Method for preparing photonic crystal material through ordered self-assembly of emulsion

A photonic crystal and self-assembly technology, applied in the direction of organic dyes, etc., can solve the problems of cumbersome process, complicated operation, long time consumption, etc., to avoid danger, simplify the preparation process, and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the photonic crystal comprises the following contents and steps:

[0044] (1) dissolving the amphiphilic branched block polymer in a water-immiscible organic solvent to form a polymer solution with a mass concentration of 0.1wt% to 10wt%; adding the polymer solution to deionized water or In the aqueous solution containing surfactants, the types of surfactants include CTAB (cetyltrimethylammonium bromide), SDS (sodium dodecyl sulfate), PVA (polyvinyl alcohol), etc., and the molecular weight of PVA is 1 ×10 4 ~5×10 5 g / mol, the molecular weight distribution (PDI) is 1-10, the mass concentration of the surfactant is 0.1wt%-10wt%, and a layered oil-water two-phase solution is formed due to phase separation, and the polymer solution accounts for the volume percentage of the water phase 1% to 35%;

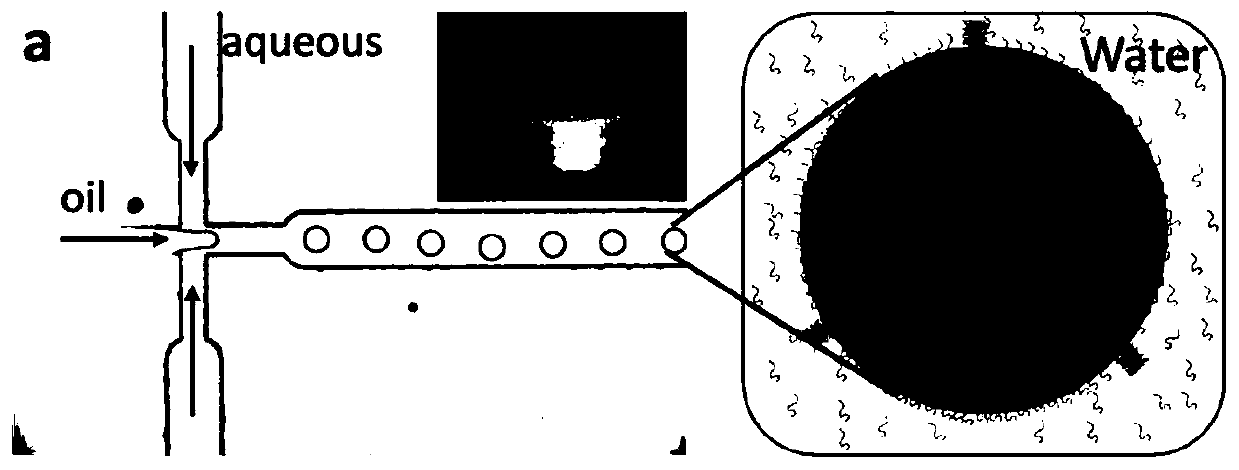

[0045] Alternatively, the polymer solution is emulsified by SPG (Shirasu Porous Glass) membrane emulsification technology, microfluidic technology or ...

Embodiment 1

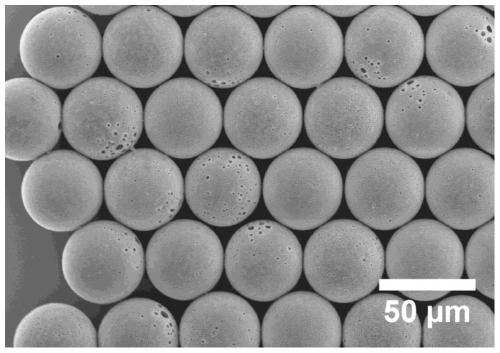

[0050] The preparation method of the ordered porous amphiphilic branched block polymer photonic crystal material in this embodiment comprises the following steps:

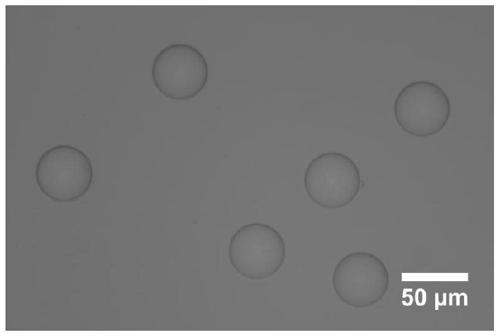

[0051] (1) Dissolving the amphiphilic branched block polymer PS-b-PEO in toluene to obtain a solution with a mass concentration of 2 wt%. Next, the toluene solution was made into micron-sized droplets with uniform size by using microfluidic technology, and the obtained droplets were dispersed into an aqueous PVA solution, wherein the mass concentration of PVA in water was 2 wt%. The setting parameters of the microfluidic equipment include: the inner diameter of the chip channel used is 150 μm, the flow rate of the dispersed phase is 240 μL / h, the flow rate of the continuous phase is 1920 μL / h, and the obtained droplet diameter is 120 μm. The molecular weight of PS-b-PEO used is 24×10 4 g / mol, the degree of polymerization of the lipophilic block PS in the main chain is 30 repeat units, the polymerization degree of ...

Embodiment 2

[0054] The preparation method of the ordered porous amphiphilic branched block polymer photonic crystal material in this embodiment comprises the following steps:

[0055] (1) The amphiphilic branched block polymer PtBA-b-PEO was dissolved in chloroform to obtain a solution with a mass concentration of 2 wt%. Next, the chloroform solution was made into micron-sized droplets with uniform size by using microfluidic technology, and the obtained droplets were dispersed into an aqueous PVA solution, wherein the mass concentration of PVA in water was 2 wt%. The setting parameters of the microfluidic equipment include: the inner diameter of the chip channel used is 150 μm, the flow rate of the dispersed phase is 240 μL / h, the flow rate of the continuous phase is 3600 μL / h, and the obtained droplet diameter is 30 μm. The molecular weight of the PtBA-b-PEO is 33×10 4g / mol, the degree of polymerization of the lipophilic block PtBA in the main chain is 30 repeat units, the degree of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com