Patents

Literature

69results about How to "Suppression of inhomogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

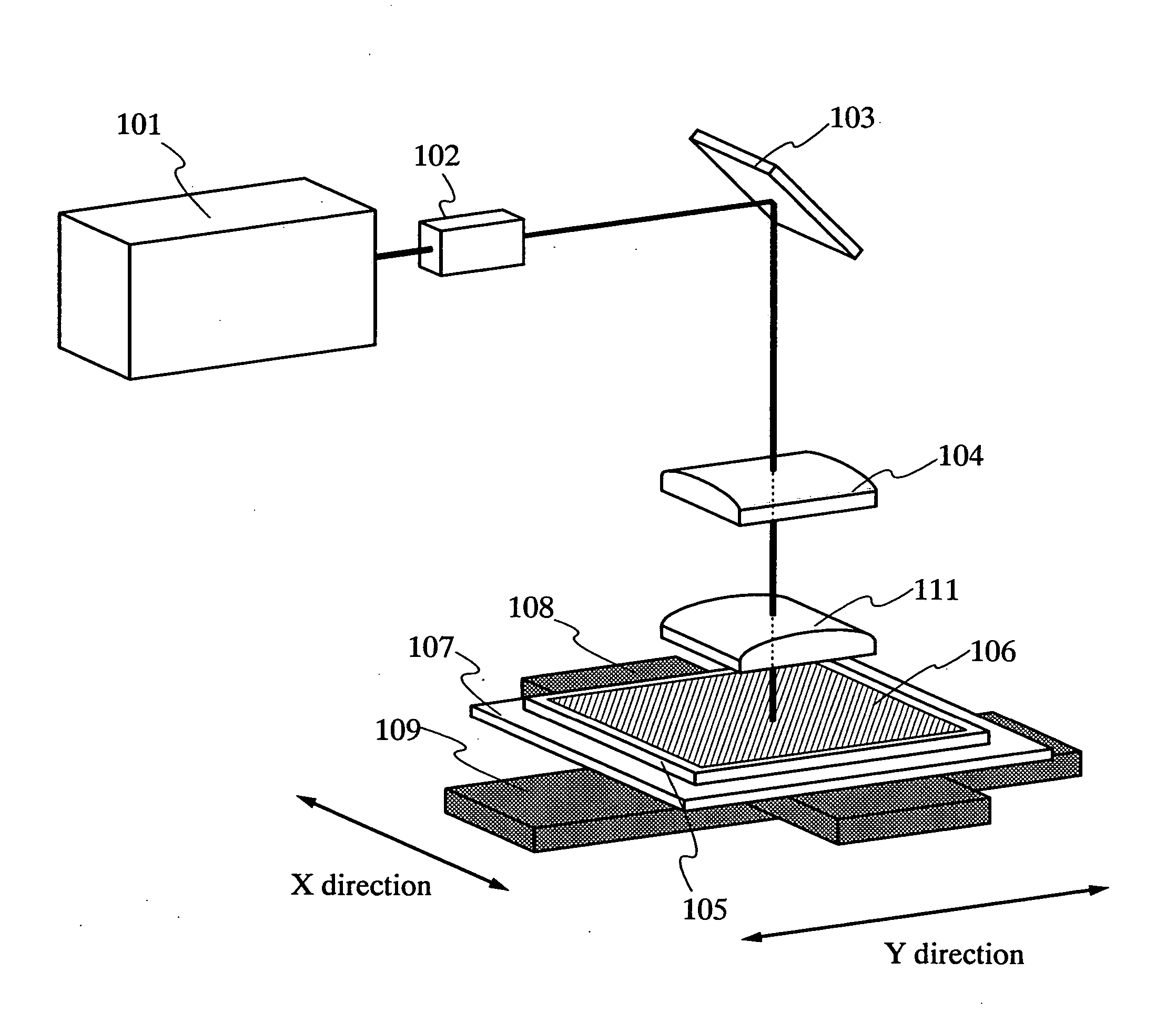

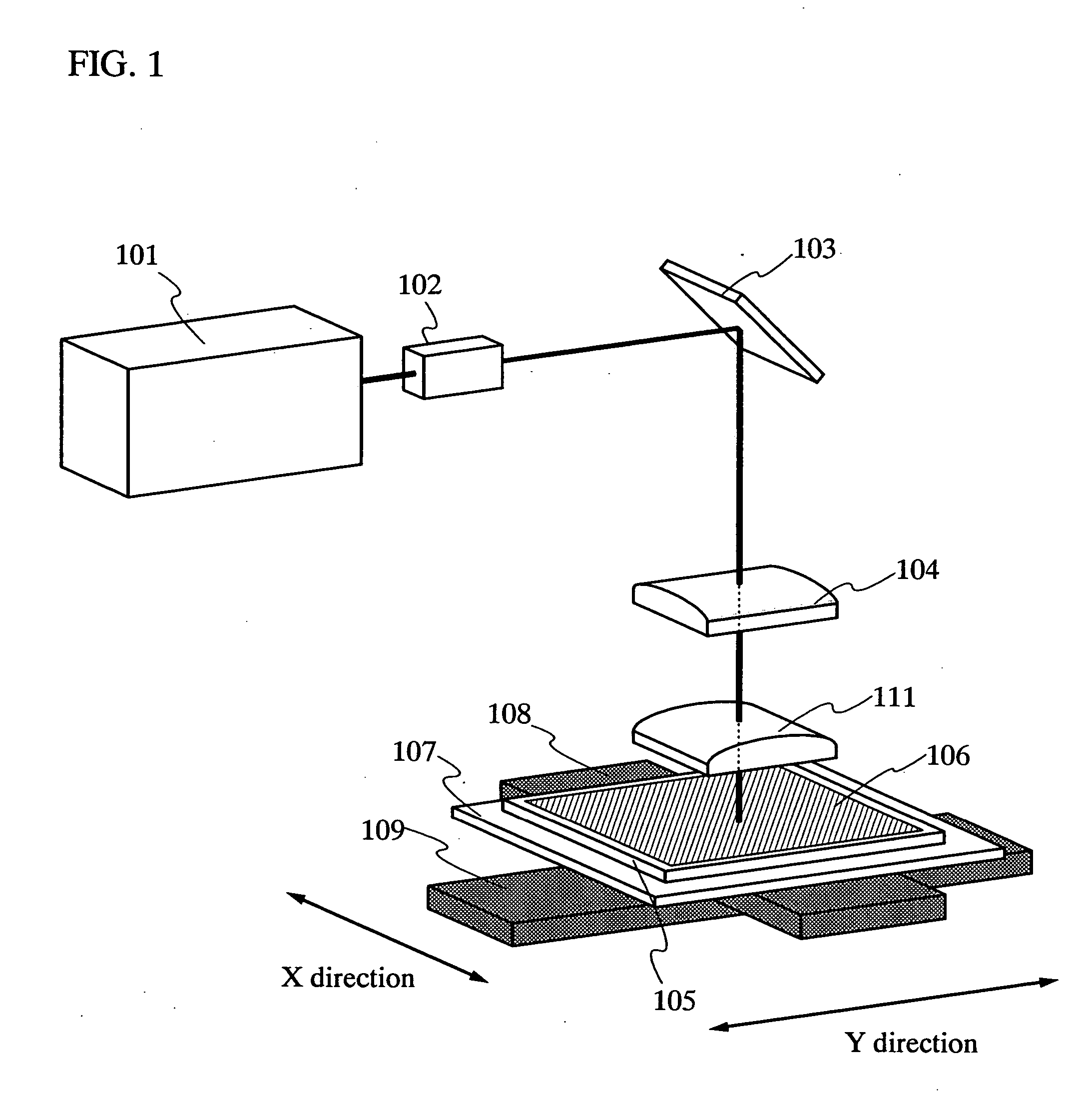

Laser irradiation method and method for manufacturing crystalline semiconductor film

ActiveUS20050139786A1Suppression of inhomogeneityHigh crystallinityPolycrystalline material growthFrom solid statePicosecondCrystallinity

Even when the laser irradiation is performed under the same condition with the energy distribution of the beam spot shaped as appropriate, the energy given to the irradiated surface is not yet homogeneous. When a semiconductor film is crystallized to form a crystalline semiconductor film using such inhomogeneous irradiation energy, the crystallinity becomes inhomogeneous in this film, and the characteristic of semiconductor elements manufactured using this film varies. In the present invention, an irradiated object formed over a substrate is irradiated with a laser beam having the pulse width that is an order of picosecond (10−12 second) or less.

Owner:SEMICON ENERGY LAB CO LTD

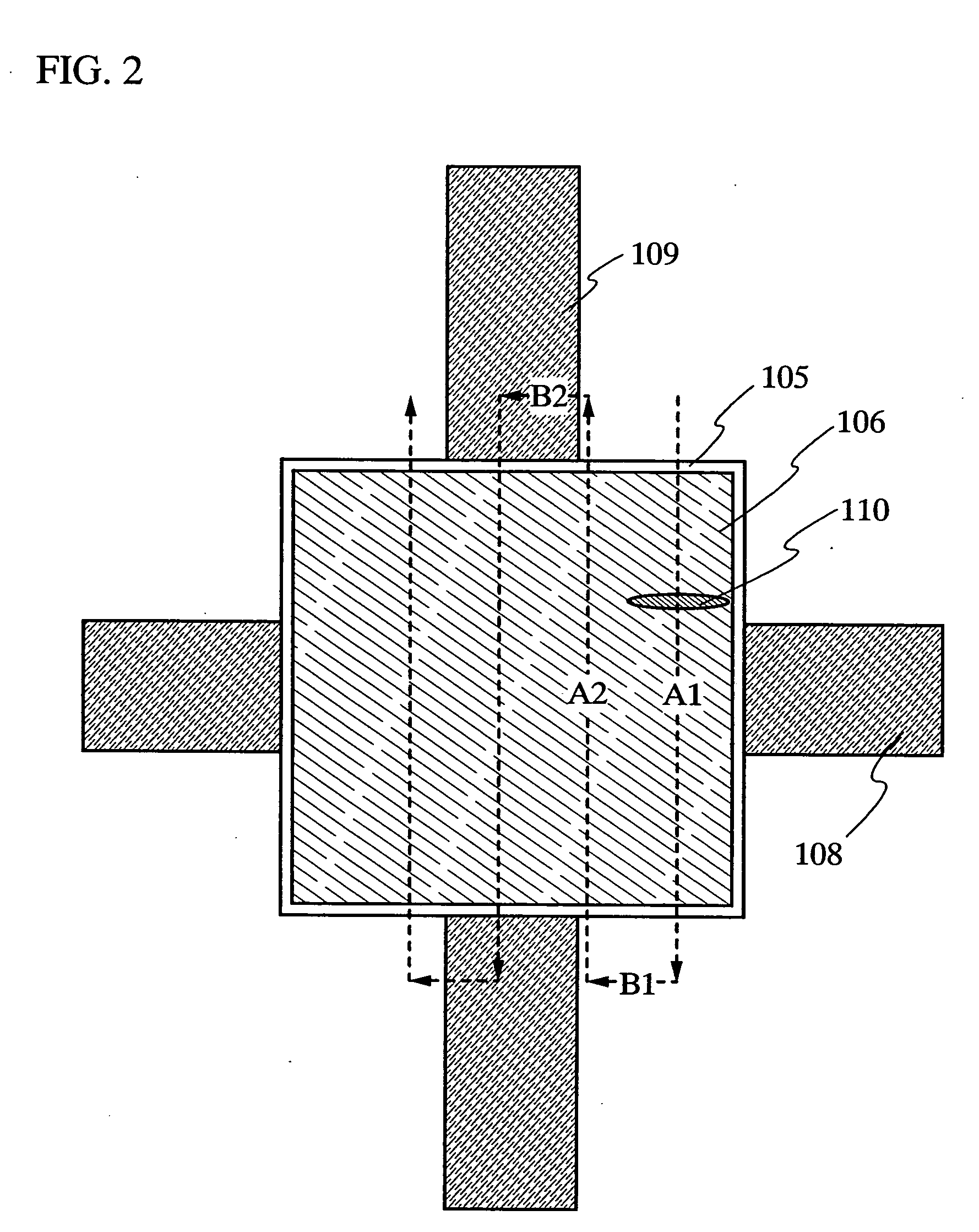

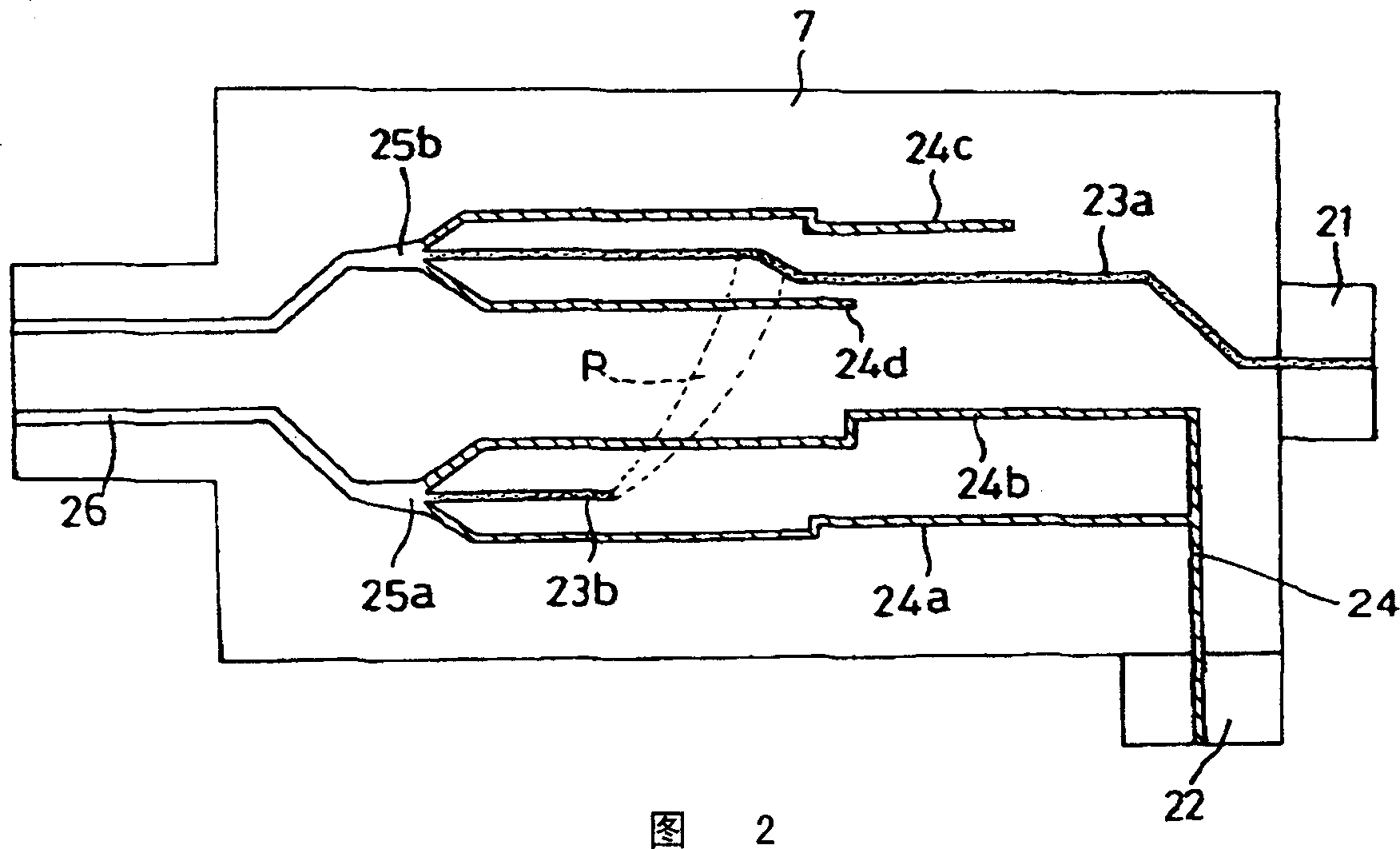

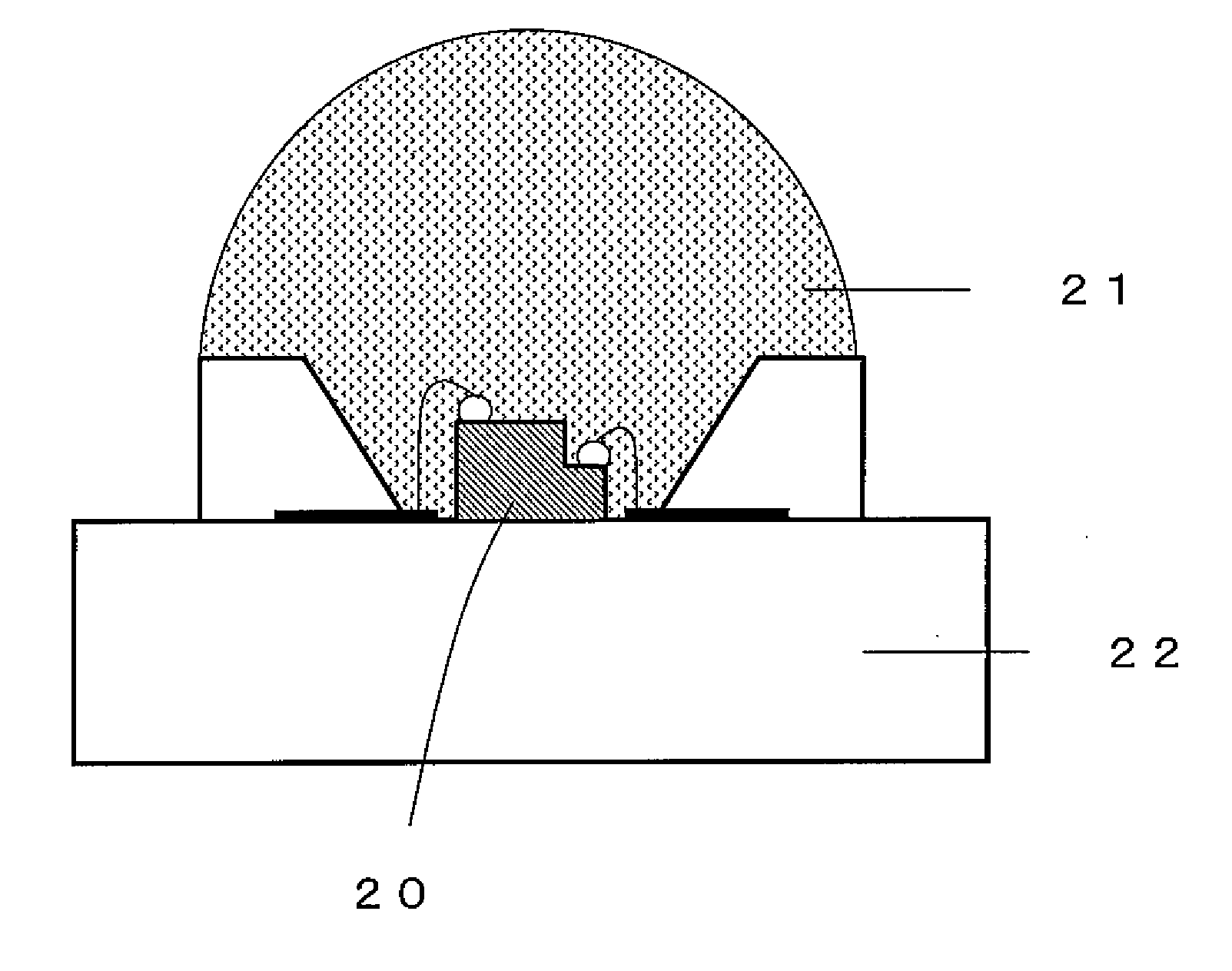

Bonding method and apparatus

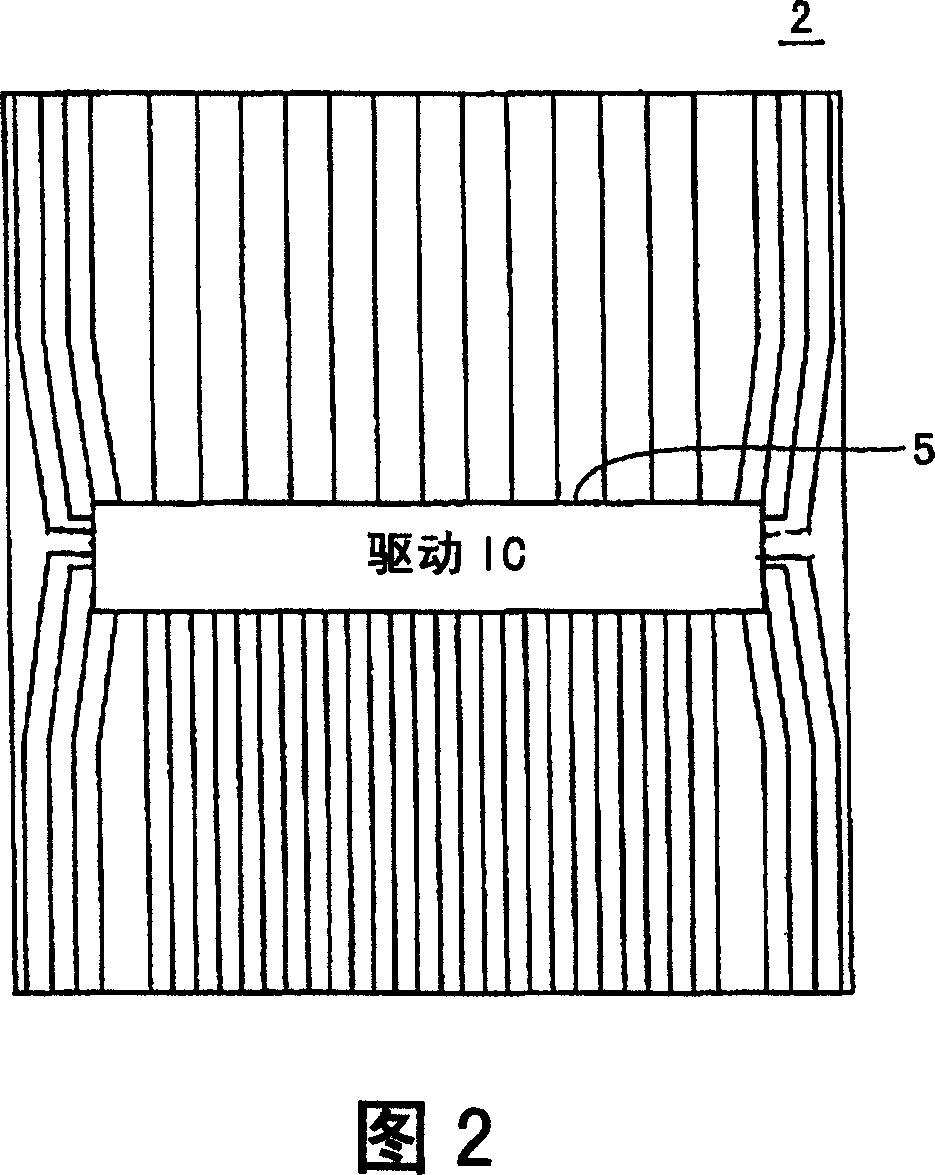

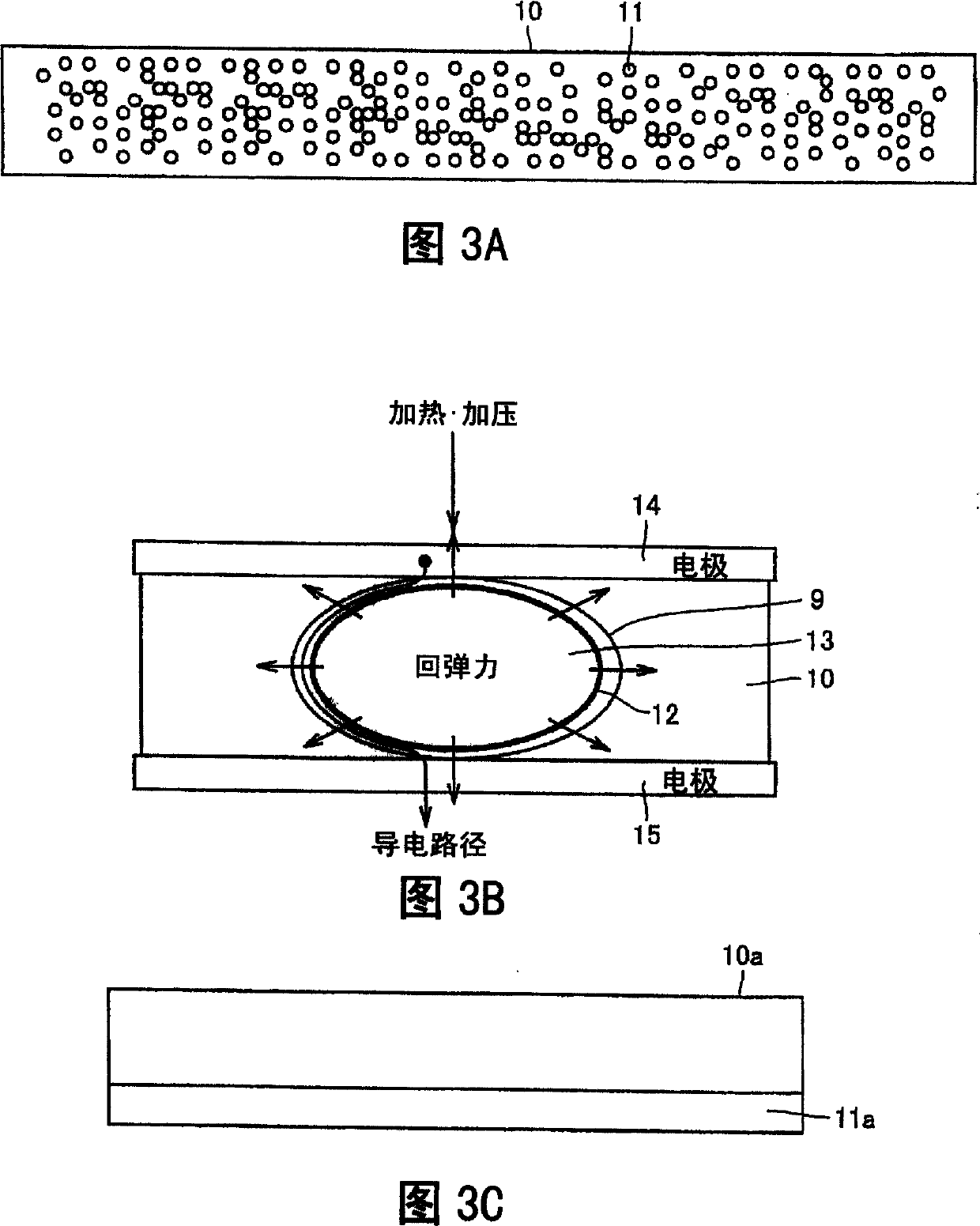

InactiveCN1818754ACurb bendingSuppression of inhomogeneityStatic indicating devicesAdhesive processes with adhesive heatingAnisotropic conductive filmAdhesive

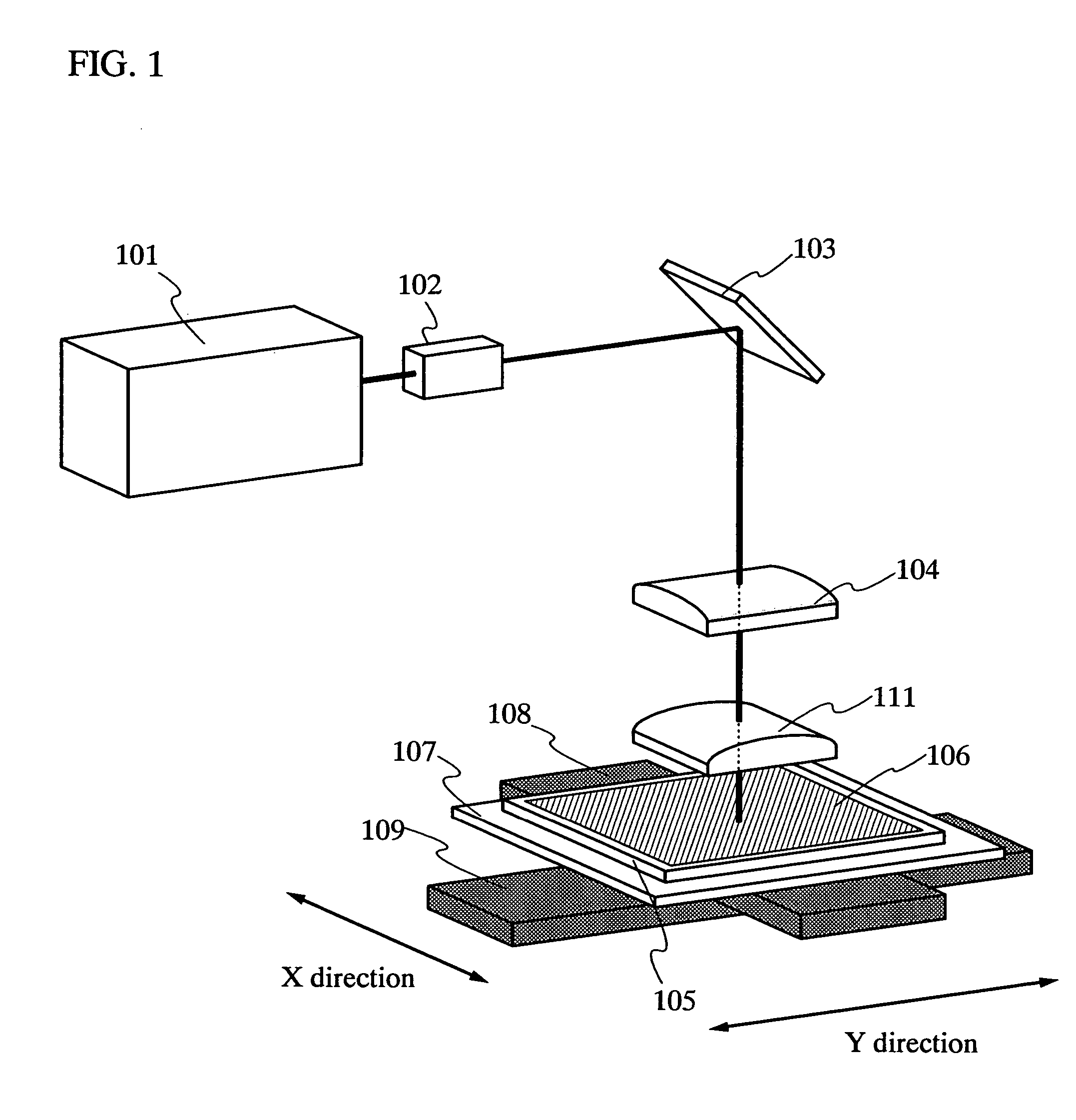

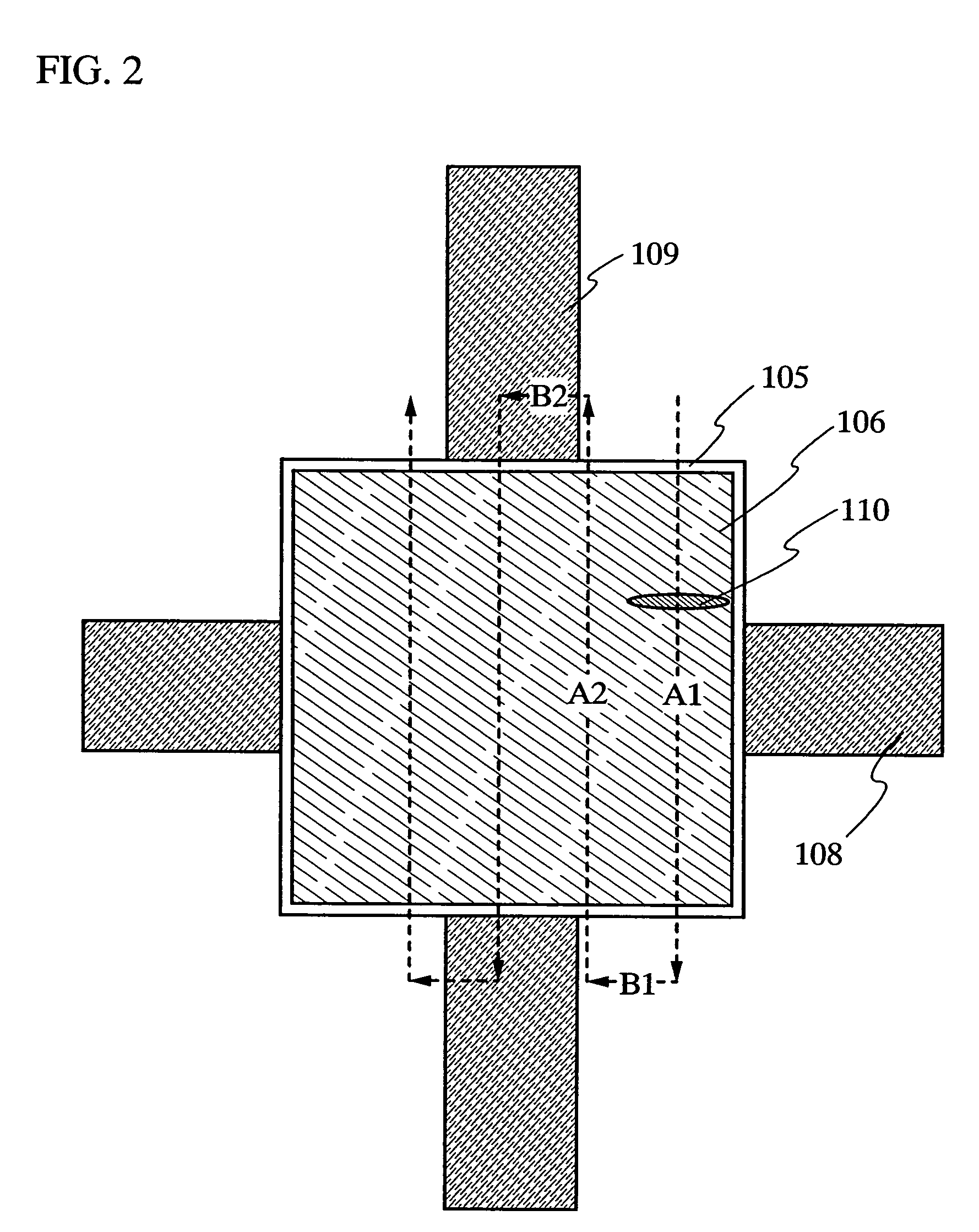

The invention provides a bonding device capable of shortening a bonding time and performing high speed and accurate mounting by irradiating a laser to an anisotropic conductive film (ACF) which is a mounting adhesive. Laser generated from a laser generator is reflected by a laser mirror, passes through an array substrate (glass substrate) through a backup glass, and then, directly irradiated to an ACF in a pinpoint manner. The laser from the laser generator is set to have a wavelength whose transmittance of transmitting the TCP and the array substrate having the ACF inserted therebetween is higher than that of the other wavelength. The ACF is welded by this laser irradiation, so that the TCP and the array substrate are bonded to each other.

