Method and device for sterilizing packaging material using high voltage pulse power

A high-voltage pulse power supply and packaging material technology, applied in disinfection, water supply equipment, packaging sterilization, etc., can solve the problems affecting the quality of items, heat shrinkage, mold invalidation, etc., and achieve the effect of enhancing the disinfection effect and reducing the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

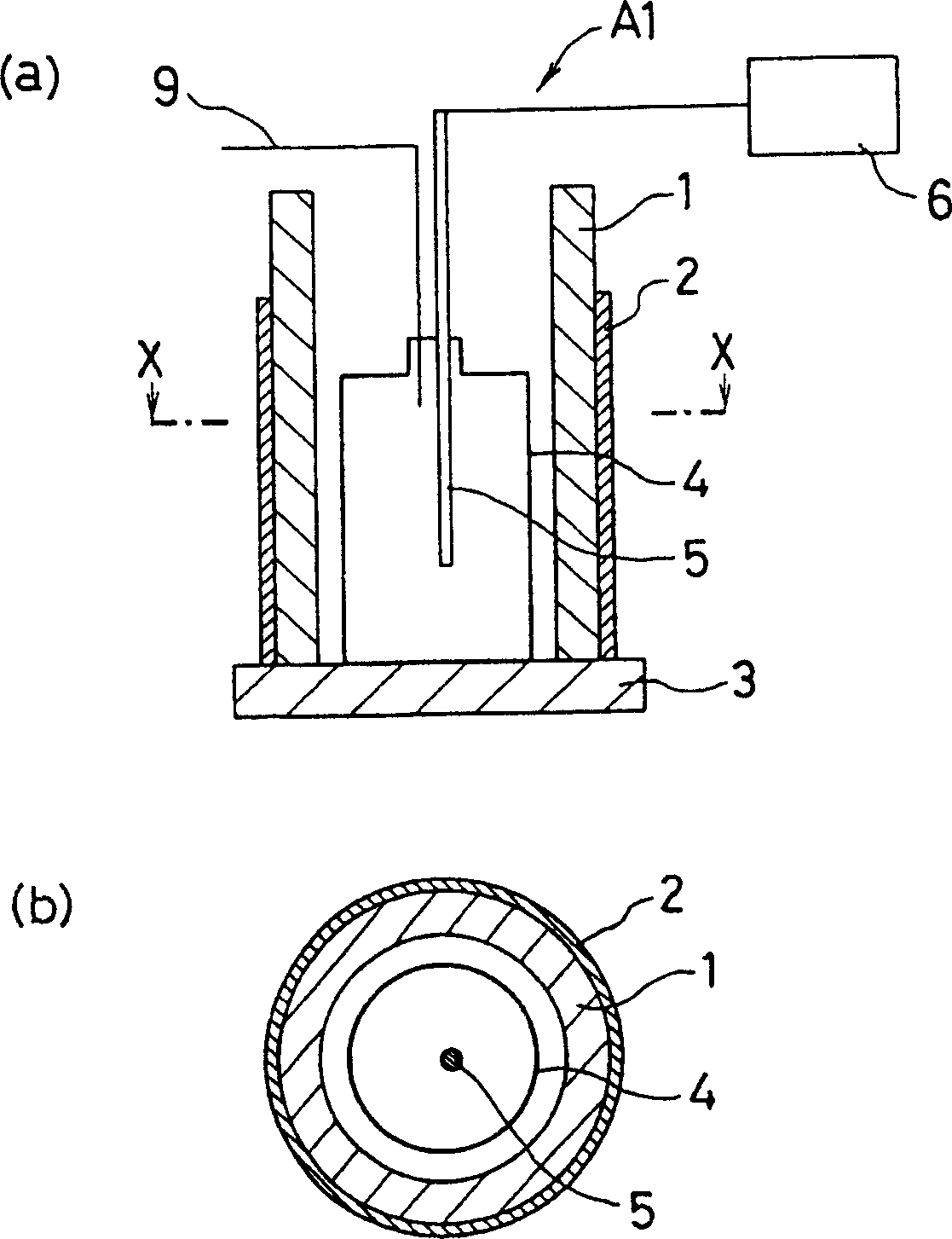

[0090] figure 1 (a) is a schematic diagram showing the sterilizer of the present invention using a high-voltage pulse power supply, figure 1 (b) is along figure 1 (a) shows the sectional view taken along the line X-X of the present invention.

