Patents

Literature

138results about How to "Produce uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for production of antibodies in plant cell culture

ActiveUS20090082548A1Rapid and consistent reproductionLack of uniformityVaccinesFused cellsBiotechnologyHigh level expression

A system and method for production of antibodies in plant cell culture, which results in highly functional antibodies, produced with a high level of expression efficiency. The present invention also encompasses host cells, vectors and methods for mass production of full size assembled immunoglobulins.

Owner:PROTALIX

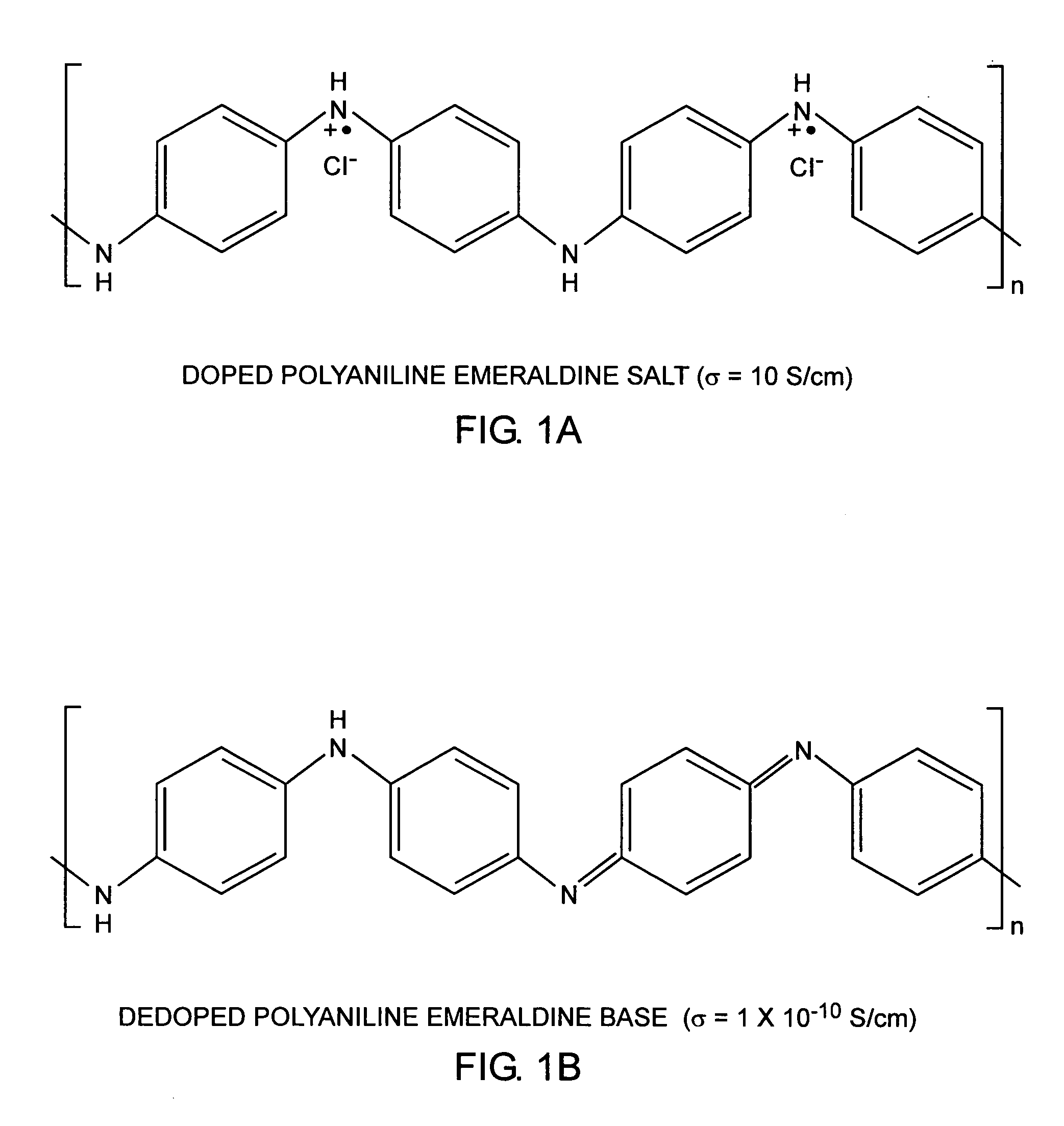

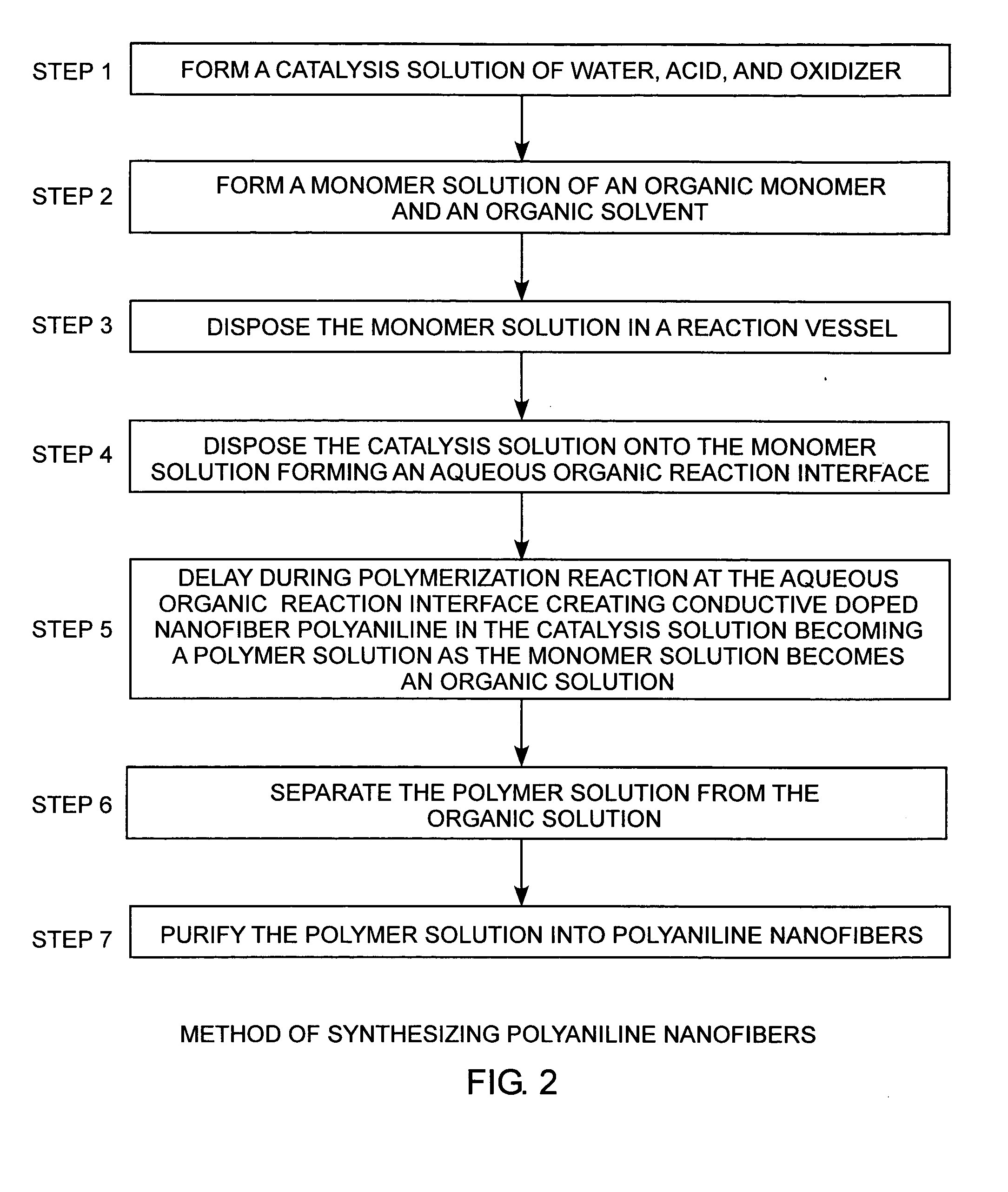

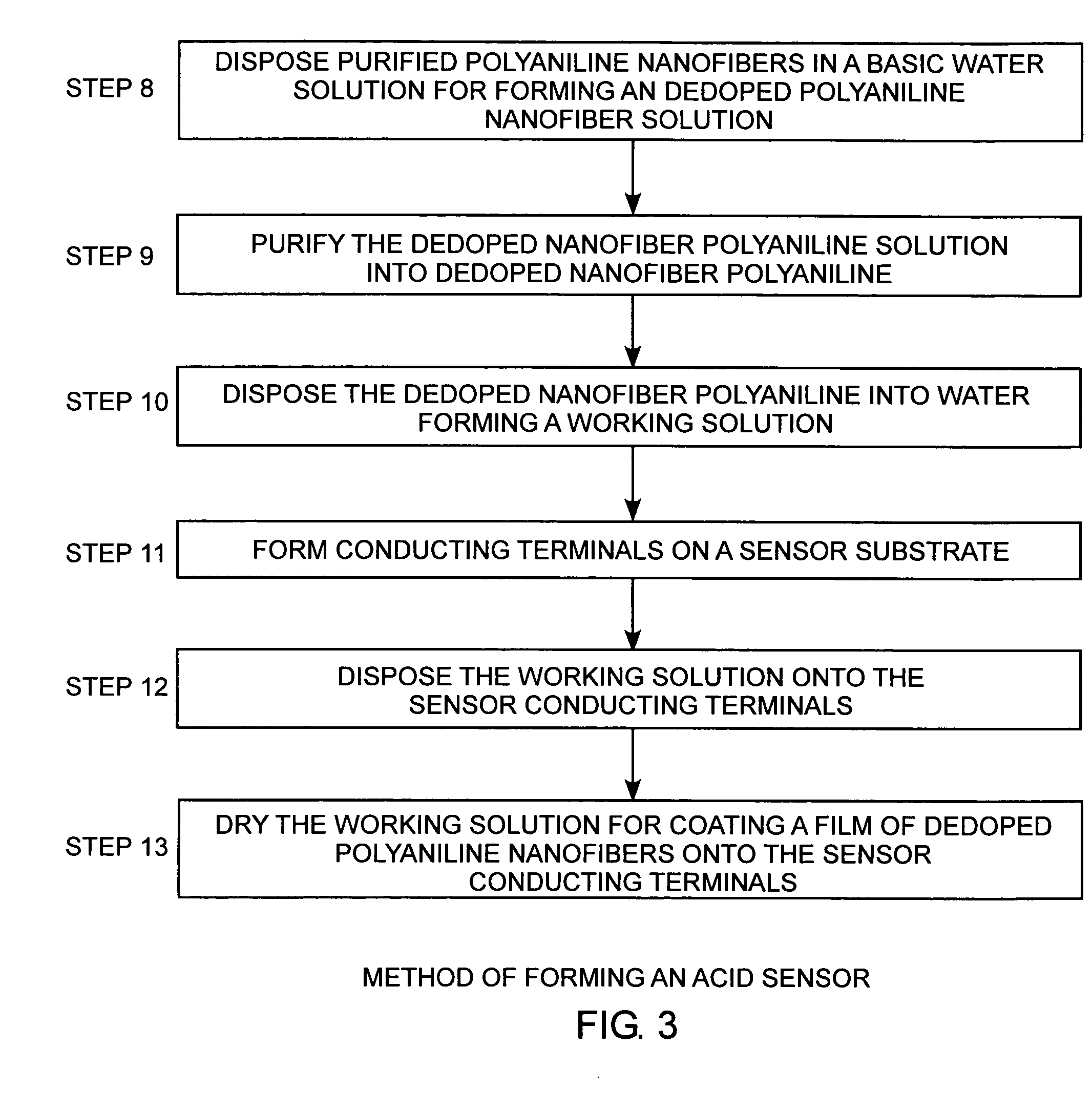

Synthetic method for conducting polymer nanofibers

ActiveUS20050131139A1High sensitivityFaster chemical time responseMaterial nanotechnologySynthetic resin layered productsFiberTime response

Polymer nanofibers, such as polyaniline nanofibers, with uniform diameters less than 500 nm can be made in bulk quantities through a facile aqueous and organic interfacial polymerization method at ambient conditions. The nanofibers have lengths varying from 500 nm to 10 μm and form interconnected networks in a thin film. Thin film nanofiber sensors can be made of the polyaniline nanofibers having superior performance in both sensitivity and time response to a variety of gas vapors including, acids, bases, redox active vapors, alcohols and volatile organic chemicals.