Owner:ORMON CORP

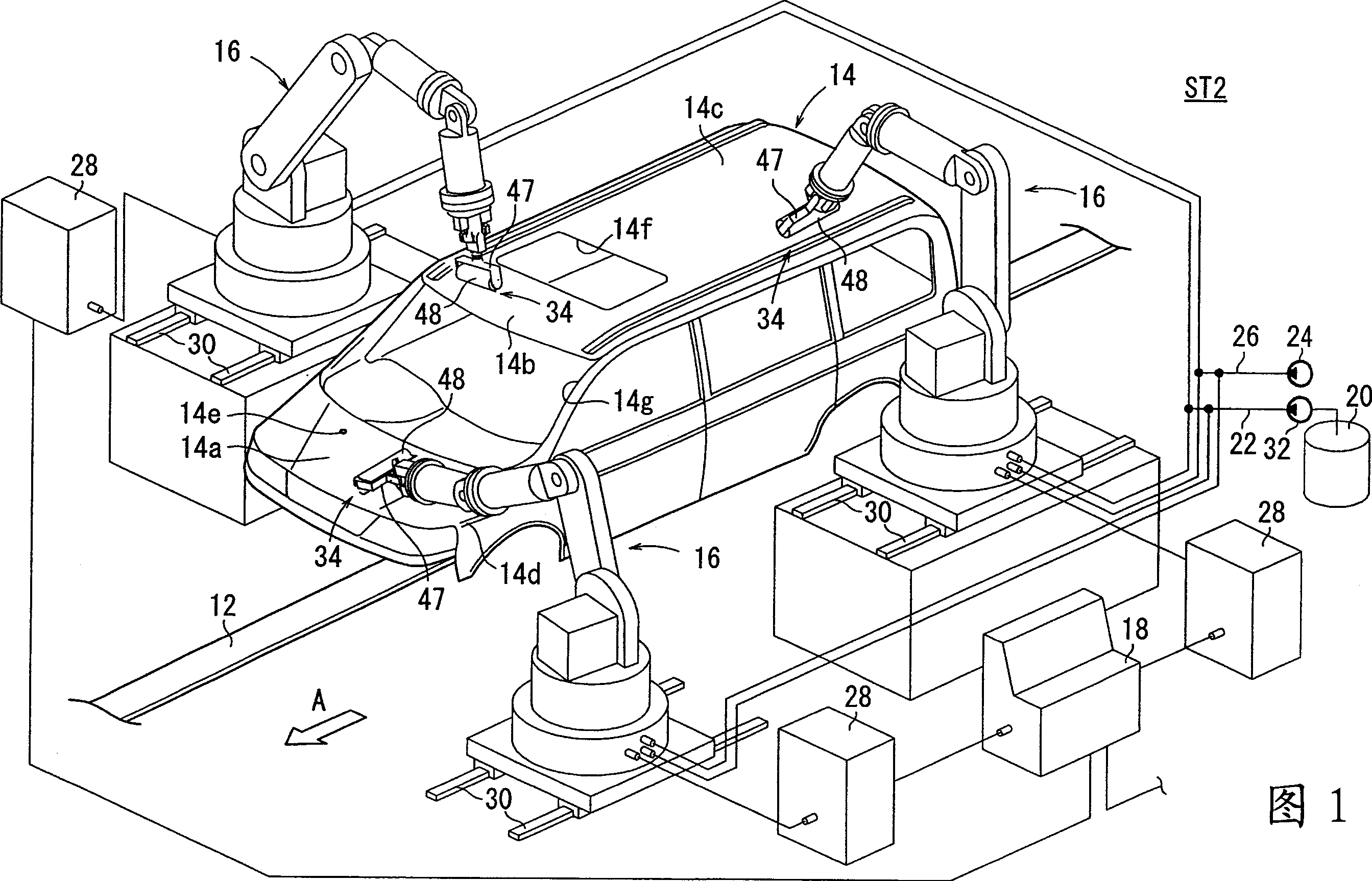

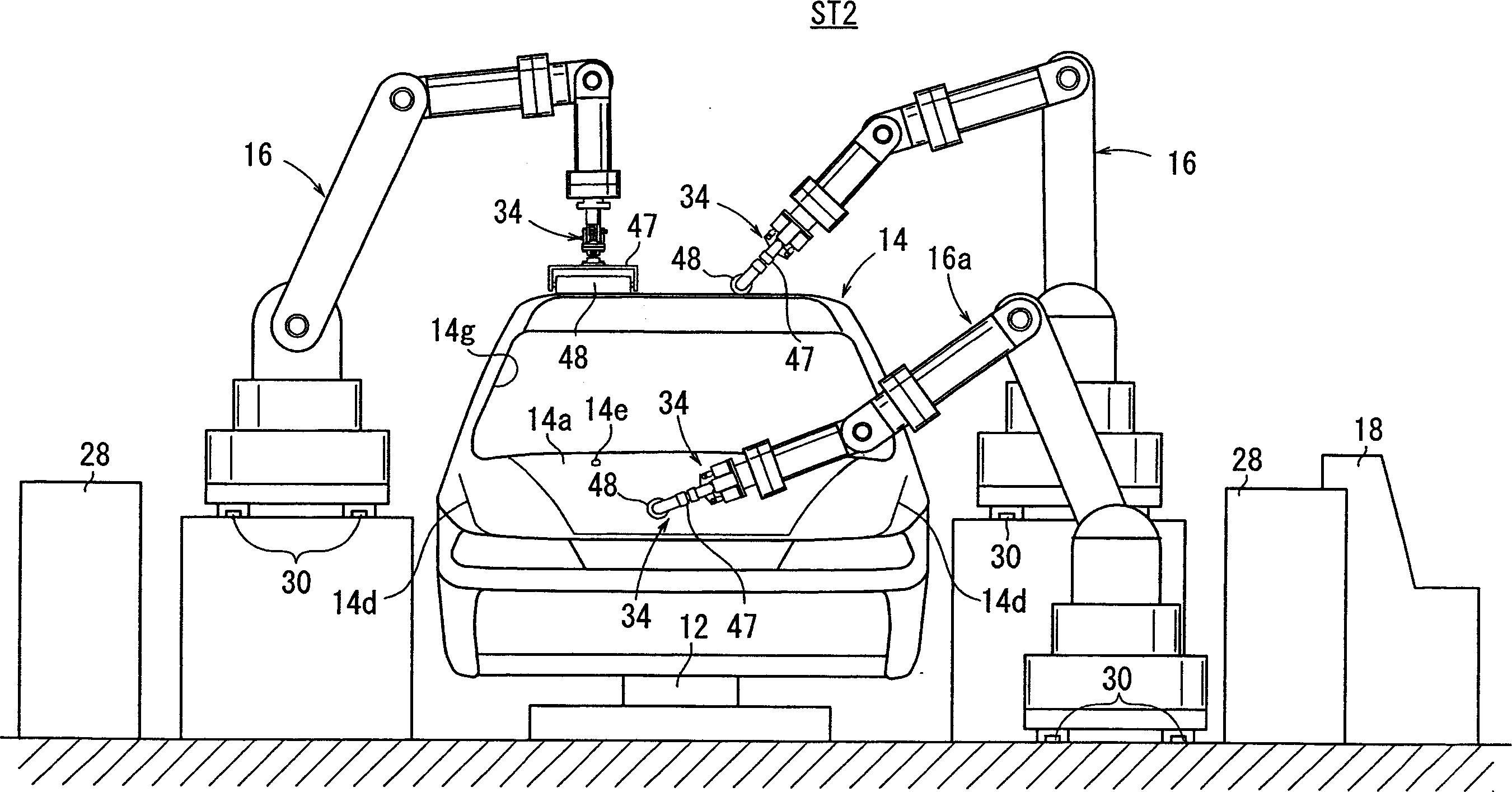

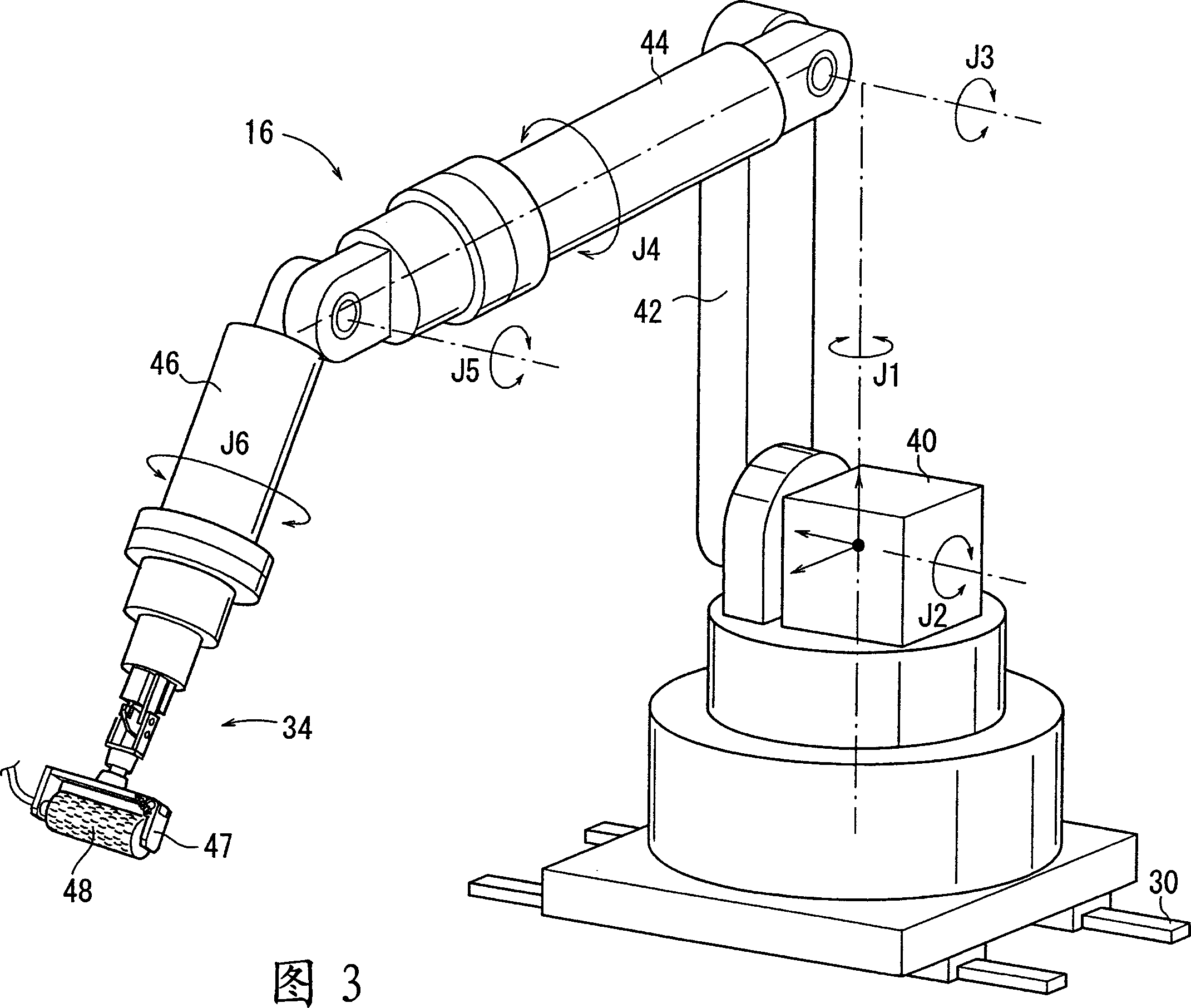

Coating system for protective layer forming material

InactiveCN1750887AInhomogeneity does not appearSuppression of inhomogeneitySpraying apparatusCoatingsCoating systemMechanical engineering

A coating system (10a), comprising a first coating station (ST1), a second coating station (ST2), and a third coating station (ST3) which are arranged in order from the upstream side of vehicles (14) in the carrying direction, wherein a plurality of robots (16) are disposed in each of these stations. In the first coating station (ST1), a protective layer forming material is supplied mainly onto the entire upper surfaces of the vehicles (14) and rough coating is performed, in the second coating station (ST2), the rough coated protective layer forming material is extensively spread for further coating, and in the third coating station (ST3), the finish coating of the protective layer forming material is performed.

Owner:HONDA MOTOR CO LTD

Polyolefine resin sparkling sheet material and productive method

InactiveCN1358620ASuppression of inhomogeneityPoor Appearance InhibitionSynthetic resin layered productsThin material handlingFoaming agentPolymer science

A sheet excellent in surface smoothness in which bubble break in a foamed layer is effectively prevented, and a method of producing this sheet stably are provided. There are provided a polyolefin resin foamed sheet comprising a polyolefin foamed layer, and a polyolefin resin non-foamed layer containing 10% by weight or more of a recycled polyolefin subjected to at least two cycles of a process comprising melting and solidifying polyolefin selected from the group consisting of polyolefin having long chain branched and polyolefin having a weight-average molecular weight of 1x105 or more, and a method of producing a polyolefin resin foamed sheet comprising a polyolefin resin foamed layer and a polyolefin resin non-foamed layer wherein a polyolefin layer 1 containing a foaming agent and a polyolefin layer 2 containing 10% by weight or more of a recycled polyolefin subjected to at least two cycles of a process comprising melting and solidifying polyolefin selected from the group consisting of polyolefin having long chain branch and polyolefin having a weight-average molecular weight of 1 x105 or more are co-extruded, and the polyolefin resin layer 1 is foamed.

Owner:SUMITOMO CHEM CO LTD

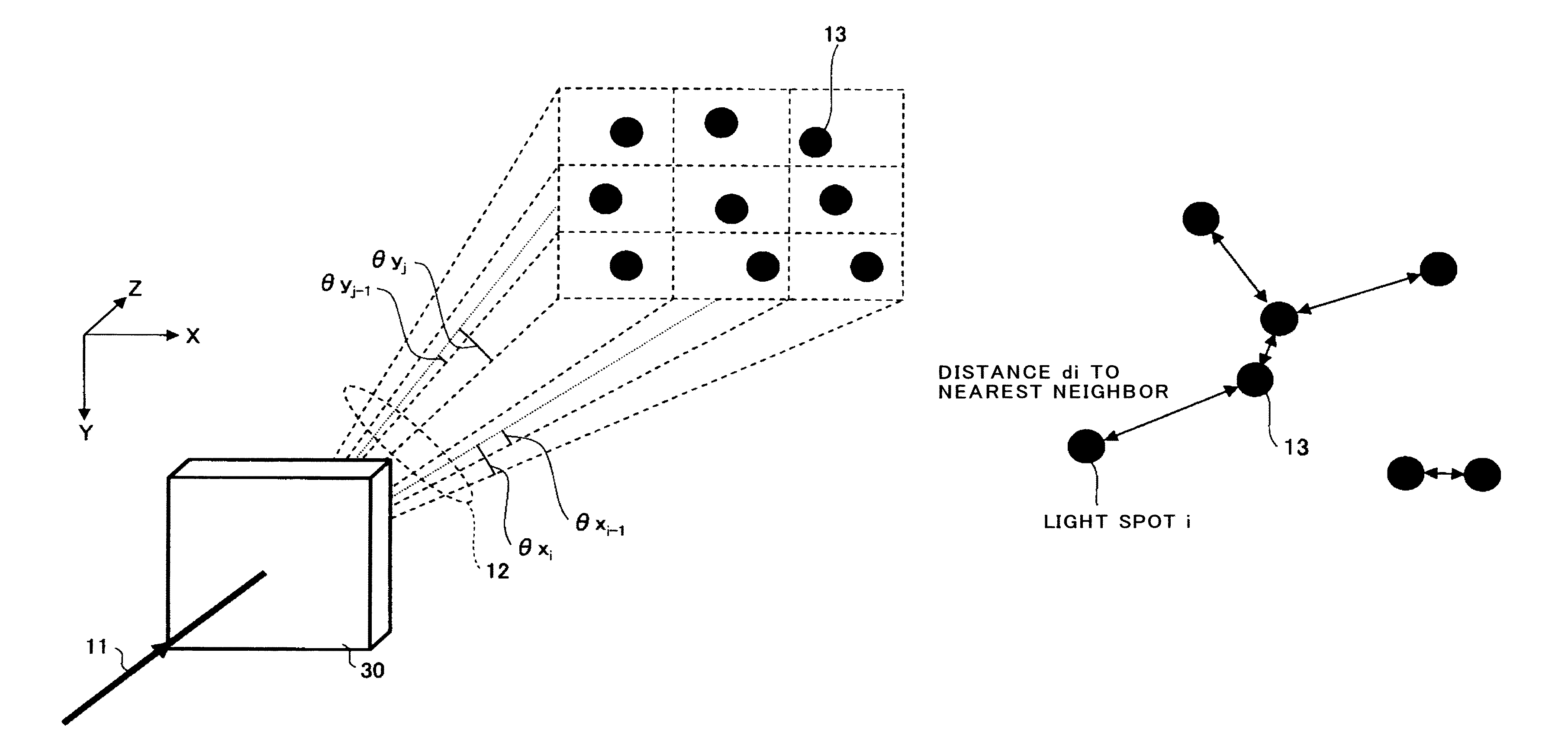

Diffractive optical element and measuring device

ActiveUS8599484B2Density inhomogeneity of light spots is suppressedAccurate measurementScattering properties measurementsDiffraction gratingsLight spotNear neighbor

Owner:ASAHI GLASS CO LTD

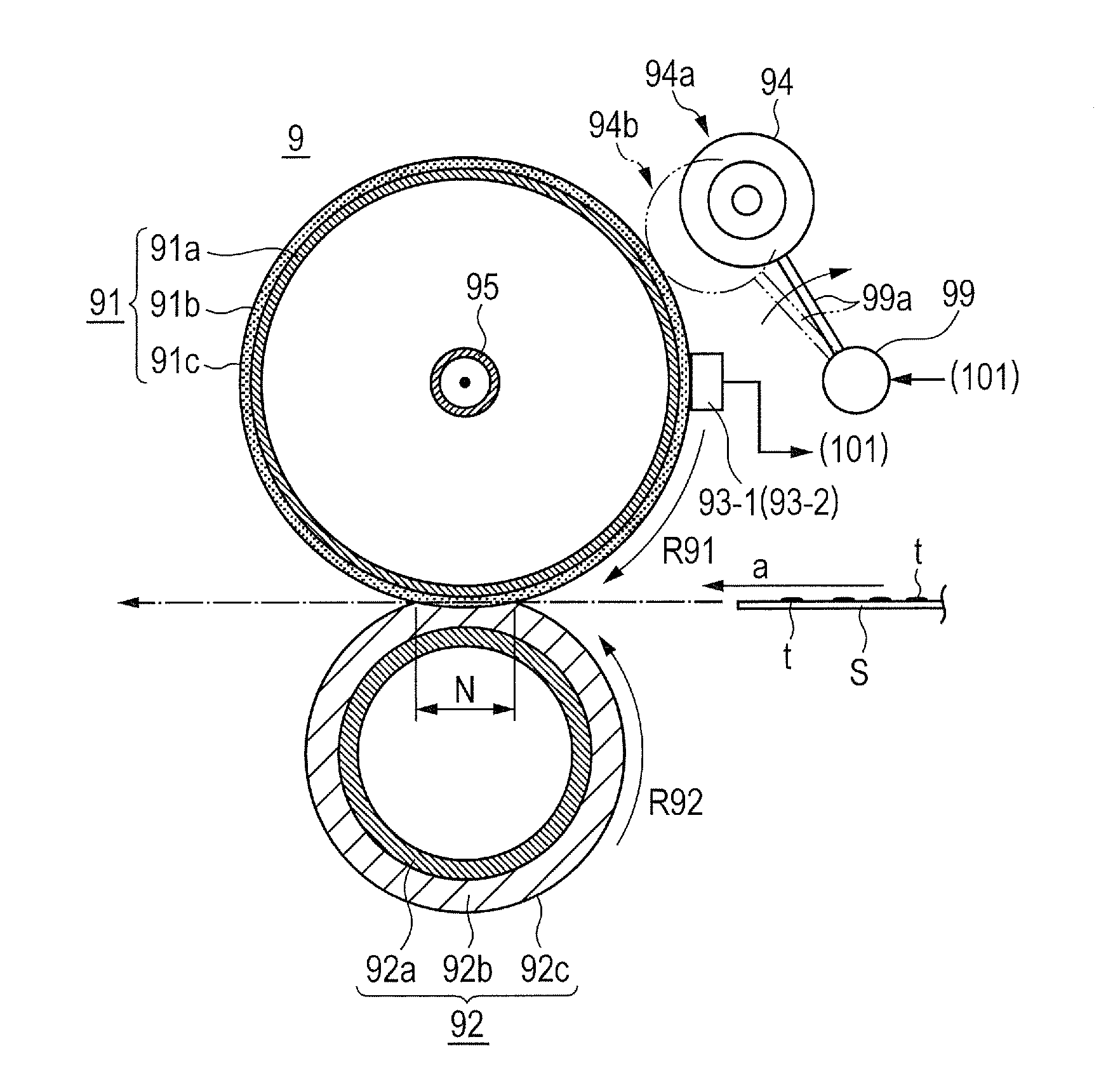

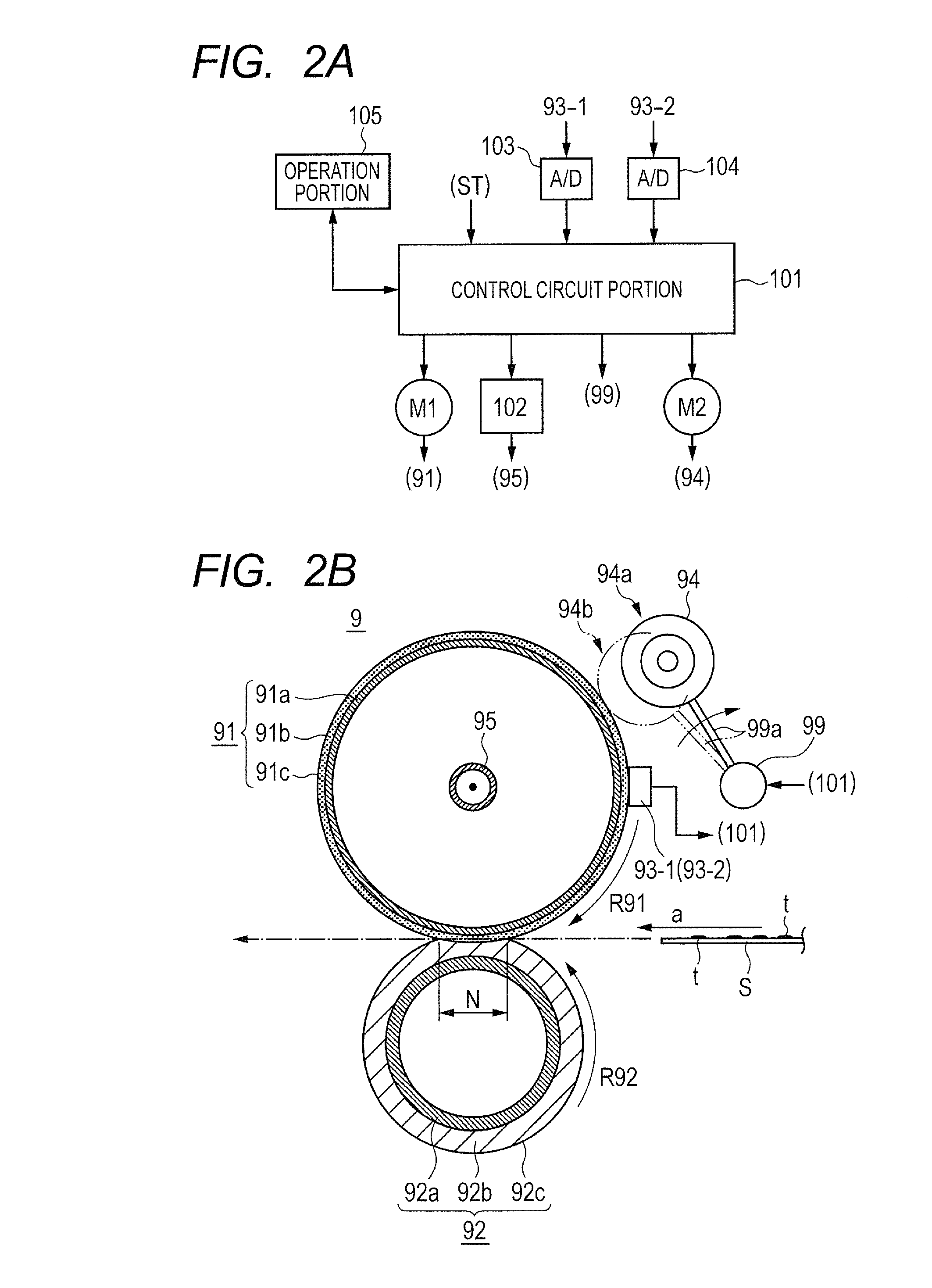

Image heating apparatus

ActiveUS20130136480A1Suppresses gloss unevennessSuppression of inhomogeneityElectrographic process apparatusEngineeringTemperature difference

In an image heating apparatus in which a heating rotating body heats a recording material bearing an image and a rubbing member rubs the heating rotating body to eliminate gloss streaks, an image failure such as gloss unevenness does not occur in a normal plain paper and a coated paper, and a toner gloss on the coated paper can be enhanced. A longitudinal temperature difference of a heating rotating body 91 is controlled within a predetermined temperature, so that the surface of the heating rotating body can be uniformly roughed. Consequently, an image failure due to scuffs on the surface of the heating rotating body and gloss unevenness due to unevenness of roughness of the surface of the heating rotating body are prevented, and thus a good fixed image can be obtained.

Owner:CANON KK

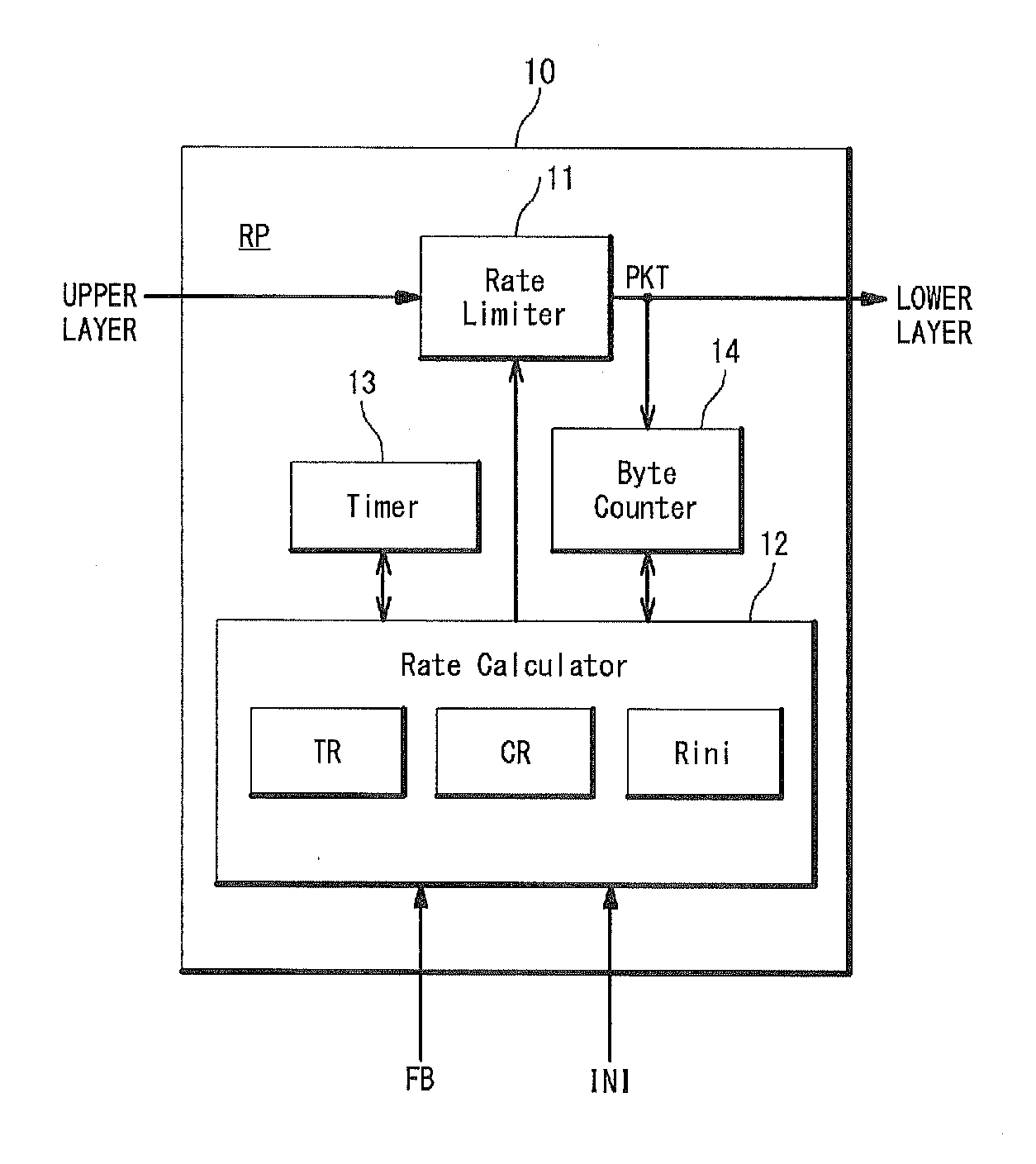

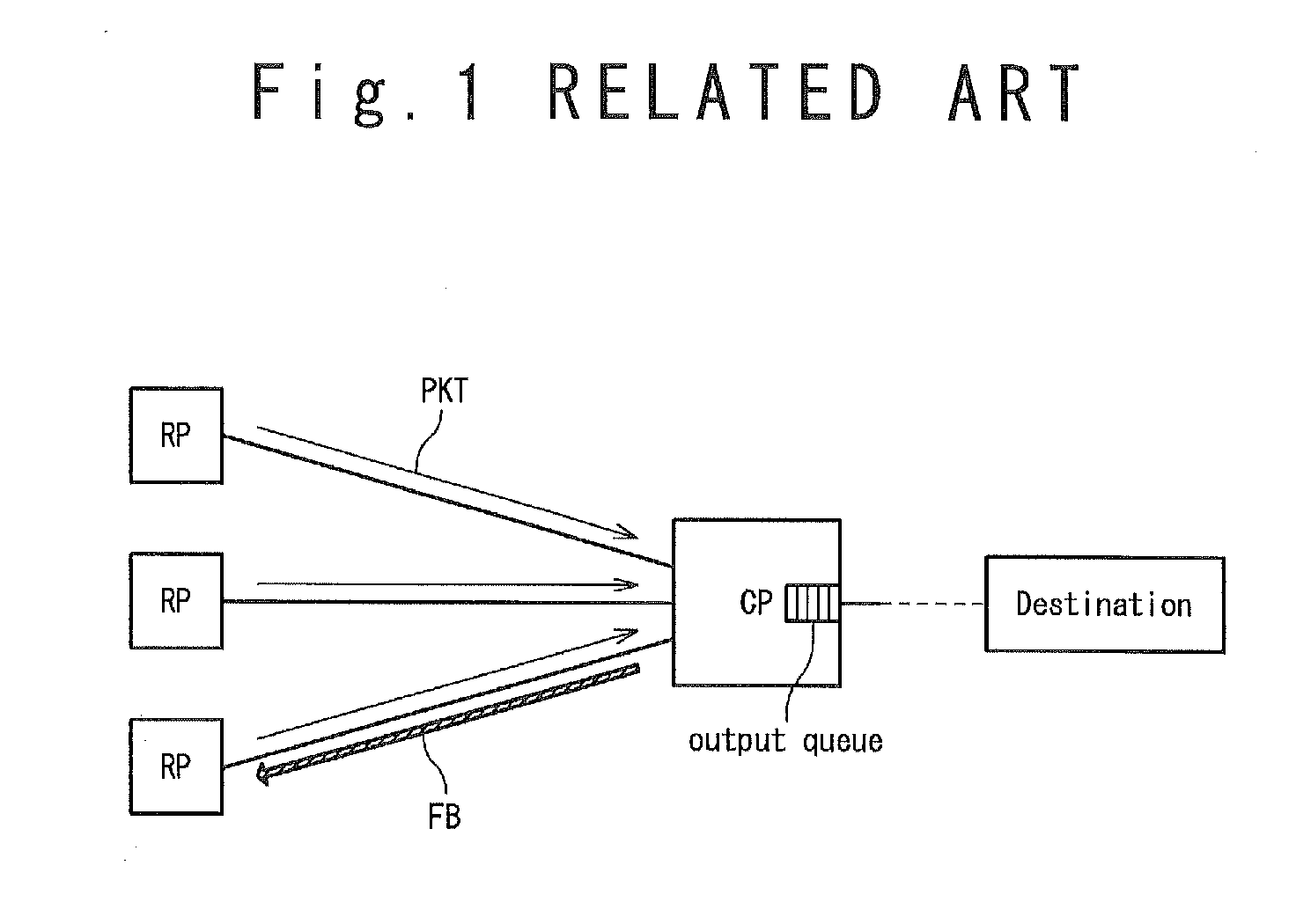

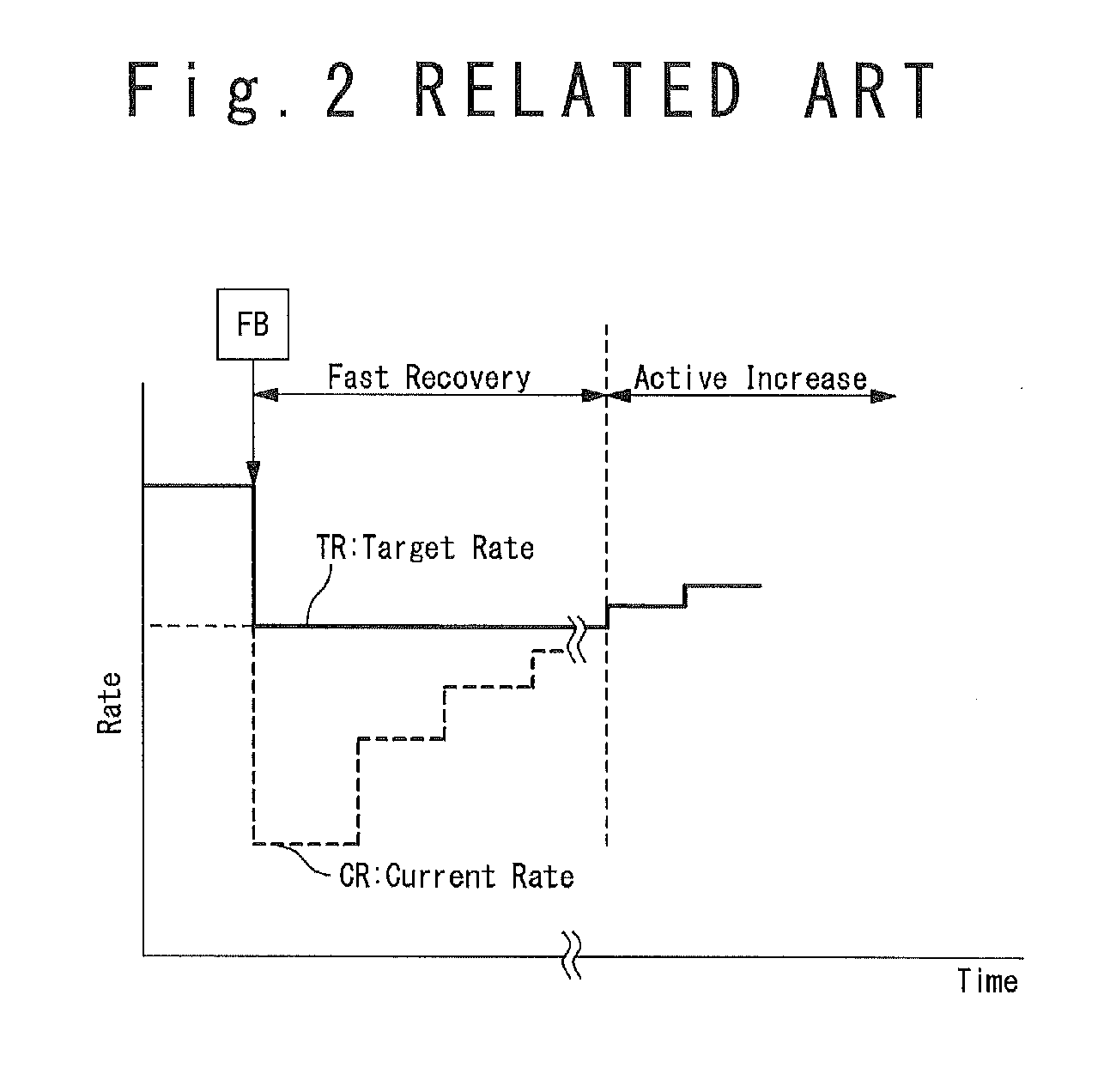

Congestion control system, congestion control method, and communication unit

InactiveUS20130159415A1Suppression of inhomogeneityData switching networksCommunication unitControl system

A congestion control system is provided with a plurality of reaction points, each of which is configured to transmit a packet to a transmission destination; and a congestion point configured to receive the packets transmitted from the plurality of reaction points. When detecting congestion in itself, the congestion point samples each of the received packets based on a predetermined algorithm, and transmits a feedback message to the reaction point as a transmission source of the sampled packet. Each of the plurality of reaction points controls a target rate based on a reception situation of the feedback message, and sets the target rate to an initial value at an initialization timing which does not depend on the feedback message.