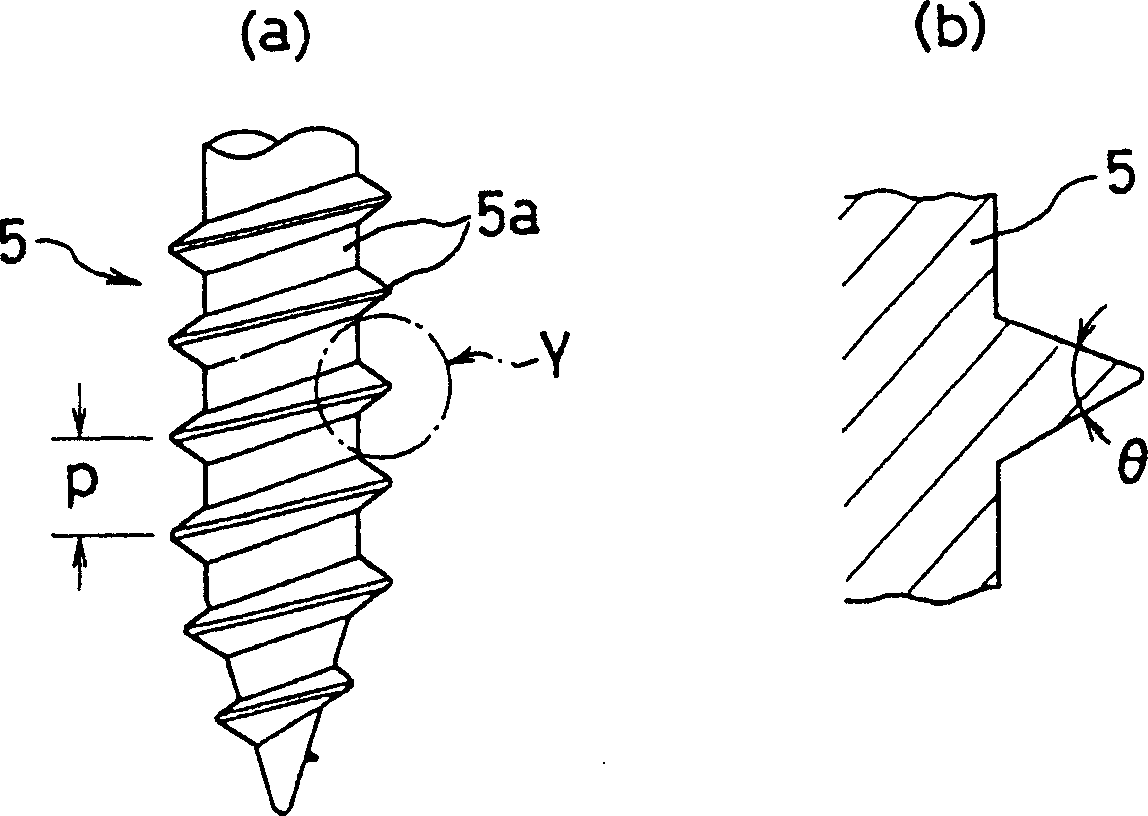

[0091] figure 2 An example of the discharge-side electrode included in the present invention is shown, wherein (a) is a schematic diagram of a part of the discharge-side electrode, and (b) is an enlarged cross-sectional view of a Y portion thereof.

