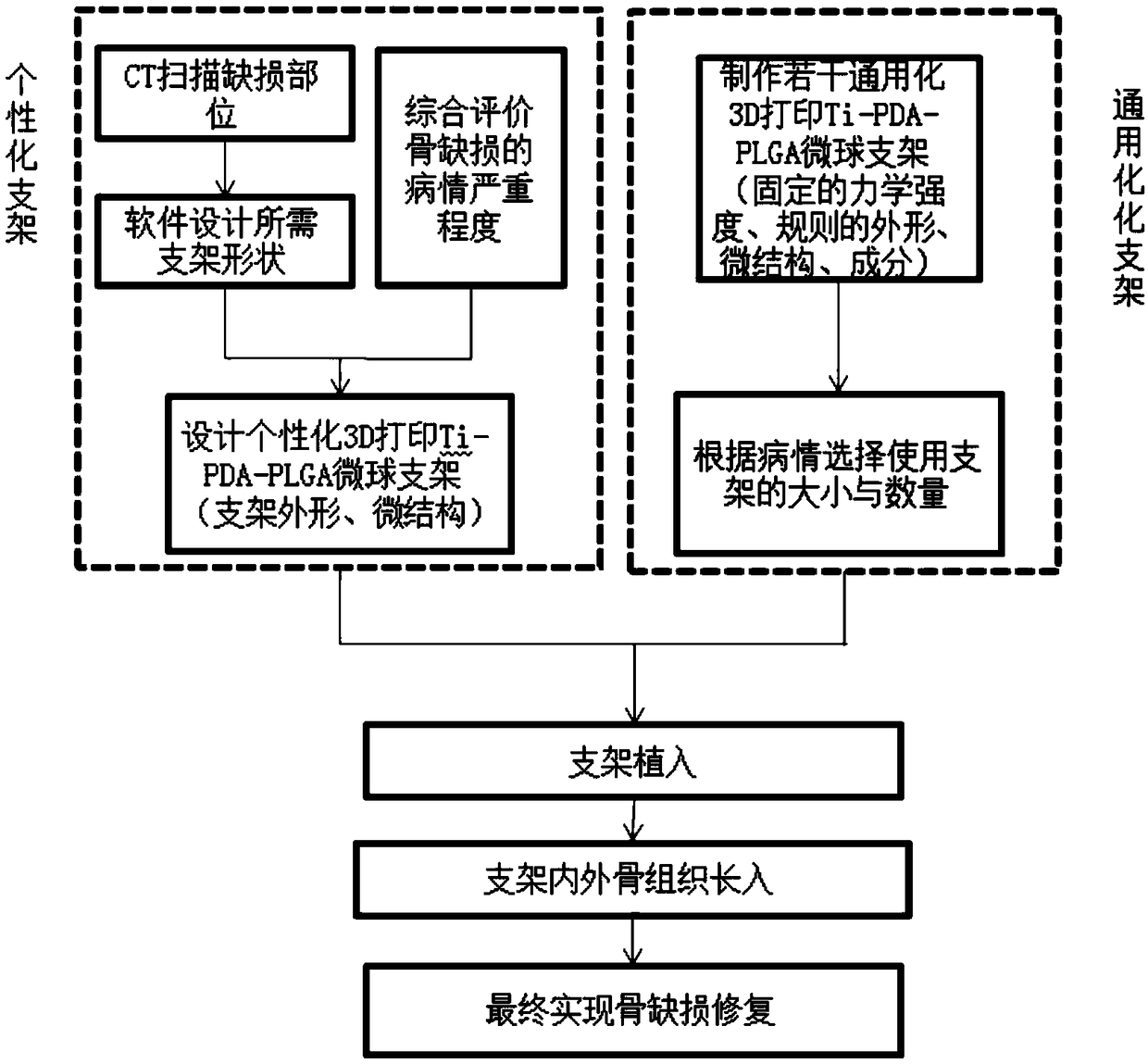

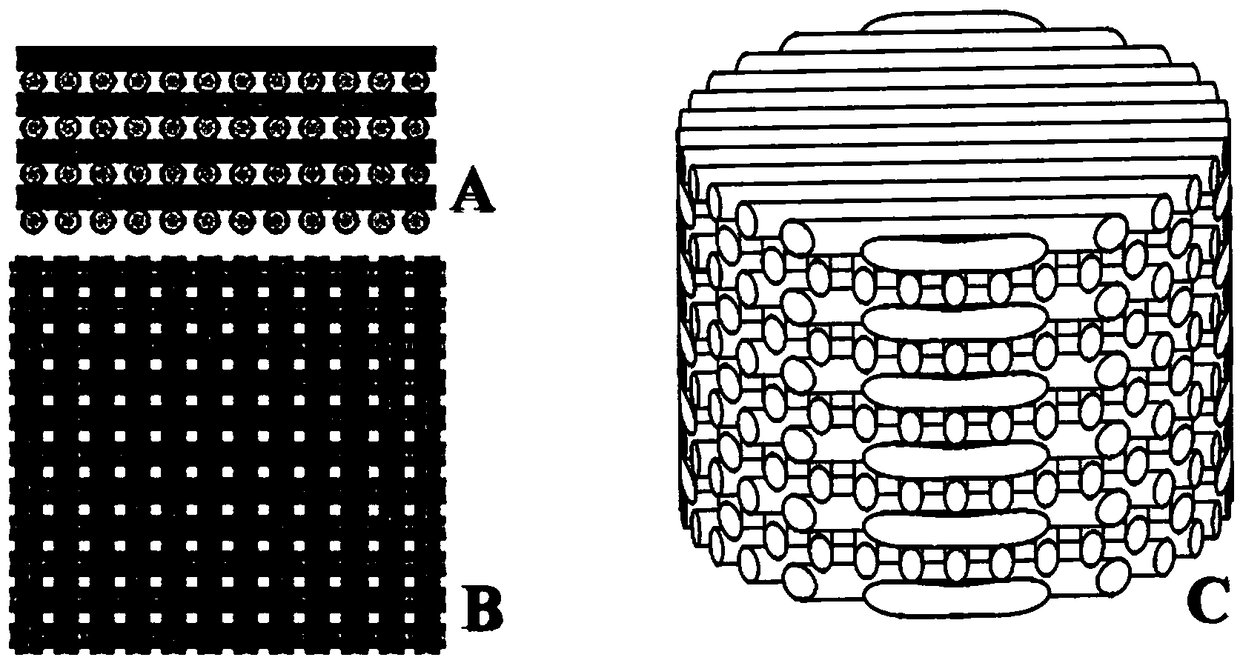

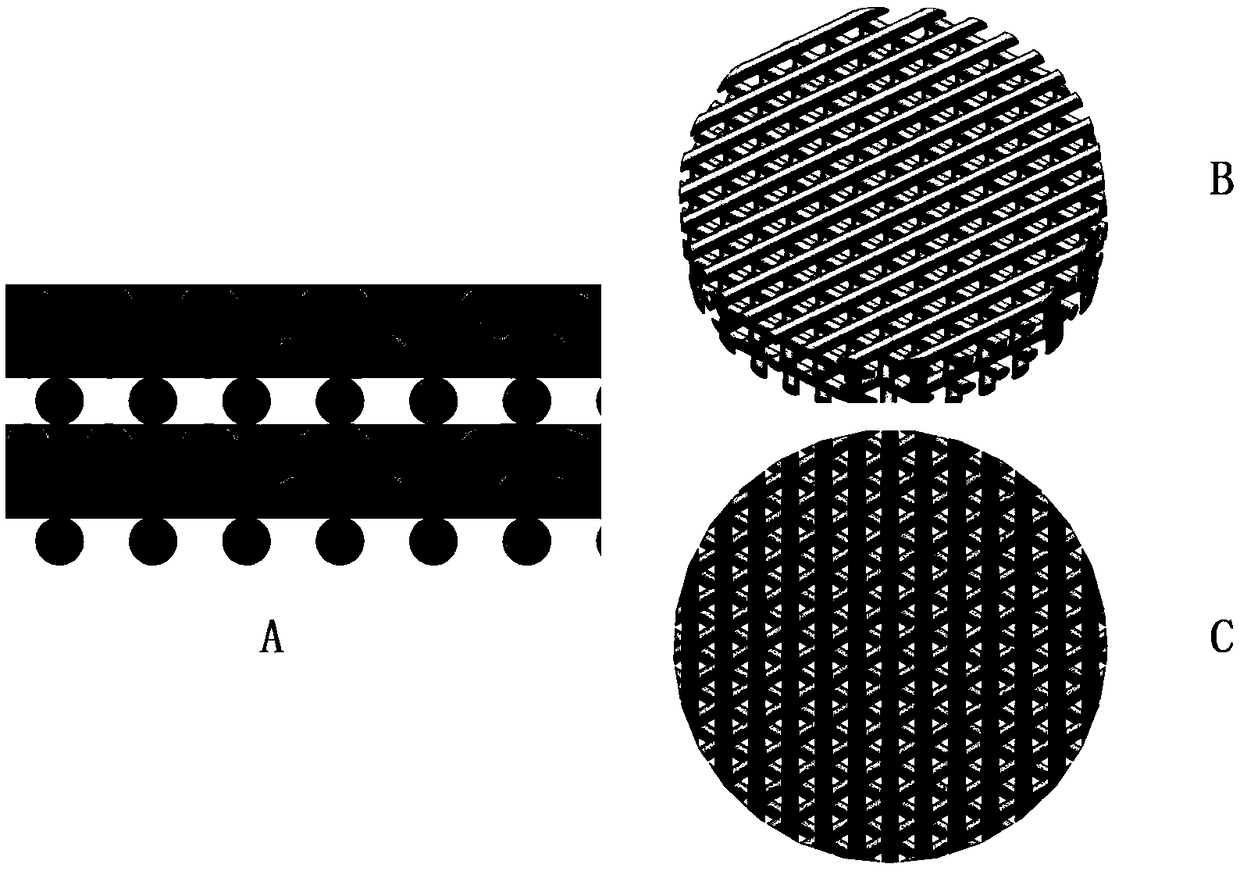

3D printed Ti-PDA-PLGA microsphere bone defect repair stent

InactiveCN108853577AAchieve fine controlAchieve sustained releaseAdditive manufacturing apparatusTissue regeneration3d printRepair tissue

The invention discloses a 3D printed Ti-PDA-PLGA microsphere bone defect repair stent. A 3D printed Ti stent is prepared by a laser sintering technology. Then, under certain conditions, dopamine is self-polymerized on the fiber surface of the 3D printed Ti stent to form a PDA coating, thereby preparing a 3D printed Ti-PDA stent; then PLGA microspheres carrying VEGF are prepared by a double emulsion-solvent evaporation method, and finally, BMP-2 and PLGA microspheres carrying VEGF are adsorbed and immobilized on the surface of the stent by an adsorption method, and finally the 3D printed Ti-PDA-PLGA microsphere bone defect repair stent is formed. The bone defect repair tissue engineering stent disclosed by the invention has the advantages of reliable mechanical property, high biological activity and safety, convenient implantation, small trauma and low cost, and can be used for the repair treatment of bone defect after bone traumas, bone tumors and bone infection.