Owner:THE AEROSPACE CORPORATION +1

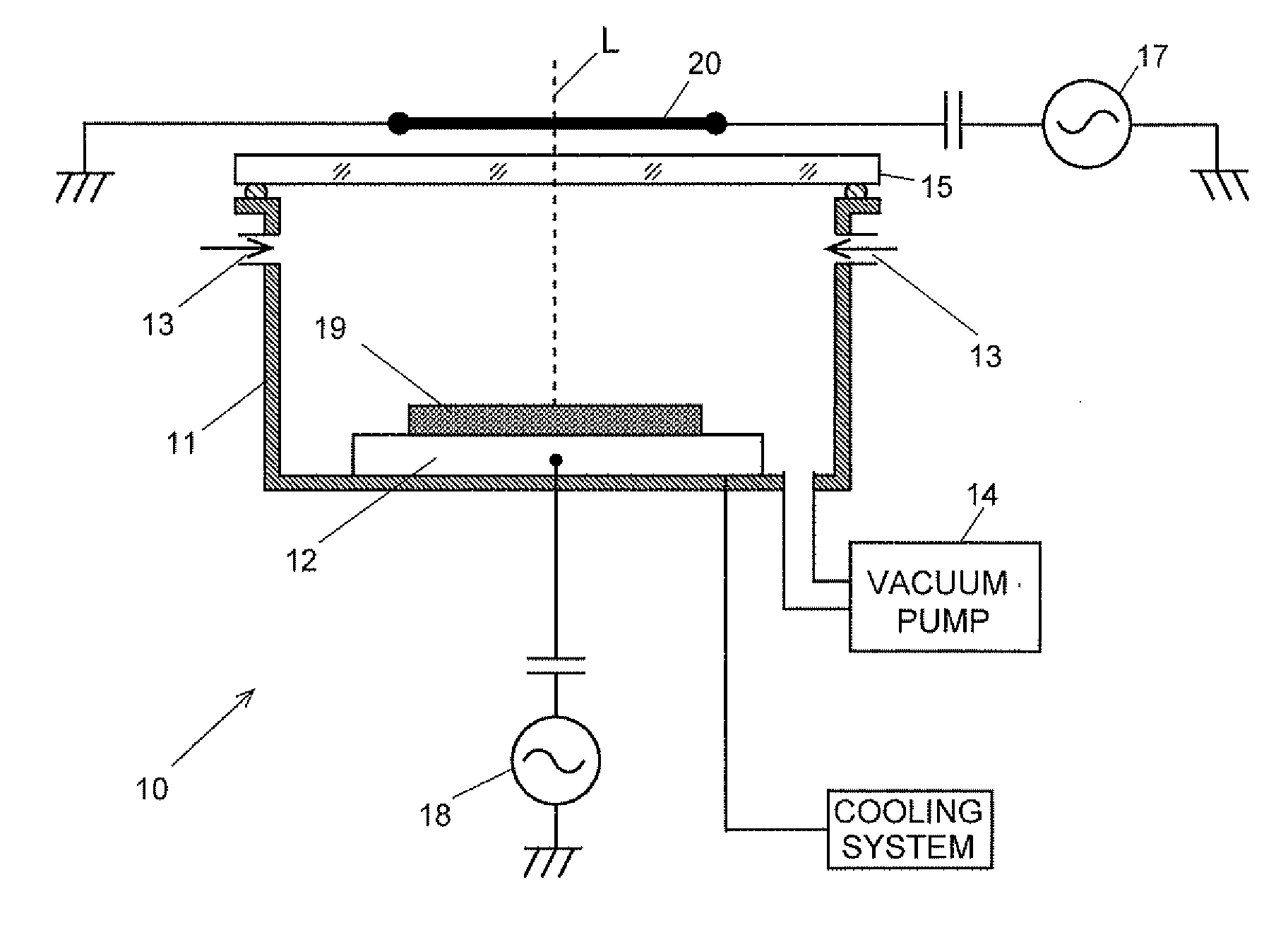

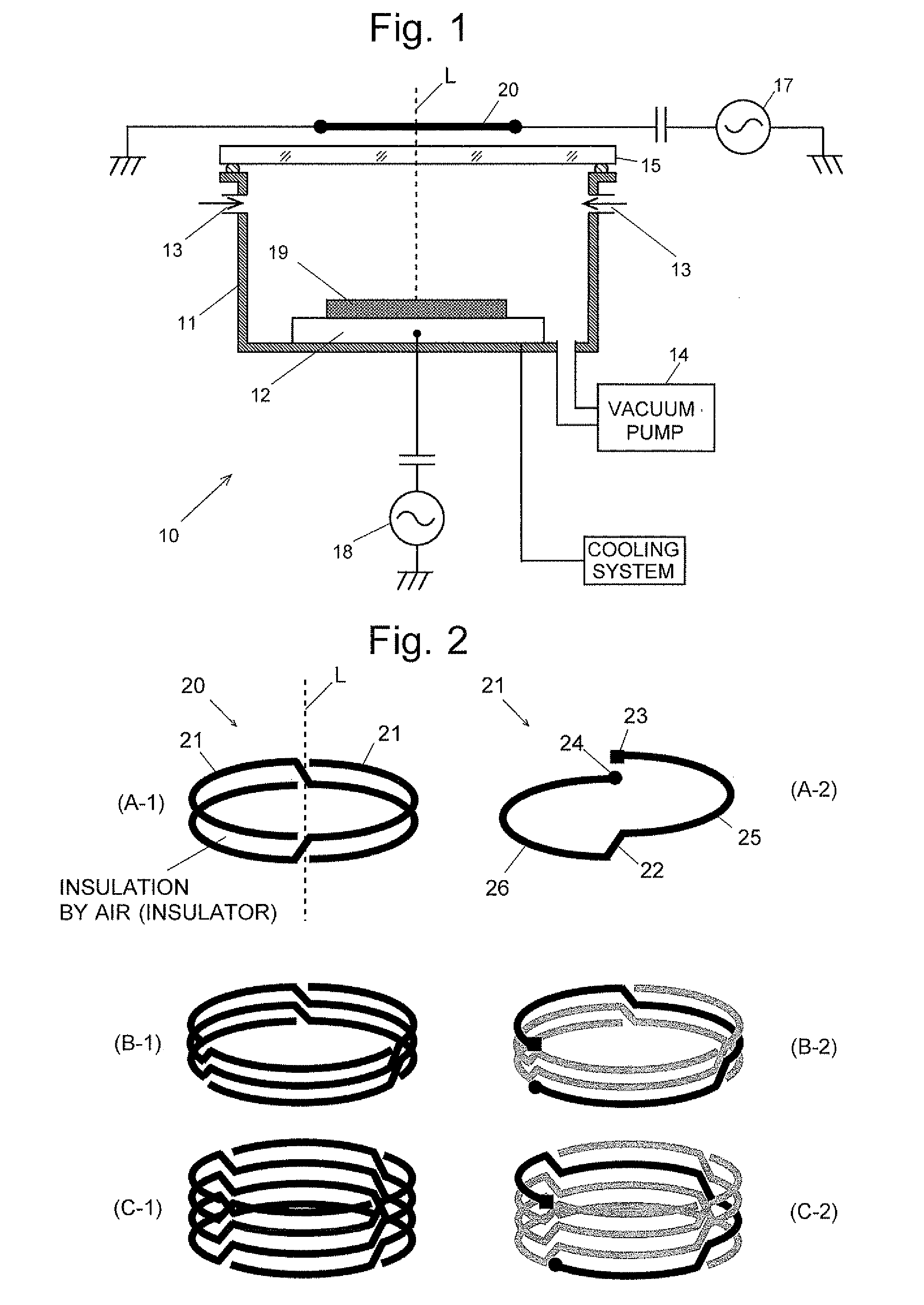

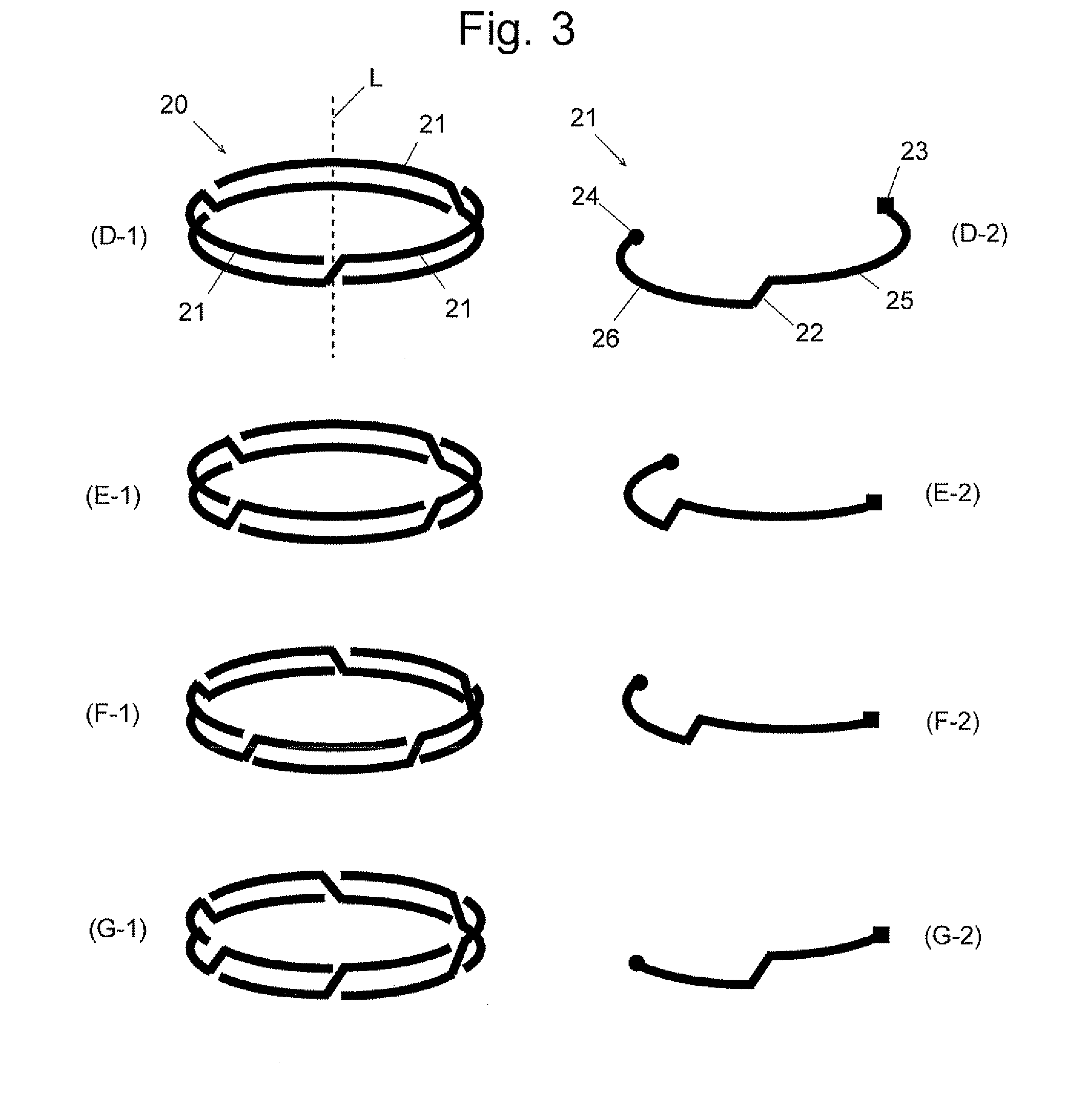

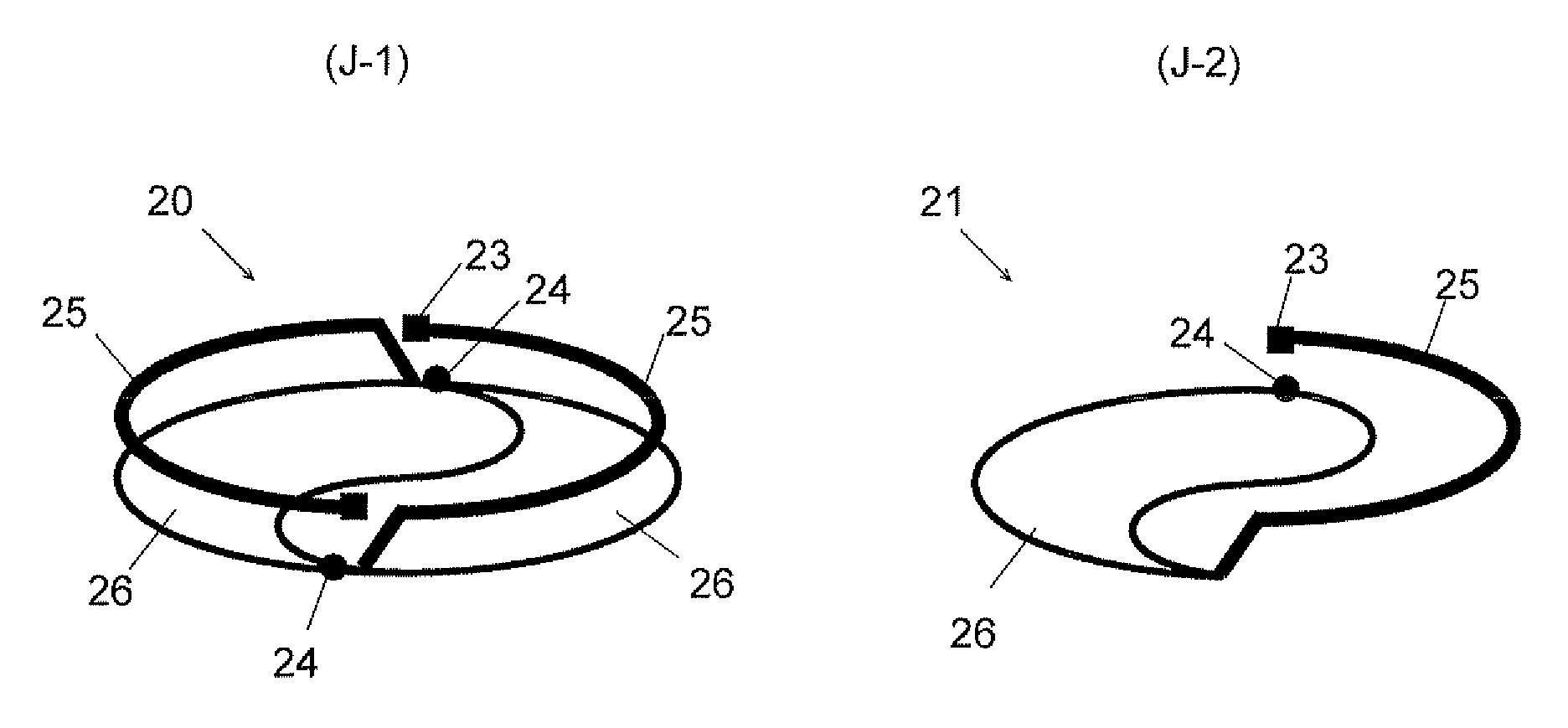

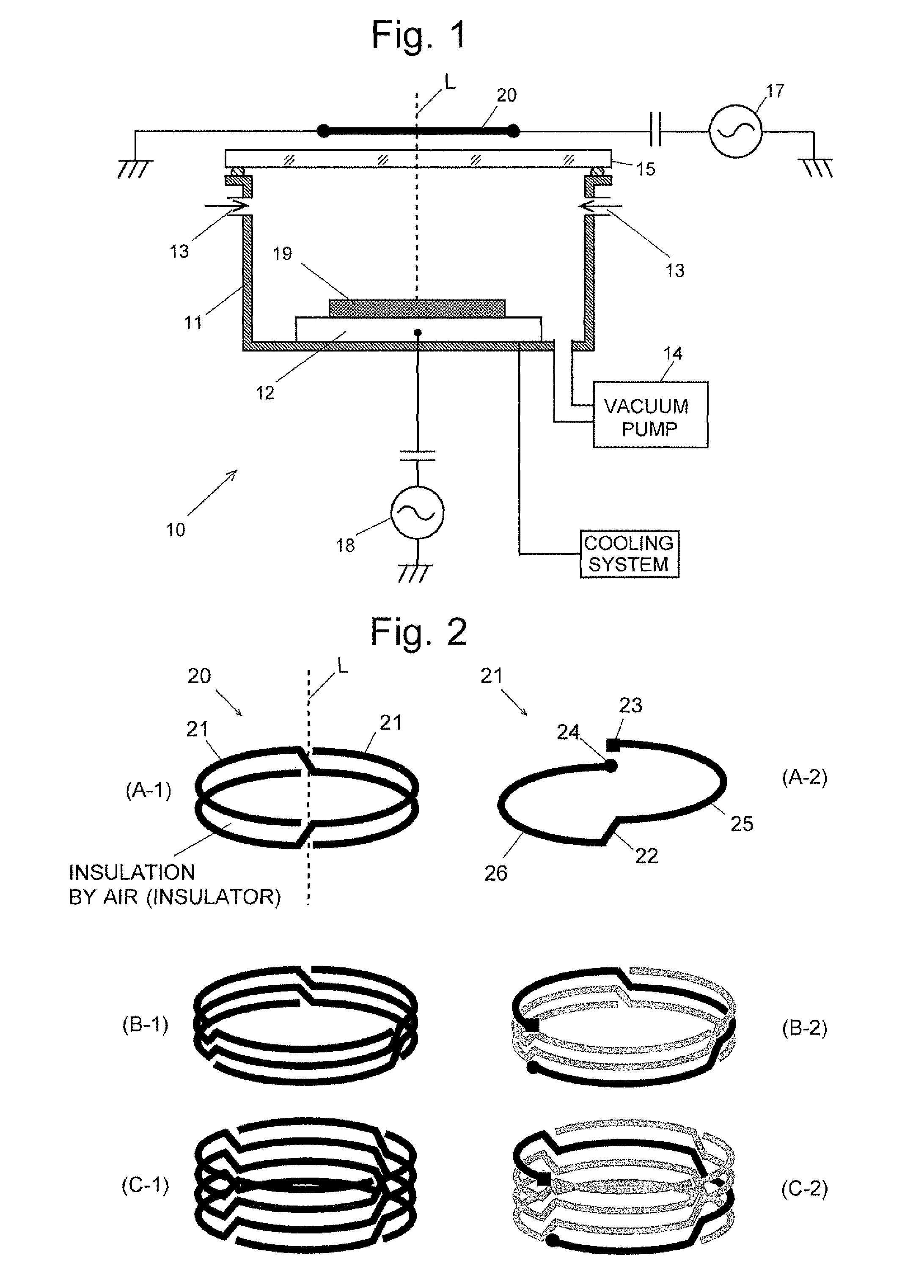

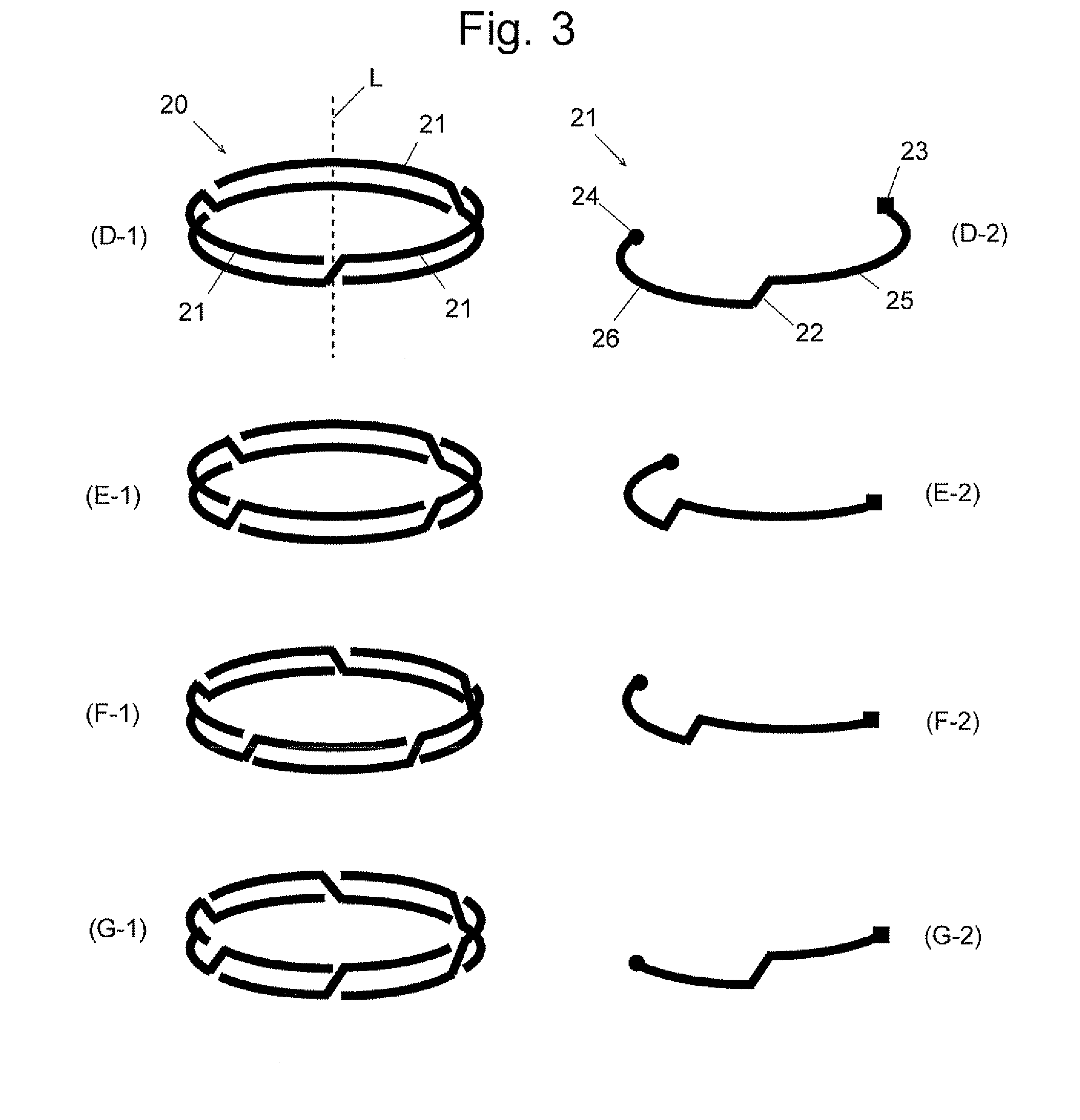

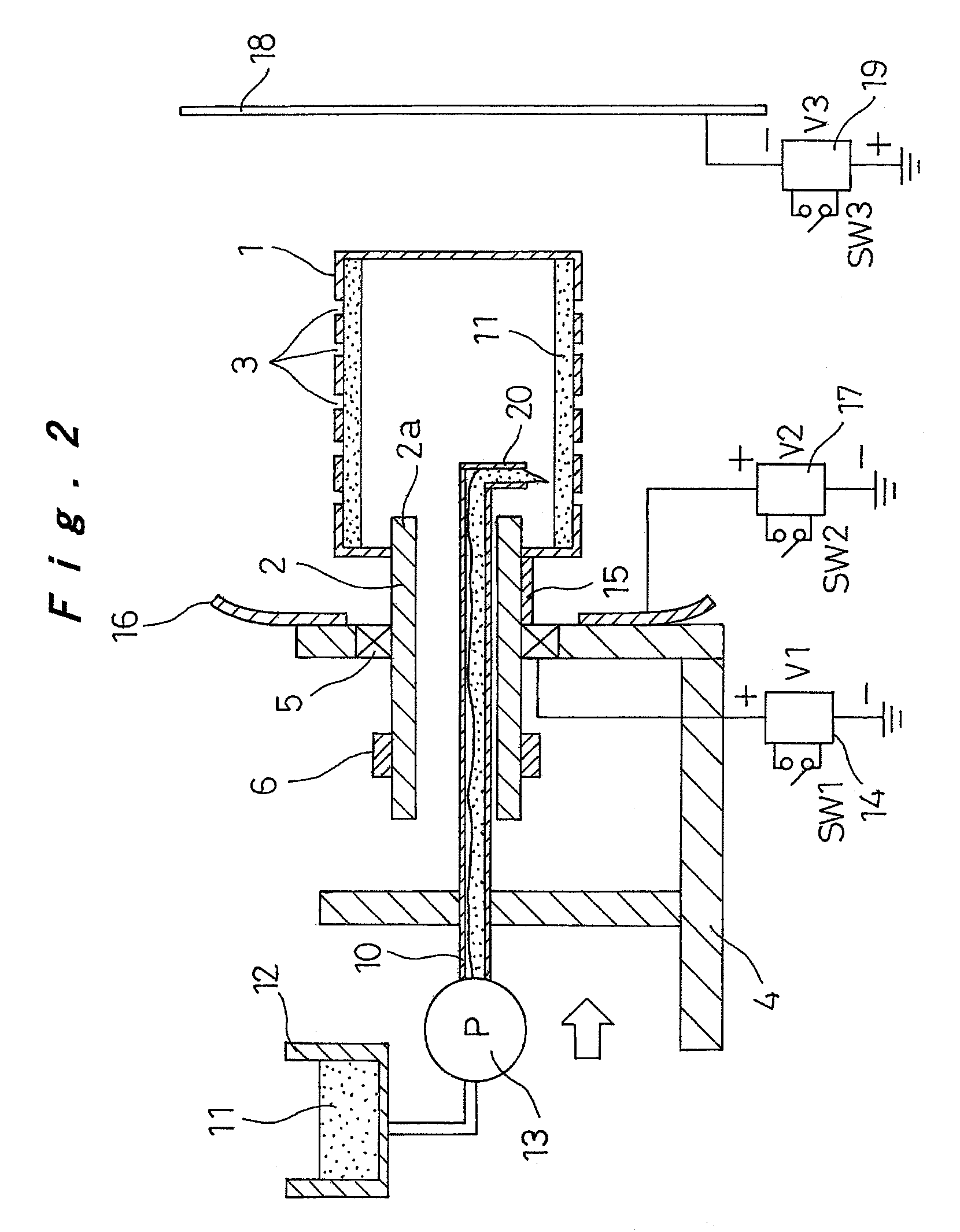

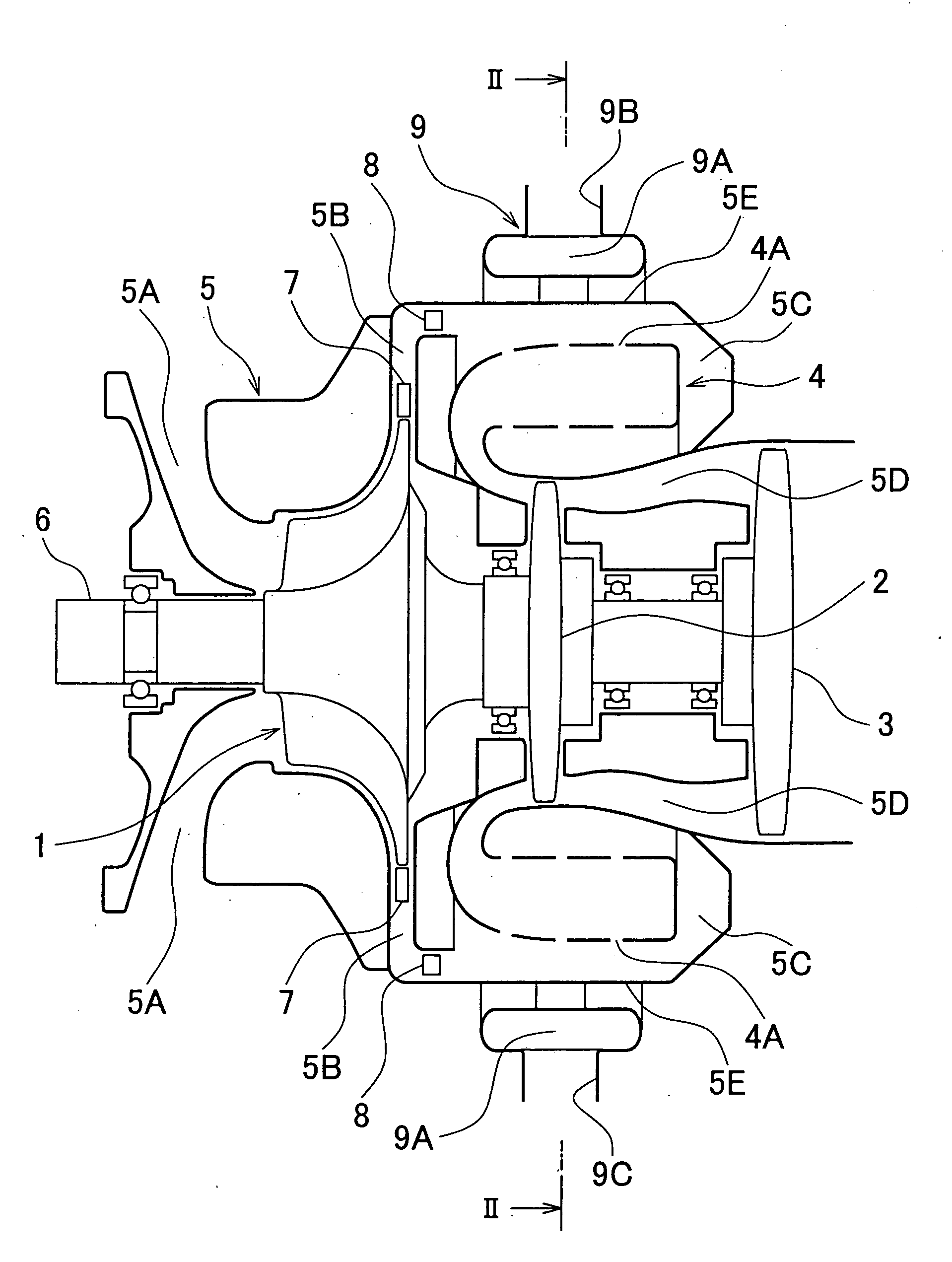

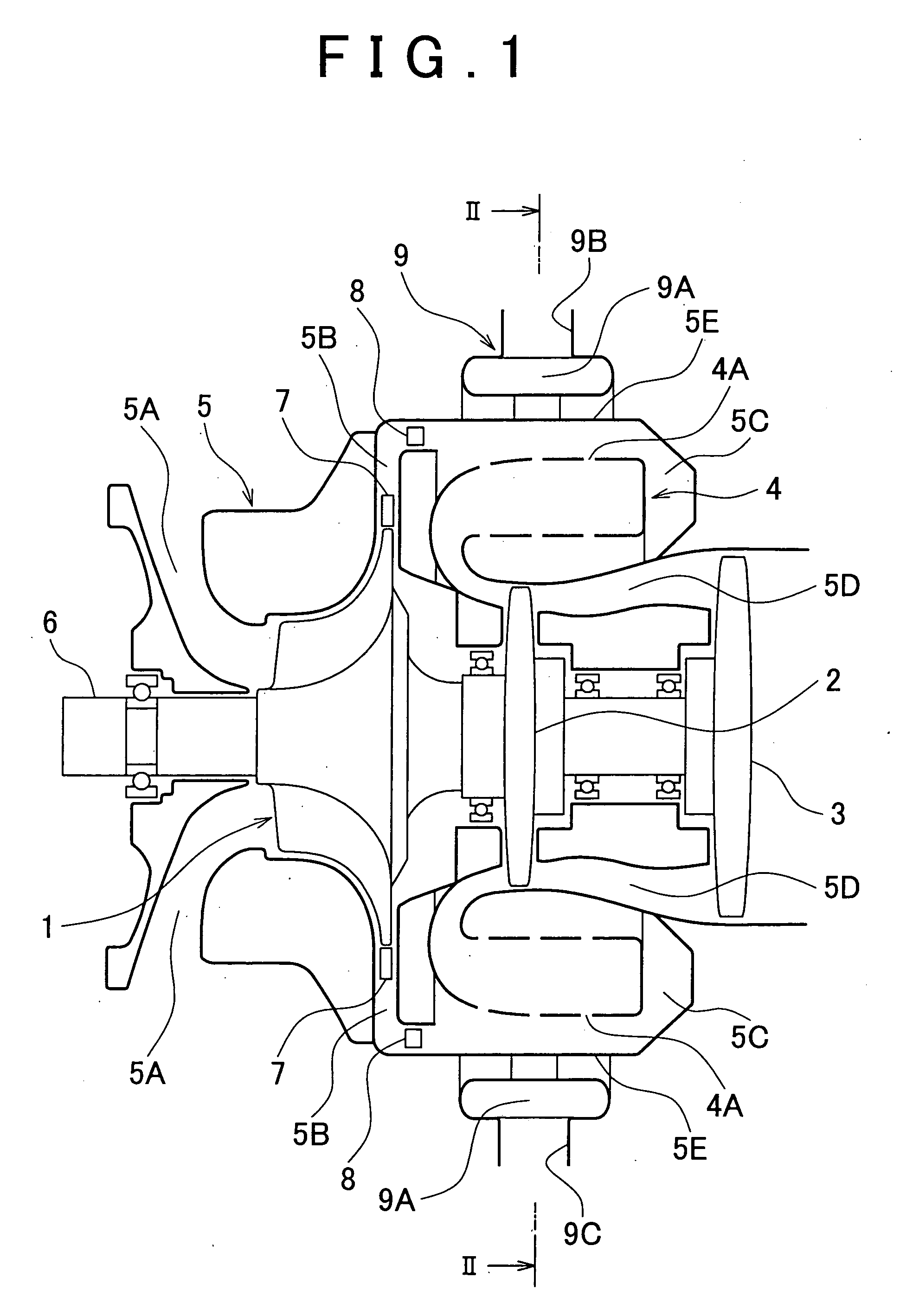

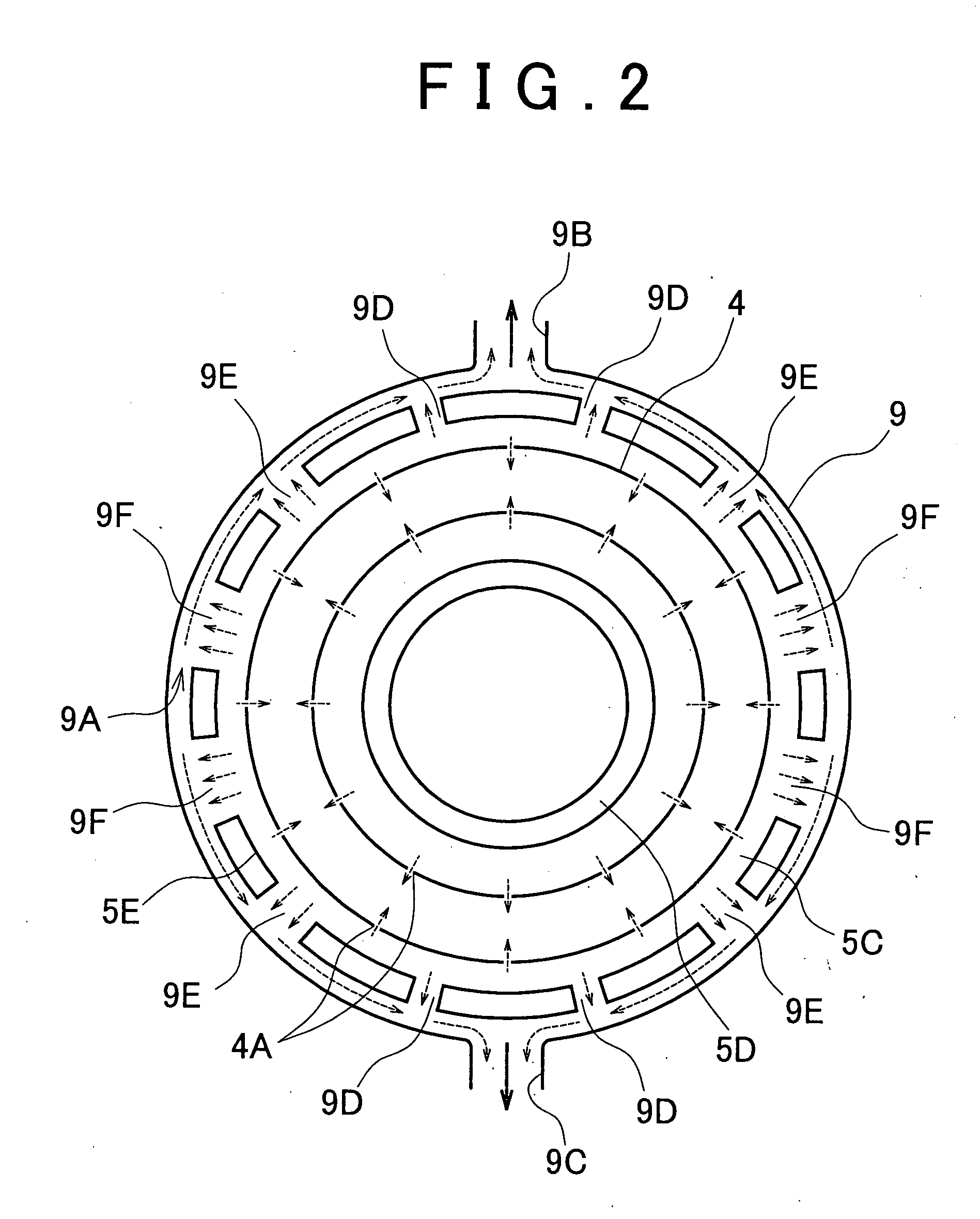

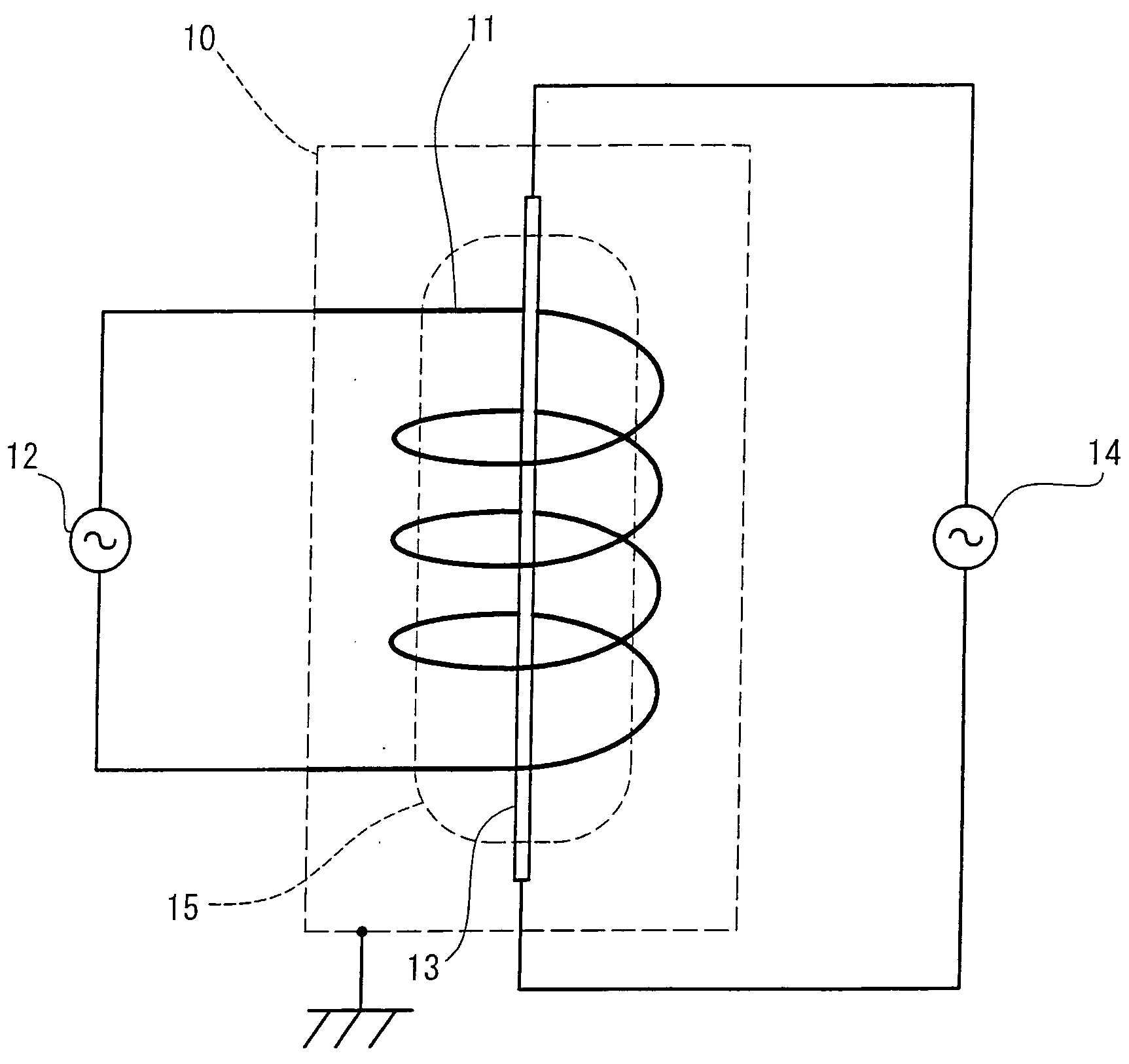

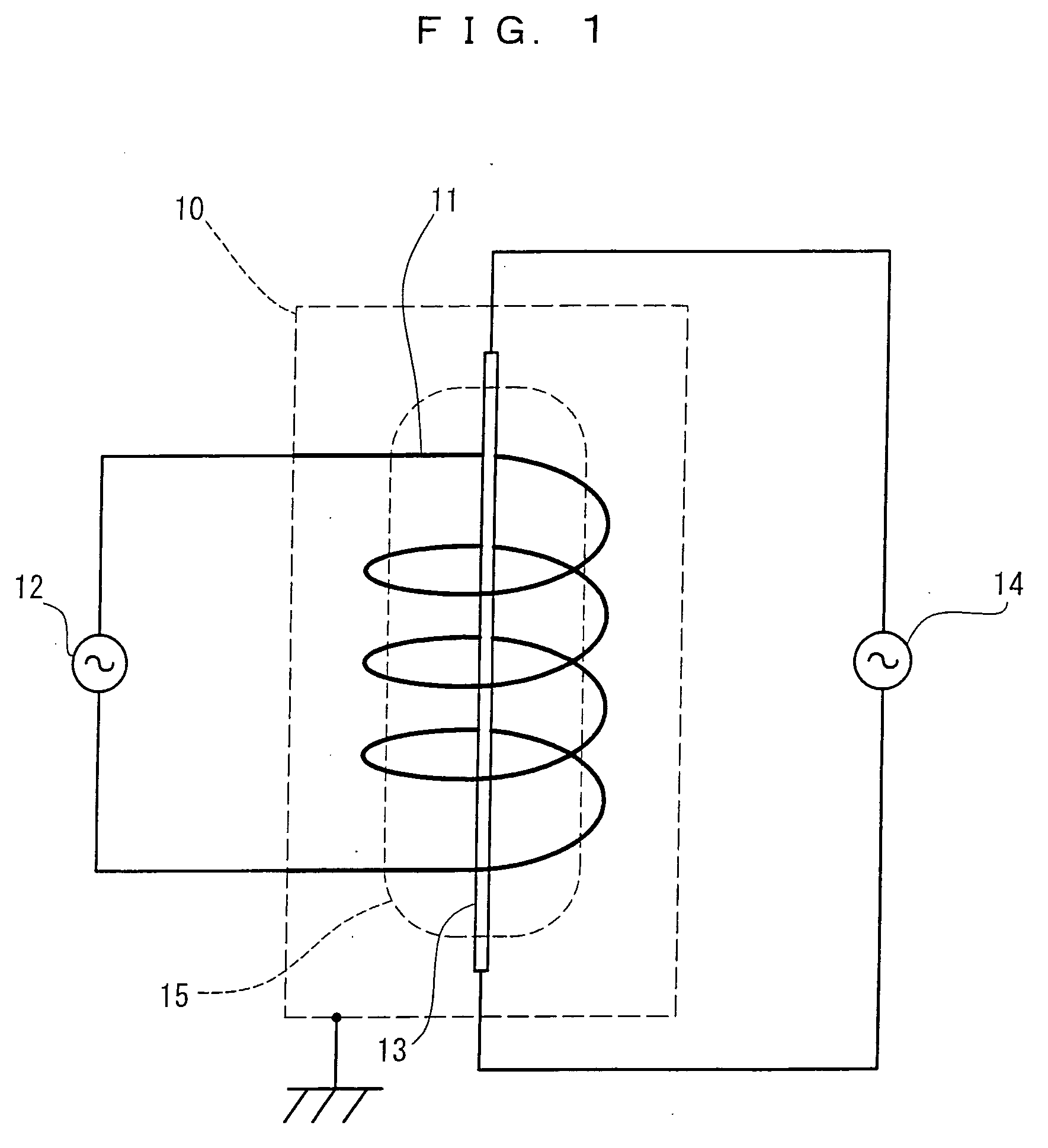

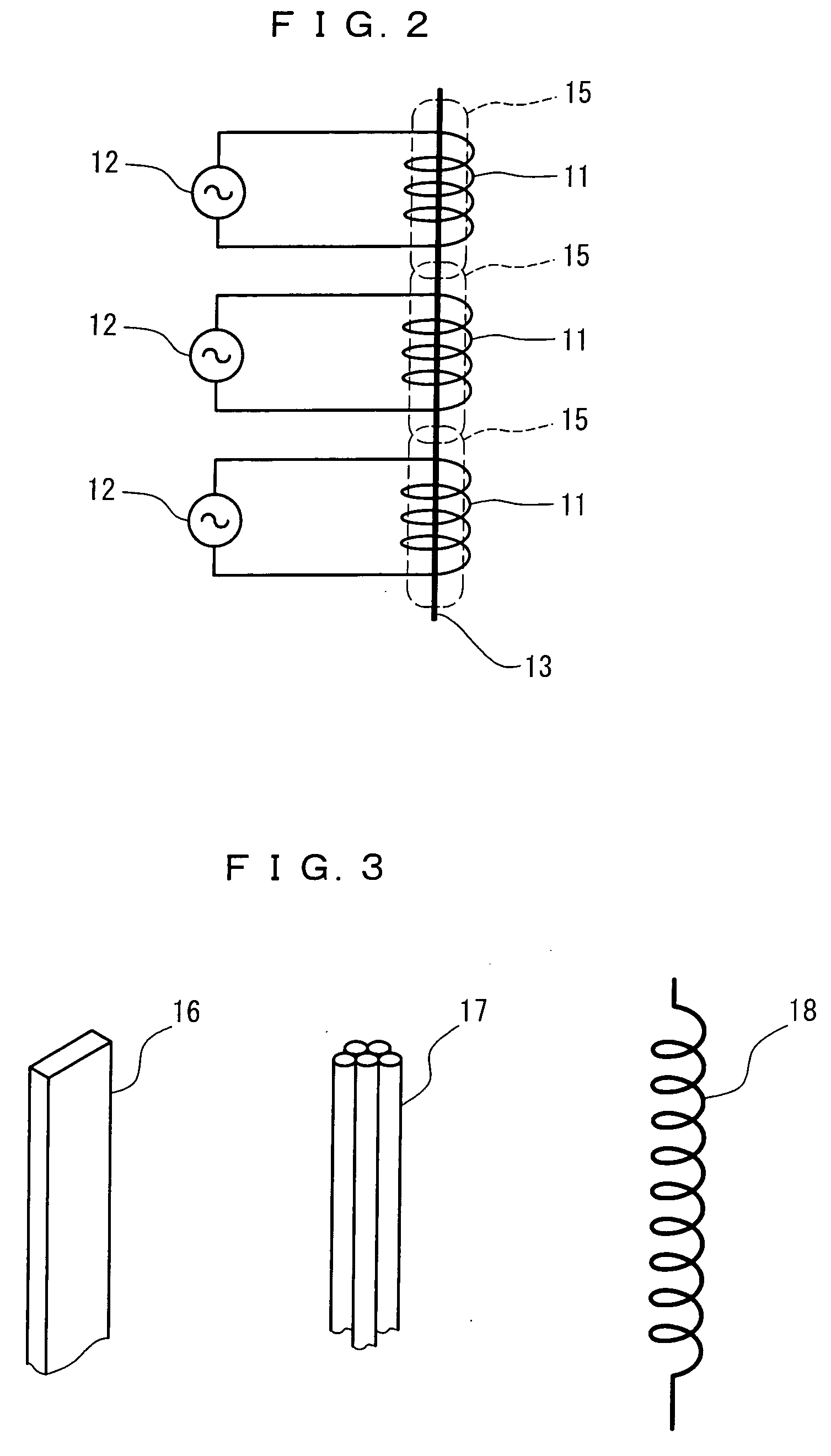

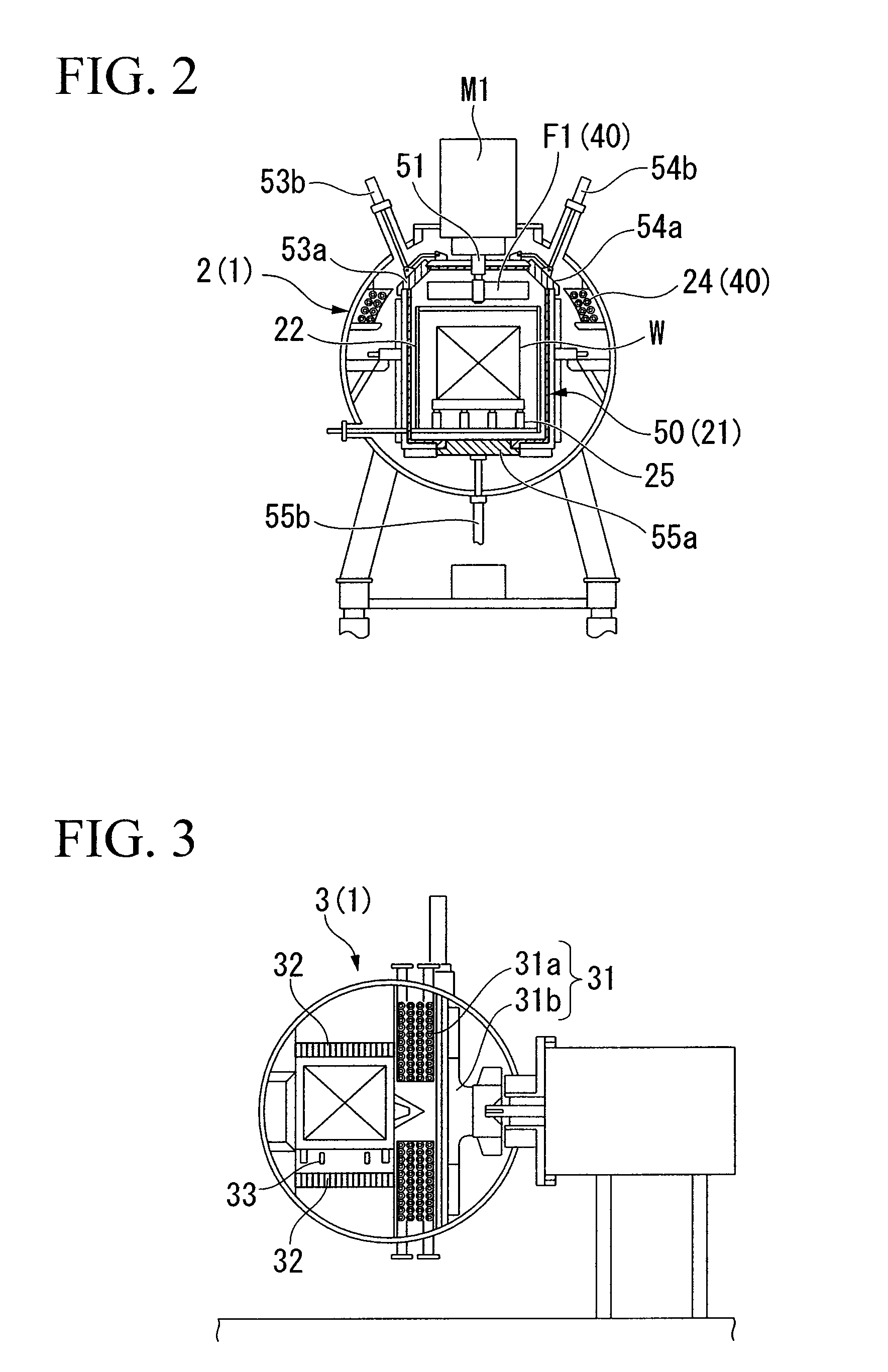

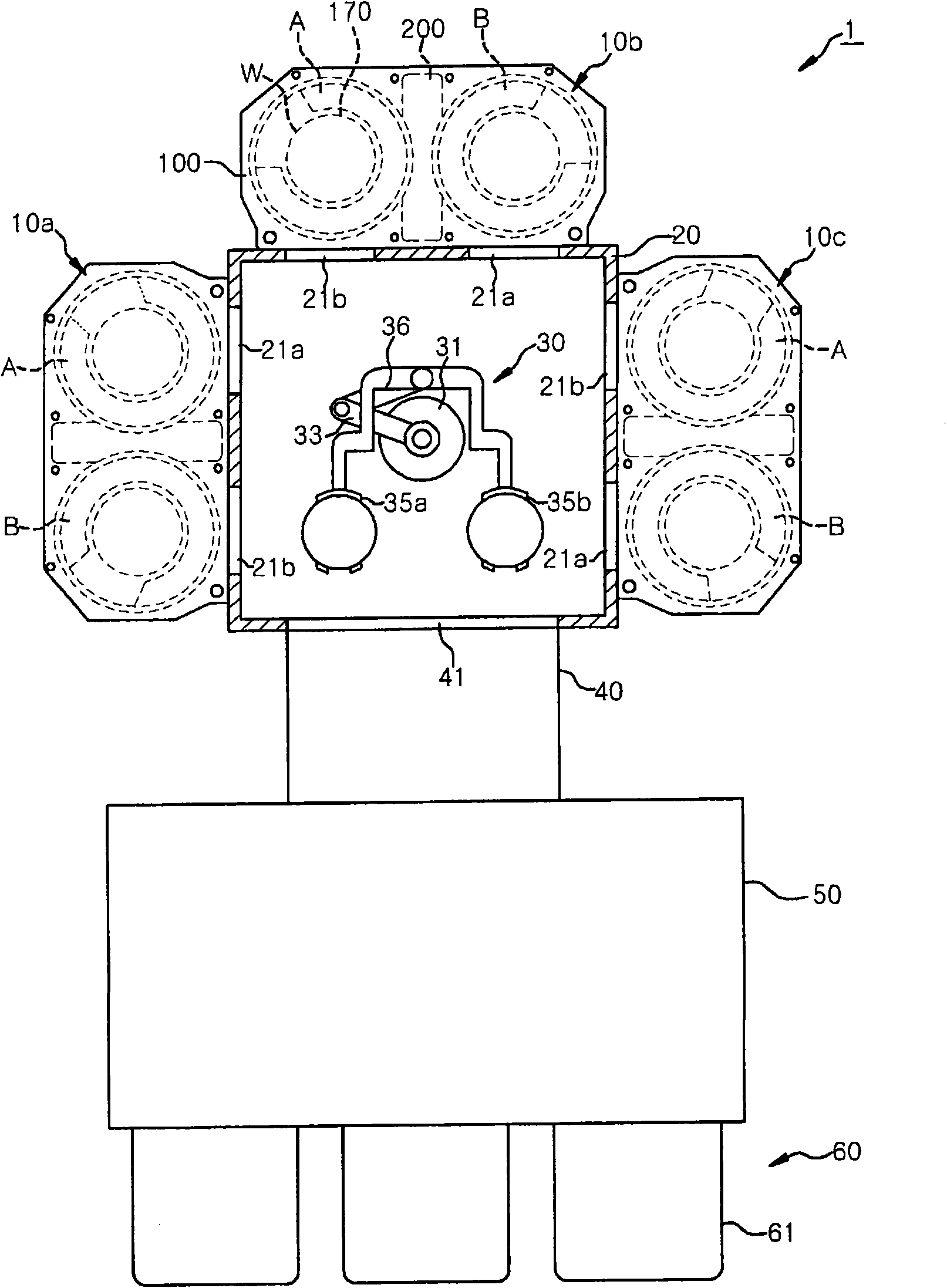

Plasma processing apparatus

ActiveUS20100066251A1Improve the level ofReduce the impactElectric discharge tubesElectric arc lampsProjection planePlasma processing

An induction coil composed of n pieces of identically shaped coil elements (where n is equal to or greater than two), which are rotation-symmetrically arranged with respect to an axis normal to the surface of an object to be processed, is provided above the object, the coil elements being electrically connected in parallel. Each of the coil elements of the induction coil encircles the aforementioned axis, with the ground end and the feed end located at the same position on a projection plane on the object with the ground end under the feed end. Each coil element has a bottom portion shaped like an arc having a predetermined width and a central angle of 360° / n, with the ground end at one end thereof, and a feed portion shaped like an arc having a predetermined width, with the feed end at one end thereof, the feed portion being located above the bottom portion and electrically connected to the same bottom portion. It is also possible to assemble a plurality of coil elements so that the ground end of each coil element is located immediately below the feed end of another coil element.

