Waterproof connector and manufacturing method thereof

一种防水连接器、制造方法的技术,应用在连接、接触件盒/底座的制造、防尘/防溅/防漏/防水/防火的连接等方向,能够解决连接器件制造工序复杂等问题,达到实现小型化、容易形成、保持接触压力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

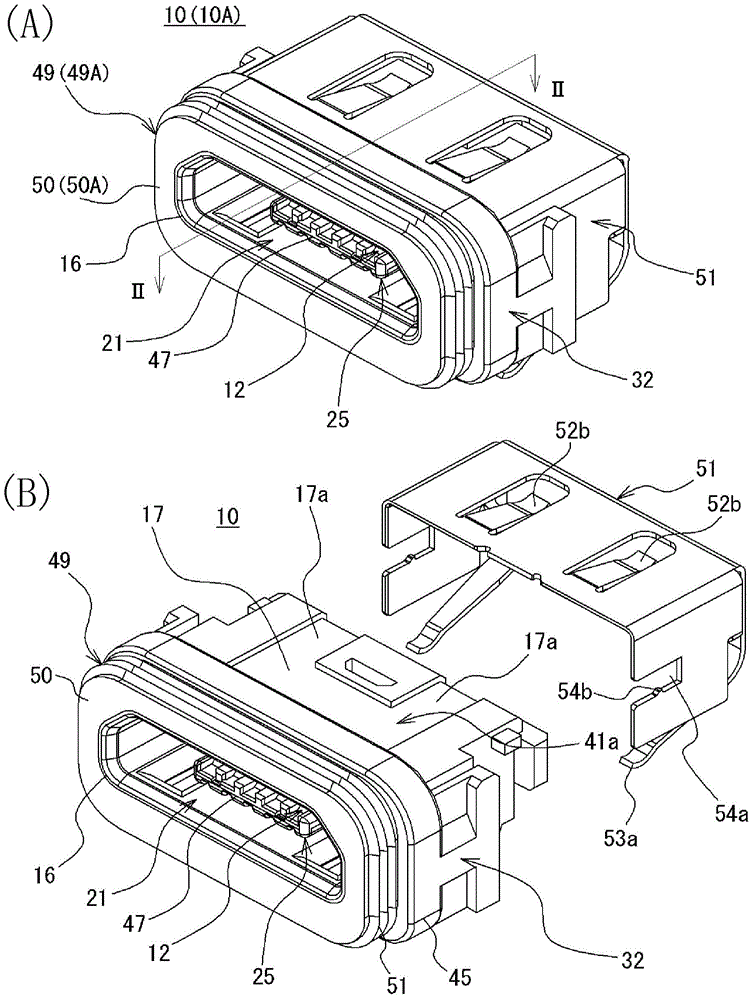

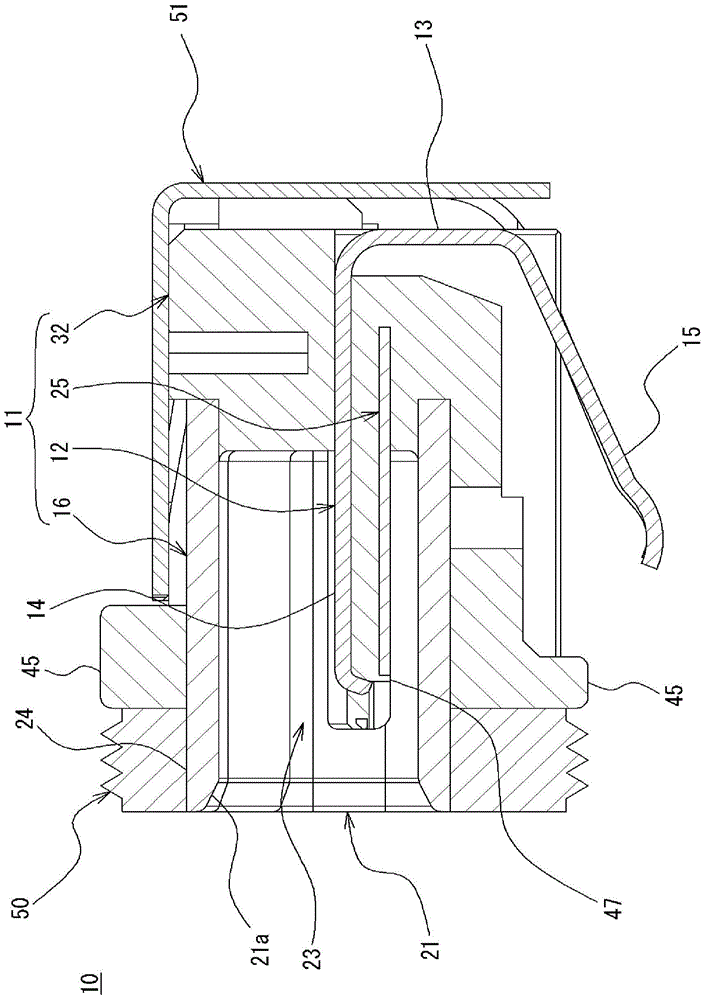

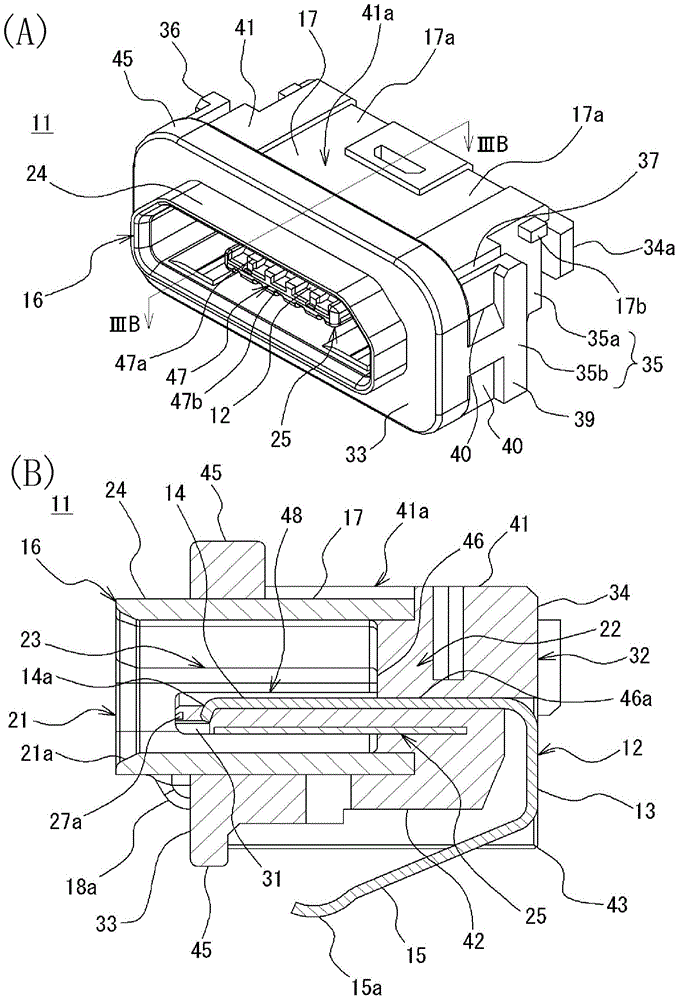

[0065] refer to Figure 1 to Figure 9 , the waterproof connector according to Embodiment 1 of the present invention will be described. The waterproof connector 10 according to Embodiment 1 of the present invention has a structure in which it is mounted on the housings of various devices constituting information terminals such as mobile phones, mobile phones, and notebook computers, and is connected to a substrate provided in the housing. Connect, and detachably insert and connect to a counterpart connector such as USB (Universal Serial Bus, Universal Serial Bus). In addition, since a well-known device can be used for the device to which a waterproof connector is attached, illustration and detailed description are abbreviate|omitted.

[0066] Such as figure 1 with figure 2 As shown, the waterproof connector 10 of Embodiment 1 is composed of the following components: a plurality of contacts 12; a metal housing 16 in which these contacts 12 are disposed; and a reinforcing mem...

Embodiment approach 2

[0111] In the waterproof connector 10 according to Embodiment 1, the structure in which the waterproof member 50 is formed by insert molding to form the waterproof portion 49 has been described. A structure in which waterproof portion 49A is formed by attaching separately formed waterproof member 50A to waterproof connector 10A of Embodiment 2 will be described. Since waterproof connector 10A of Embodiment 2 differs from waterproof connector 10 of Embodiment 1 only in the structure of waterproof portion 49A, the same reference numerals are assigned to other common structures, and detailed description thereof will be omitted.

[0112] Such as figure 1 As shown in (A), the waterproof connector 10A of Embodiment 2 is composed of the following components: an insert molded body 11 composed of a plurality of contacts 12 , a housing 16 , a reinforcing member 25 and a housing 32 ; the waterproof part 50A on the molded body 11; and the shield case 51. In addition, since the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com