Owner:南京冬尚生物科技有限公司

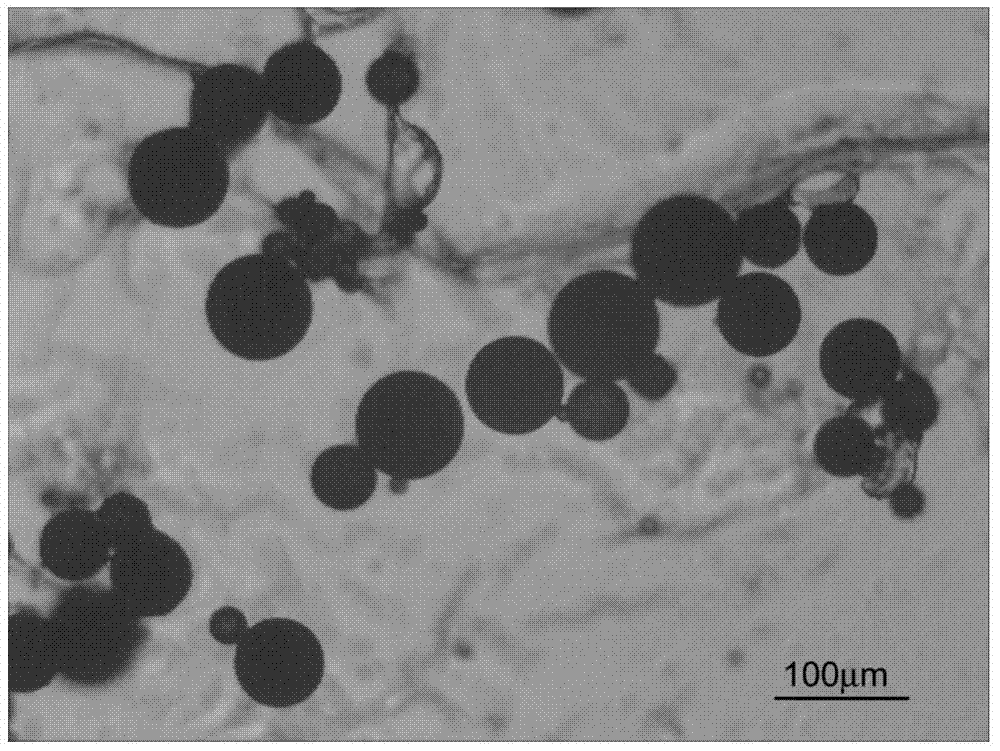

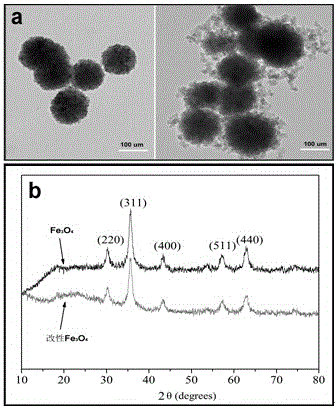

Prepn. of magnetic molecular pellets by complex emulsion process (W1/0/W2 type)

This invention provides a method to prepare a kind of new magnetic polymer microballs, in which a double emulsion method is employed and the obtained magnetic polymer microballs have a particle size range of 50nm~80micron. The magnetic particles embedded in the microballs have a mass fraction of 0.5~50% of the total microballs. The main technique flow includes the preparation of initial emulsion, reemulsification, addition of alkali, removal of organic solvent, solidification of second emulsion drops, washing and separation of magnetic microballs and drying of microballs. It has the characteristics that double emulsions embedded with ferrous salt solution are prepared by the double emulsion method at first and organic or inorganic alkali is added so that ferrous salts are transferred into magnetic particles. Double emulsion drops are then solidified so as to produce magnetic polymer microballs. The particle size of the microballs can be adjusted by modulating the viscosity of initial emulsion, the rotation speed of outer aqueous phase when reemulsification and the concentration of outer aqueous phase stabilizers, while the magnet content can be adjusted by modulating solute concentration in inner aqueous phase and the volume ratio of inner aqueous phase and oil phase. The magnetic microballs can serve as carriers for all kinds of enzymes, antibodies and target drugs and are widely used in the fields of cell separation, clinical diagnosis, target drug carries, immobilized enzymes and affinity separation. This invention has the advantages of simple method, good repeatability, high raw materials availability, low cost, controllable particle size of microballs and uniform and controllable magnet content in microballs.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

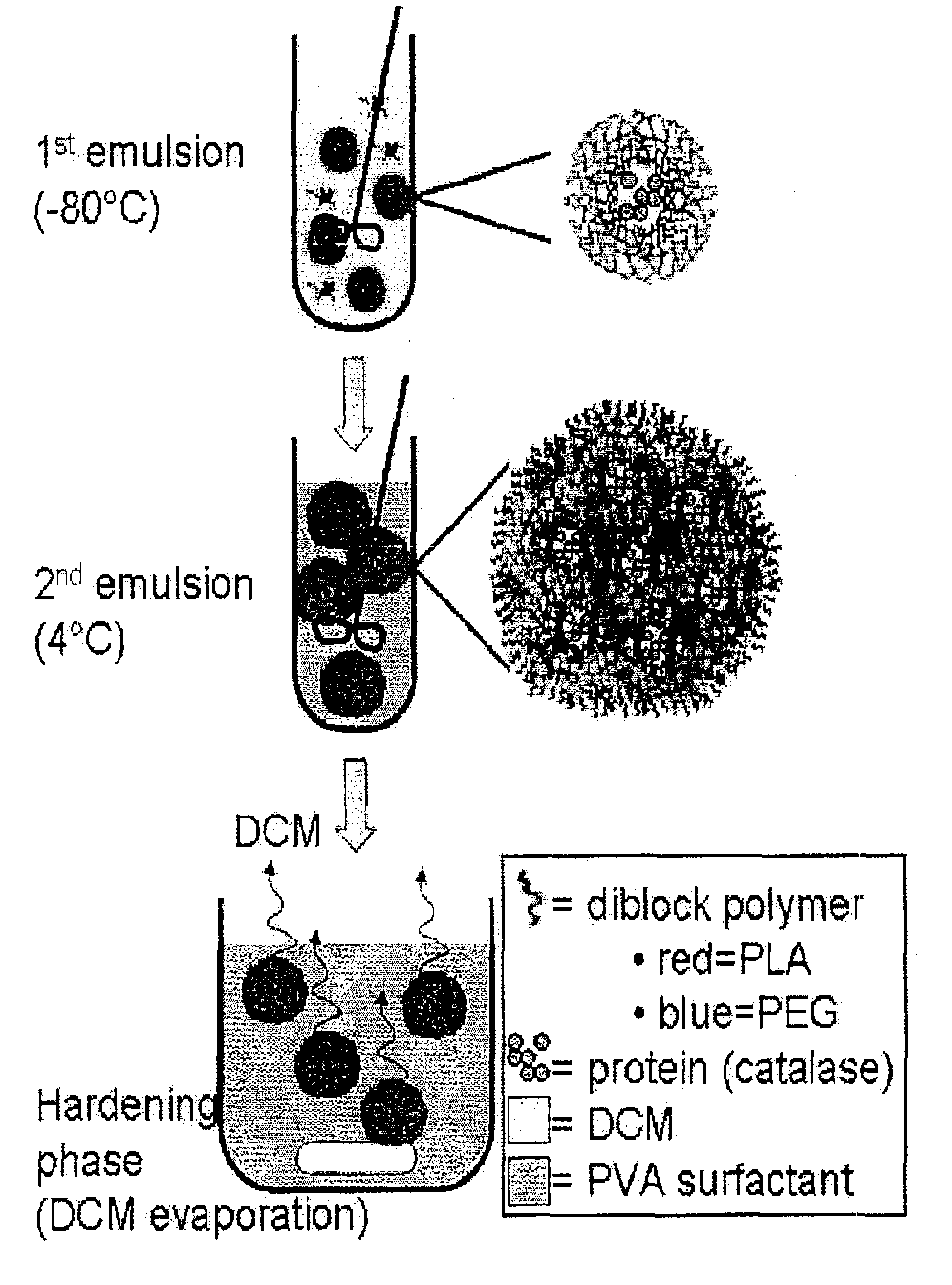

Method and compositions for polymer nanocarriers containing therapeutic molecules