Owner:NEC CORP +1

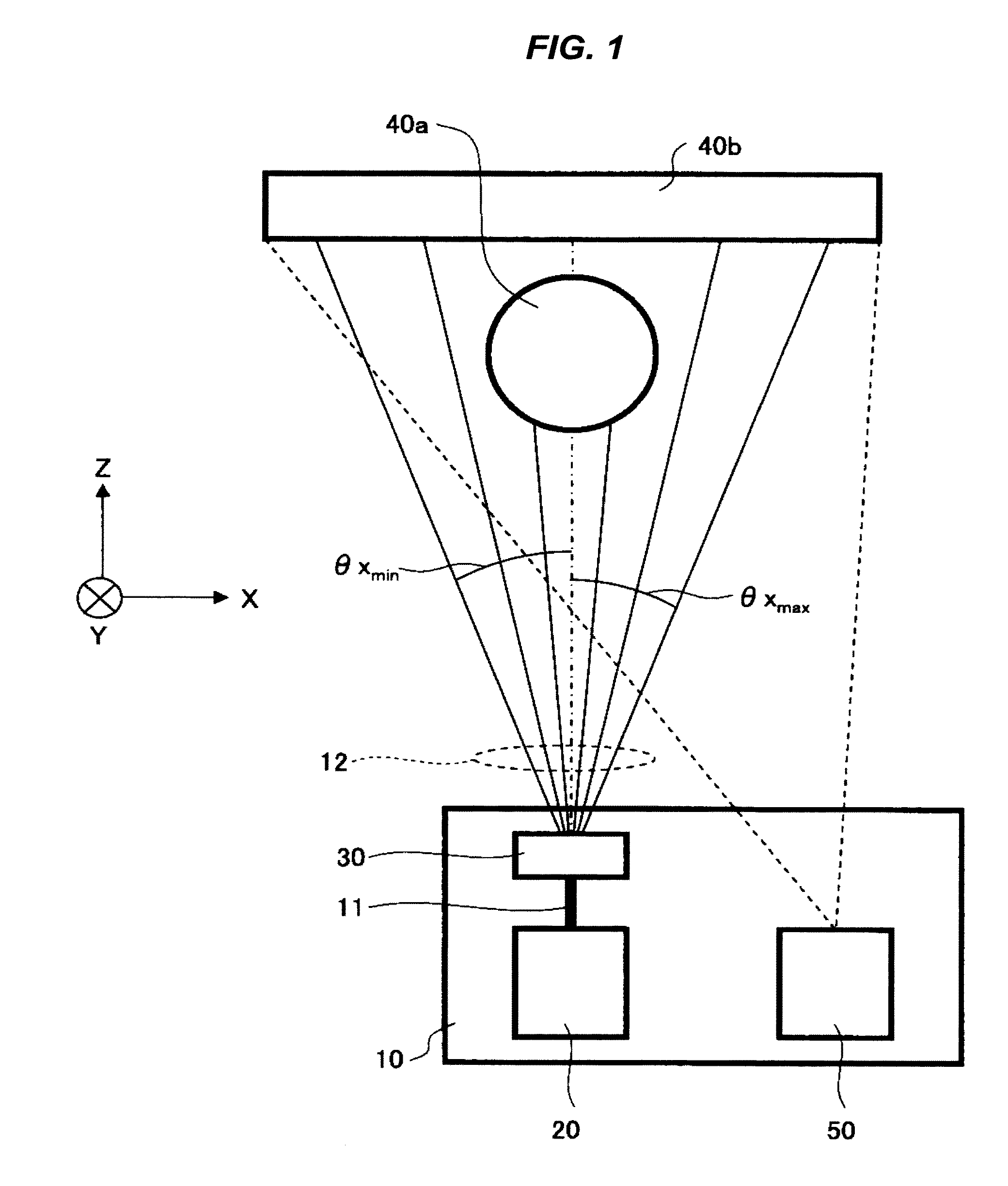

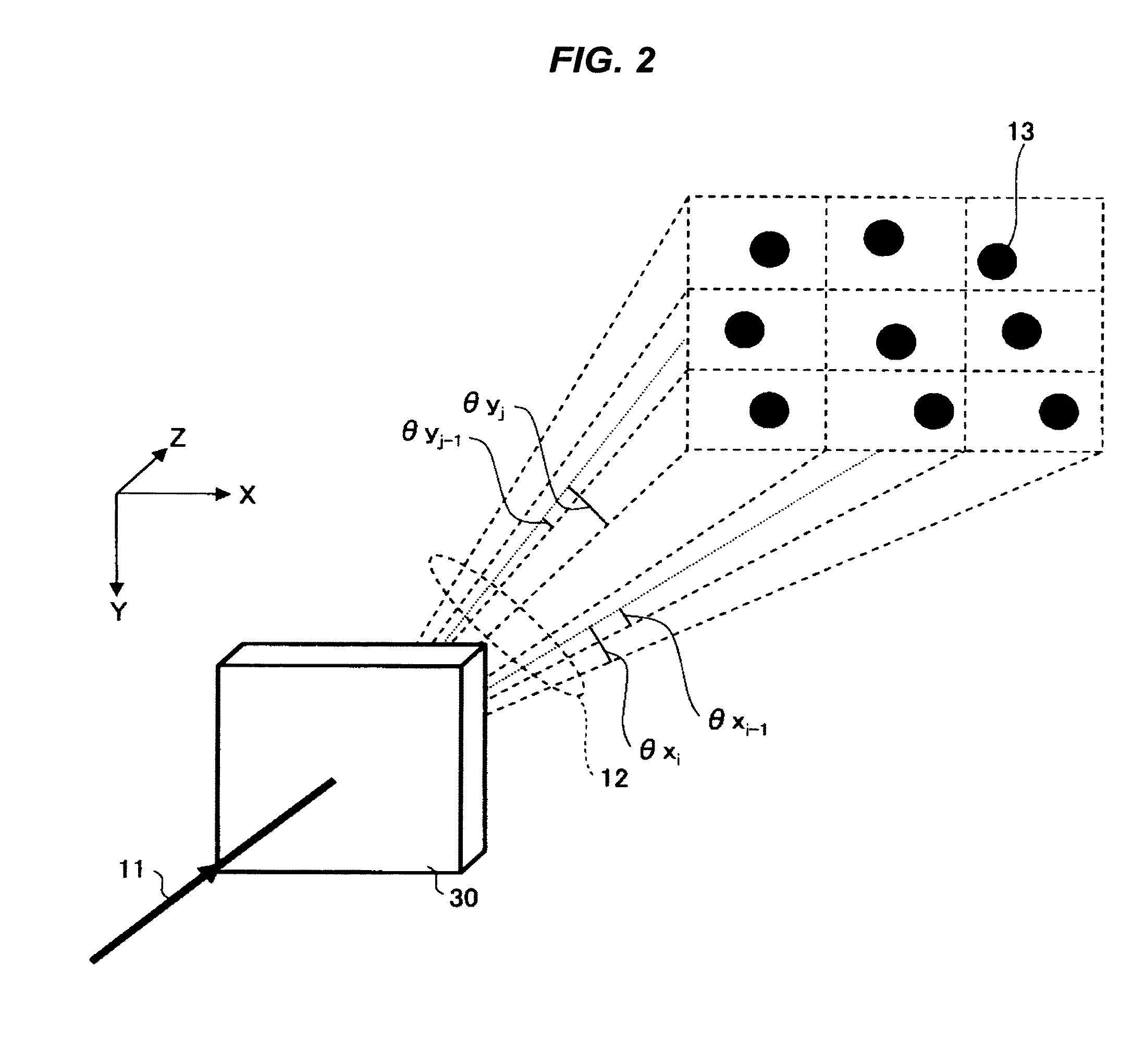

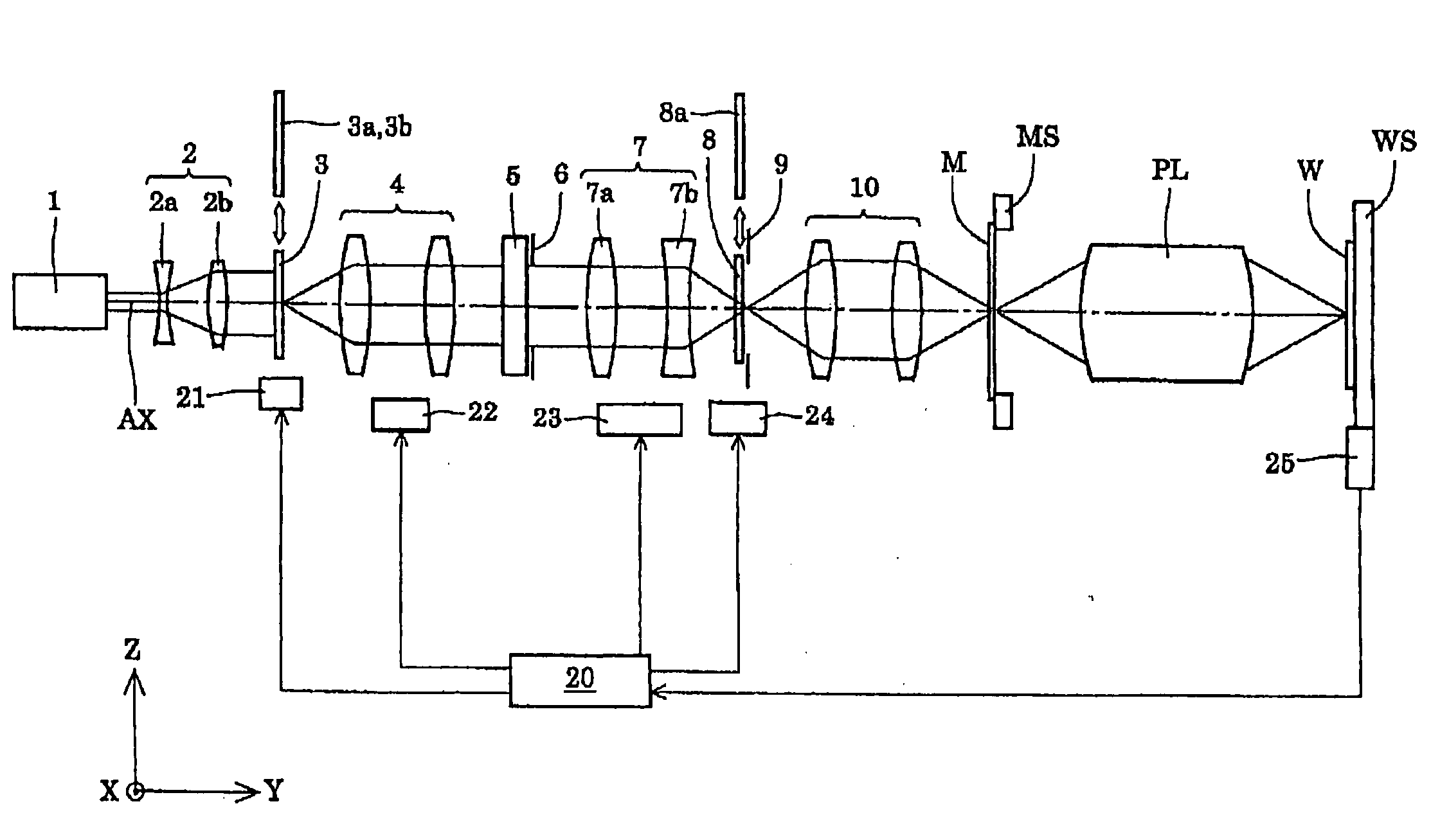

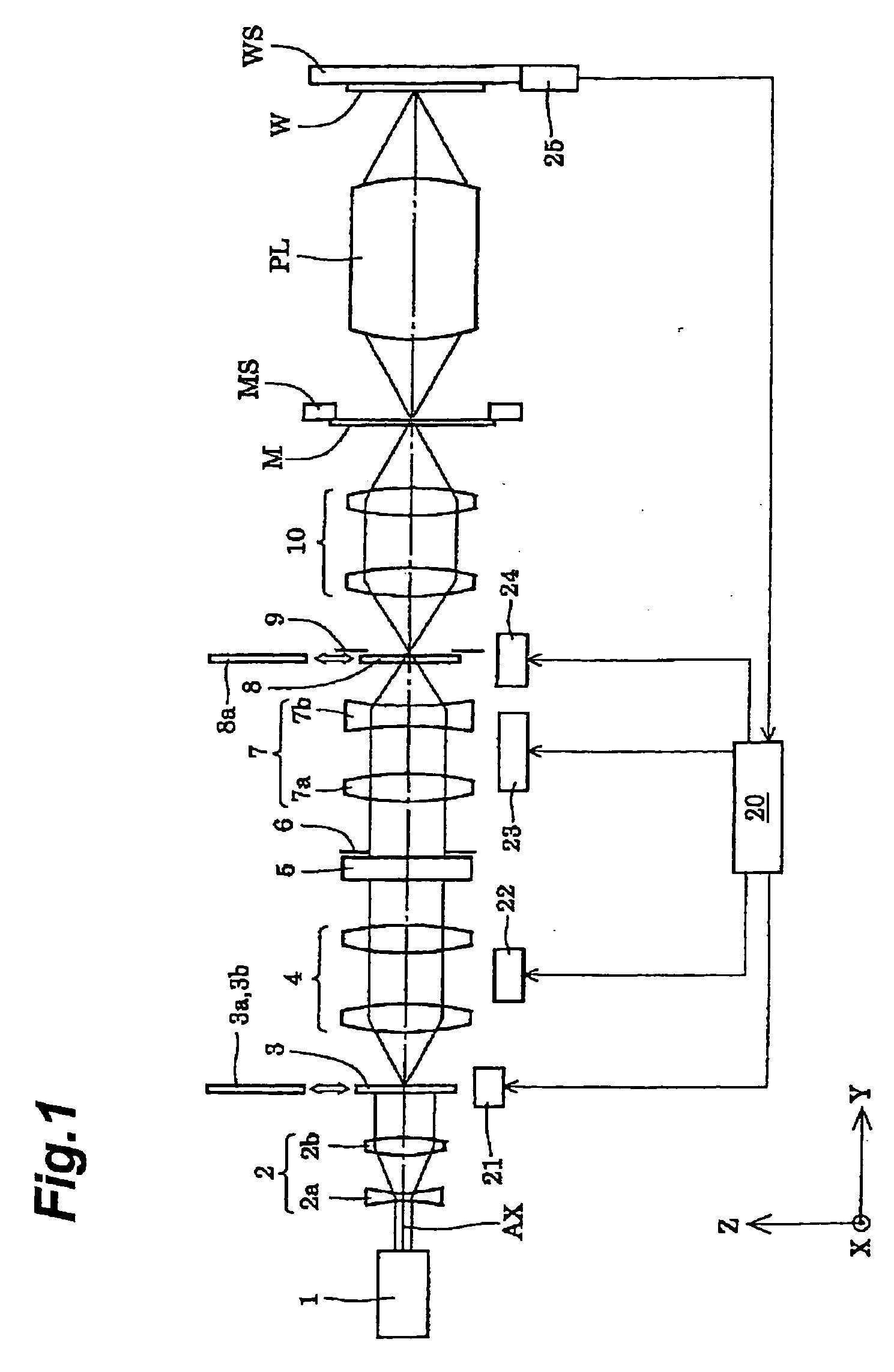

Illuminant distribution evaluation method, optical member manufacturing method, illumination optical device, exposure apparatus, and exposure method

InactiveUS20060166142A1Suppression of inhomogeneityPhotometrySemiconductor/solid-state device manufacturingPhysicsLight source

Owner:NIKON CORP

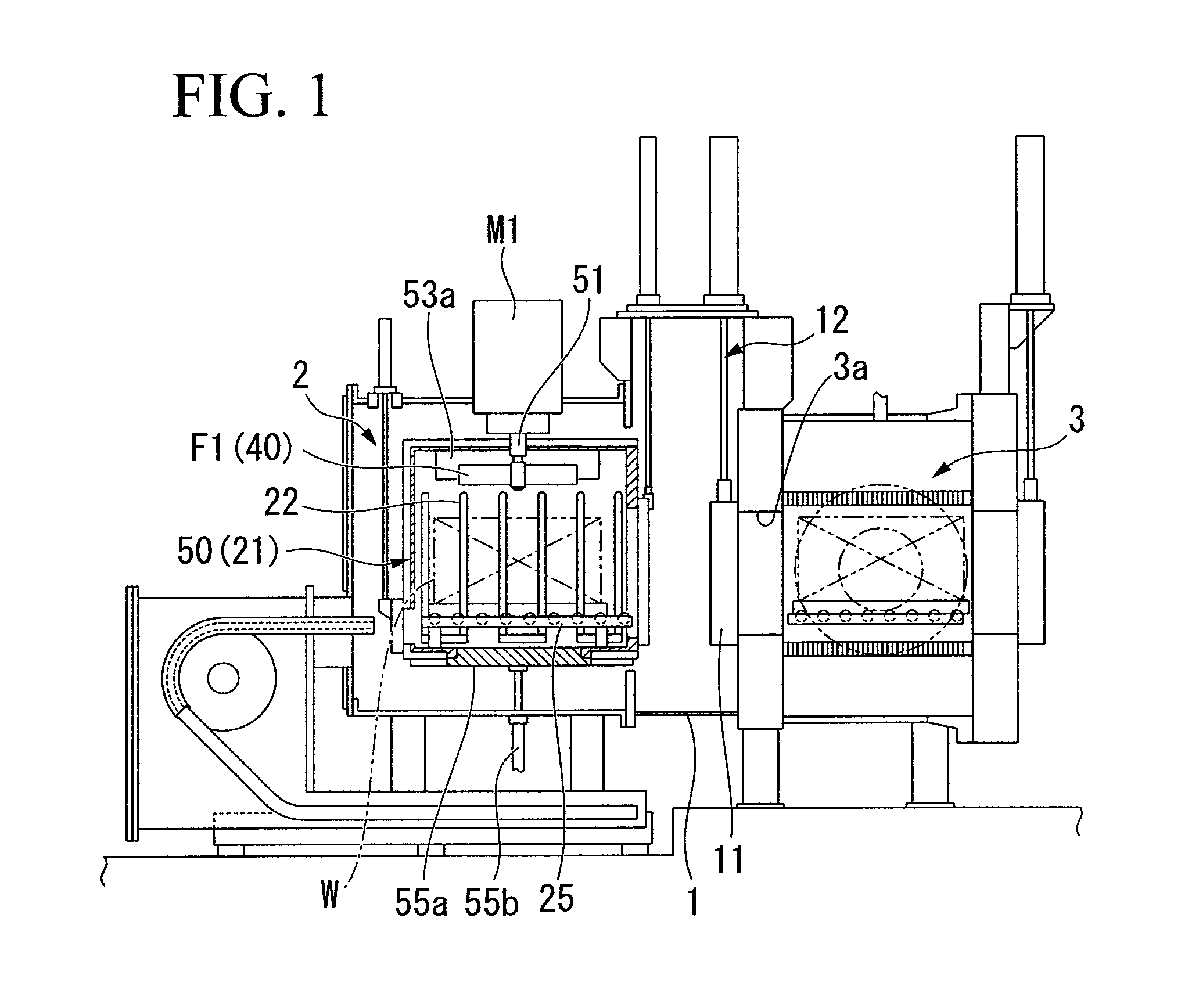

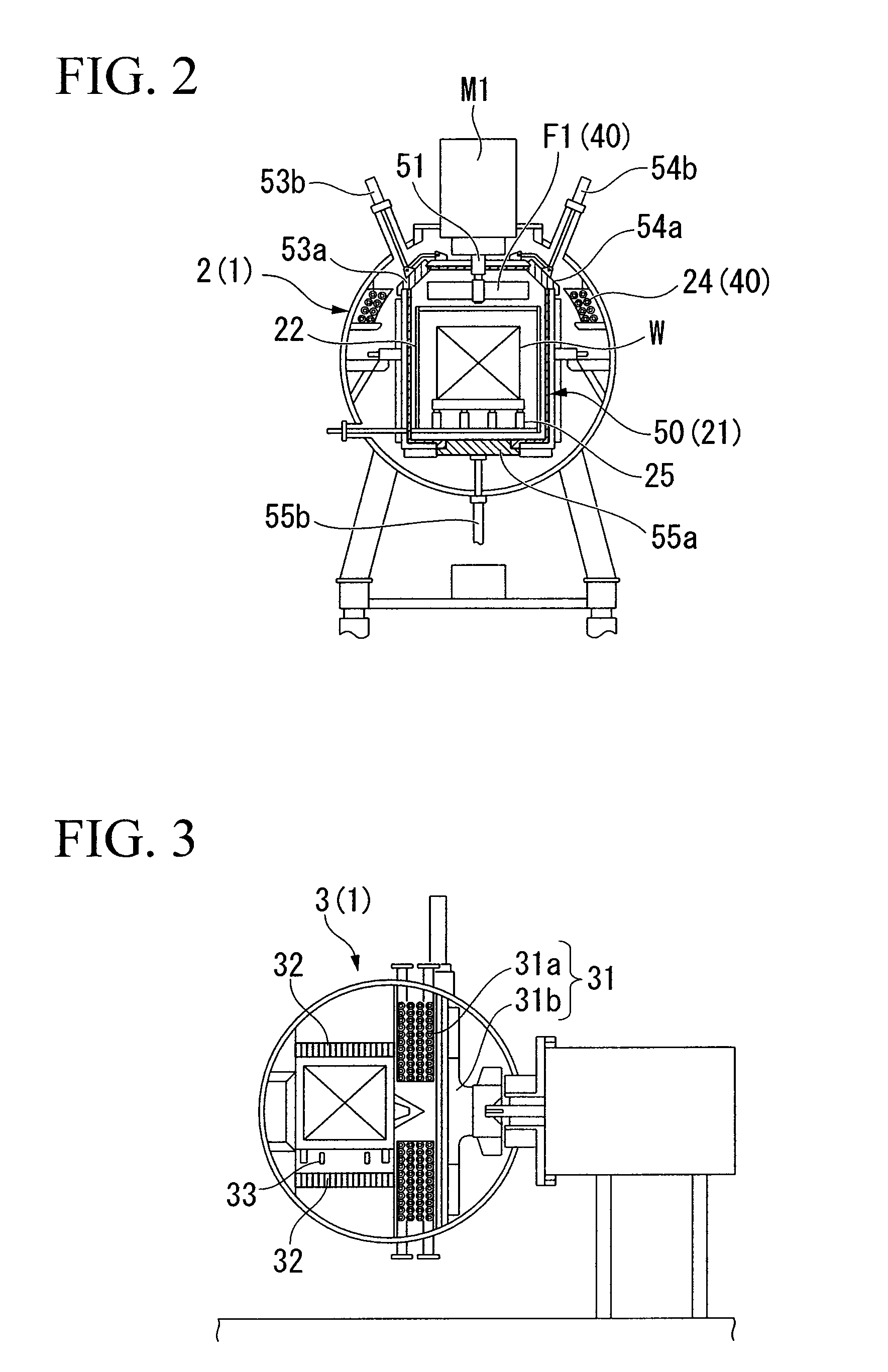

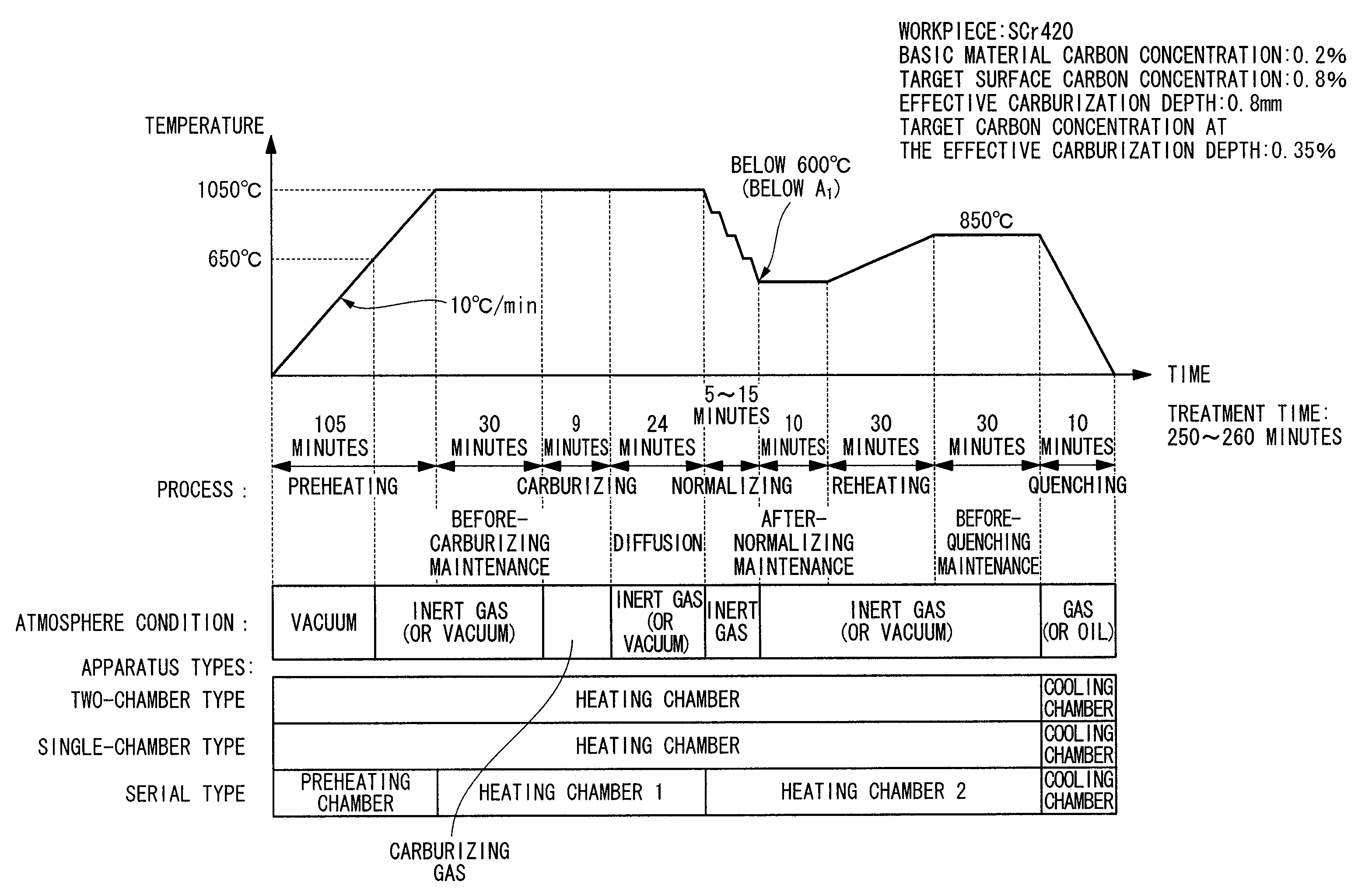

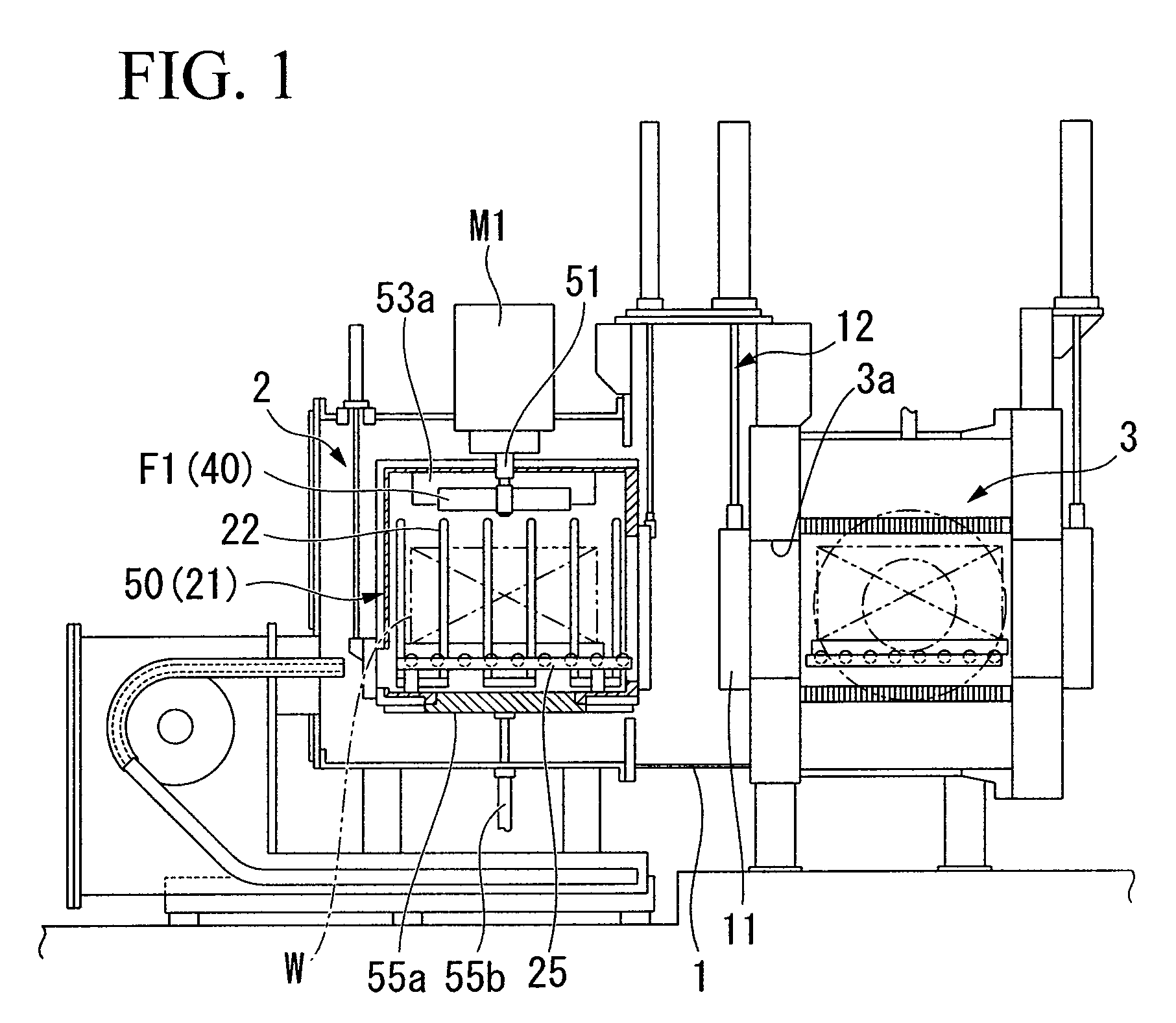

Vacuum carburization method and vacuum carburization apparatus

InactiveUS20080216922A1Reduce processing timeSuppression of inhomogeneitySolid state diffusion coatingProperty valueQuenching

There are provided a method, between a diffusion process and a quenching process, a normalizing process of performing step cooling in which a temperature lowering treatment and a temperature keeping treatment are alternately repeated plural times so that a temperature history from the first temperature to a predetermined temperature satisfies a predetermined condition; an after-normalizing maintaining process of maintaining the temperature of the whole workpiece for a predetermined time after the normalizing process so that the whole workpiece becomes the predetermined temperature, thereby producing fine crystal grains in the workpiece; and a reheating process of raising the temperature of the workpiece to the second temperature, after the after-normalizing keeping process. According to the invention, even when a process temperature is set high to make rapid progress of carburization and diffusion and thus the process time is shortened, uniformity in temperature is achieved between a surface and a inside of a workpiece by the high-temperature process and crystal grains are prevented from being coarse, thereby obtaining a workpiece having a predetermined property value.

Owner:IHI CORP

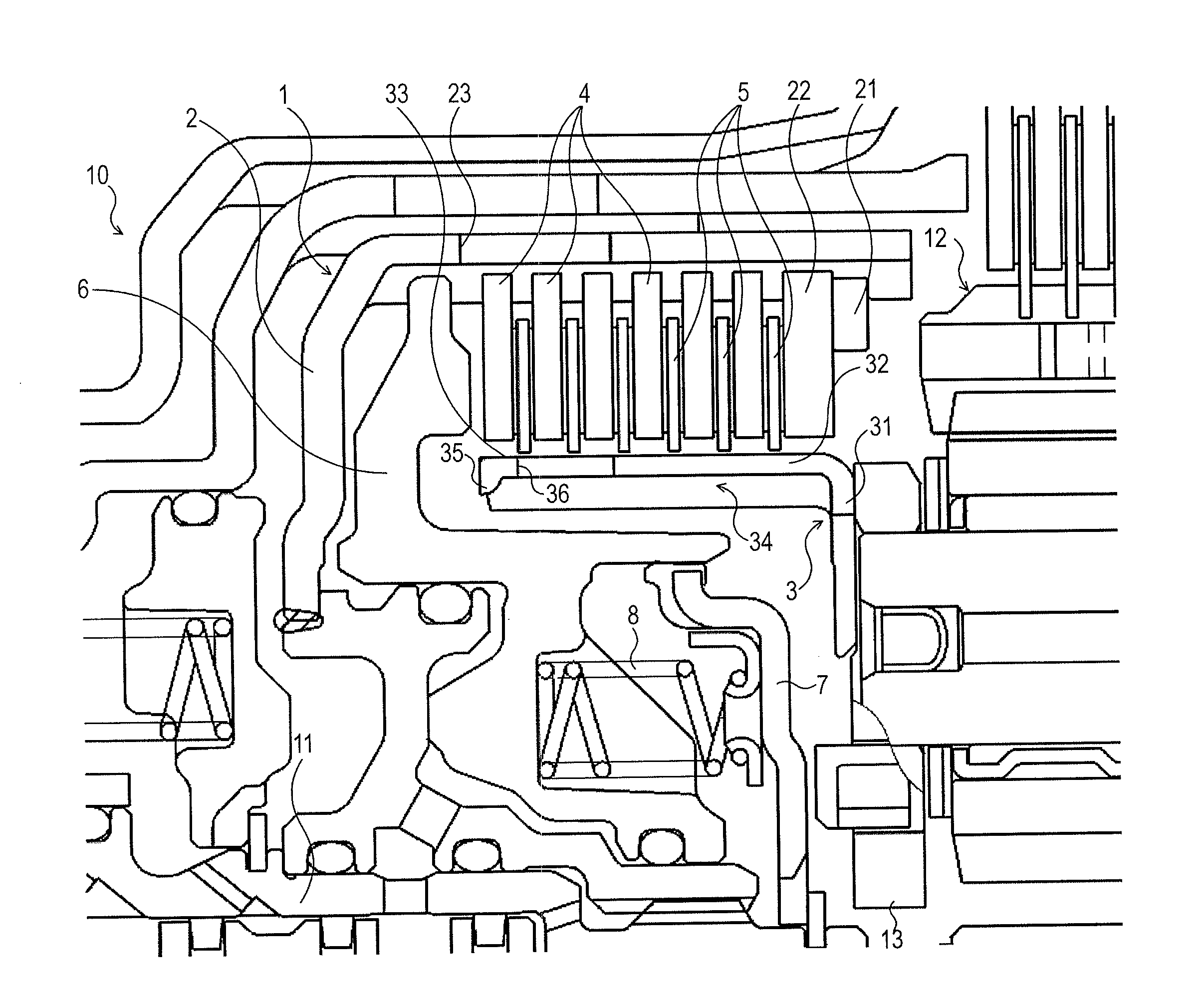

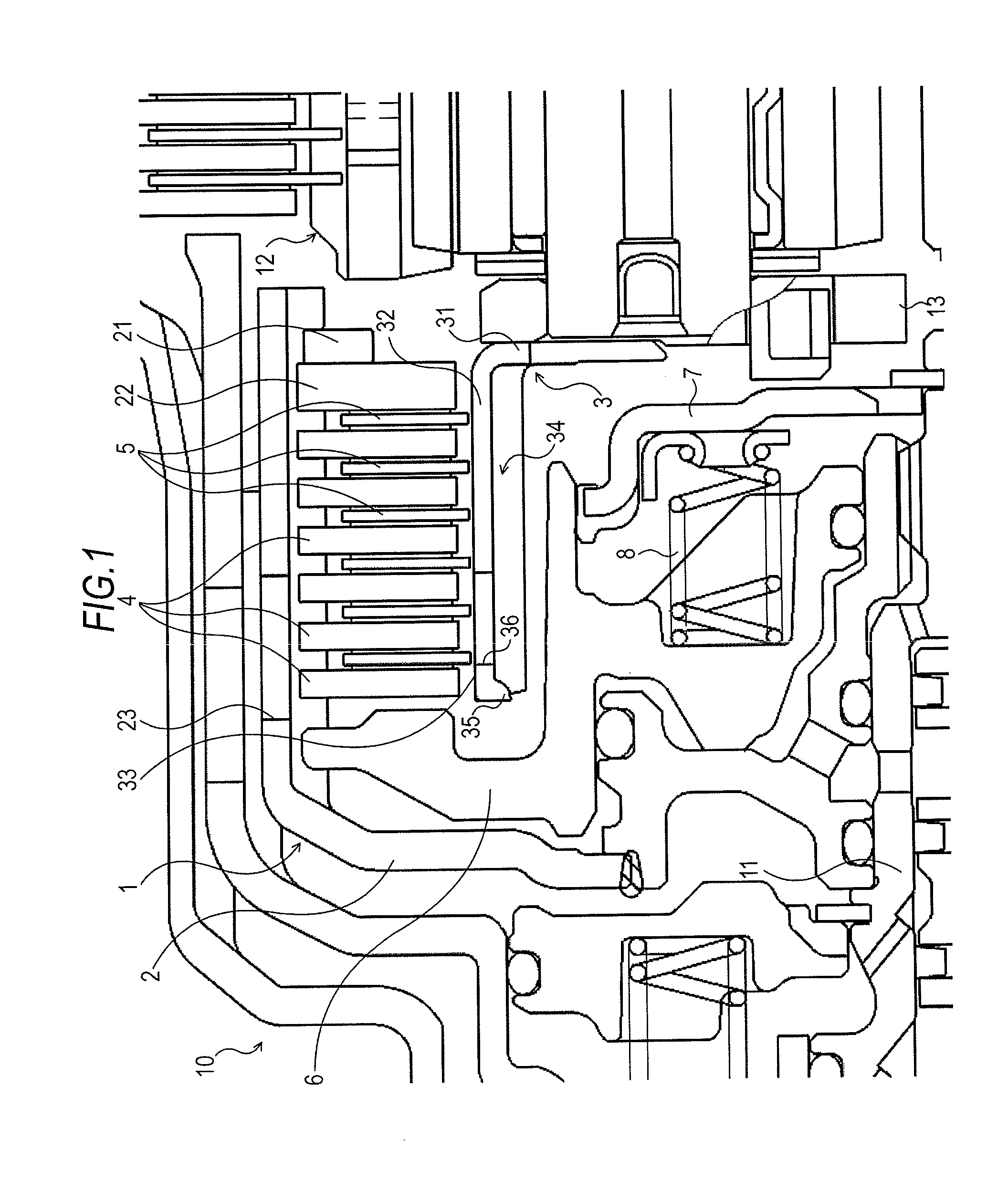

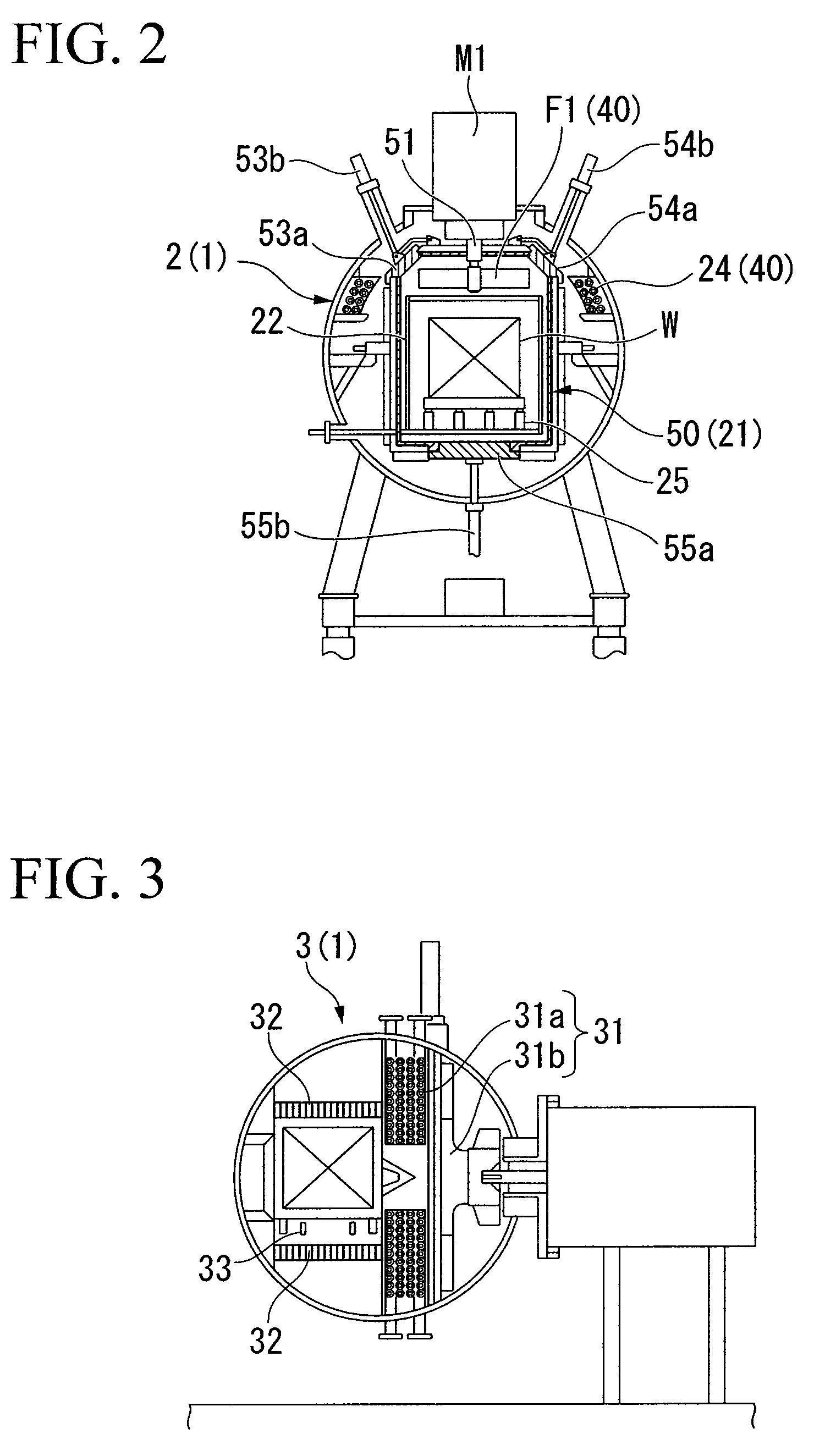

Multi-plate clutch and manufacturing method of clutch hub

ActiveUS20120080284A1Well formedEffectively lubricate and coolMetal-working apparatusFriction clutchesEngineeringClutch

A multi-plate clutch including a clutch hub having a cylindrical portion; a plurality of clutch plates splined to the outer periphery of the cylindrical portion of the clutch hub, and a plurality of spline teeth being formed on the outer periphery of the cylindrical portion of the clutch hub. A recessed portion is formed on the inner side of each spline tooth, and a weir portion is formed at one end of each recessed portion by depressing one portion of the spline tooth to the inner side on one end side of the cylindrical portion. Thus forming a depressed portion, and removing, with one portion of the depressed portion left behind, a portion of the cylindrical portion on the one end side of the one portion of the depressed portion.

