Bending processing method of heat exchanger

A heat exchanger and bending processing technology, applied in the field of heat exchanger bending processing, can solve problems such as inability to bend processing, and achieve the effect of avoiding buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

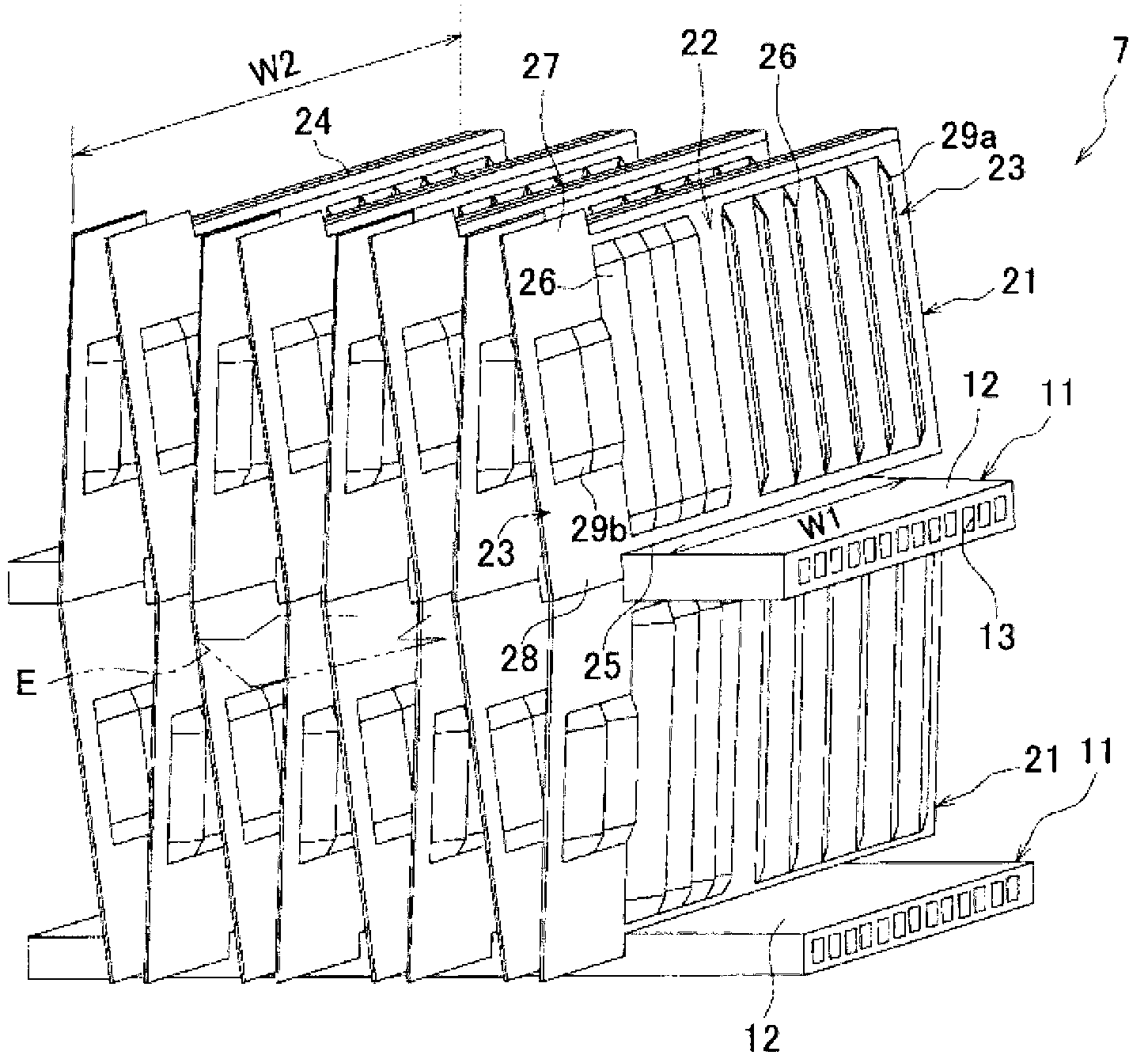

[0051] The bending processing method of the heat exchanger related to the present invention will be described in detail below with reference to the drawings and specific embodiments.