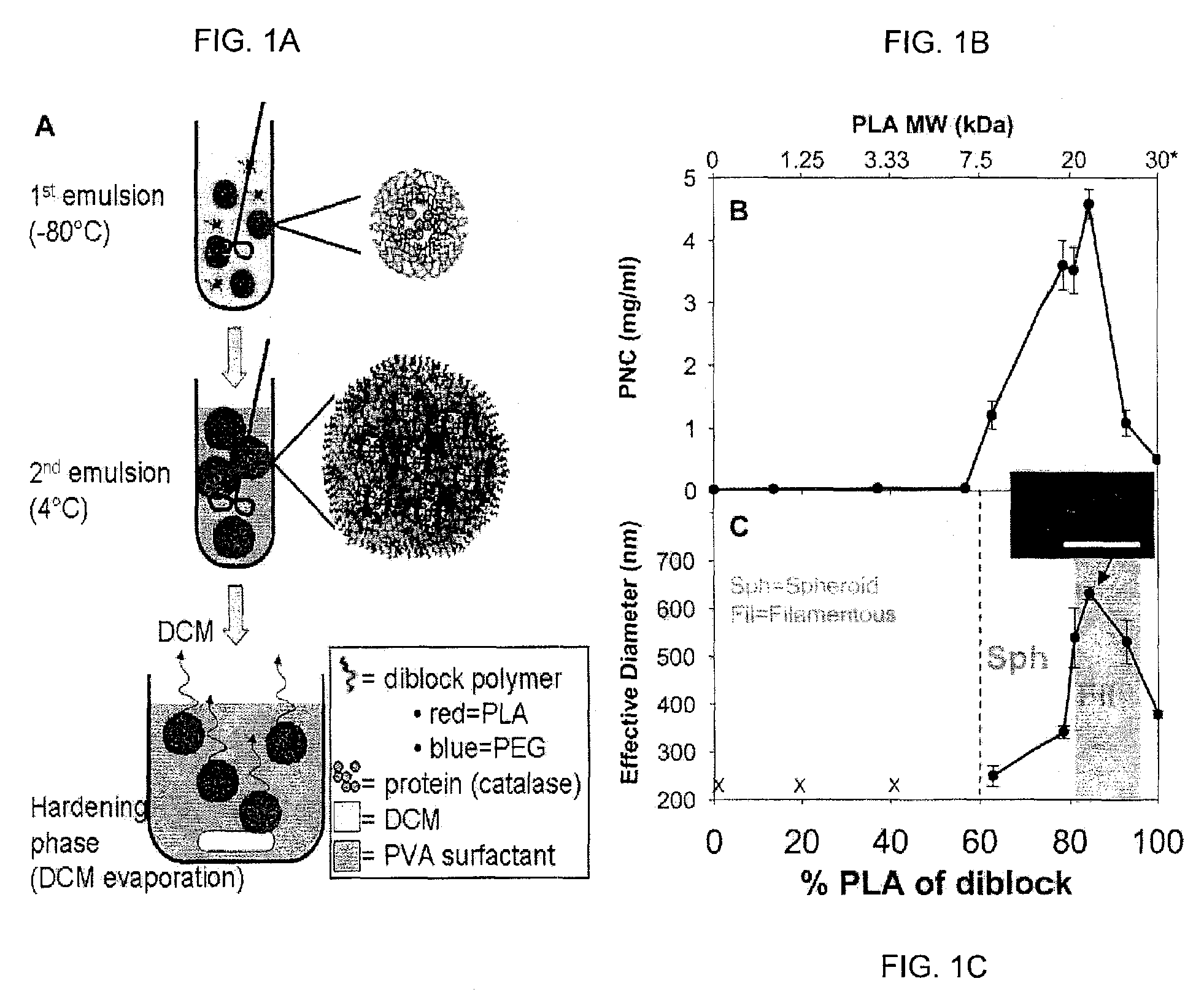

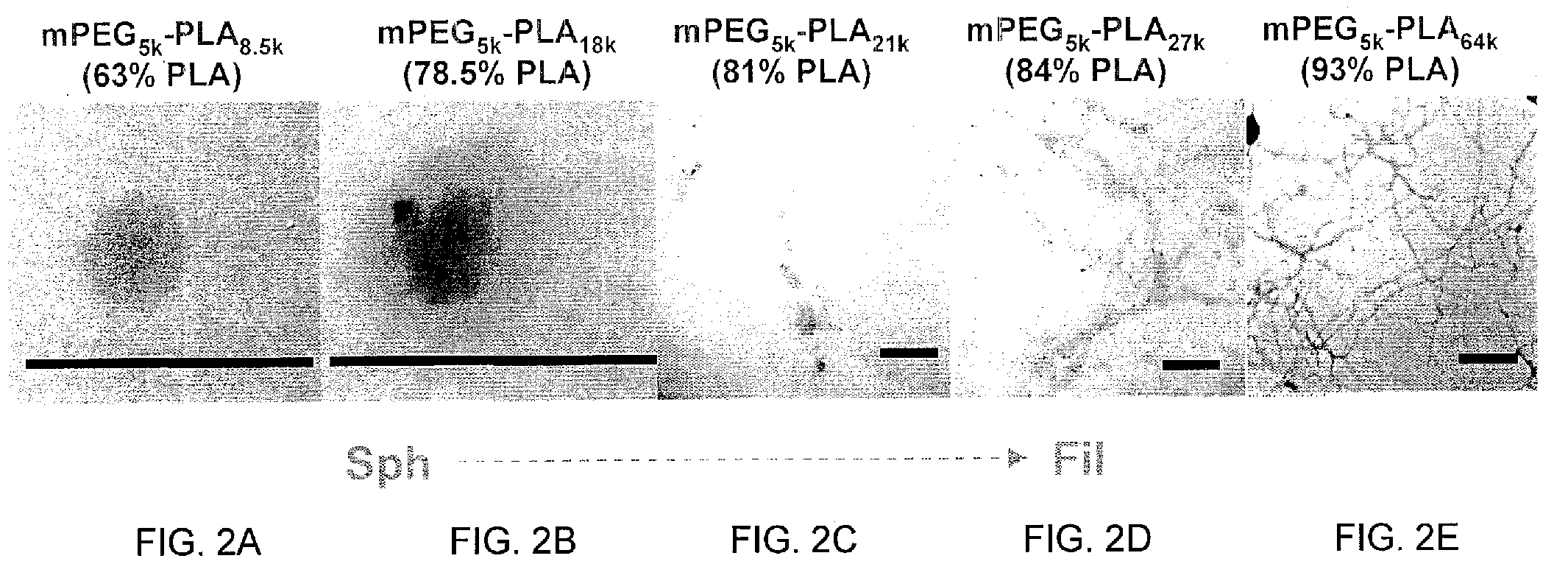

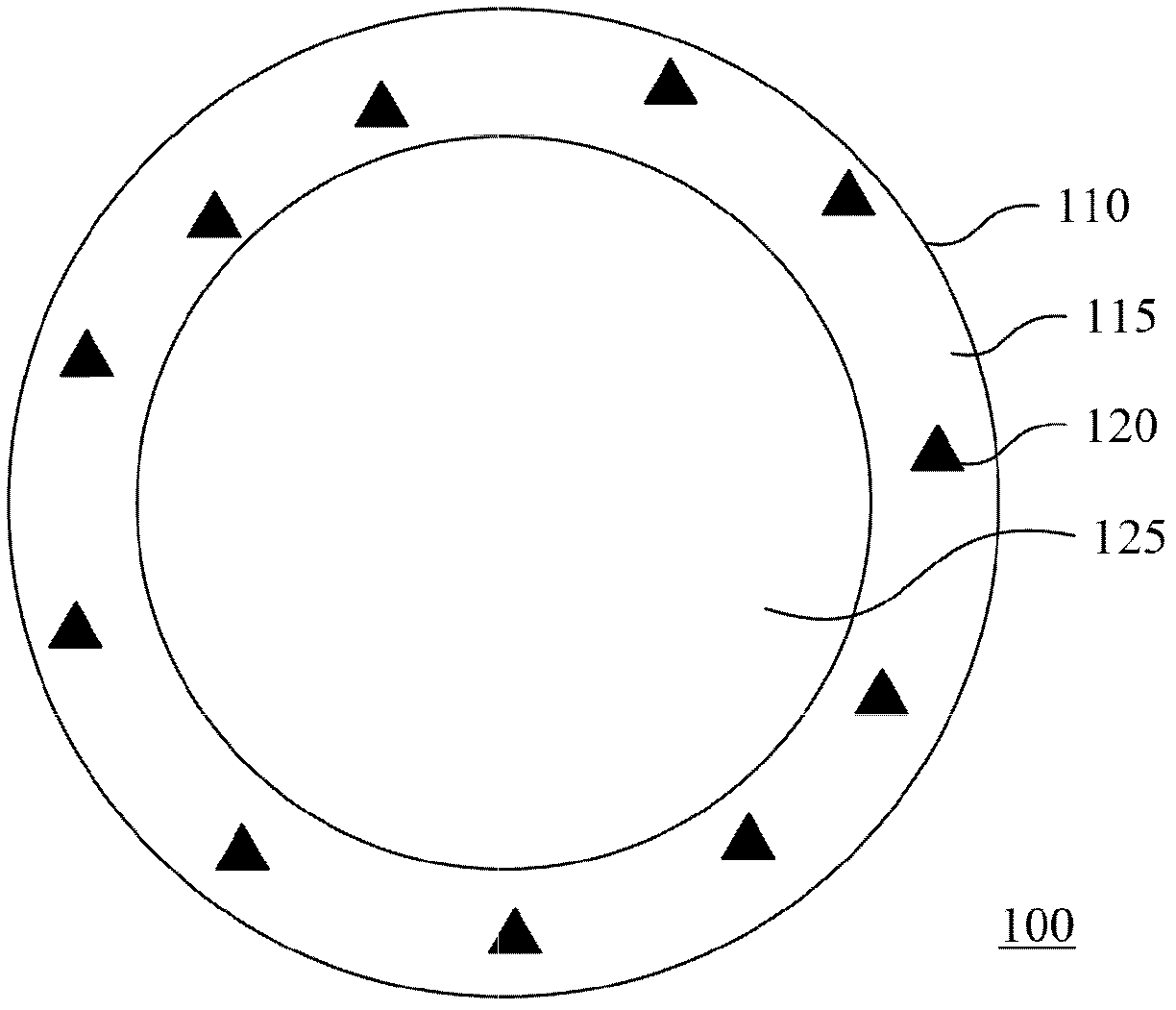

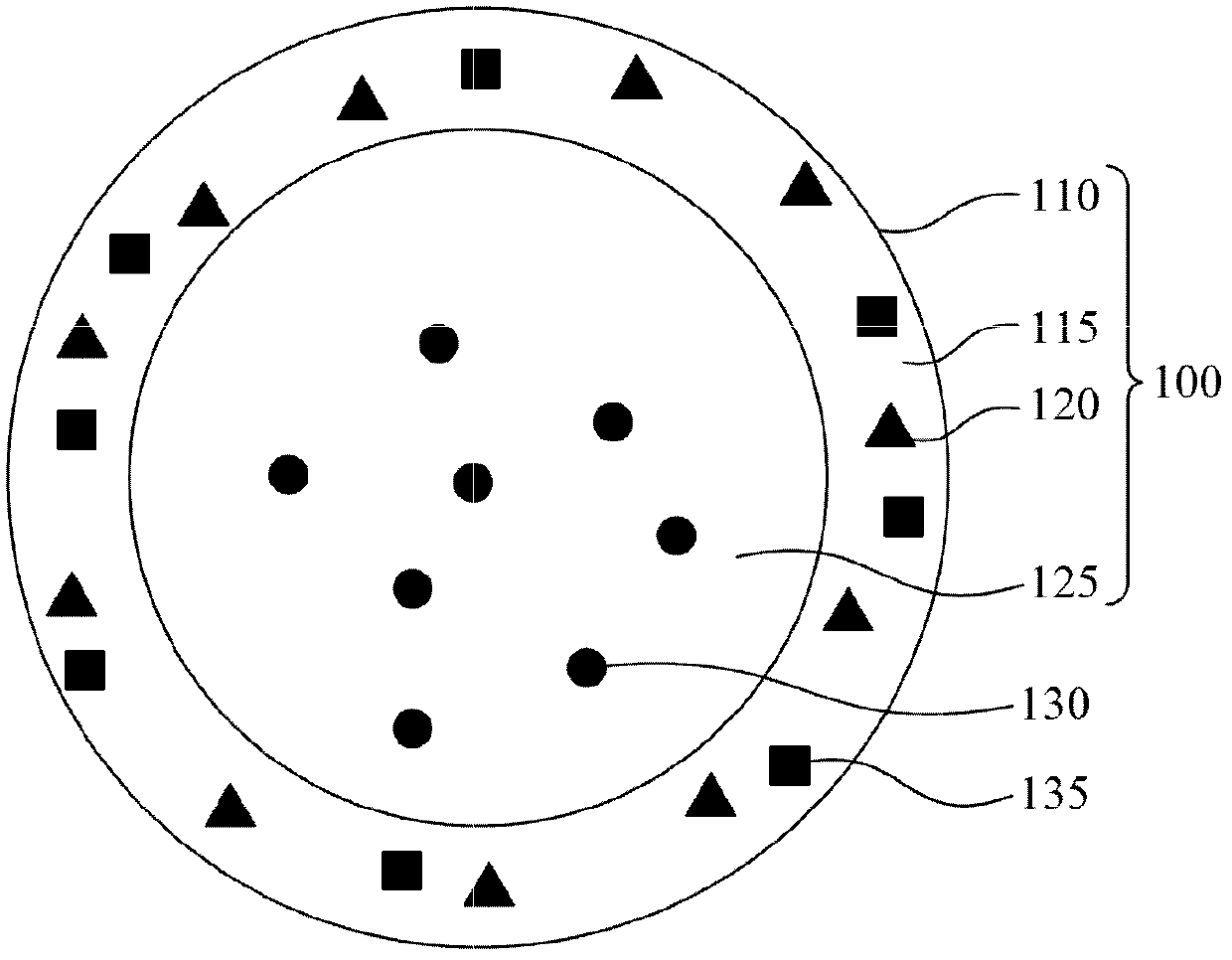

ActiveUS7927629B2Improve enzymatic activityRetain biological activityBiocidePeptide/protein ingredientsFreeze thawingActive enzyme

