Medical titanium alloy preparation method

A technology of titanium alloys and mixtures is applied in the field of preparation of medical titanium alloys, which can solve the problem of bacterial infection at the implantation site, and achieve the effect of inhibiting the growth of bacteria, less equipment investment, and good osteogenesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

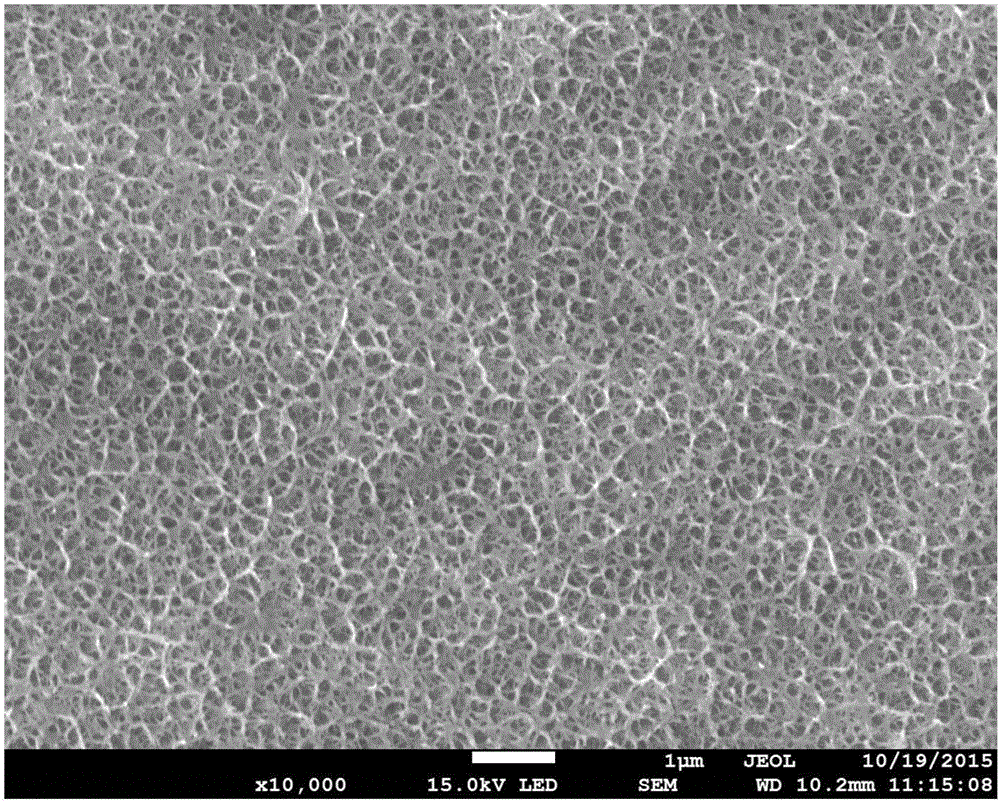

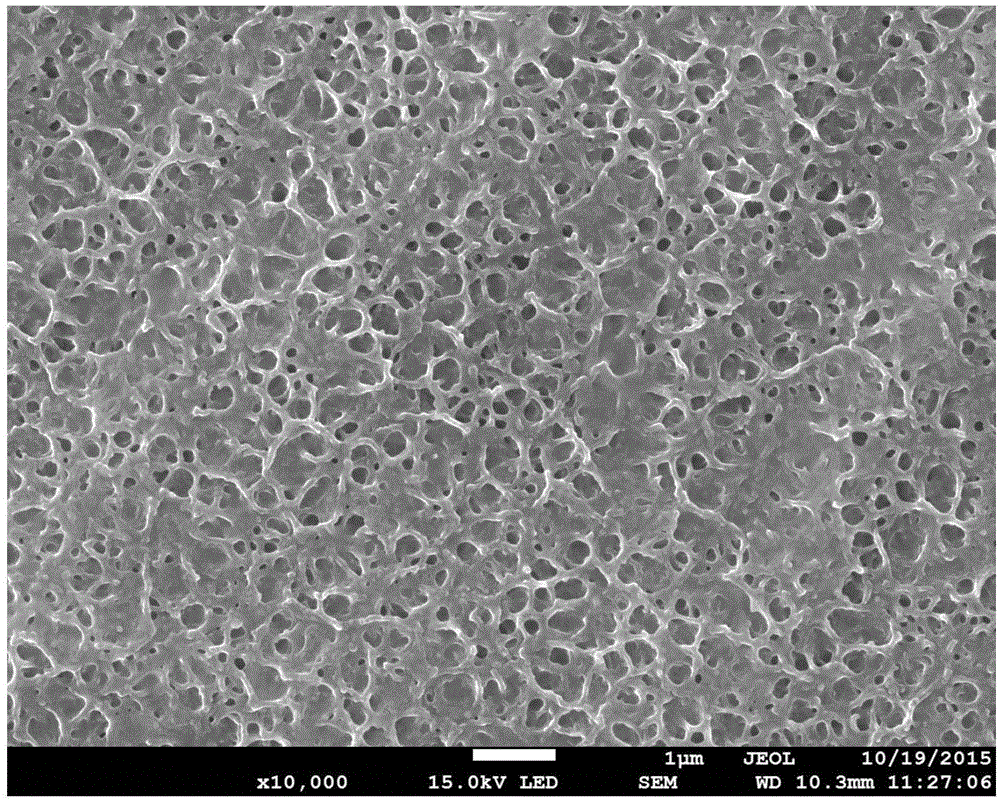

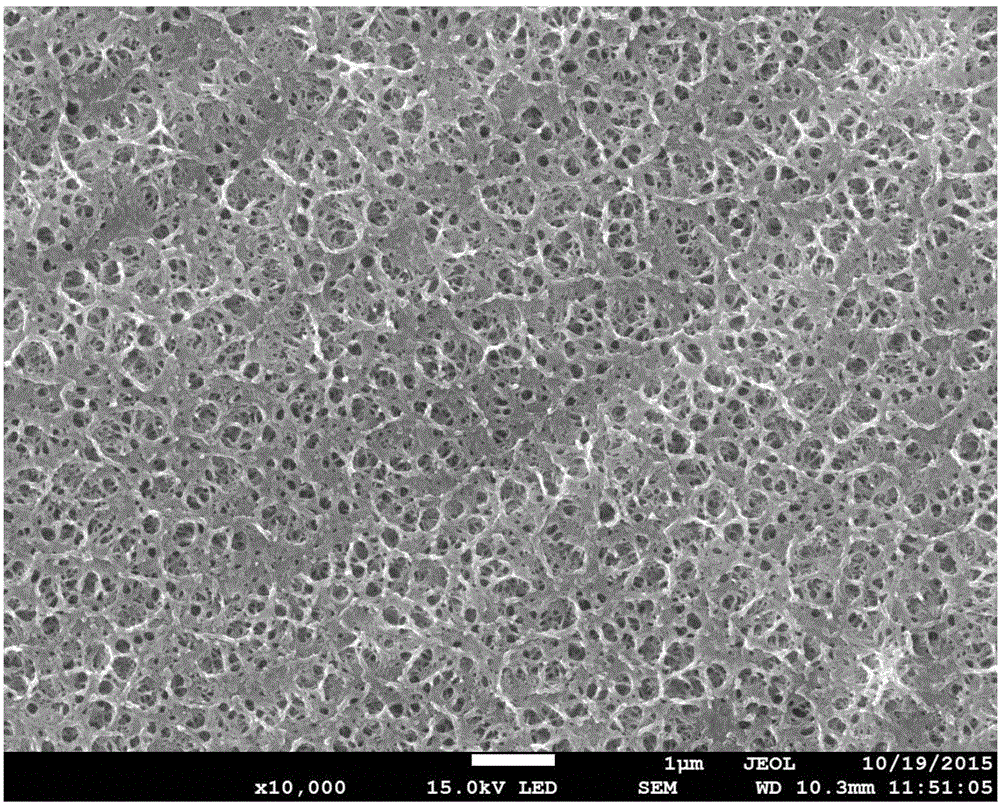

Image

Examples

Embodiment 1

[0040] (1) Dissolve 60mg of PLGA (polylactic-co-glycolic acid copolymer), 6.5mg of Pluronic F-68 in 2ml of dichloromethane, 40Hz ultrasonic vibration for 10min, then completely dissolve 100mg of antibiotic in 0.5mL of deionized water, and then dissolve the antibiotic Add the solution into the PLGA (polylactic-co-glycolic acid) solution, shake it upside down, so that the PLGA (poly-lactic-co-glycolic acid) solution fully wraps the drug to form a primary emulsion, and then add 5.5mL of 25mg / mL to the primary emulsion Polyvinyl alcohol solution, 40Hz ultrasonic oscillation for 10min, slowly inject the mixed solution into 34.5mL of 25mg / mL polyvinyl alcohol solution after oscillation, gently stir with a magnetic stirrer for 20h, and finally obtain powdery white particles similar to salt in the lower layer of the solution. Put this solution into a centrifuge tube, centrifuge at a speed of 5000r / min for 30min, wash with deionized water, centrifuge three times, collect the particles, ...

Embodiment 2