Owner:SAMCO

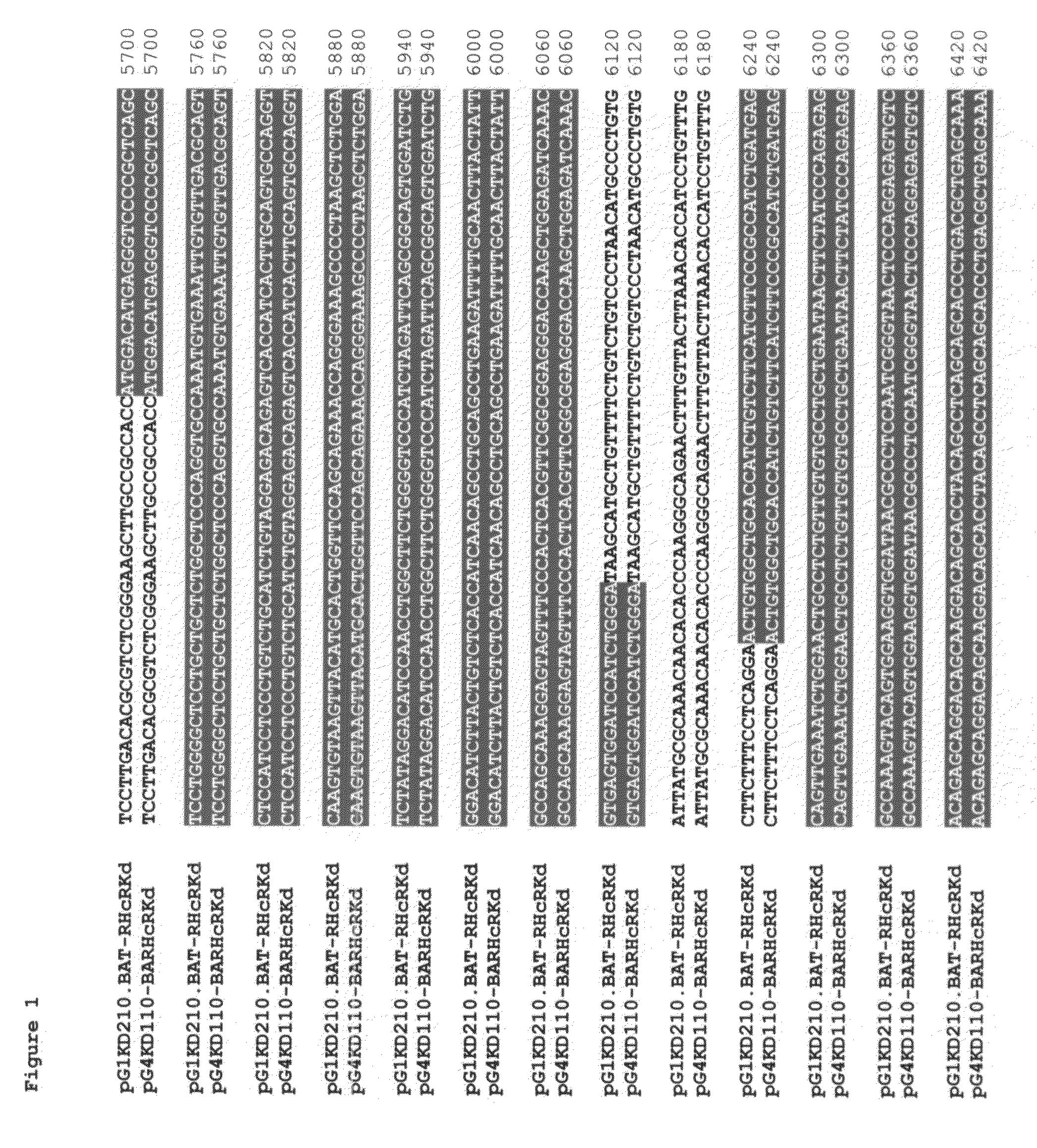

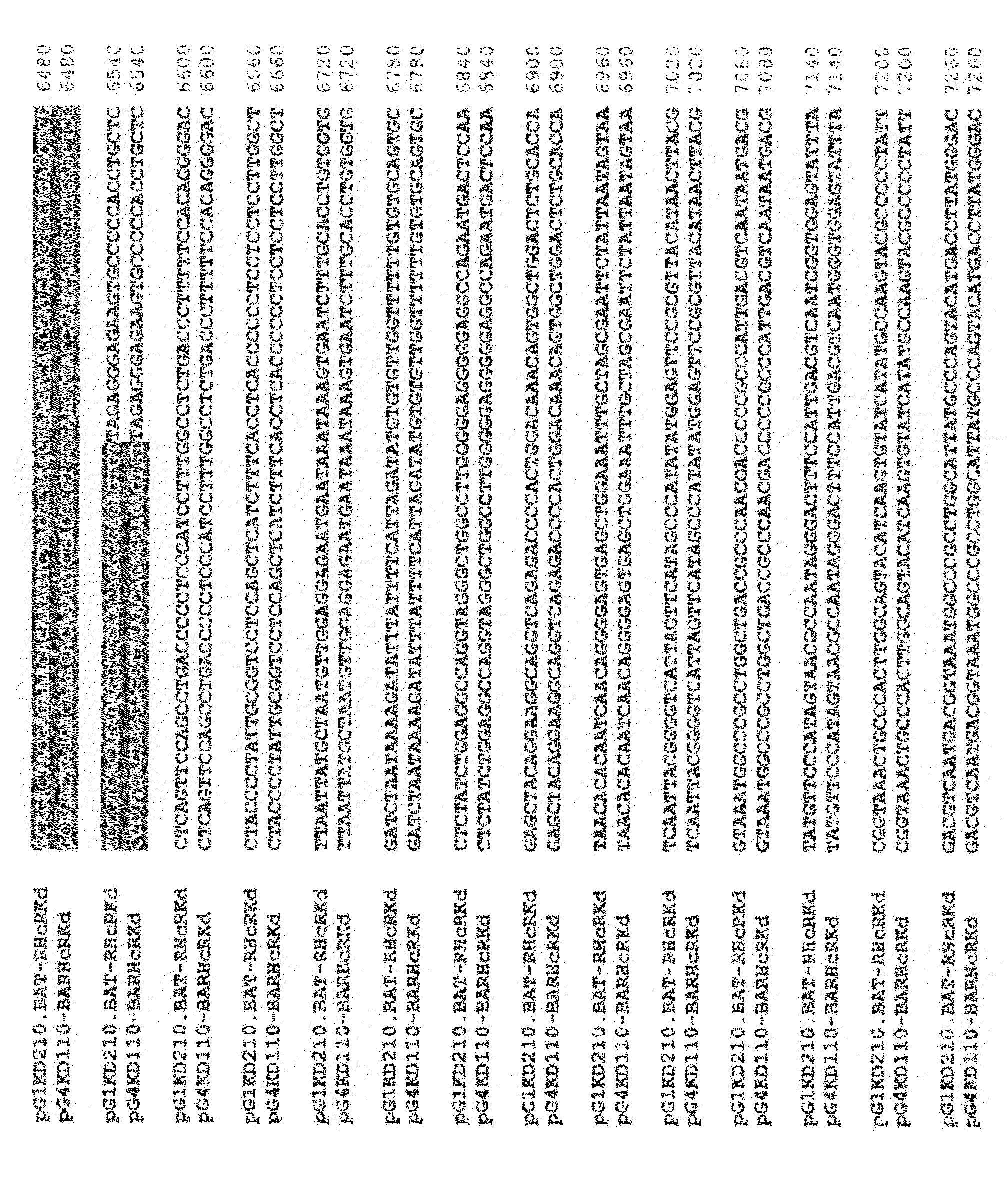

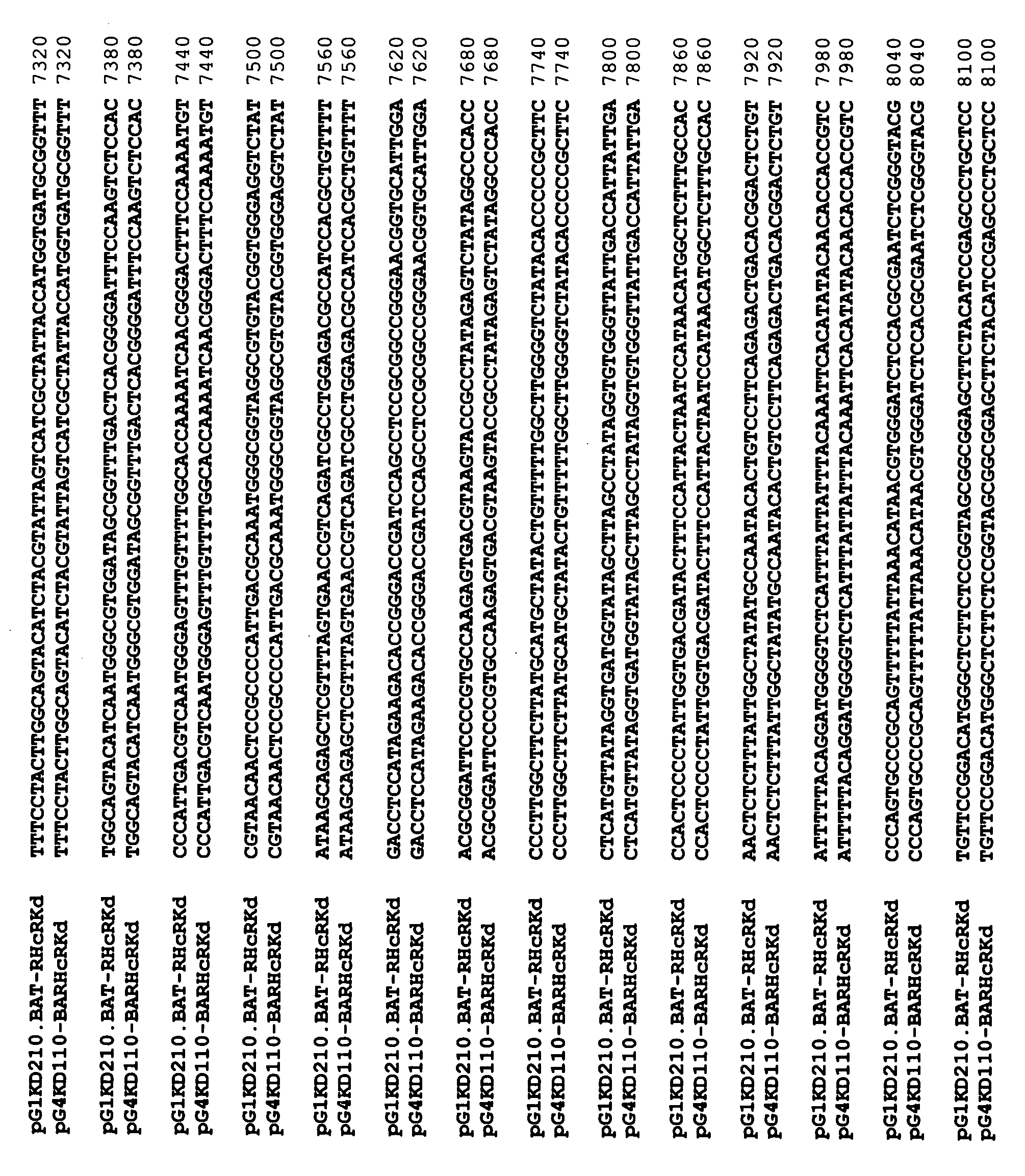

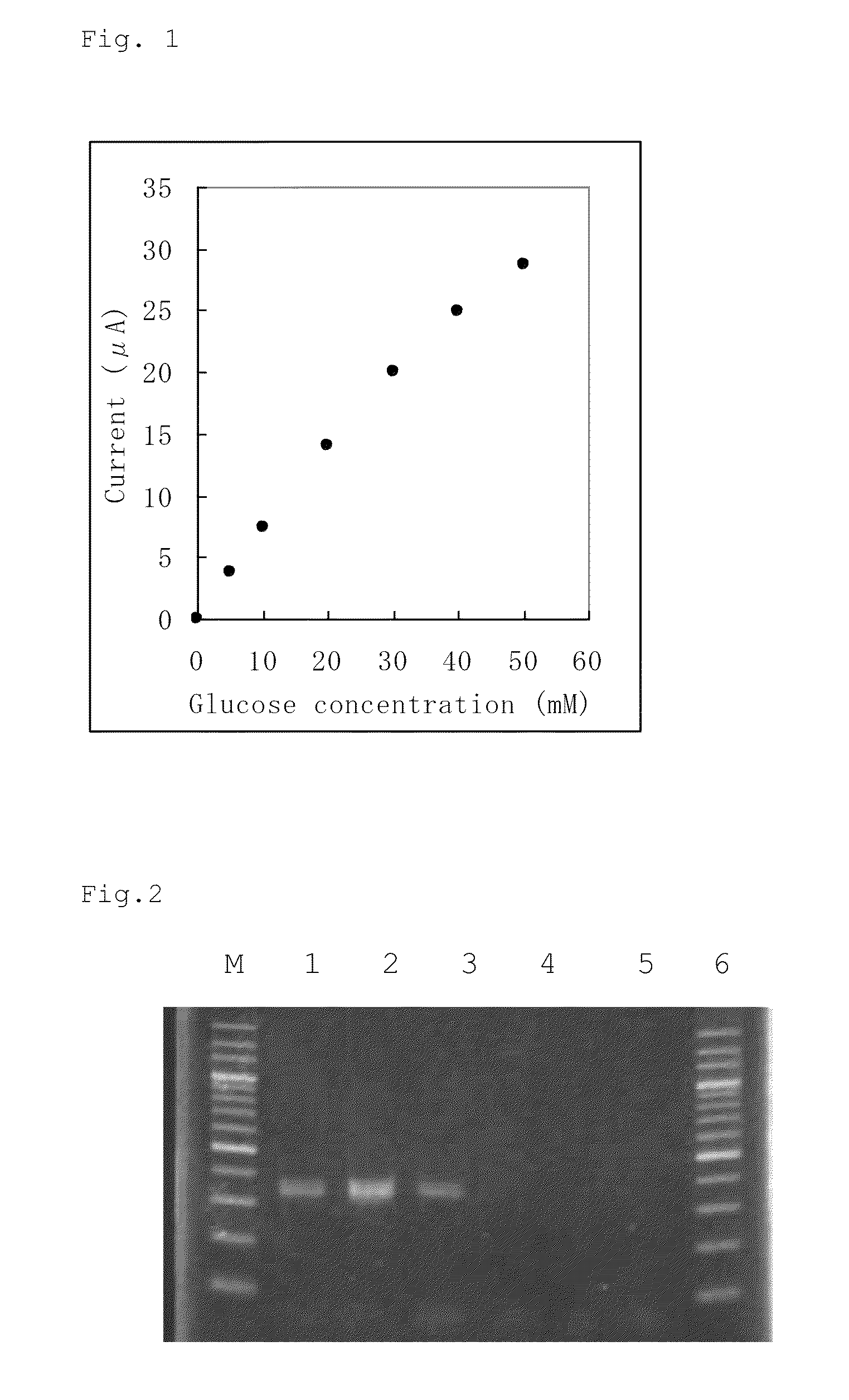

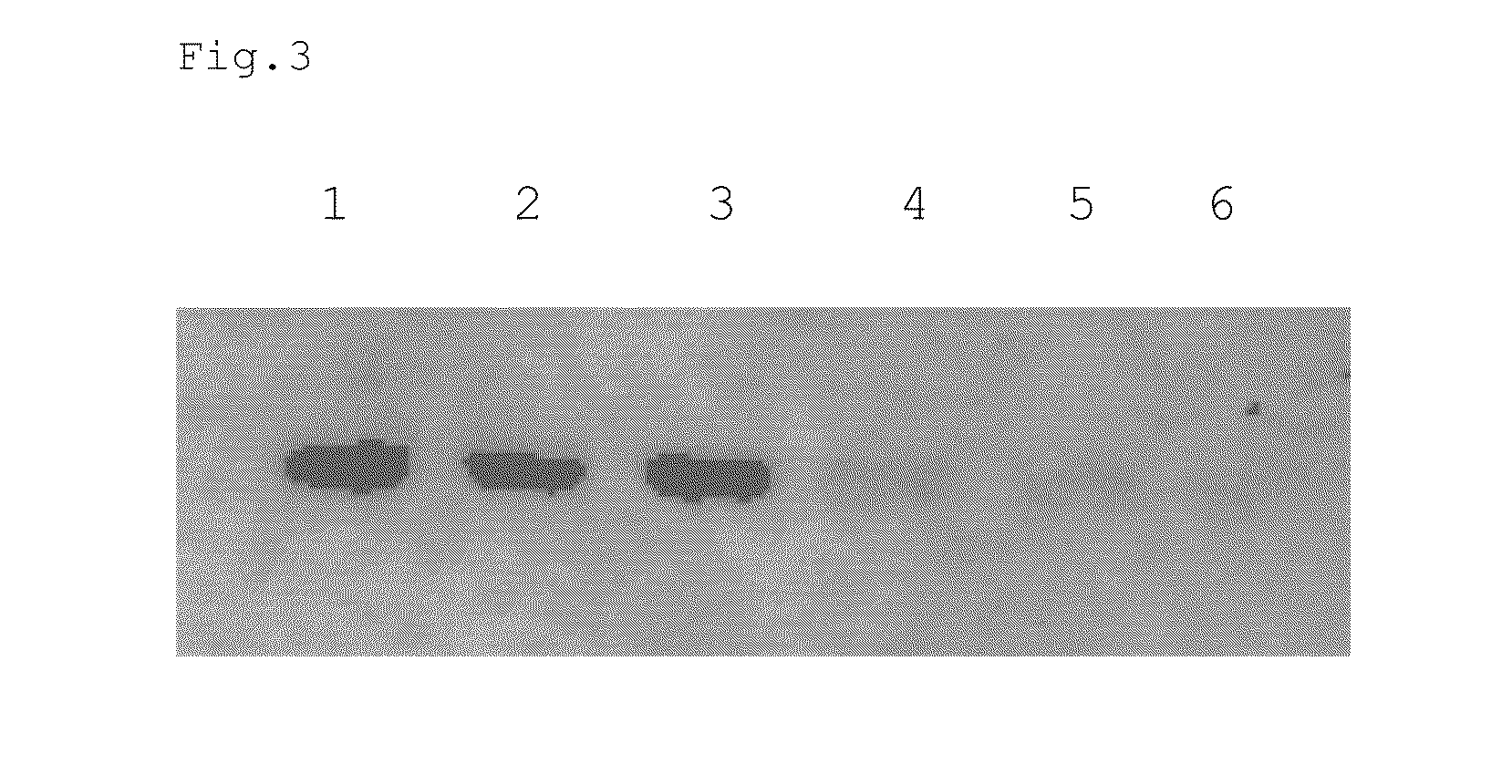

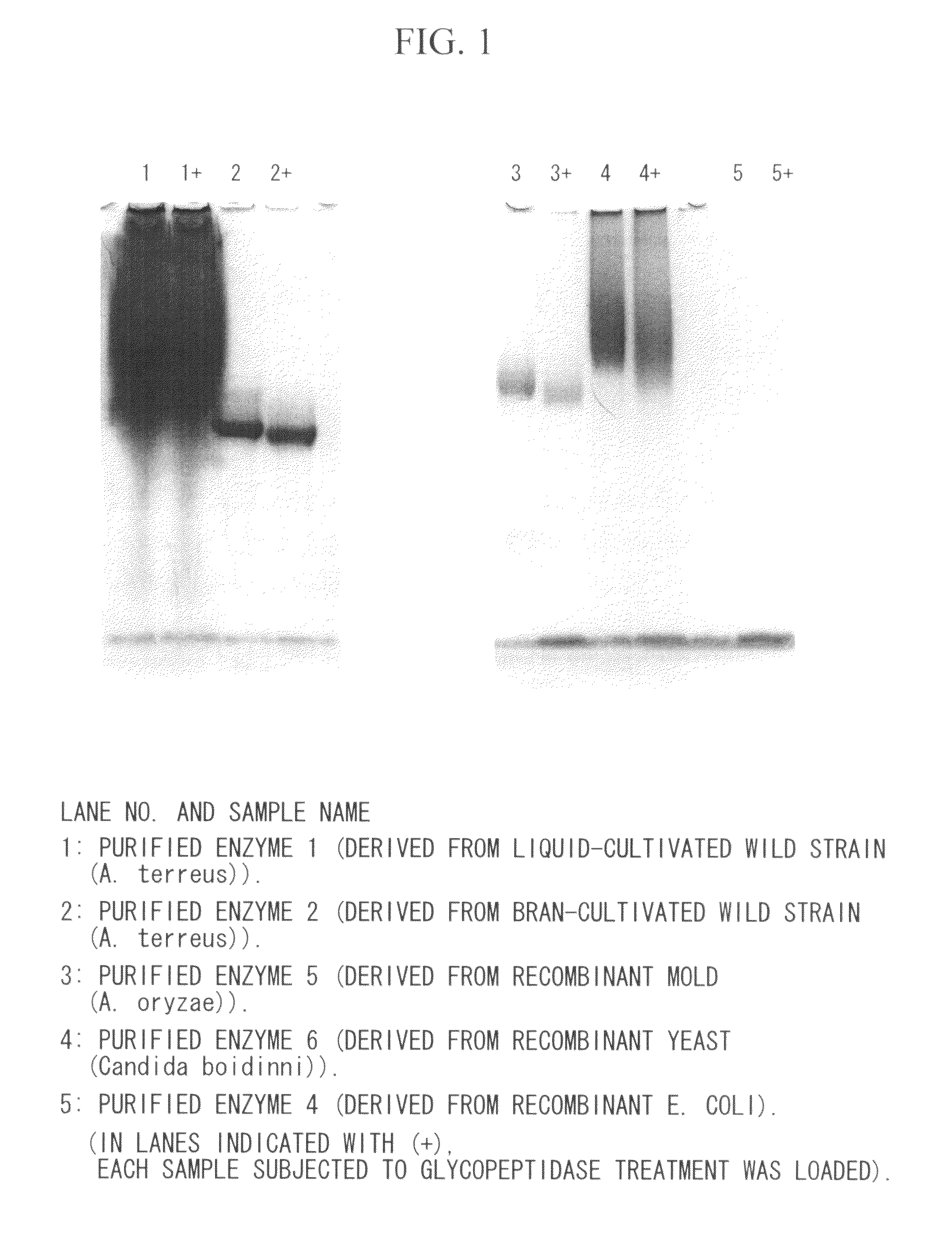

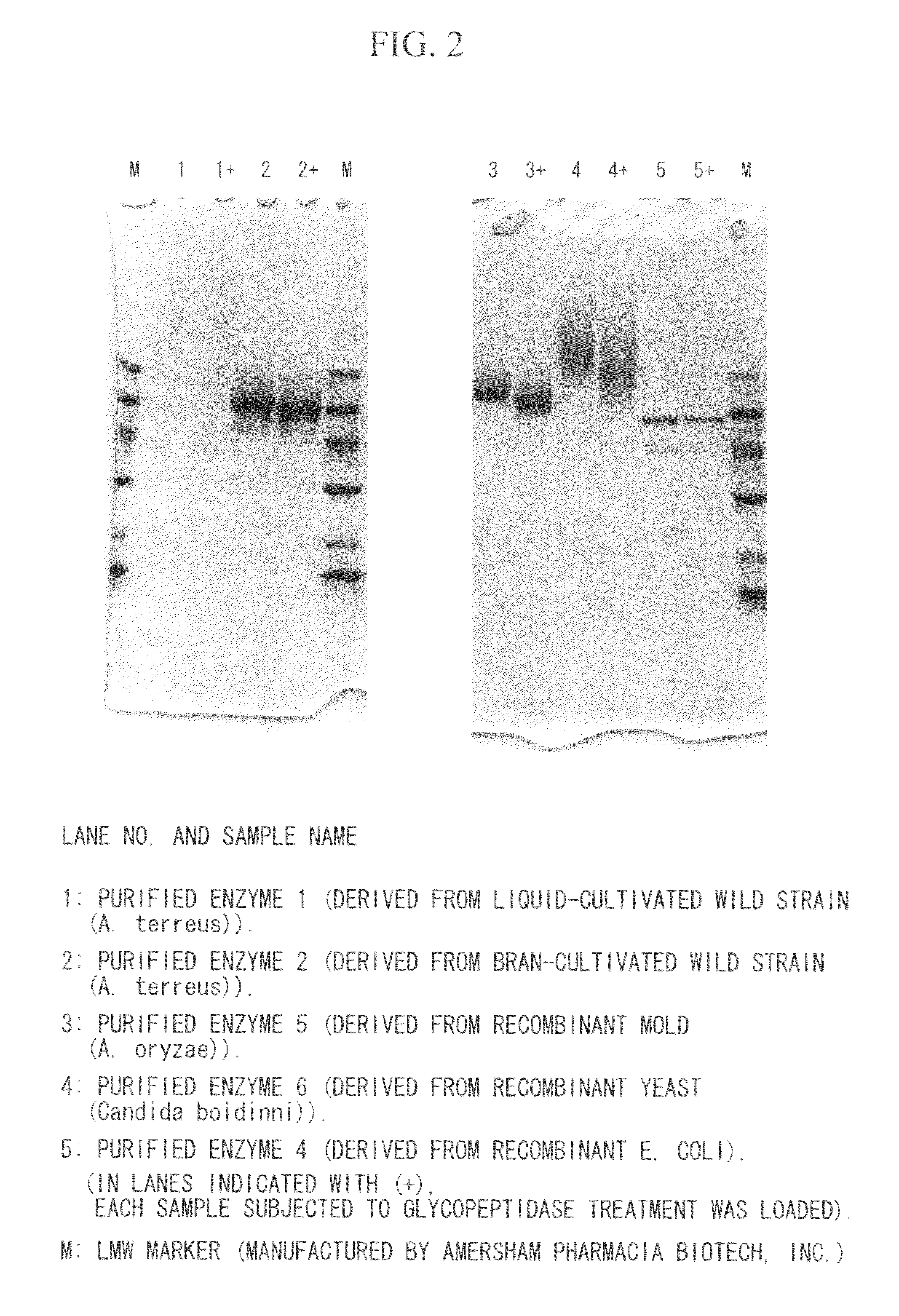

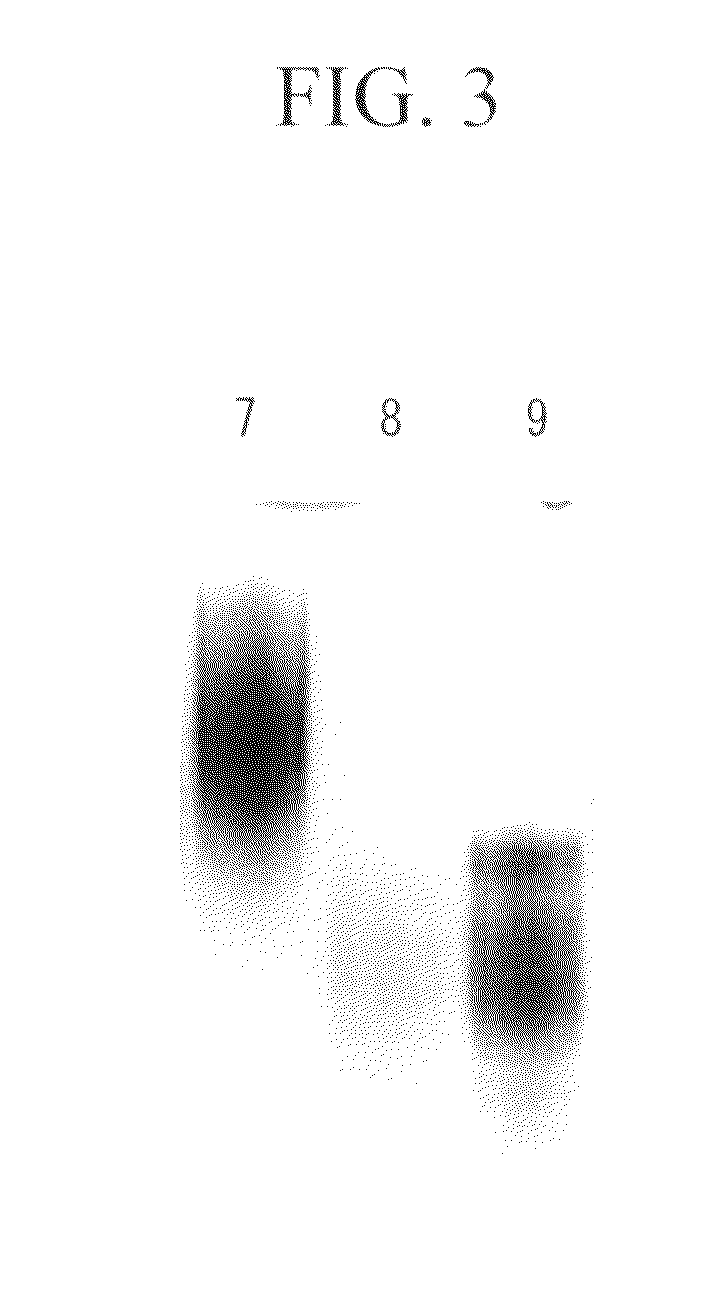

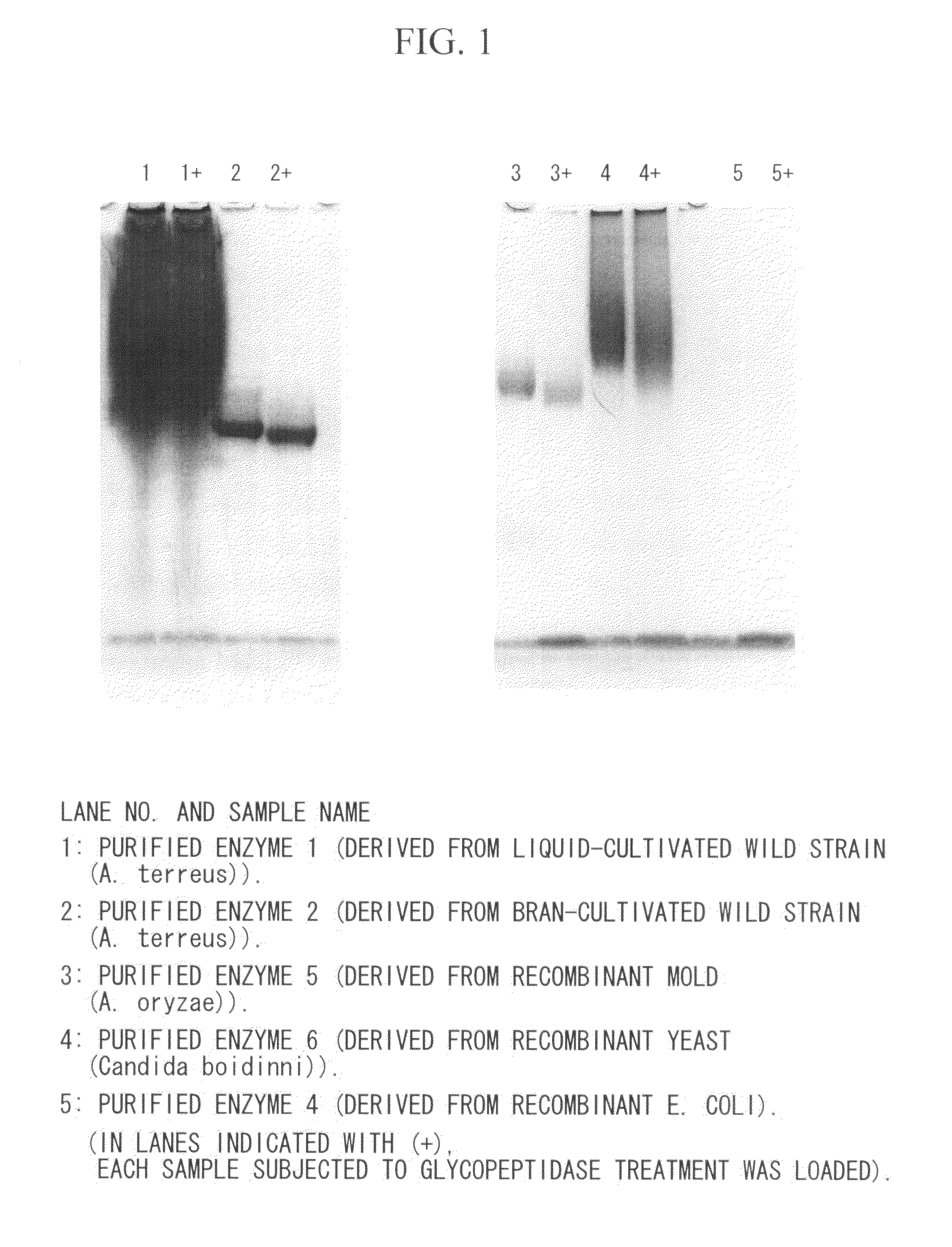

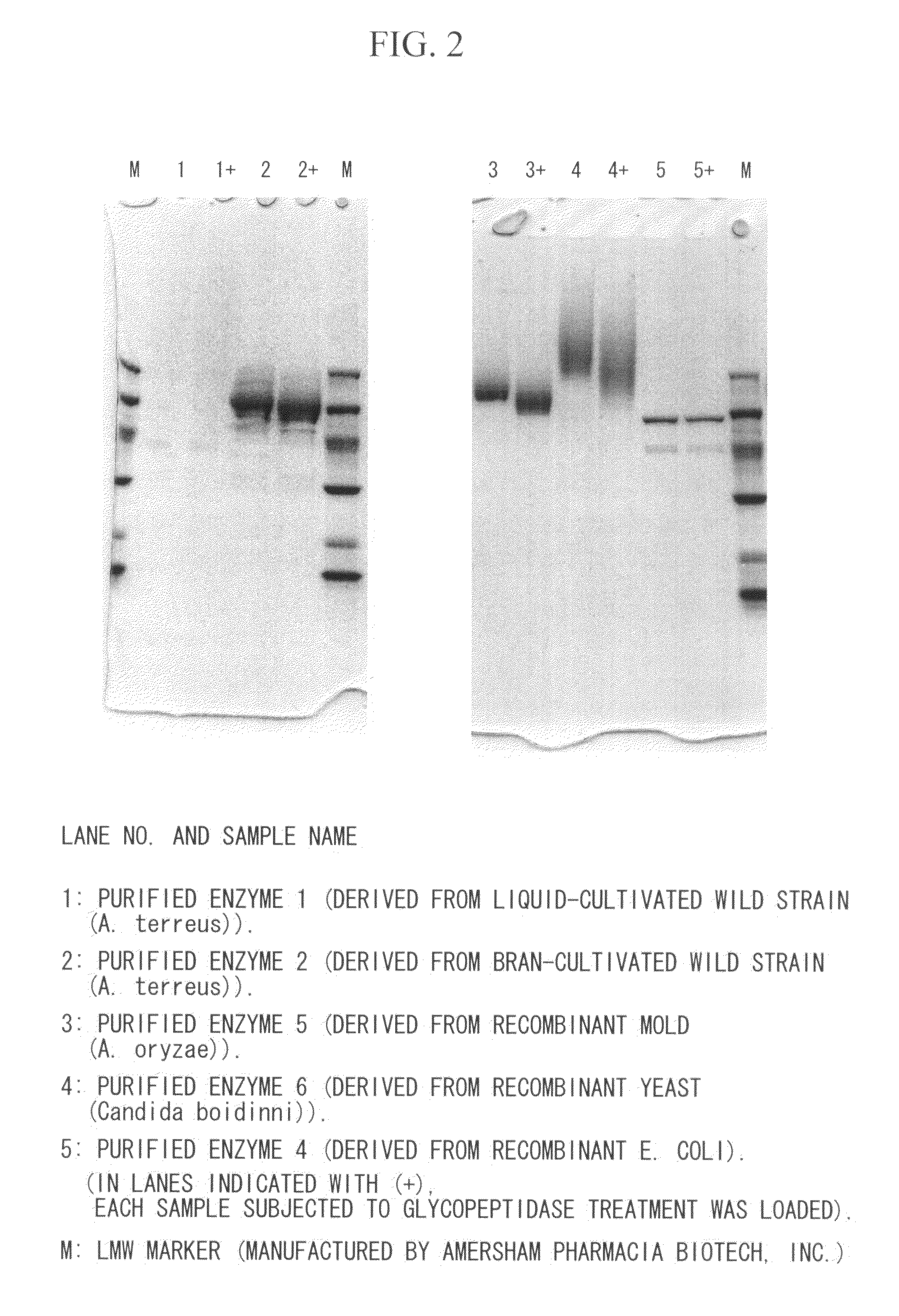

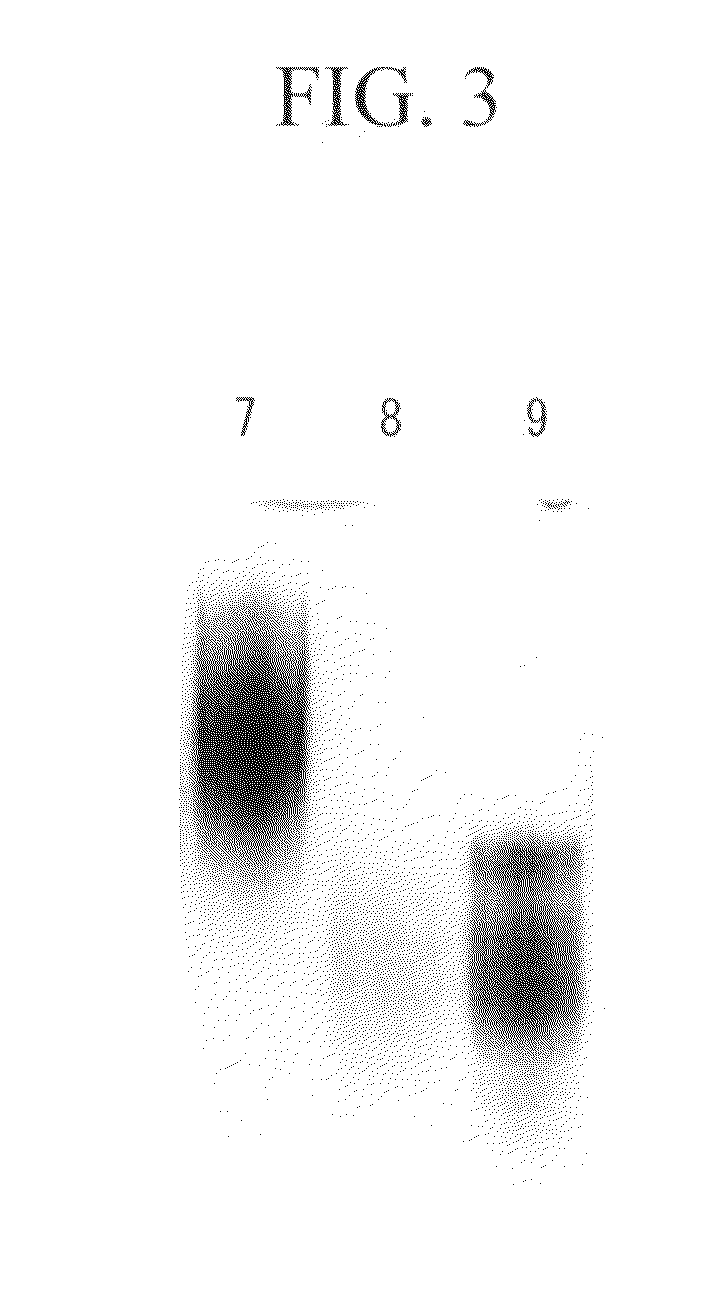

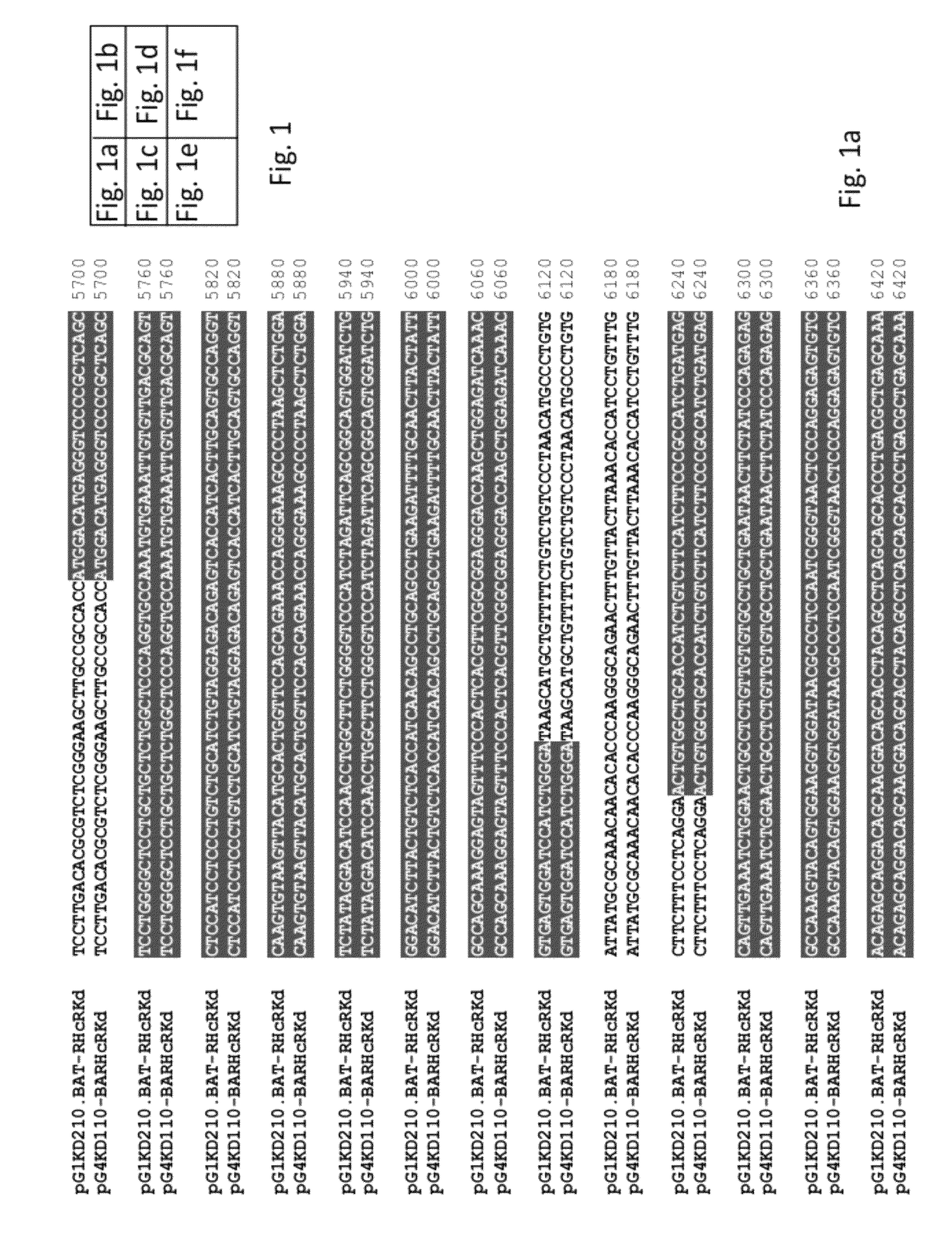

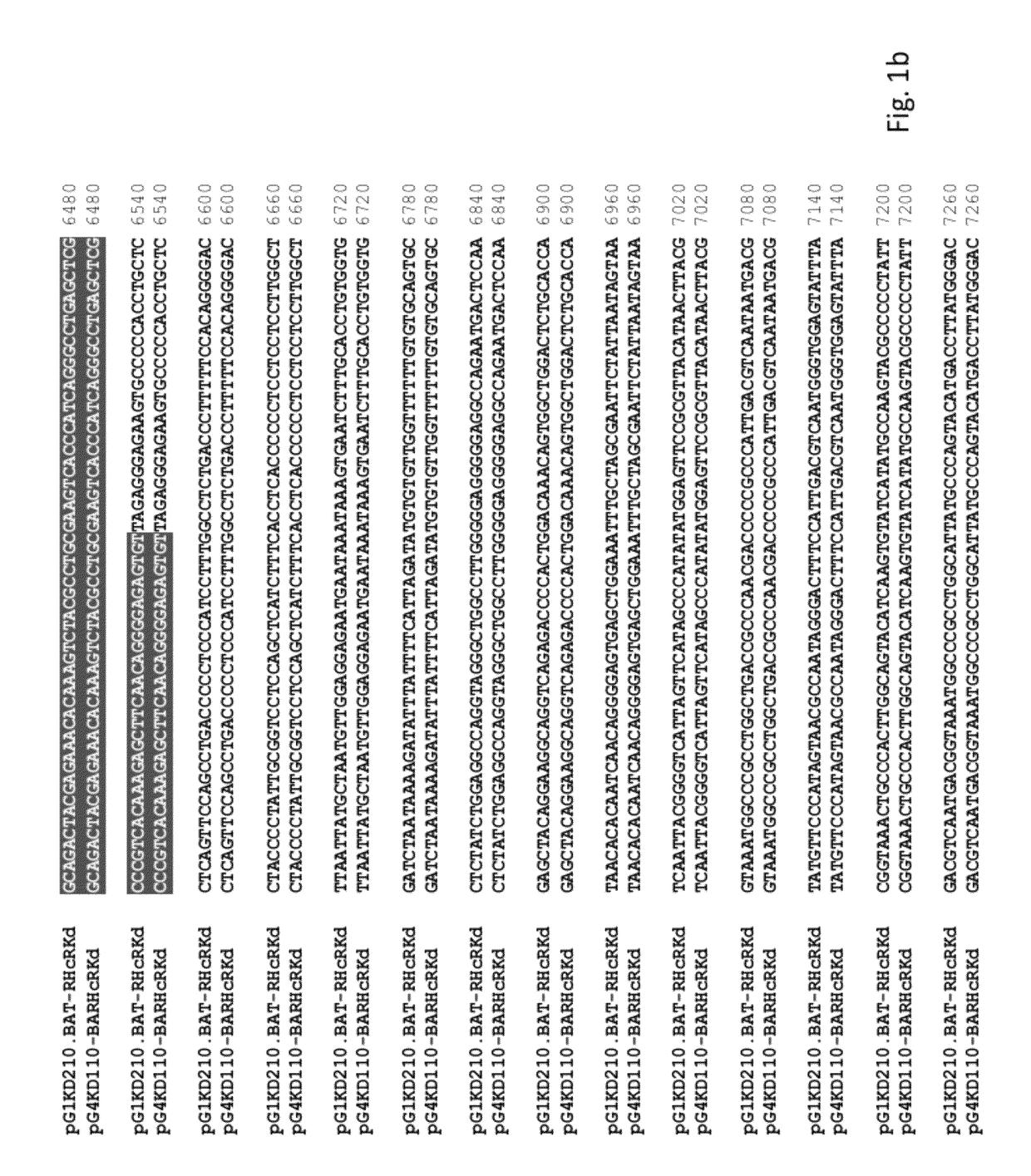

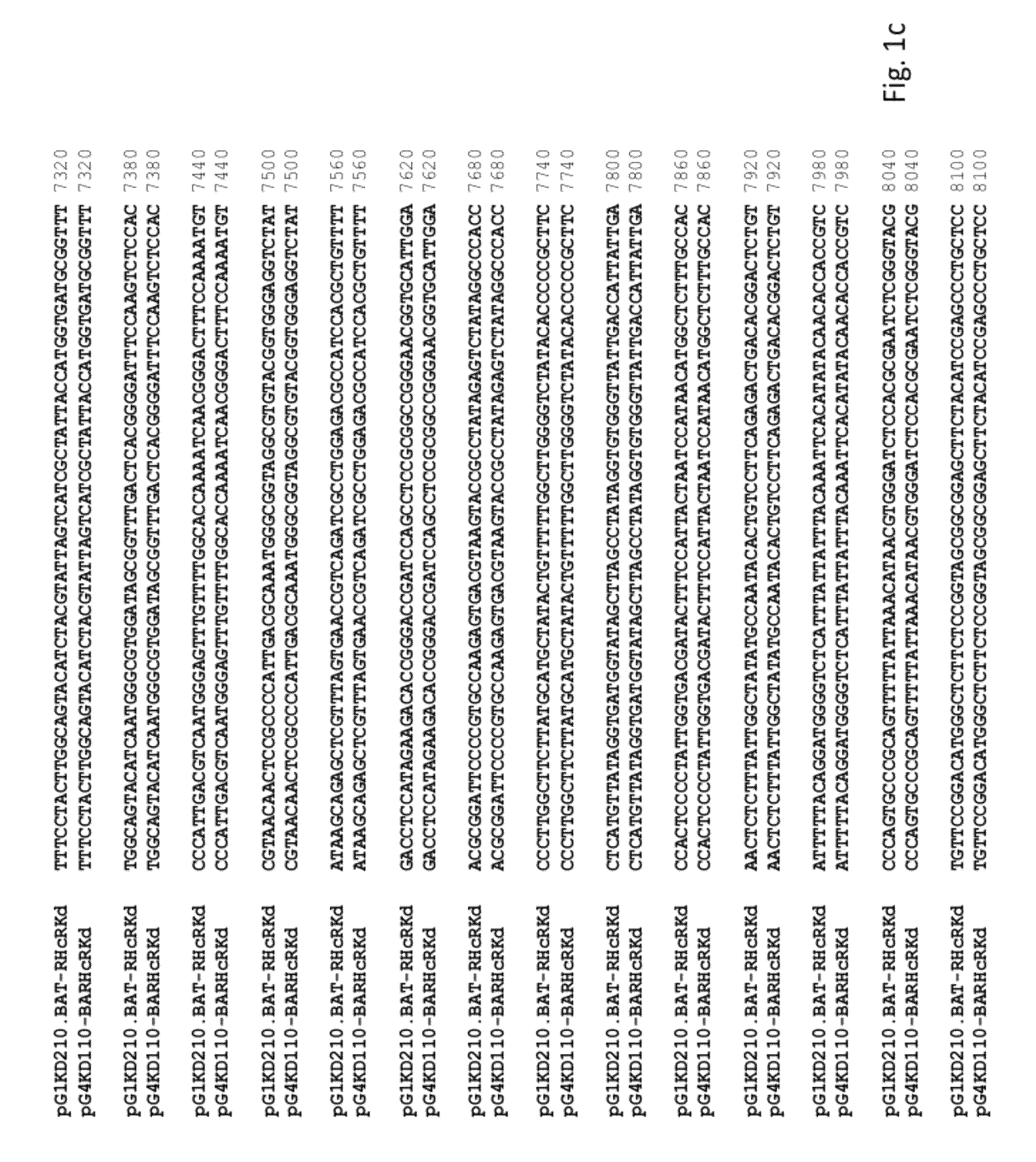

FAD-conjugated glucose dehydrogenase gene

InactiveUS8492130B2Maintain good propertiesEasy to identifyBacteriaSugar derivativesNucleotidePolynucleotide

An object of the present invention is to provide: a novel gene (polynucleotide) encoding an FAD-conjugated glucose dehydrogenase having excellent properties that it has excellent reactivity to glucose, excellent thermal stability, and excellent substrate-recognition performance and also has a low activity for maltose; a process for the production of the enzyme using a transformant cell transfected with the gene; and a method for the