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

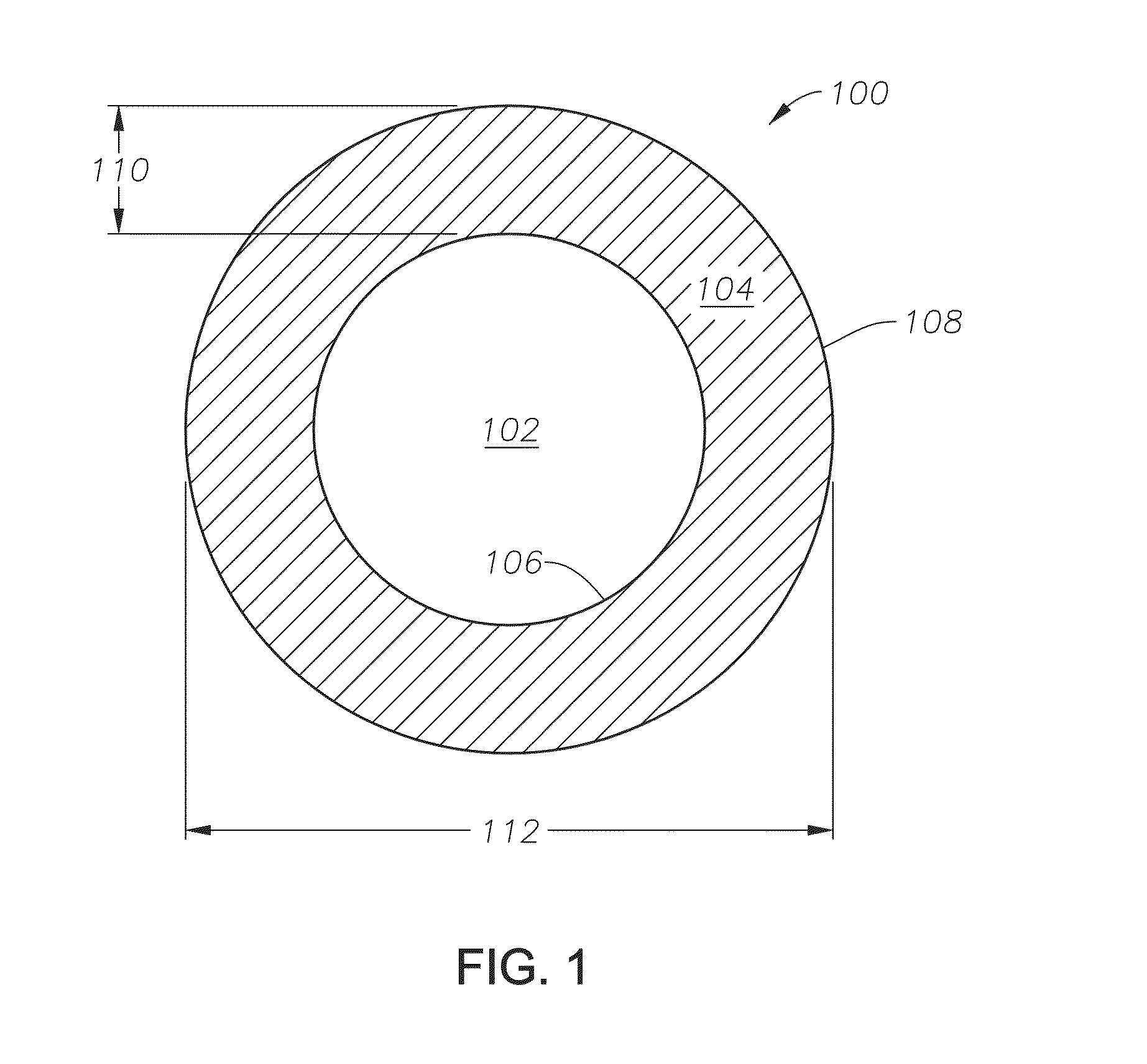

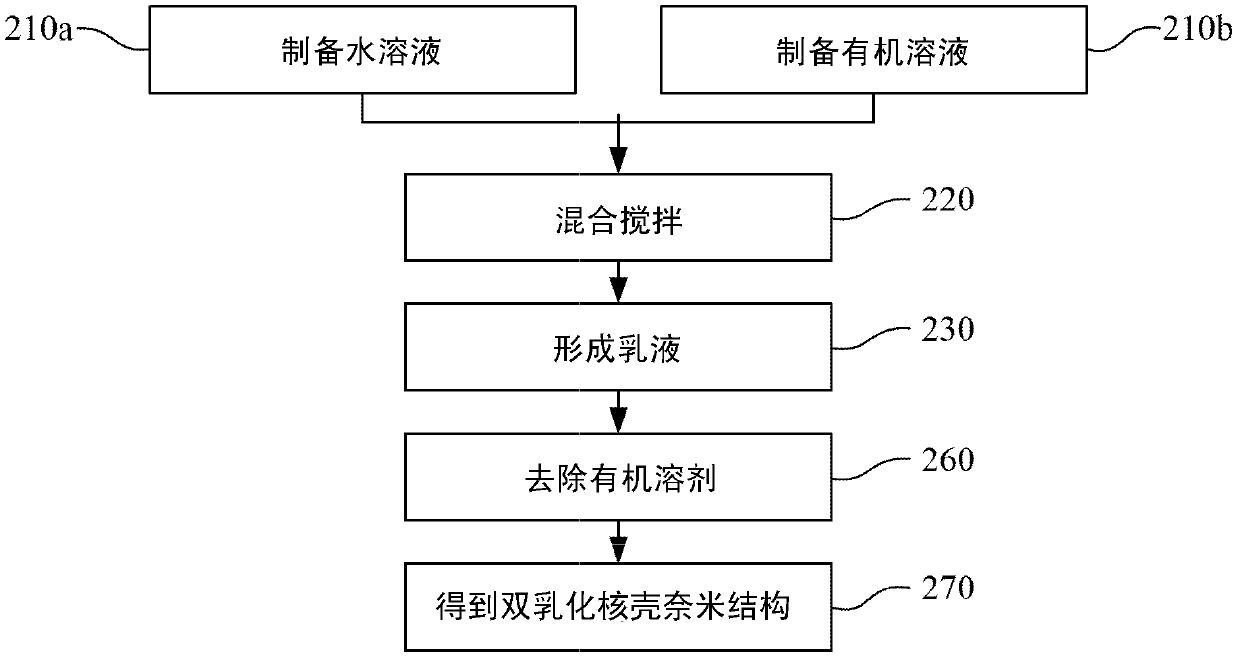

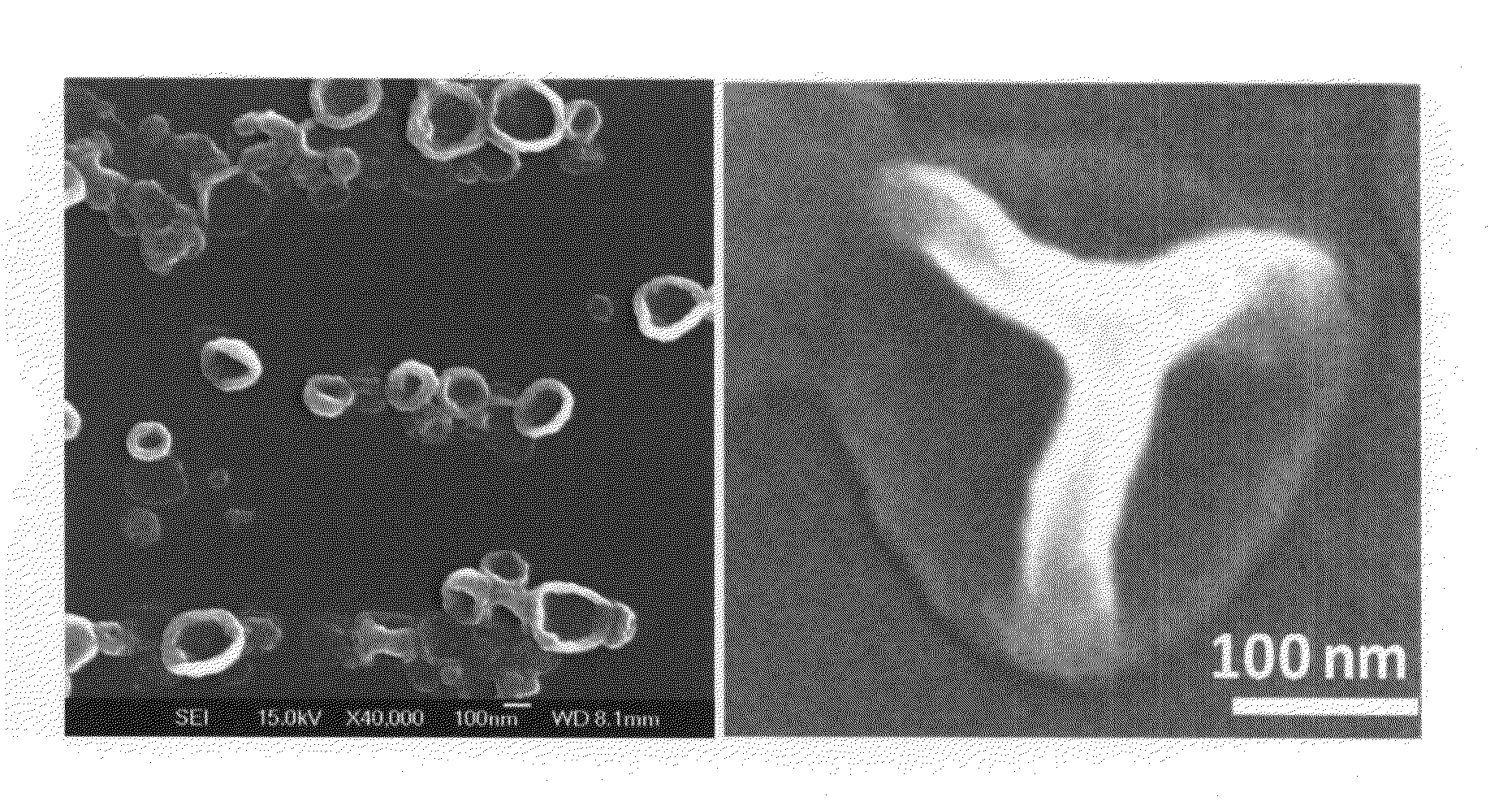

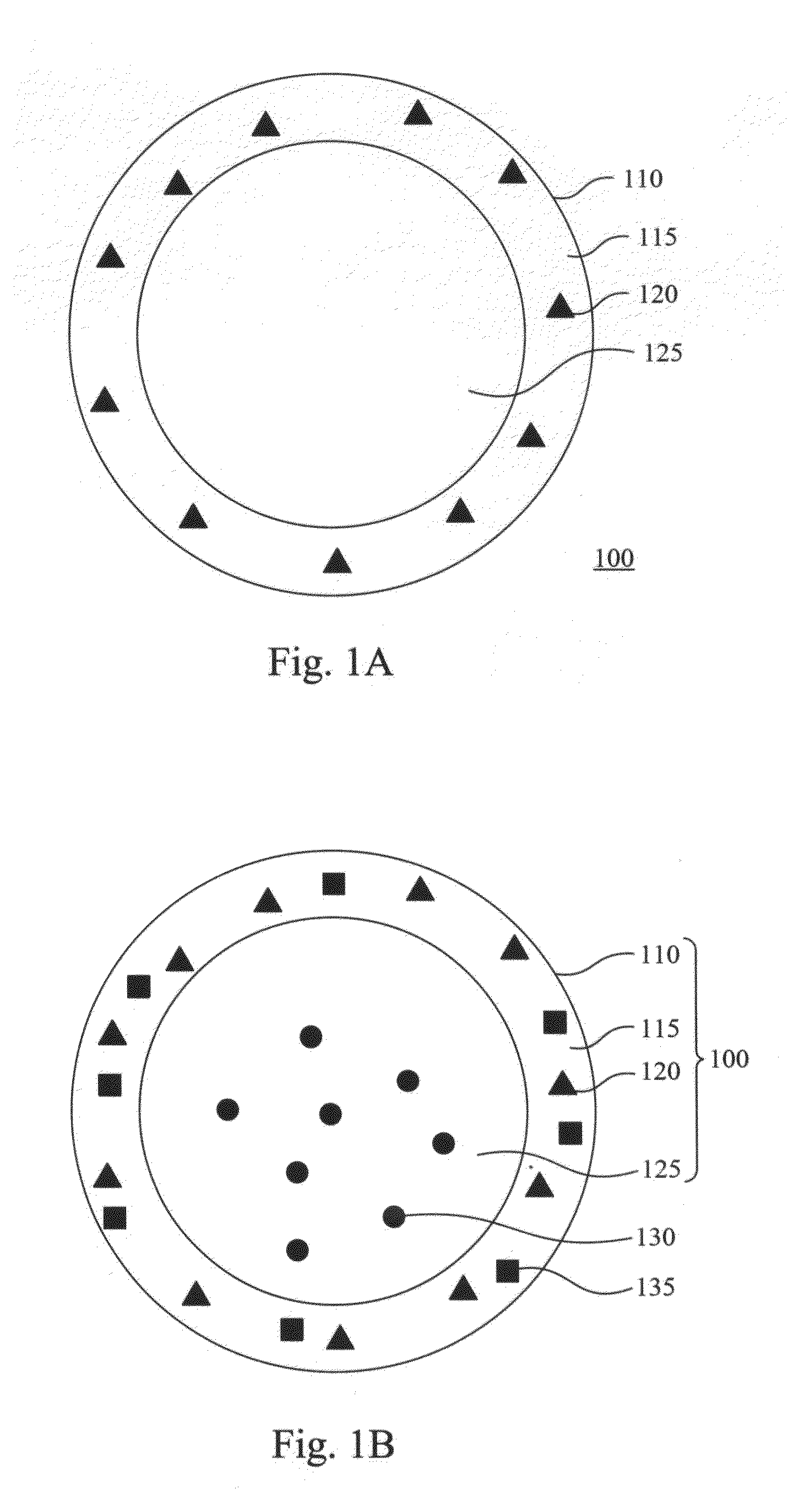

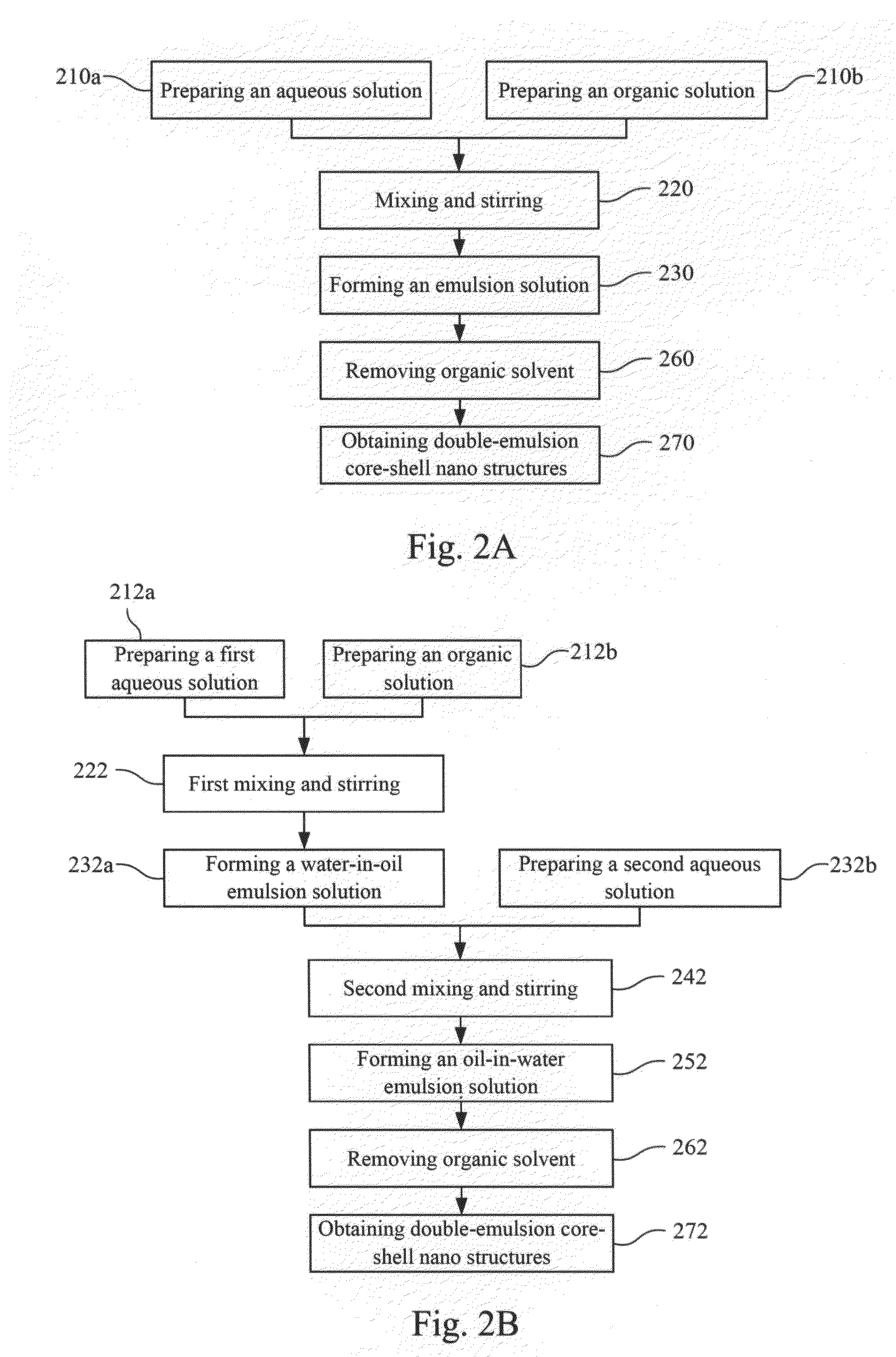

Double emulsion core-shell nano-structure and preparation methods thereof

InactiveCN103126985AEasy Mixing Stirring StepsPharmaceutical non-active ingredientsEmulsion deliveryPolymer scienceNano structuring

A double-emulsion core-shell nano-structure and preparation methods thereof are provided. The double-emulsion core-shell nano-structure is a structure of an oil shell enclosing a water core. The double-emulsion core-shell nano-structure can be prepared by simply mixing and stirring to emulsify an aqueous solution of a water soluble polymer and an organic solution of hydrophobic paramagnetic nanoparticles

Owner:SPRING FOUND OF NCTU

Double emulsion core-shell nano-structure and preparation methods thereof

InactiveUS20130137917A1Simple emulsifying methodSuitable for usePowder deliveryElectrotherapyPolymer scienceNano structuring

A double-emulsion core-shell nano-structure and preparation methods thereof is provided. The double-emulsion core-shell nano-structure is a structure of an oil shell enclosing a water core. The double-emulsion core-shell nano-structure can be prepared by simply mixing and stirring to emulsify an aqueous solution of a water soluble polymer and an organic solution of hydrophobic paramagnetic nanoparticles.

Owner:NAT CHIAO TUNG UNIV

Method for preparing photonic crystal material through ordered self-assembly of emulsion

The invention relates to a method for preparing a photonic crystal material through ordered self-assembly of an emulsion. The method comprises the following steps: dissolving an amphiphilic branched block polymer in a water-insoluble organic solvent to form a polymer solution, and dispersing the polymer solution in an aqueous solution containing a surfactant to form micron-sized liquid drops; under the conditions that the temperature is 0-60 DEG C and the relative humidity is 5-80%, completely volatilizing the organic solvent in the amphiphilic branched block polymer solution, carrying out reversed-phase emulsification in the volatilization process to form a water-in-oil-in-water double emulsion, and self-assembling nano-water drops in an oil phase to form an ordered arrangement structurein order to obtain the solid photonic crystal material with the ordered porous structure. The photonic crystal material comprises the ordered porous structure, and the color of reflected light coversthe whole visible light range. The preparation method provided by the invention is simple to operate and high in repeatability, and the problems of tedious process, long consumed time, complex operation, harsh preparation conditions and the like of a traditional preparation method are avoided.

