Method for manufacturing impact absorber for vehicle

A shock absorption and vehicle technology, applied in the direction of manufacturing tools, vehicle parts, vehicle safety arrangements, etc., can solve the problems of weight increase, increase the thickness of bumper reinforcement 1, etc., and achieve the reduction of tensile strength, small weight, and small thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

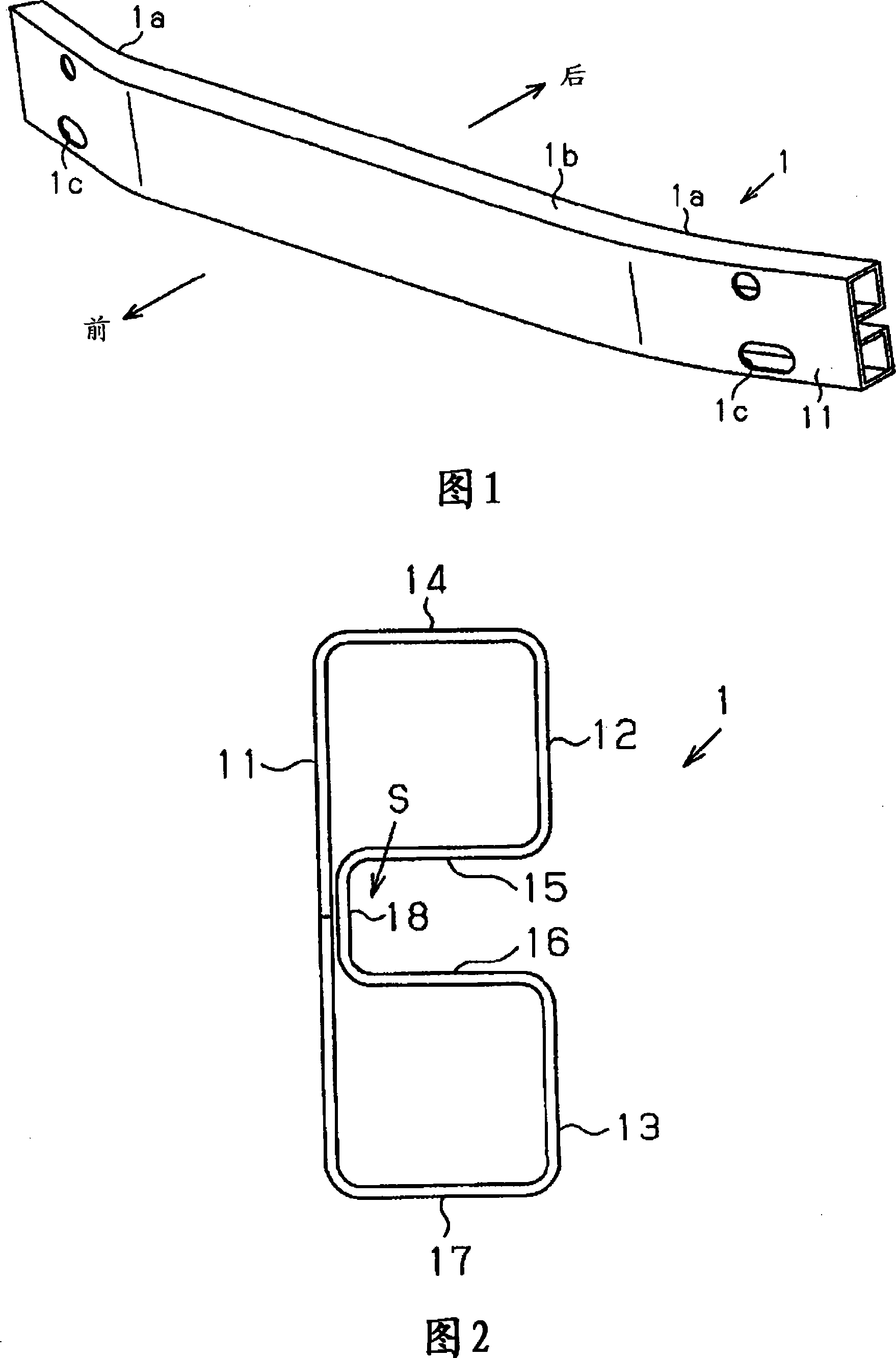

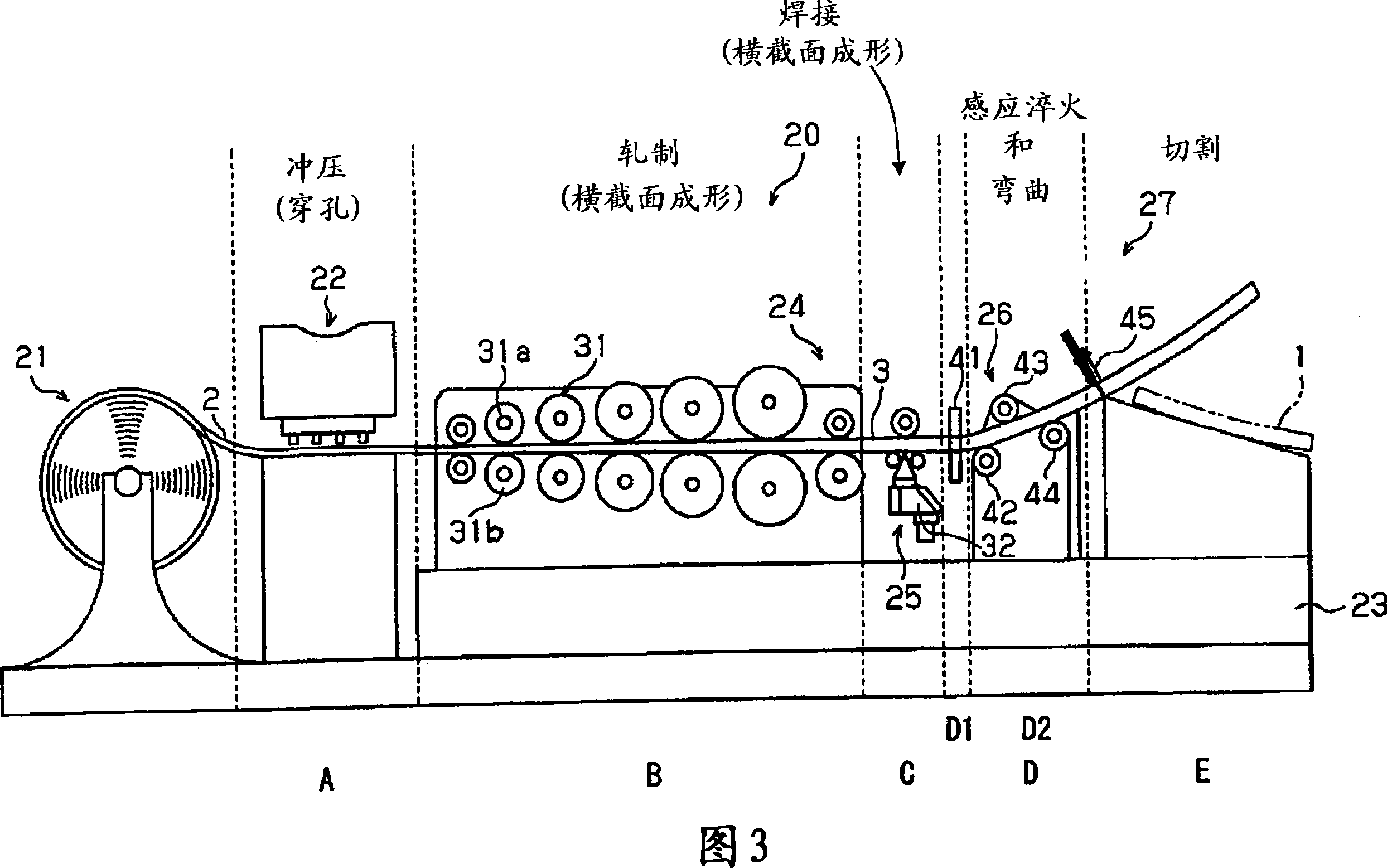

[0019] 1 and 2 are a perspective view and a cross-sectional view respectively showing a bumper reinforcement 1 manufactured by a method of manufacturing a vehicle impact absorber of the present invention. The bumper reinforcement 1 is suitable for a bumper device mounted to the front of a vehicle for absorbing impact mainly applied from the front of the vehicle.