determination of glucose, a reagent composition for use in the determination of glucose, a biosensor for use in the determination of glucose and others, each characterized by using the enzyme obtained. The invention relates to a polynucleotide encoding an FAD-conjugated glucose dehydrogenase, comprising a polypeptide containing an amino acid sequence: X1-X2-X3-X4-X5-X6 (wherein X1 and X2 independently represent an aliphatic amino acid residue; X3 and X6 independently represent a branched amino acid residue; and X4 and X5 independently represent a heterocyclic amino acid residue or an aromatic amino acid residue); and others.

Owner:PHC CORP

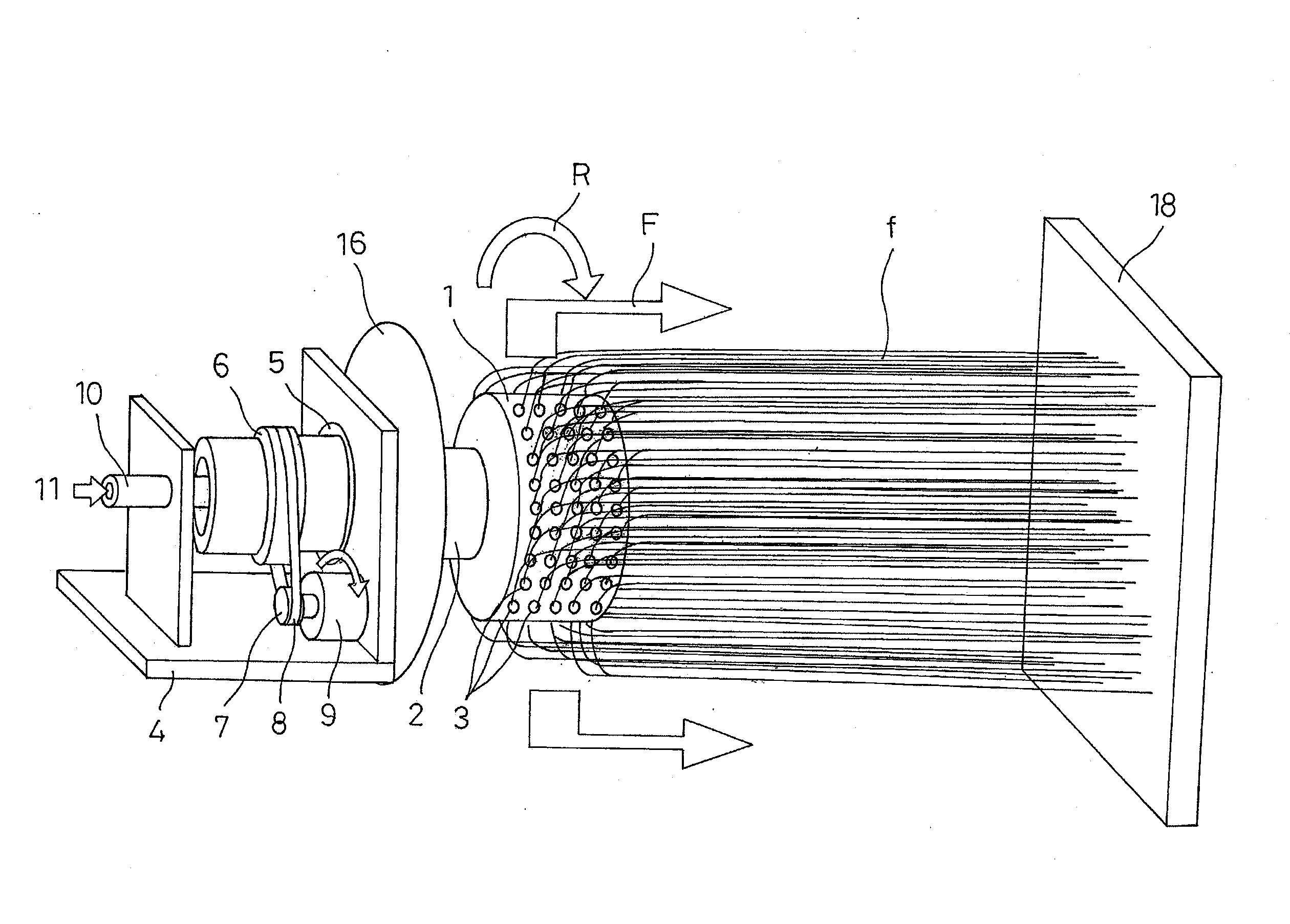

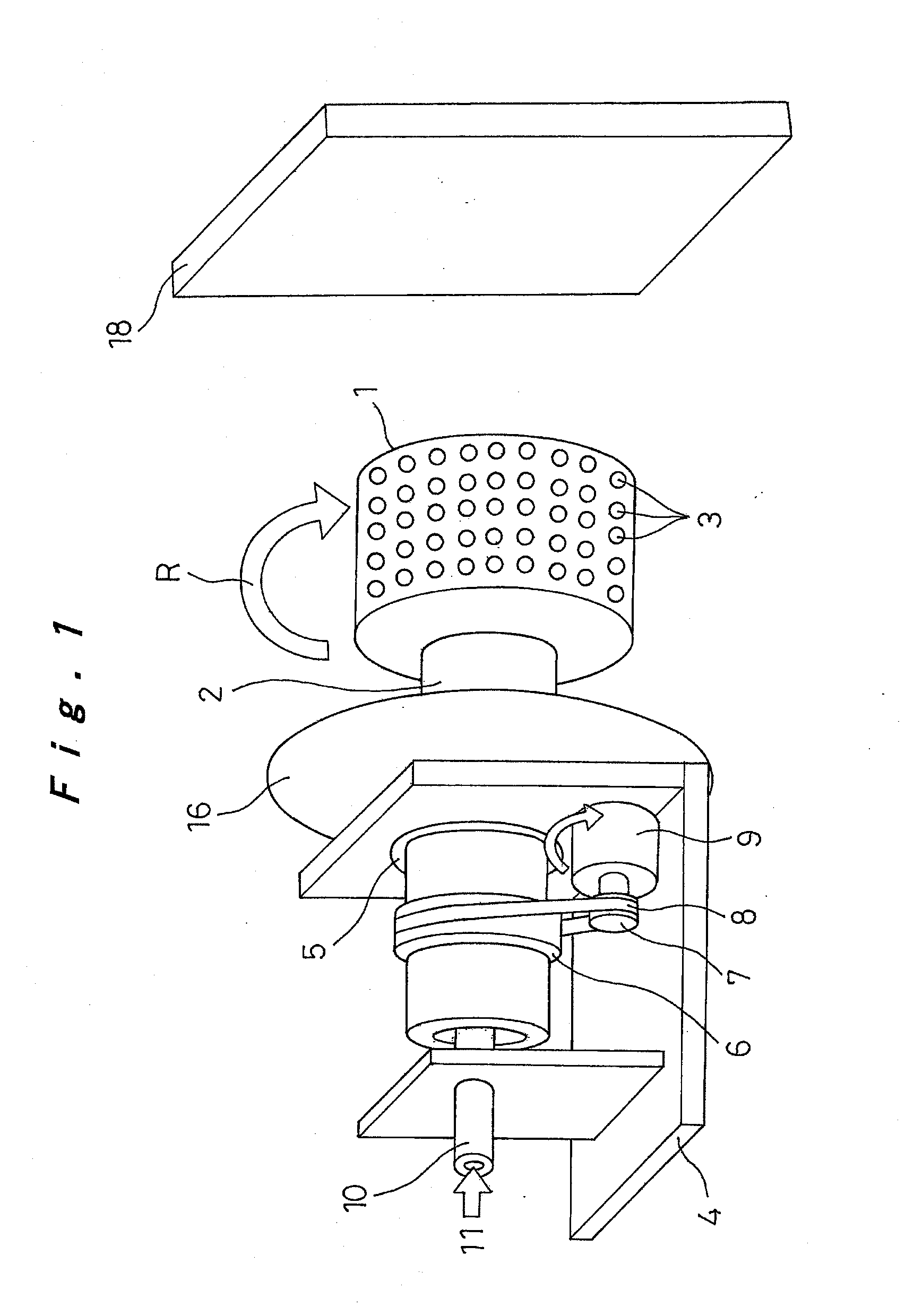

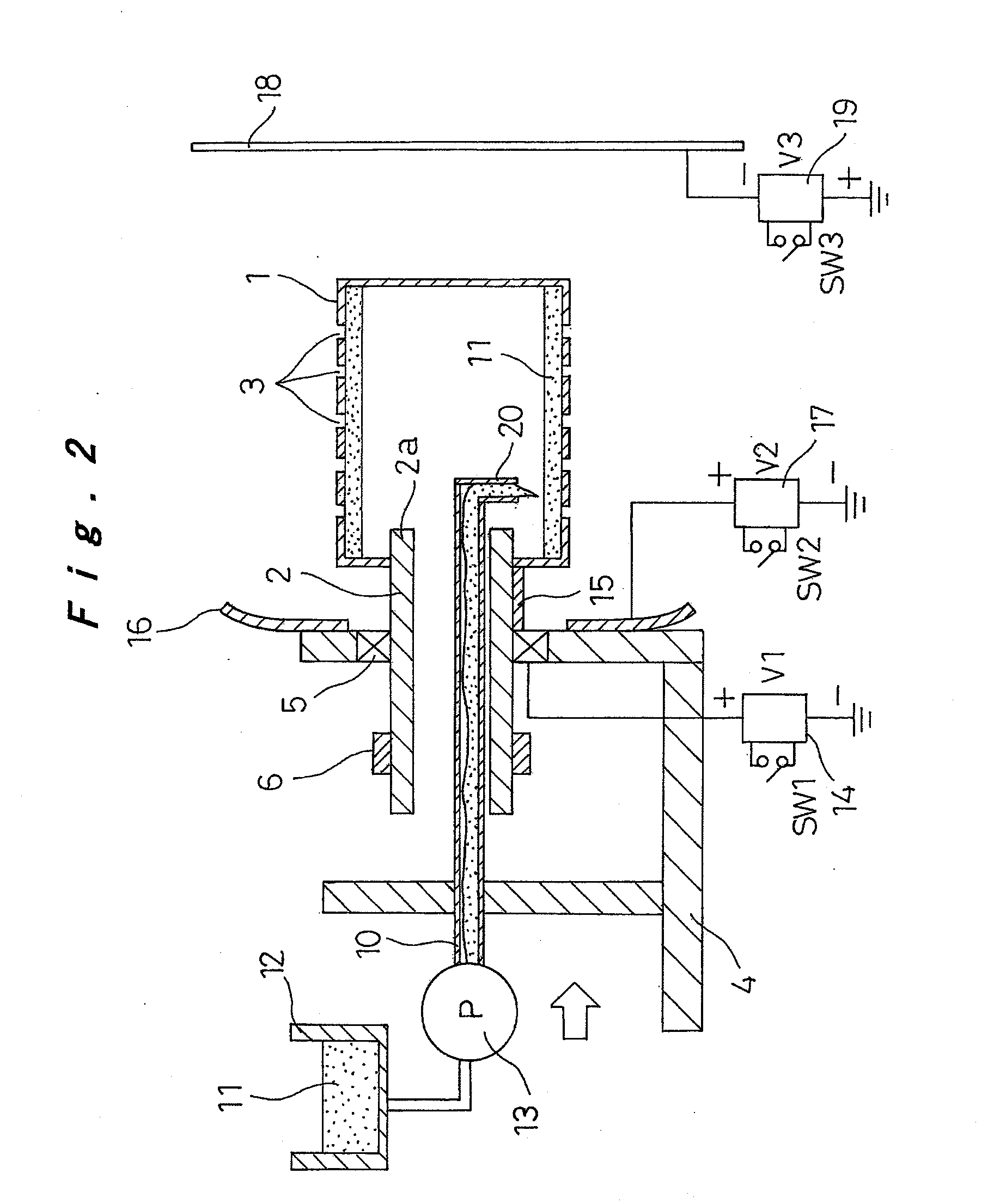

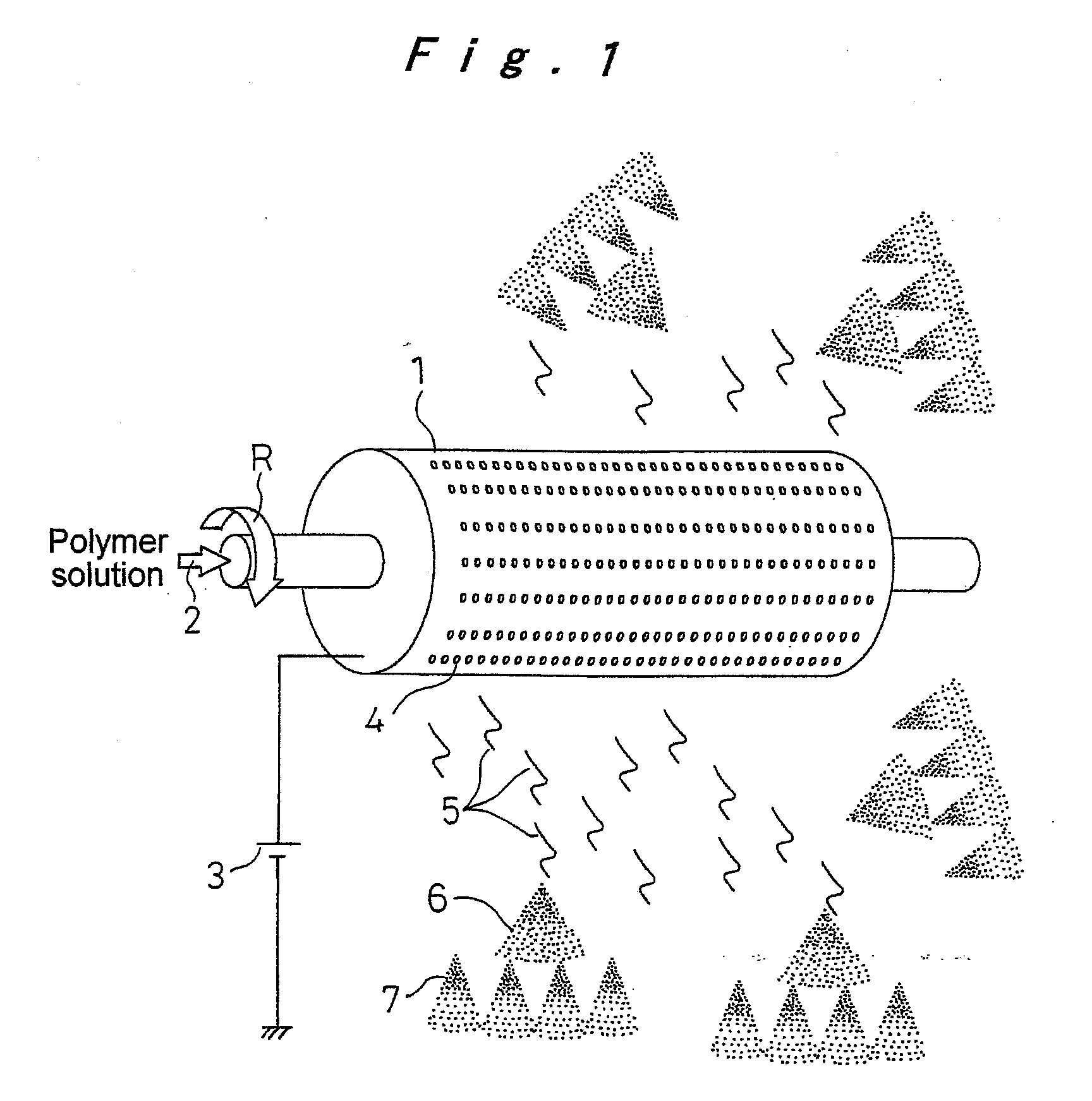

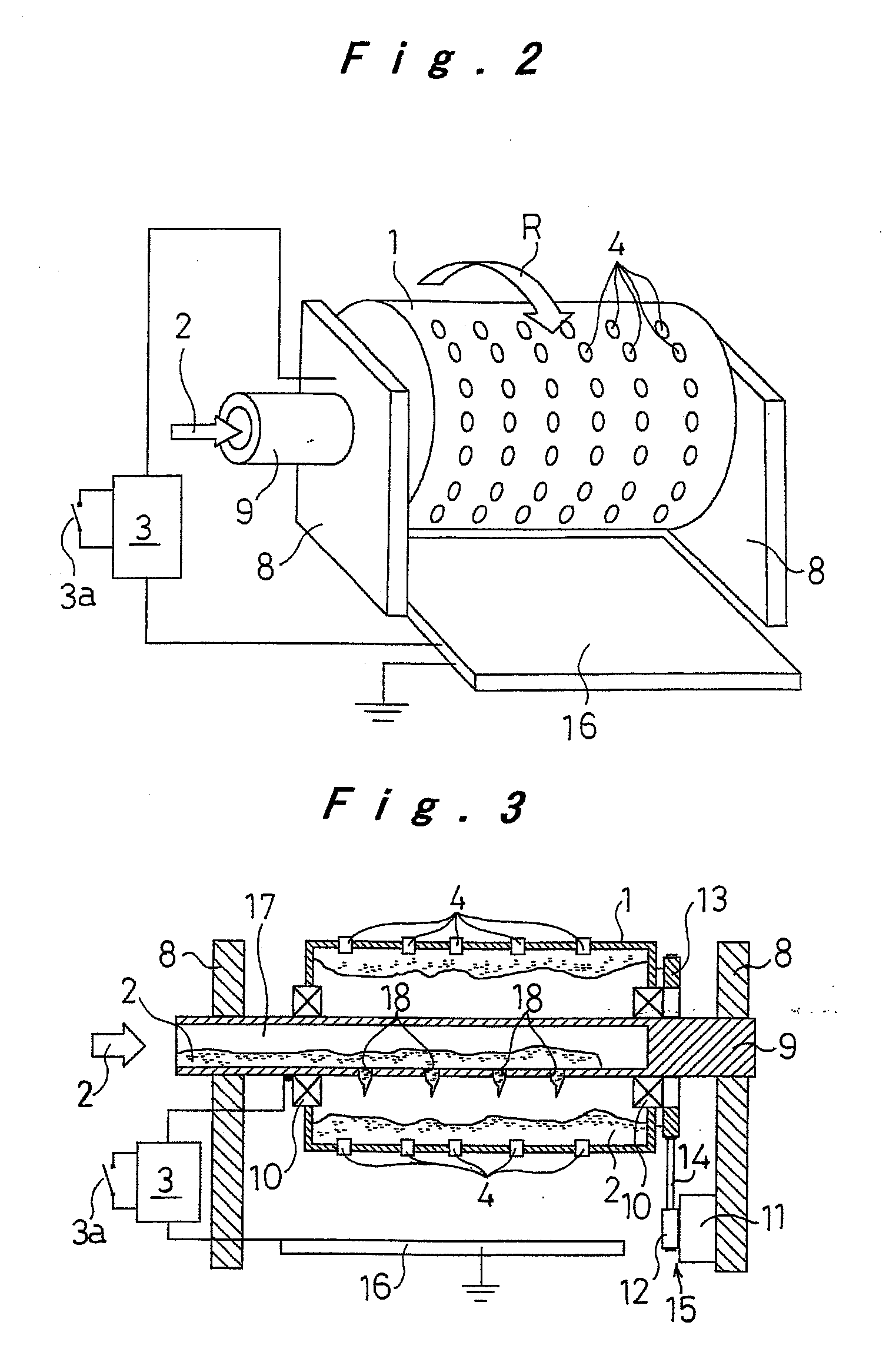

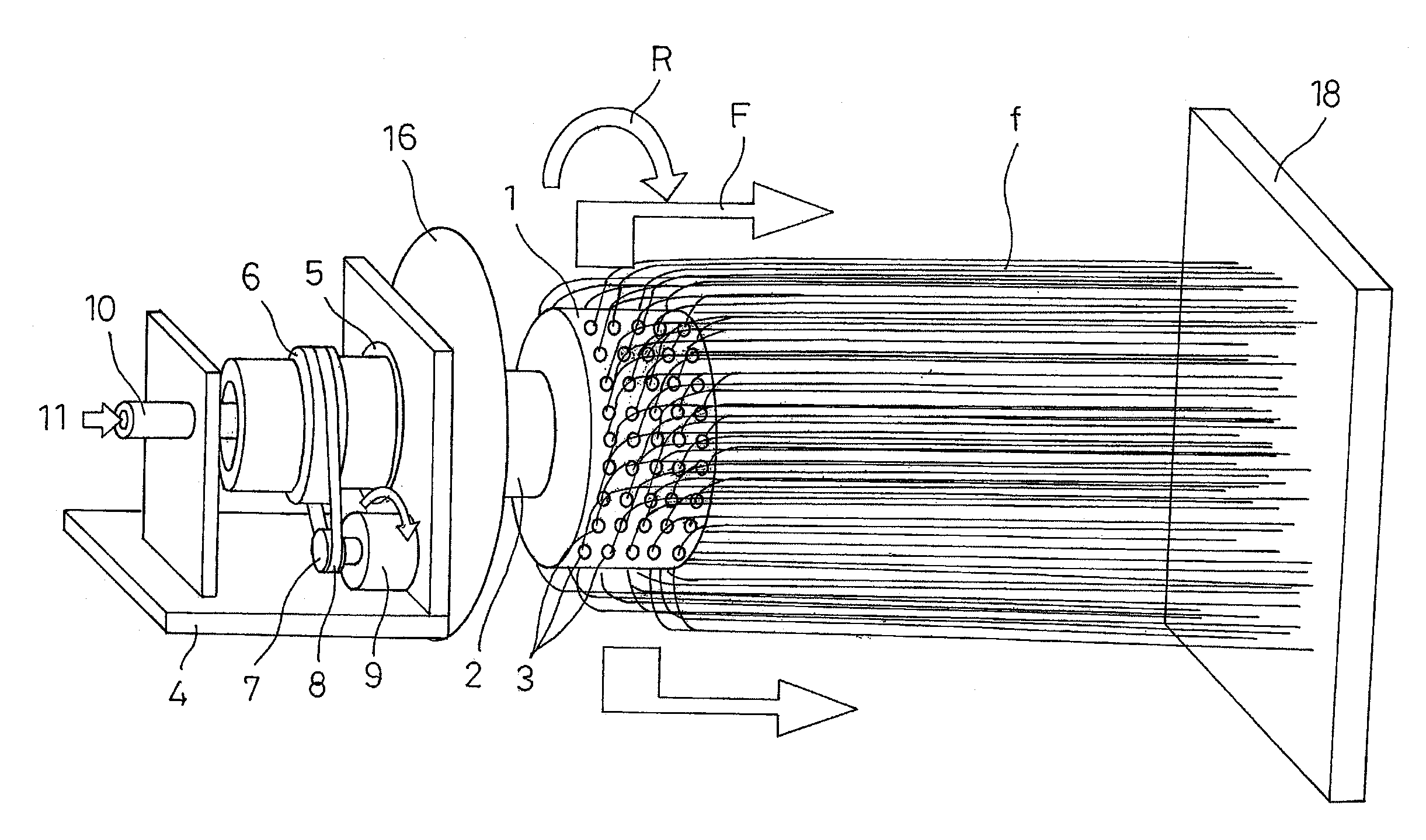

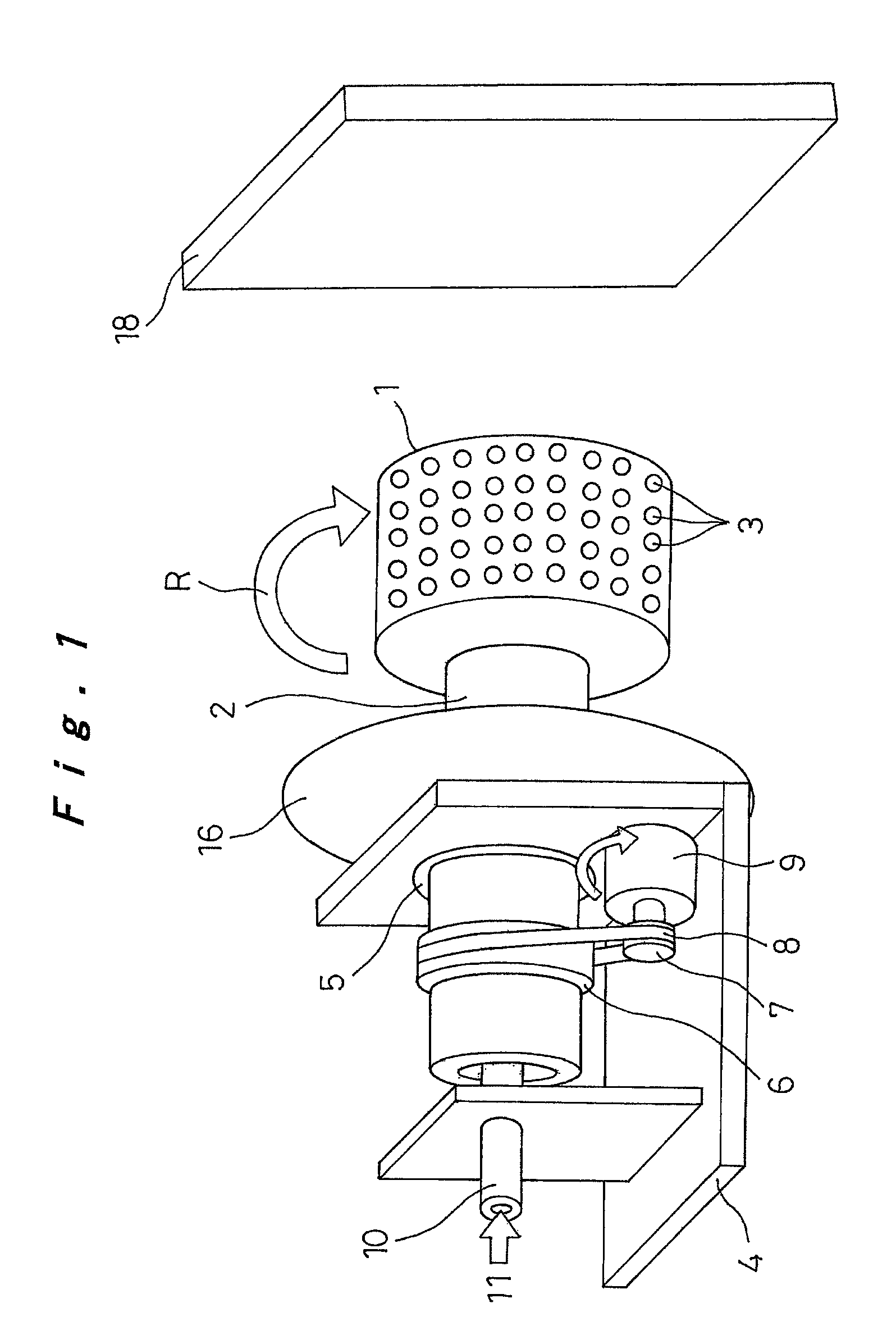

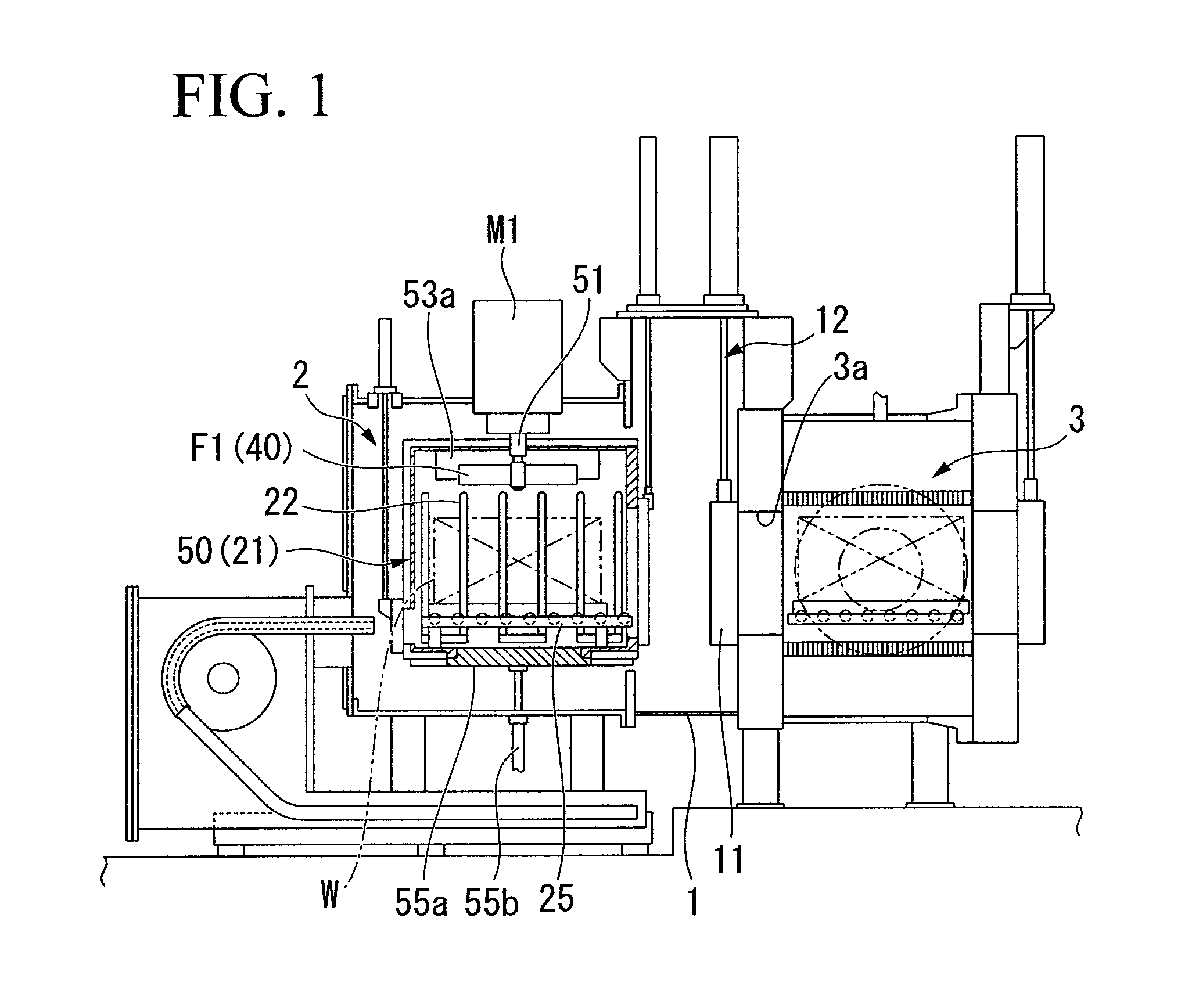

Method and apparatus for producing nanofibers and polymer web

ActiveUS20100072674A1Efficient and stable productionEnsure efficient flowElectric discharge heatingFilament/thread formingProduction rateNanofiber