[0044](1) Dissolve 50mg of PLGA (polylactic-co-glycolic acid) and 6mg of Pluronic F-68 in 2ml of dichloromethane, 30Hz ultrasonic vibration for 8min, then completely dissolve 90mg of antibiotics in 0.4mL of deionized water, and then dissolve the antibiotic solution Add to the PLGA (polylactic-co-glycolic acid) solution, shake up and down gently, so that the PLGA (poly-lactic-co-glycolic acid) solution fully wraps the drug to form a primary emulsion, and then add 5 mL of 25 mg / mL polyethylene to the primary emulsion Alcohol solution, 30Hz ultrasonic oscillation for 8min, slowly inject the mixed solution into 34mL of 25mg / mL polyvinyl alcohol solution after oscillation, gently stir with a magnetic stirrer for 18h, and finally obtain powdery white particles similar to salt in the lower layer of the solution. Put this solution into a centrifuge tube, centrifuge at a speed of 5000r / min for 20min, wash with deionized water, centrifuge three times, collect the particles, and vacuum fr...

Embodiment 3

[0048] (1) Dissolve 70mg of PLGA (polylactic acid glycolic acid copolymer), 7mg of Pluronic F-68 in 2ml of dichloromethane, 50Hz ultrasonic vibration for 12min, then completely dissolve 110mg of antibiotics in 0.6mL of deionized water, and then dissolve the antibiotic solution Add to the PLGA (polylactic-co-glycolic acid) solution, shake up and down gently, so that the PLGA (poly-lactic-co-glycolic acid) solution fully wraps the drug to form a primary emulsion, and then add 6mL of 25mg / mL polyethylene to the primary emulsion Alcohol solution, 50Hz ultrasonic oscillation for 12min, after oscillation, slowly inject the mixed solution into 35mL of 25mg / mL polyvinyl alcohol solution, stir gently with a magnetic stirrer for 22h, and finally obtain powdery white particles similar to salt in the lower layer of the solution. Put this solution into a centrifuge tube, centrifuge at a speed of 5000r / min for 40min, wash with deionized water, centrifuge 3 times, collect particles, and vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com