Method for synthesizing nonspherical polymer microparticles

A synthesis method and polymer technology, applied in the field of non-spherical polymer microparticle synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

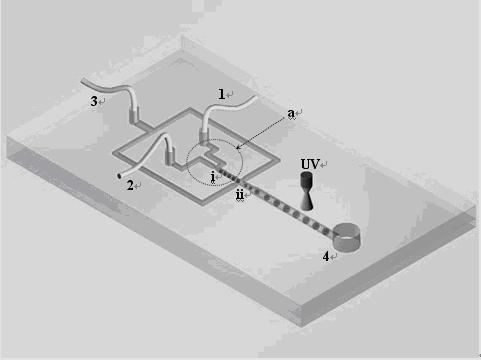

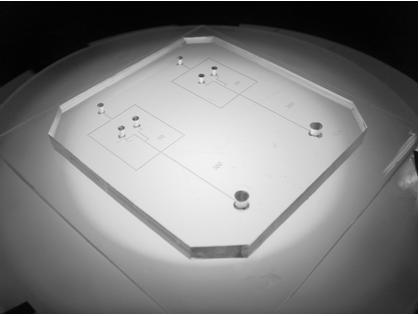

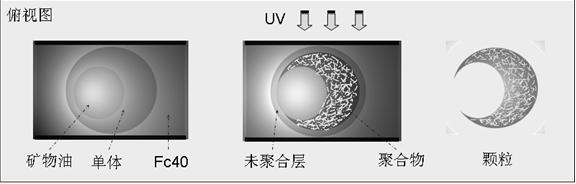

[0036] Synthesis of meniscus-shaped polymer particles using figure 1 chips shown, see the actual figure 2 , use a syringe pump to continuously perfuse mineral oil into reservoir A1, continuously perfuse 33% PEGDA aqueous solution (containing 4% tween20 and 1.5 mg / ml photoinitiator) into reservoir B2, and continuously perfuse Fc40 into reservoir C3 (containing 2% EA); oil-in-water droplets (mineral oil / 33% PEGDA aqueous solution) continuously formed at position i, and flowed along the channel through position ii, forming a mononuclear double emulsion at position ii (mineral oil / 33% PEGDA aqueous solution / Fc40); when the formed double emulsion flows through the ultraviolet lamp irradiation area, the 33% PEGDA aqueous solution undergoes a polymerization reaction to form a gel (see image 3 and Figure 4 ); due to the quenching effect of oxygen on free radicals, the polymerization reaction of PEGDA at the Fc40 interface was inhibited, forming an unpolymerized thin layer, resu...

Embodiment 2

[0038] The synthesis of polymer microparticles with many-legged morphology adopts the method described in Example 1 to adjust the flow velocity of the internal phase, the middle phase and the external phase to form triple-nuclear, quadri-nuclear and penta-nuclear double emulsions respectively (see Figure 8 (a)-(c)), under UV light, polymer microparticles with uniform distribution of tripods, tetrapods and pentapods were formed (see Figure 8 (d)-(j)).

Embodiment 3

[0040] Synthesis of magnetic polymer microparticles and investigation of their magnetic response, PEGDA, magnetic nanoparticle aqueous solution (9.2% Fe 3 o 4 ) and pure water according to the ratio of 4:2:4 (volume ratio) to make a solution of 10 ml, add Tween20 (4%) and photoinitiator (final concentration is 1.5 mg / ml), the mixed solution is used as the intermediate phase, the internal Phase and external phase are mineral oil and Fc40 (containing 2% EA) respectively, according to the method described in embodiment 1, form non-spherical magnetic polymer microparticles (see Figure 9 (a)). The elemental analysis spectrum shows that the polymer microparticles contain Fe (see Figure 9 (b)), and the magnetic microparticles have a magnetic response and can be attracted by a magnet (see Figure 9 (c)). The synthesized magnetic polymer microparticles are dispersed on the interface of water and Fc40, and then a parallel external magnetic field is applied, and the magnetic polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com