Owner:AISIN AW CO LTD

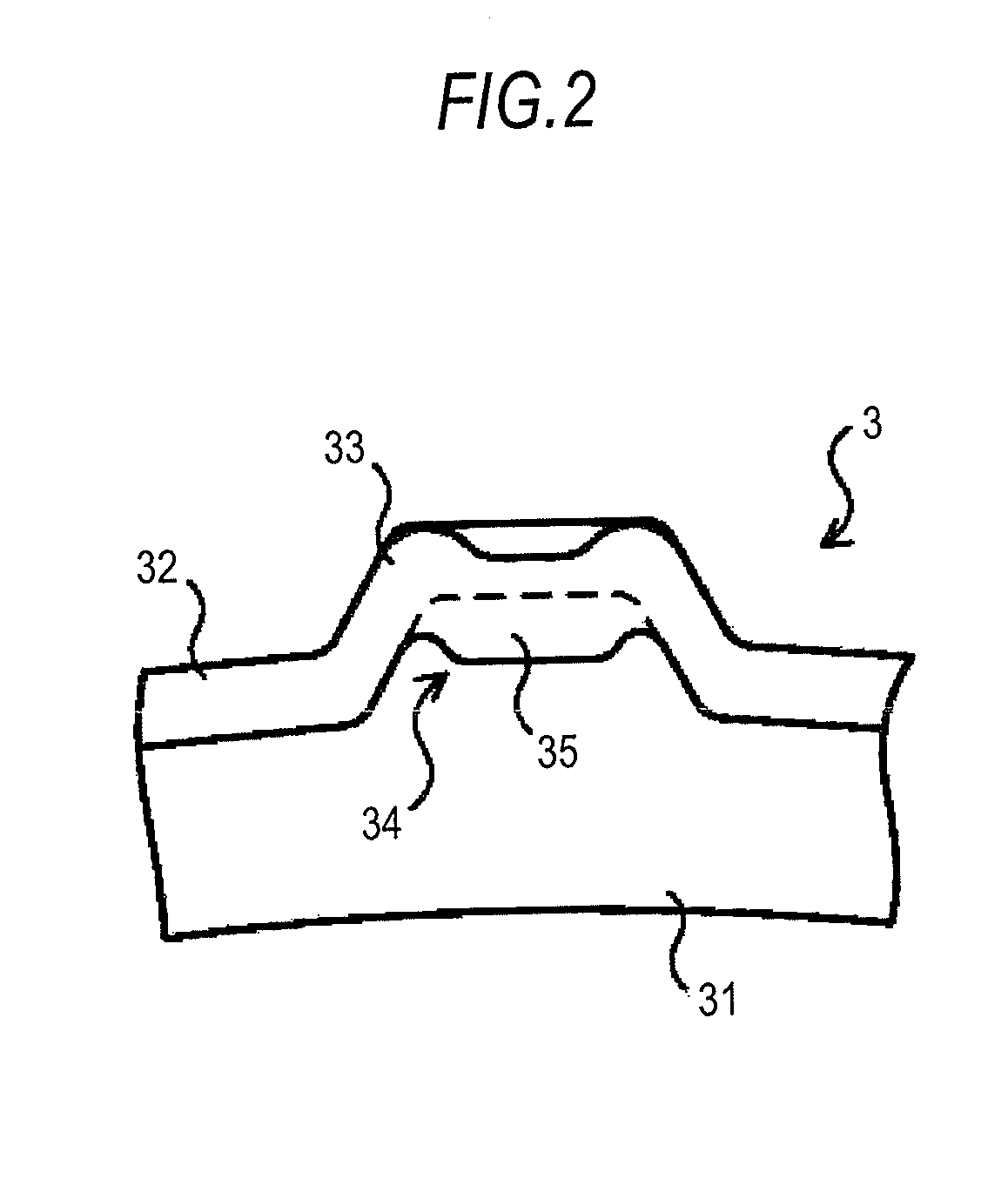

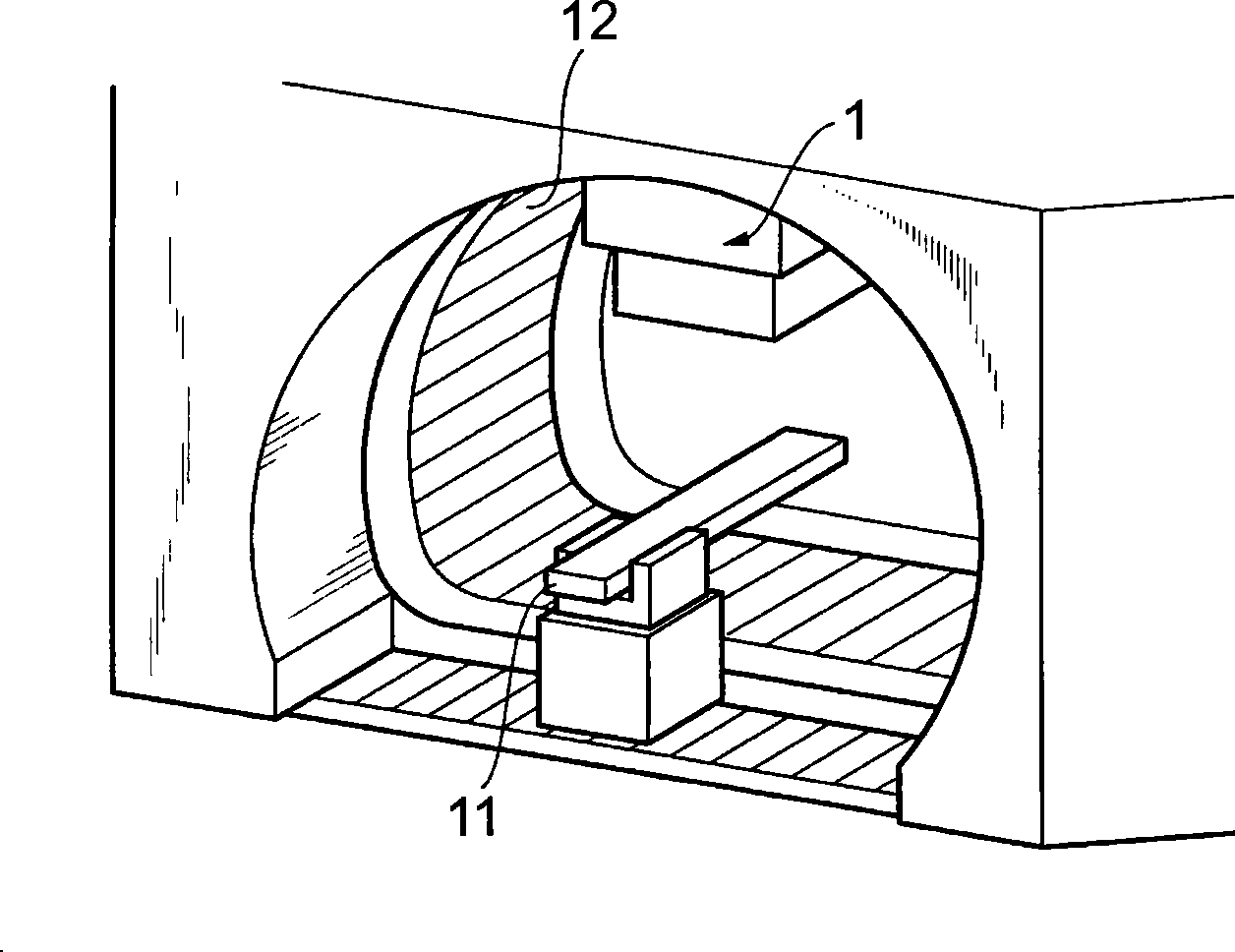

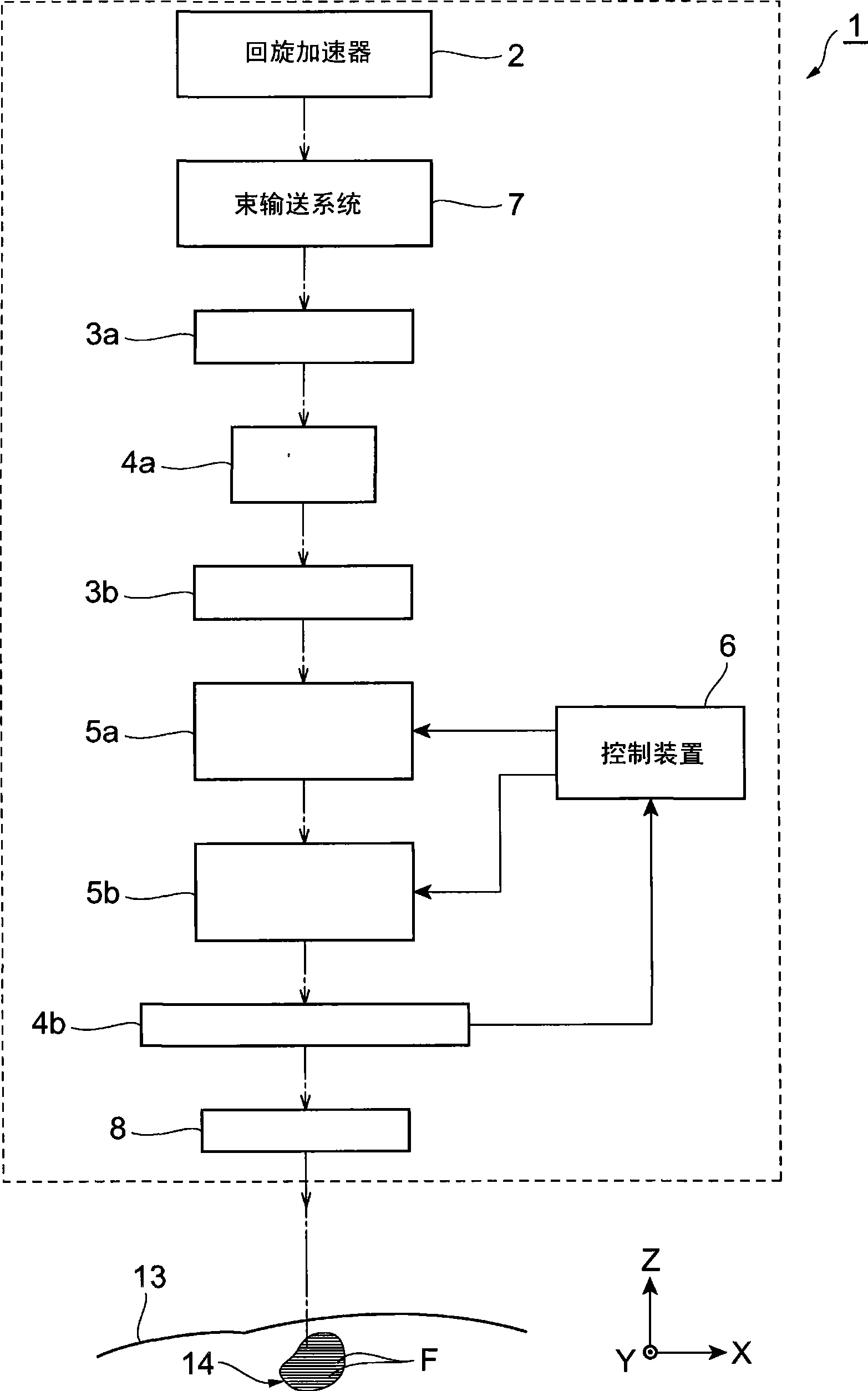

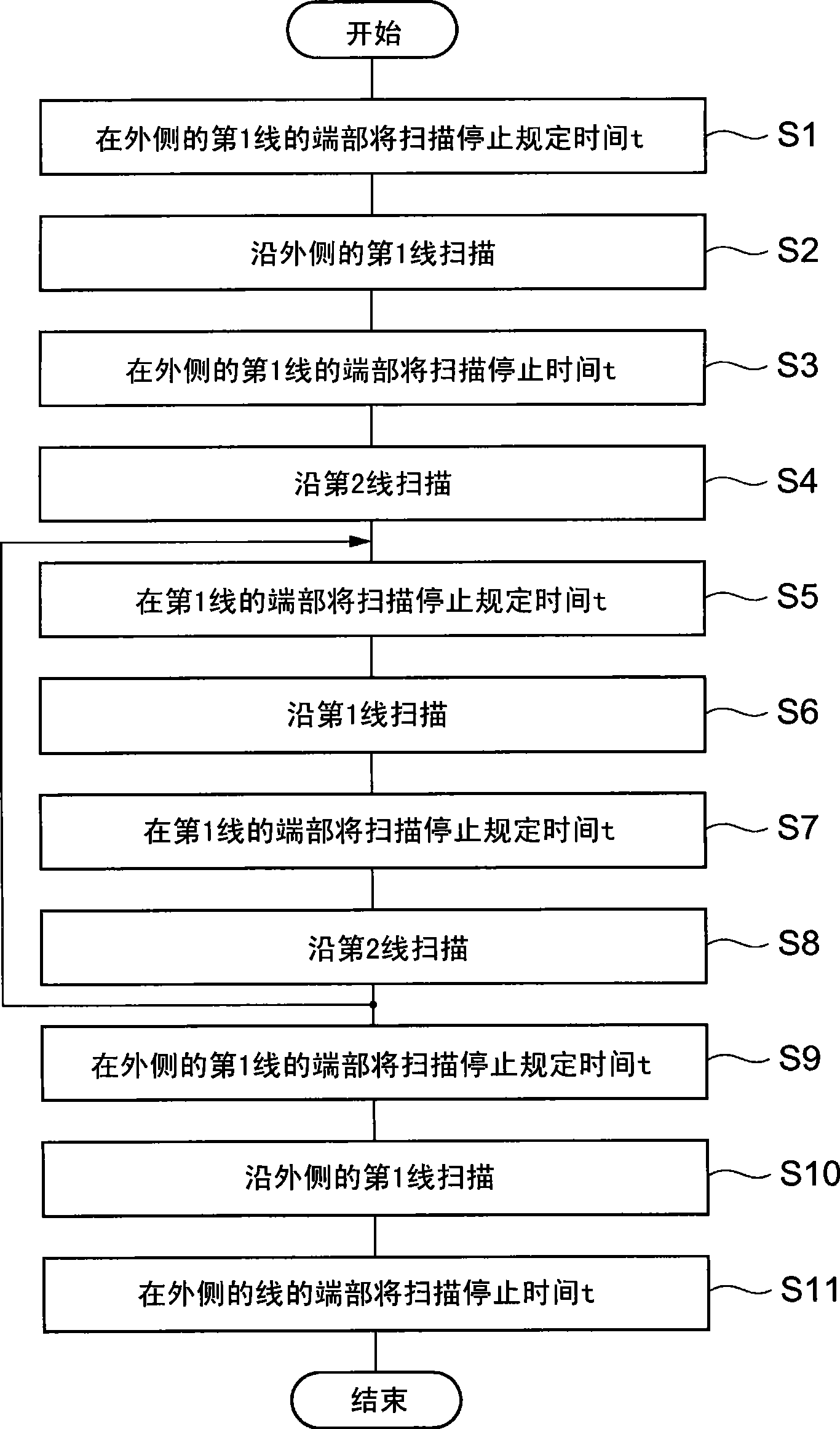

Charged particle ray irradiation device

ActiveCN101543663ASuppression of inhomogeneityBeam deviation/focusing by electric/magnetic meansRadiation diagnosticsIrradiationAtomic physics

The invention provides a charged particle ray irradiation device capable of simply inhibiting unevenness and lowering of an edge portion of ray quantity distribution of the charged particle rays. The charged particle ray irradiation device (1) comprises scan electromagnets (5a, 5b) used for scanning a charged particle ray (R), and a control device (6) used for controlling the scan electromagnets (5a, 5b). In the charged particle ray irradiation device (1), a control mechanism (6) changes the scan speed when irradiating the charged particle ray (R) along the irradiation ray so as to modify theedge portion of ray quantity distribution of the charged particle ray (R). Thus, the edge portion of ray quantity distribution may be controlled without controlling intensity of the charged particle ray (R) such that unevenness and lowering of the edge portion of ray quantity distribution may be simply inhibited.

Owner:SUMITOMO HEAVY IND LTD

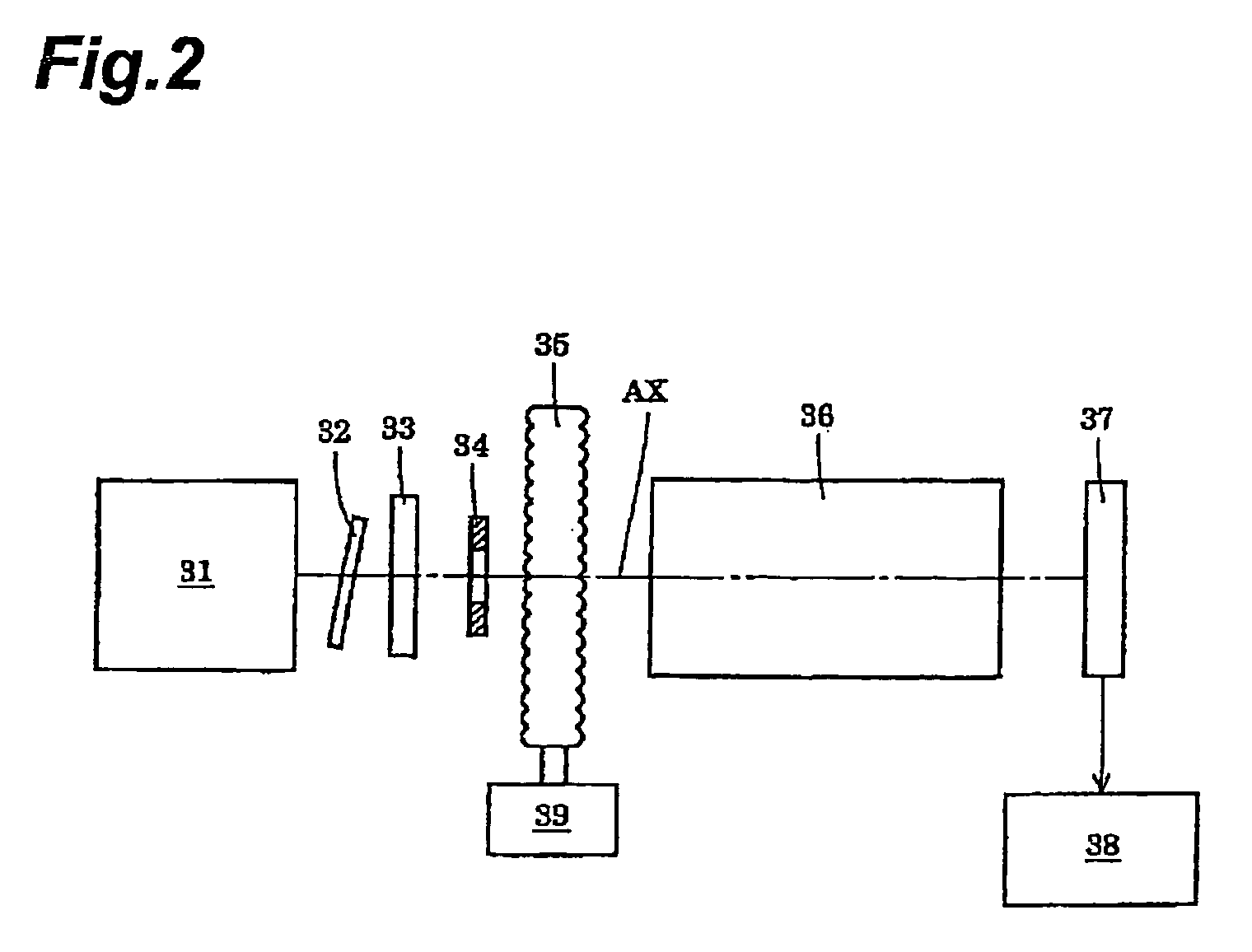

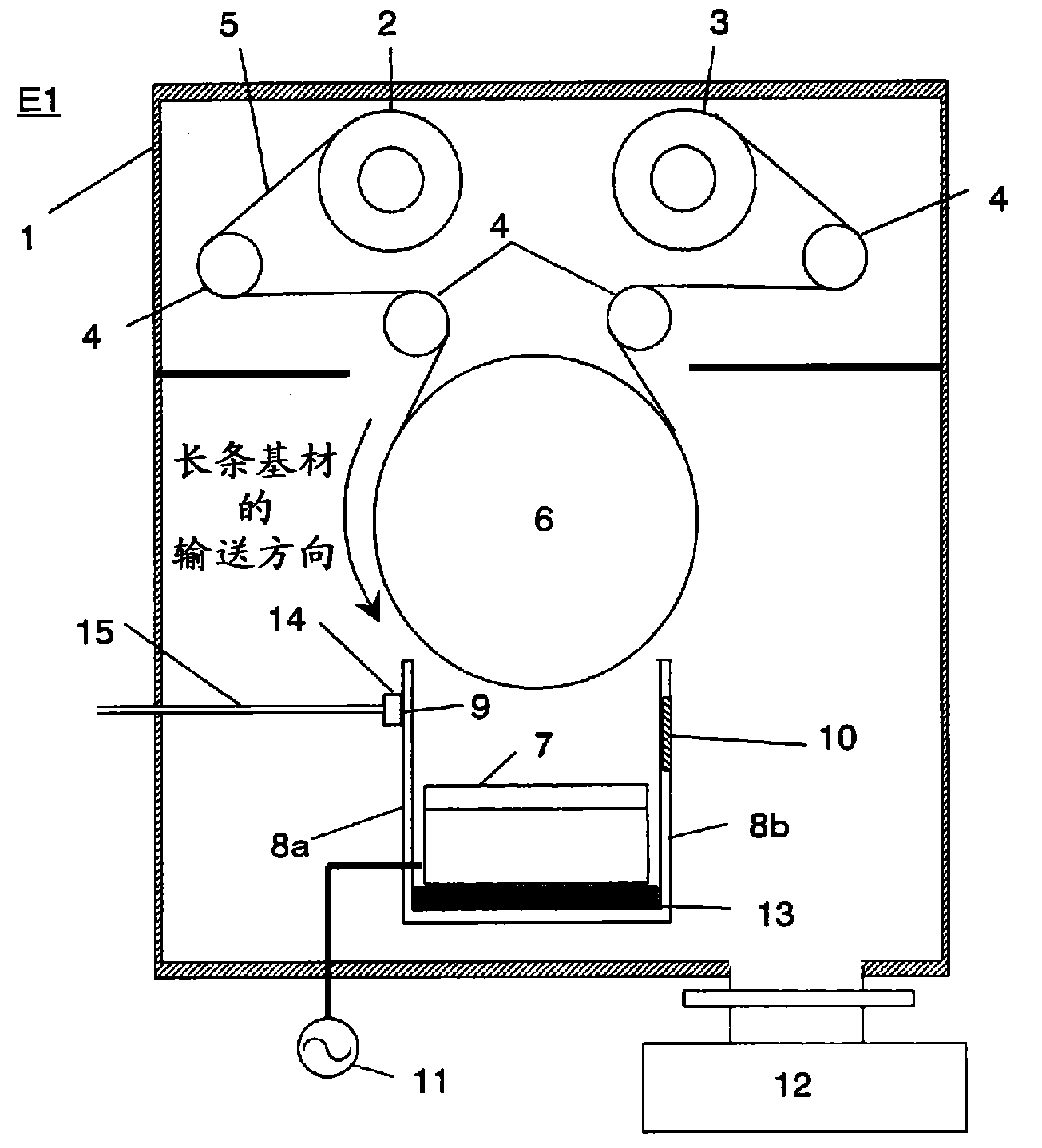

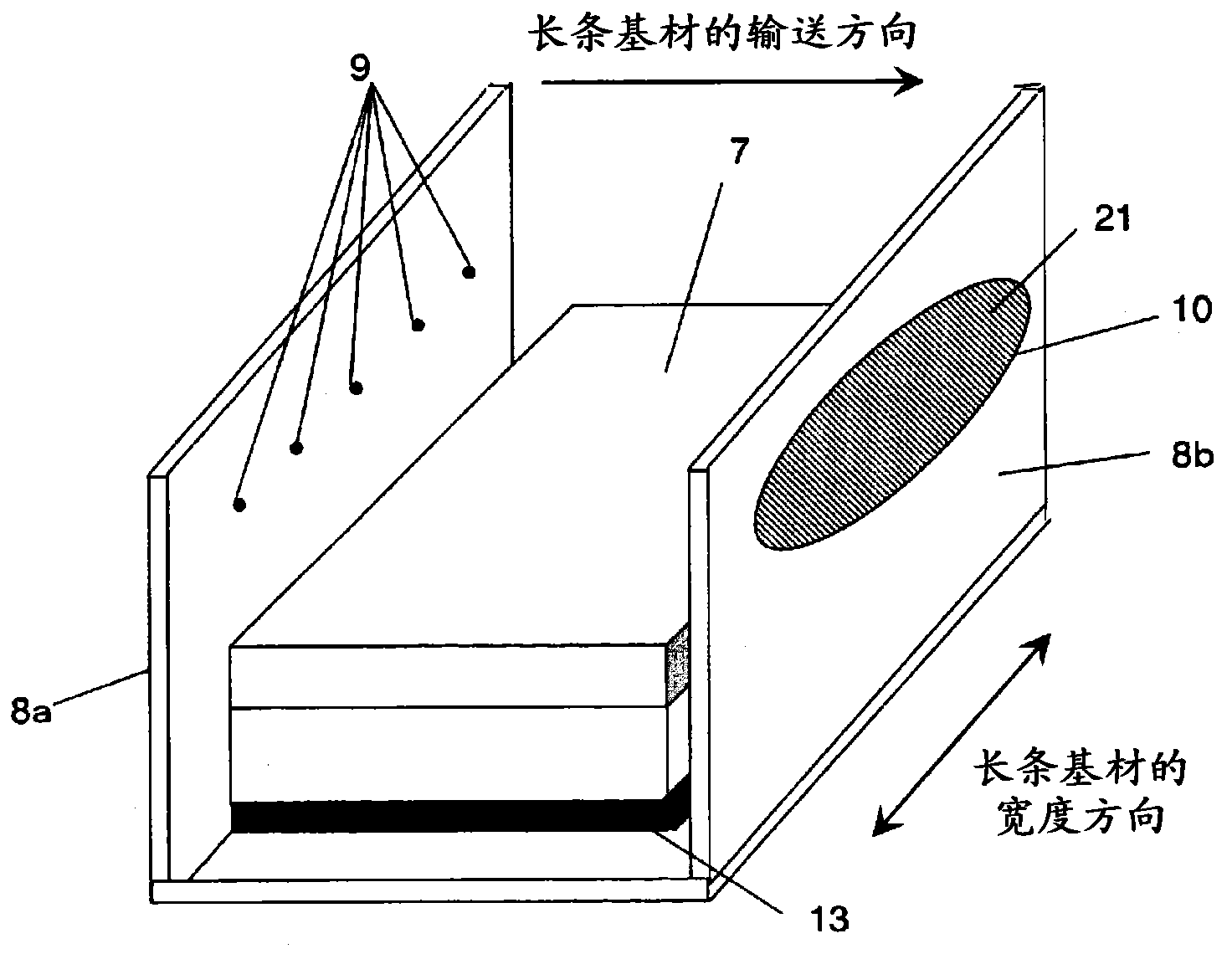

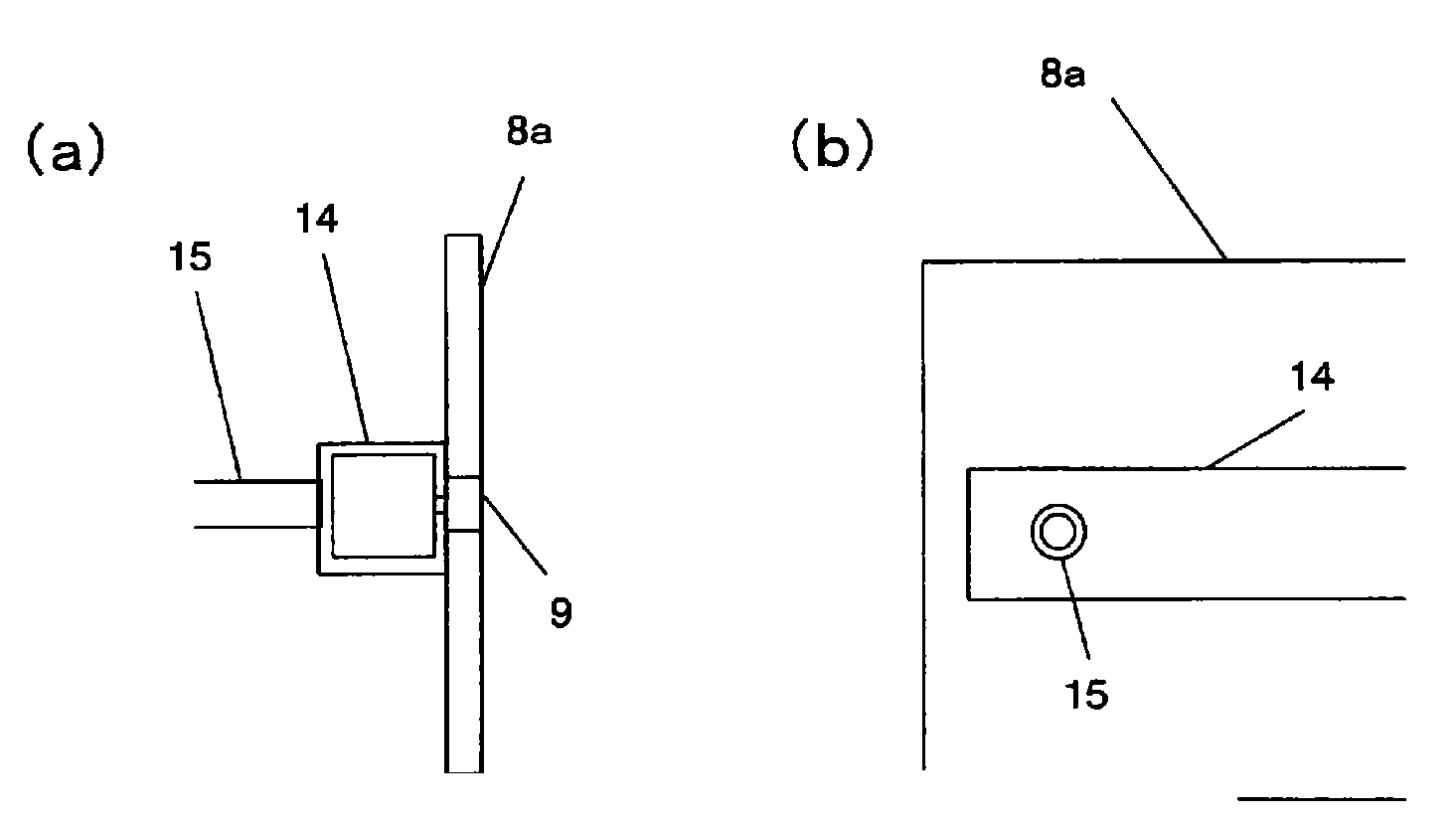

Plasma CVD apparatus, plasma CVD method, reactive sputtering apparatus, and reactive sputtering method

ActiveCN103459661AReduce defectsReduce qualityElectric discharge tubesVacuum evaporation coatingEngineeringGas supply

Provided is a plasma CVD apparatus that is a vacuum film formation apparatus provided with a main roll and a plasma generating electrode in a vacuum container, and forming a thin film on a surface of an elongated base material while transporting the elongated base material along a surface of the main roll, wherein at least one side wall extending in the width direction of the elongated base material is provided on each of an upstream side and a downstream side in the transportation direction of the elongated base material and sandwiches a film forming space so as to surround the film forming space sandwiched between the main roll and the plasma generating electrode, the side walls are electrically insulated from the plasma generating electrode, and at least one row of a gas supply hole row that forms a plurality of gas supply holes aligning in the width direction of the elongated base material is provided on either one of the side walls on the upstream side and the downstream side of the transportation direction of the elongated base material.

Owner:TORAY IND INC

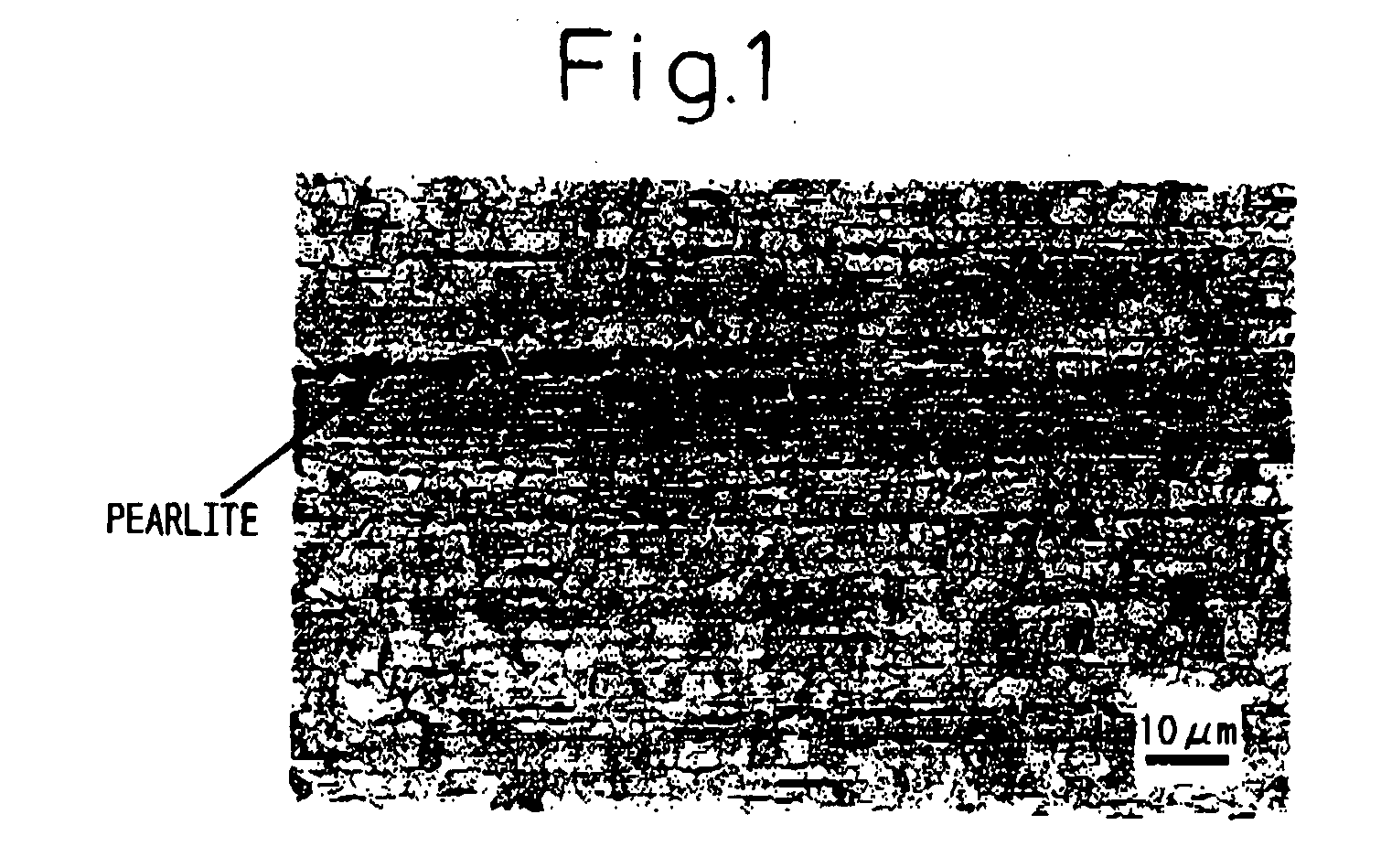

Steel superior in machinability and method of production of same

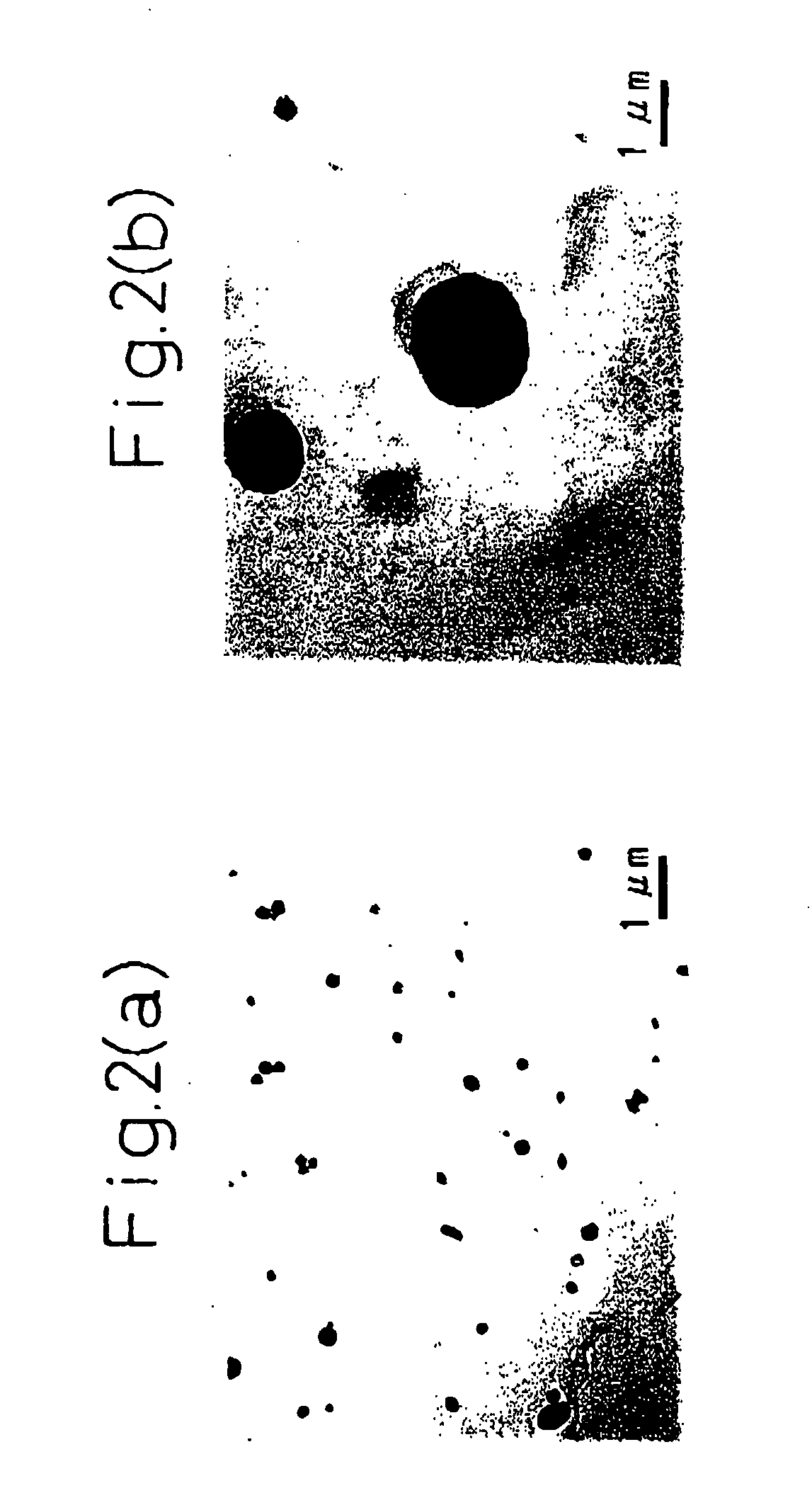

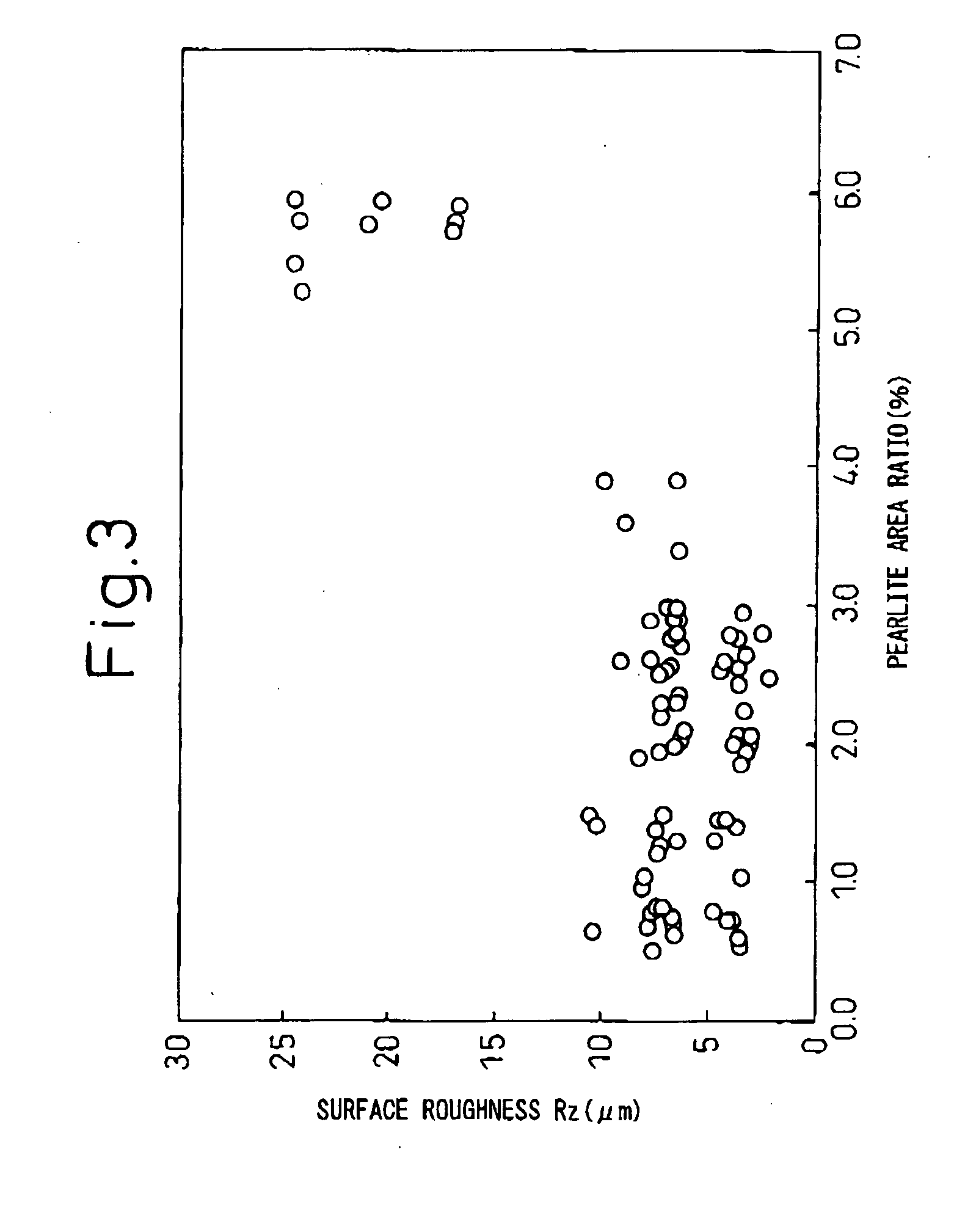

The present invention provides steel superior in machinability comprised of, by wt %, C: 0.005 to 0.2%, Si: 0.001 to 0.5%, Mn: 0.2 to 3.0%, P: 0.001 to 0.2%, S: 0.03 to 1.0%, T.N: 0.002 to 0.02%, T.O: 0.0005 to 0.035%, and the balance of Fe and unavoidable impurities, said steel satisfying one or both of Mn / S in the steel being 1.2 to 2.8 or an area ratio of pearlite over a grain size of 1 μm in a microstructure of the steel being not more than 5%.