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

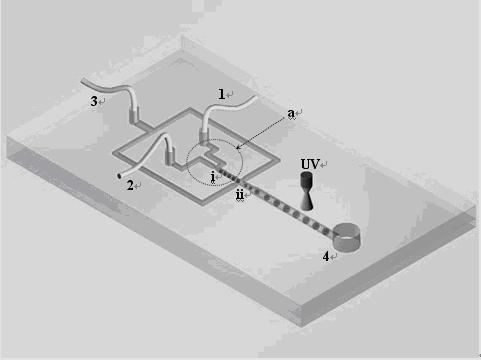

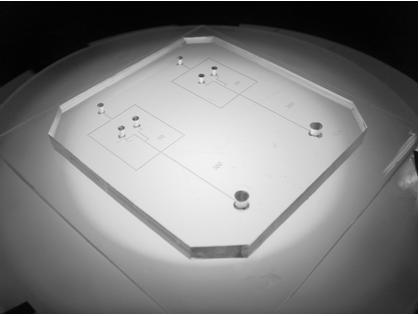

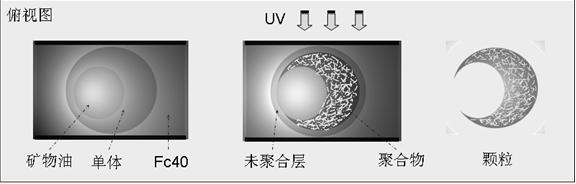

Method for synthesizing nonspherical polymer microparticles

The invention provides a method for synthesizing nonspherical hydrogel microparticles. In a first stage, oil-in-water droplets are formed by adopting a T-channel structure; and in a second stage, oil / water / oil double emulsion is formed by adopting a flow focusing structure. Under the irradiation of ultraviolet light, the intermediate phase of the double emulsion is polymerized to form the hydrogel microparticles, and polymerization reaction on an interface of an external phase and the intermediate phase is suppressed, so that hydrogel cannot wrap internal-phase oil cores, and the hydrogel microparticles taking the internal-phase oil cores as templates are formed. The method has the advantages that: the volume velocity ratio of the internal phase to the intermediate phase is controlled to form a series of hydrogel microparticles with similar shapes; the number of internal cores of single double emulsion is controlled to form hydrogel microparticles with different shapes such as meniscal shapes and polypod shapes; additives in a monomer solution are controlled to form hydrogel microparticles with special functions such as fluorescence and magnetism; and compared with microparticles formed by a photoetching method, the microparticles formed by the method have three-dimensional shape structures.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Coenzyme-linked glucose dehydrogenase and polynucleotide encoding the same

ActiveUS8691547B2Maintain good propertiesLow activity toward maltoseAnimal cellsBacteriaNucleotidePolynucleotide

The present invention provides members that produce on a large scale a coenzyme-linked glucose dehydrogenase which has excellent substrate-recognizing ability toward glucose while providing low action on maltose. The present invention relates to a polynucleotide encoding a soluble coenzyme-linked glucose dehydrogenase that catalyzes the oxidation of glucose in the presence of an electron acceptor and has an activity toward maltose of 5% or lower; a polypeptide encoded by the nucleotide sequence of the polynucleotide; a recombinant vector carrying the polynucleotide; a transformed cell produced using the recombinant vector; a method for producing a polypeptide comprising culturing the transformed cell and collecting from the cultivated products a polypeptide that links to FAD to exert the glucose dehydration activity; a method for determination of glucose using the polypeptide; a reagent composition for determination of glucose; and a biosensor.

Owner:PHC CORP

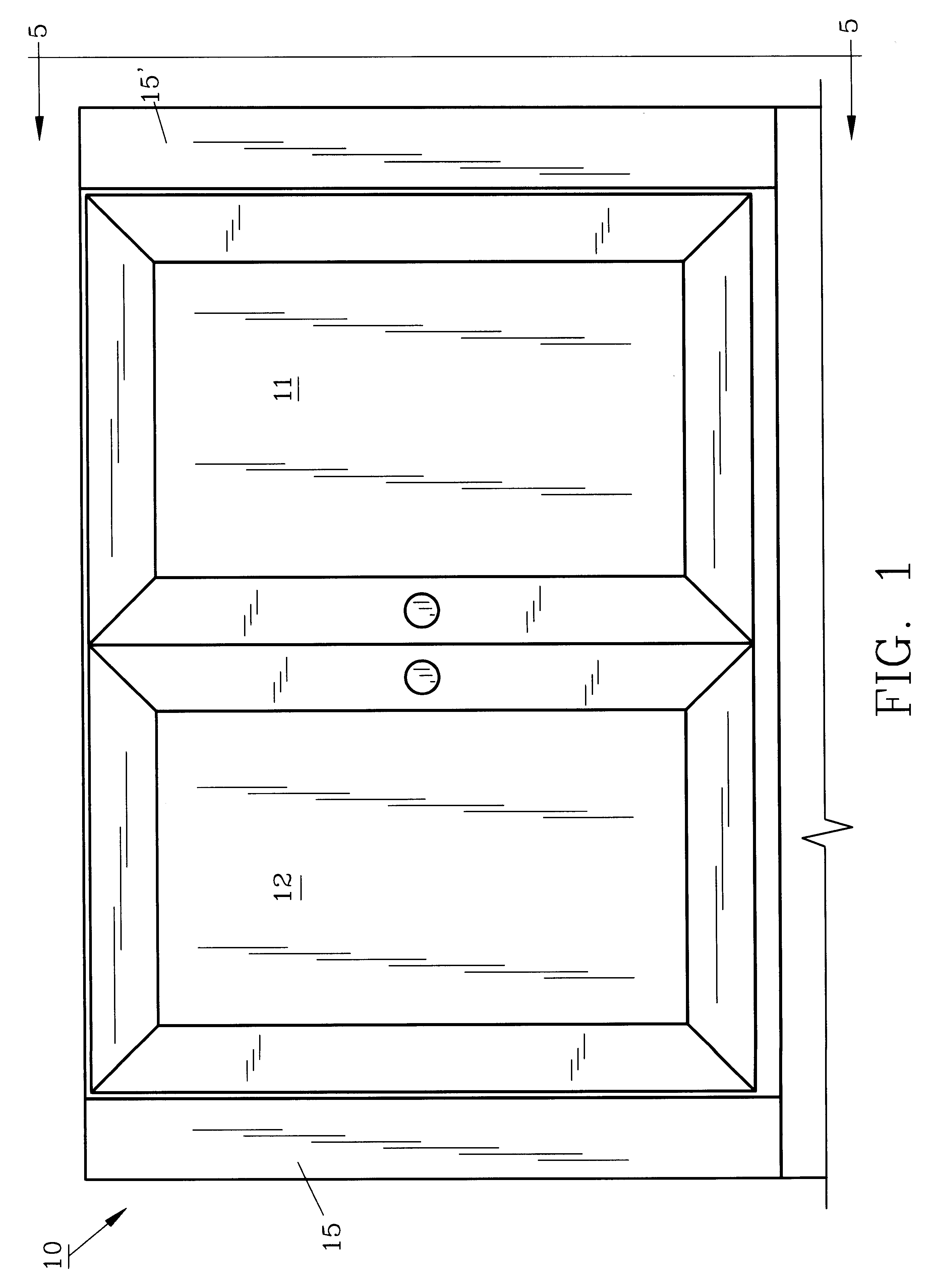

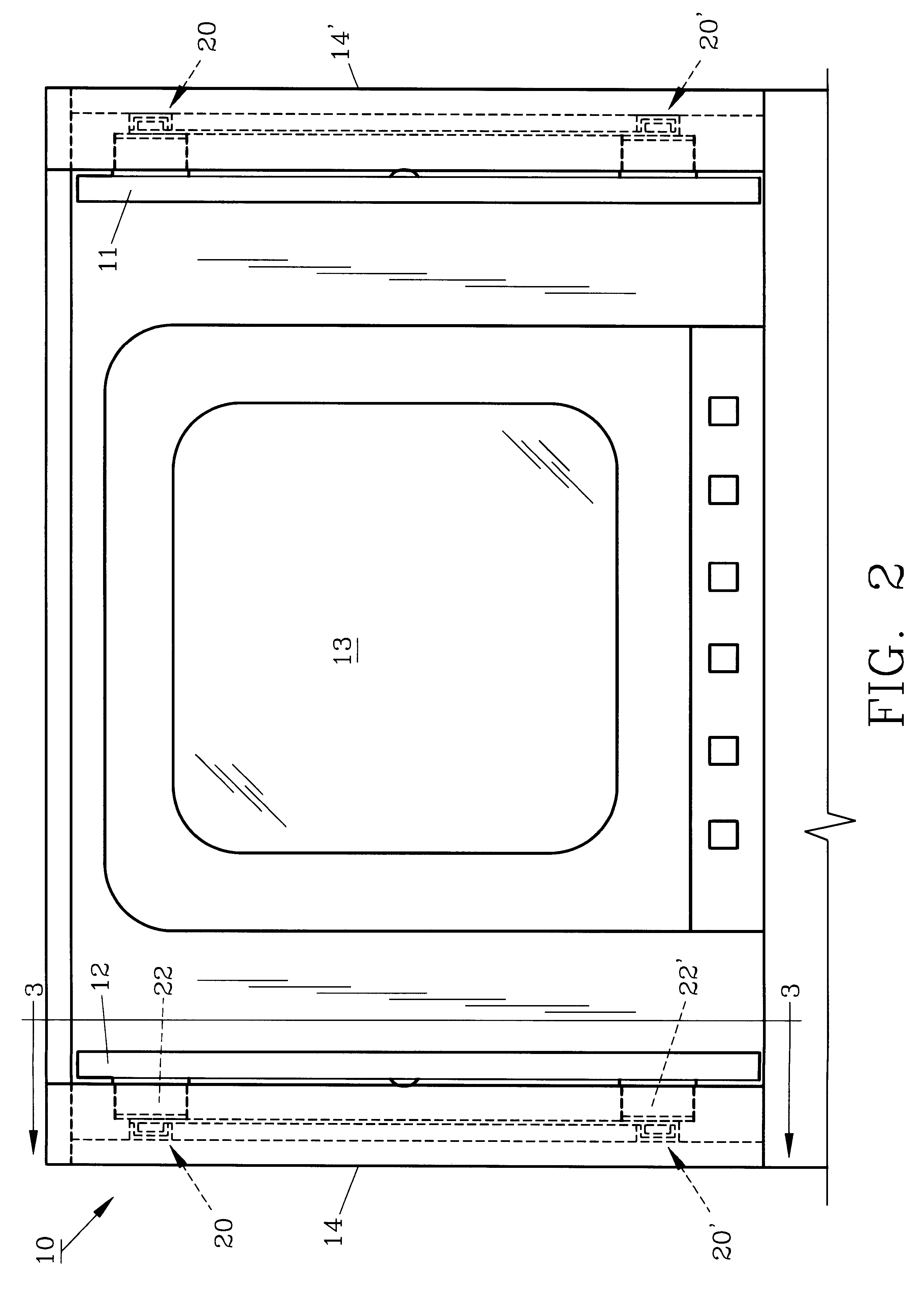

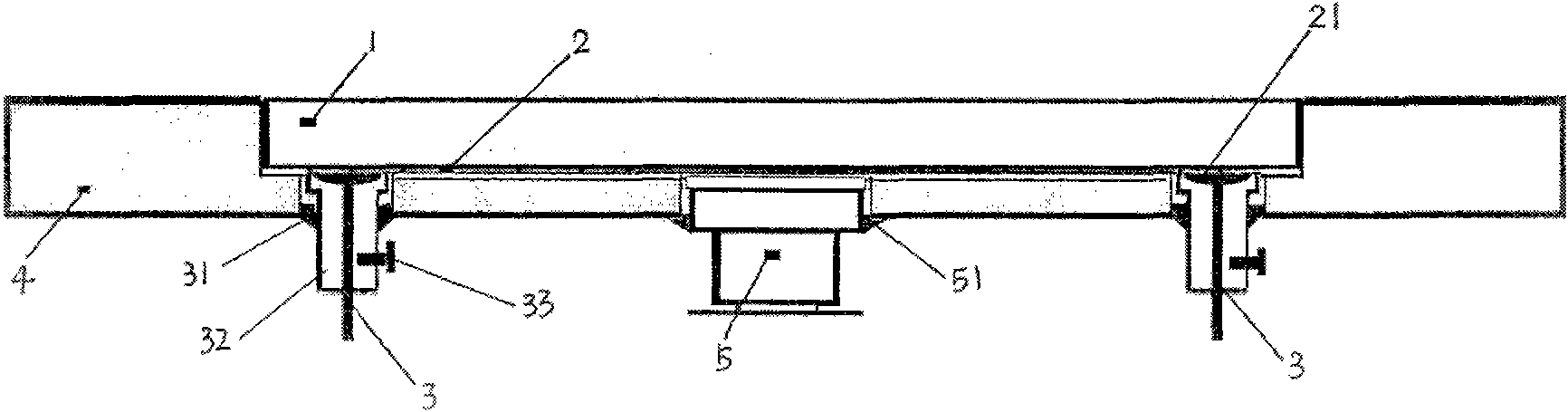

Sliding door hardware assembly and method

A hardware assembly is provided for cabinet sliding doors as are used with entertainment centers. The hardware assembly includes a u-shaped spacer which is attached to a slotted plate in selective fashion to provide infinite relative positioning. The hardware assembly can be quickly installed and adjusted by inexperienced personnel which is useful in finishing the cabinet and thereafter, daily usage.

Owner:LYON JOHN E

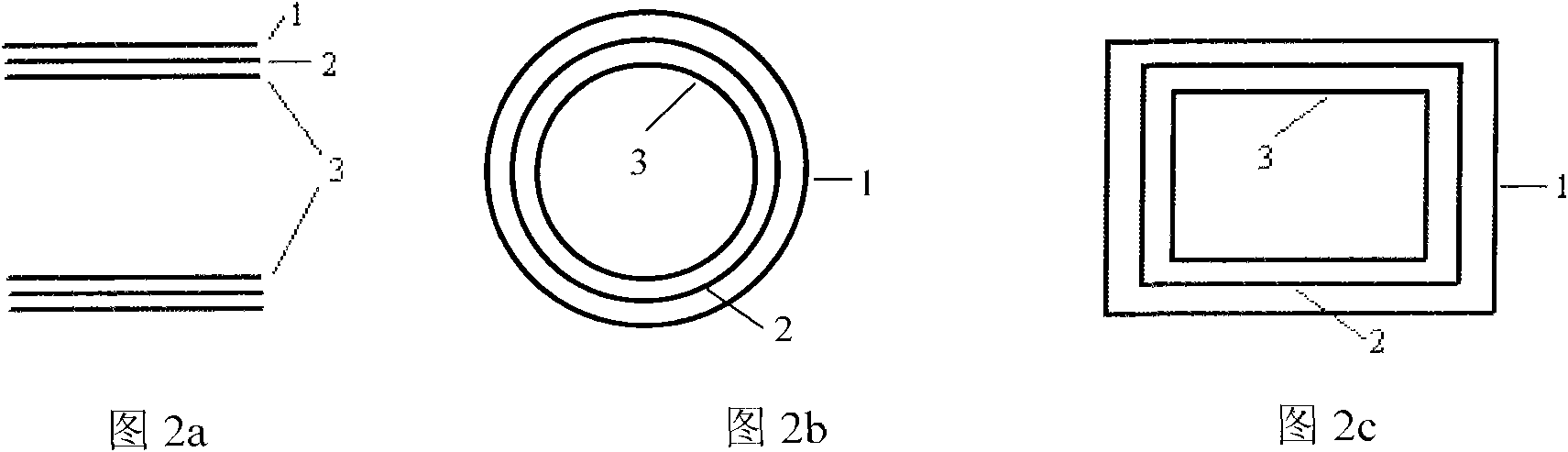

Dielectric barrier corona discharge reactor

InactiveCN102026468AReduce air gap discharge field strengthArcing suppressionPlasma techniqueCorona dischargeStrong pulse

The invention discloses a dielectric barrier corona discharge reactor which comprises an outer electrode, an inner electrode and a dielectric barrier layer positioned between the outer electrode and the inner electrode, wherein the outer electrode is connected with a power supply, and the inner electrode is grounded. The dielectric barrier corona discharge reactor can generate and transmit more charges under same external voltage and discharge spatial clearance due to corona ionization effect and simultaneously output higher discharge power. The dielectric barrier corona discharge reactor can obtain stronger pulse voltage and current during discharge and enable energy during the discharge to be more centralized.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

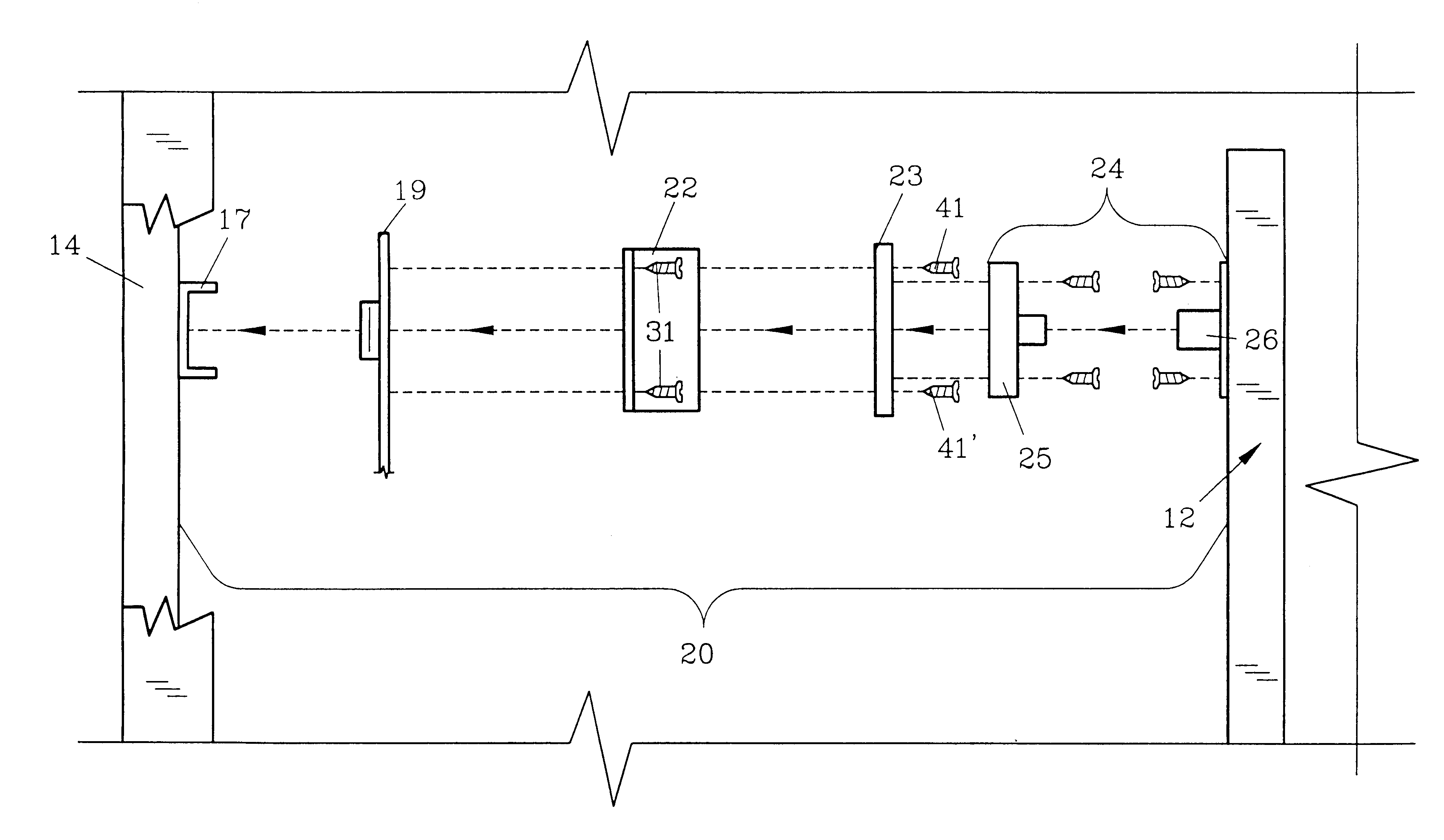

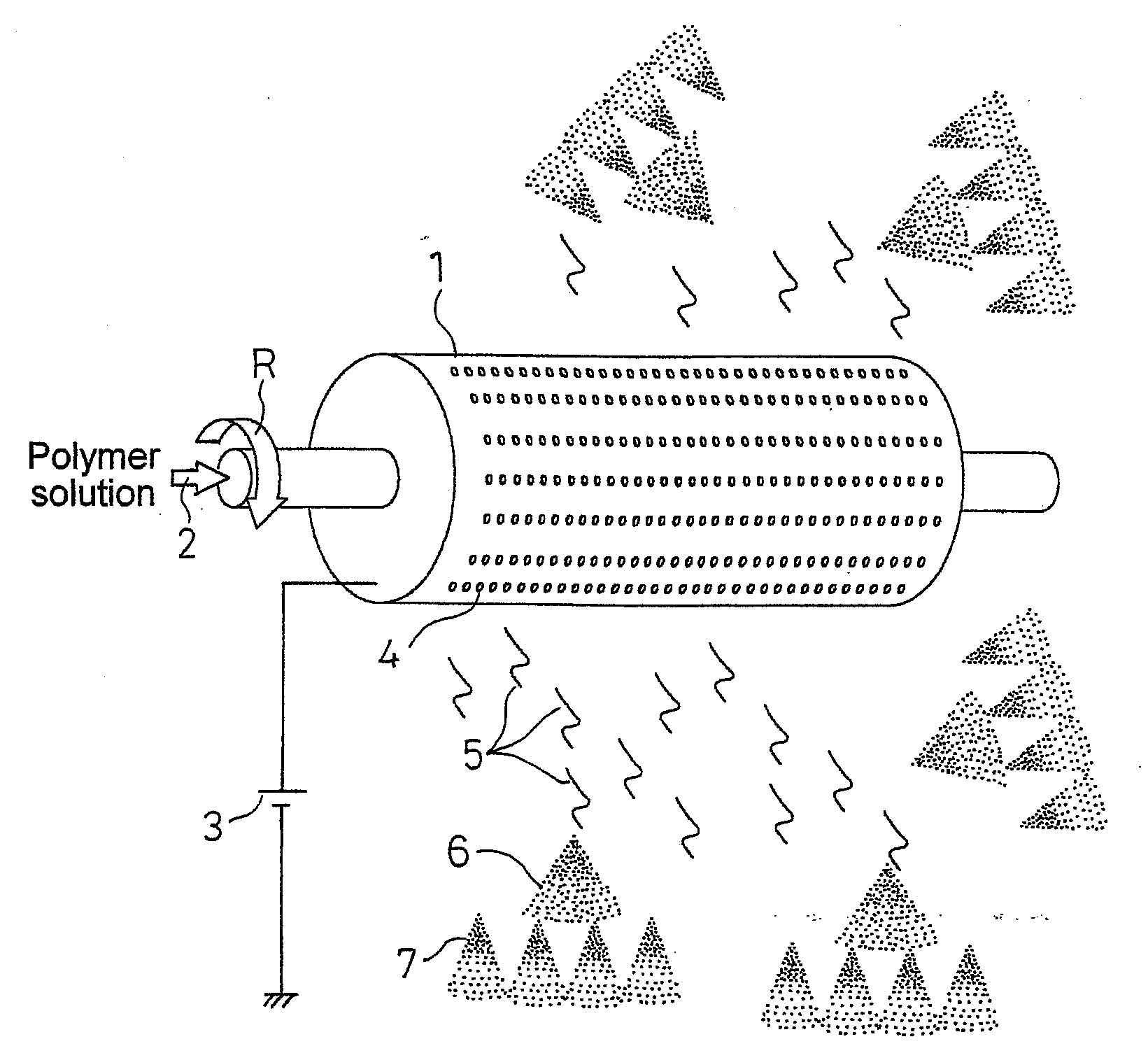

Method and apparatus for producing nanofibers and polymeric webs

InactiveUS20090127748A1Simplify solutionLarge potential differenceElectric discharge heatingFilament/thread formingSolventProduction rate

A polymer solution that is prepared by dissolving a polymeric substance in a solvent is supplied into a cylindrical container serving as a rotating container having a plurality of small holes. The cylindrical container is driven to rotate by rotation drive means, and an electric field is applied by high voltage generating means to polymeric filaments discharged from the small holes so that they become electrically charged. Then, primary and secondary electrostatic explosions associated with the centrifugal force and the evaporation of the solvent take place, drawing the polymeric filaments and producing nanofibers made of the polymeric substance. These nanofibers are deposited to produce a polymeric web. Accordingly, by employing a simple structure, nanofibers and a polymeric web utilizing them can be produced evenly with excellent productivity.

Owner:PANASONIC CORP

Plasma processing apparatus

ActiveUS8314560B2Retain axial symmetryImprove uniformityElectric discharge tubesElectric arc lampsProjection planePlasma processing

Owner:SAMCO

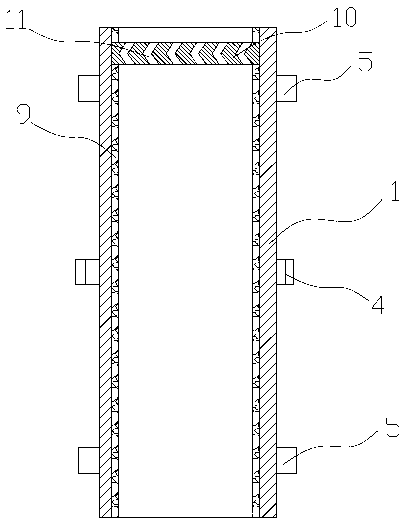

Novel electrical heating unit

InactiveCN102045900AGood thermal conductivityImprove heat utilizationOhmic-resistance heatingHeating filmAlumina ceramic

The invention relates to a novel electrical heating unit which at least comprises a substrate and an electrical heating film attached to the substrate, wherein the at least one substrate is made of aluminum oxide ceramics; the aluminum oxide ceramic substrate is in a plane-shaped structure; and at least one electrical heating film is attached to at least one surface of the aluminum oxide ceramic substrate. Thus, the electrical heating films can generate heat on one surface of the substrate, on which the electrical heating film is arranged, and the heat is evenly generated from the attached surface and transmitted through the aluminum oxide ceramic substrate so as to generate uniform heating effect.

Owner:潘洁英

Coenzyme-Linked Glucose Dehydrogenase and Polynucleotide Encoding the Same

ActiveUS20120122130A1Maintain good propertiesReduced activityFungiBacteriaNucleotideGlucose polymers

The present invention provides members that produce on a large scale a coenzyme-linked glucose dehydrogenase which has excellent substrate-recognizing ability toward glucose while providing low action on maltose. The present invention relates to a polynucleotide encoding a soluble coenzyme-linked glucose dehydrogenase that catalyzes the oxidation of glucose in the presence of an electron acceptor and has an activity toward maltose of 5% or lower; a polypeptide encoded by the nucleotide sequence of the polynucleotide; a recombinant vector carrying the polynucleotide; a transformed cell produced using the recombinant vector; a method for producing a polypeptide comprising culturing the transformed cell and collecting from the cultivated products a polypeptide that links to FAD to exert the glucose dehydration activity; a method for determination of glucose using the polypeptide; a reagent composition for determination of glucose; and a biosensor.

