Anodizing device, continuous anodizing device, and film forming method

A technology of anodic oxidation and counter electrode, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] Hereinafter, the anodizing apparatus, continuous anodizing apparatus, and film forming method of the present invention will be described in detail by using the drawings.

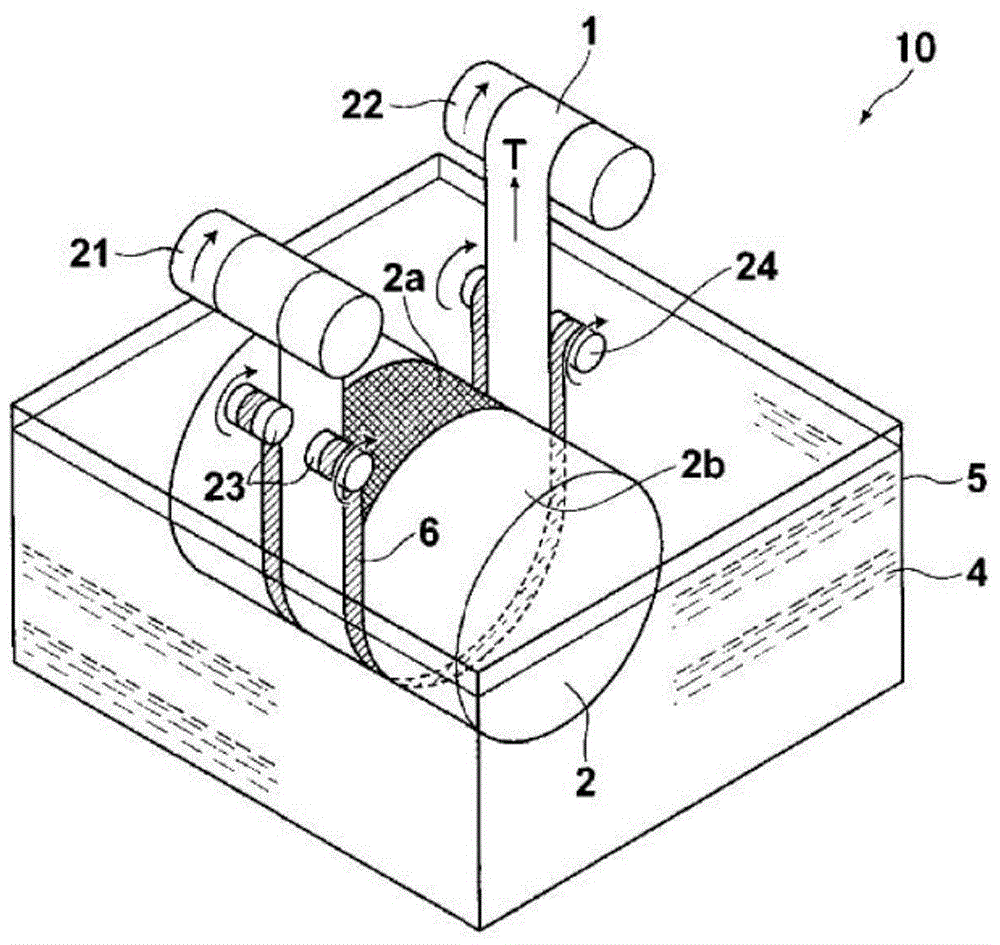

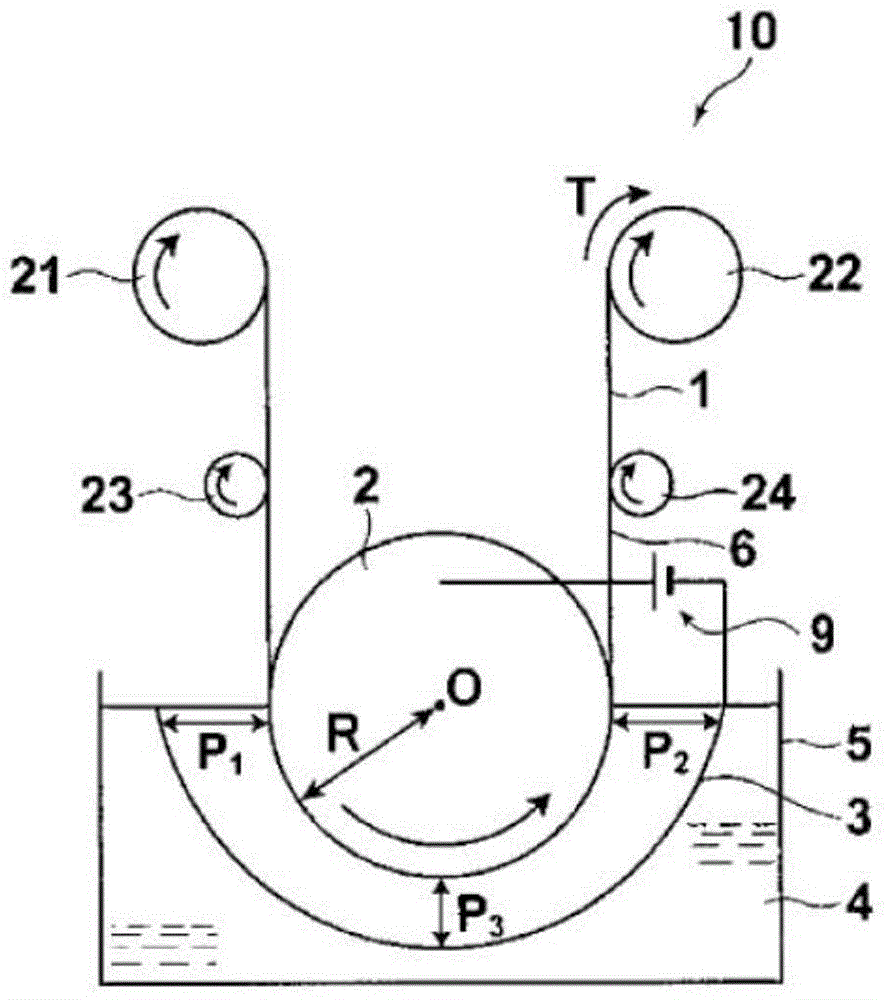

[0098] figure 1 is a schematic perspective view showing an anodizing apparatus of an embodiment for achieving the first object of the present invention, and figure 2 is used to achieve figure 1 A schematic cross-sectional view of the anodizing apparatus of an embodiment of the first object is shown.

[0099] Hereinafter, a general anodizing apparatus for achieving the first to fourth objects of the present invention will be described.

[0100] like figure 1 and figure 2 As shown, the anodizing device 10 of the present invention has: a power supply drum 2, which closely contacts and supports a belt made of anodizable metal or a composite conductive metal foil (at least one surface of which is composed of anodizable metal) Fabricated strip 1 (hereinafter, also referred to simply as "ribbon 1"), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com