Owner:NIPPON STEEL CORP

Current steering element and non-volatile memory element incorporating current steering element

ActiveUS20130171799A1Suppression of inhomogeneityHigh currentSolid-state devicesSemiconductor/solid-state device manufacturingNon-volatile memoryCorrosion

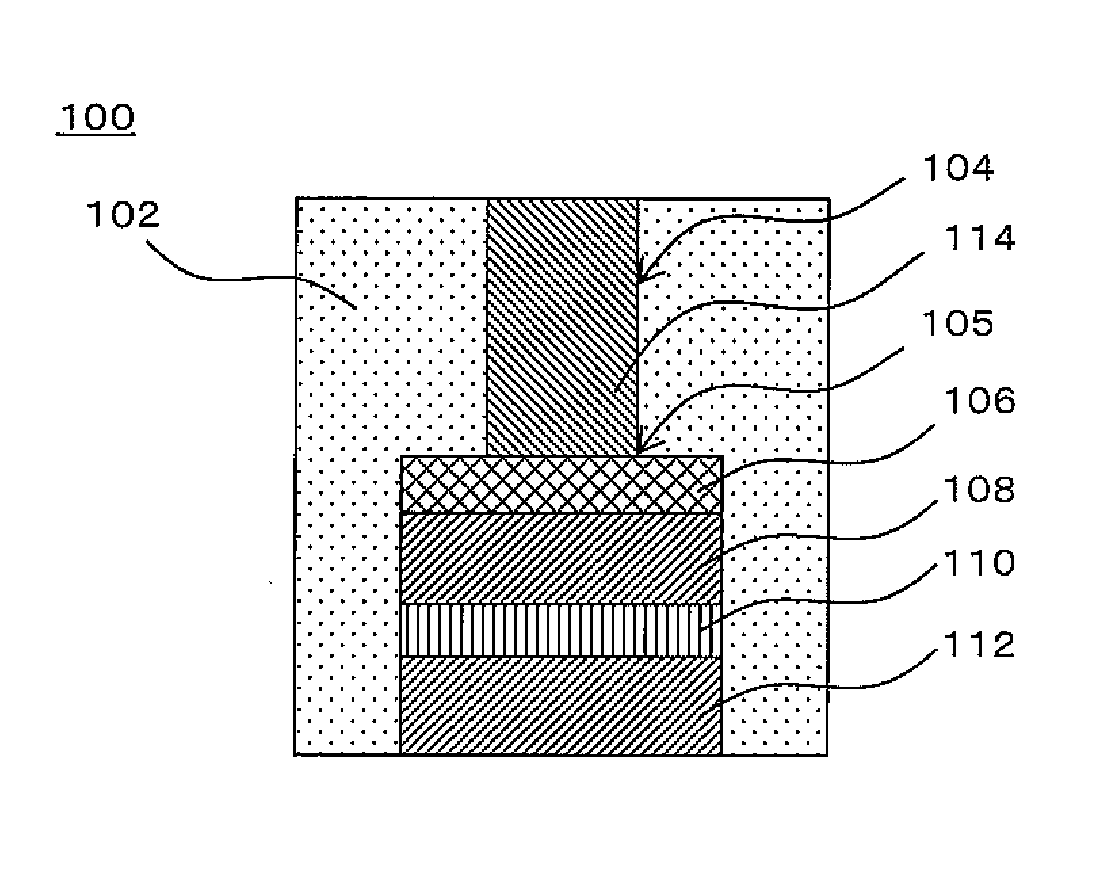

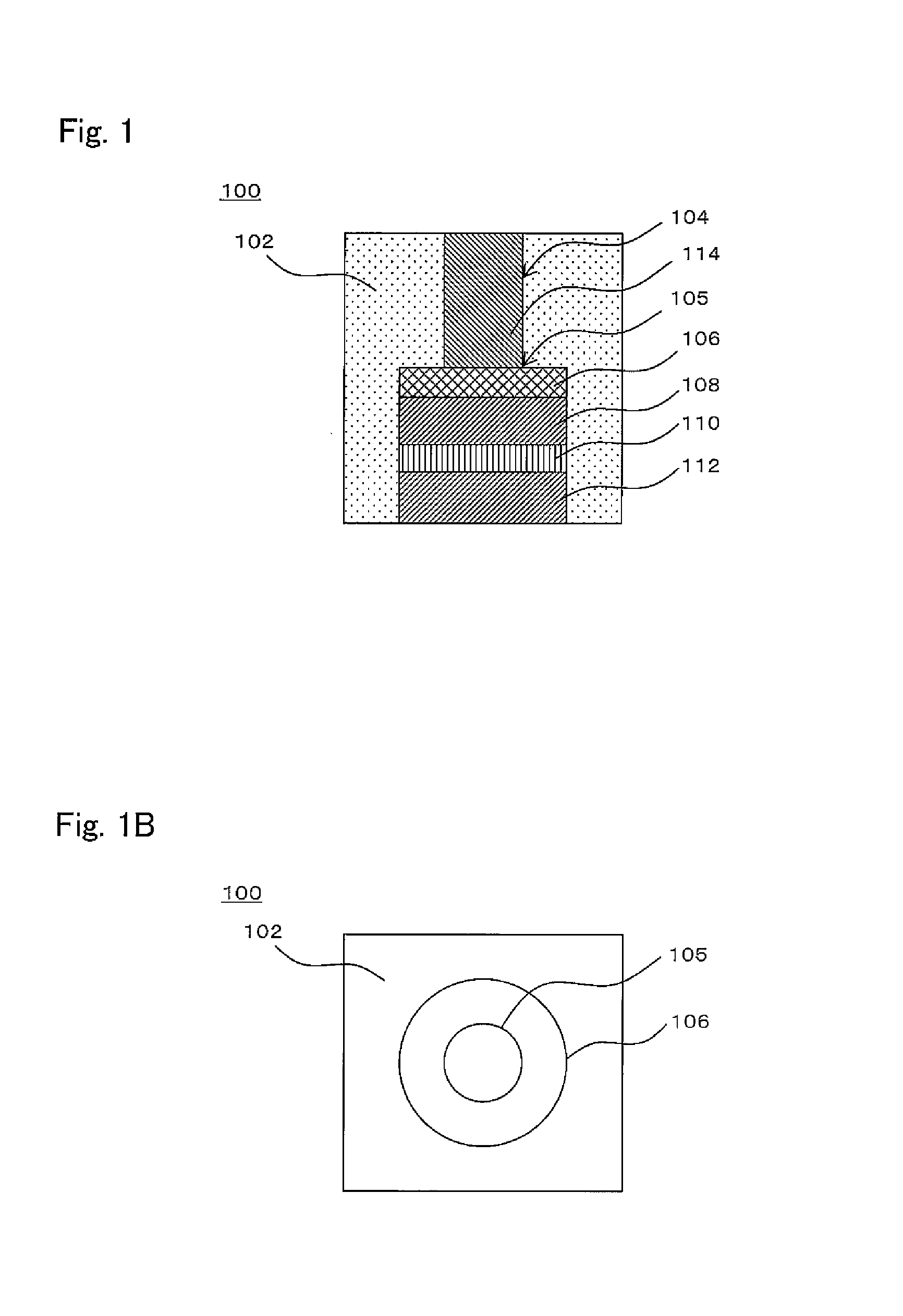

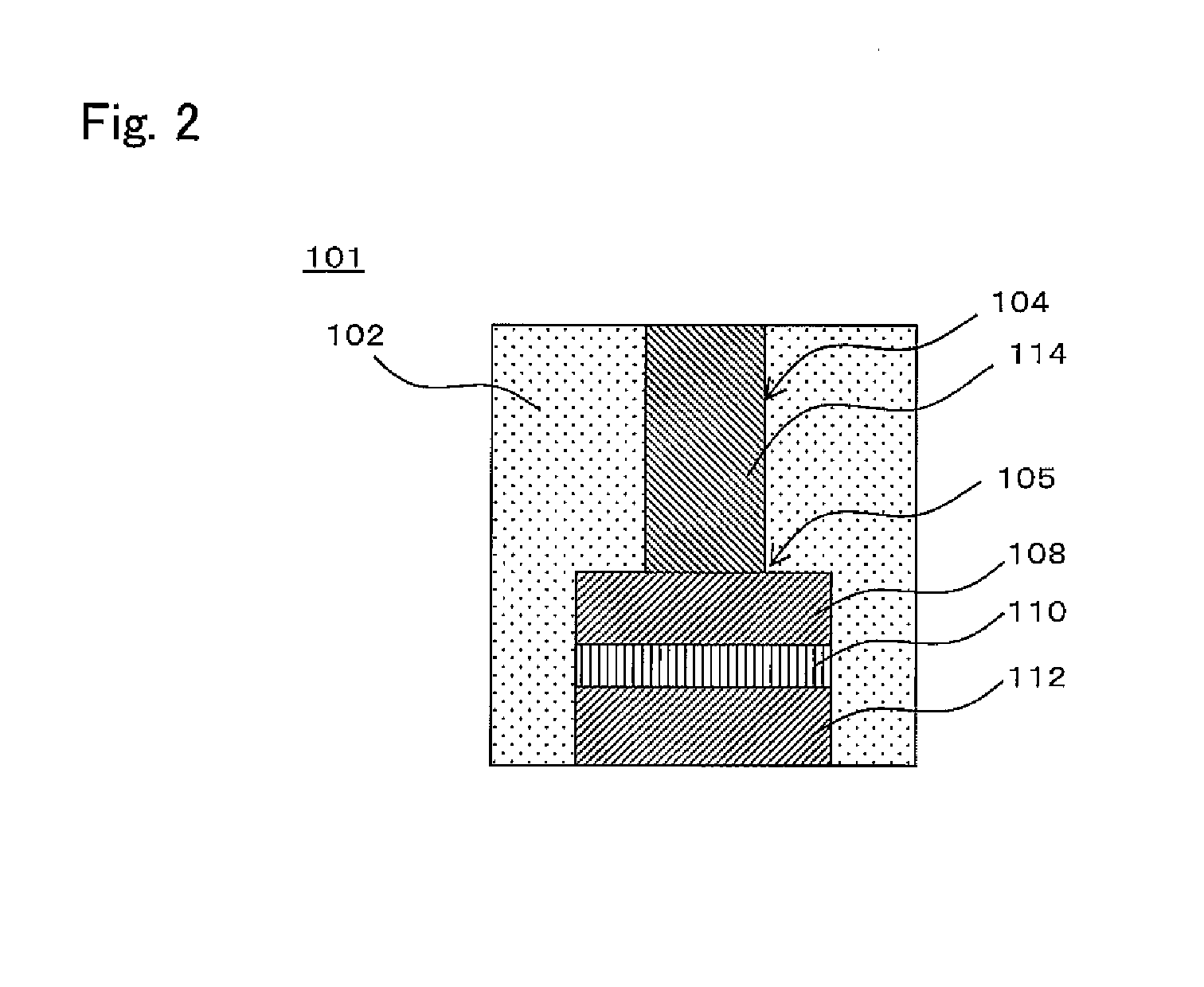

A current steering element (100) formed such that the current steering element covers a lower opening (105) of a via hole (104) formed in an interlayer insulating layer (102), comprises: a corrosion-suppressing layer (106) formed on a lower side of a lower opening of the via hole such that the corrosion-suppressing layer covers an entire portion of the lower opening; a second electrode layer (108) formed under the corrosion-suppressing layer and comprising a material different from a material of the corrosion-suppressing layer; a current steering layer (110) formed under the second electrode layer such that the current steering layer is physically in contact with the second electrode layer; and a first electrode layer (112) formed under the current steering layer such that the first electrode layer is physically in contact with the current steering layer; and the first electrode layer, the current steering layer and the second electrode layer constitute one of a MSM diode and a MIM diode.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Laser irradiation method and method for manufacturing crystalline semiconductor film

ActiveUS7608527B2Suppression of inhomogeneityHigh crystallinityPolycrystalline material growthFrom solid stateOptoelectronicsPicosecond

Even when the laser irradiation is performed under the same condition with the energy distribution of the beam spot shaped as appropriate, the energy given to the irradiated surface is not yet homogeneous. When a semiconductor film is crystallized to form a crystalline semiconductor film using such inhomogeneous irradiation energy, the crystallinity becomes inhomogeneous in this film, and the characteristic of semiconductor elements manufactured using this film varies. In the present invention, an irradiated object formed over a substrate is irradiated with a laser beam having the pulse width that is an order of picosecond (10−12 second) or less.

Owner:SEMICON ENERGY LAB CO LTD

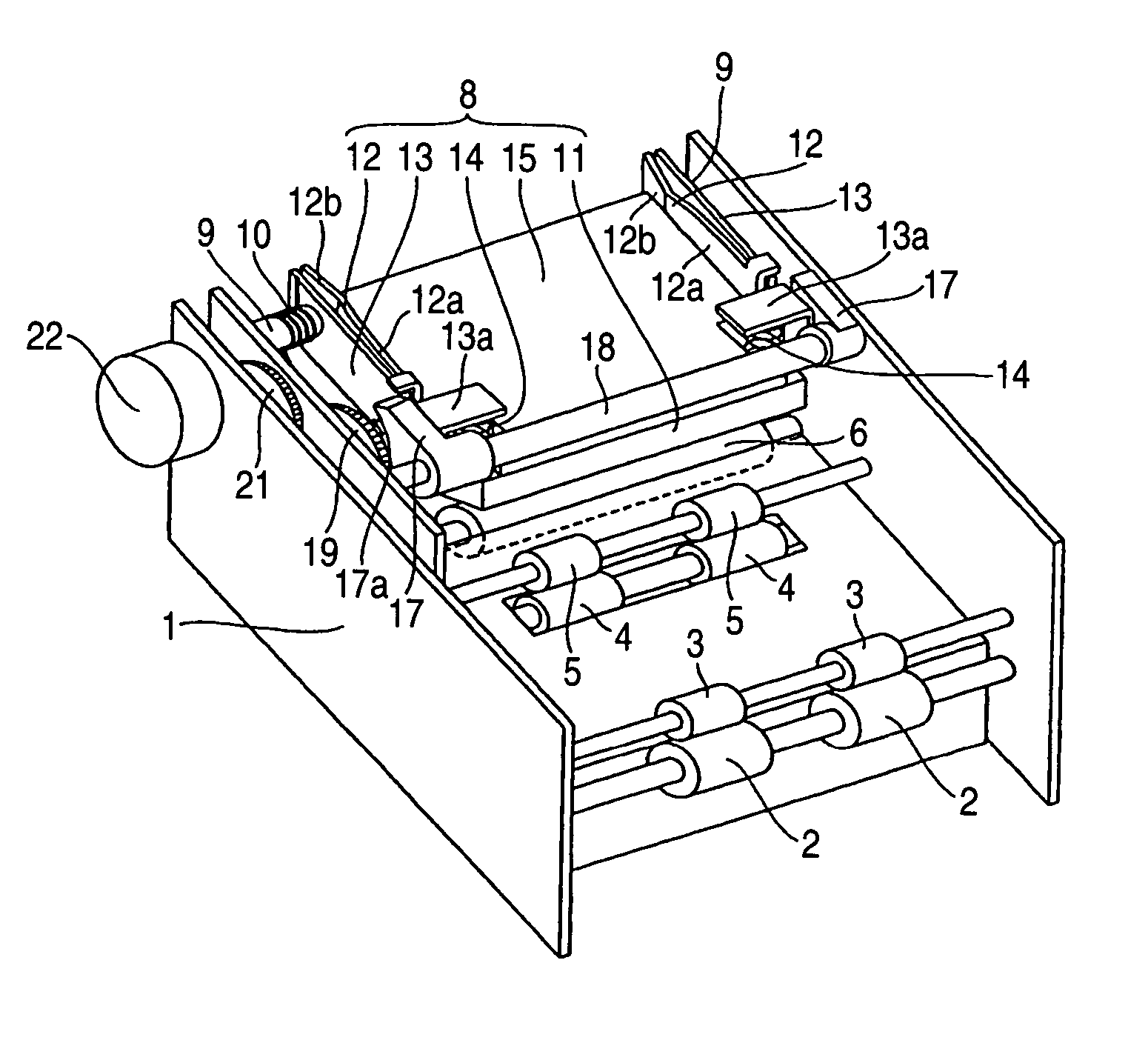

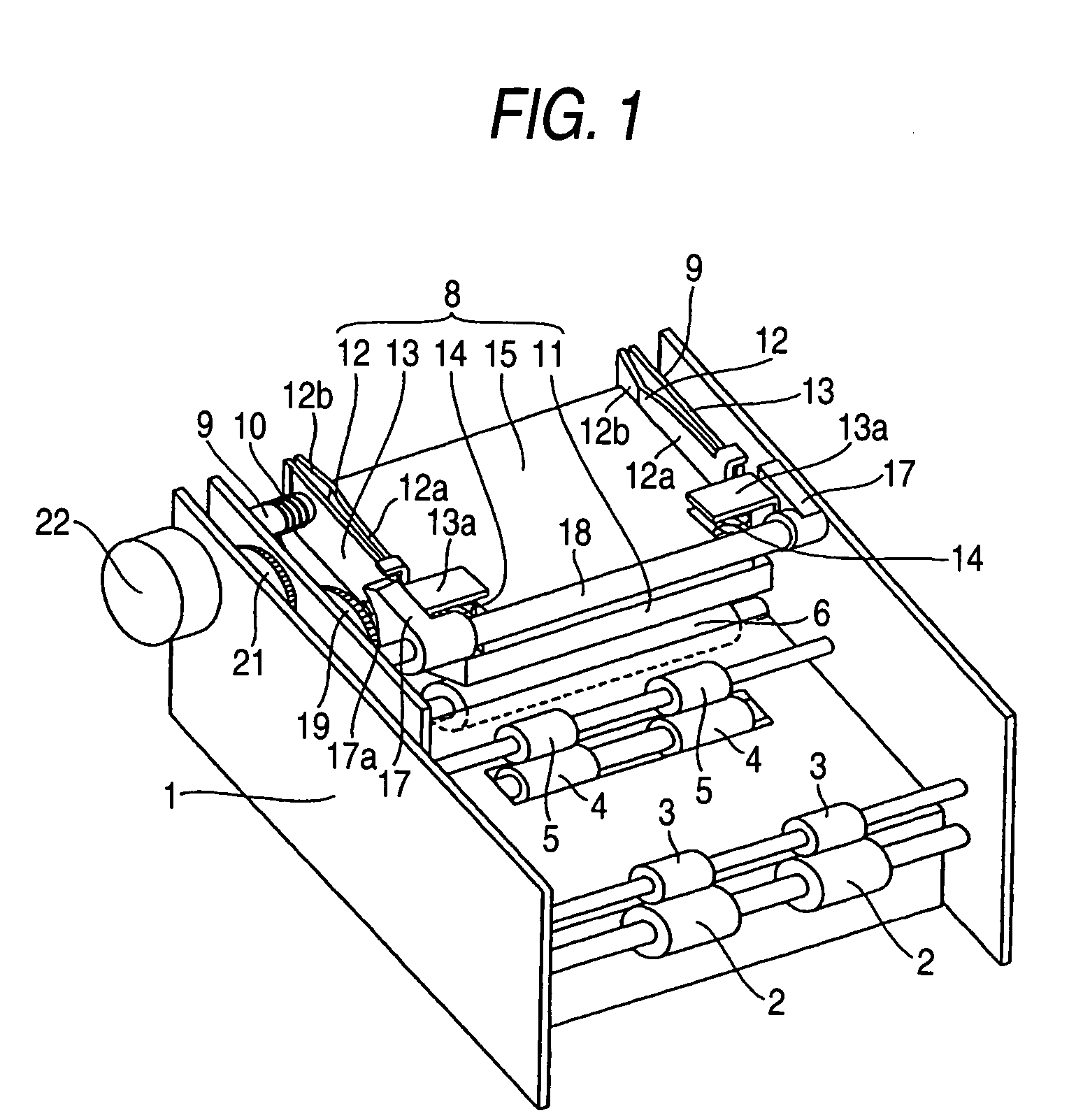

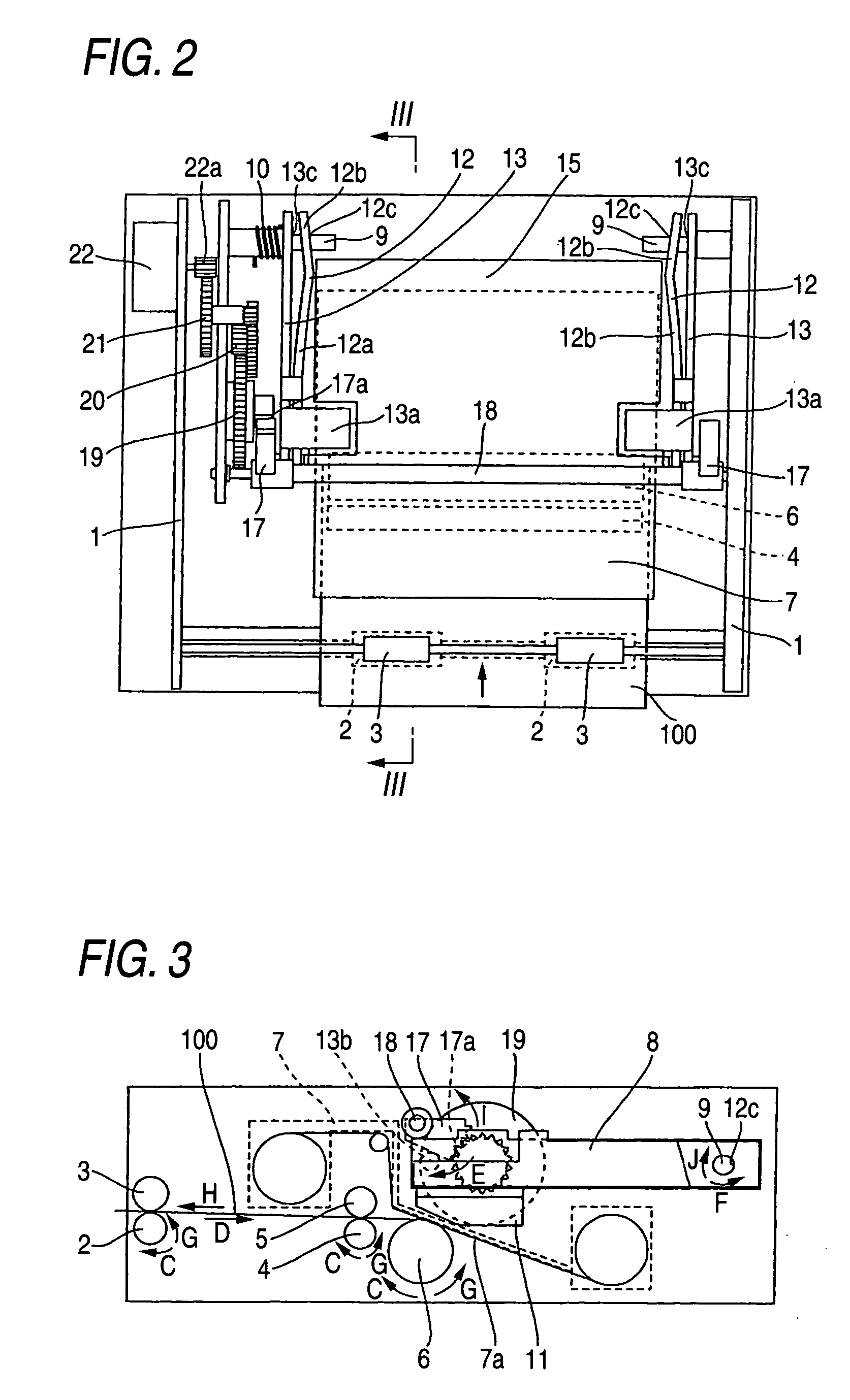

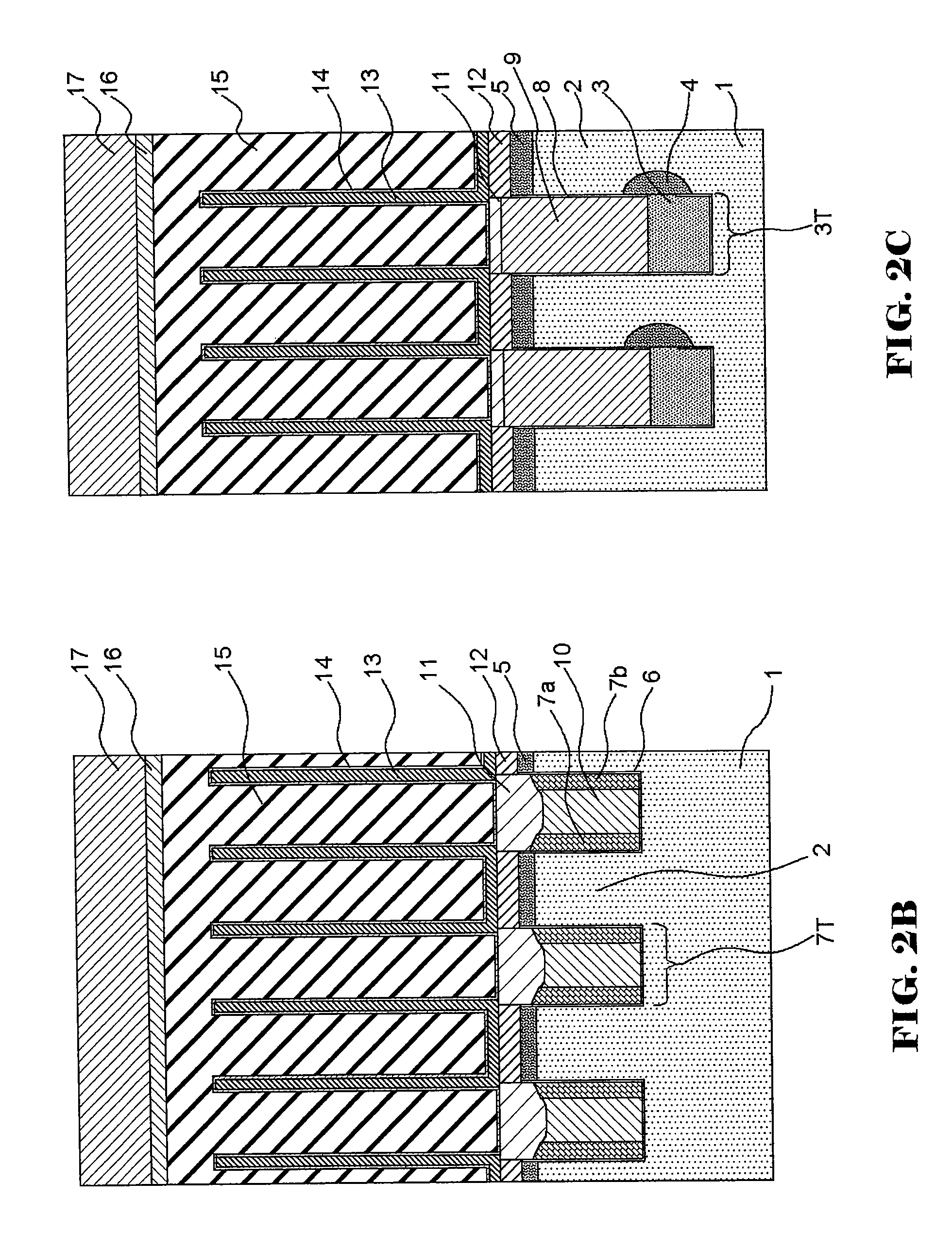

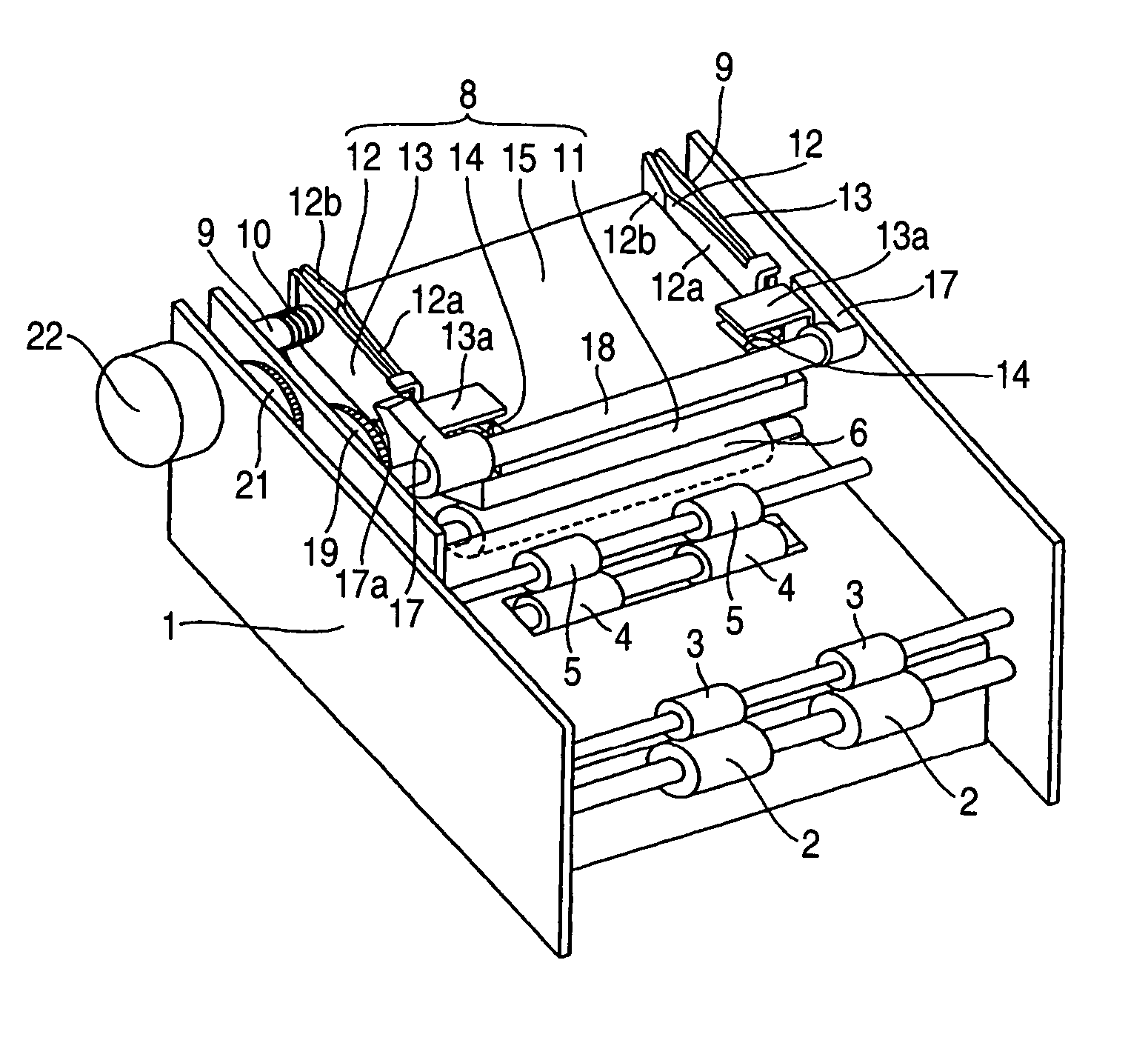

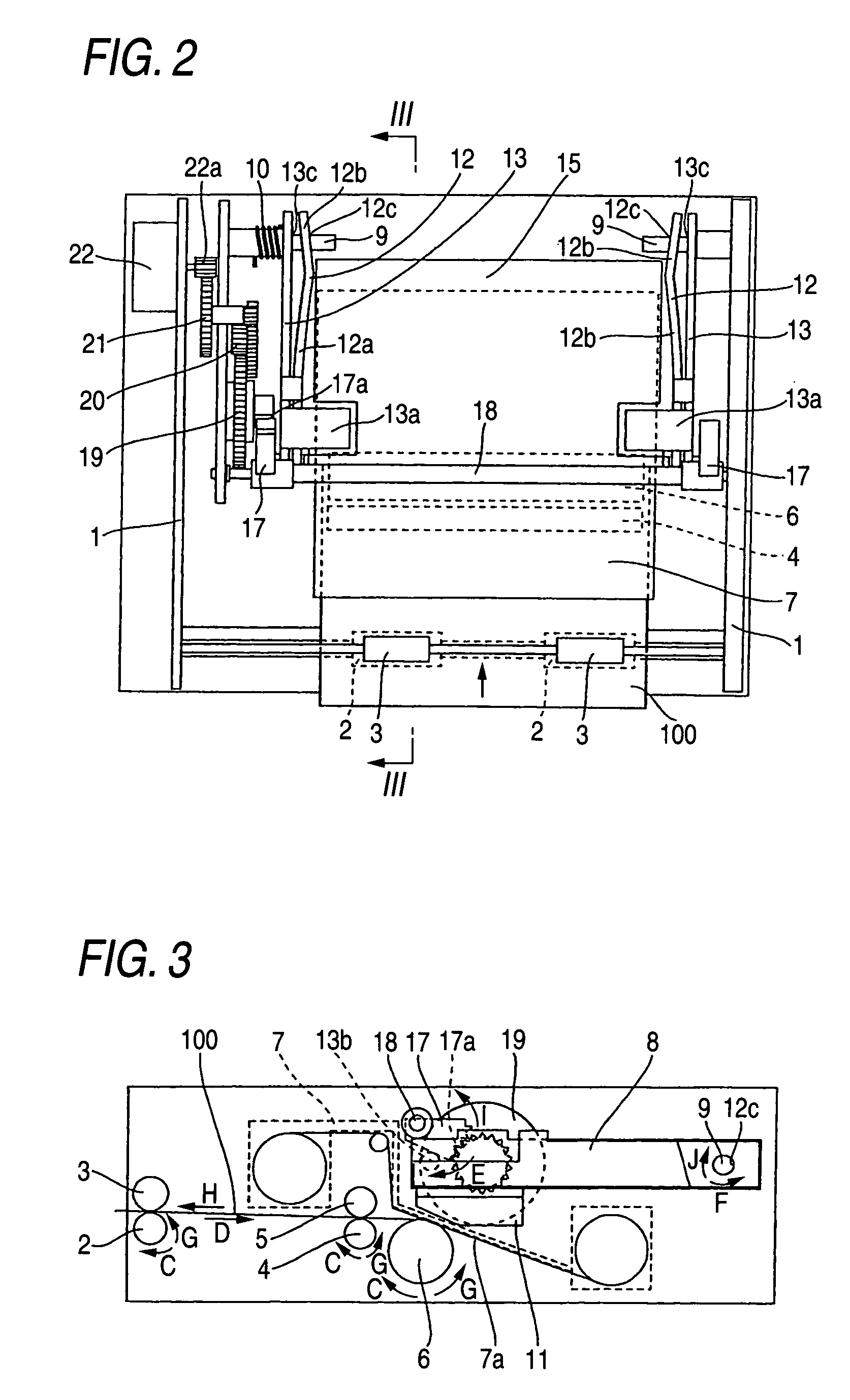

Thermal-transfer printer

The thermal-transfer printer includes: a pair of head attaching arms 12 having fitting holes 12c respectively inserted with support shafts 9 and having center lines inclined to axis lines of the supporting shafts 9 by a predetermined inclination angle; and supporting shaft attaching portions 12b being bent by bending lines 12d that intersects with a line connecting the fitting holes 12c and a printing position of a thermal head 11 relative to a sheet 100. The fitting hole 12c of respective supporting shaft attaching portion 12b are attached to the supporting shafts 9 in a state of being elastically bent in directions opposed to each other such that predetermined inclination angles of the supporting shafts 9 of center lines of the fitting hole 12c of the supporting shaft attaching portion 12b relative to axis lines of the supporting shafts 9 are reduced.