Owner:PHC CORP

Method and apparatus for producing nanofibers and polymer web

ActiveUS8110136B2Efficient and stable productionEnsure efficient flowElectric discharge heatingPhysical treatmentProduction rateEvaporation

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

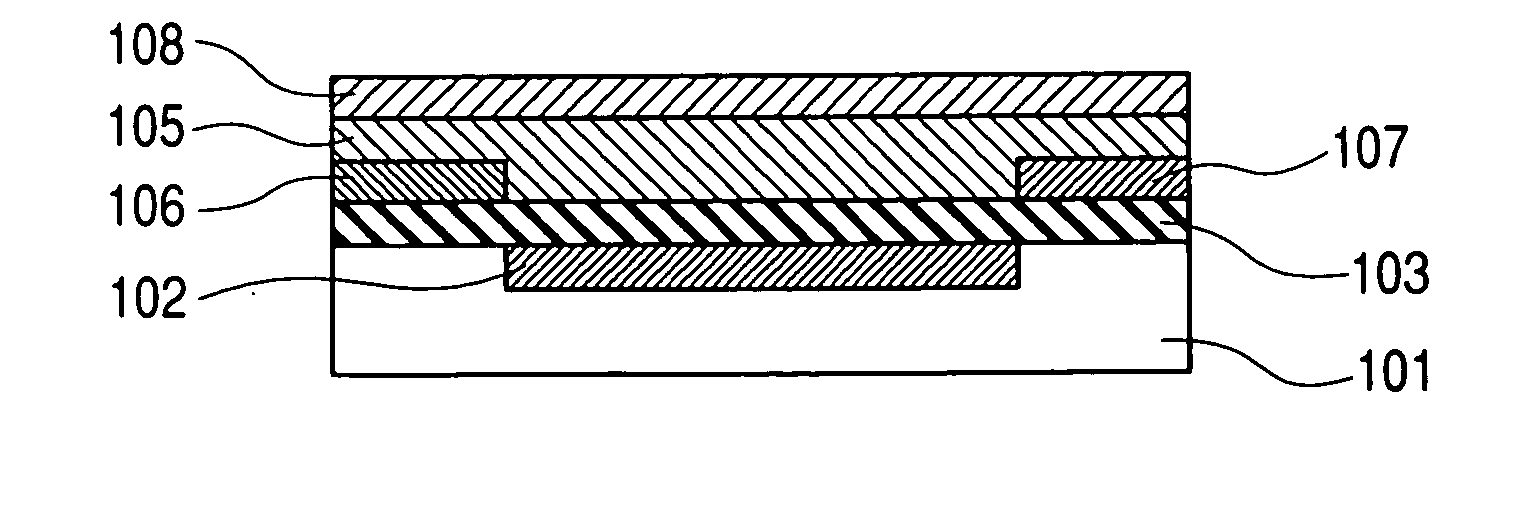

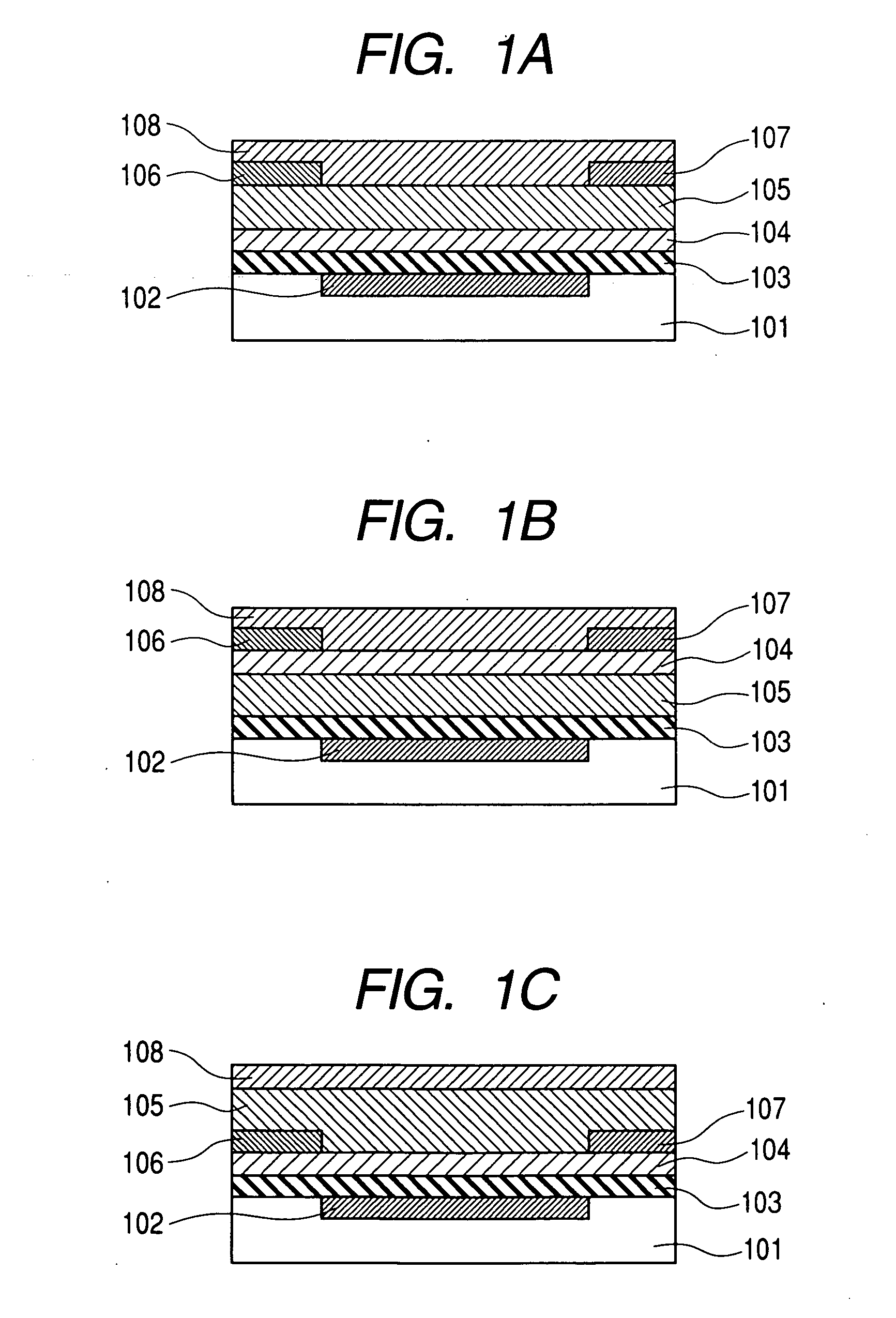

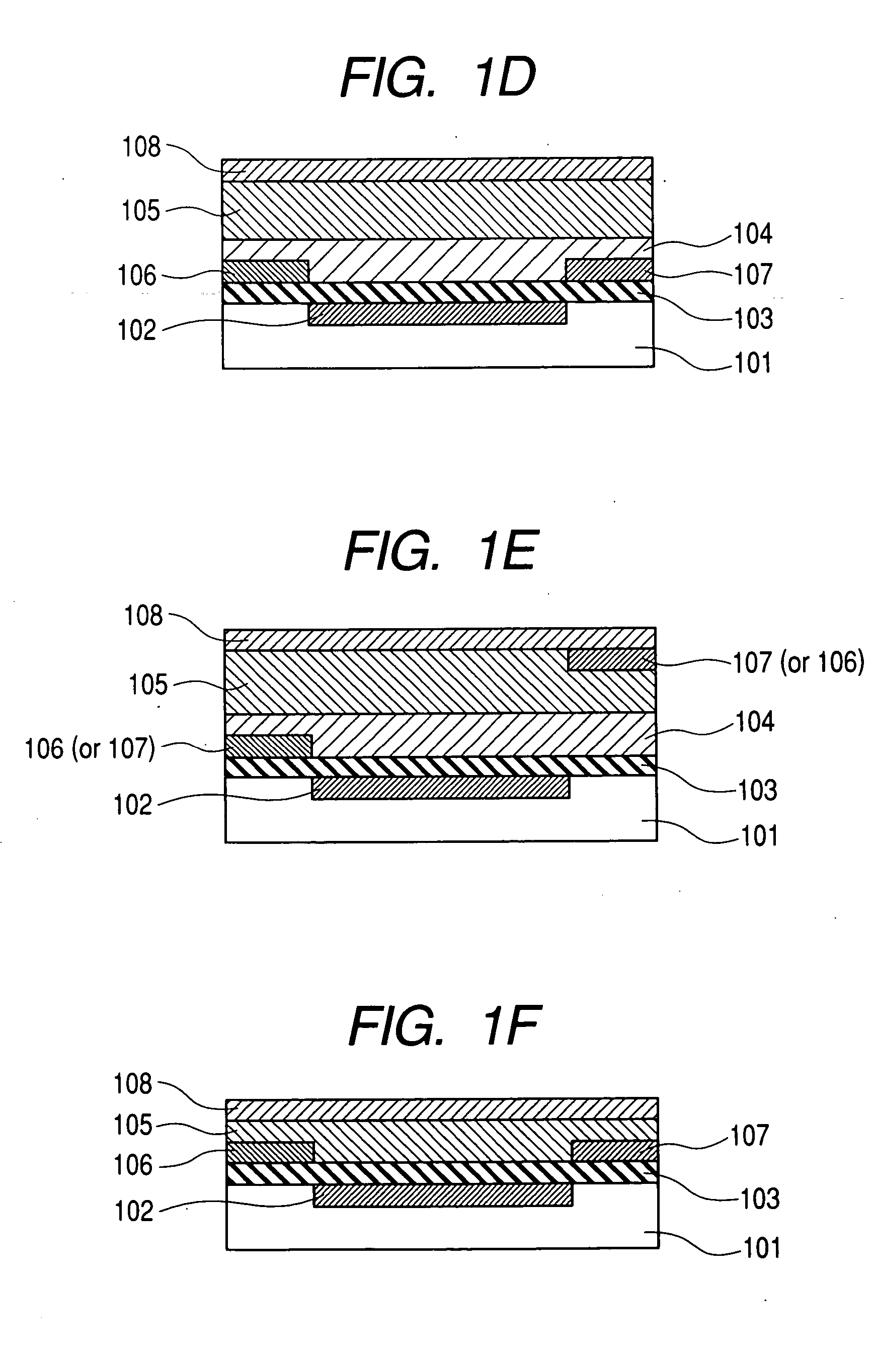

Organic semicounductor device, process for producing the same, and organic semiconductor apparatus

InactiveUS20050287697A1Low costImprove mobilityTransistorSemiconductor/solid-state device detailsElectrical conductorOrganic semiconductor

The present invention provides an organic semiconductor device, which can be produced uniformly on a large substrate, having a high mobility and capable of greatly modulating the drain current by varying the voltage applied to a gate electrode. The present invention provides an organic semiconductor device having at least a substrate, an organic semiconductor, a gate insulating film and conductors, and having electrodes for applying bias, wherein a polymer layer, which is different from the gate insulating film, is provided in contact with the organic semiconductor, and the polymer layer is formed of a copolymer of methyl methacrylate and divinylbenzene, or the like; a process for producing the organic semiconductor device; and an organic semiconductor apparatus using the organic semiconductor device.

Owner:CANON KK

Air-bleed gas turbine

InactiveUS20090000307A1Smooth and efficient rotationProduce uniformEngine manufacturePump componentsCombustorTurbine

An air-bleed gas turbine includes a compressor; a combustor; a turbine; and an air bleed portion by which compressed air, which is supplied from the compressor to a circular space that surrounds the combustor, is partially supplied to a device outside the air-bleed gas turbine. The air bleed portion includes an air bleed passage that is communicated with an air bleed port which is connected to the device outside the air-bleed gas turbine, and a communication passage that is communicated with the circular space. The air bleed passage is communicated with the circular space through the communication passage. The flow passage area of the communication passage is increased as the distance from the air bleed port increases in the circumferential direction of the circular space.

Owner:TOYOTA JIDOSHA KK

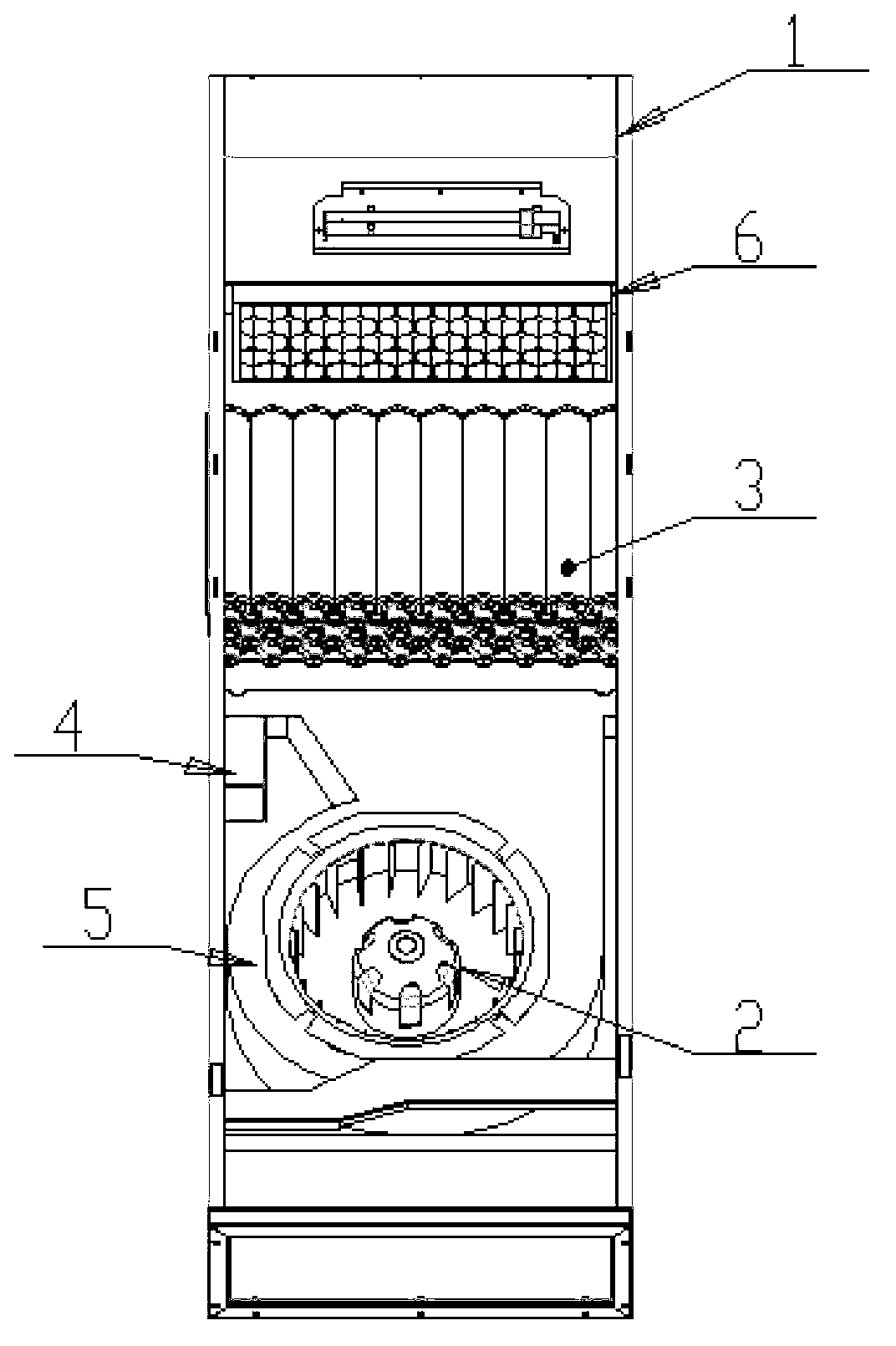

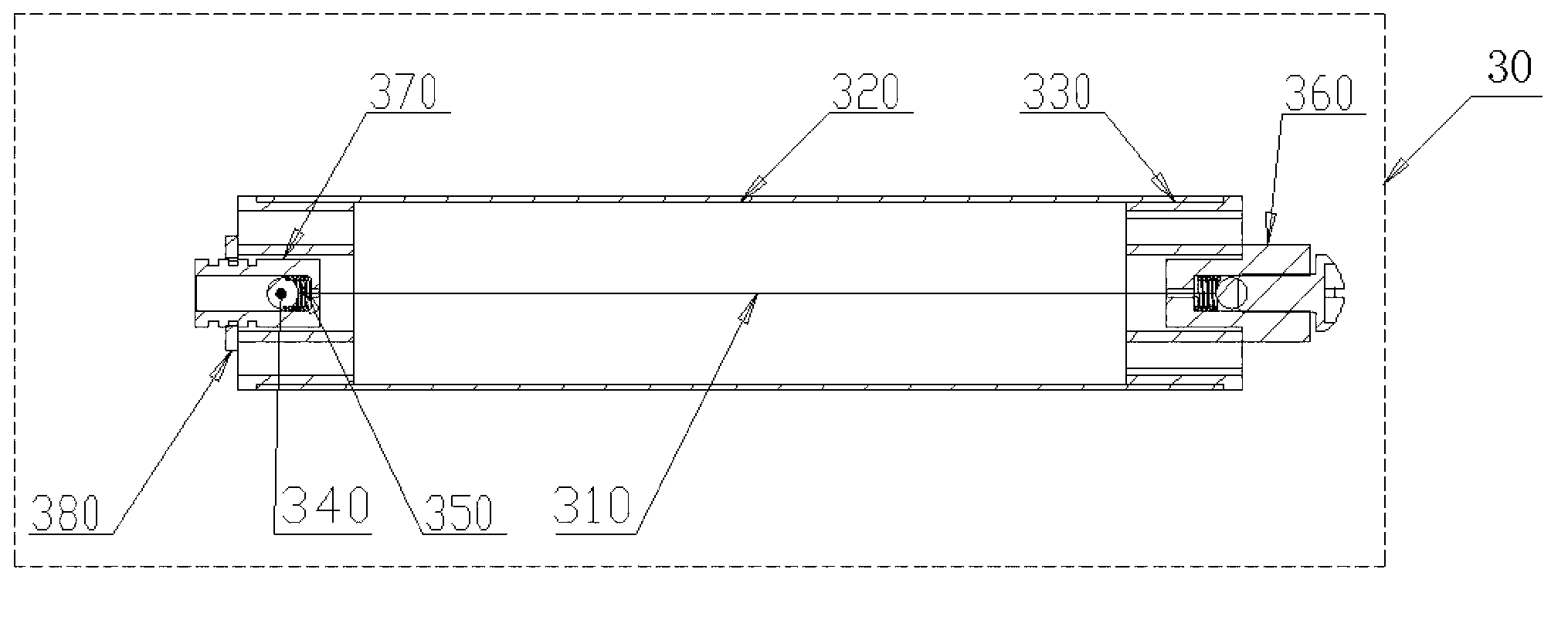

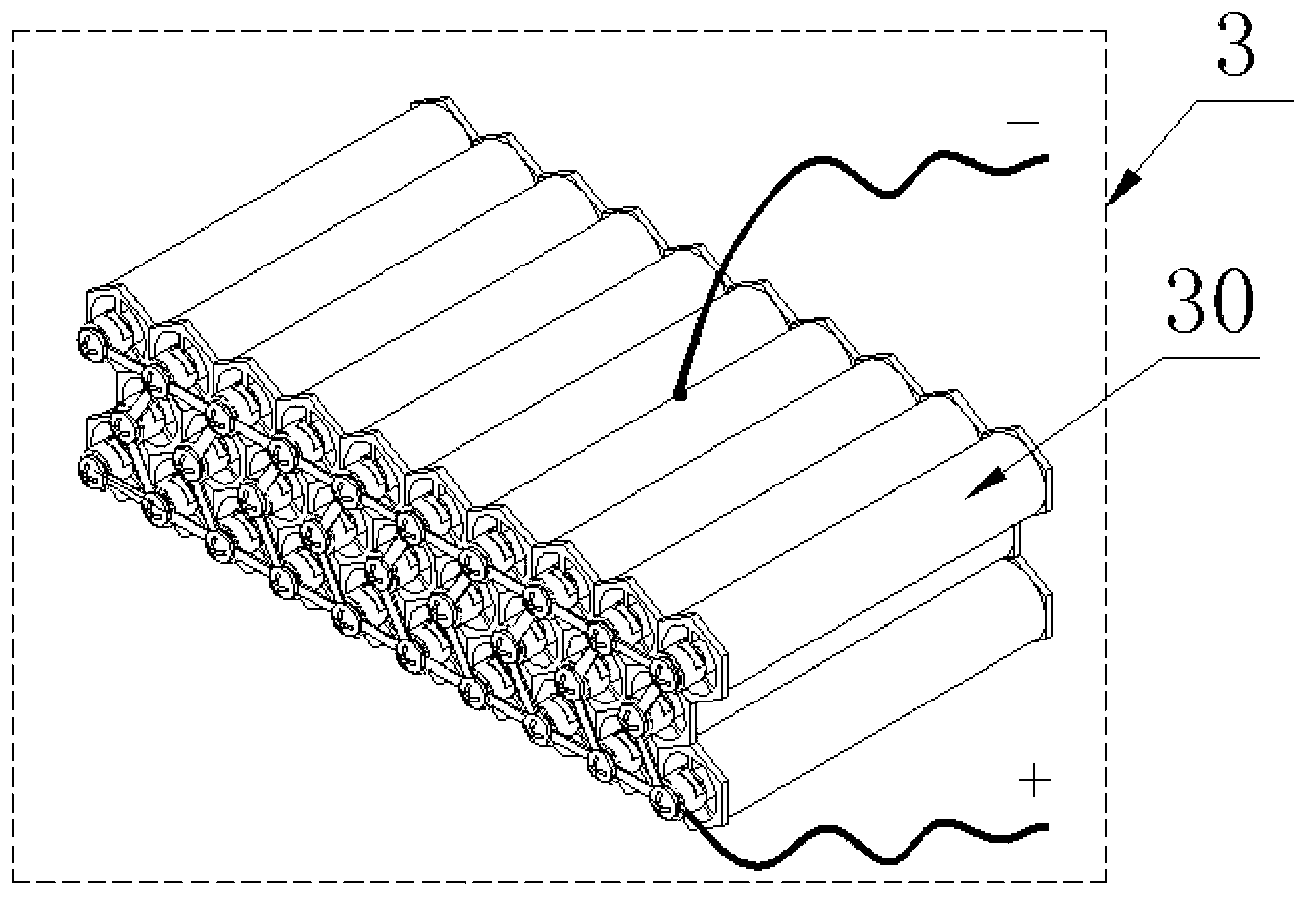

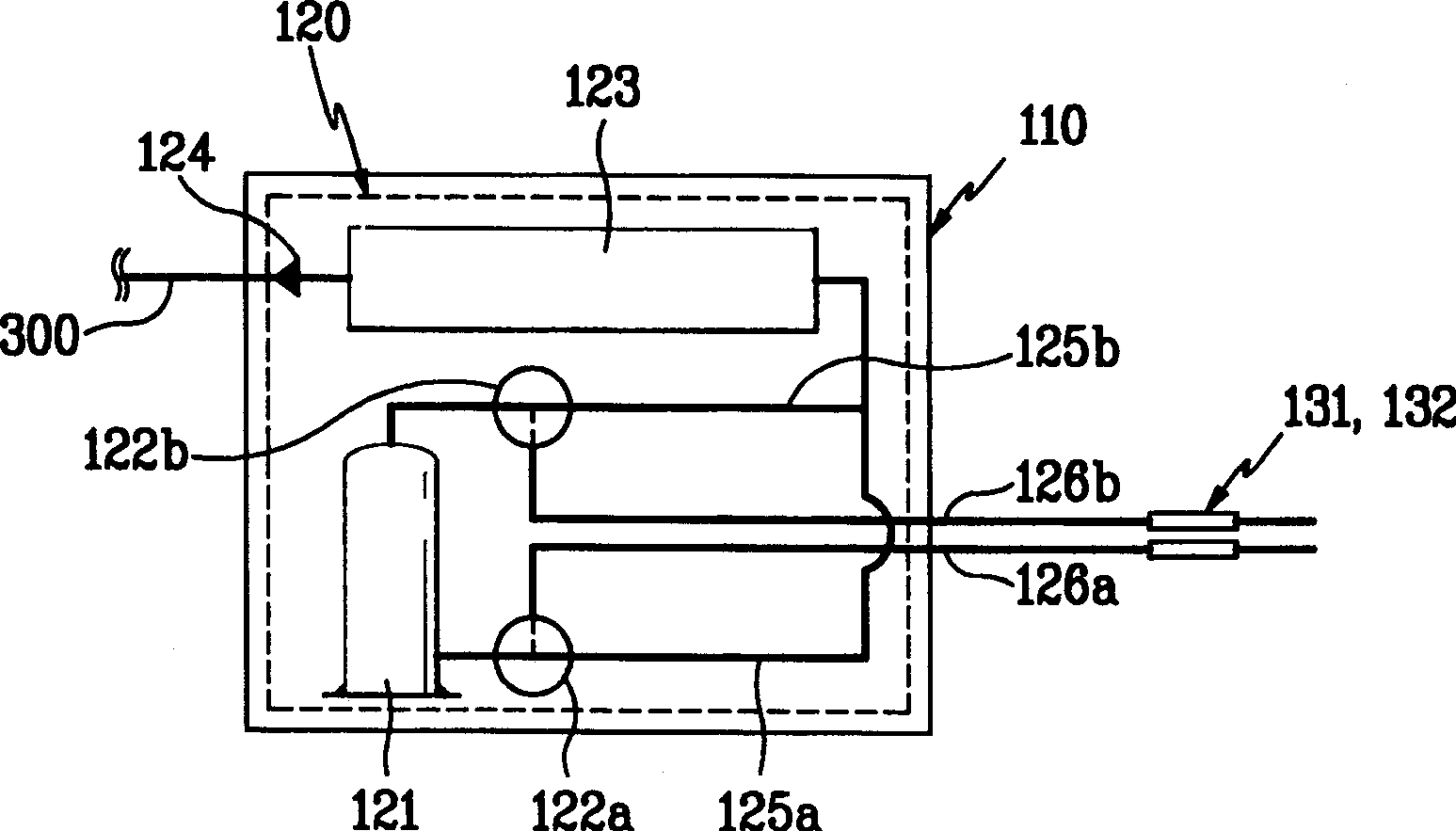

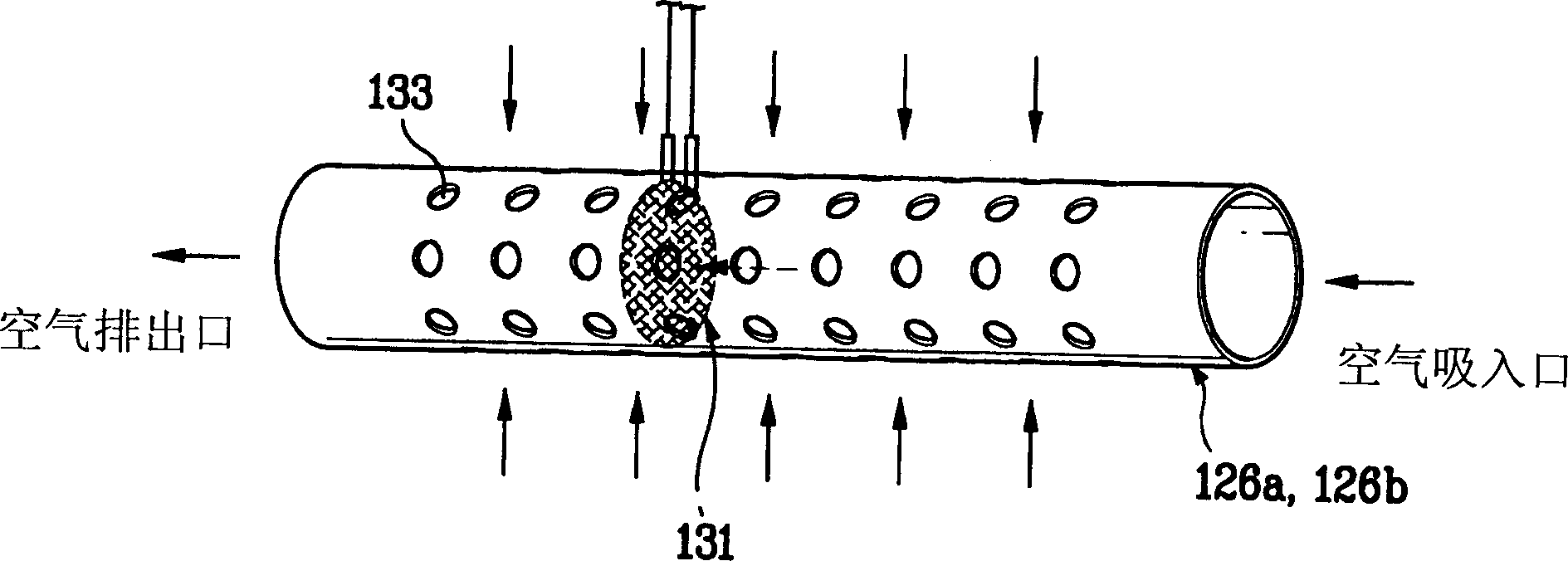

Plasma air disinfection machine

ActiveCN103007328AImprove stabilityImprove reliabilityDeodrantsPlasma generatorMechanical engineering

The invention discloses air purification and disinfection equipment capable of generating uniform high-concentration plasma. The equipment mainly comprises a housing (1), a fan (2), a plasma generator (3) and a boosting power supply (4), wherein the plasma generator (3) consists of a plurality of cylindrical plasma fundamental reaction units (30); the cylindrical plasma fundamental reaction units (30) comprise positive electrodes and negative electrodes; the positive electrodes are discharge electrode wires (310); the negative electrodes are hollow metallic circular tubes (320); the metallic circular tubes take the discharge electrode wires as center shafts; end covers (330) made of non-conducting insulation materials are arranged at the two ends of each metallic circular tube (320); and a plurality of hollow through holes (B) are formed in the two end covers (330). According to the equipment, air entering an air disinfection machine can be excited to be the uniform high-concentration plasma, so that indoor air can be disinfected, sterilized, dedusted and deodorized rapidly and effectively.

Owner:LAOKEN MEDICAL TECH

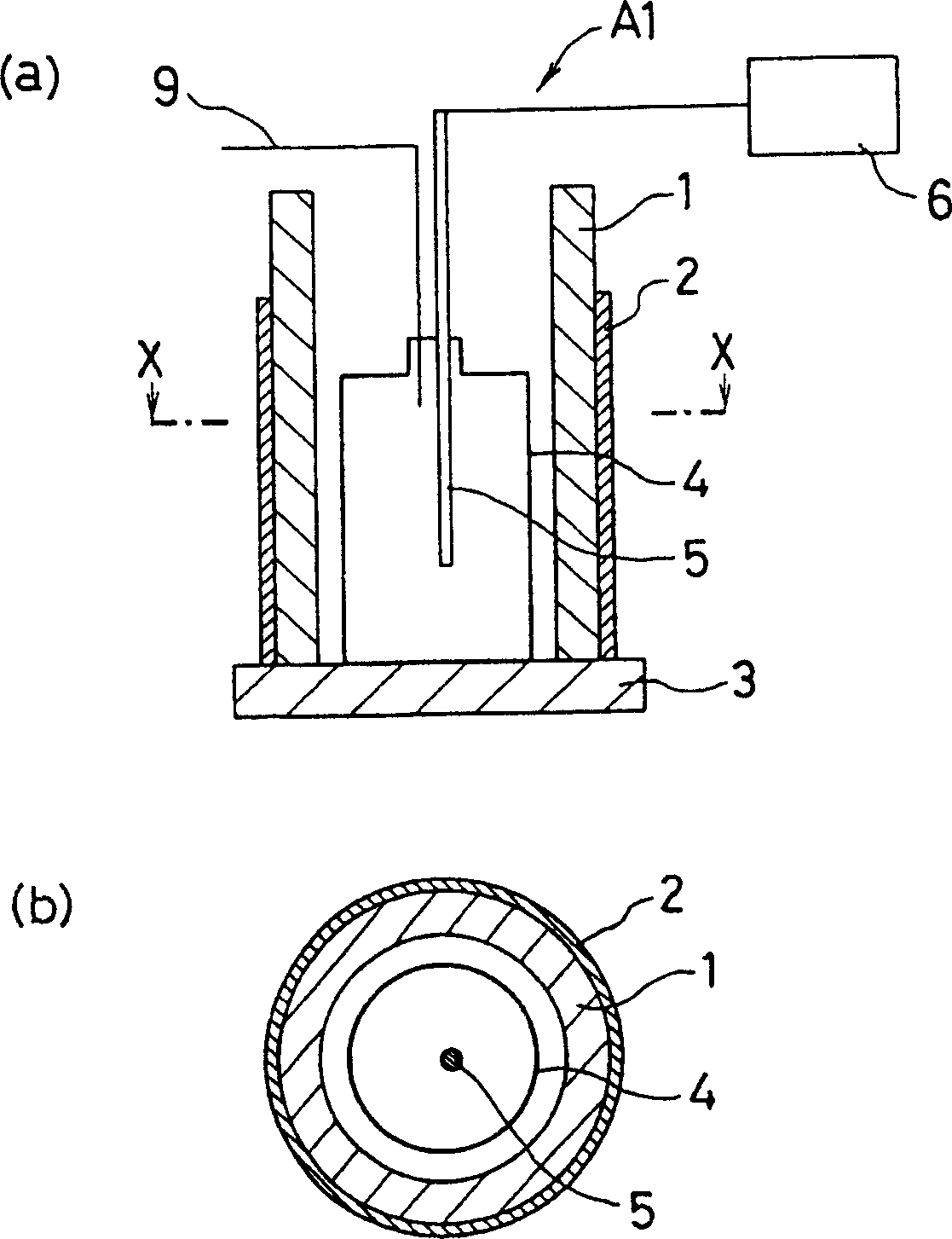

Apparatus and method for producing carbon film using plasm cvd and carbon film

ActiveUS20070104867A1Increase electron densityLow powerLamp detailsLuminescent screen lampsCarbon filmVacuum chamber

Provided is a method for uniformly producing a carbon film at a low cost with low power consumption. The method for producing a carbon film, including: a step of disposing a cylindrical member having an opening in part thereof in a vacuum chamber; a step of disposing a substrate inside the cylindrical member; a step of introducing a gas for carbon film production into the vacuum chamber; and a step of applying a voltage for plasma generation to the cylindrical member to thereby generate a plasma in the cylindrical member and to produce the carbon film on the surface of the substrate by the plasma.

Owner:PURERON JAPAN

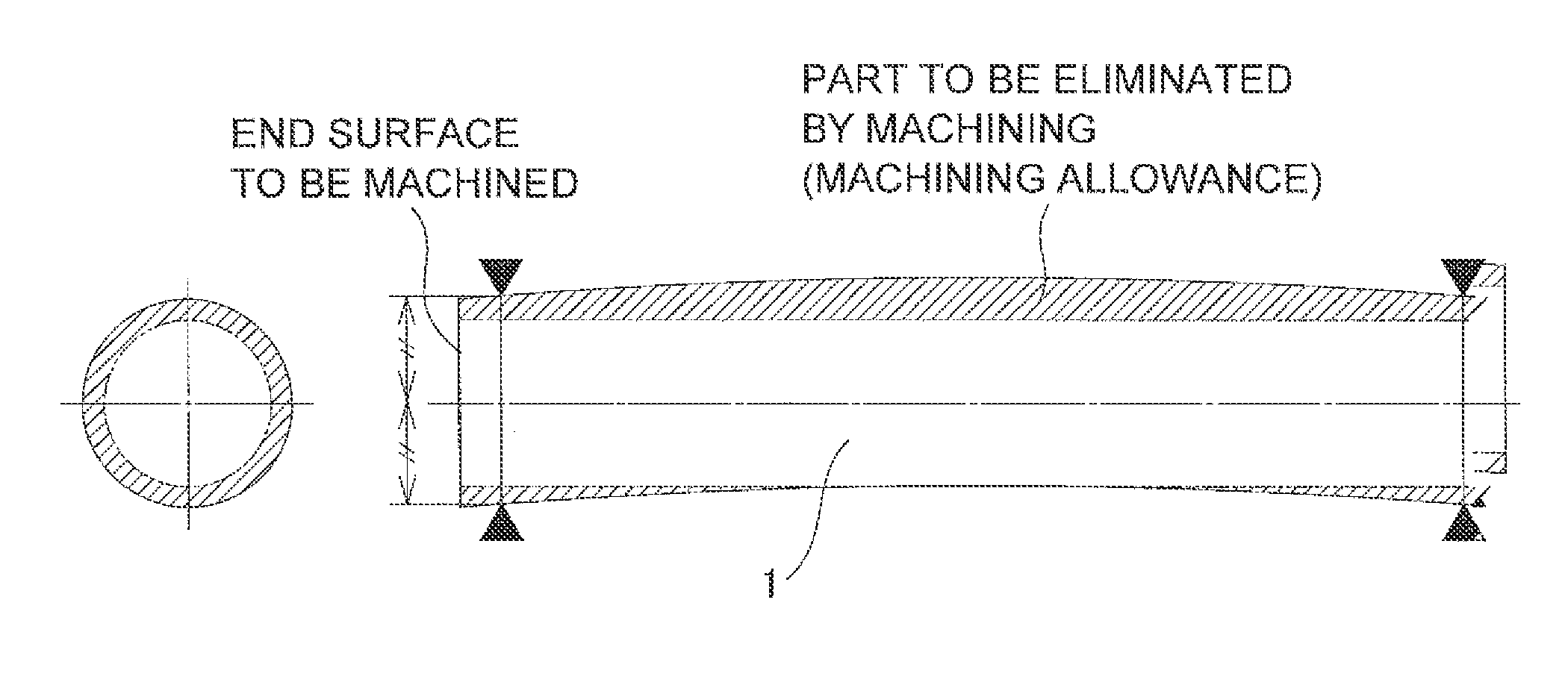

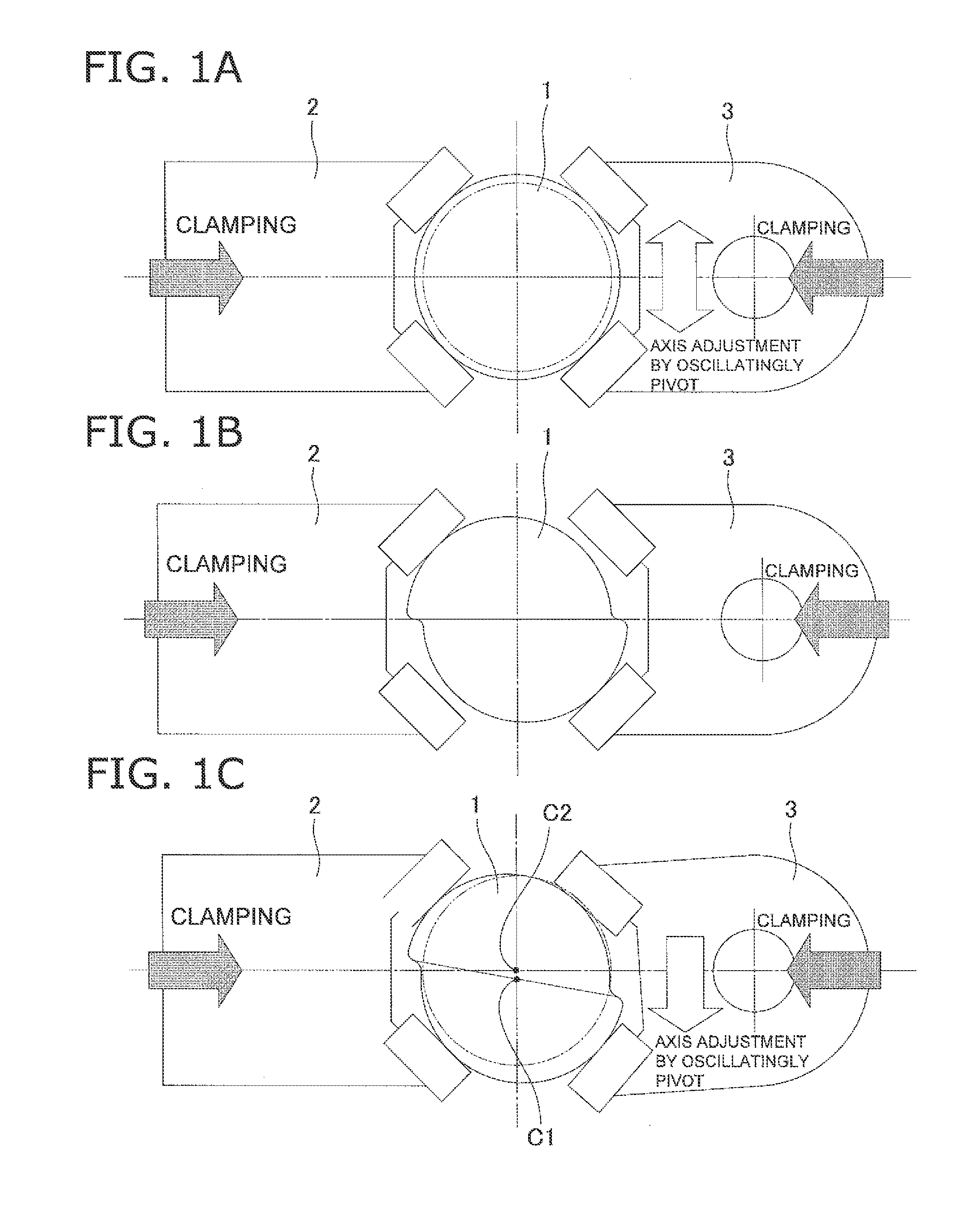

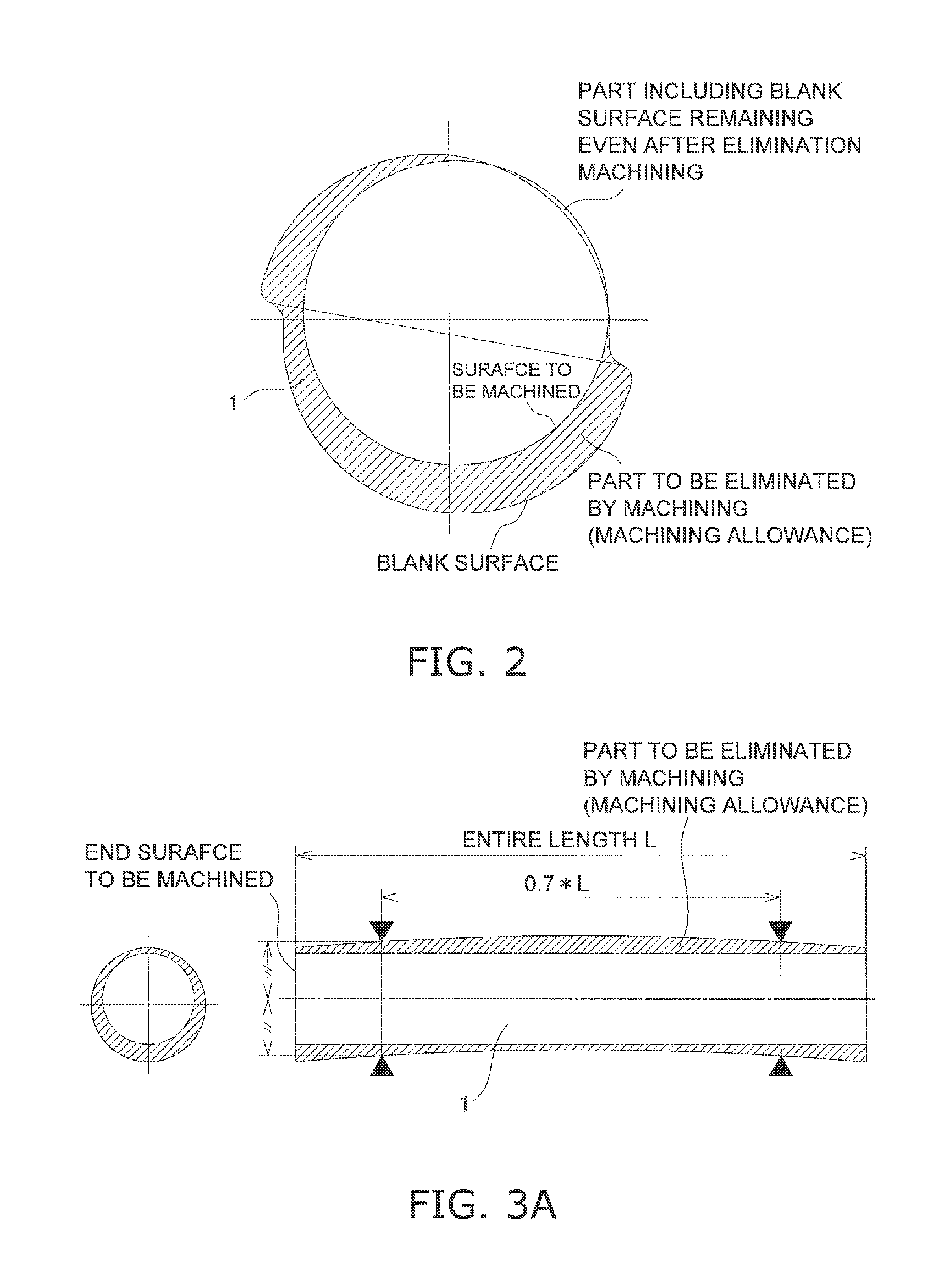

Center hole machining method for shaft blank and center hole machining apparatus

ActiveUS20120259452A1Reduce material costsThe relative position is appropriateCamsDrilling/boring measurement devicesEngineeringMachining

A center hole machining method includes first to fifth steps. The first step includes obtaining outer peripheral shape data of a plurality of portions of the shaft blank in an axial direction. The second step includes obtaining a center axis by comparing measured data of the portions of the shaft blank with design data. The third step includes calculating a minimum distance from the center axis to the outer periphery in each of the portions of the shaft blank. The fourth step includes shifting the center axis in a direction of making the minimum distance greater than the machining dimension and repeatedly executing the third step when the minimum distance is less than or equal to the machining dimension. The fifth step includes boring the center hole in an end surface of the shaft blank at a position arranged on a line extended from the center axis.