[0092] exist figure 1 (a) and (b), the sterilizer A1 of the present invention has the pulse power supply 6 (corresponding to Figure 9 The power supply B) shown in (a), the discharge-side electrode 5 applied with the high-voltage pulse generated by the pulse power supply 6, is used for entering and exiting the discharge-side electrode 5 into the packaging material 4 and taken out therefrom device (not shown), and the ground-side electrode 2 installed by being placed around the outer ...

no. 2 example

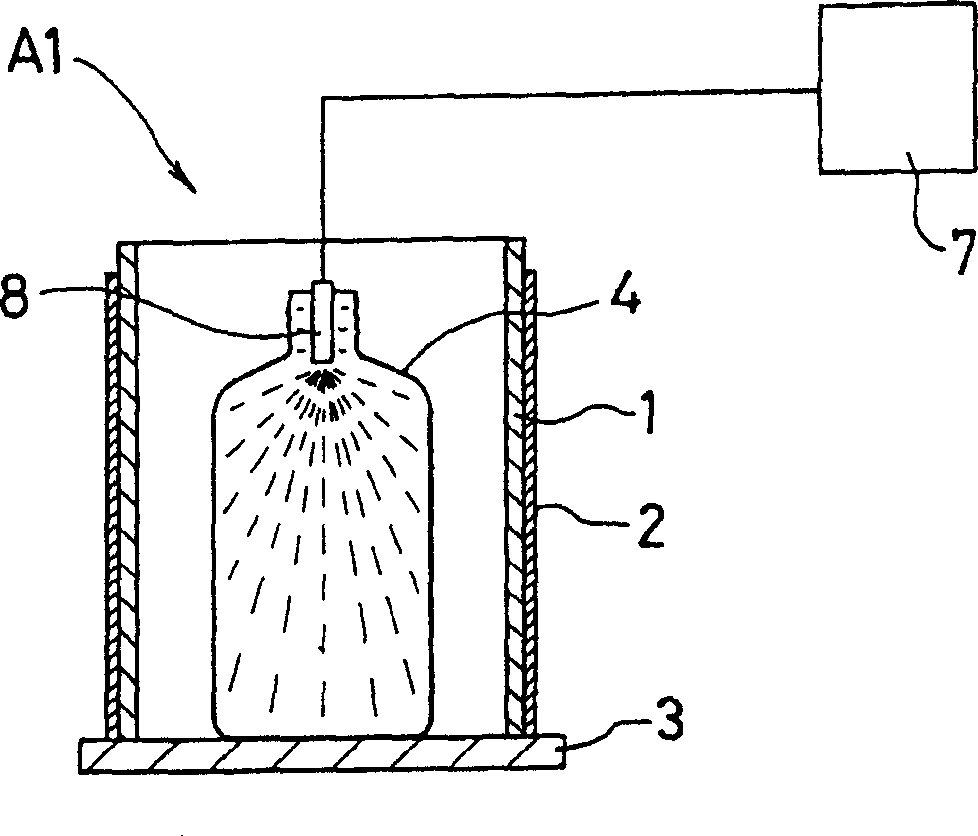

[0109] The second embodiment of the present invention is similar to the first embodiment of the present invention, except that a common round rod electrode is used as the discharge side electrode, and as image 3 As shown, the sterilizer A1 of the present invention has a liquid supply device 7 for supplying water or an aqueous solution to the inner surface of the packaging container 4 before discharging.

[0110] Moreover, in image 3 In , components similar to those of the first embodiment of the present invention are denoted by the same reference numerals, and explanations are omitted.

[0111] In the second embodiment of the present invention, first, as image 3 As shown, the packaging container 4 is installed in the treatment tank 1, and the process of providing water or an aqueous solution for the inner surface of the packaging container is carried out. This water supply process is accomplished by means of liquid supply means 7 and spraying means 8 for supplying water o...

no. 3 example

[0118] The third embodiment of the present invention is similar to the first and second embodiments of the present invention, except that the first and second embodiments are combined, the sterilizer A1 of the present invention has a gas introduction device 9 and a liquid supply device 7; water or aqueous solution is conveyed from the liquid supply device 7 by pressure, and is sprayed in a radial direction through the injection member 8 inserted into the top of the packaging container, so that the water particles are almost evenly attached to the inner surface of the packaging material 4; thereafter, for example, include A gas mixture of 50% or more of argon is supplied from the gas introduction device 9 at a rate of 10 liters / min or less, and is sprayed in the radial direction through the injection member 10 inserted into the upper part of the packaging container 4 to clear the surface of the packaging container 4. Flowing excess moisture; the discharge side electrode 5 is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com