Dielectric barrier corona discharge reactor

A dielectric barrier and corona discharge technology, applied to electrical components, plasma, etc., can solve problems such as small diameter of discharge filaments, damage to materials, and spark breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

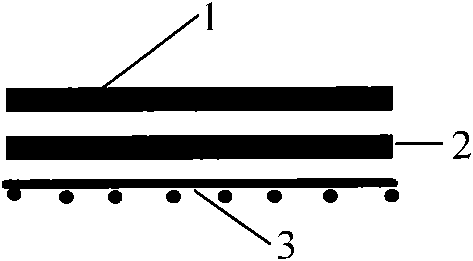

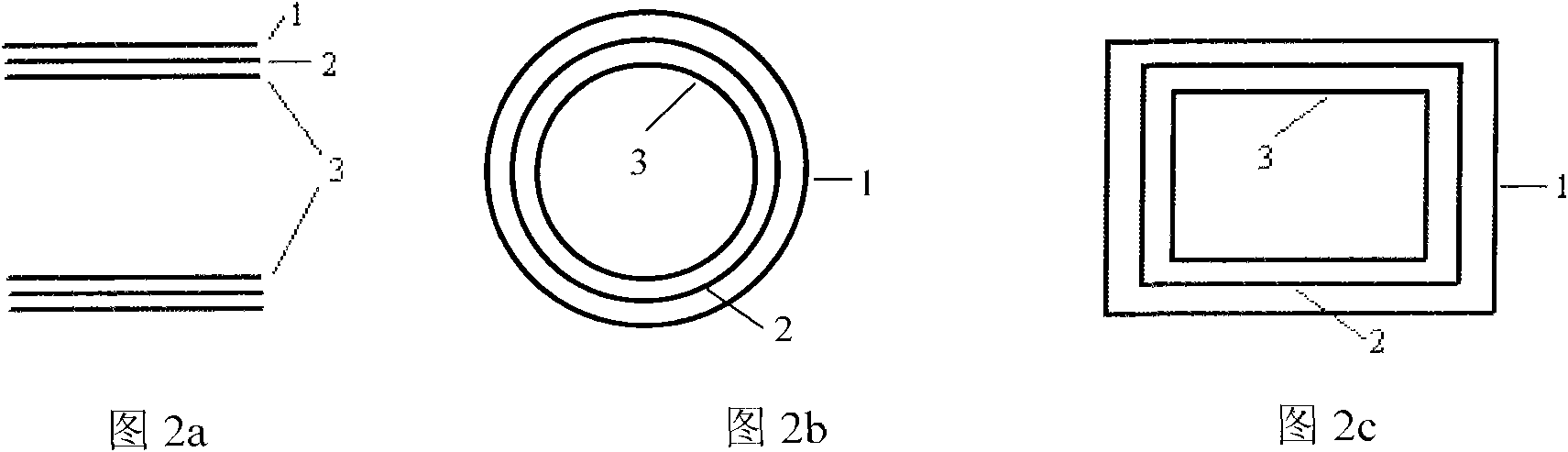

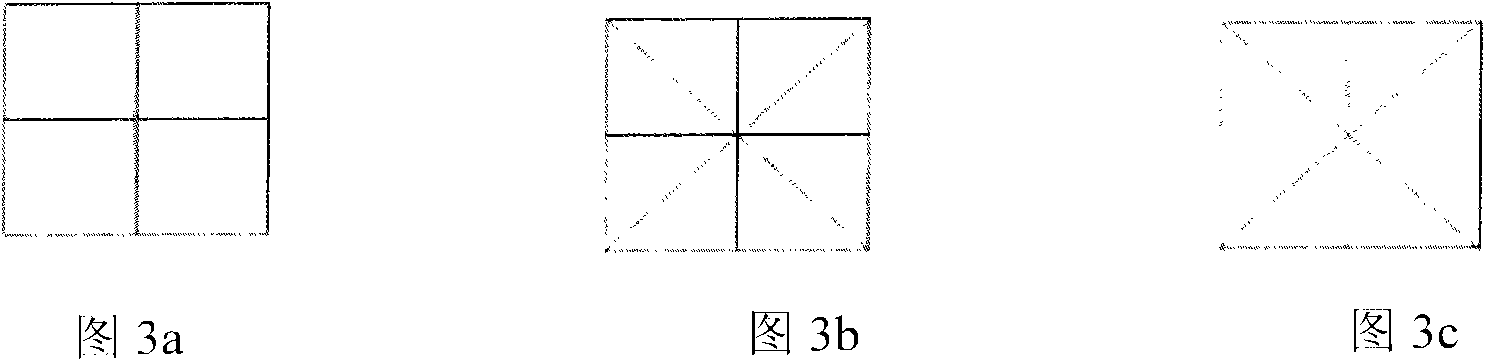

Method used

Image

Examples

specific Embodiment 1

[0038] Specific embodiment one: Atmospheric pressure plasma sterilization

[0039] The inactivation experiment of the bacteria on the surface of the glassware was done by using an atmospheric pressure dielectric barrier corona discharge reactor. The results show that the plasma generated by this discharge reactor can make 10 6 The magnitude of Bacillus subtilis was completely inactivated in 2 minutes, and the spores of Bacillus subtilis var. niger and Bacillus stearothermophilus were all inactivated after 5 minutes. This shows that the bactericidal effect of the discharge reactor plasma of the present invention is very effective. Moreover, during the sterilization process, the temperature inside the discharge reactor does not increase significantly, so it will not affect the properties of the material itself.

[0040]This is because a large amount of ultraviolet light can be emitted during the plasma generation process, and this high-energy ultraviolet light can destroy nucl...

specific Embodiment 2

[0043] Specific embodiment two: plasma surface modification

[0044] The use of plastic materials as tissue culture materials is becoming more common due to their low cost, ease of use, and ease of sterilization. However, the surface of untreated materials is hydrophobic and cannot provide enough binding sites for cells and bioactive molecules to effectively bind to their surfaces.

[0045] Put the petri dish and culture bottle into the discharge reactor, discharge to generate plasma, and process in the discharge reactor for 10-15 minutes. The surface of the culture dish and culture flask treated with plasma changes from hydrophobic to hydrophilic, which acquires the ability to support cell adhesion and spreading, increases the number and speed of cell reproduction, and thus is more suitable for cell culture.

[0046] The plasma discharge reactor is suitable for the treatment of large-scale cell culture dishes, can inhibit the proliferation of spores, and improve the reliabil...

specific Embodiment 3

[0047] Specific embodiment three: polluted gas treatment

[0048] Pollution gases refer to flue gases and malodorous gases. The reactor is used for polluted gas treatment. like Figure 4 As shown, it has a cylindrical gas-collecting tank, and the two ends of the gas-collecting tank are provided with an air inlet and an air outlet. The tank is equipped with a discharge reactor, and the distance between the inner and outer electrodes of the discharge reactor is 40mm. Due to the large flow of polluted gas in practical applications, multiple corona discharge units are placed in parallel in order to increase the treatment capacity of polluted gases and improve the treatment efficiency.

[0049] In the same applied voltage and discharge space gap, the discharge reactor can generate and transmit more charges and output higher discharge power because of the corona ionization effect. Stronger pulse voltage and current can be obtained during discharge, which makes the energy more con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com