Owner:KOMATSU NTC LTD

Foaming agent and its preparation method

The invention relates to a foaming agent and a preparation method thereof, and belongs to the technical field of preparation of foamed aluminum and foamed aluminum alloy. The foaming agent has a composition ratio of 20-25% by weight of quicklime, 30-40% by weight of coke, 10-15% by weight of potassium carbonate, and the balance is calcium sulfate. The steps of preparing foamed aluminum and foamed aluminum alloy with the foaming agent mentioned in the present invention: (1) melting process: put the aluminum alloy ingot into the crucible, heat it to 680-720 ° C and keep the temperature until it melts; (2) increase Viscosity process and foaming process: Add 1.5~3% foaming agent to the aluminum melt and stir for 5 minutes at a stirring speed of 1500~2000rpm to increase the viscosity of the melt and distribute the foaming agent in the aluminum melt (3) Heat preservation process: After the foaming agent is mixed evenly, keep the temperature at 680-720°C for 5-10 minutes. (4) Cooling process: After the aluminum foam is formed, it is naturally cooled in the air or forced to water. The foaming agent of the invention has low cost, is economical and effective, and can replace TiH2 foaming agents.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

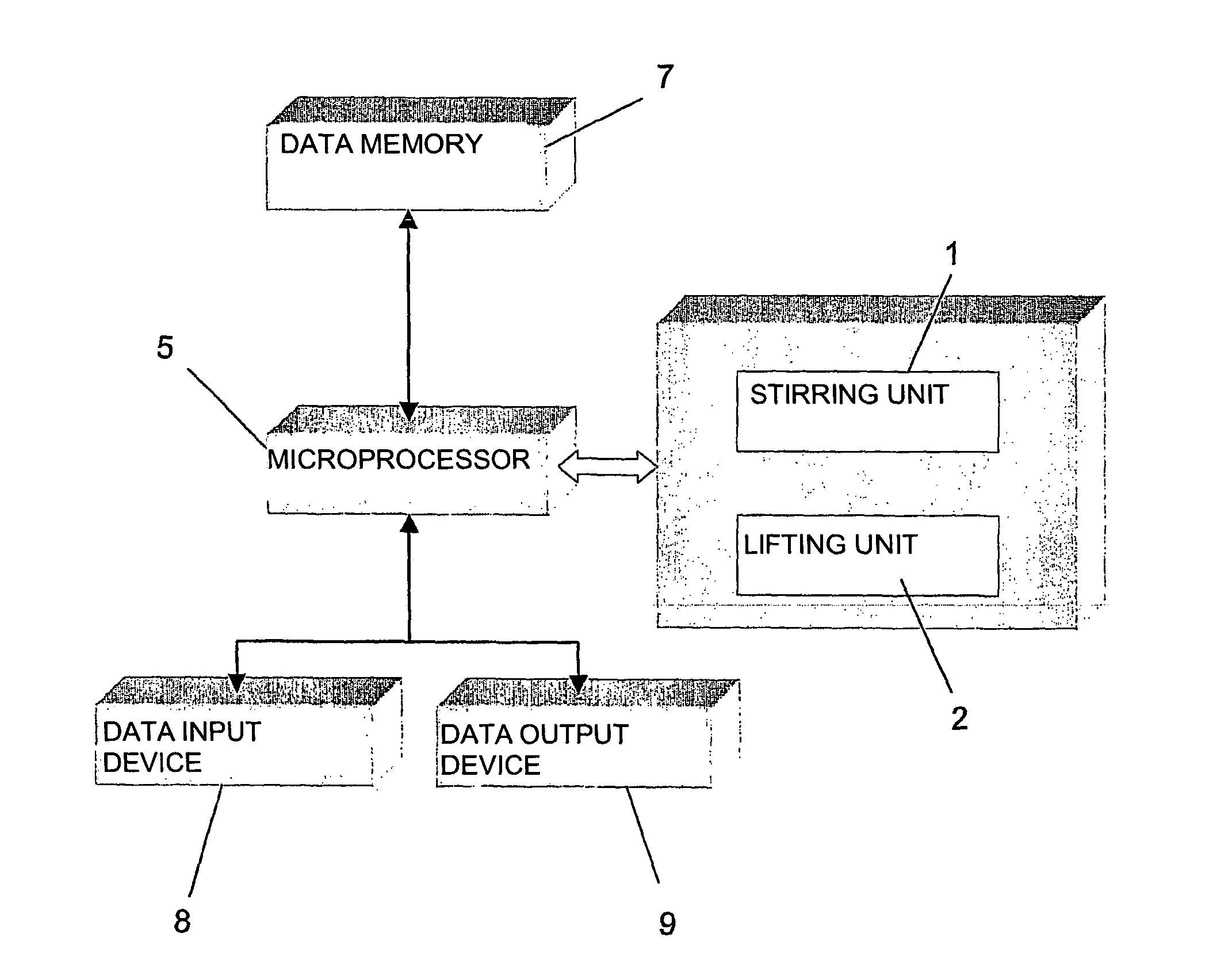

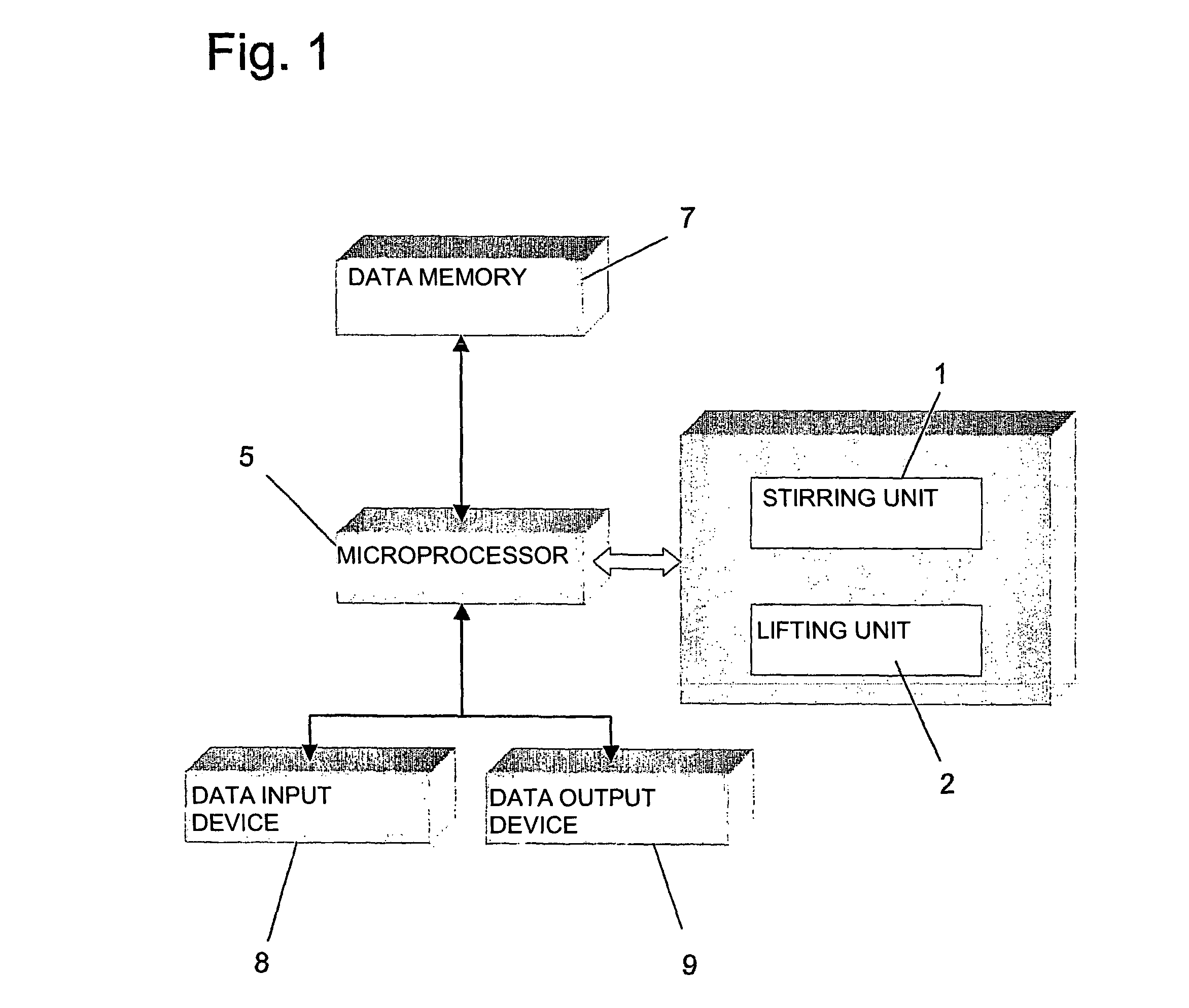

Program controlled stirrer and method for the operation thereof

InactiveUS7751934B2Minimize the differenceImprove efficiencySampled-variable control systemsOther chemical processesPower flowEngineering

The invention relates to a program controlled stirrer for producing pharmaceutical or cosmetic recipes, comprising a stirring unit which consists of a stirring tool which engages with a mixing receptacle. According to the invention, the stirring unit is coupled to a micro-processor which determines the length of stirring time and stirring speed at the stirring unit in a program-controlled manner. The micro-processor executes a data-processing program with the following steps: input of variable data; input of constant data; determination of the length of stirring time and stirring speed in order to produce the desired amount of the recipe by combining the variable and constant data; conversion of the determined length of stirring time and stirring speed into corresponding first current or voltage values; control of the stirring unit with said first current or voltage values. Preferably, the size of the receptacle is inputted as variable data, whereby the data-processing program calculates the number of necessary rotations of the stirring tool using the constant data stored in the data memory, then controls the stirring unit correspondingly.

Owner:KONIETZKO ALBRECHT

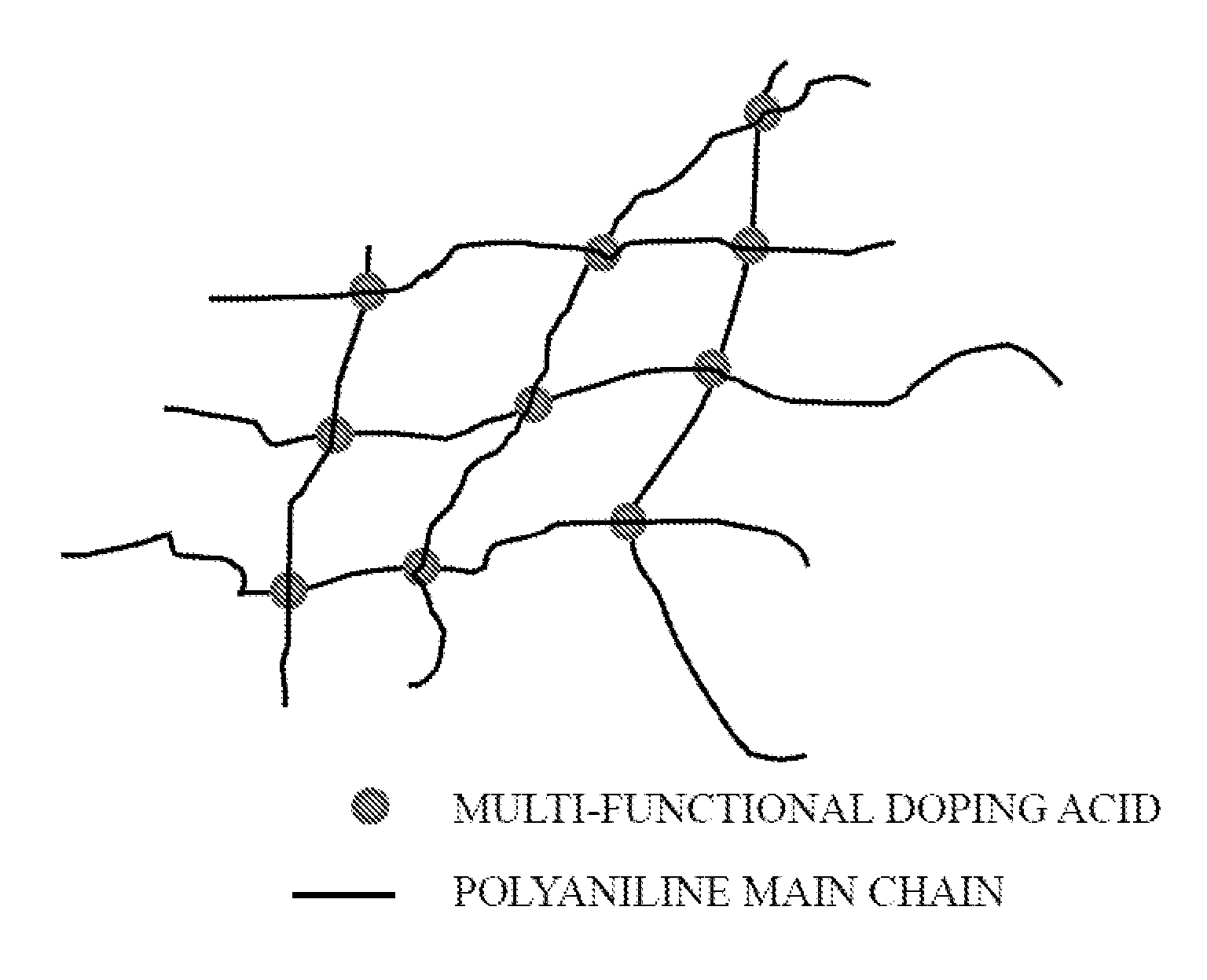

Conductive polymer, synthesis method thereof, and electroactive electrode covered with said conductive polymer

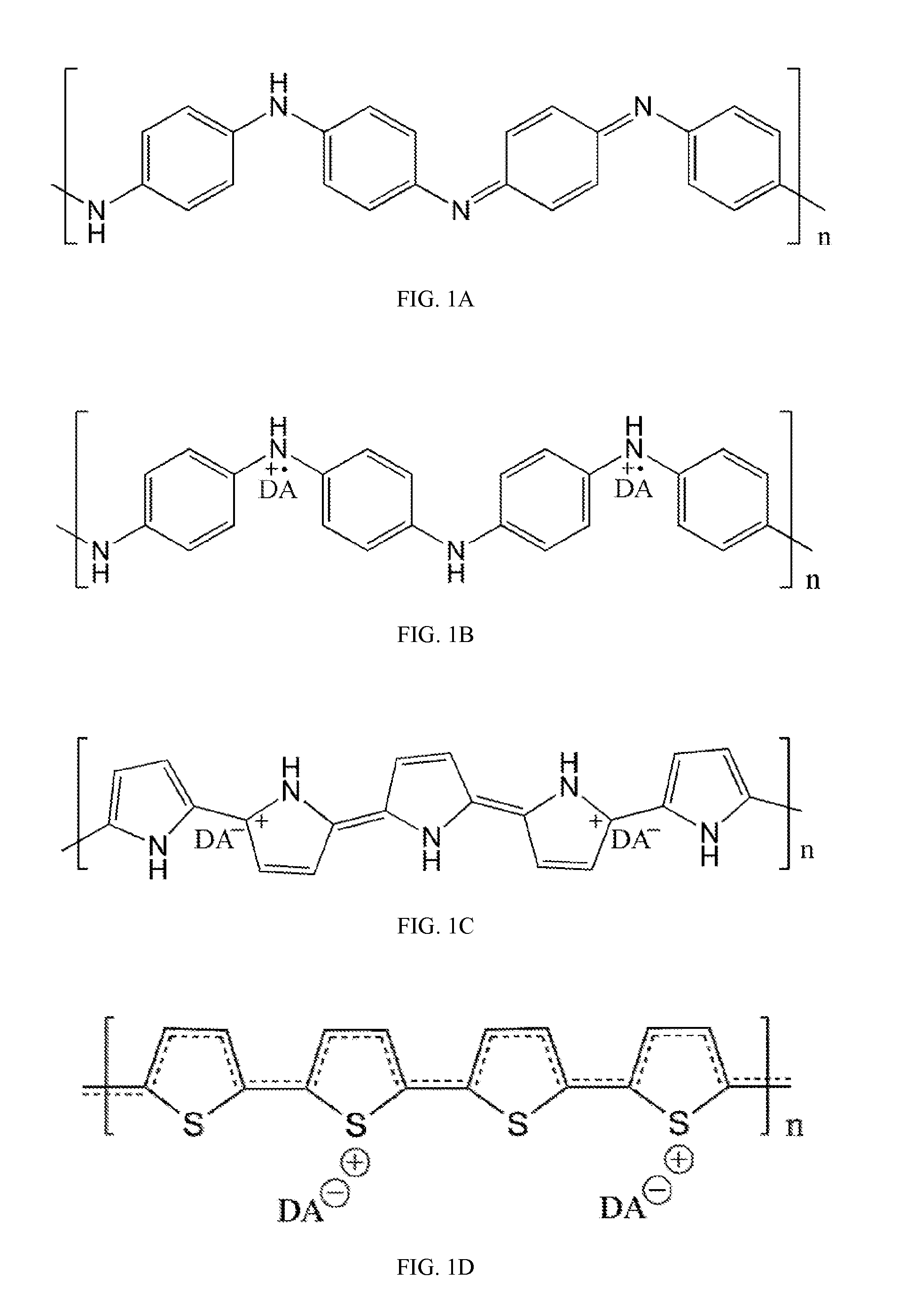

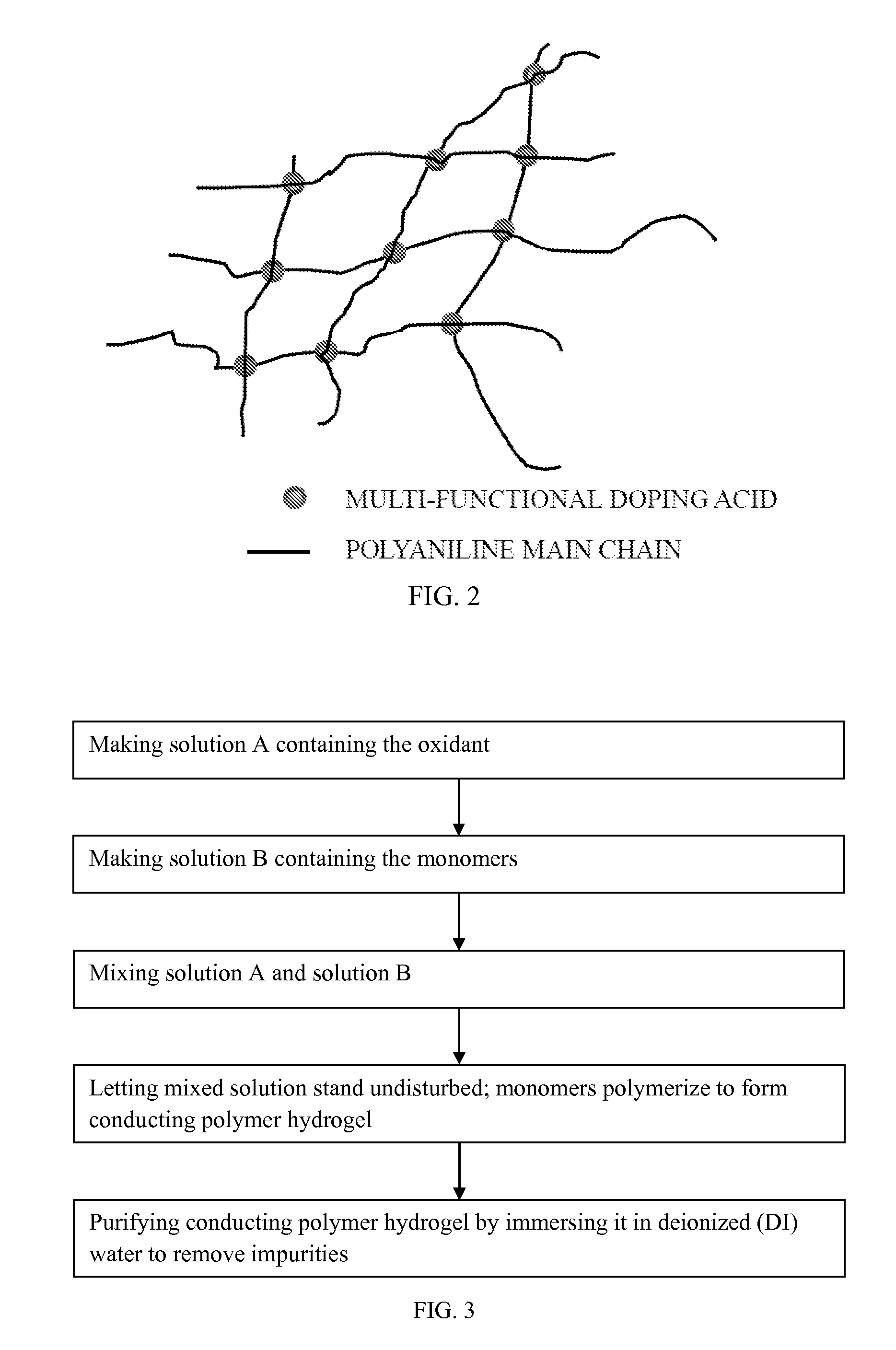

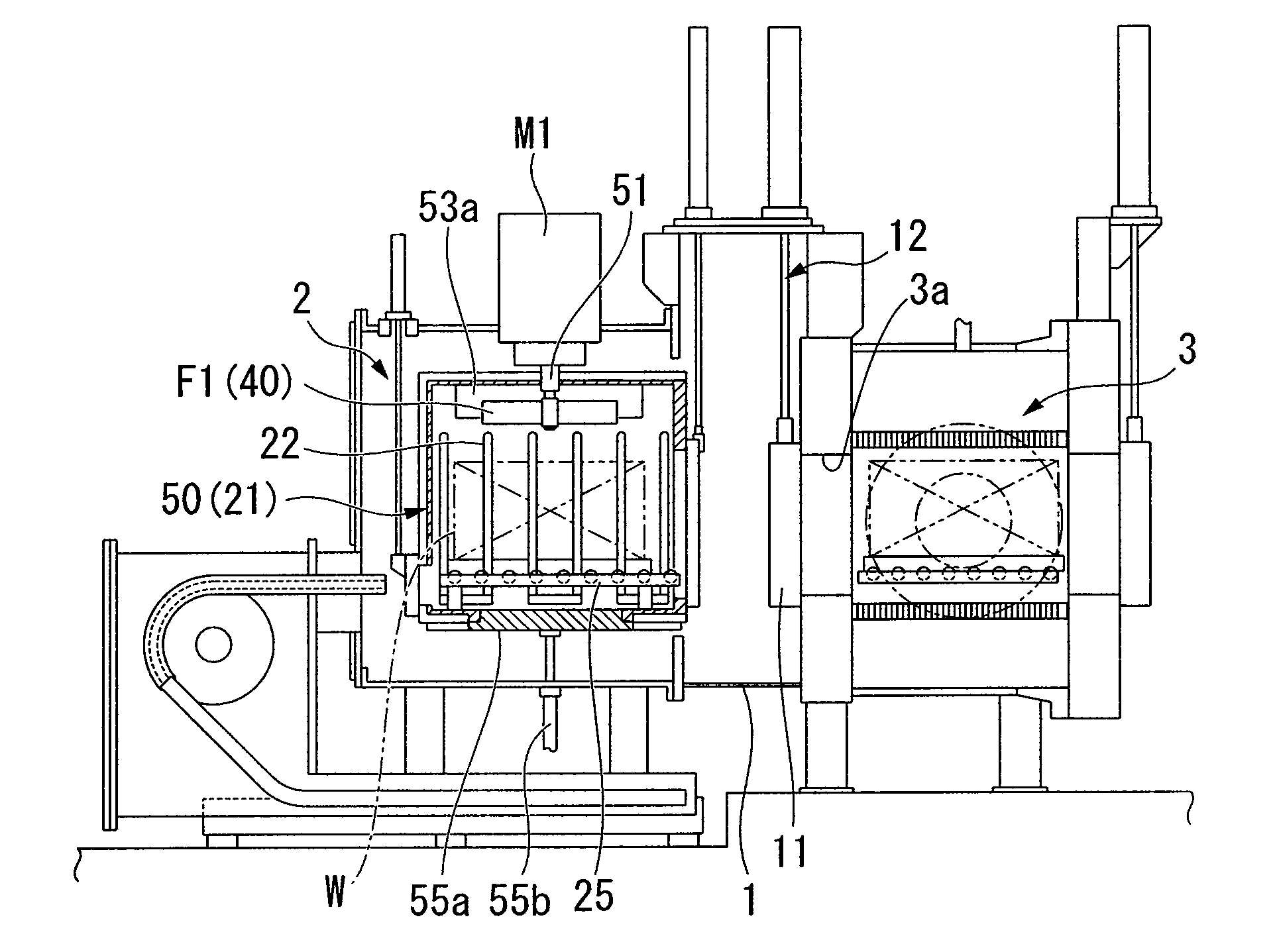

ActiveUS20130171338A1Improve ionic conductivityGood biocompatibilityHybrid capacitor electrodesCell electrodesSynthesis methodsConductive polymer

The present invention provides a conducting polymer, a synthesis method thereof, and an electroactive electrode covered with the said conducting polymer. The conducting polymer is synthesized as follows: use the polybasic acid as dopant and crosslinking agent, and polymerize monomers into conducting polymer hydrogel. The monomers are selected one or more from pyrrole or its derivatives, thiophene or its derivatives, aniline or its derivatives. The acid group of the polybasic acid contains phosphate or polybasic acid which contains at least two substituents per molecule selected from sulfate, nitrate or carboxylic in which the molecular weight of at least one acid group is no more than 800. The mole ratio of the acid group in polybasic acid to monomers of the conducting polymer is 1:12-12:1. The preparation applied in the invention is simple, and need not to import any impurity. The conducting polymer hydrogel has high ionic conductivity, super hydrophilicity, and good biocompatibility.

Owner:NANJING UNIV

Vacuum carburization method and vacuum carburization apparatus

InactiveUS20080216922A1Reduce processing timeSuppression of inhomogeneitySolid state diffusion coatingProperty valueQuenching

There are provided a method, between a diffusion process and a quenching process, a normalizing process of performing step cooling in which a temperature lowering treatment and a temperature keeping treatment are alternately repeated plural times so that a temperature history from the first temperature to a predetermined temperature satisfies a predetermined condition; an after-normalizing maintaining process of maintaining the temperature of the whole workpiece for a predetermined time after the normalizing process so that the whole workpiece becomes the predetermined temperature, thereby producing fine crystal grains in the workpiece; and a reheating process of raising the temperature of the workpiece to the second temperature, after the after-normalizing keeping process. According to the invention, even when a process temperature is set high to make rapid progress of carburization and diffusion and thus the process time is shortened, uniformity in temperature is achieved between a surface and a inside of a workpiece by the high-temperature process and crystal grains are prevented from being coarse, thereby obtaining a workpiece having a predetermined property value.

Owner:IHI CORP

Polysilicon granule preparation system and preparation method

ActiveCN103213989AInhibit adhesion depositionProduce uniformEnergy inputSilicon compoundsCycloneFluidized bed

The invention discloses a polysilicon granule preparation system, and solves the problems of the polysilicon particles in prior art, such as easy deposition on wall of a fluidized bed reactor, nonuniform particle size, low utilization rate of the polysilicon seed crystal and large loss rate of polycrystalline silicon fine powder. The system comprises an aslant arranged rotating fluidized bed, a first stage cyclone separator, a second stage cyclone separator, a carrier gas filter, a material preheating tank and a tail gas buffer tank. The reaction cylinder in the middle of the rotating fluidized bed can rotate relatively to end sockets at the two ends; and the rotating fluidized bed is provided with a baffle plate. The invention can effectively restrain deposition of the polycrystalline silicon particles in the fluidized bed reactor wall, improve utilization rate of polycrystalline silicon and reduce the loss rate of polycrystalline silicon fine powder. The invention also discloses a preparation method of polycrystalline silicon particles. The preparation method has advantages of stable process, good continuity of operations, high utilization rate of polycrystalline silicon, high efficiency of polycrystalline production and uniform size of the obtained polysilicon granules.