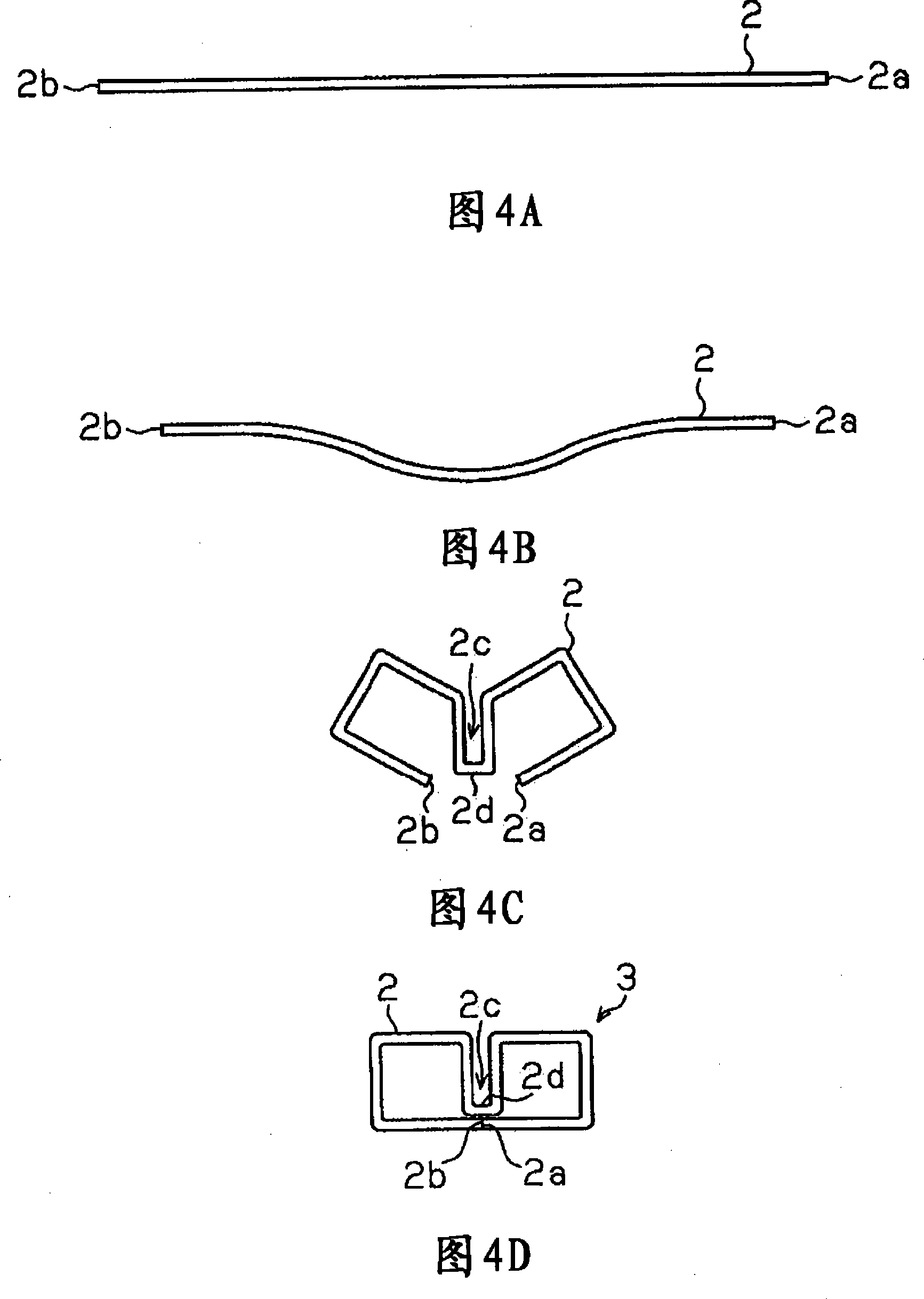

[0020] As shown in FIGS. 1 and 2, the bumper reinforcement 1 is made of a strip-shaped high-tensile-strength steel plate and made into a long hollow structure. The bumper reinforcement 1 includes: a front wall 11 serving as a receiving surface for a load applied from the front of a vehicle; walls 11 facing each other in parallel; a pair of upper walls 14, 15 connecting the upper rear wall 12 to the front wall 11; and a pair of lower walls 16, 17 connecting the lower rear wall 13 to the front wall 11, so that the bumper reinforcement 1 has a constant cross-sectional configuration resembling the letter B along its lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com