Microencapsulation method of concrete water-based repair agent

A technology of microencapsulation and repairing agent, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of easy instability, coalescence and delamination, Ostrich ripening, etc., and achieve the effect of low cost and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

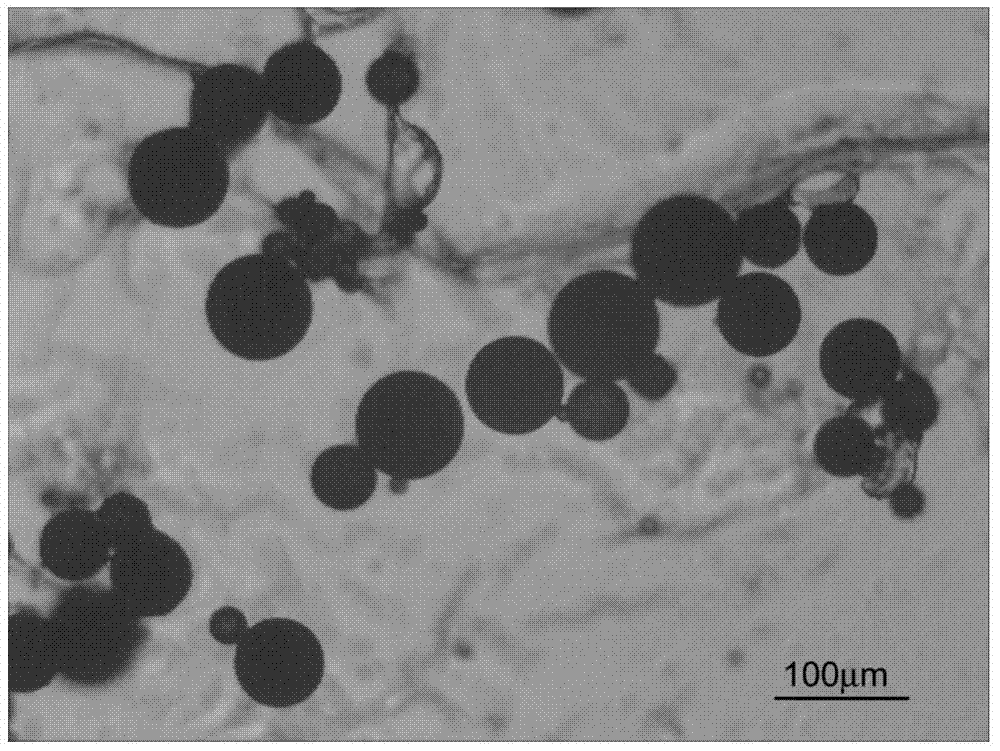

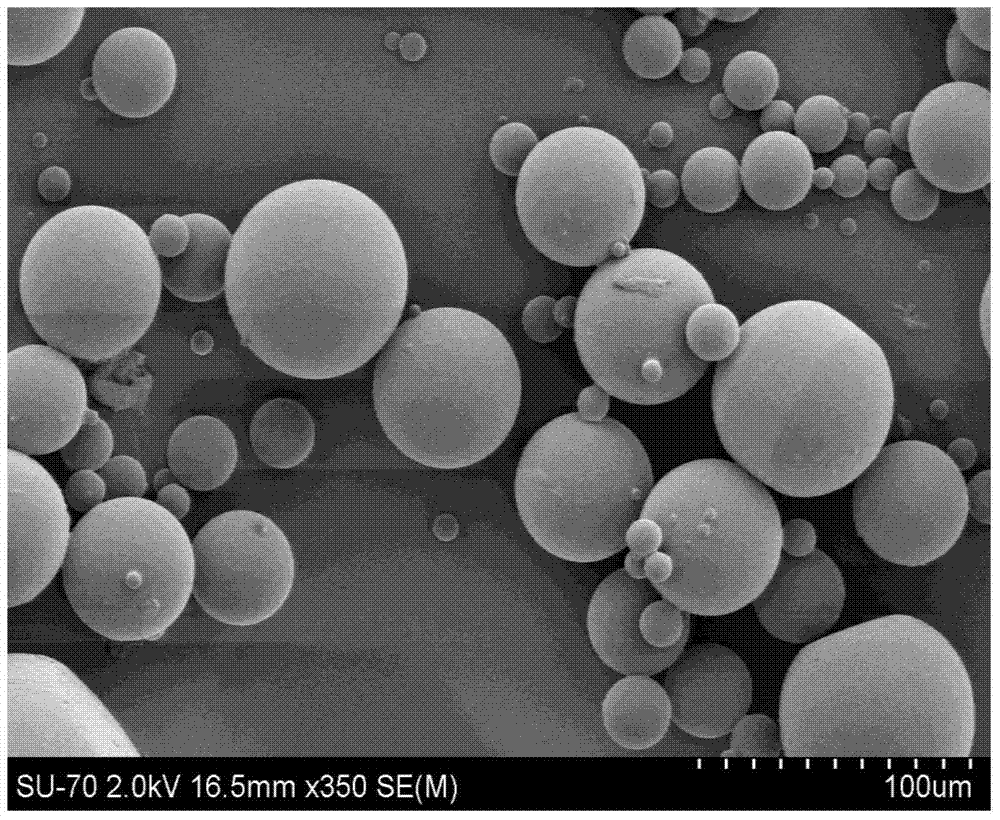

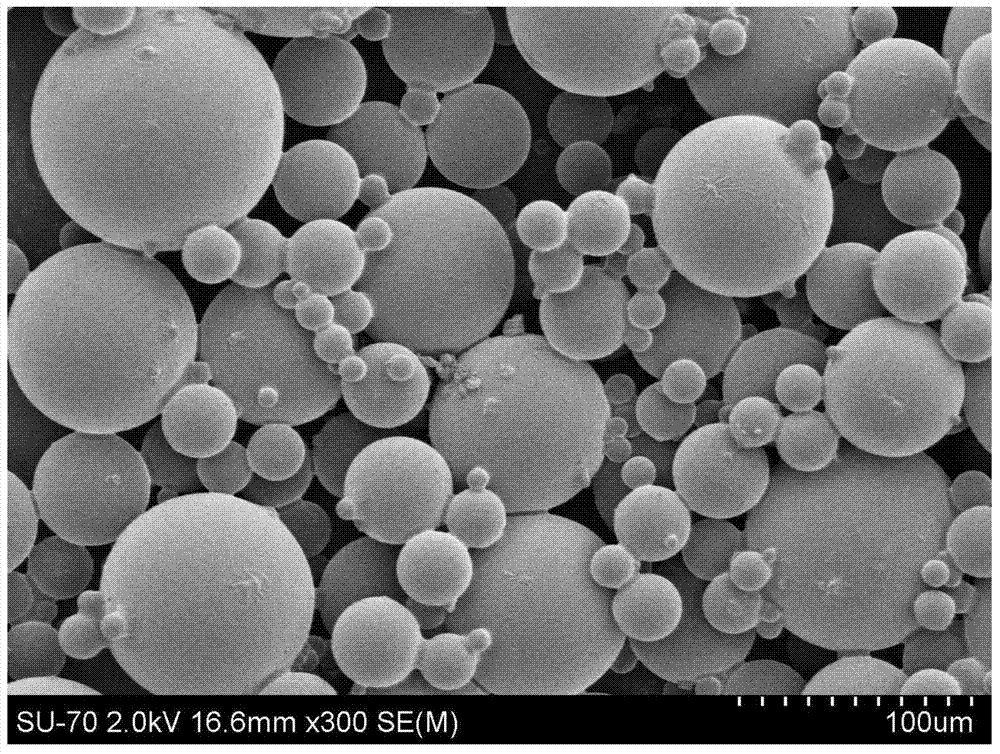

Image

Examples

Embodiment 1

[0037] S11: Prepare the inner water phase, prepare 30 mL of aluminum dihydrogen phosphate solution with a concentration of 1 mol / L, drop 5 drops (about 0.25 ml) of 5 wt% gelatin aqueous solution, and adjust the viscosity of the inner water phase;

[0038] S12: Prepare the oil phase, pour an appropriate amount of 5wt% NaOH aqueous solution into the commercially available styrene as the washing liquid, oscillate, separate the liquid, and remove the slightly red NaOH washing liquid after washing, repeat several times until the NaOH washing The liquid is colorless. Then add 5g of anhydrous sodium sulfate, seal it, and dry it in a dark place for more than 3 days to remove moisture. Finally, distill under reduced pressure and keep the middle distillate away from light and low temperature. This is styrene without polymerization inhibitor (hydroquinone).

[0039] Take 15 mL of the above-treated styrene and mix it with 15 mL of the toluene that has been processed by distillation to pr...

Embodiment 2

[0047] S21: prepare the inner water phase, prepare 30 mL of sodium silicate solution with a concentration of 1 mol / L, drop 2 drops (about 0.1 ml) of 5 wt% xanthan gum aqueous solution, and adjust the viscosity of the inner water phase;

[0048] S22: Prepare the oil phase, pour an appropriate amount of NaOH aqueous solution with a concentration of 5wt% into commercially available styrene as the washing liquid, oscillate, separate the liquid, and remove the slightly red NaOH washing liquid after washing, repeat several times until the NaOH washes The liquid is colorless. Then add 5g of anhydrous sodium sulfate, seal it, and dry it in a dark place for more than 3 days to remove moisture. Finally, distill under reduced pressure and keep the middle distillate away from light and low temperature. This is styrene without polymerization inhibitor (hydroquinone).

[0049] Take 30 mL of the above-treated styrene and mix it with 15 mL of distilled chloroform to prepare a chloroform solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com