Non-aqueous electrolyte secondary battery

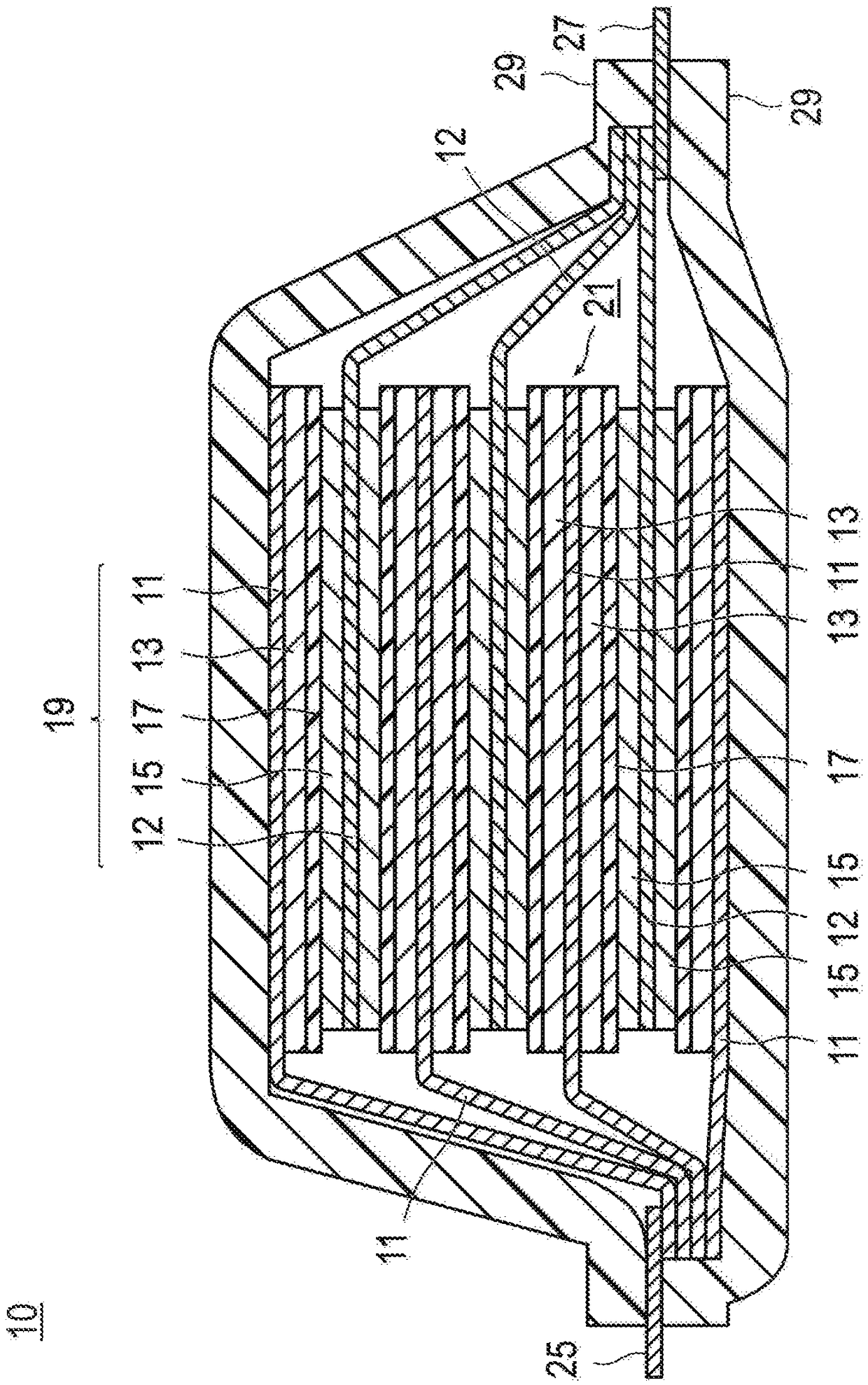

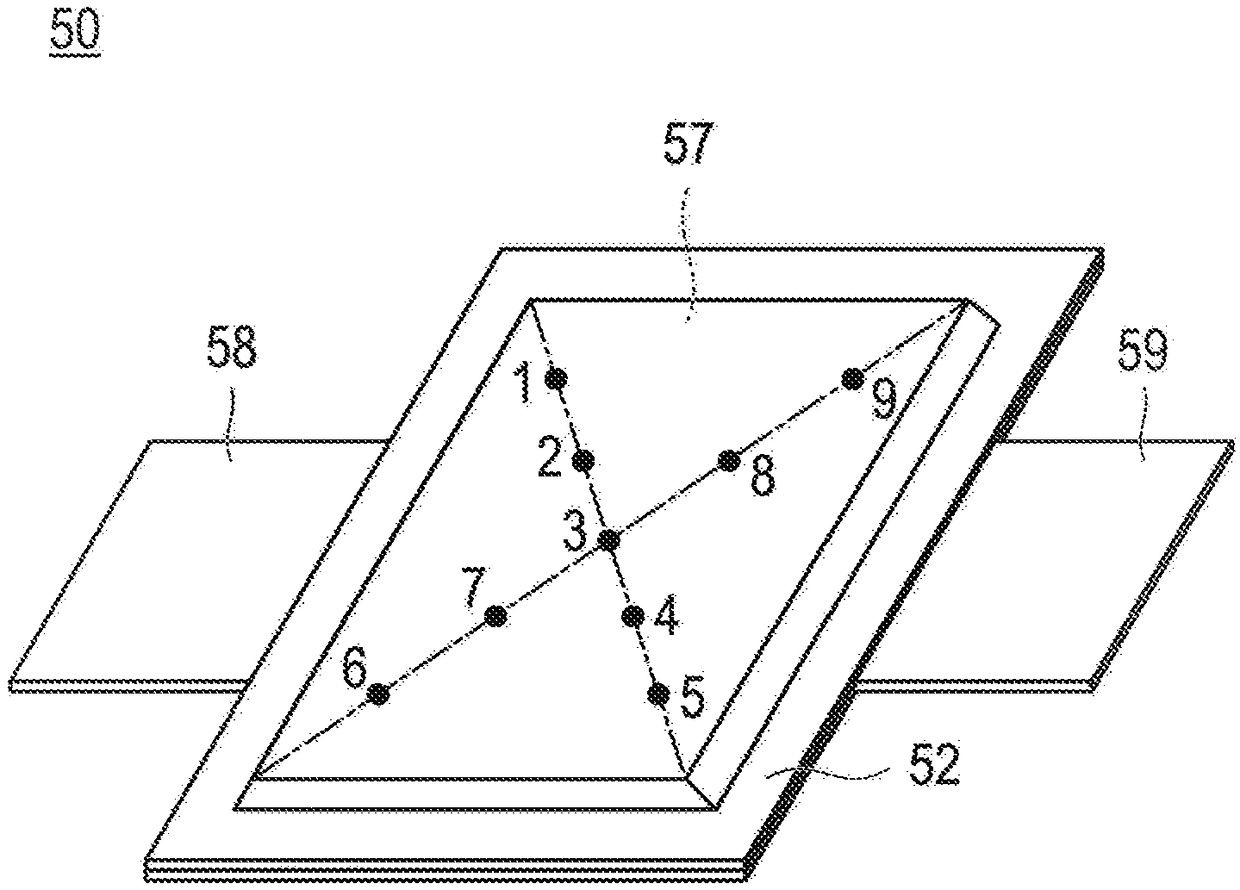

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of large expansion and contraction of the negative electrode, reduced electrode cycle life, and inability to obtain charge and discharge capacity, etc. , to achieve the effect of suppressing the unevenness of the distance between electrodes and excellent cycle durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0278] Hereinafter, although an Example and a comparative example are used and it demonstrates in detail, this invention is not limited to the following Example at all.

