Novel electrical heating unit

A technology of electric heating and electric heating film, which is applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of difficult heating effect, affecting heating efficiency, and small thermal conduction power, so as to improve heat utilization rate and heating effect , the effect of reducing the temperature limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

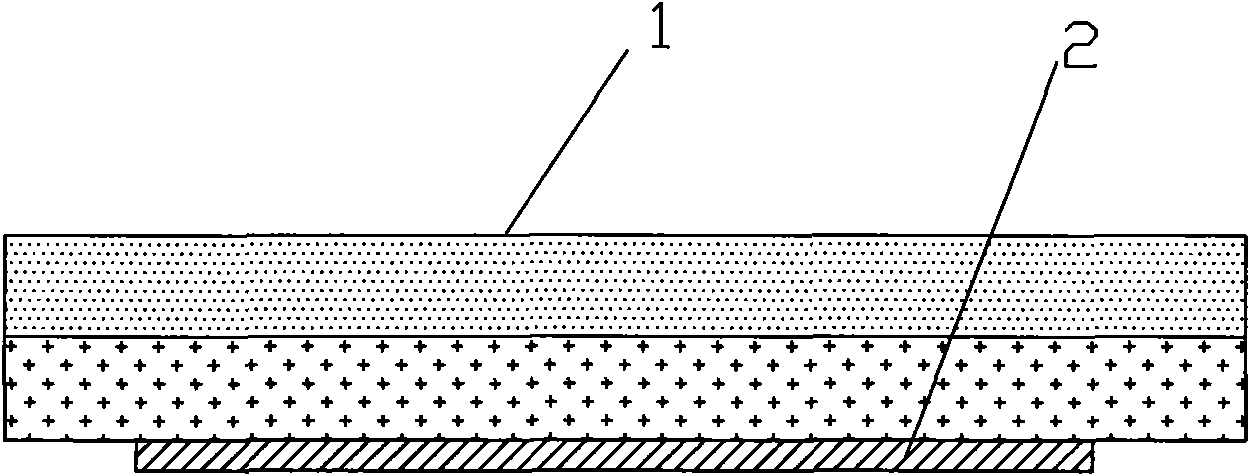

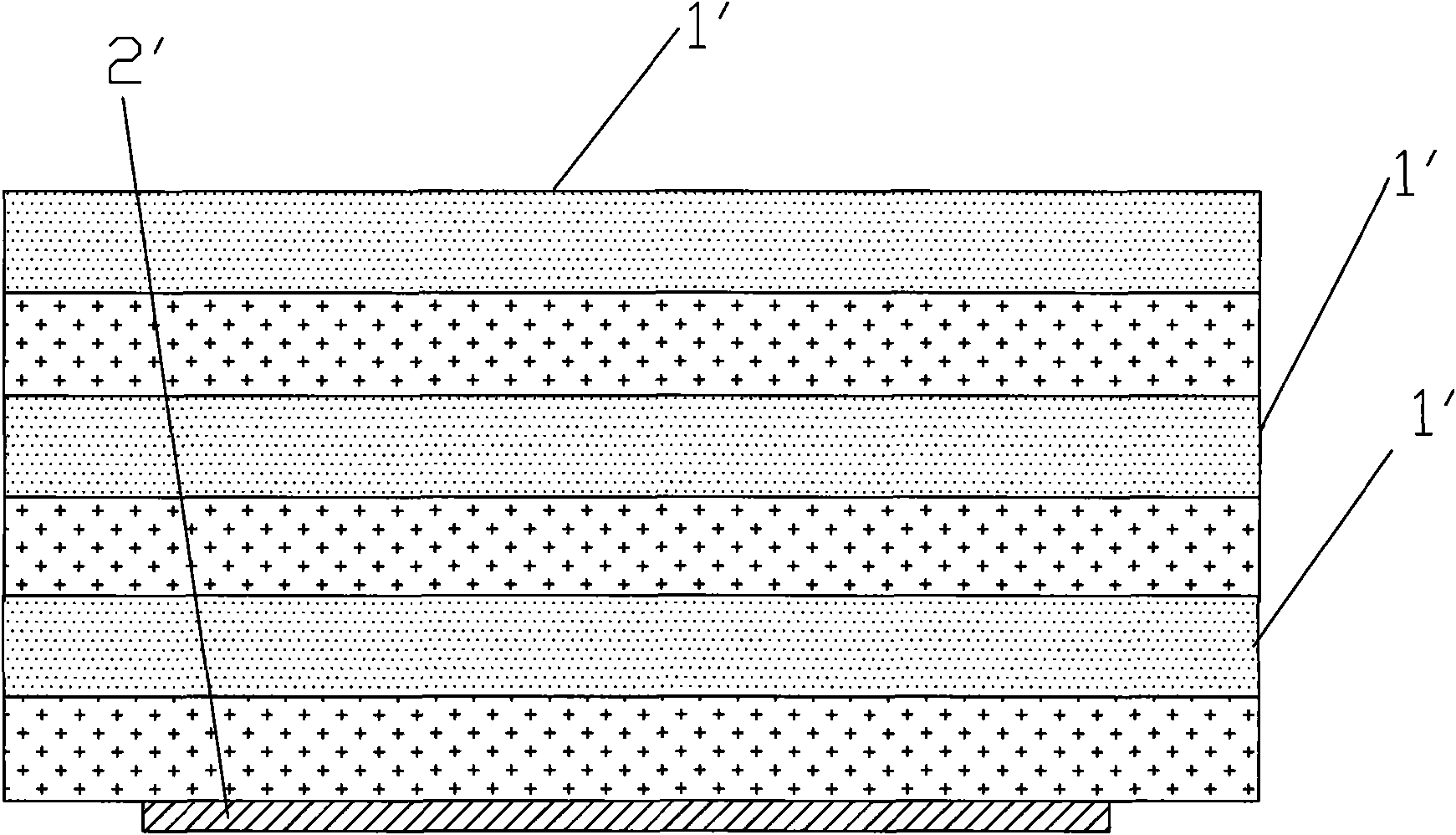

[0025] Such as figure 1 As shown, an implementation of the present invention only includes a simple alumina ceramic substrate 1 and an electric heating film 2 attached to the alumina ceramic substrate 1, and the alumina ceramic substrate 1 is a plate-shaped structure for convenience. Installed in various application places, usually, the alumina ceramic substrate 1 is made into a circle; The upper surface of the sheet 1 gradually increases to the lower surface. The boundary line of the alumina ceramic substrate 1 in the figure is not the actual boundary of the alumina ceramic substrate 1, but is set to represent the different densities of the alumina ceramic substrate 1. A line of , to clearly represent the difference in density of the alumina ceramic substrate 1 .

[0026] The electric heating film 2 does not need to completely cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com