Owner:FUNAI ELECTRIC CO LTD

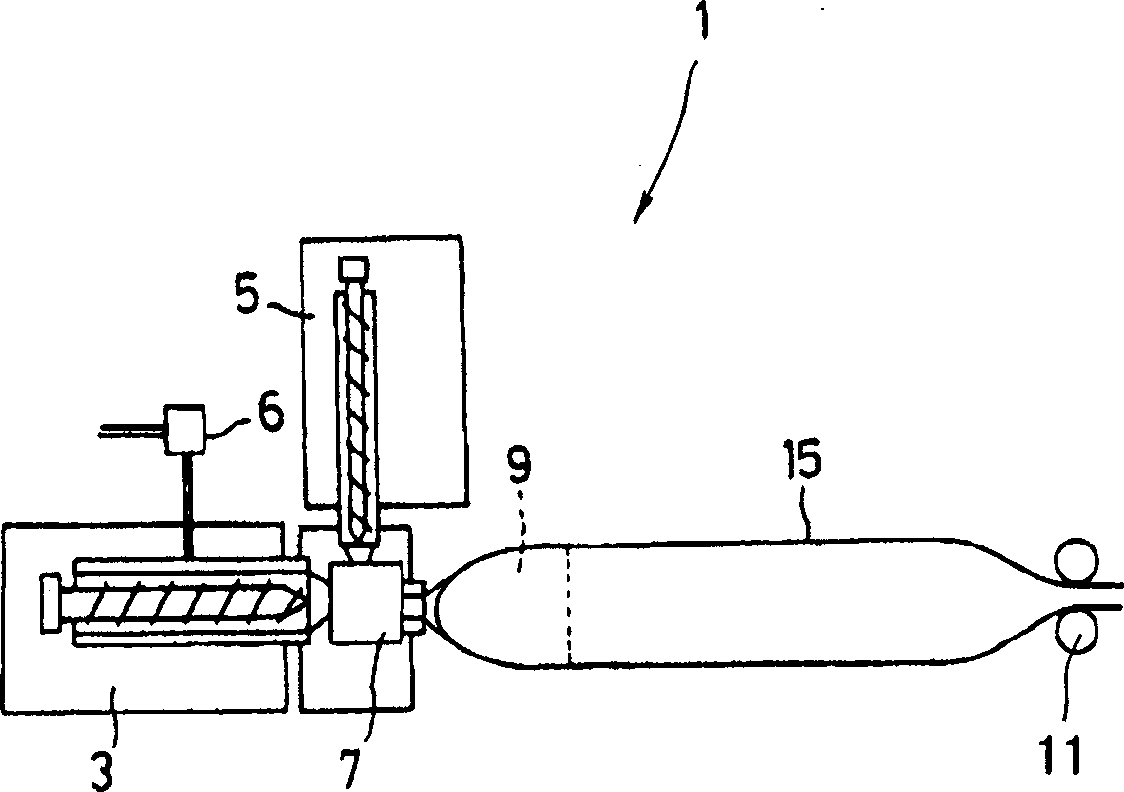

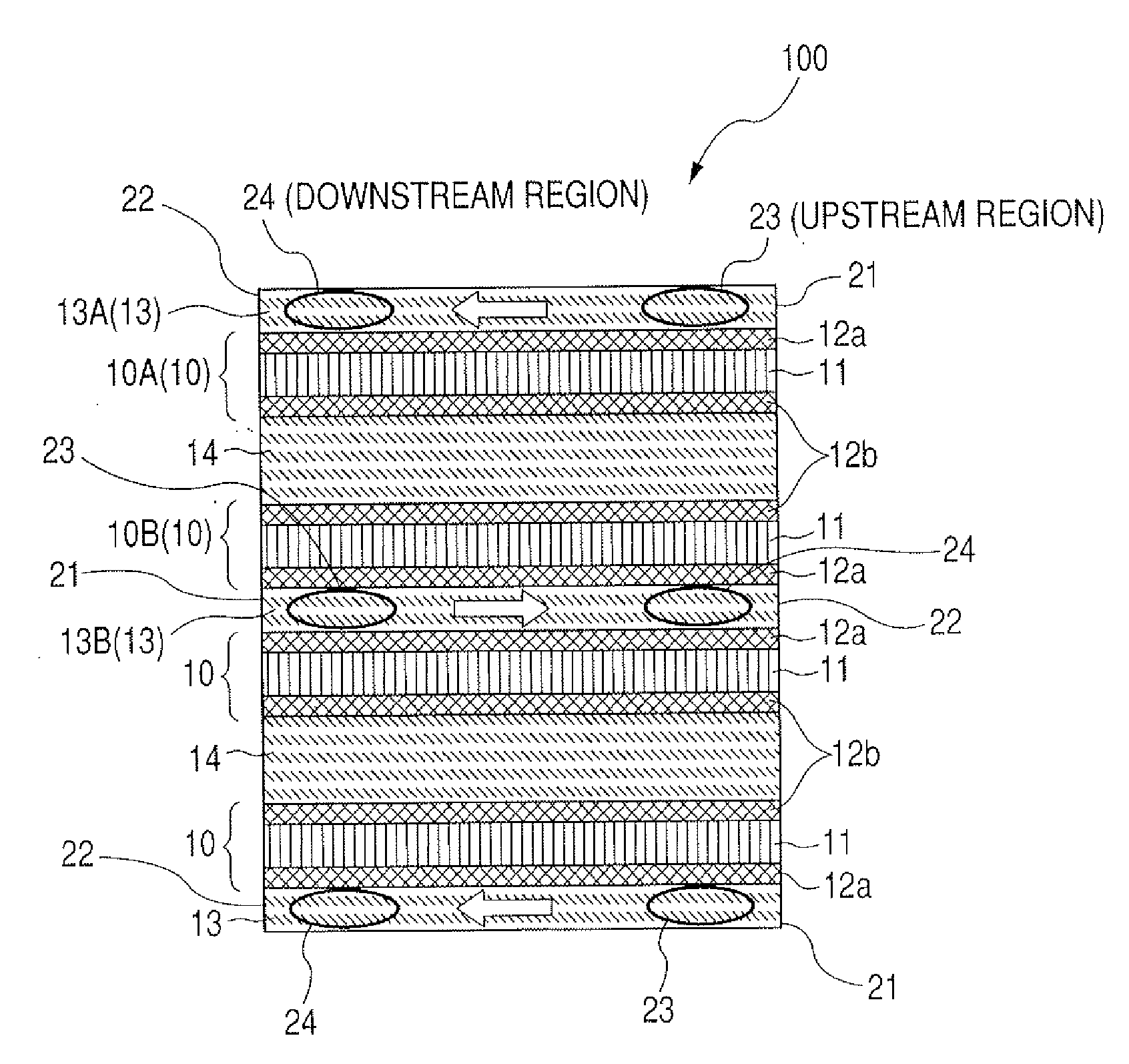

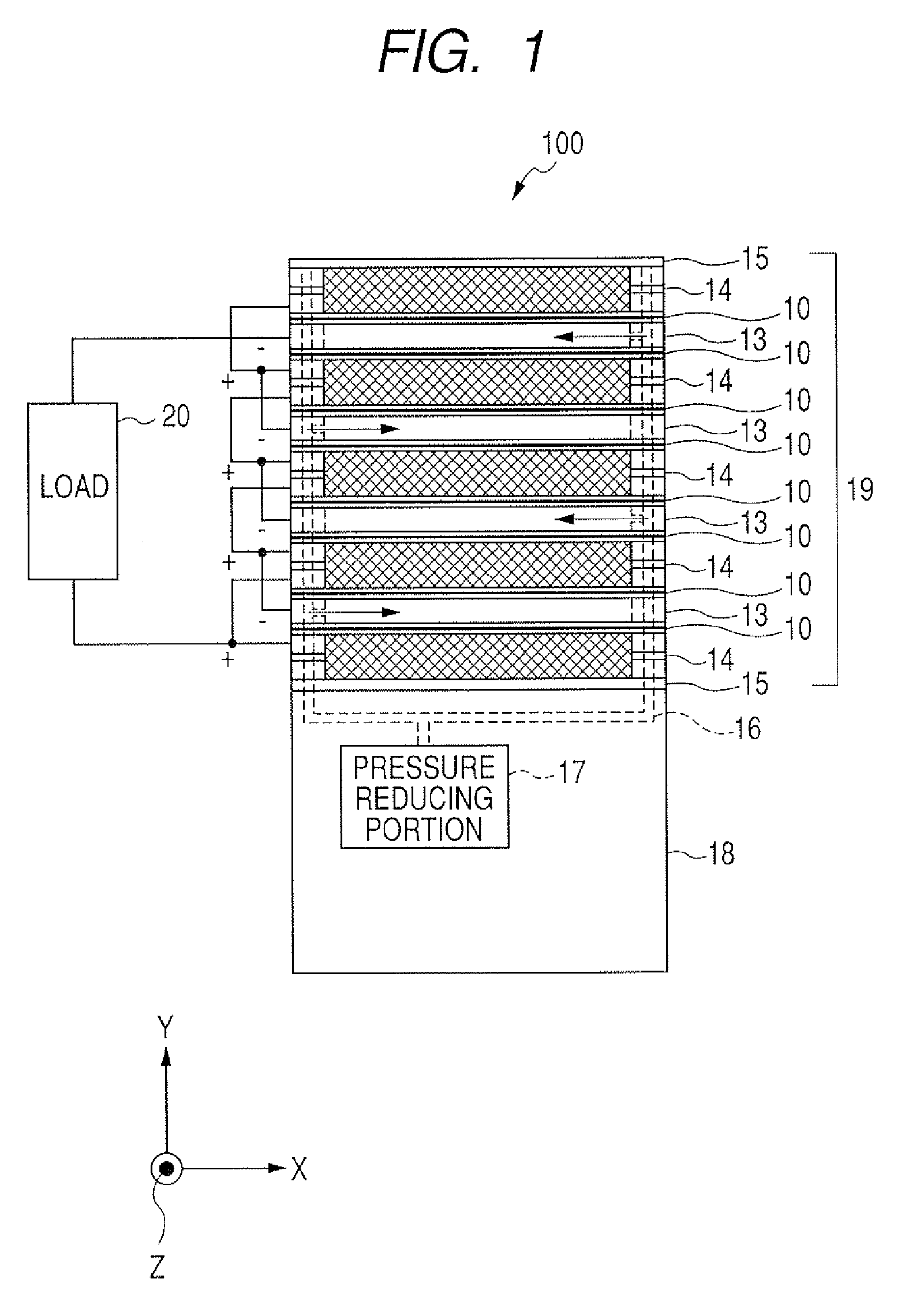

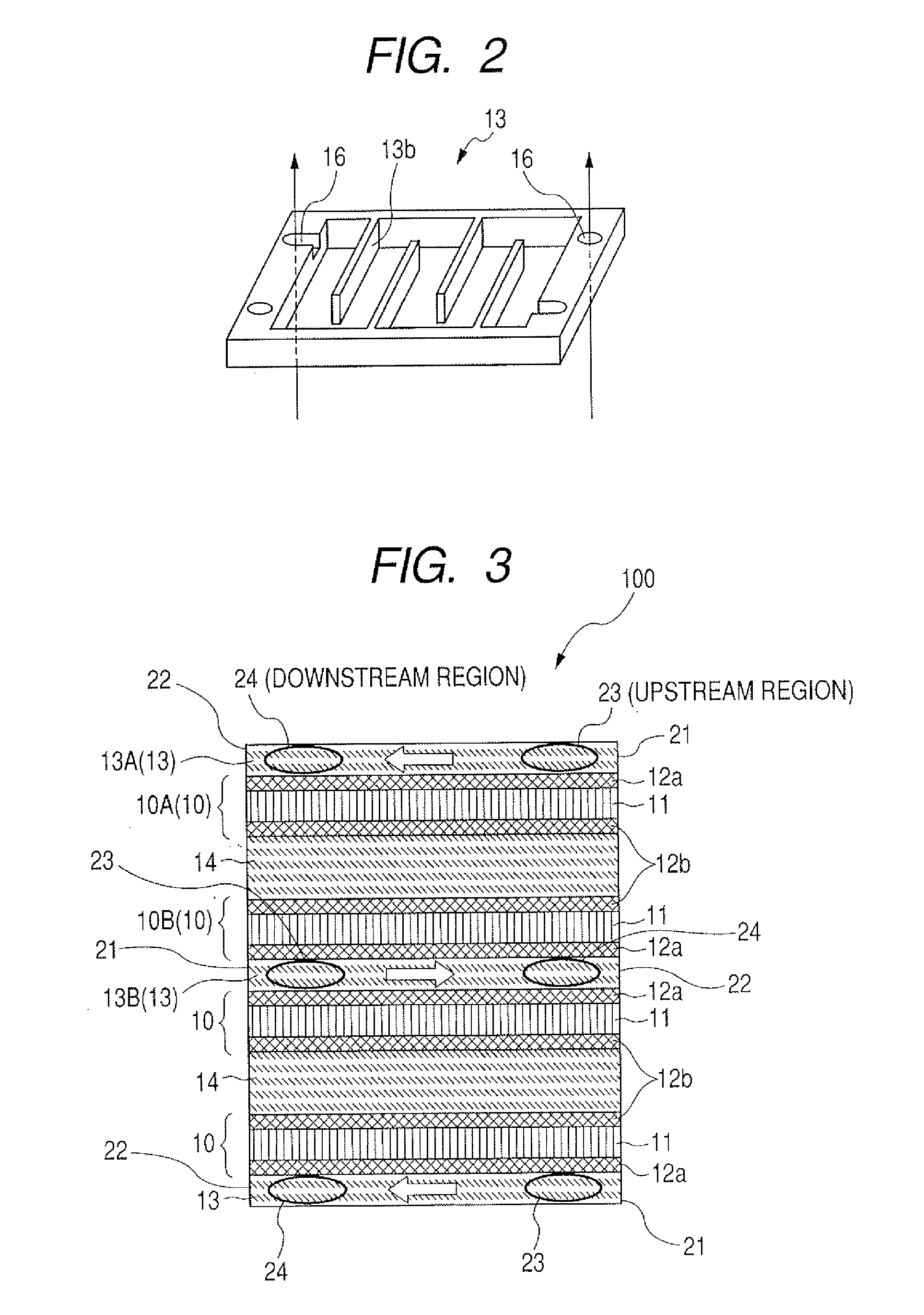

Fuel cell

InactiveUS20070248870A1Decrease nonuniformity of moistureFast power generationFuel cells groupingWater management in fuel cellsFuel cellsHydrogen

There is provided a fuel cell in which produced water can be efficiently conveyed to an upstream region of hydrogen gas flow, thereby quickly increasing the power generation performance of an electrolyte membrane after activation in a short period of time and giving a stable output for a long period of time and in which the directions of hydrogen gas flows in a first and a second fuel supply layers that share one oxygen supply layer are set to be opposite to each other.

Owner:CANON KK

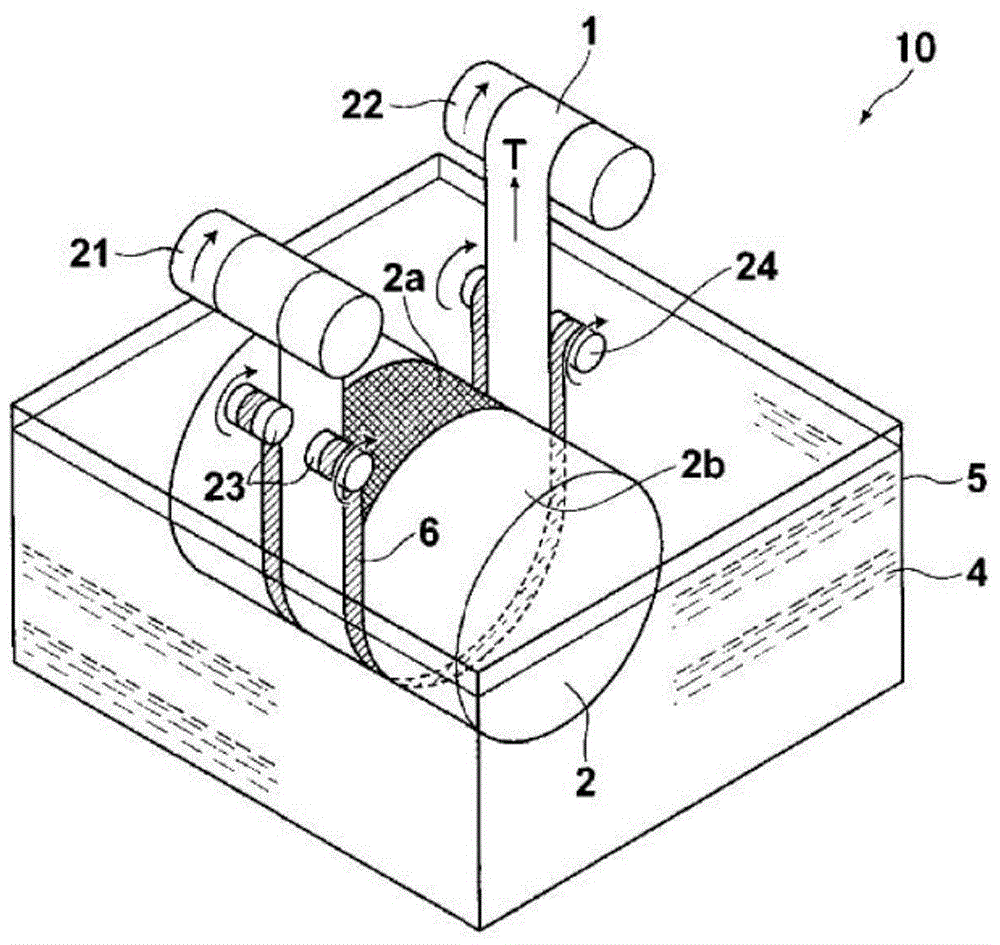

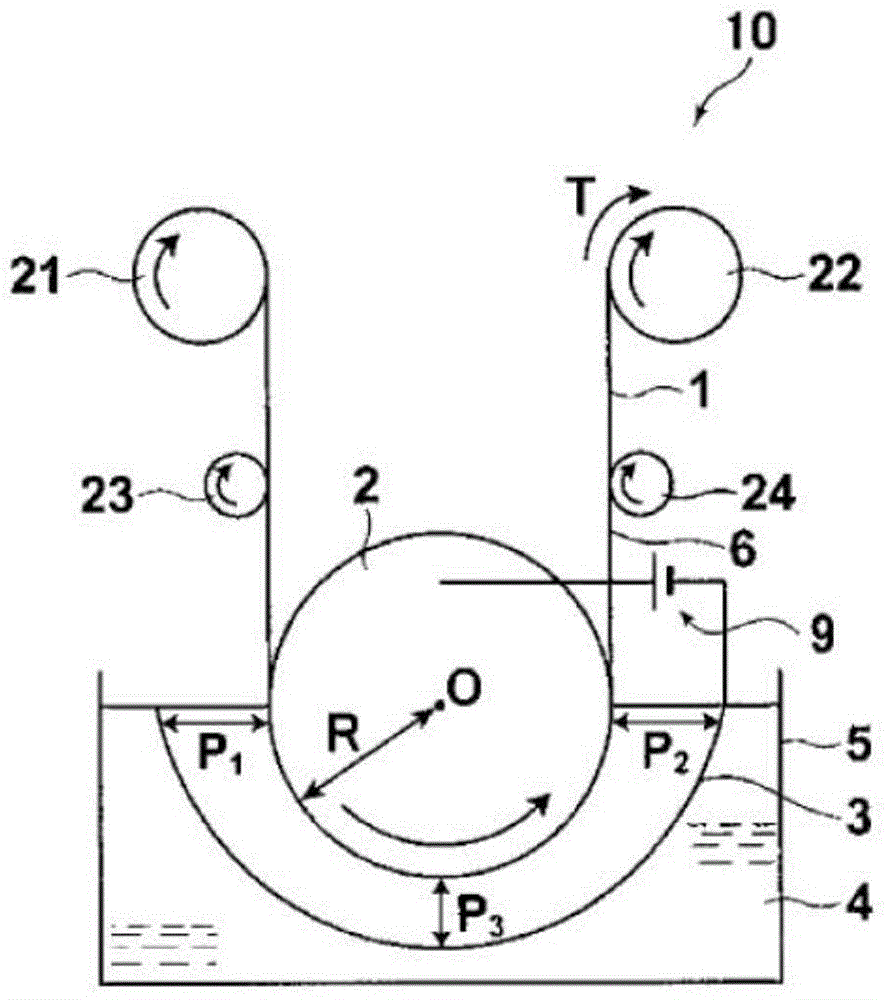

Anodizing device, continuous anodizing device, and film forming method

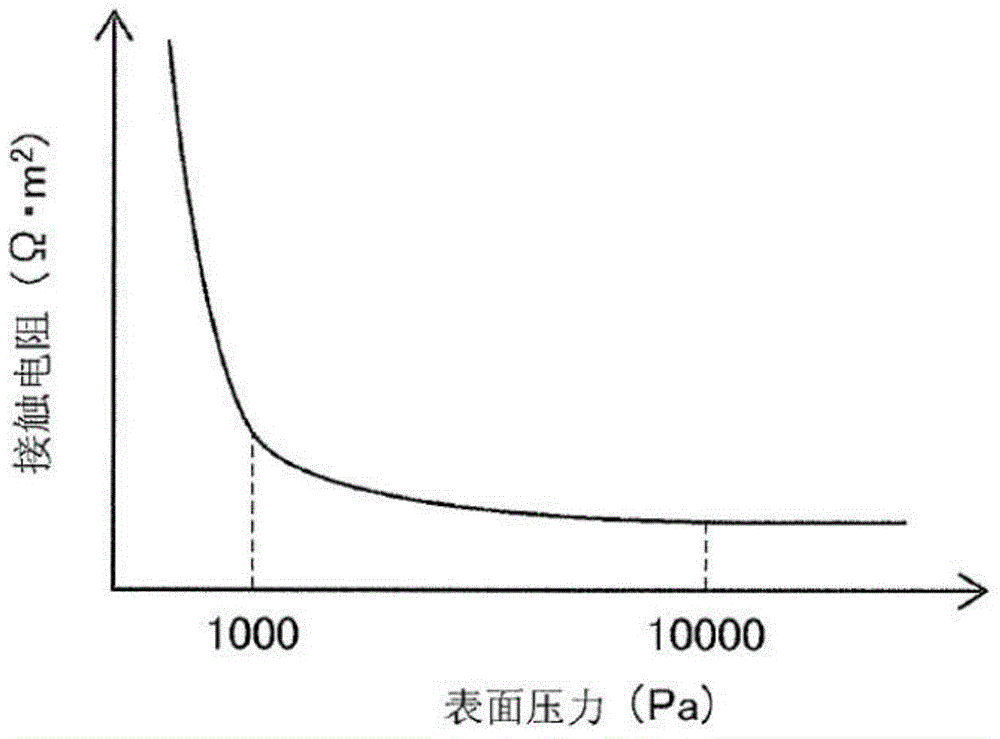

InactiveCN103608492AReduce contact resistanceInhibitionAnodisationElectrolysis componentsAnodizingElectrolysis

An anodizing device has: a power supply drum that supports, in close contact therewith, a belt-like object consisting of an anodizable metal or consisting of a composite conductive metal foil that is a metal anodizable at least on one side surface thereof and has at least a part configured with a conductive material, to which the belt-like object is closely attached; an opposing electrode provided facing the power supply drum; an electrolysis tank filled with an electrolyte, into which part of the power supply drum supporting the belt-like object in close contact therewith and the opposing electrode are immersed; a protection member formed of a non-conductive material, by which the lateral direction end portions of the belt-like object supported by the power supply drum in close contact therewith and a portion of the power supply drum, to which the belt-like object is not closely attached, are covered and protected from the electrolyte; and a driving unit for making the belt-like object closely attached to the power supply drum and the protection member travel concurrently in the electrolyte in synchronization with the circumferential speed of the power supply drum. If tensile force per unit width applied to the belt-like object wound on the power supply drum is denoted by T (N / m) and the radius of the power supply drum is denoted by R (m), the value of the tensile force (T) per unit width applied to the belt-like object that is made to travel concurrently in the electrolyte is 1000*R or more.

Owner:FUJIFILM CORP

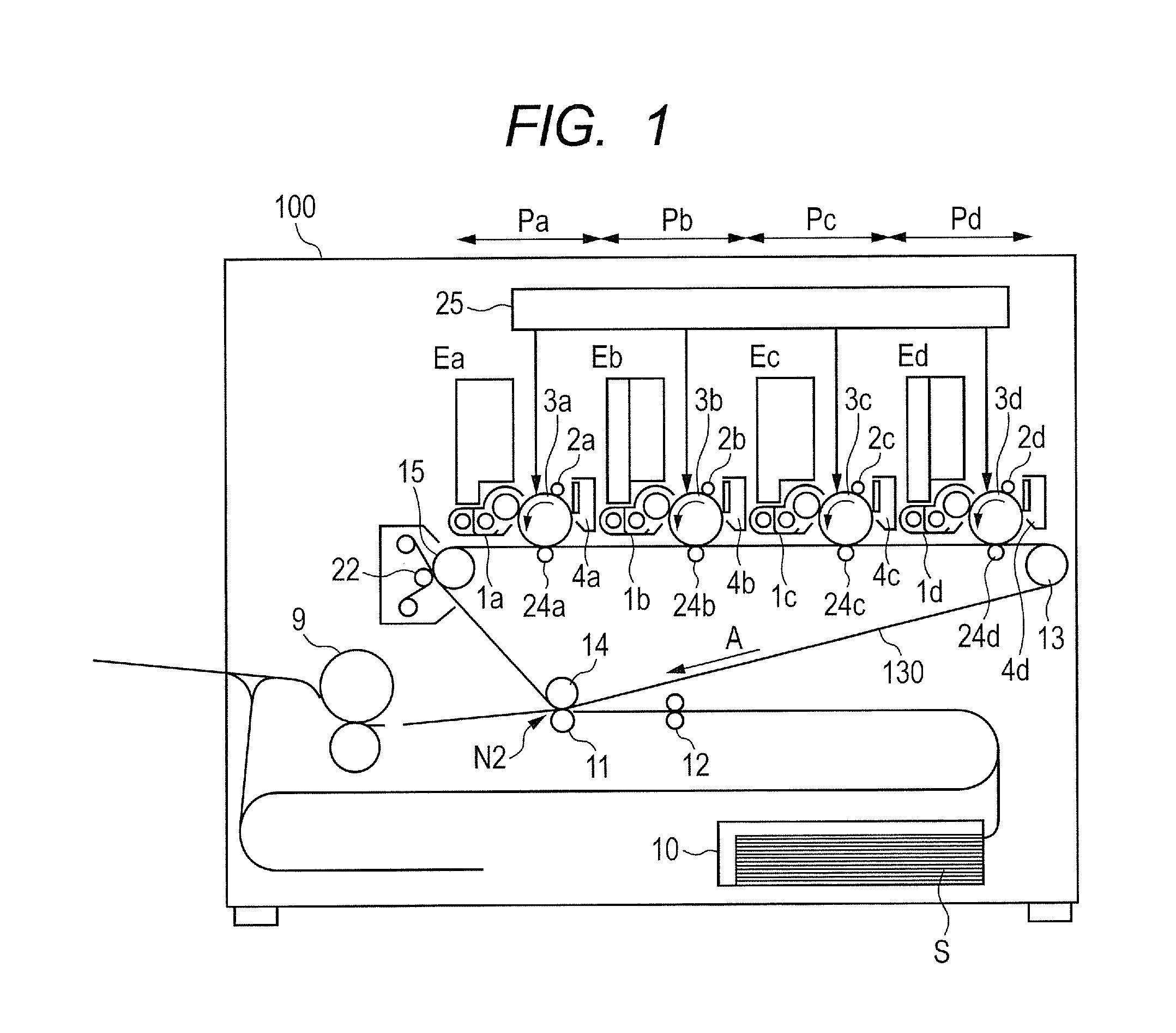

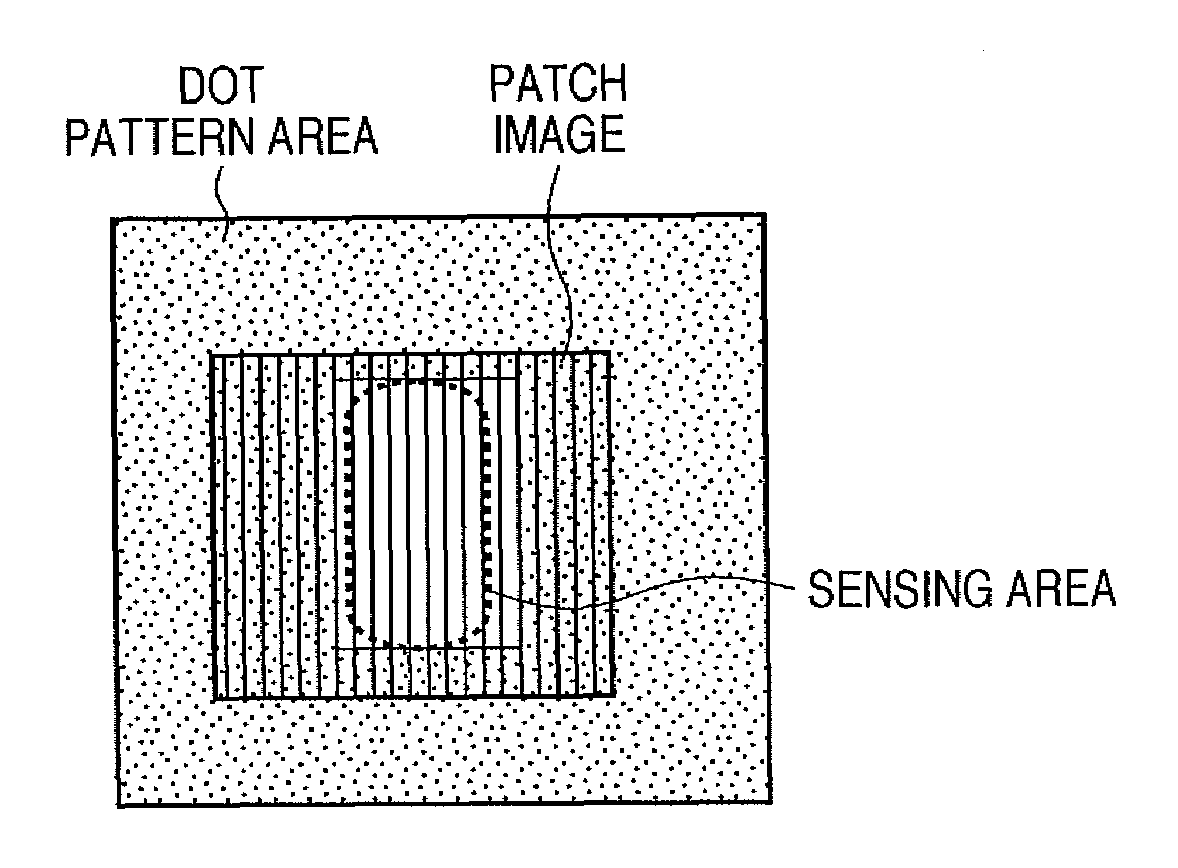

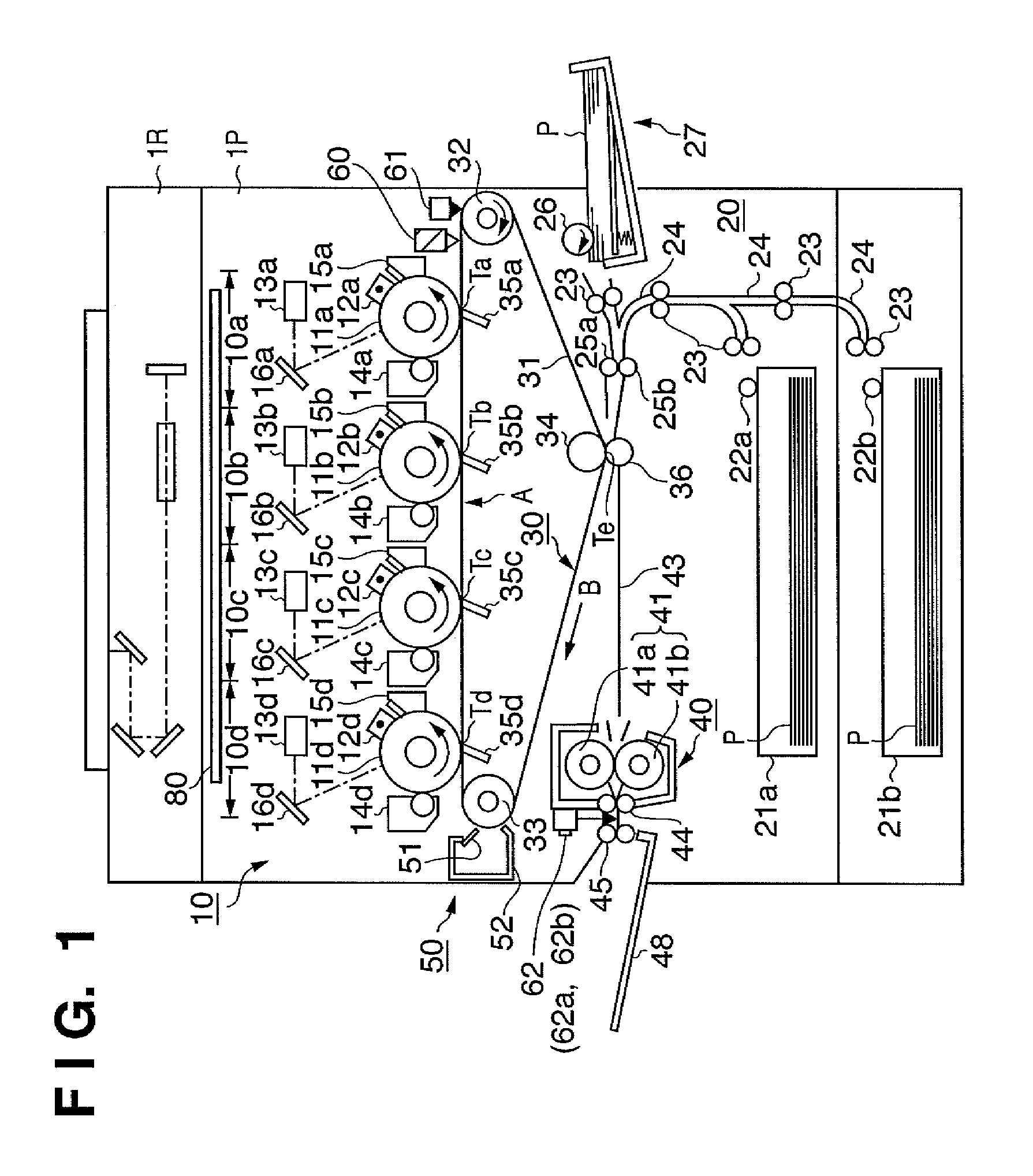

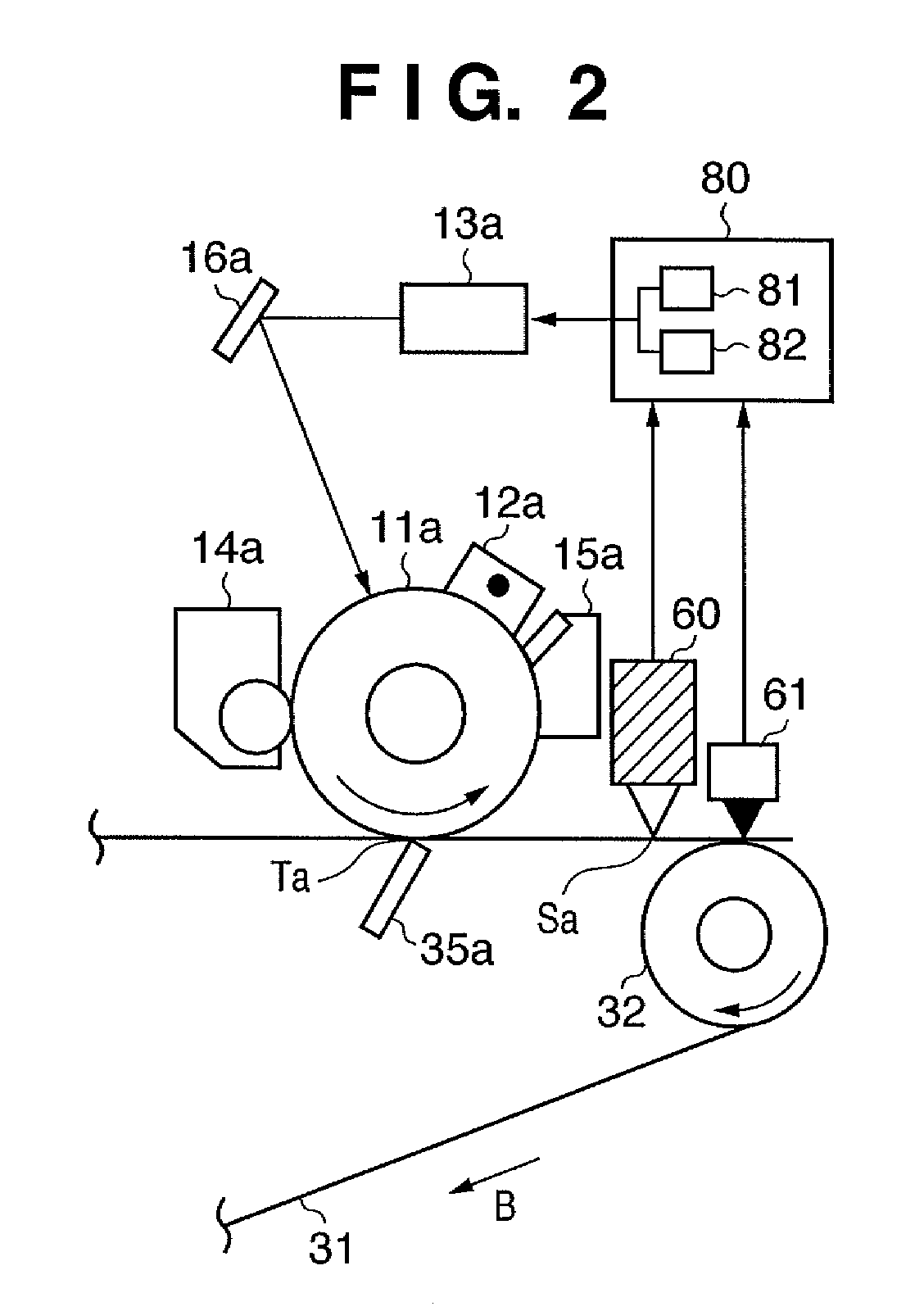

Image forming apparatus and control method thereof

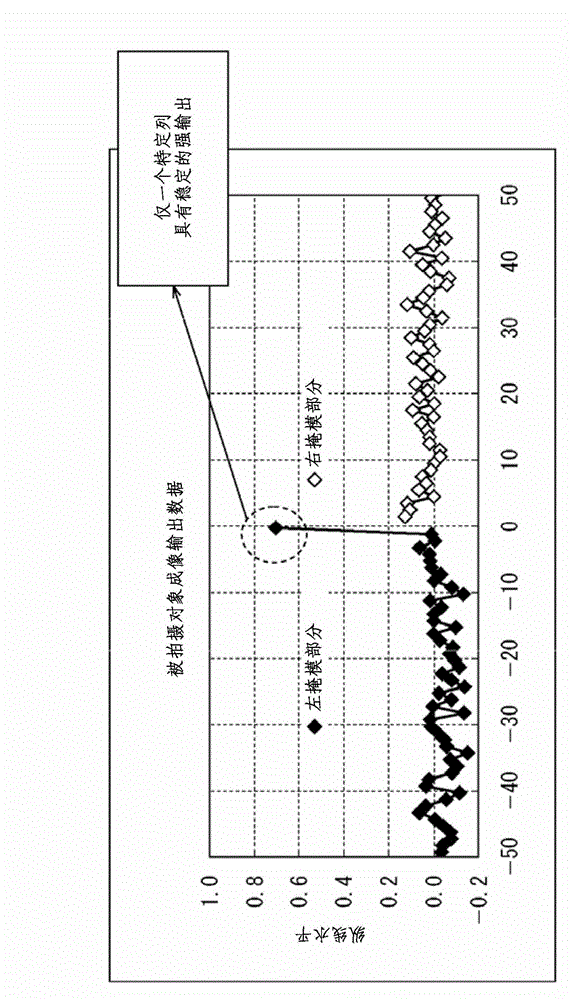

InactiveUS7773897B2Suppression of inhomogeneityElectrographic process apparatusPrintingStabilization controlLogical operations

An area signal generation unit and a logical operation circuit control a dot pattern forming unit which forms a dispersed dots image by dispersing dot developer images each having the area of at least one dot, so as not to form a dot pattern in the area of a patch image to be formed by a patch image forming unit or the sensing area of the patch image. An image forming apparatus capable of avoiding the influence of a dispersed dots image on a patch image with suppressing nonuniformity caused by a line-like image when forming a patch image for color stabilization control, is provided.