Owner:TIANJIN UNIV

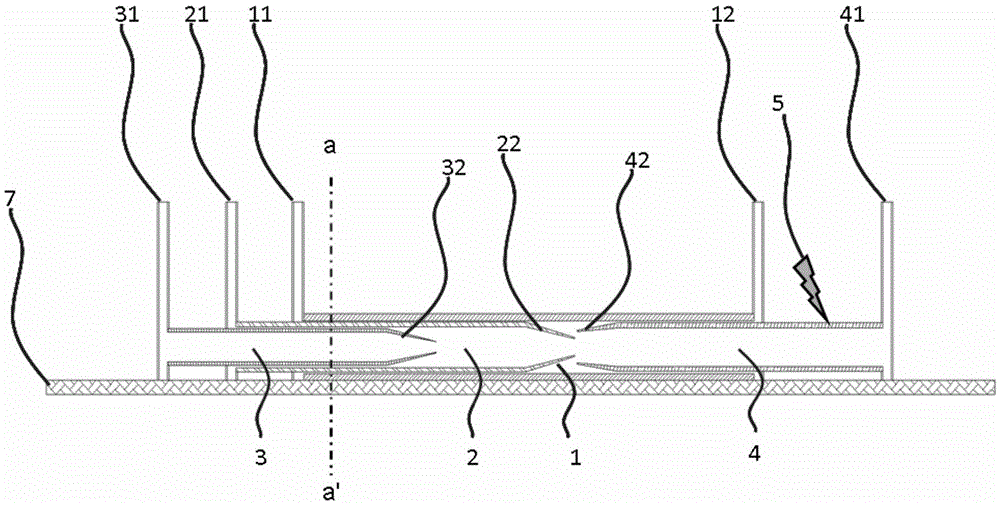

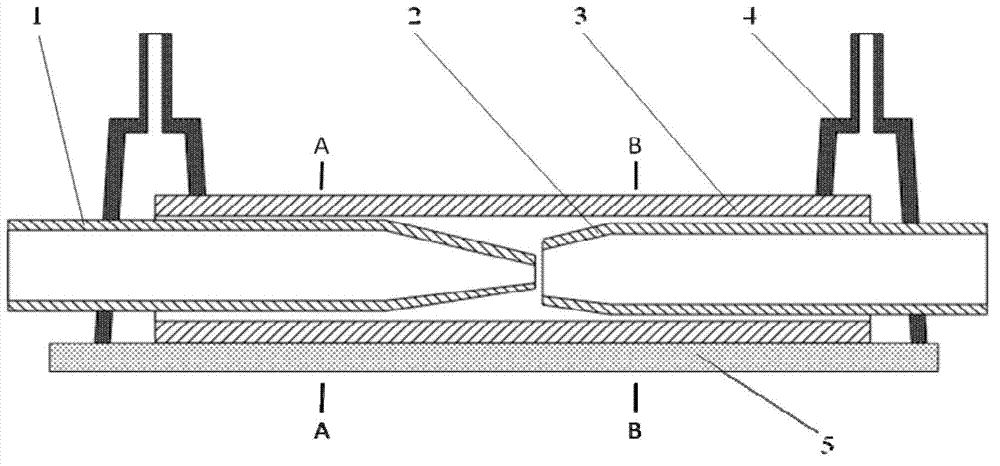

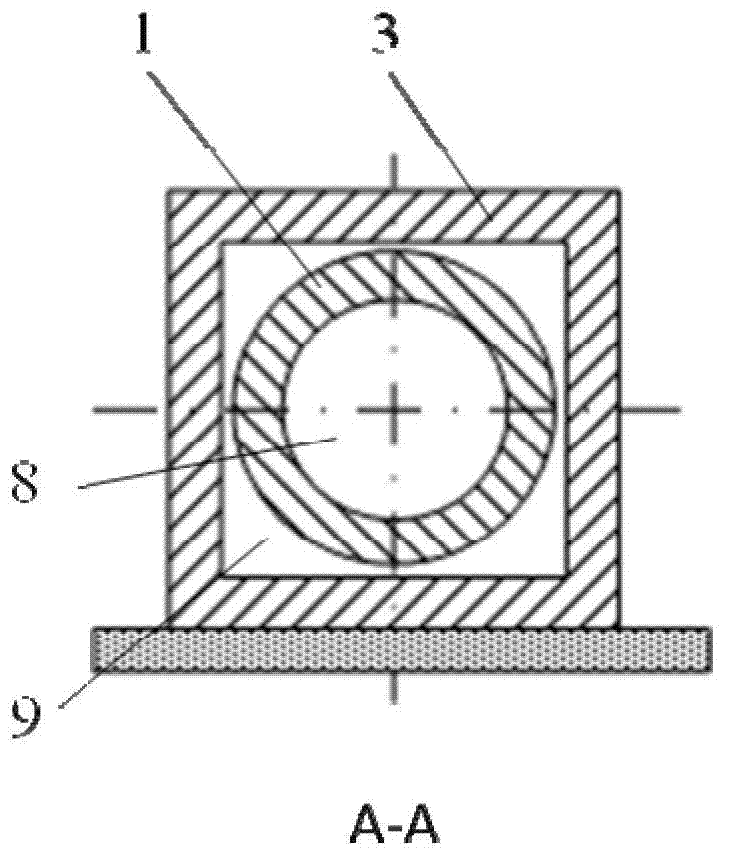

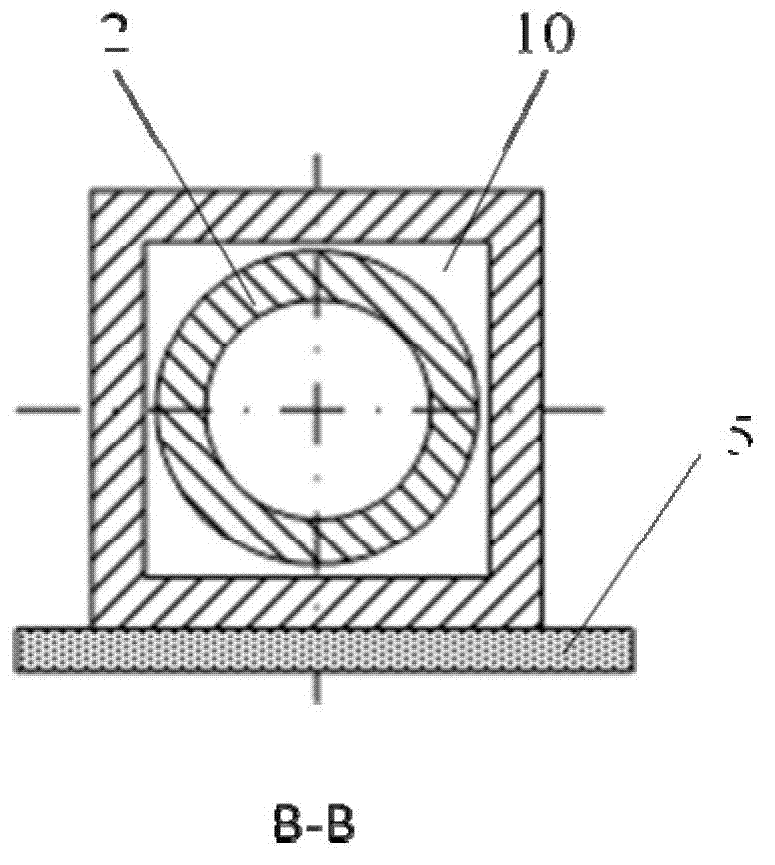

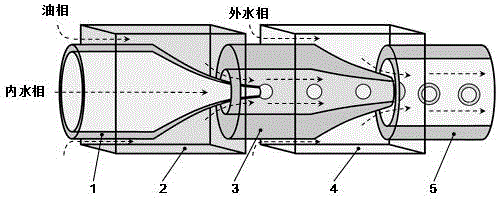

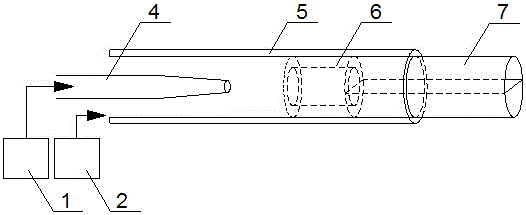

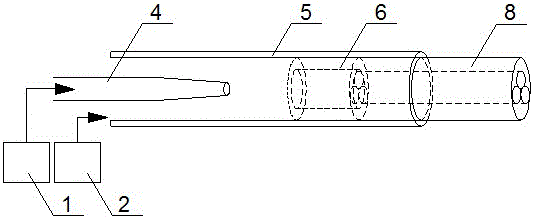

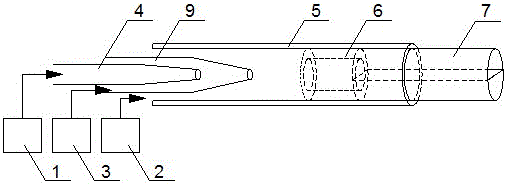

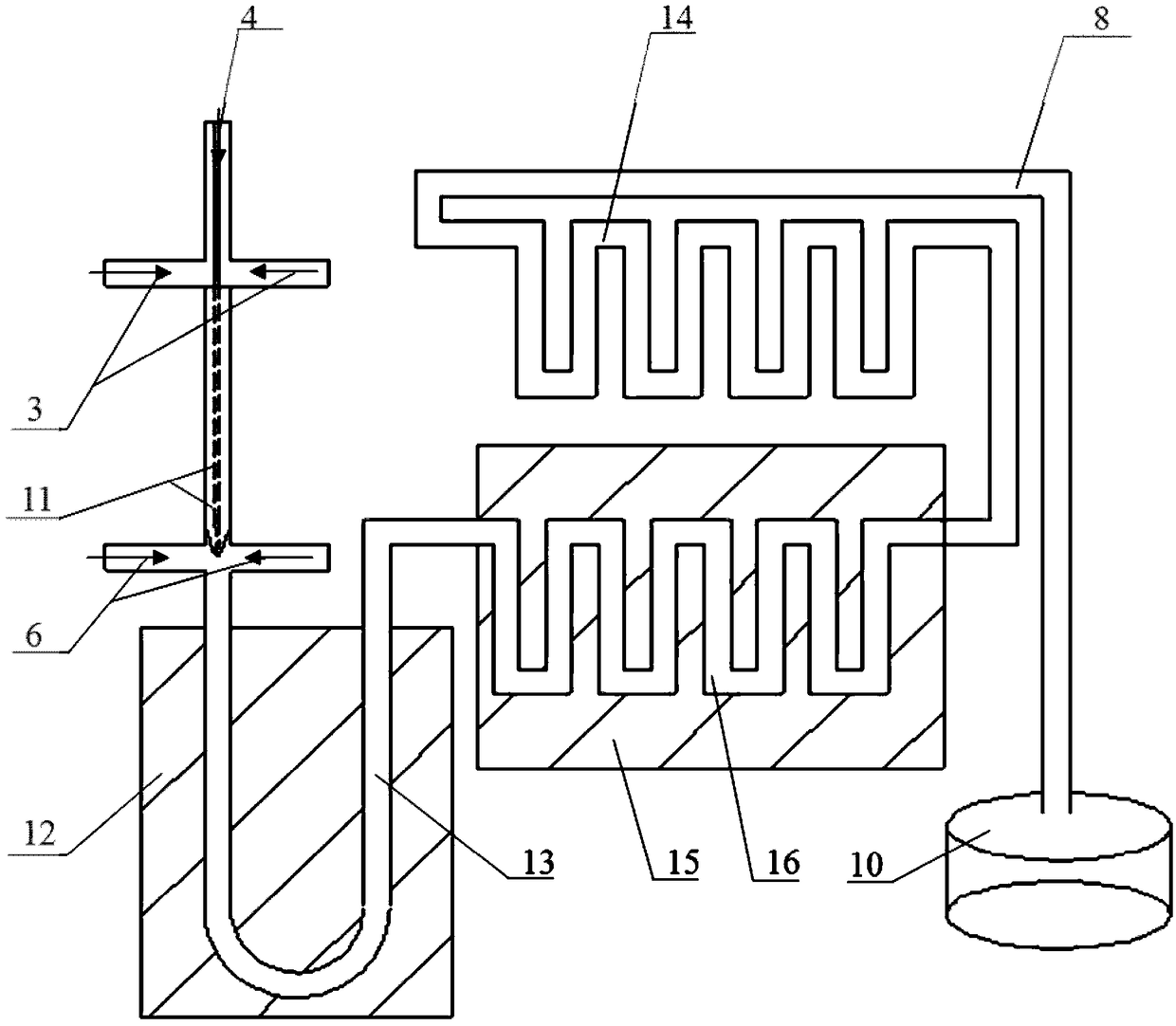

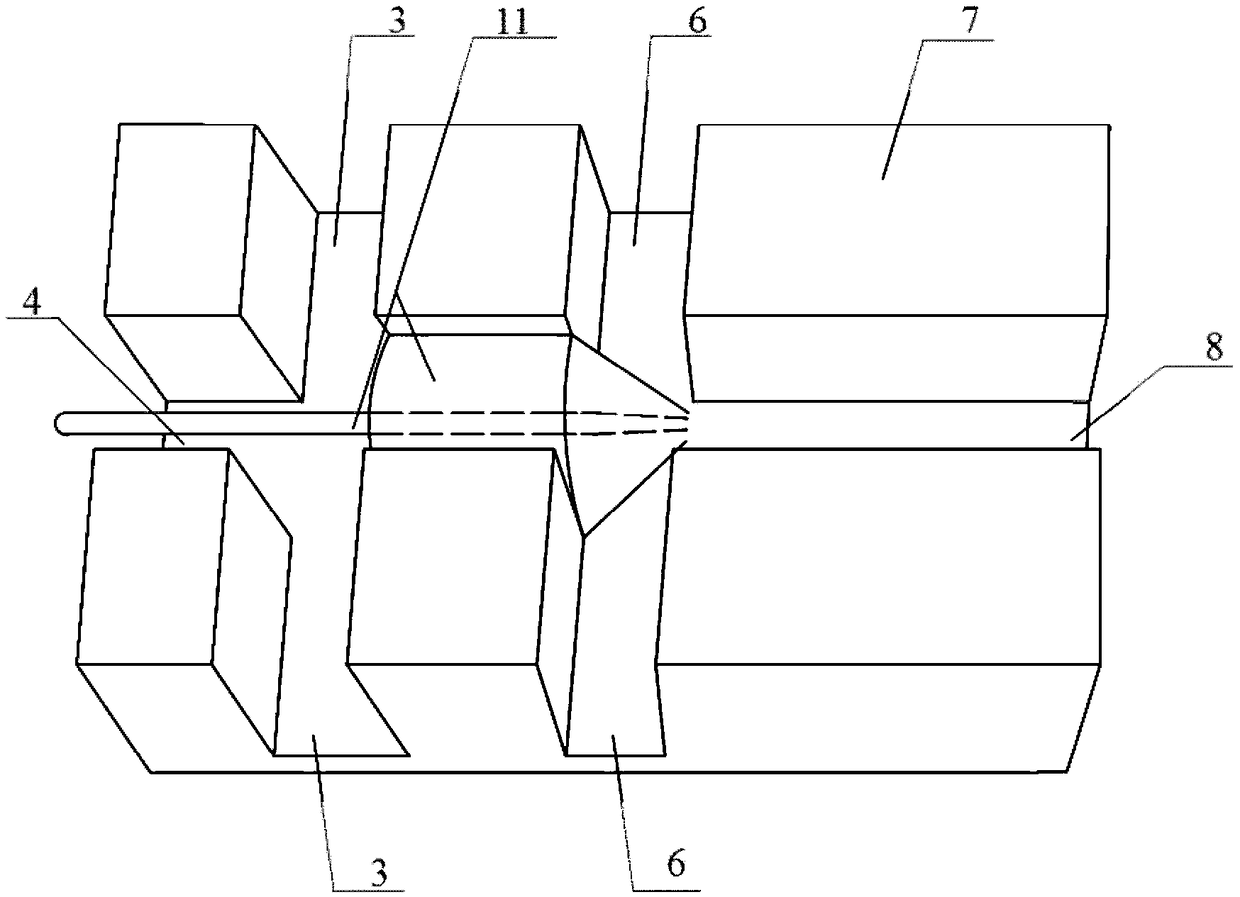

Microfluidic device capable of rapidly preparing emulsion in multiple dimensions

InactiveCN105921188AGuaranteed outputIncrease productionPreparing sample for investigationLaboratory glasswaresMicrofluidicsCapillary Tubing

The invention discloses a microfluidic device capable of rapidly preparing an emulsion in multiple dimensions. The microfluidic device comprises an internal phase capillary, an external phase capillary, a compression capillary and a split capillary, wherein the internal phase capillary, the external phase capillary, the compression capillary and the split capillary are coaxially arranged, the internal phase capillary is located at the inner front end of the external phase capillary, the compression capillary is located in the inner middle of the external phase capillary, the split capillary is located at the inner rear end of the external phase capillary, an emulsion forming section is reserved between the internal phase capillary and the compression capillary, and an inlet end of the split capillary is connected with an outlet end of the compression capillary. The preparation device provided by the invention has a simple channel and less construction steps and does not need complicated channel machining, single emulsion and double emulsions are split in multiple dimensions, the emulsion is split and the yield of the emulsion is improved under the condition that the yield and the homogeneity of the emulsion are guaranteed.

