Polyolefine resin sparkling sheet material and productive method

A polyolefin resin and polyolefin foaming technology, applied in the field of polyolefin resin foam sheet, can solve the problems of high melt viscosity, uneven thickness of non-foamed layer, unsatisfactory surface appearance of foamed layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

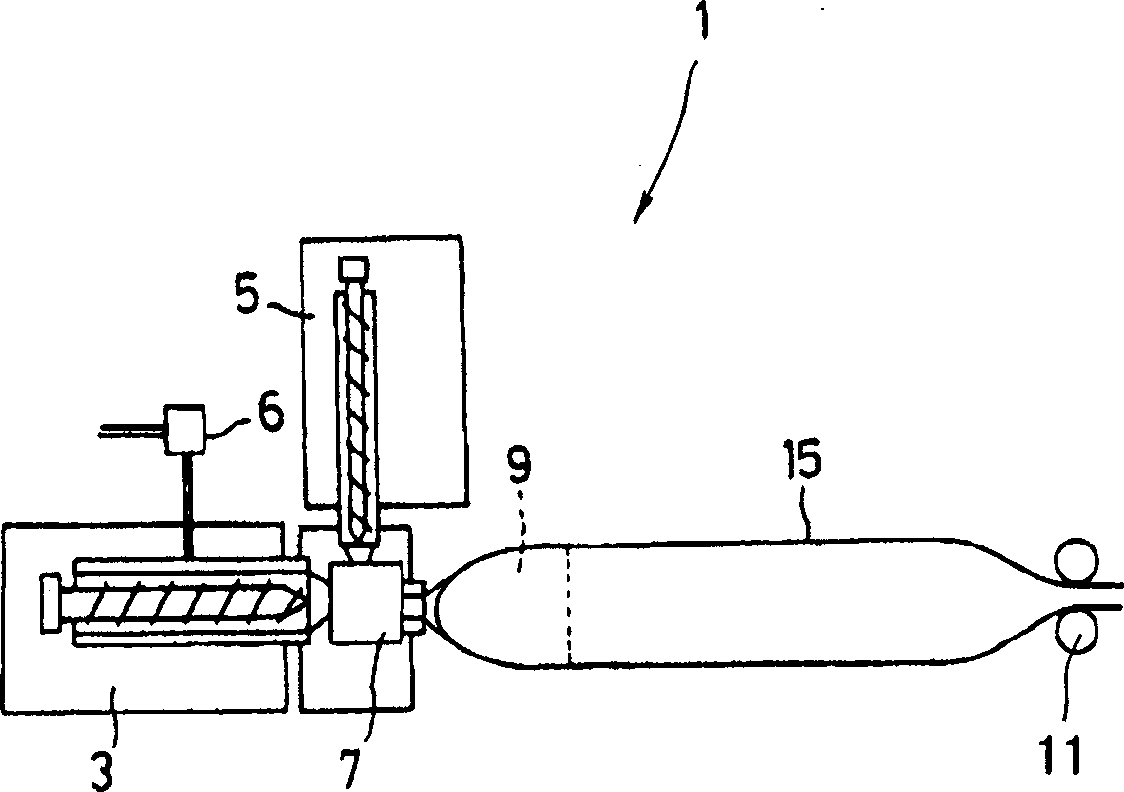

[0097] Non-foamed layer / foamed layer / non-foamed layer polyolefin resin foamed sheets having two-type and three-layer structures were prepared as follows. (Constituent material of the foam layer)

[0098] As a constituent material of the foamed layer, a mixture prepared by blending polypropylene and polyethylene obtained by a two-step polymerization method in a weight ratio of 70 / 30 was used. The method of producing this propylene, the method of pelletizing it, and the mixing method of the foamed layer constituent materials will be described below. (1) Synthesis of solid catalyst

[0099]A 200L stainless steel reactor equipped with a stirrer was purged with nitrogen, and then 80L of hexane, 6.55mol of tetrabutoxytitanium, 2.8mol of diisobutyl phthalate and 98.9mol of tetraethoxy silane to obtain a homogeneous solution. Then, while keeping the temperature of the reactor at 5° C., 51 L of a solution of butylmagnesium chloride in diisobutyl ether was gradually added dropwise ov...