Owner:CANON KK

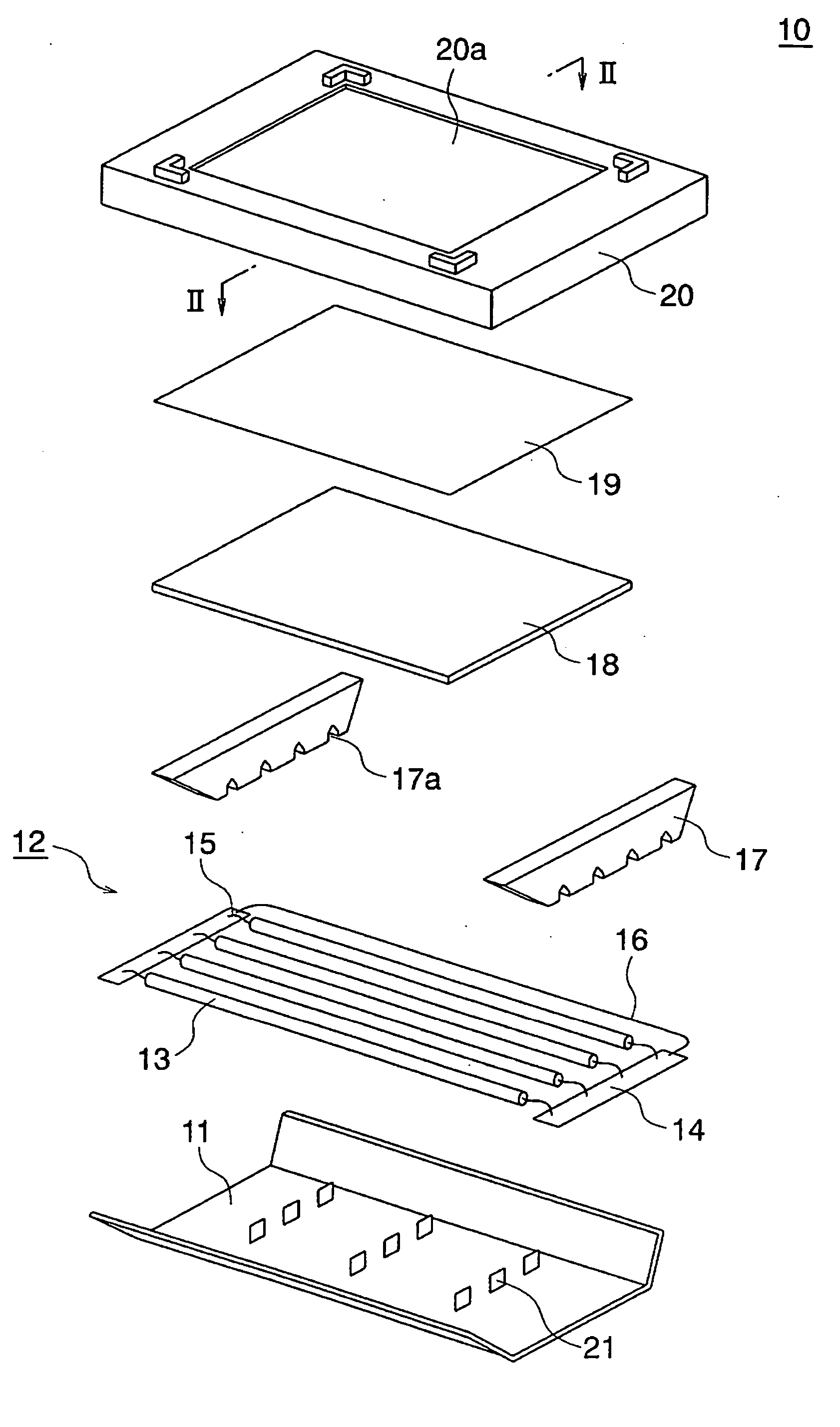

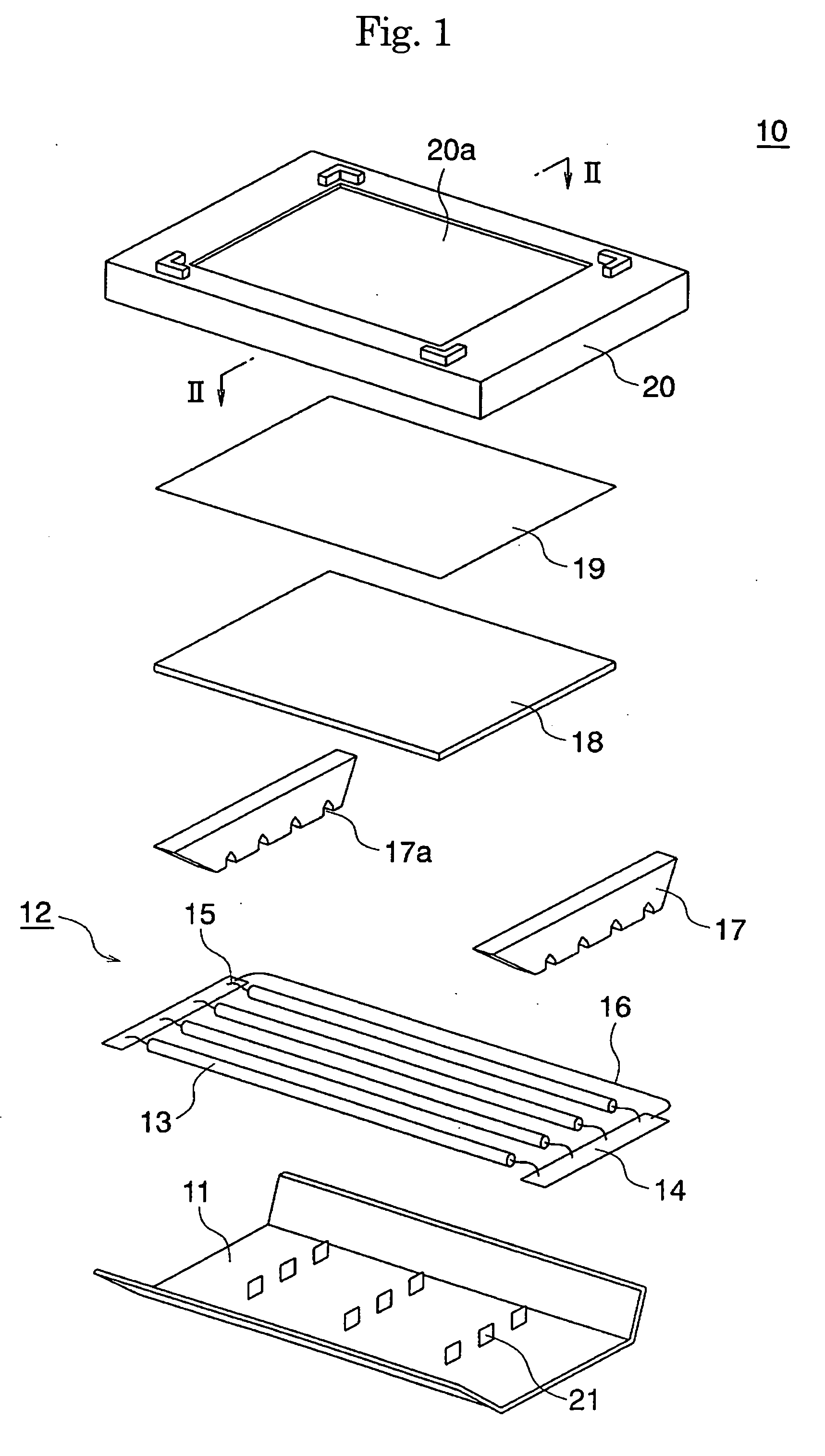

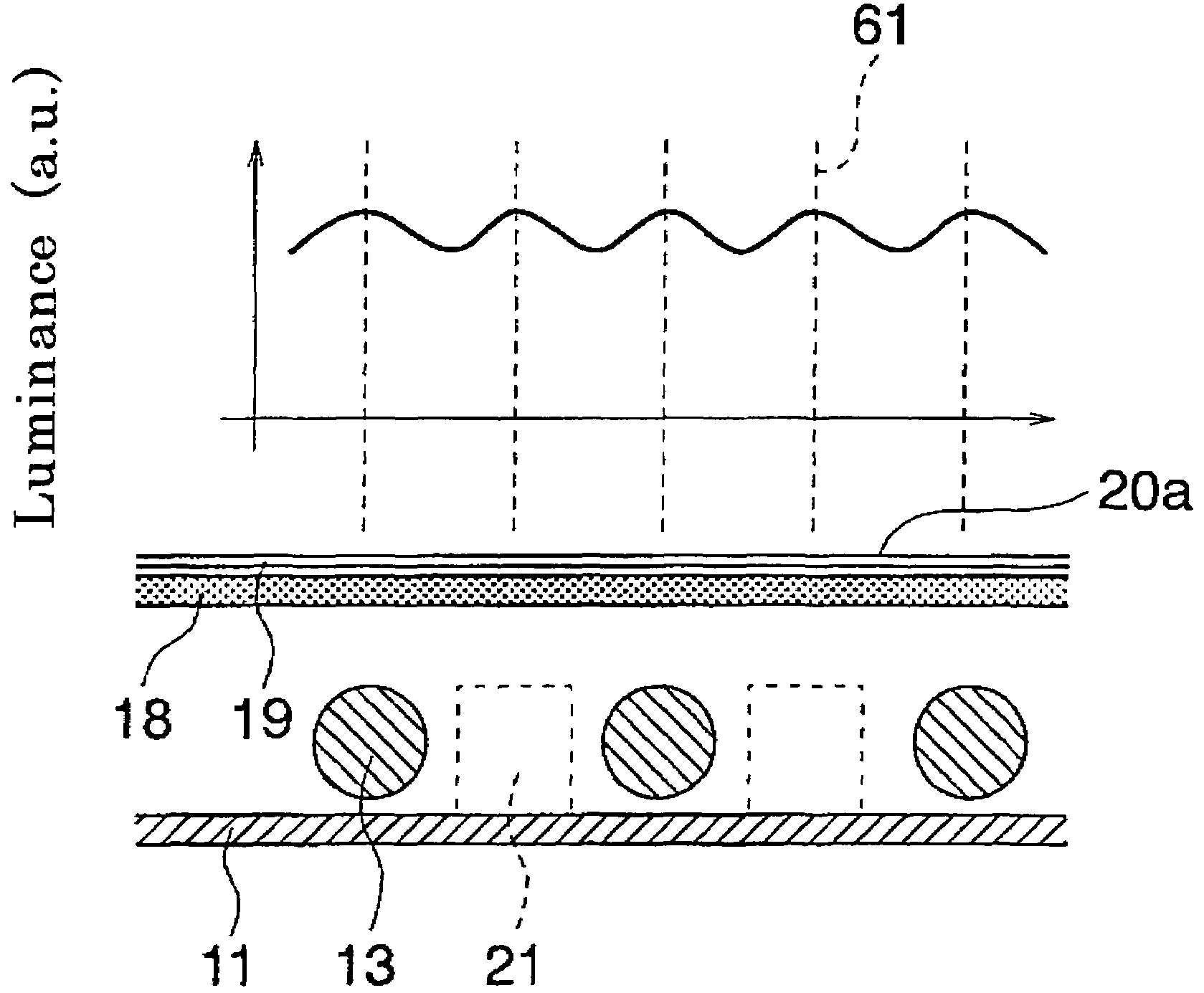

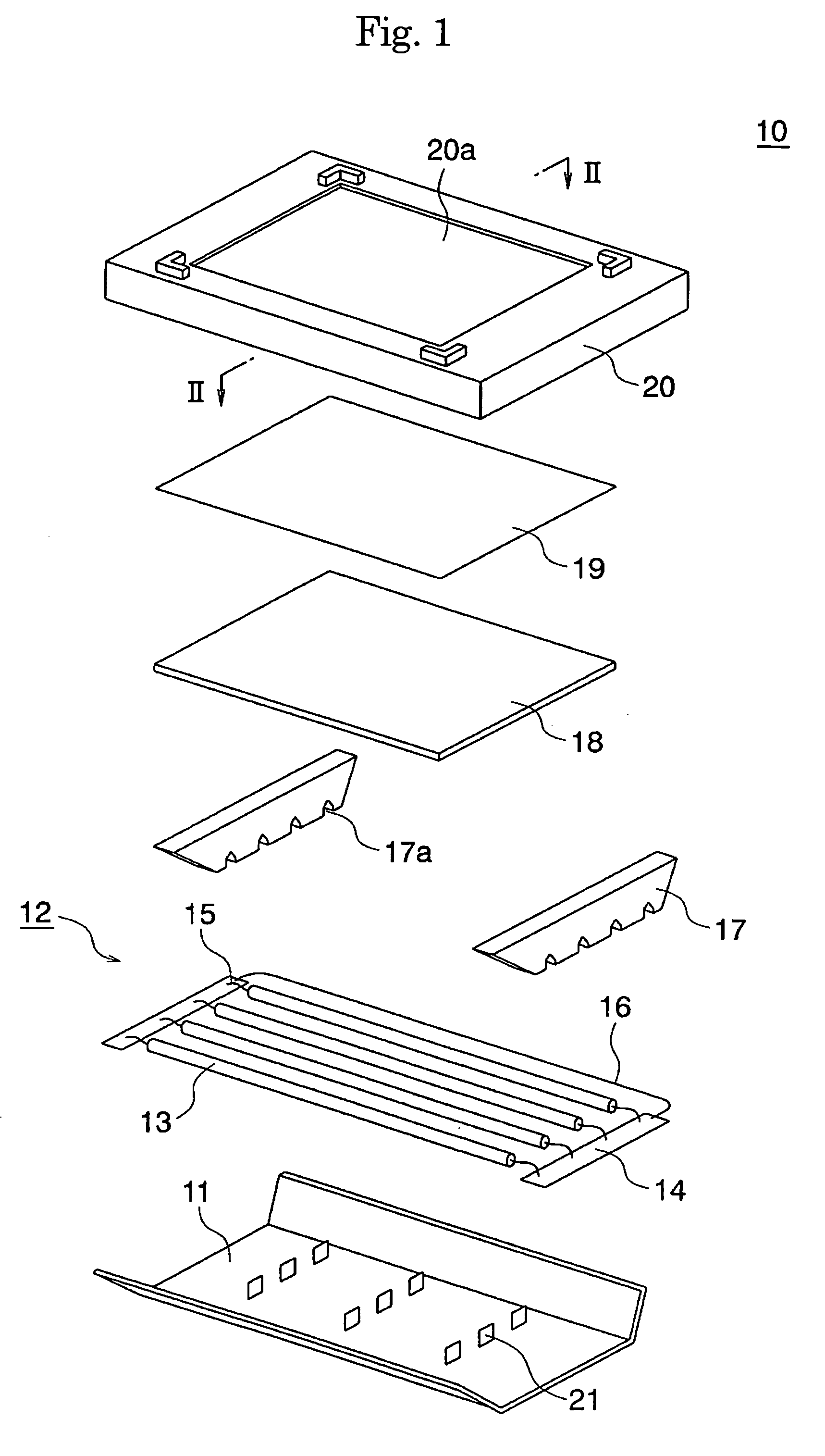

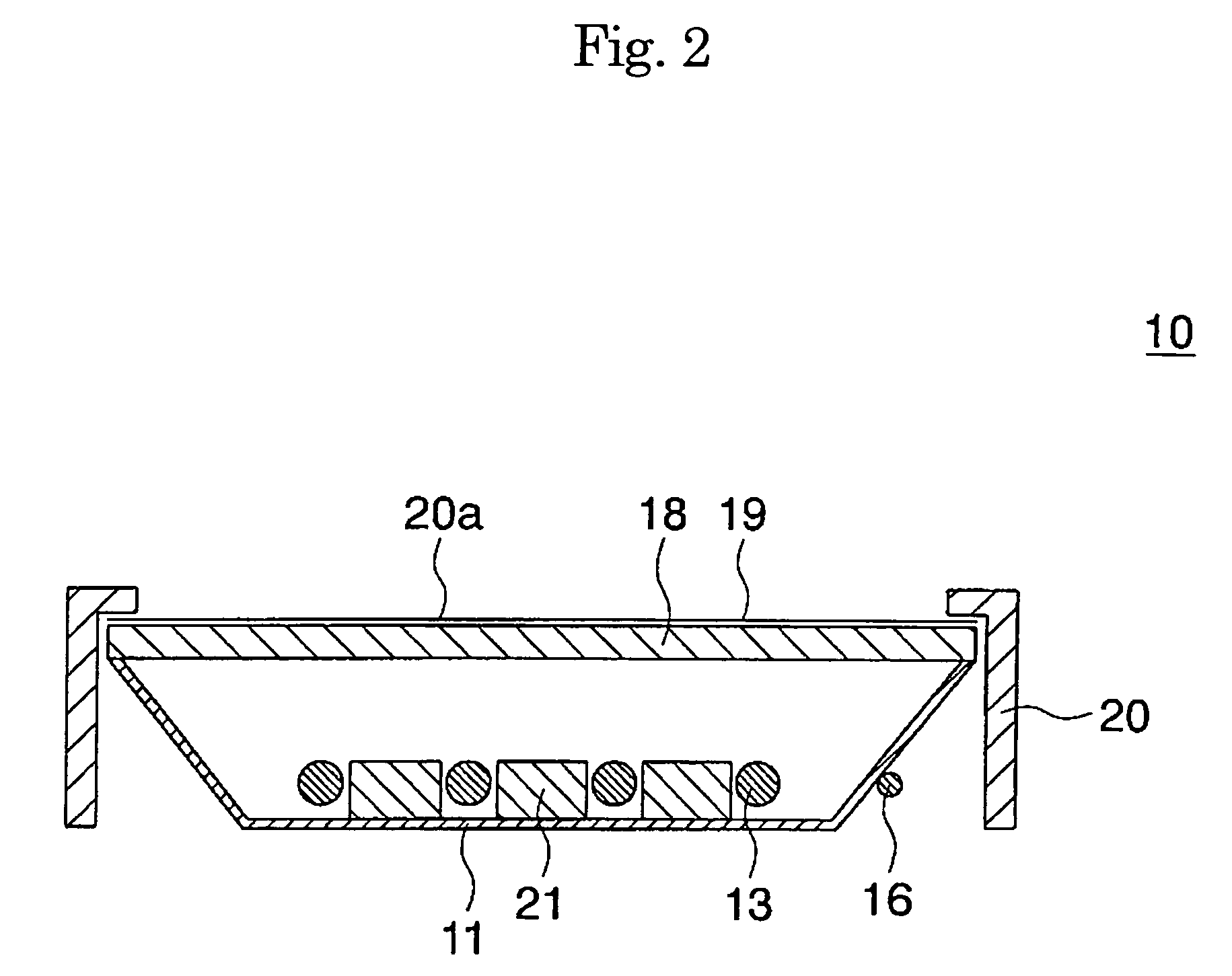

Lighting apparatus having a uniform luminance profile

ActiveUS20060083025A1Suppression of inhomogeneityIncrease brightnessNon-electric lightingPoint-like light sourceLight equipmentEngineering

A direct-emission backlight unit for use in an LCD device includes a plurality of elongate lamps at the rear of a light diffusion plate and a plurality of reflecting members arranged in a matrix on a rear reflecting plate. The reflecting members are disposed in the gap between adjacent lamps, and reflect light emitted by the lamps toward the diffusion plate for achieving a uniform luminance profile of the emission surface of the backlight unit.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

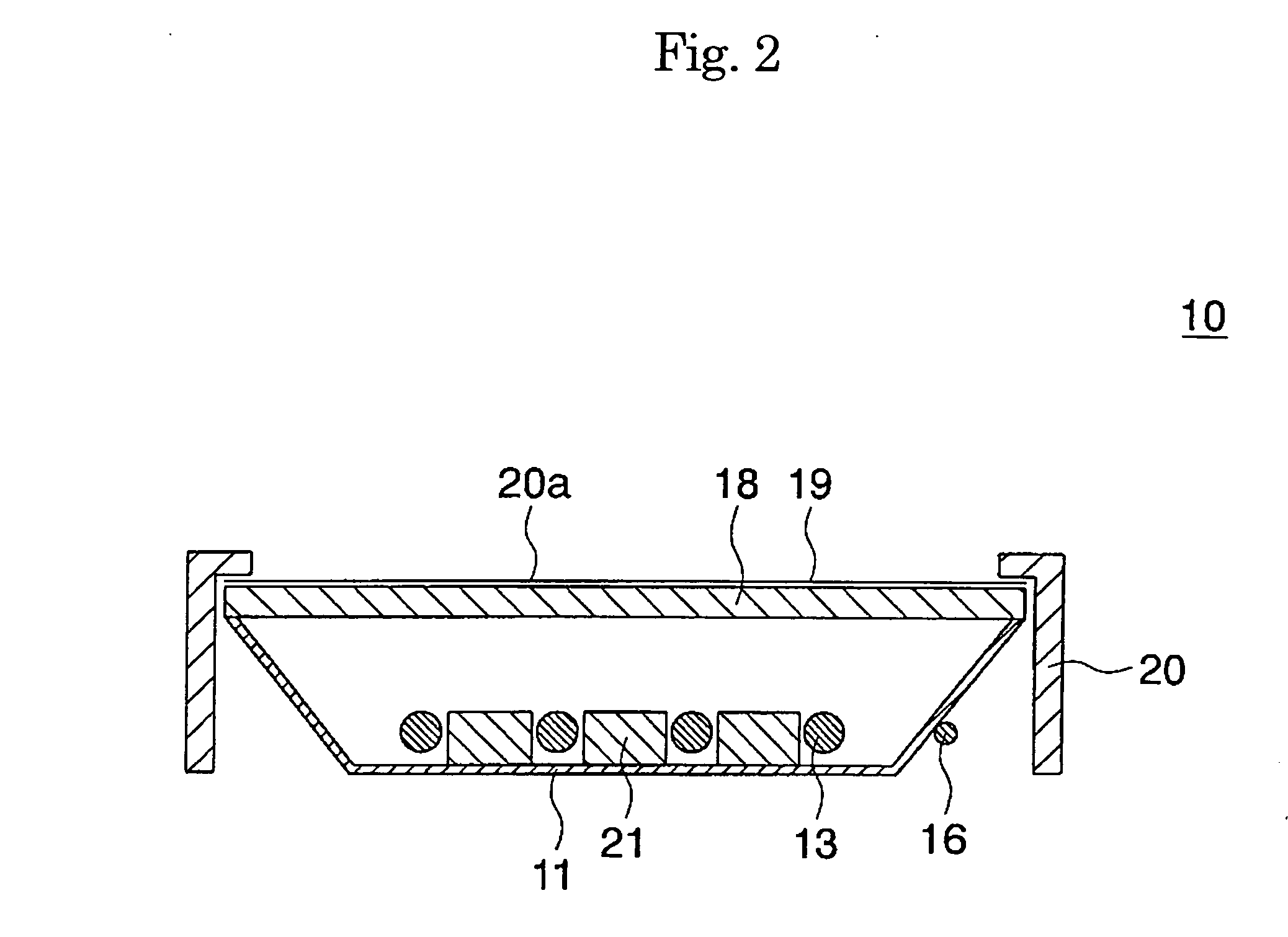

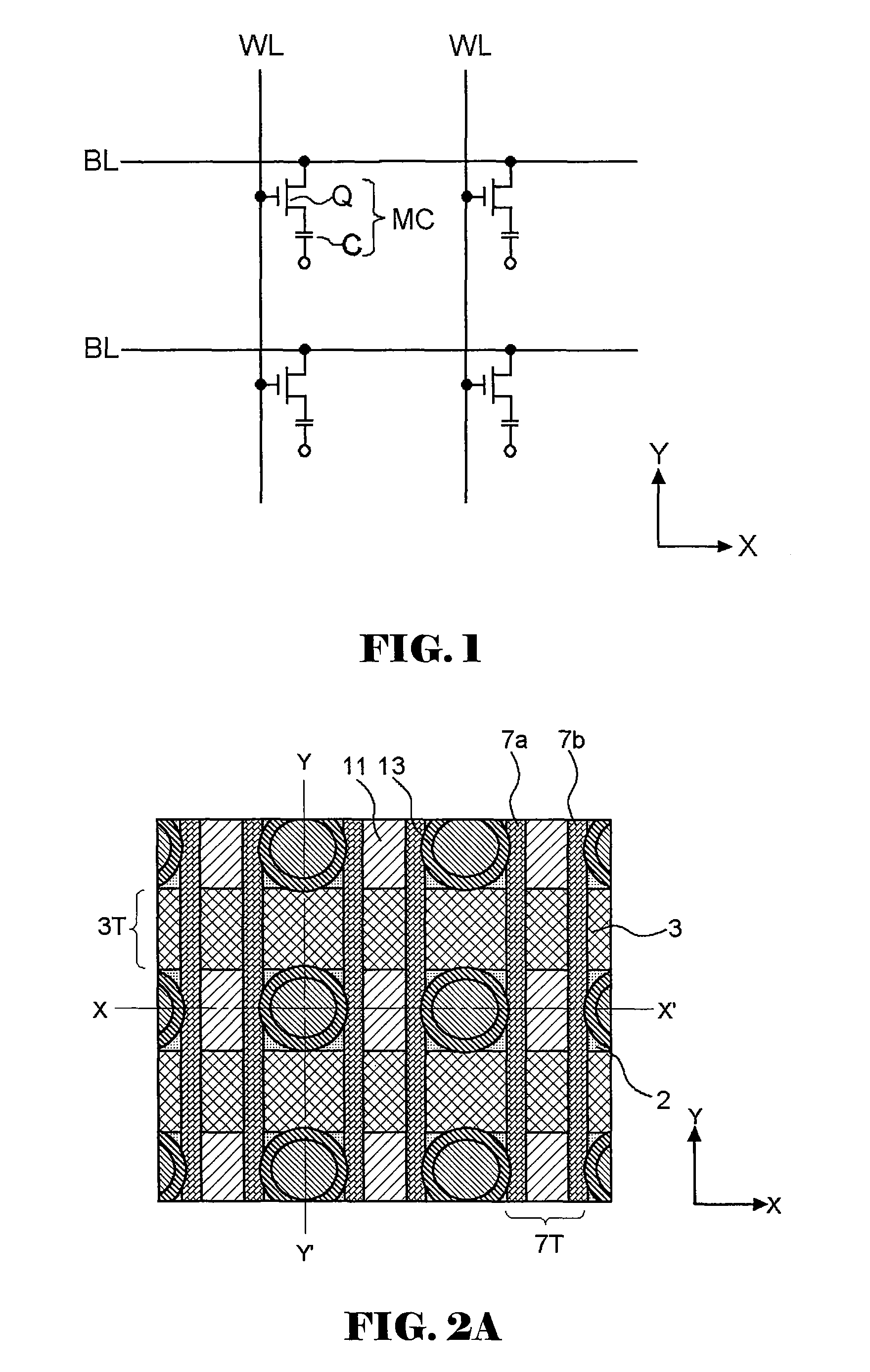

Method of manufacturing semiconductor device

InactiveUS8247298B2Suppression of inhomogeneityReduce unevennessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Disclosed is a method of manufacturing a semiconductor device comprising: forming a first layer on a sidewall of a trench formed on a main surface of a semiconductor substrate, filling up the trench with a protective film, etching back the protective film by a dry etching method so that a height of a surface of the protective film is lower than an opening of the trench and removing the first layer exposed by the etching-back.

Owner:LONGITUDE LICENSING LTD

Thermal-transfer printer

InactiveUS7073962B2Suppression of inhomogeneityPower drive mechanismsStructural engineeringThermal Head

The thermal-transfer printer includes: a pair of head attaching arms 12 having fitting holes 12c respectively inserted with support shafts 9 and having center lines inclined to axis lines of the supporting shafts 9 by a predetermined inclination angle; and supporting shaft attaching portions 12b being bent by bending lines 12d that intersects with a line connecting the fitting holes 12c and a printing position of a thermal head 11 relative to a sheet 100. The fitting hole 12c of respective supporting shaft attaching portion 12b are attached to the supporting shafts 9 in a state of being elastically bent in directions opposed to each other such that predetermined inclination angles of the supporting shafts 9 of center lines of the fitting hole 12c of the supporting shaft attaching portion 12b relative to axis lines of the supporting shafts 9 are reduced.