Owner:SOUTHEAST UNIV

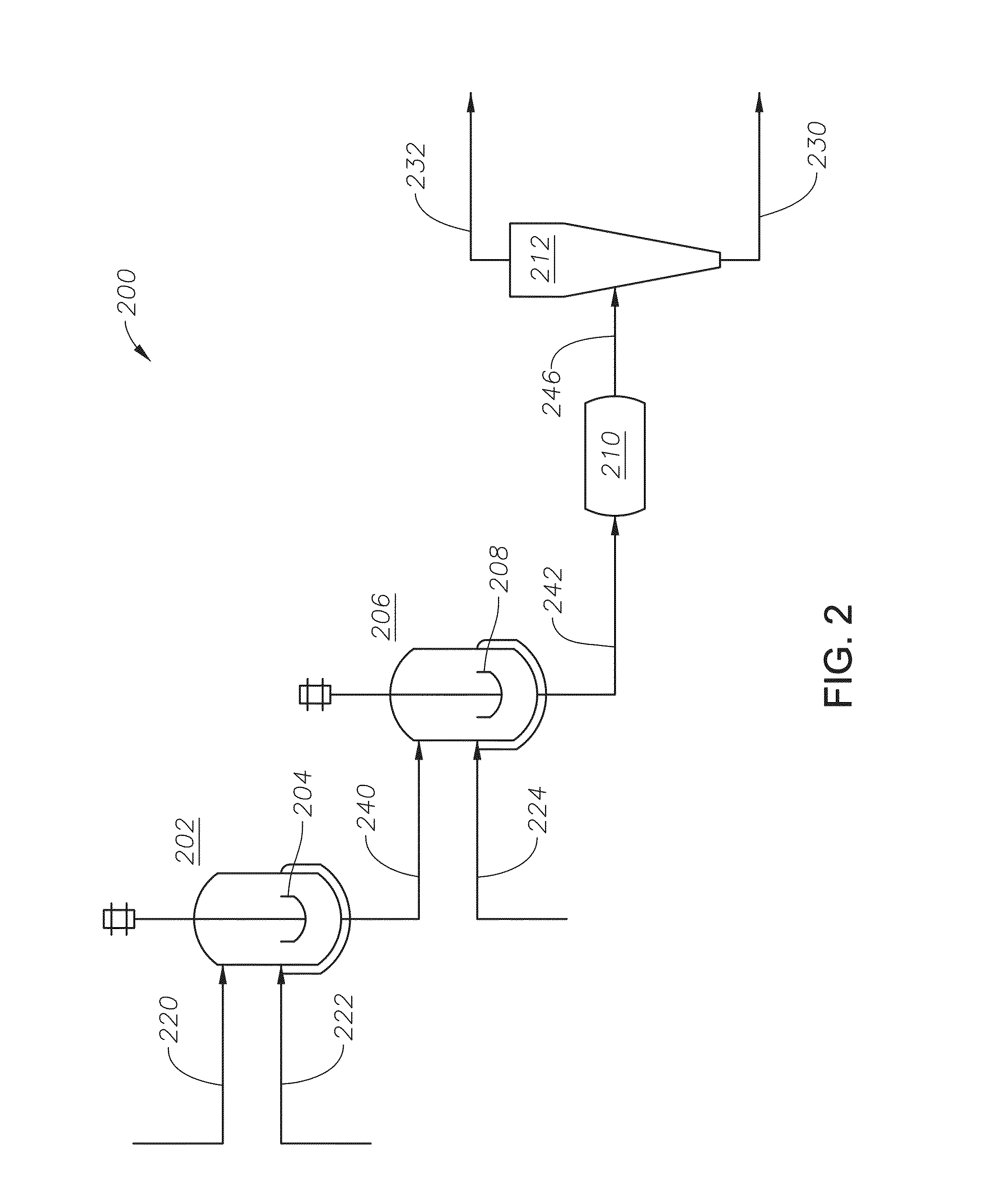

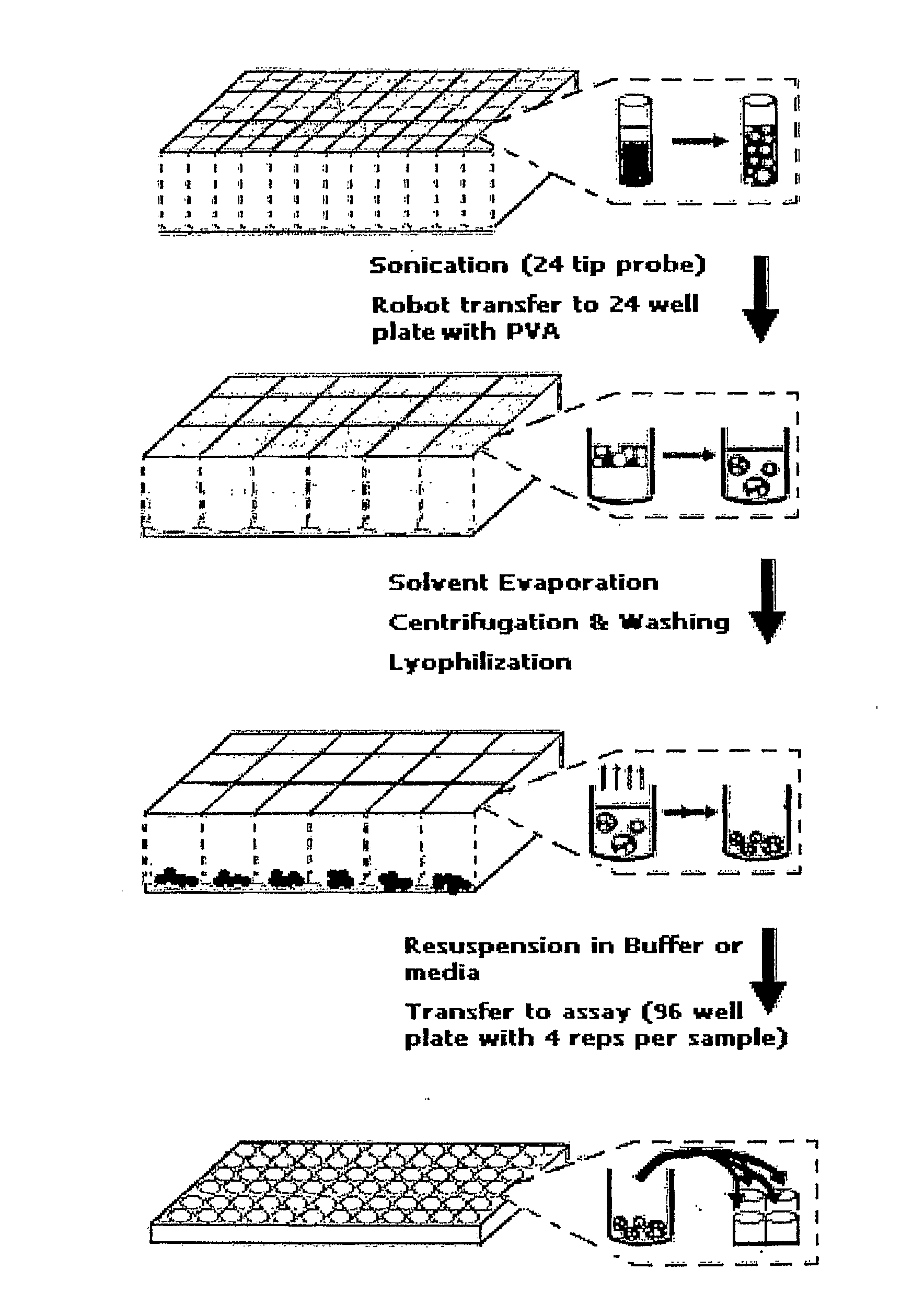

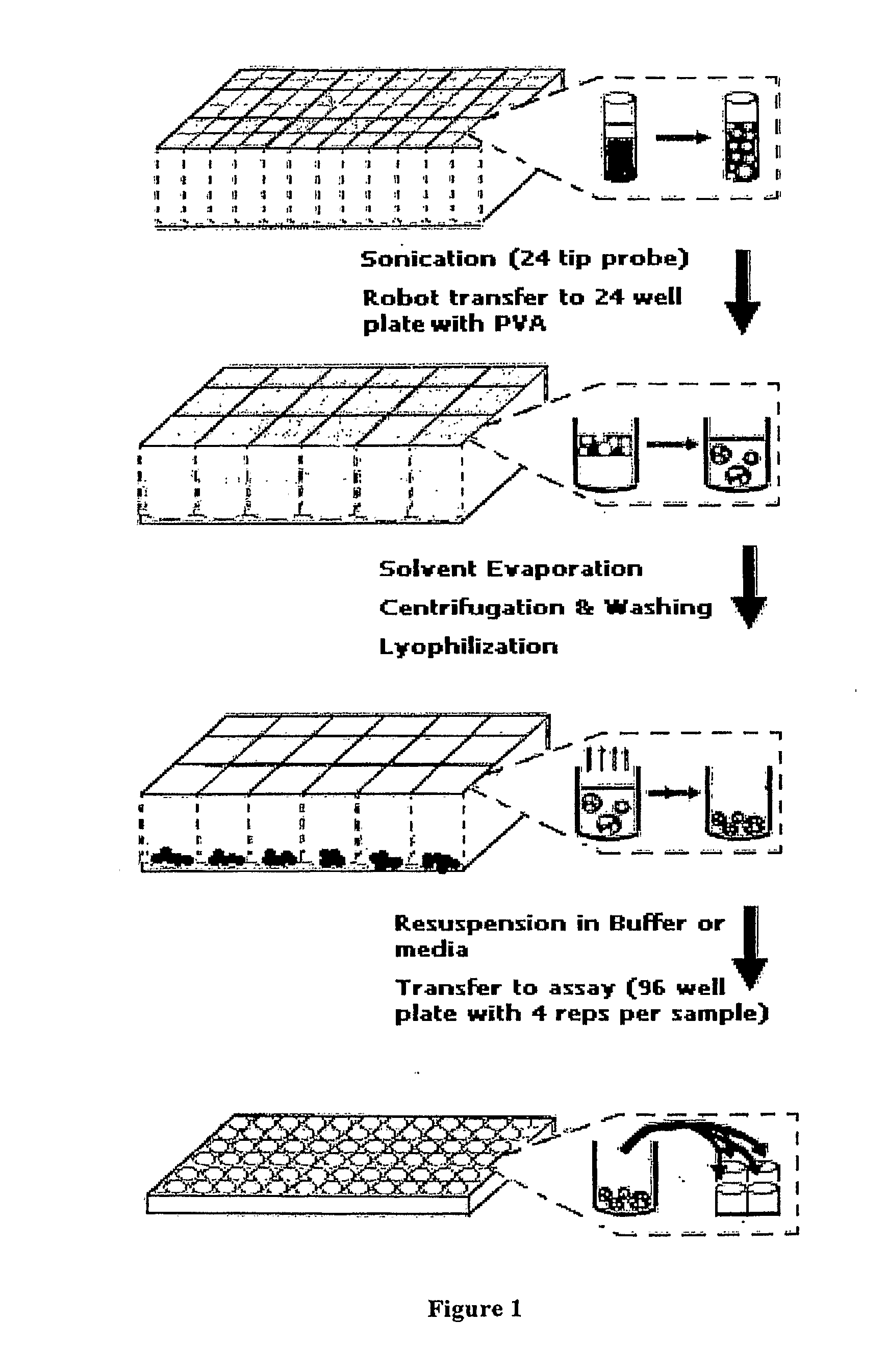

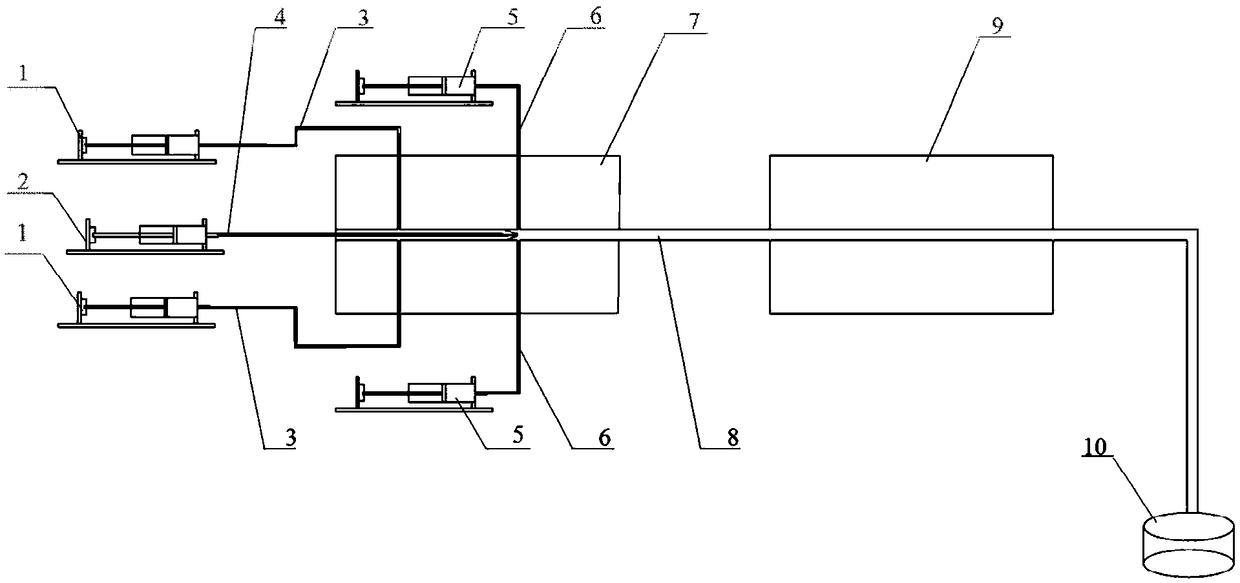

High-throughput fabrication of microparticles

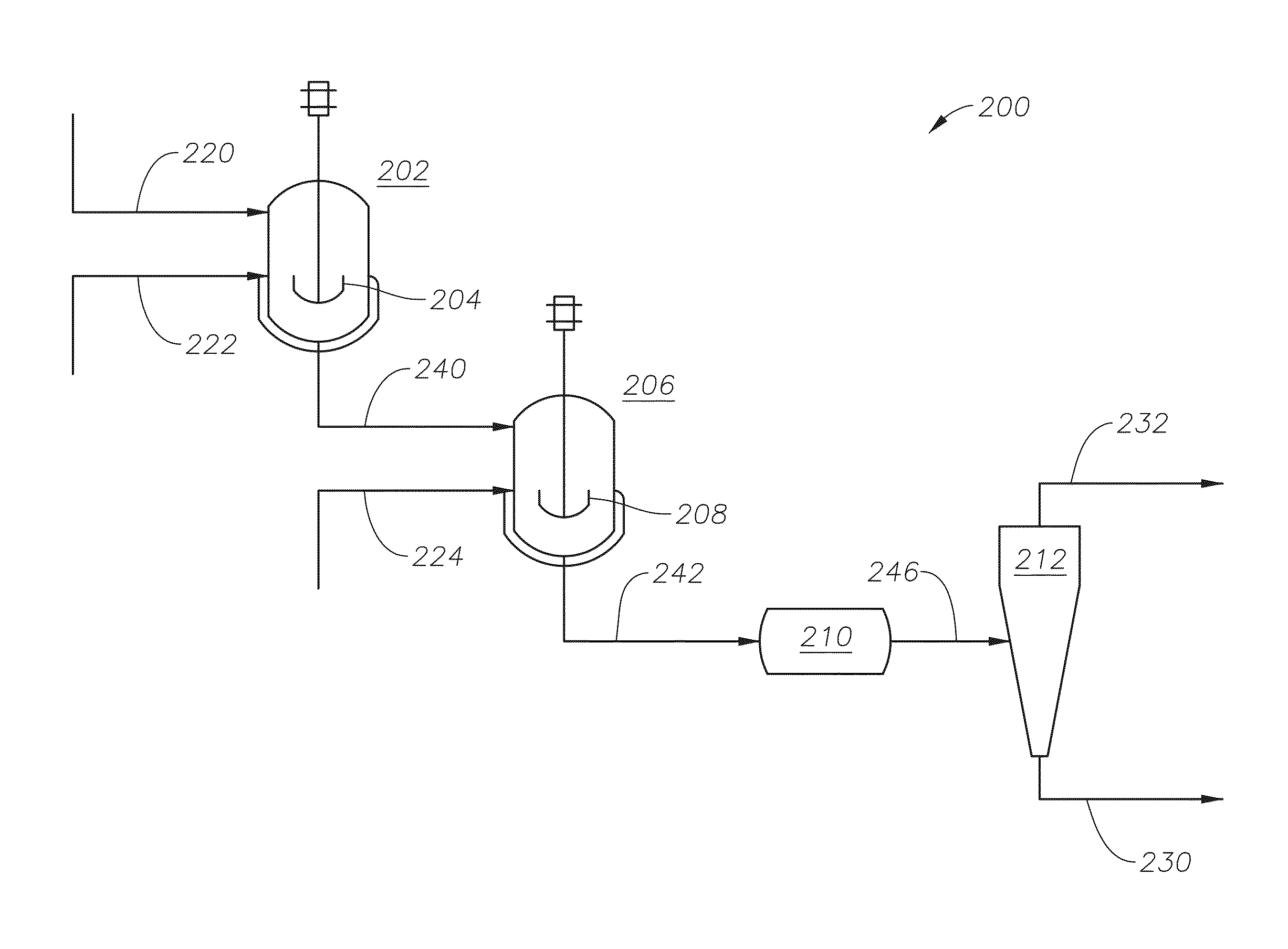

InactiveUS20110163469A1Reduce particle agglomerationPromote absorptionAuxillary shaping apparatusGranular deliveryFreeze-dryingMicroparticle

The high-throughput fabrication of microparticles based on the double emulsion / solvent evaporation technique for screening and optimizing microparticle formulations for particular characteristics allows for the preparation of multiple microparticle formulations in parallel. The system involves the formation of an emulsion containing aqueous bubbles with the payload in an organic phase containing the polymer or polymer blend being used for the microparticles. This first emulsion is then transferred to a larger aqueous phase, and a second waterin-oil-in water emulsion is formed. The organic solvent is then removed, and the resulting particles are optionally washed and / or freeze dried. The resulting microparticles are similar or better than microparticles prepared using the traditional one formulation at a time approach. The high-throughput fabrication of microparticles is particularly useful in optimizing microparticles formulations for drug delivery.

Owner:MASSACHUSETTS INST OF TECH

Preparation device of porous microspheres and method thereof

InactiveCN109289950AEasy to operateGood monodispersityLaboratory glasswaresMicroballoon preparationChemical reactionNanoparticle

The invention discloses a preparation device and a preparation method of porous microspheres. The preparation device comprises an external phase fluid injector, an intermediate phase fluid injector, an internal phase fluid injector and a microfluidic chip unit, wherein the microfluidic chip unit comprises an external phase input channel, an intermediate phase input channel, an internal phase inputchannel, a multinuclear double emulsion generating microstructure and a mainstream channel; the multinuclear double emulsion generating microstructure comprises a dual concentric glass capillary; a flow velocity controllable gas is introduced into the internal phase channel through the internal phase fluid injector; and a liquid containing nanoparticles is introduced into the external phase channel through the external phase fluid injector. Convenient control of the size and porous parameters of the porous microspheres is realized, and the nanoparticles help enhance the emulsion stability andcontrollability of the interfacial tension. According to the prepared porous microspheres, no components will be remained in the microspheres, thus not affecting the subsequent application. In addition, the porous microspheres for storing specific gases can be applied to chemical reactions.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com