Bonding method and apparatus

A bonding method and bonding device technology, applied in the bonding method of adhesive heating, printed circuit dielectrics, transparent dielectrics, etc., can solve the problems of time-consuming bonding, complicated control, and easy conduction of heat to other components. Achieve high-speed and high-precision mounting, and suppress warping and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

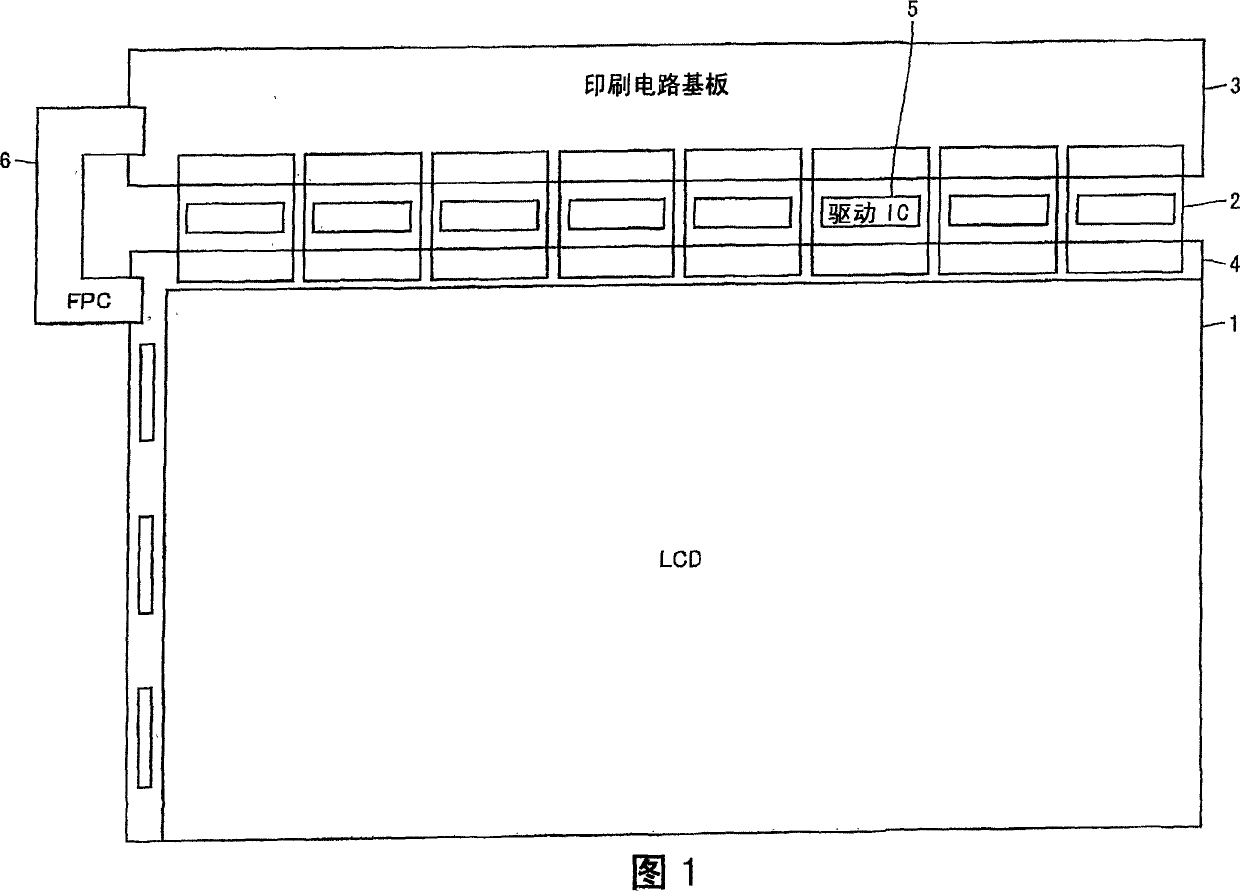

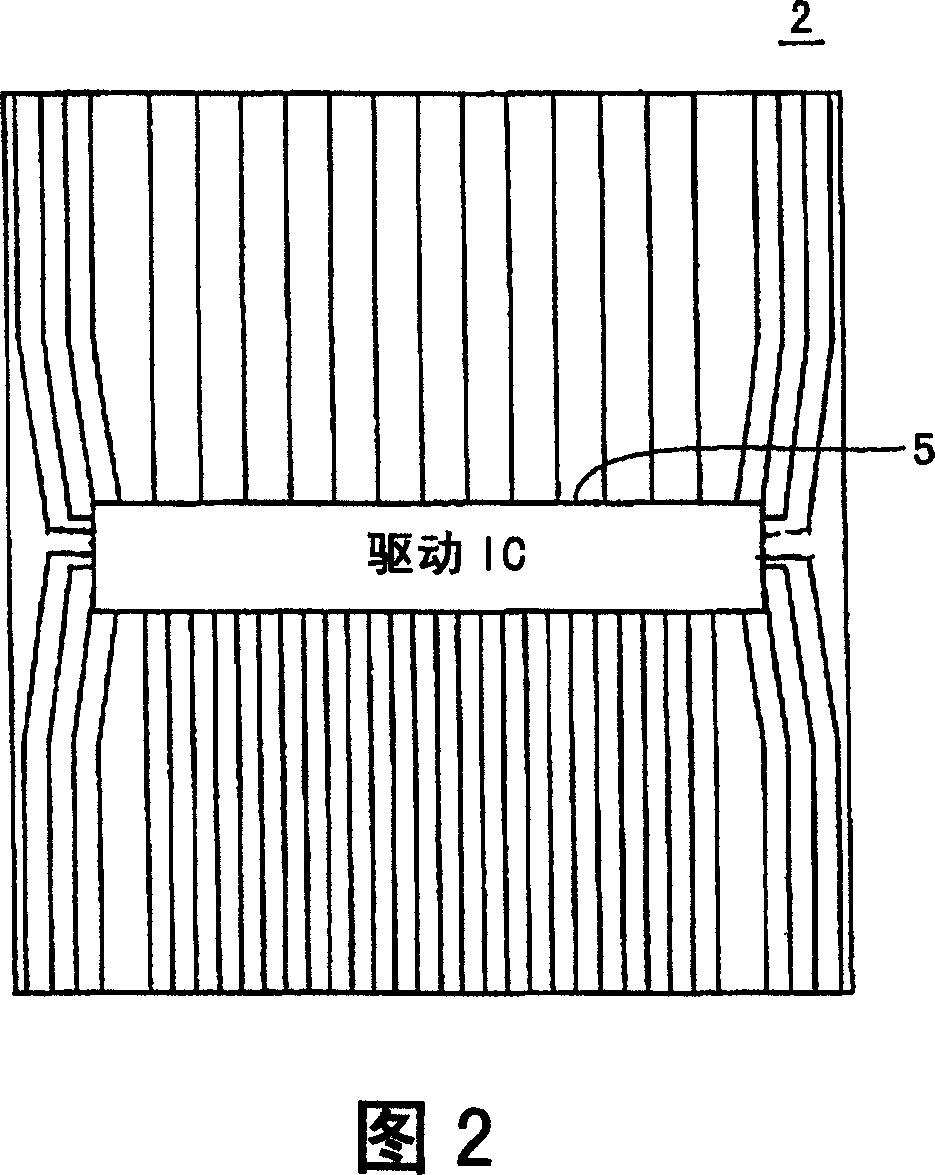

[0061] FIG. 1 is a schematic block diagram illustrating a liquid crystal display device according to a first embodiment of the present invention.

[0062] As shown in FIG. 1 , the liquid crystal display device according to the first embodiment of the present invention includes: a liquid crystal display panel (hereinafter also referred to as LCD) 1; Set on the periphery of LCD1; printed circuit board 3, which is used to drive the liquid crystal material mounted on the LCD; TCP2, which is arranged between the printed circuit board 3 and the liquid crystal display panel LCD1, including the composition for driving the liquid crystal display panel A drive IC 5 for the element; a flexible substrate (hereinafter also referred to as FPC) 6 for electrically connecting the printed circuit board 3 and the interface portion 4 .

[0063] Hereinafter, regarding the bonding apparatus according to the embodiment of the present invention, the bonding method of TCP including the driver IC 5 use...

no. 2 approach

[0113] In recent years, along with the development of microfabrication technology, the wiring pitch has also been significantly narrowed. Along with this, high-precision joining is required. However, a certain degree of variation in the manufacturing stage must also be taken into consideration, and it is generally necessary to design the wiring pitch and the like in consideration of the variation in the manufacturing stage. That is, it is necessary to design the wiring pitch with a certain degree of safety factor.

[0114] In the second embodiment of the present invention, an alignment correction method that enables highly accurate bonding even when the wiring pitch is further reduced will be described.

[0115] FIG. 10 is a diagram illustrating alignment correction according to the second embodiment of the present invention.

[0116] Here, a case where the lower electrode on the TCP side is joined to the upper electrode on the array substrate (glass substrate) side will be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com