Owner:FUNAI ELECTRIC CO LTD

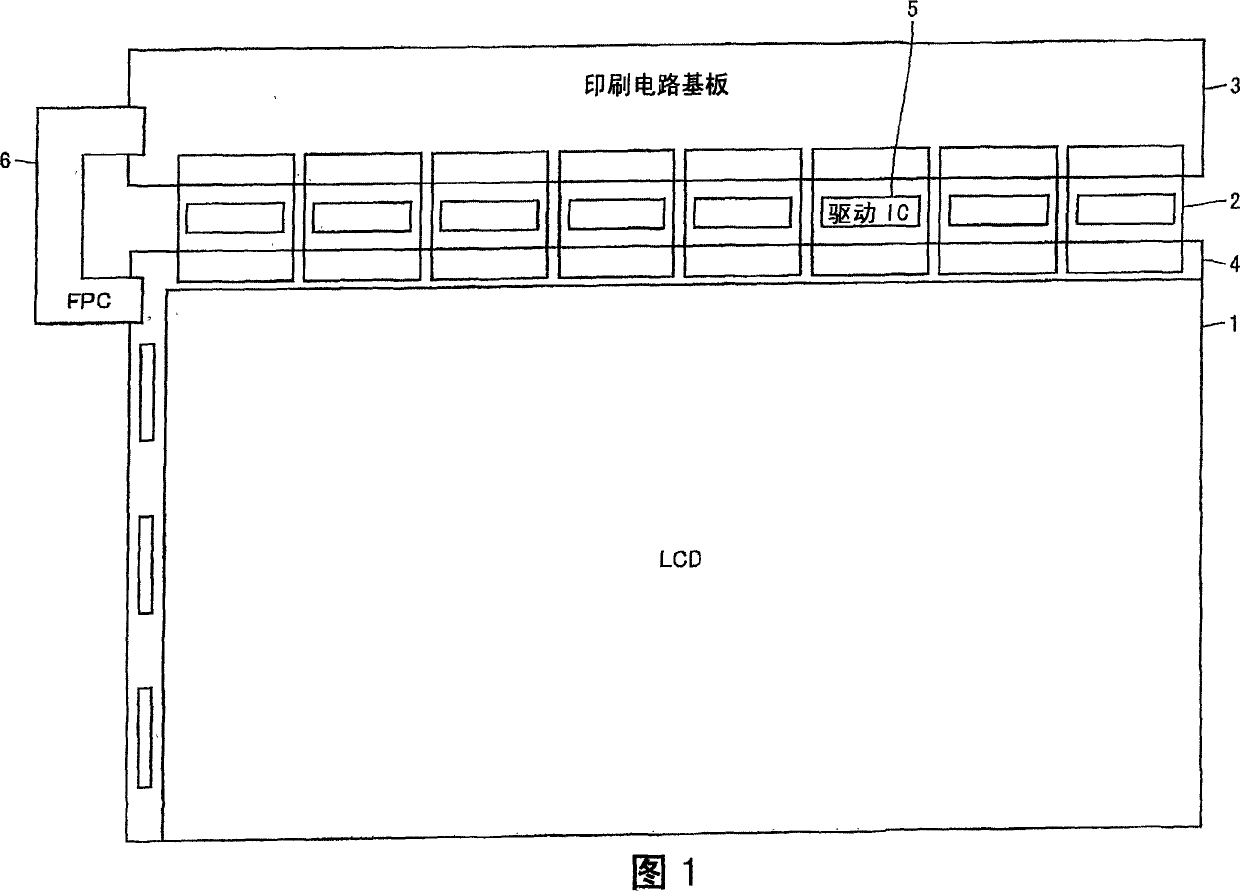

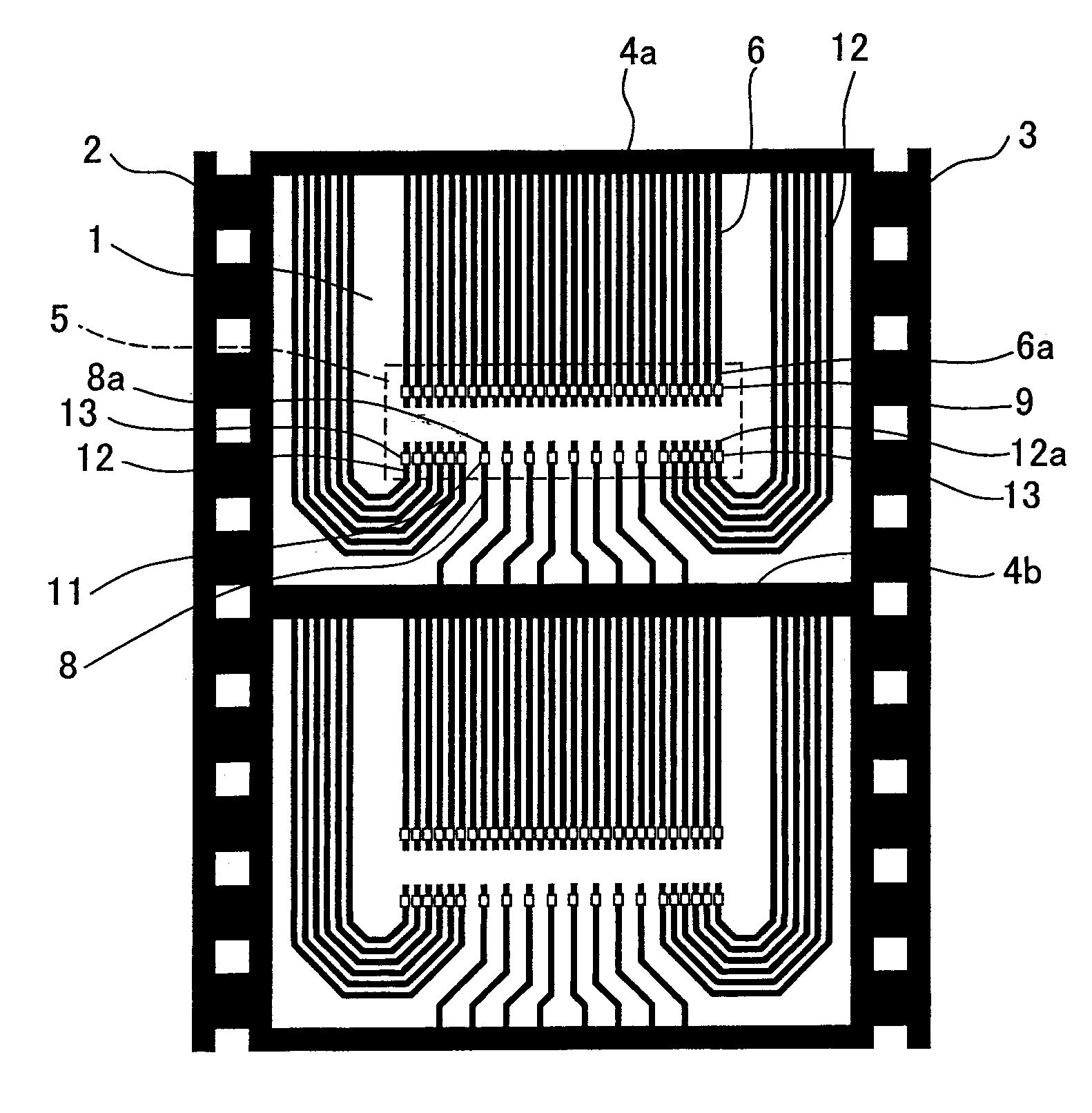

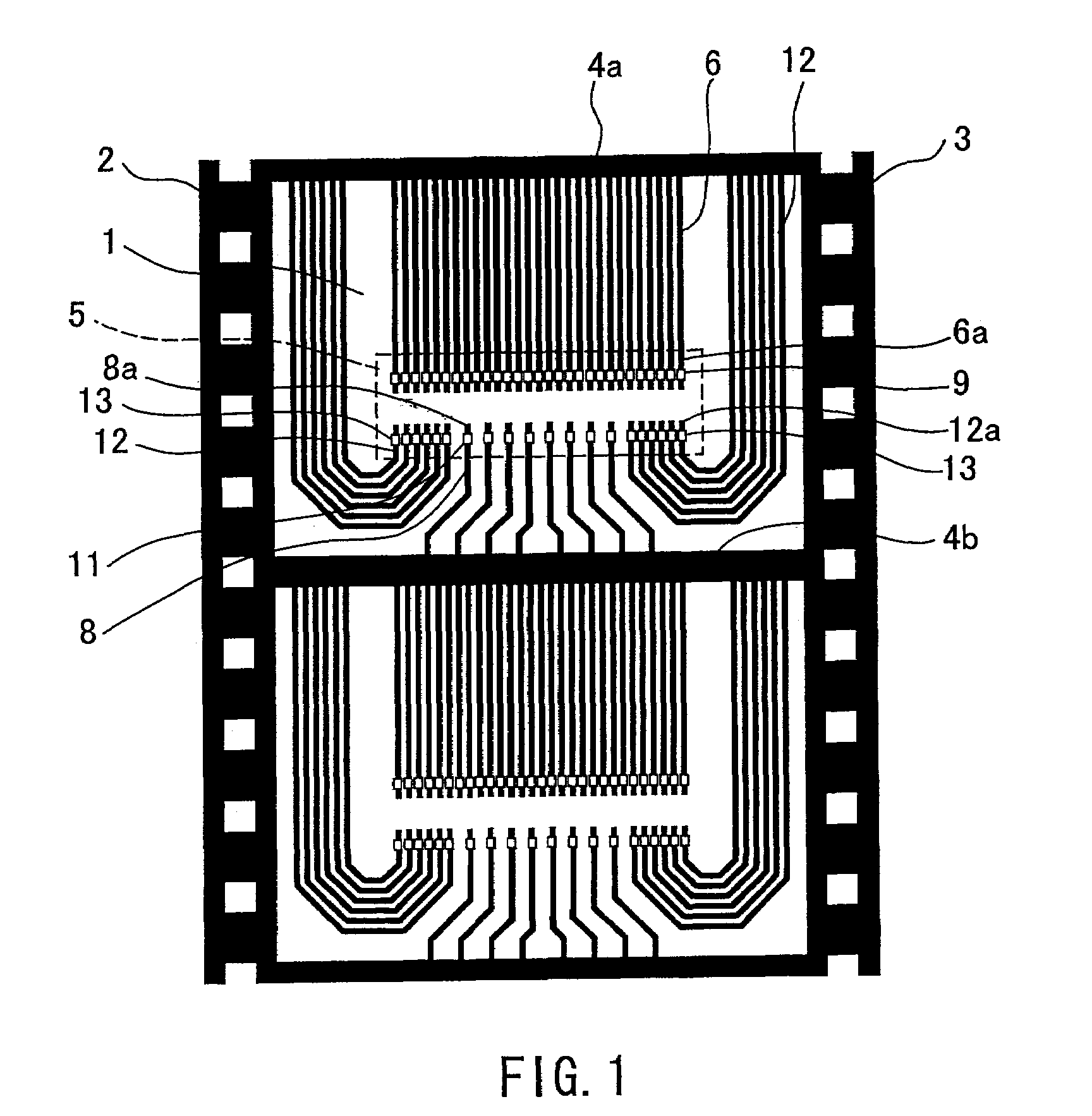

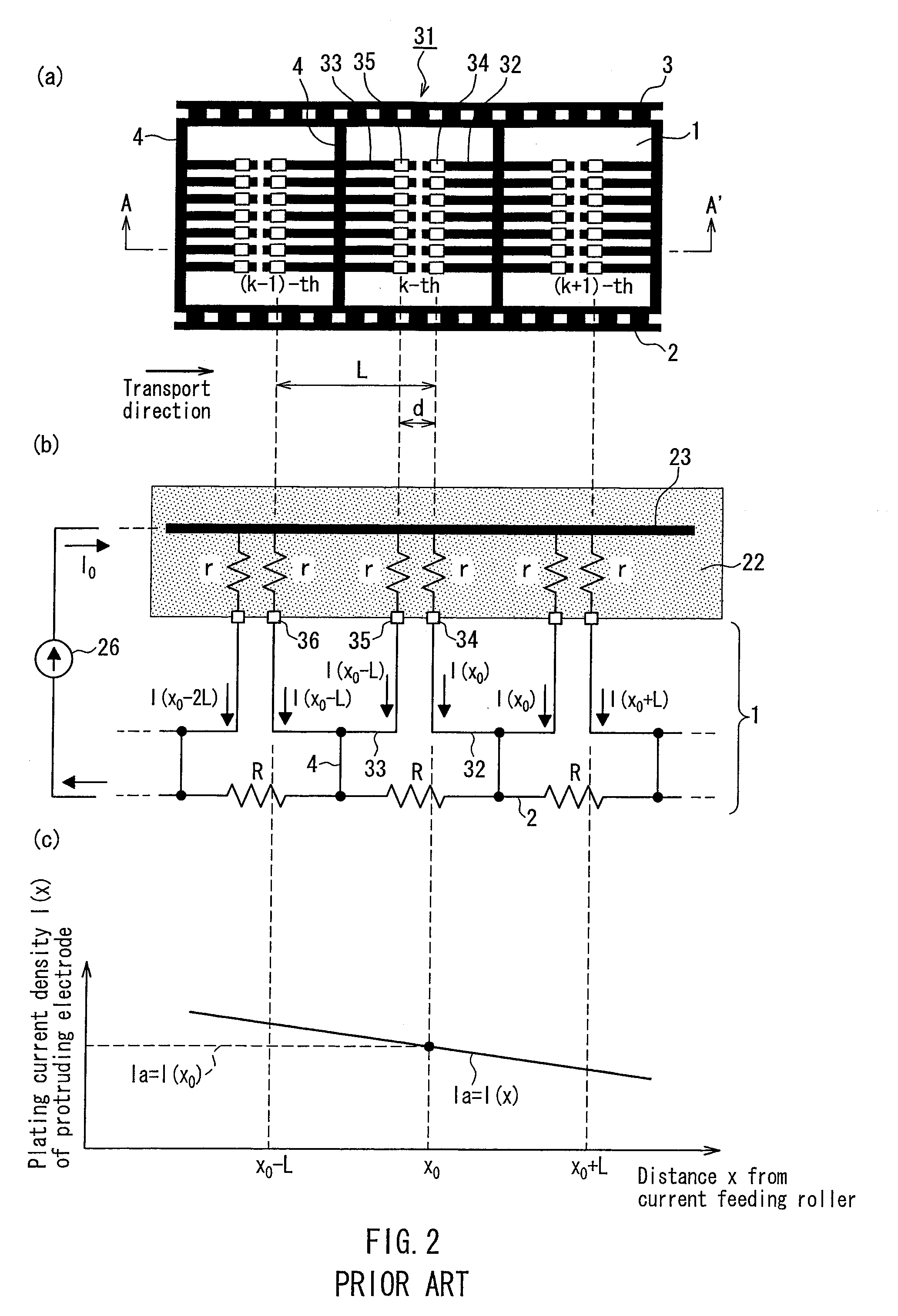

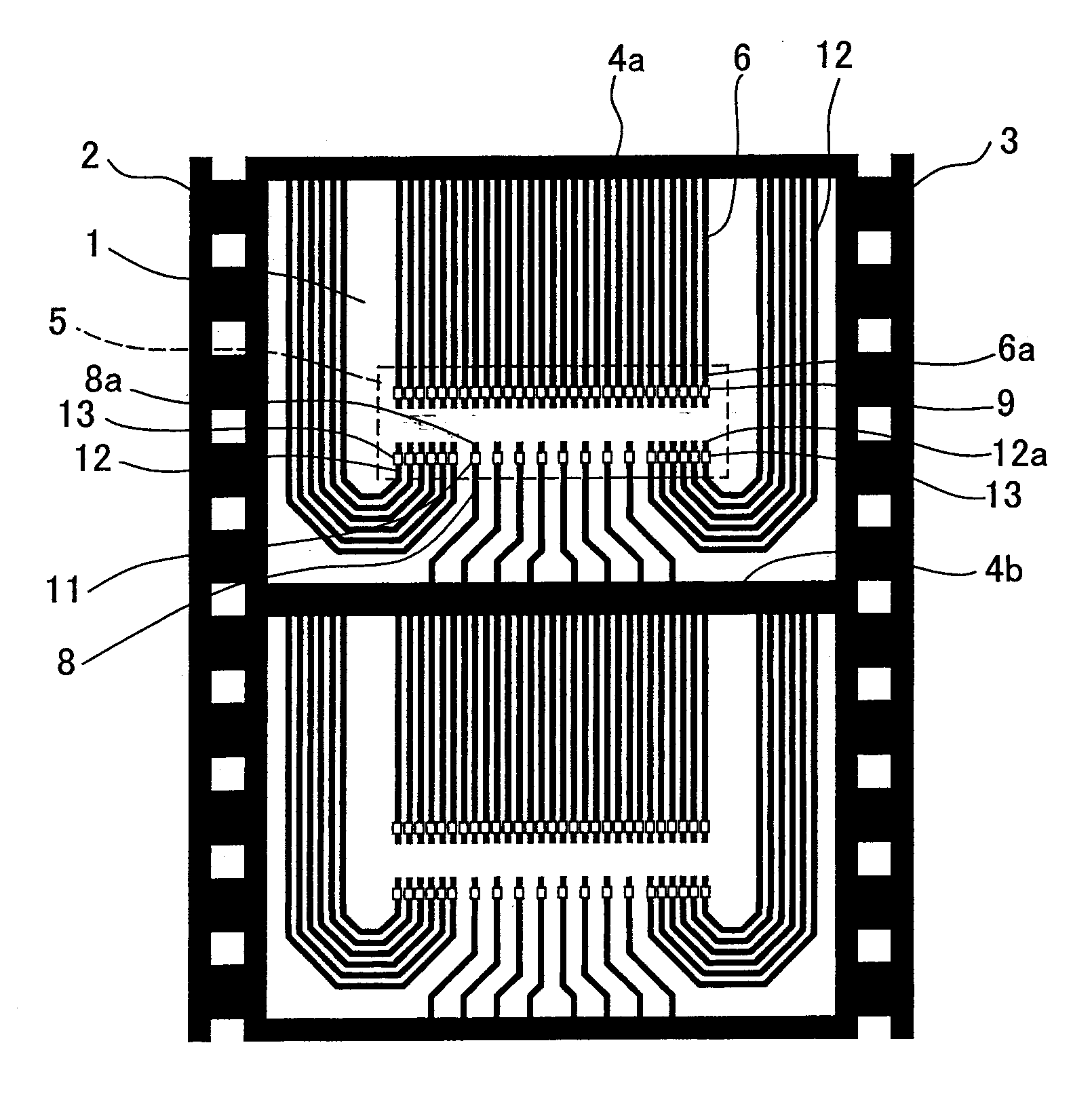

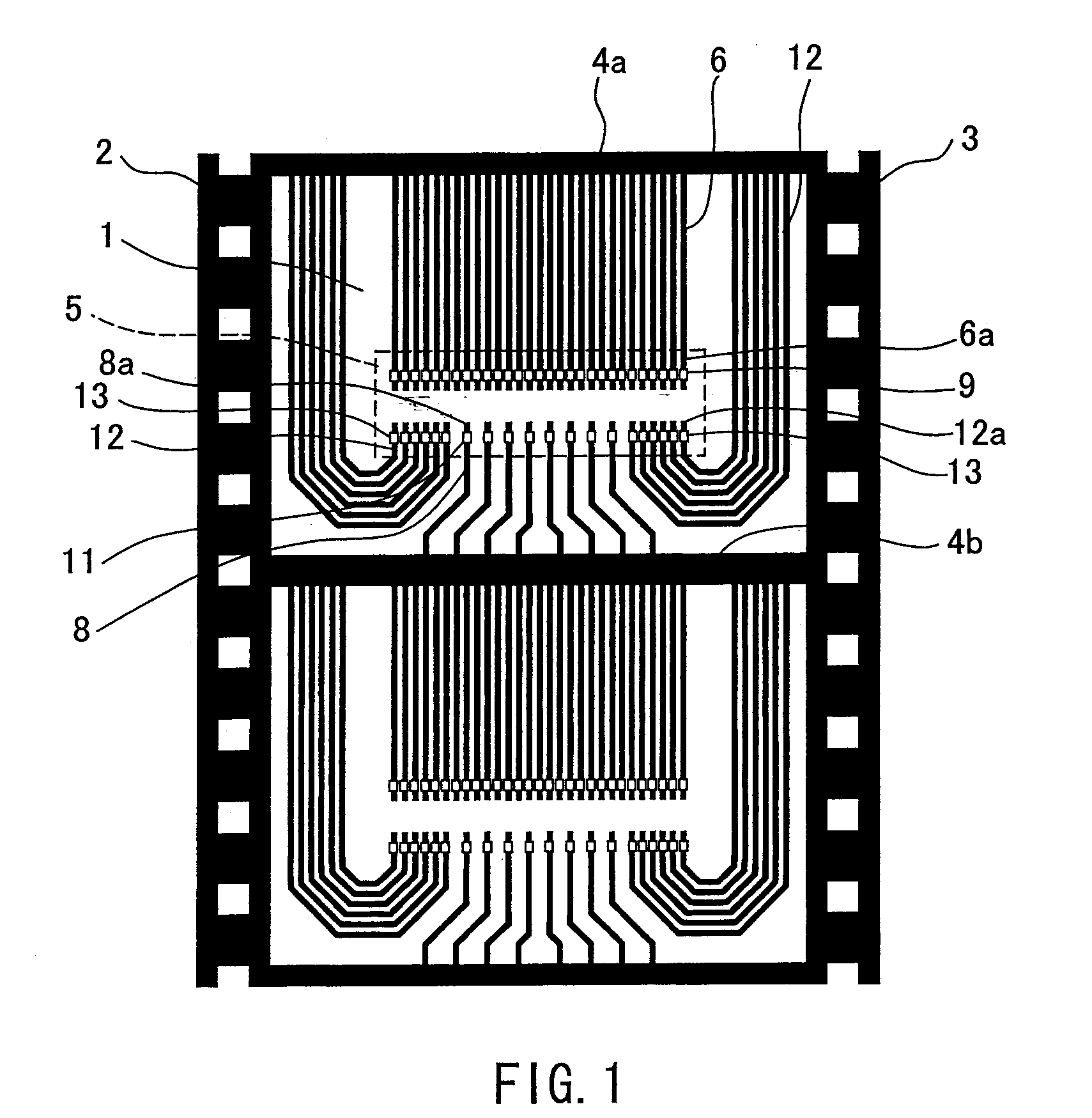

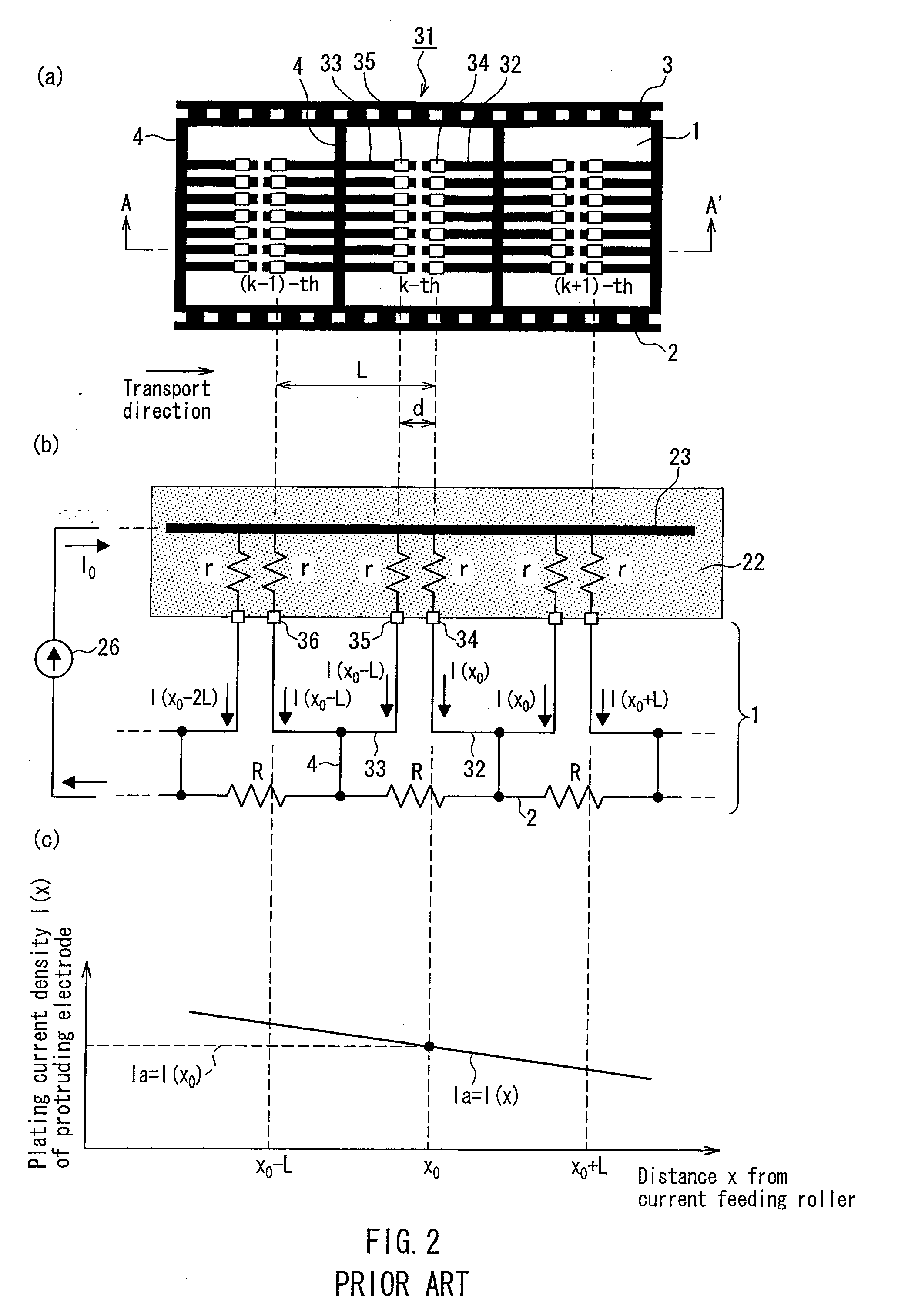

Wiring board and method for producing the same

ActiveUS7442074B2Suppression of inhomogeneityPrinted circuit aspectsSolid-state devicesElectrical conductorPower strip

A wiring board includes first and second feeding electrodes (2, 3) provided along both sides of an insulating substrate (1), feeding bus lines (4) extending in a traverse direction and connected to both the feeding electrodes, and conductor wirings (6, 8, 12) having one side terminals forming inner leads having protruding electrodes (9, 11, 13) and the other side terminals connected to the feeding bus lines. The inner leads in each unit region are arranged in two lines extending in the traverse direction. The inner leads of a first group are arranged with a dense wiring pitch, and the inner leads of a second group include a dense pitch region in which a wiring pitch is the same as that of the inner leads of the first group, and a sparse pitch region in which a wiring pitch is longer than that of the inner leads of the first group. The inner leads (6) of the first group and the inner leads (12) in the dense pitch region of the second group are connected to the feeding bus line on one side of each region, and the inner leads (8) in the sparse pitch region of the second group are connected to the feeding bus line on the other side of each unit region. Non-uniformity of heights of the protruding electrodes due to a difference in the wiring pitches of the inner leads can be suppressed easily.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Lighting apparatus having a uniform luminance profile

ActiveUS7354173B2Suppression of inhomogeneityIncrease brightnessNon-electric lightingPoint-like light sourceLight equipmentEngineering

A direct-emission backlight unit for use in an LCD device includes a plurality of elongate lamps at the rear of a light diffusion plate and a plurality of reflecting members arranged in a matrix on a rear reflecting plate. The reflecting members are disposed in the gap between adjacent lamps, and reflect light emitted by the lamps toward the diffusion plate for achieving a uniform luminance profile of the emission surface of the backlight unit.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

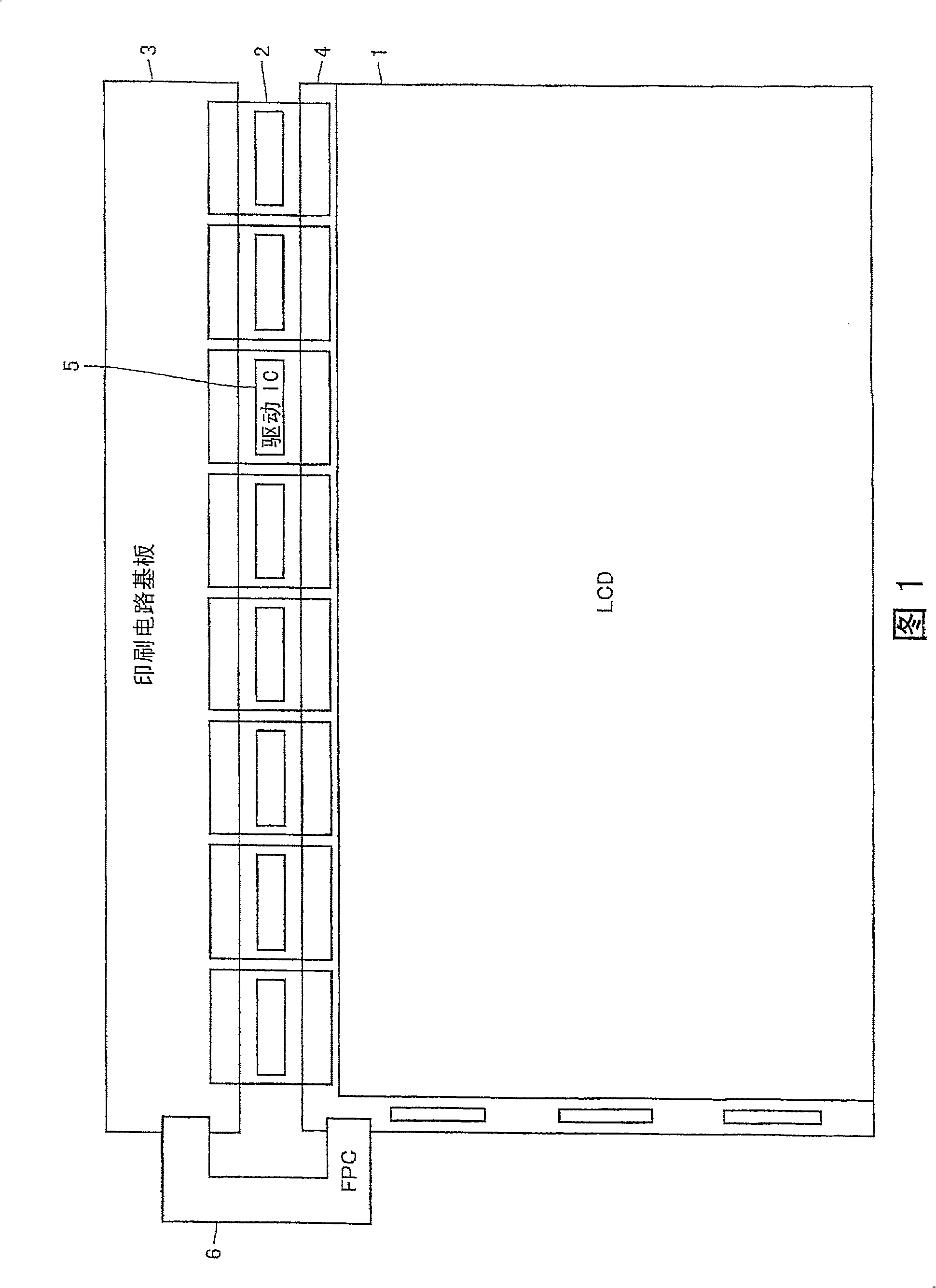

Bonding method and apparatus

InactiveCN100424556CCurb bendingSuppression of inhomogeneityStatic indicating devicesSemiconductor/solid-state device manufacturingAnisotropic conductive filmAdhesive

The invention provides a bonding device capable of shortening a bonding time and performing high speed and accurate mounting by irradiating a laser to an anisotropic conductive film (ACF) which is a mounting adhesive. Laser generated from a laser generator is reflected by a laser mirror, passes through an array substrate (glass substrate) through a backup glass, and then, directly irradiated to an ACF in a pinpoint manner. The laser from the laser generator is set to have a wavelength whose transmittance of transmitting the TCP and the array substrate having the ACF inserted therebetween is higher than that of the other wavelength. The ACF is welded by this laser irradiation, so that the TCP and the array substrate are bonded to each other.

Owner:ORMON CORP

Vacuum carburization method and vacuum carburization apparatus

InactiveUS8152935B2Reduce processing timeSuppression of inhomogeneitySolid state diffusion coatingProperty valueQuenching

There are provided a method, between a diffusion process and a quenching process, a normalizing process of performing step cooling in which a temperature lowering treatment and a temperature keeping treatment are alternately repeated plural times so that a temperature history from the first temperature to a predetermined temperature satisfies a predetermined condition; an after-normalizing maintaining process of maintaining the temperature of the whole workpiece for a predetermined time after the normalizing process so that the whole workpiece becomes the predetermined temperature, thereby producing fine crystal grains in the workpiece; and a reheating process of raising the temperature of the workpiece to the second temperature, after the after-normalizing keeping process. According to the invention, even when a process temperature is set high to make rapid progress of carburization and diffusion and thus the process time is shortened, uniformity in temperature is achieved between a surface and a inside of a workpiece by the high-temperature process and crystal grains are prevented from being coarse, thereby obtaining a workpiece having a predetermined property value.

Owner:IHI CORP

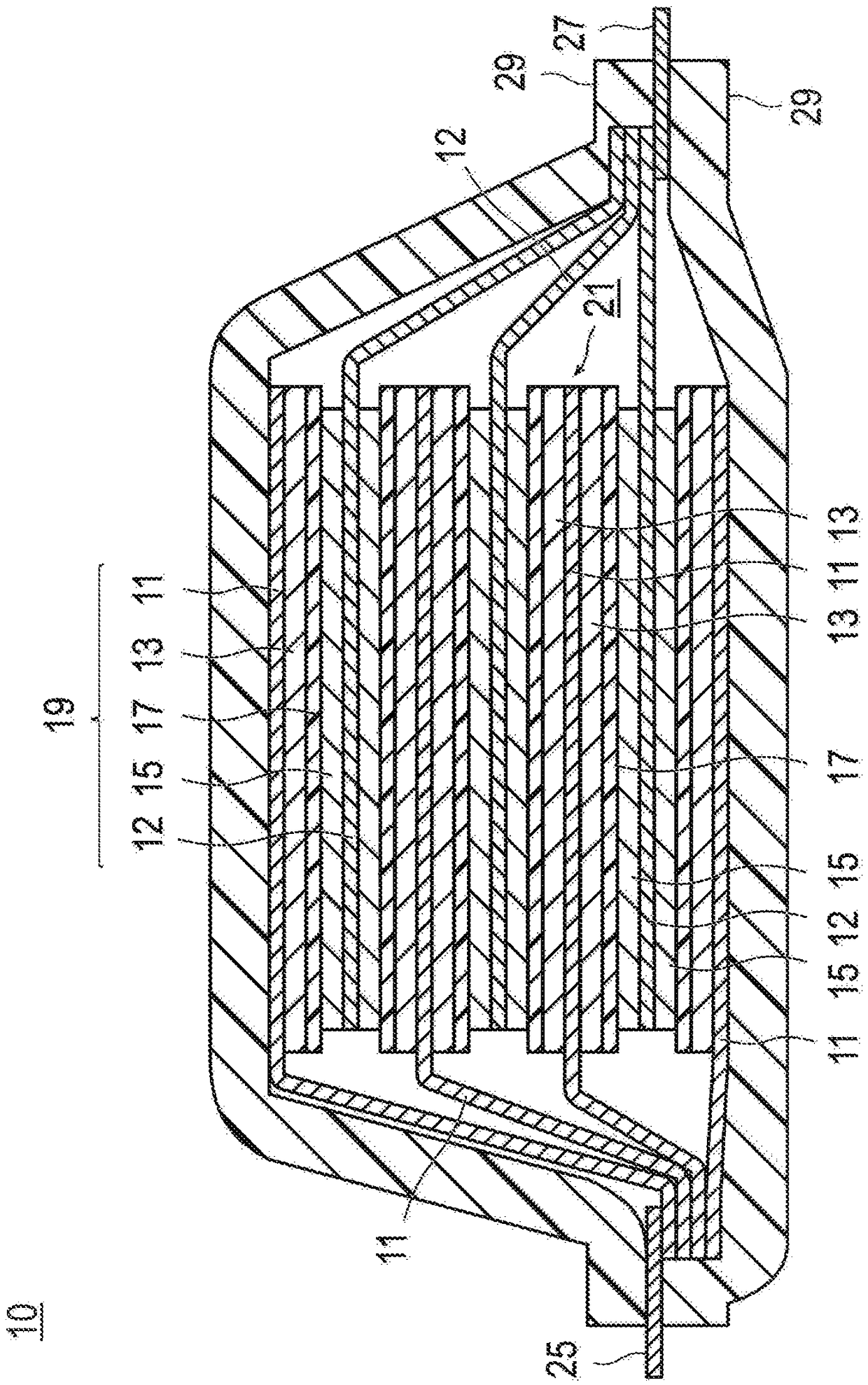

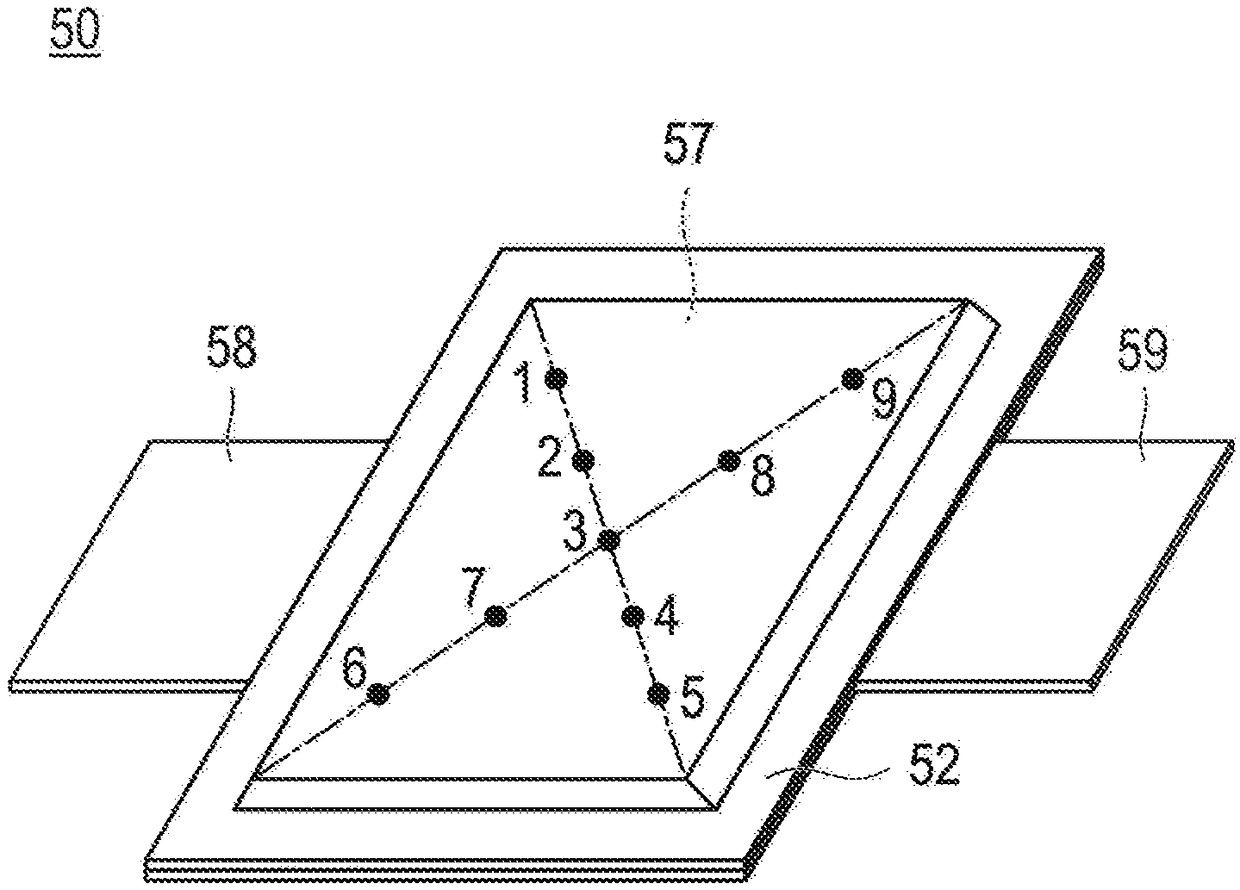

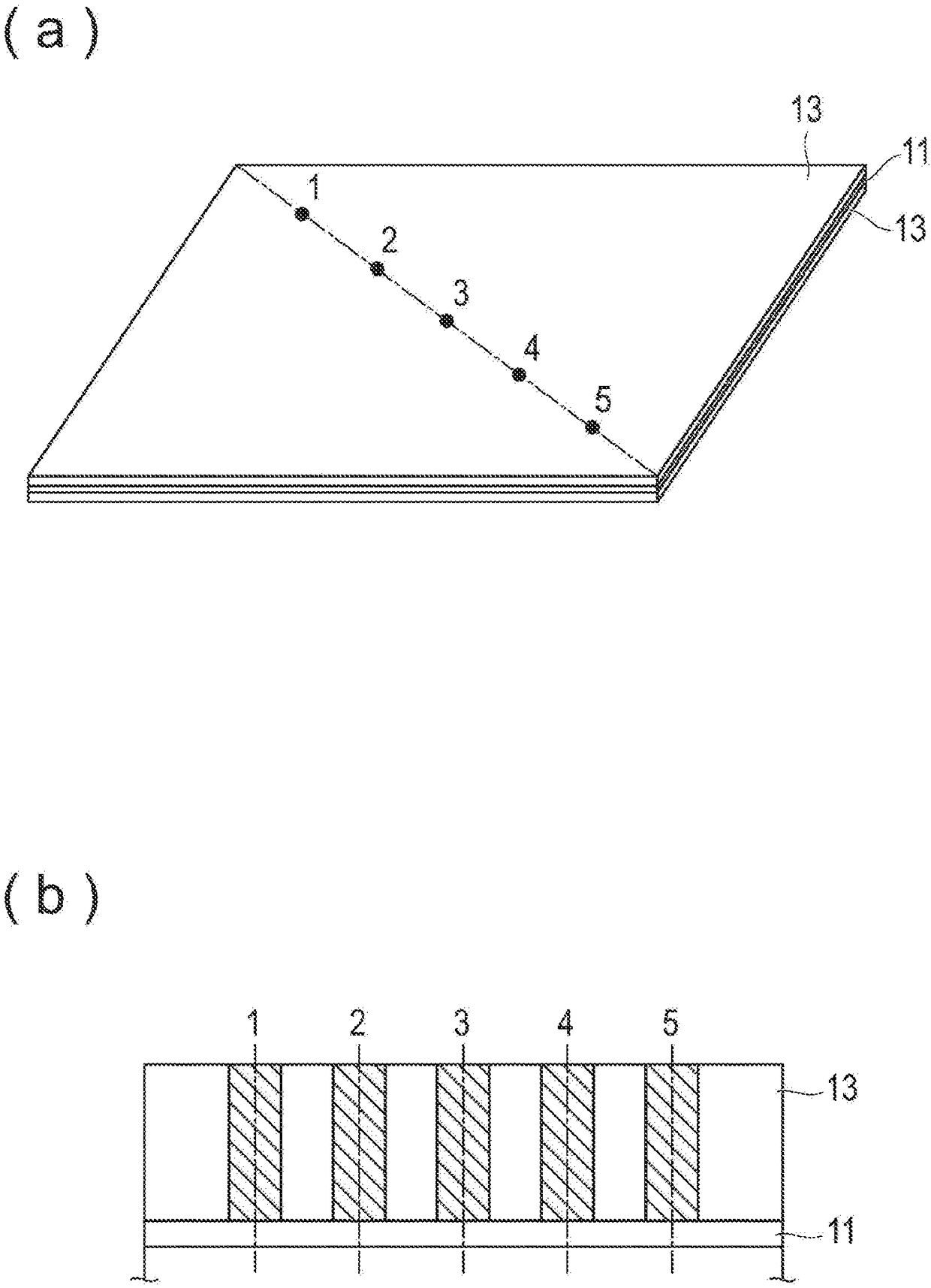

Non-aqueous electrolyte secondary battery

ActiveCN109075376ASuppression of unevenness in the distance between electrodesExcellent cycle durabilityFinal product manufactureNegative electrodesChemistryAqueous electrolyte

The invention is to provide a means for achieving adequate charge / discharge cycle characteristics in a non-aqueous electrolyte secondary battery having large capacity and a large area even when a mixture of a high-capacity Si material and a carbon material that swells little is used as a negative electrode active material. A non-aqueous electrolyte secondary battery in which the value of the ratioof the battery volume (the product of the thickness of the battery and the projected area of the battery including a battery exterior body) with respect to the rated capacity is 10 cm<3> / Ah or less and the rated capacity is 3 Ah or more, said non-aqueous electrolyte secondary battery comprising a power generation element that includes: a positive electrode in which a positive electrode active material layer including a positive electrode active material is formed on the surface of a positive electrode current collector; a negative electrode in which a negative electrode active material layerincluding a negative electrode active material is formed on the surface of a negative electrode current collector; and a separator. The non-aqueous electrolyte secondary battery is characterized in that: the negative electrode active material layer contains a negative electrode active material represented by formula (1) alpha (Si material) and beta (carbon material) (in the formula, the Si material is one or more substances selected from the group consisting of Si-containing alloys and SiOx (x represents the number of oxygen atoms satisfying the valence of Si) that is a mixture of amorphous SiO2 particles and Si particles, the carbon material is one or more substances selected from the group consisting of graphite, hardly graphitizable carbon, and amorphous carbon, alpha and beta representthe mass% of the individual components in the negative electrode active material layer, 80 <= alpha + beta <= 98, 0.1 <= alpha <= 40, and 58 <= beta <= 97.9); and when a plurality of discretionary locations within the plane of the negative electrode active material layer are selected and the area ratios (%) of the Si material and the carbon material in the area of the field of view in each of images of a cross section of the negative electrode active material layer are denoted respectively as S (%) and (100-S) (%), the difference between the maximum value and the minimum value of S is within5%.

Owner:ENVISION AESC JAPAN LTD

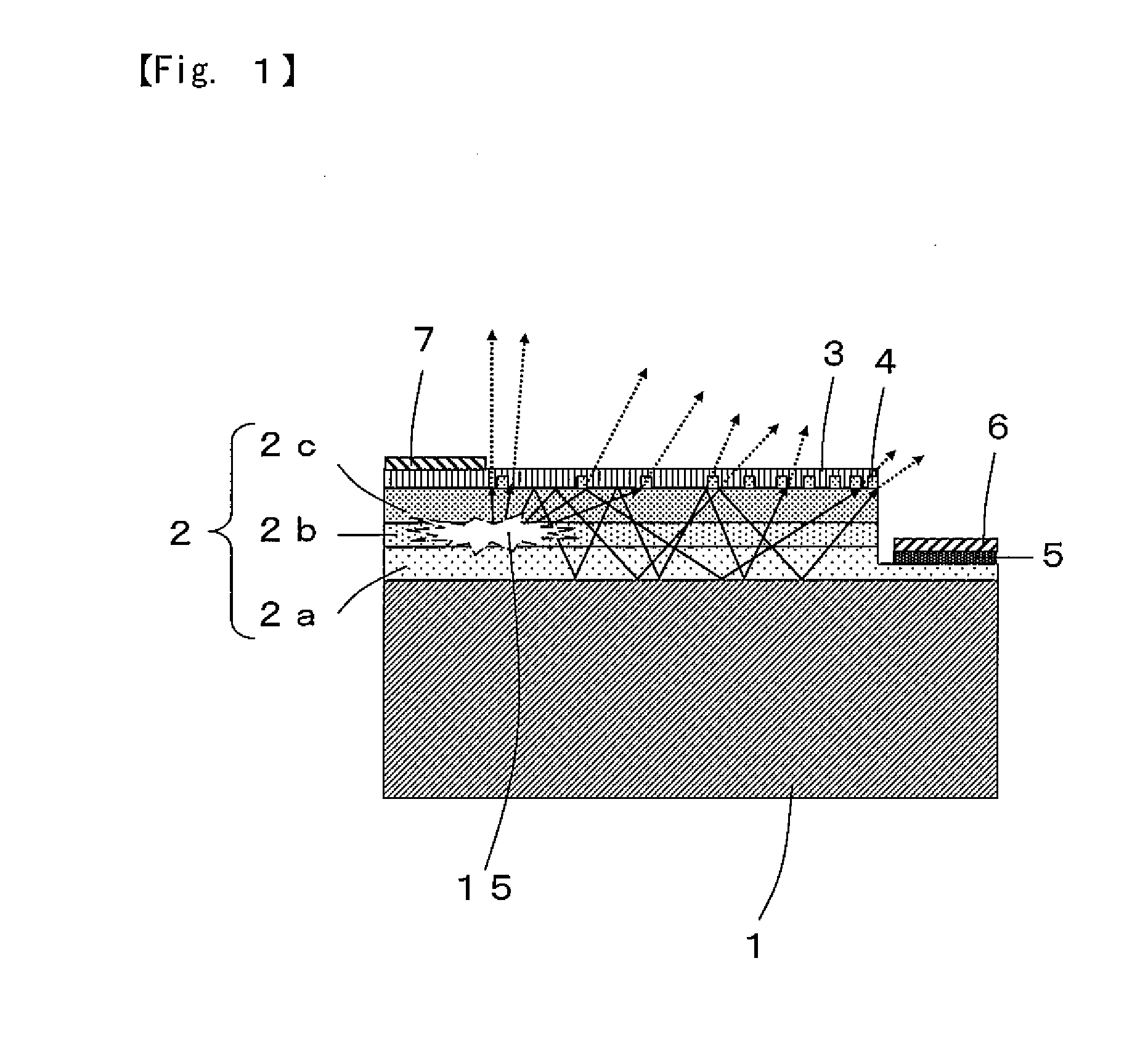

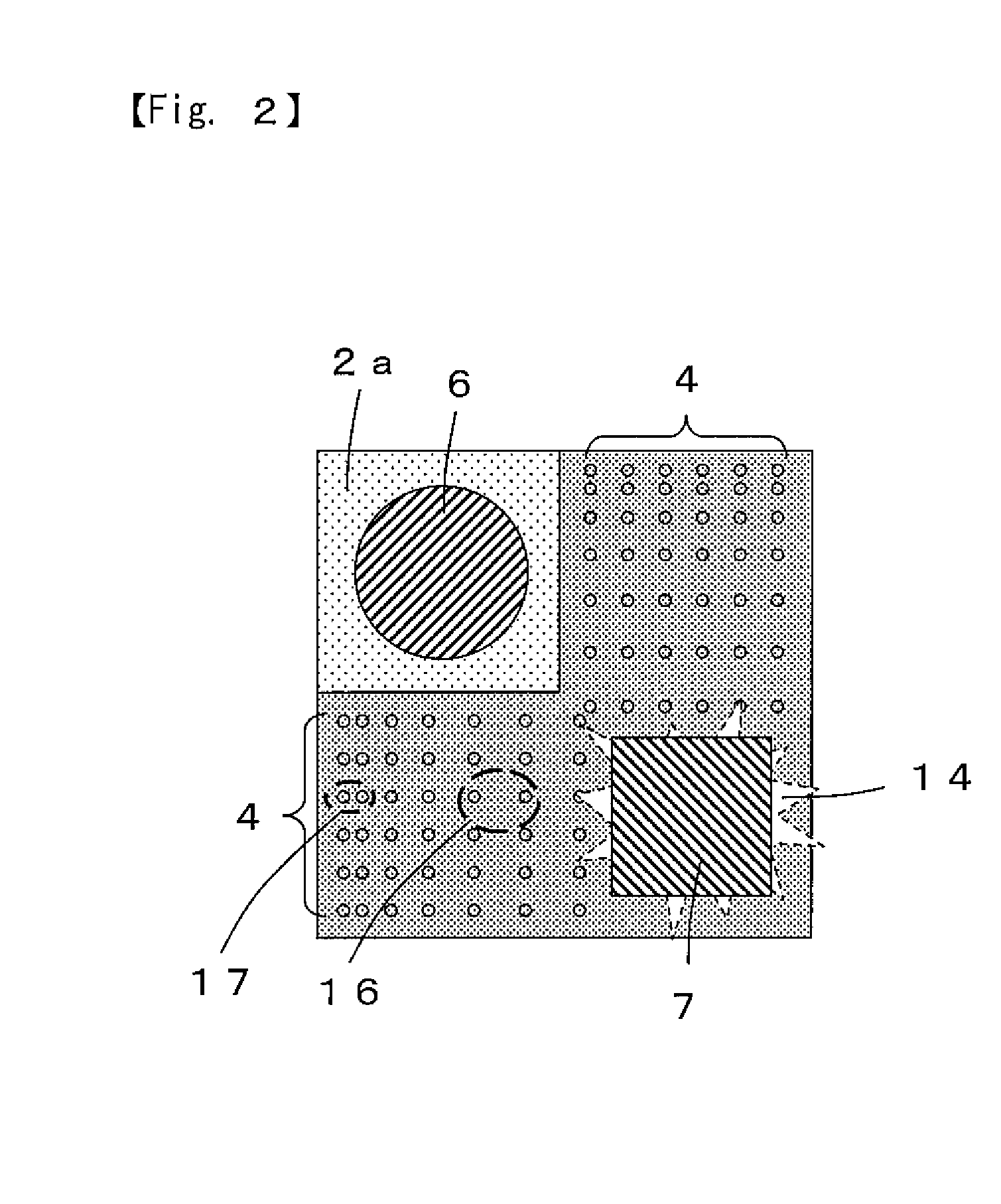

Light Emitting Element and Illumination Device

InactiveUS20100289047A1Suppression of inhomogeneityImprove extraction efficiencySemiconductor devicesLuminous intensitySemiconductor

Provided is a light emitting element capable of improving light extraction efficiency and suppressing the nonuniformity of emission intensity distribution over the entire surface of a light extraction surface. The light emitting element is provided with a semiconductor multilayer body having an n-type semiconductor layer and an emission layer and a p-type semiconductor layer, and an electrode pad connected to the p-type semiconductor layer. The semiconductor multilayer body has a large number of projections on one main surface thereof through which the light from the emission layer is emitted. The main surface of the semiconductor multilayer body has a first region located in the vicinity of the electrode pad, and a second region being further separated from the electrode pad than the first region. The interval between the projections in the second region is smaller than that in the first region.

Owner:KYOCERA CORP

Wiring board and method for producing the same

ActiveUS20070119614A1Suppression of inhomogeneityPrinted circuit aspectsSolid-state devicesElectrical conductorMetallic Lead

A wiring board includes first and second feeding electrodes (2, 3) provided along both sides of an insulating substrate (1), feeding bus lines (4) extending in a traverse direction and connected to both the feeding electrodes, and conductor wirings (6, 8, 12) having one side terminals forming inner leads having protruding electrodes (9, 11, 13) and the other side terminals connected to the feeding bus lines. The inner leads in each unit region are arranged in two lines extending in the traverse direction. The inner leads of a first group are arranged with a dense wiring pitch, and the inner leads of a second group include a dense pitch region in which a wiring pitch is the same as that of the inner leads of the first group, and a sparse pitch region in which a wiring pitch is longer than that of the inner leads of the first group. The inner leads (6) of the first group and the inner leads (12) in the dense pitch region of the second group are connected to the feeding bus line on one side of each region, and the inner leads (8) in the sparse pitch region of the second group are connected to the feeding bus line on the other side of each unit region. Non-uniformity of heights of the protruding electrodes due to a difference in the wiring pitches of the inner leads can be suppressed easily.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Imaging device and imaging apparatus

ActiveCN102867833ASuppression of inhomogeneityTelevision system detailsSolid-state devicesComputer vision

Disclosed herein is an imaging device including at least one special pixel with a configuration having a layout made different from the layout of the configuration of each pixel other than the special pixel. The special pixel is a pixel having an imaging characteristic steadily different from that of the other pixels. A difference in layout between the configuration of the special pixel and the configuration of the other pixels is used to suppress a non-uniformity of the imaging characteristic exhibited by the special pixel.

Owner:SONY SEMICON SOLUTIONS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com