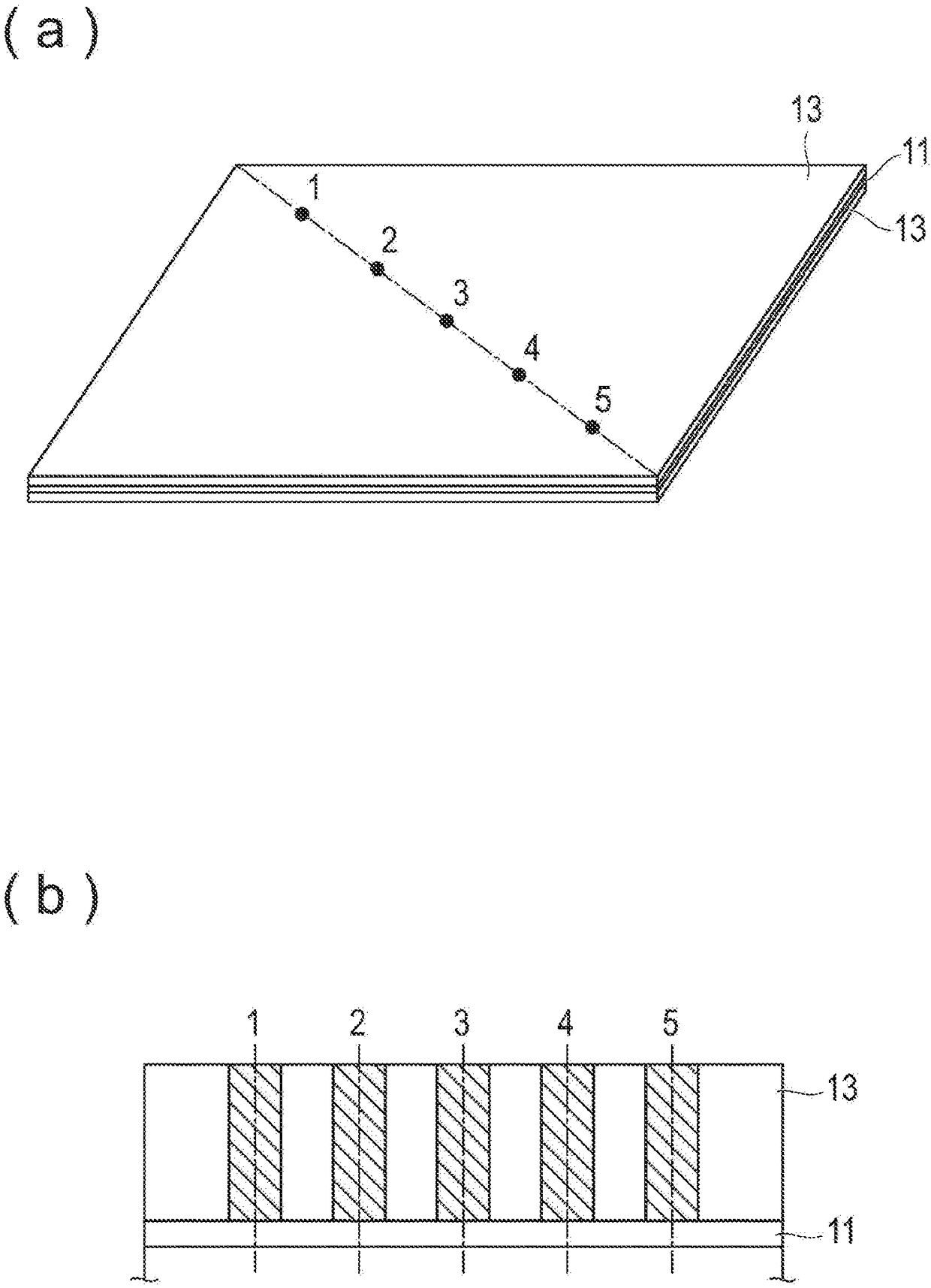

[0279] 1. Fabrication of positive electrode

[0280] 94% by mass of NMC composite oxide as a positive electrode active material, 3% by mass of acetylene black as a conductive additive, 3% by mass of polyvinylidene fluoride (PVdF) as a binder, and An appropriate amount of N-methyl-2-pyrrolidone (NMP) was mixed to prepare a positive electrode active material slurry. The obtained positive electrode active material slurry was coated on the surface of an aluminum foil (thickness: 20 μm) as a positive electrode current collector, dried at 120°C for 3 minutes, and then compression-molded with a roller press to produce a positive electrode active material with a rectangular planar shape. material layer. Similarly, a positive electrode active material layer was formed on the back surface, and a positive electrode in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com