Owner:ZHEJIANG JINGGONG NEW MATERIAL TECH

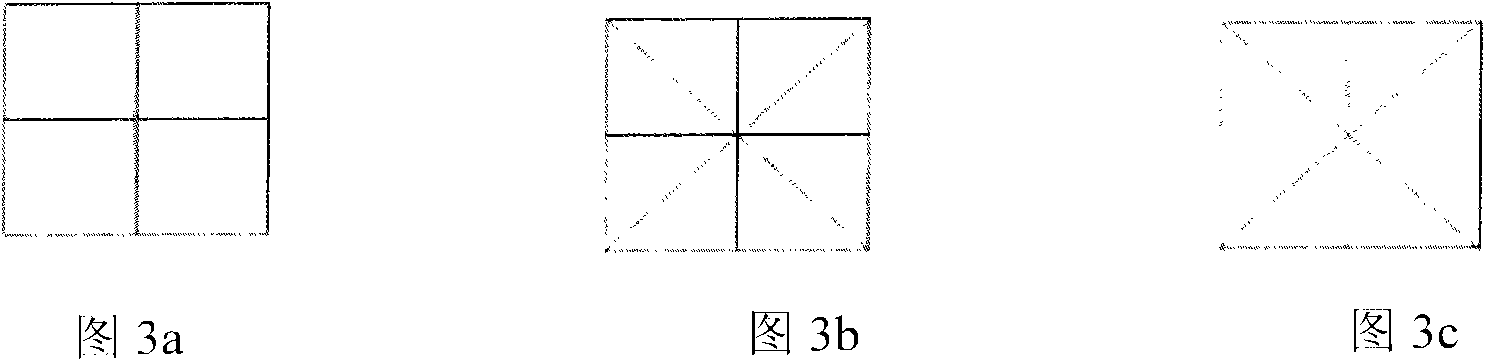

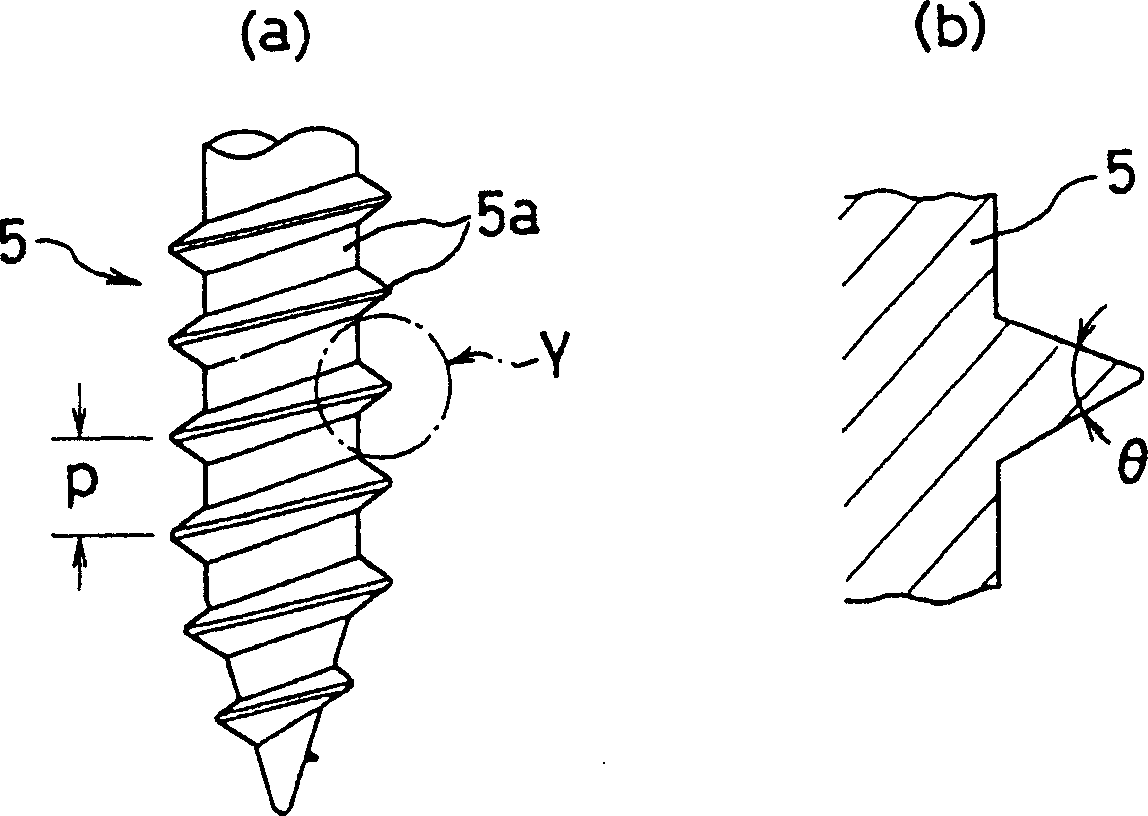

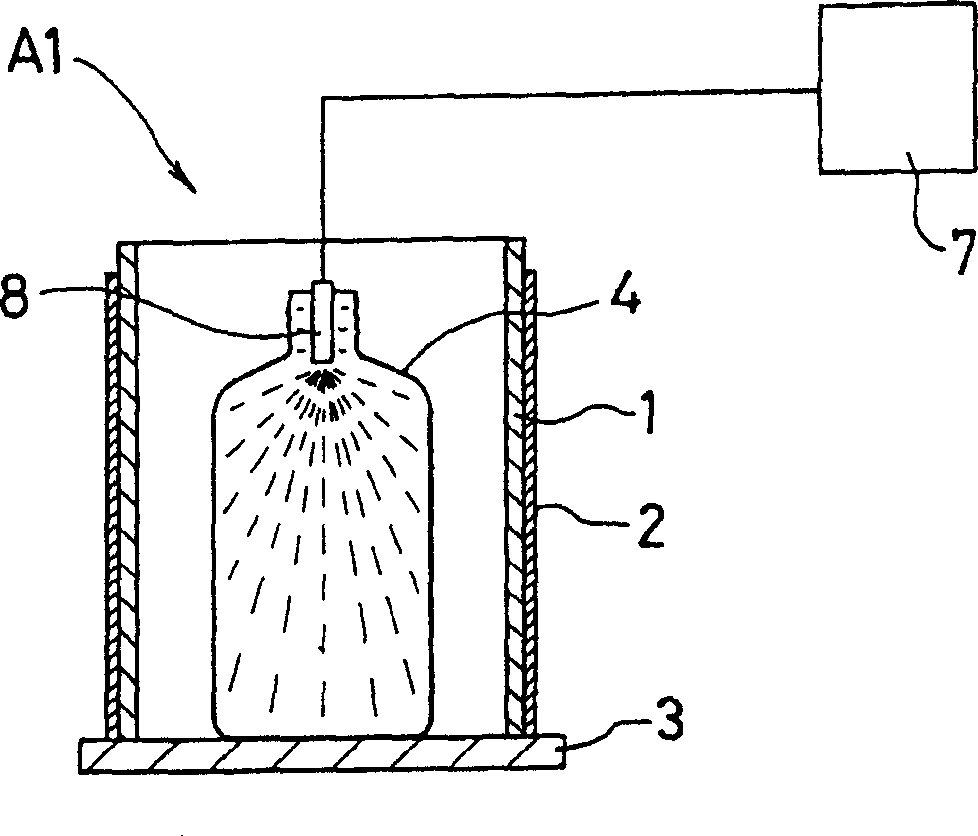

Method and device for sterilizing packaging material using high voltage pulse power

InactiveCN1491863AProduce uniformLower breakdown voltagePackage sterilisationLavatory sanitoryRoom temperatureEngineering

Provided is a method for sterilizing a packaging material and a sterilizer used therefor, which do not cause unevenness in the sterilization effect, and uses high voltage pulses permitting to improve the sterilization effect. The purpose can be achieved by using such a discharge side electrode as is provided with unevenness having continuous projections on the discharge side surface, in the method in which the sterilizer is provided with a power source for generating high voltage, a discharge side electrode to which the high voltage generated by the power source is applied, and a ground side electrode arranged so as to be opposed to the discharge side of the discharge side electrode, and sterilizes a packaging material to be sterilized by placing it between both electrodes under normal temperature and normal pressure, and applying the high voltage pulses thereto in a gas atmosphere.

Owner:DAI NIPPON PRINTING CO LTD +1

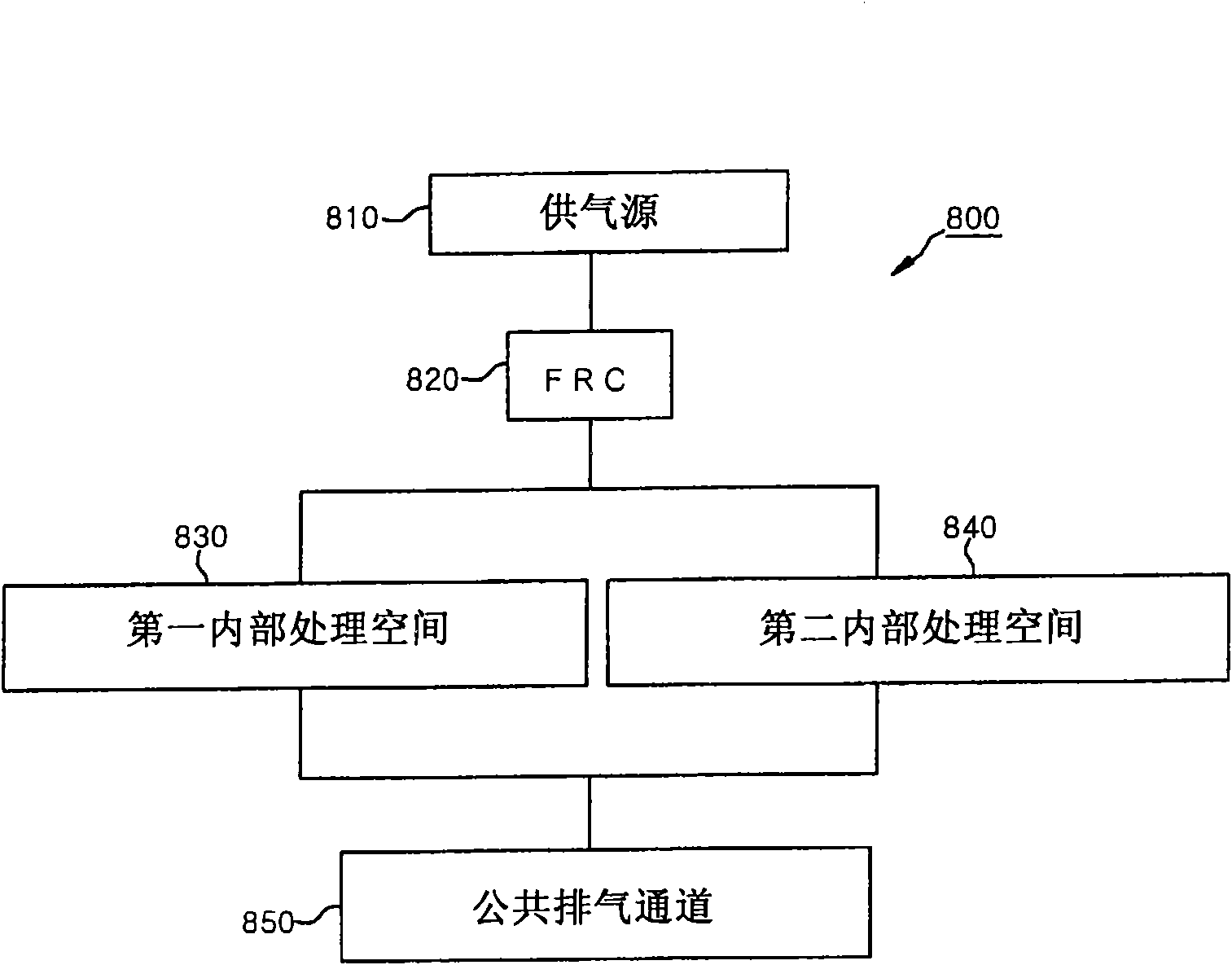

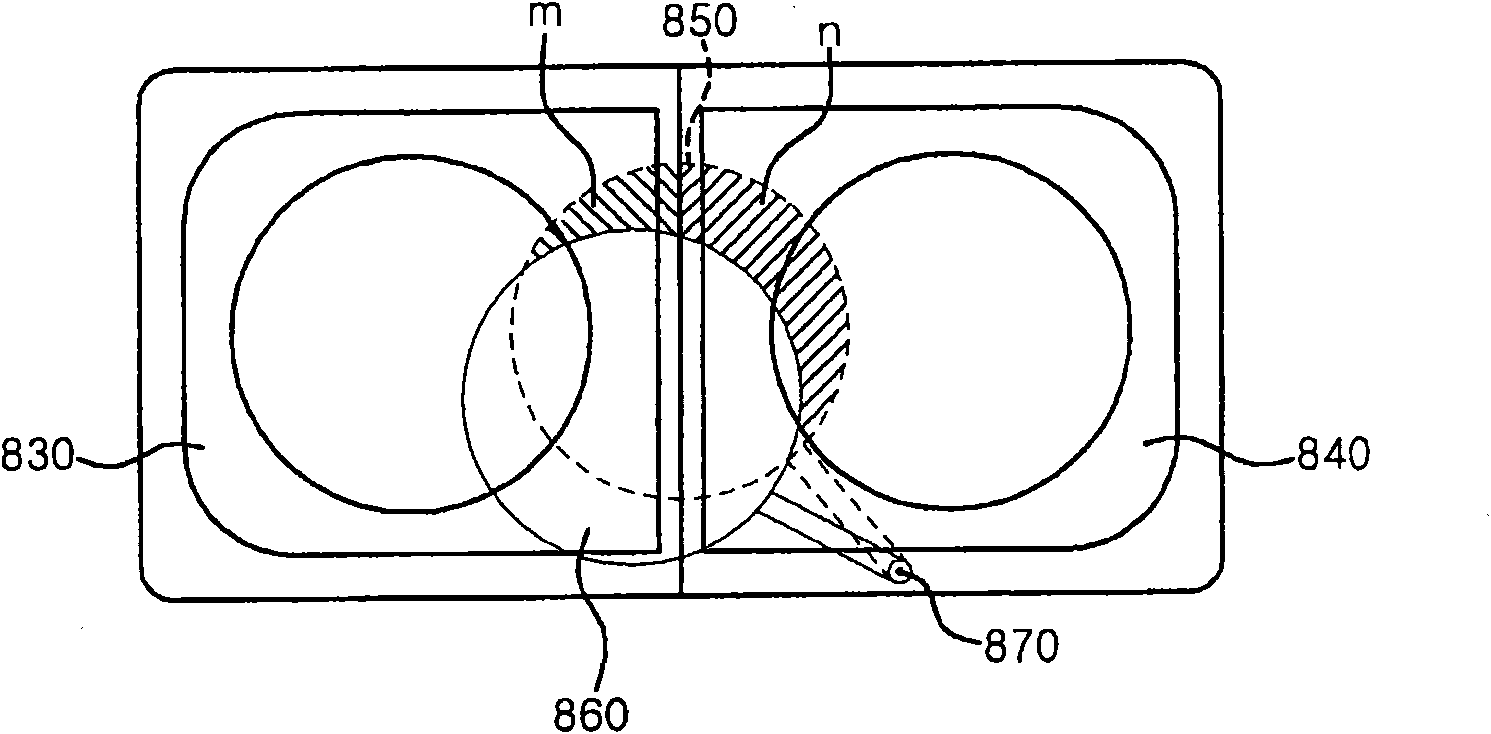

Multi-workpiece processing chamber and workpiece processing system including the same

ActiveCN101779269AImprove uniformityImprove the conductivity of the exhaustSemiconductor/solid-state device manufacturingProcess regionMechanical engineering

A multi-workpiece processing chamber according to the present invention comprises a chamber housing which forms at least two internal processing spaces therein; at least one partition member which is provided in the chamber housing and partitions the chamber housing into at least two internal processing spaces; and the respective internal processing spaces being coupled with the partition member and having a symmetric shape to generate a processing reaction uniformly. The multi-workpiece processing chamber according to the present invention has internal processing spaces that have a symmetric shape by being coupled with a partition member. Thus, a processing reaction uniformly occurs across the internal processing areas and reproducibility and uniformity of a workpiece processing process may improve.

Owner:AFO株式会社

System and method for production of antibodies in plant cell culture

ActiveUS8119406B2Rapid and consistent reproductionLack of uniformityVaccinesFused cellsBiotechnologyHigh level expression

A system and method for production of antibodies in plant cell culture, which results in highly functional antibodies, produced with a high level of expression efficiency. The present invention also encompasses host cells, vectors and methods for mass production of full size assembled immunoglobulins.

Owner:PROTALIX

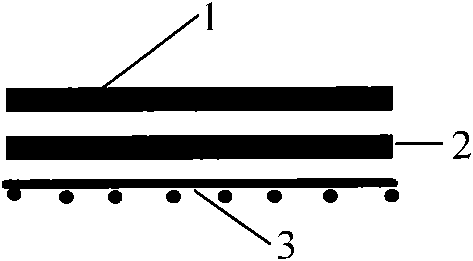

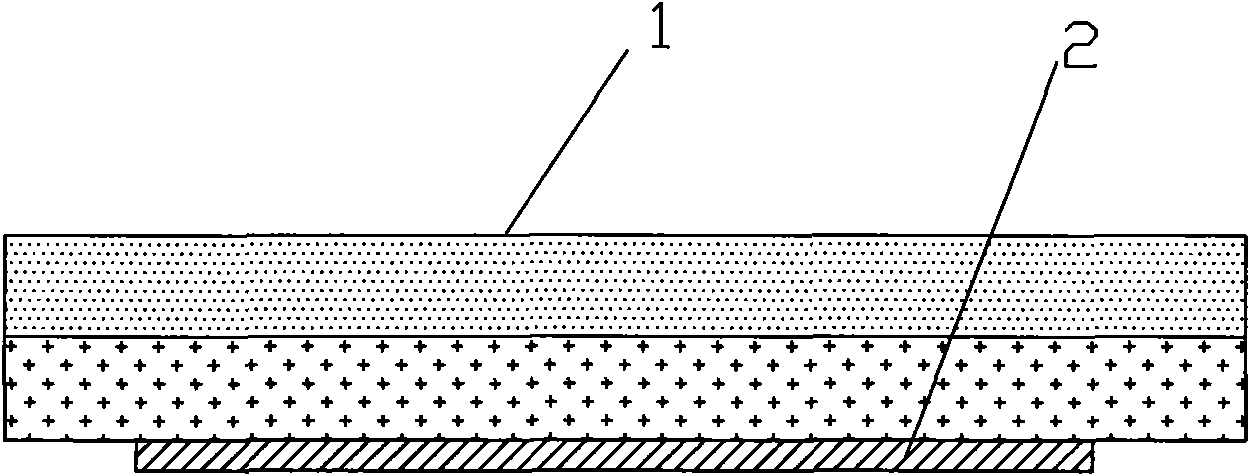

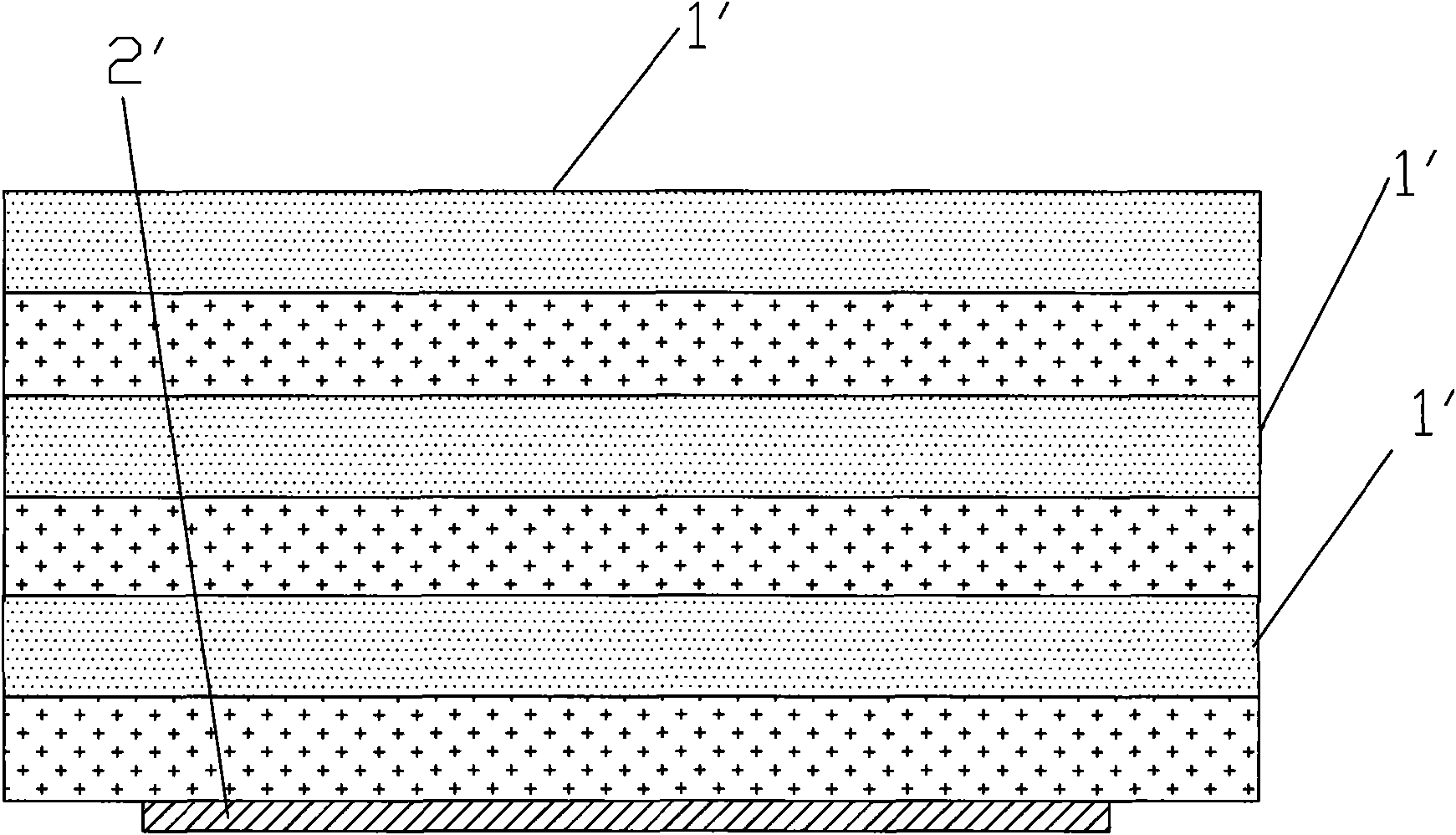

Novel nano-carbon-fiber heating floor and preparation method thereof

ActiveCN105155815AImprove conductivityHigh strengthLighting and heating apparatusElectric heating systemCarbon fibersInsulation layer

The invention provides a novel nano-carbon-fiber heating floor and a preparation method thereof. The preparation method comprises the following steps: (1) placing nano polyacrylonitrile fibers prepared by electrostatic spinning in a roasting oven, performing heat treatment by using air as a medium, and performing carbonization treatment under nitrogen environment so as to obtain carbonized nano polyacrylonitrile fibers; (2) stirring plant protoplasm fibers and a cationic surface active agent under a closed condition and normal temperature till a uniform mixture is obtained, adding the carbonized nano polyacrylonitrile fibers and nano graphite powder in the mixture, stirring the carbonized nano polyacrylonitrile fibers, the nano graphite powder and the mixture at a high speed, and preparing sheet type flexible macromolecule materials by a hot-pressing technology; (3) fixing metal-sheet electrodes at both ends of the sheet type flexible macromolecule materials by a silver solution so as to form a conductive heating layer; and (4) shearing a solid-wood layer, an insulation layer, the conductive heating layer, a temperature control layer, another solid-wood layer and a surface treatment layer with appropriate sizes from bottom to top, and performing combination so as to form the nano-carbon-fiber heating floor.

Owner:浙江康辉木业有限公司

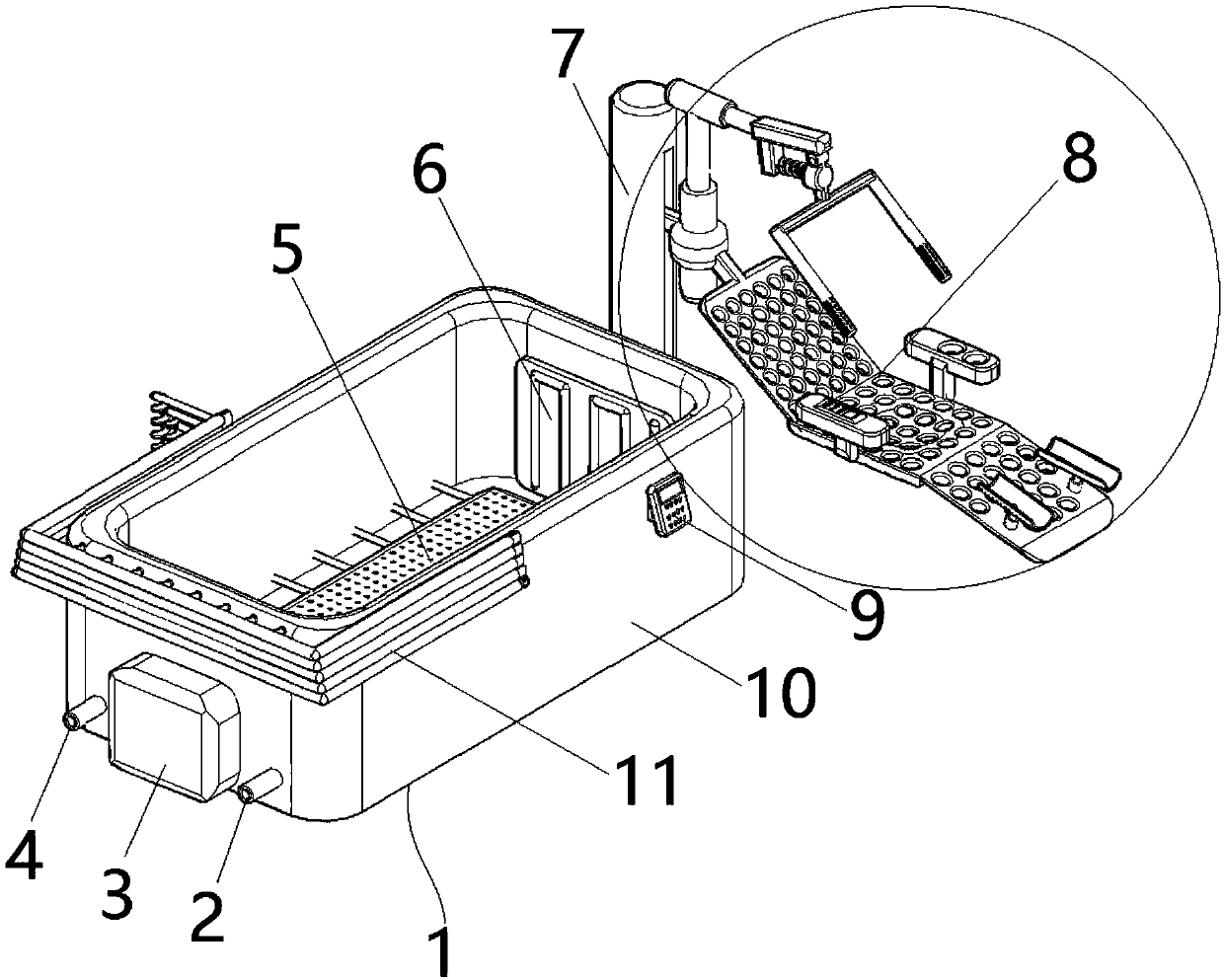

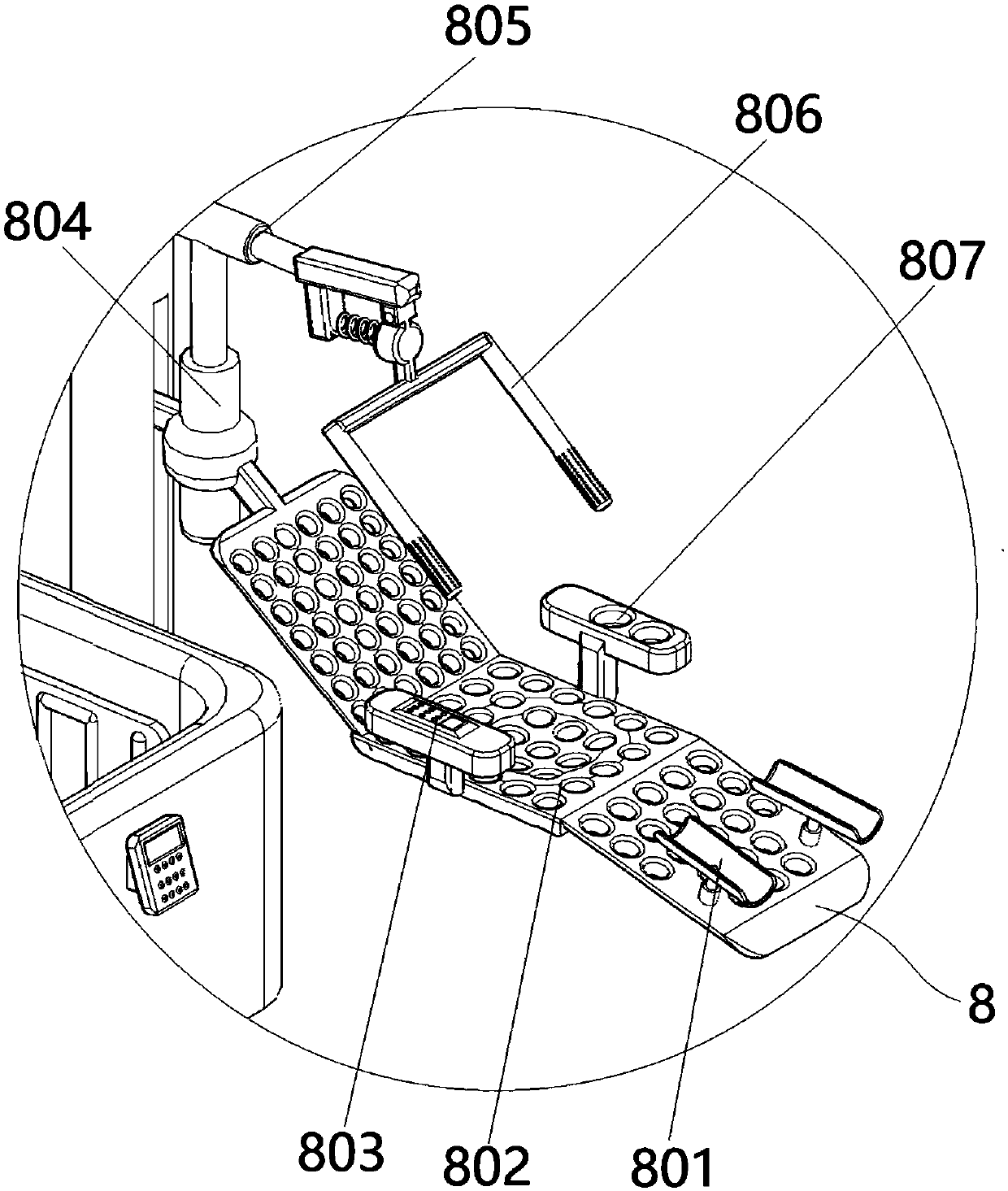

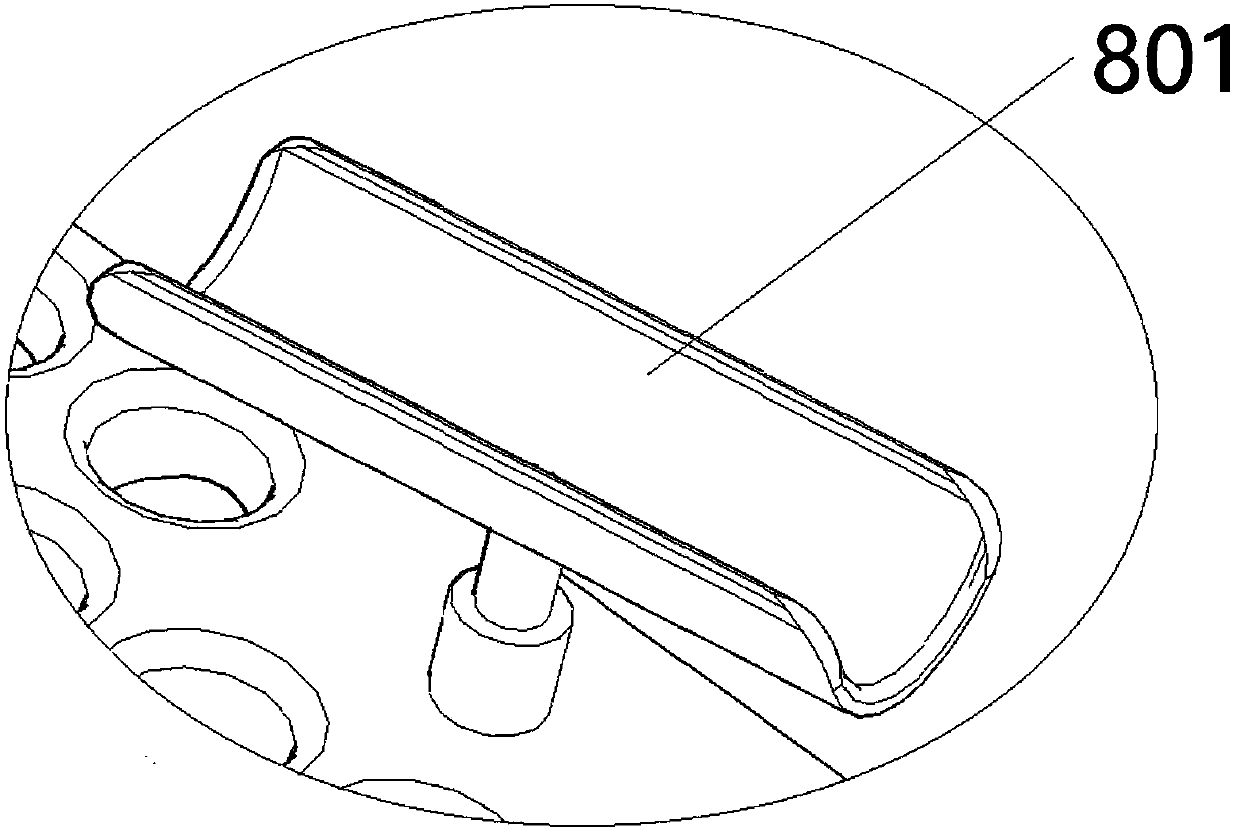

Jetting treatment groove equipment for department of neurology

ActiveCN107854303AGood for water therapyImprove the effect of jet therapyGymnastic exercisingBathing devicesWhole bodyTherapeutic effect

The invention discloses jetting treatment groove equipment for the department of neurology. The equipment includes a rotary column, a movable chair and treatment water spraying pipes; a treatment water groove is formed in an equipment body; the treatment water spraying pipes are movably installed on the side wall of the upper end of the treatment water groove through shafts; the treatment water spraying pipes are composed of water pipes, a rotary fixing plate and sprayers, and fixed on the side wall of the treatment water groove through the rotary fixing plate; a second controller is also arranged at the upper end of the outer wall of one side of the treatment water groove; the bottom side of the outer wall of the other side of the treatment water groove is sequentially provided with a water pump device and a frothing machine; the water pump device is communicated with the treatment water spraying pipes through water pipes; the bottom of the other side of the treatment water groove isfixedly provided with a rotary base; the movable chair is arranged on the rotary column. According to the jetting treatment groove equipment for the department of neurology, since sprayers are symmetrically arrayed and arranged on all transverse pipes at the upper ends of the treatment water pipes, more convenience is provided for carrying out water spraying treatment on the whole body of a treated user, and the jetting treatment effect is effectively improved.

Owner:郝建

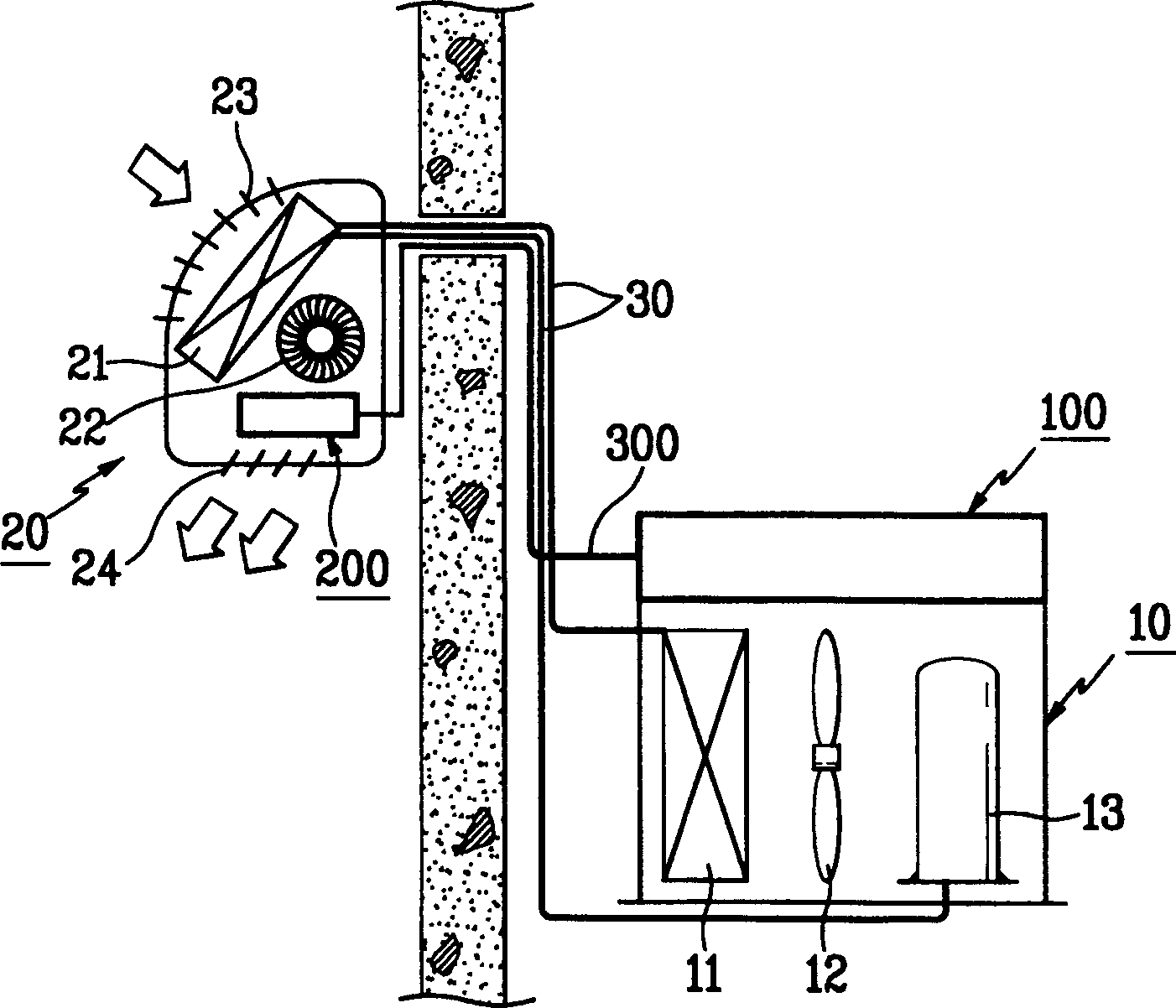

Air purifier

InactiveCN1420317AImprove performanceReduce the space occupiedMechanical apparatusLighting and heating apparatusCold mediumEngineering

An air cleaner is composed of outdoor unit, indoor unit containing cold medium, oxygen generator and cold medium tube. Said oxygen generator consists of oxygen generating unit in outdoor unit, oxygenexhauster and oxygen delivering tubes. Said oxygen generating unit comprises casing and mechanical unit consisting of air pump, switching valves, adsorbing column with nitrogen adsorbent therein, oxygen delivery pipes and test valve, and air delivery pipes.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com