Embodiment 2

[0110] Sheets were produced in the same manner as in Example 1 except that the following resin mixture was used as a constituent material of the non-foamed layer, and its physical properties were evaluated. The results are listed in Table 1. The non-foamed layer of the resulting foamed sheet contained 48% by weight of recycled polyolefin resin. (Constituent material of non-foaming layer)

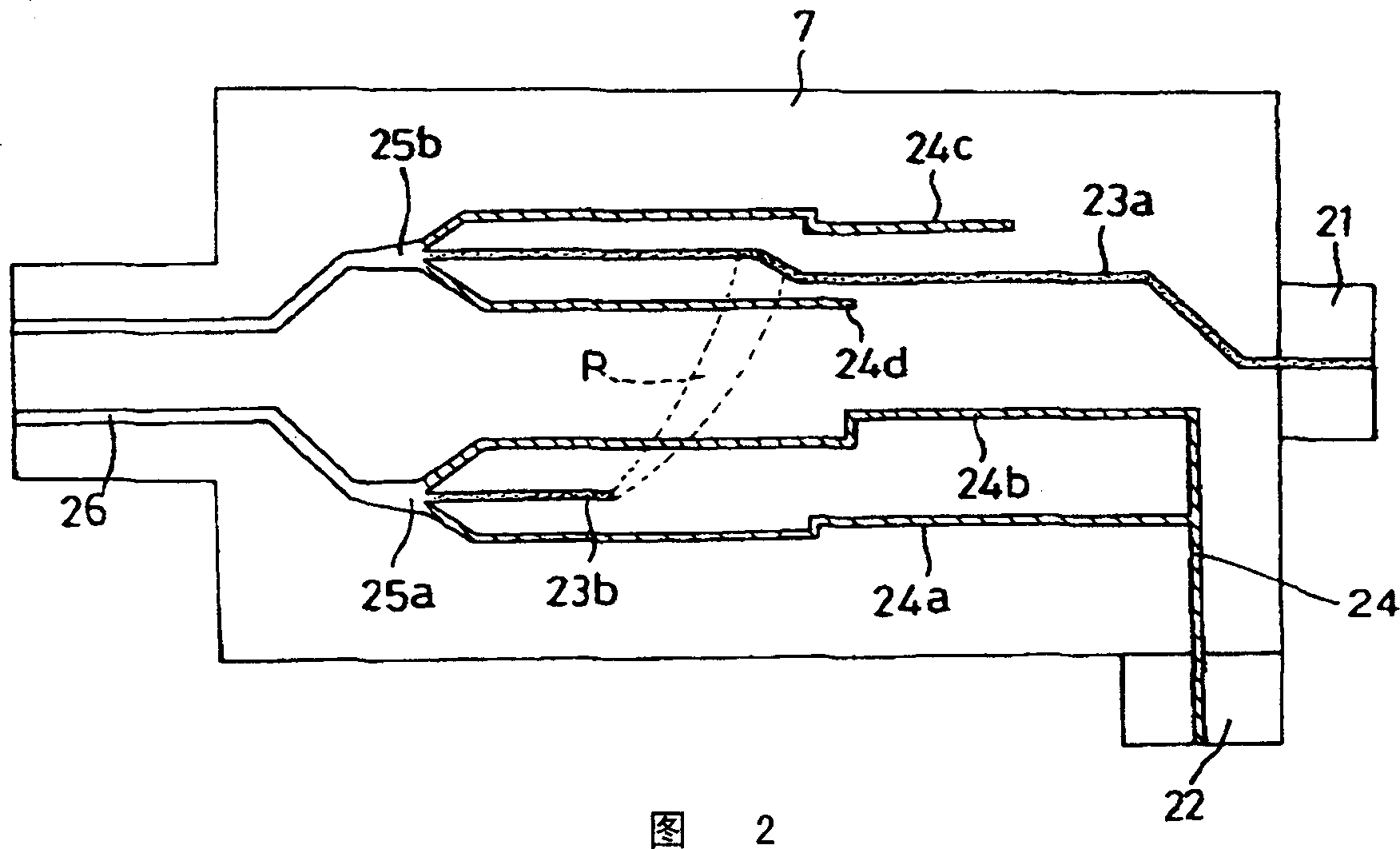

[0111] A foam layer having the same composition as that of the foam layer of the foam sheet produced in Example 1, and a non-foam layer made of polypropylene having long chain branches (Polypropylene PF814, produced by Montel) were used. On both sides of the constituent resin of the thermally plasticized foam layer, laminate the constituent resin of the thermally plasticized non-foam layer, and co-extrude from a die head controlled at 210°C, while the above foam layer The constituent resin was foamed to obtain a sheet. Along the inner mold core that has been cooled by 6°C circulating wate...

Embodiment 3

[0113] Use the resin (A) and resin (B) described below as the constituent materials of the non-foamed layer, and prepare three types of five-layer polyolefin-based resin foamed sheets by the co-extrusion foaming method according to the following method, the sheet The composition of the material is non-foamed layer of resin (A) / non-foamed layer of resin (B) / foamed layer / non-foamed layer of resin (B) / non-foamed layer of resin (A), and to The physical properties of the sheets were evaluated. The results are listed in Table 1. (Constituent material of non-foaming layer) Resin (A)

[0114] With a co-rotating twin-screw extruder (trade name: PCM45; manufactured by Ikegai K.K.), at a screw speed of 200 rpm, polypropylene pellets having long chain branches (trade name: Polypropylene PF814, manufactured by Montel) were melt-kneaded , extruded at a die head temperature of 240°C to obtain strands, cooled in water and solidified, and then cut with a cutting machine to obtain resin pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com