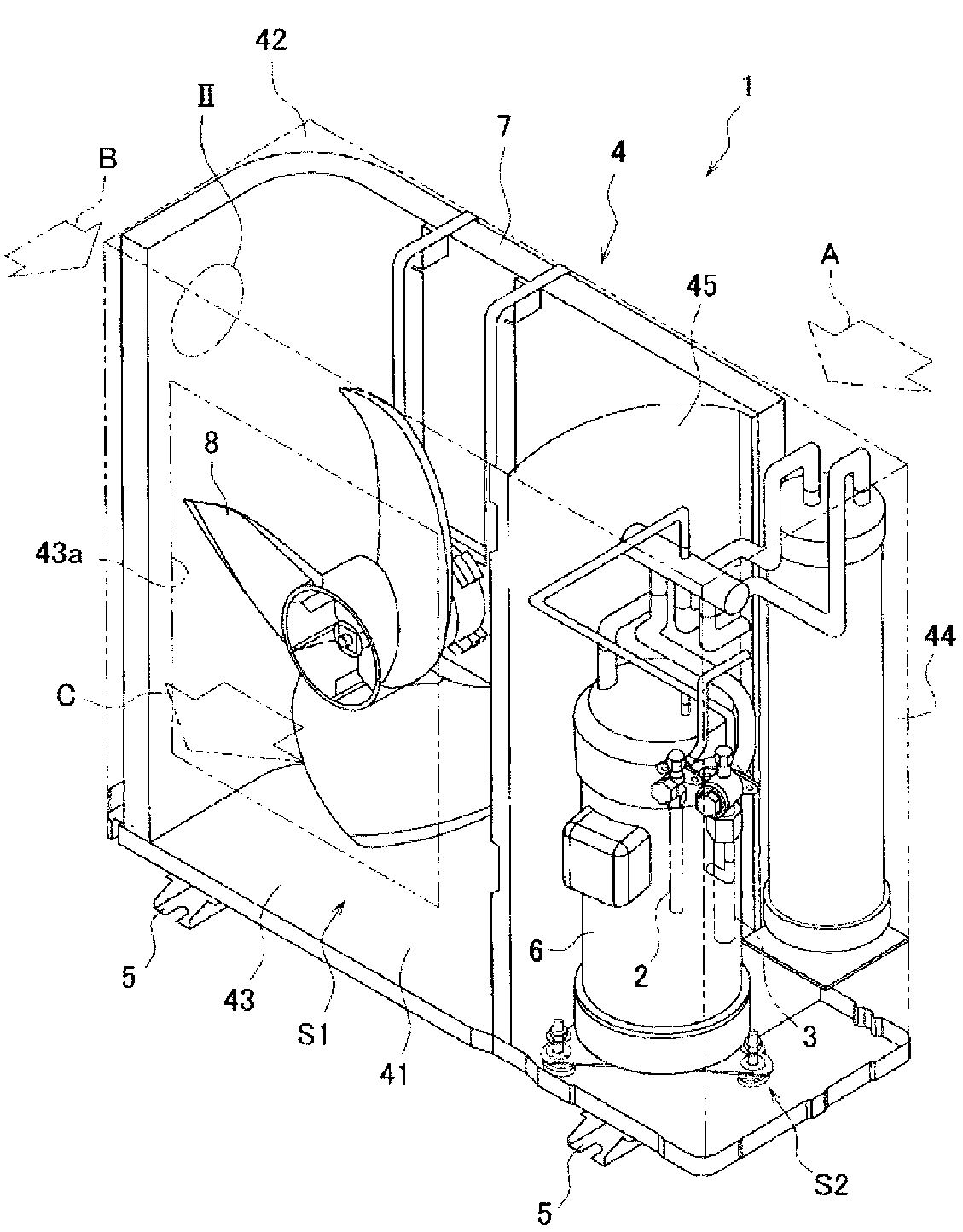

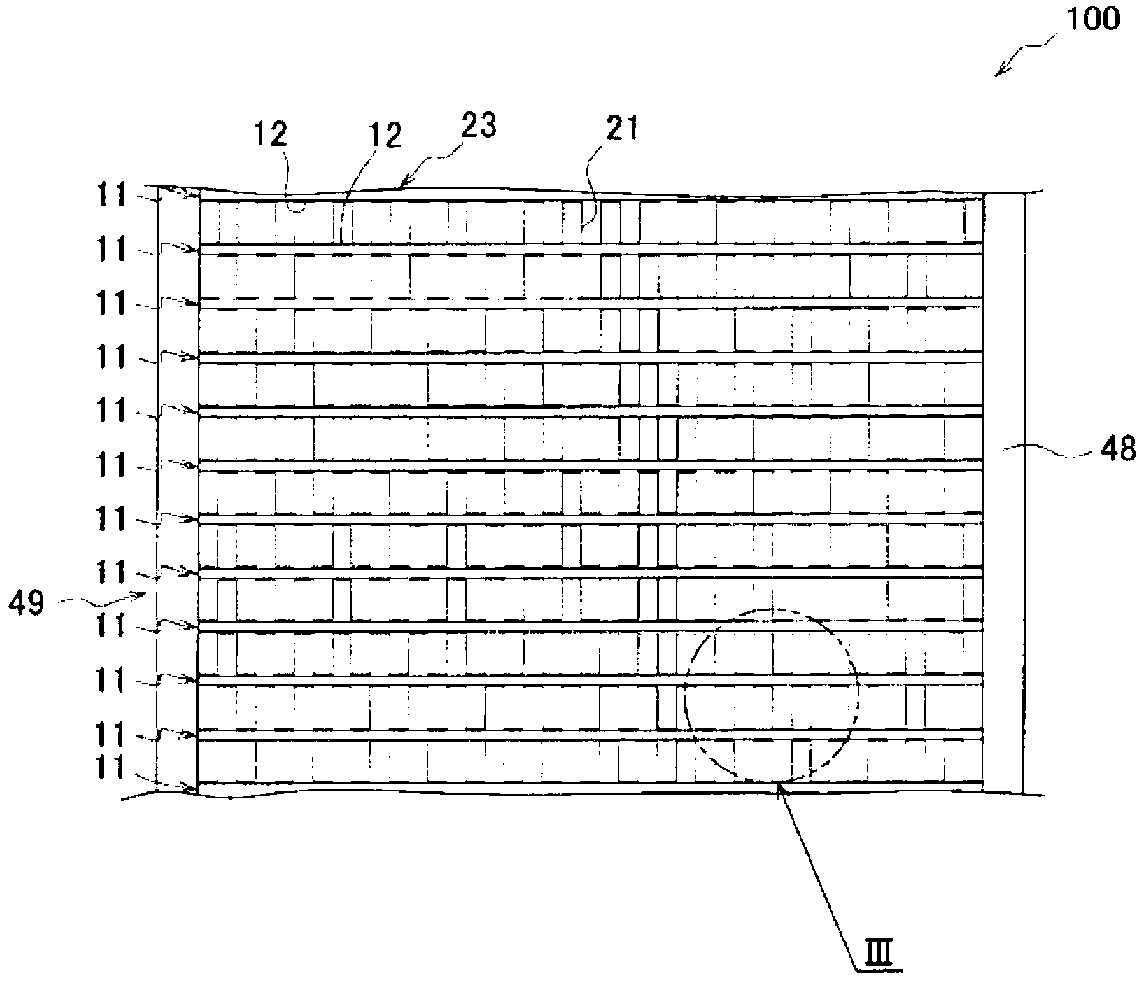

[0052] figure 1 A simplified perspective view showing the internal structure of the outdoor unit 1 of the outdoor heat exchanger 7, which is an embodiment of the heat exchanger bent by the heat exchanger bending method of the present invention. The outdoor unit 1 is an air conditioner that performs air conditioning through a vapor compression refrigeration cycle. The outdoor unit 1 is connected to an indoor unit (not shown in the figure) via refrigerant connecting pipes 2 and 3 . In addition, in the following description, figure 1 The front side of the paper is referred to as the "front", figure 1 The back side of the paper is referred to as the "back side", figure 1 The left side of the page of the figure 1 The right side of the paper is referred to as the "right side", figure 1 The upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com